Assembly process method for 3D Plus encapsulating device

A technology for packaging devices and assembly processes, which is applied in the direction of electrical components, assembling printed circuits with electrical components, and manufacturing printed circuits. It can solve problems such as not meeting standard requirements and no solder infiltration of device pins, and achieve good solder joint consistency. , Improve the effect of capillary action, the effect of stable and reliable device assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

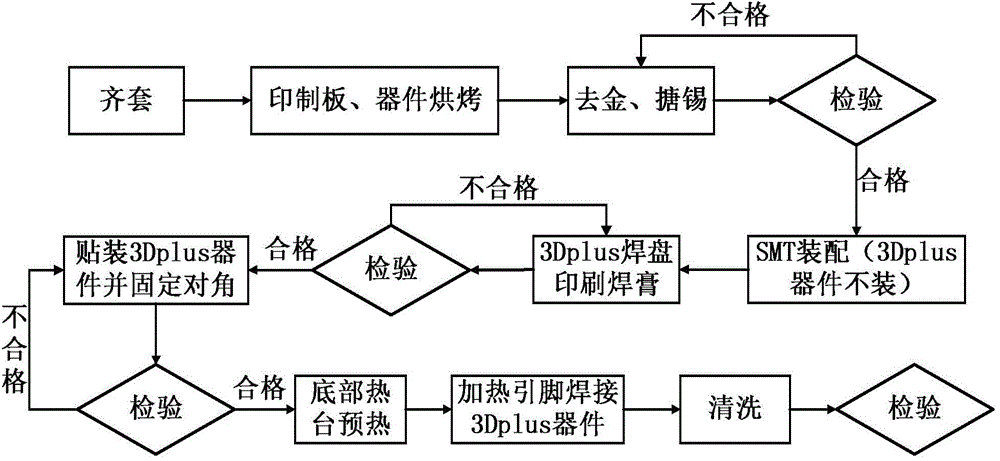

[0015] refer to figure 1 . In the invention of the 3D PLUS packaged device assembly process, the 3D PLUS packaged device complete set, printed board / device baking, gold removal, and tinning treatment process are the same as the current manual assembly process, the difference is that This assembly technology first uses the printing and patch technology in the SMT assembly technology to print the solder paste on the printed board pad with the stencil and complete the 3D PLUS packaging device placement, and controls the printed board soldering through the thickness of the stencil. The thickness of the solder paste printed on the disk is 0.12mm. Use the maintenance workstation to complete the mounting of 3D PLUS packaged devices. The lateral offset of the 3D PLUS packaged device pins is controlled within 15% of the pin width. After mounting, it is fixed with a soldering iron spot welding 3D PLUS packaged device diagonal pins; secondly, use the hot stage welding technology and too...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com