Automatic welding machine for braided wire

An automatic welding machine and braiding technology, which is applied in welding equipment, high-frequency current welding equipment, metal processing equipment, etc., can solve the problems that the automatic welding function cannot be realized, and the consistency of solder joints is not good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

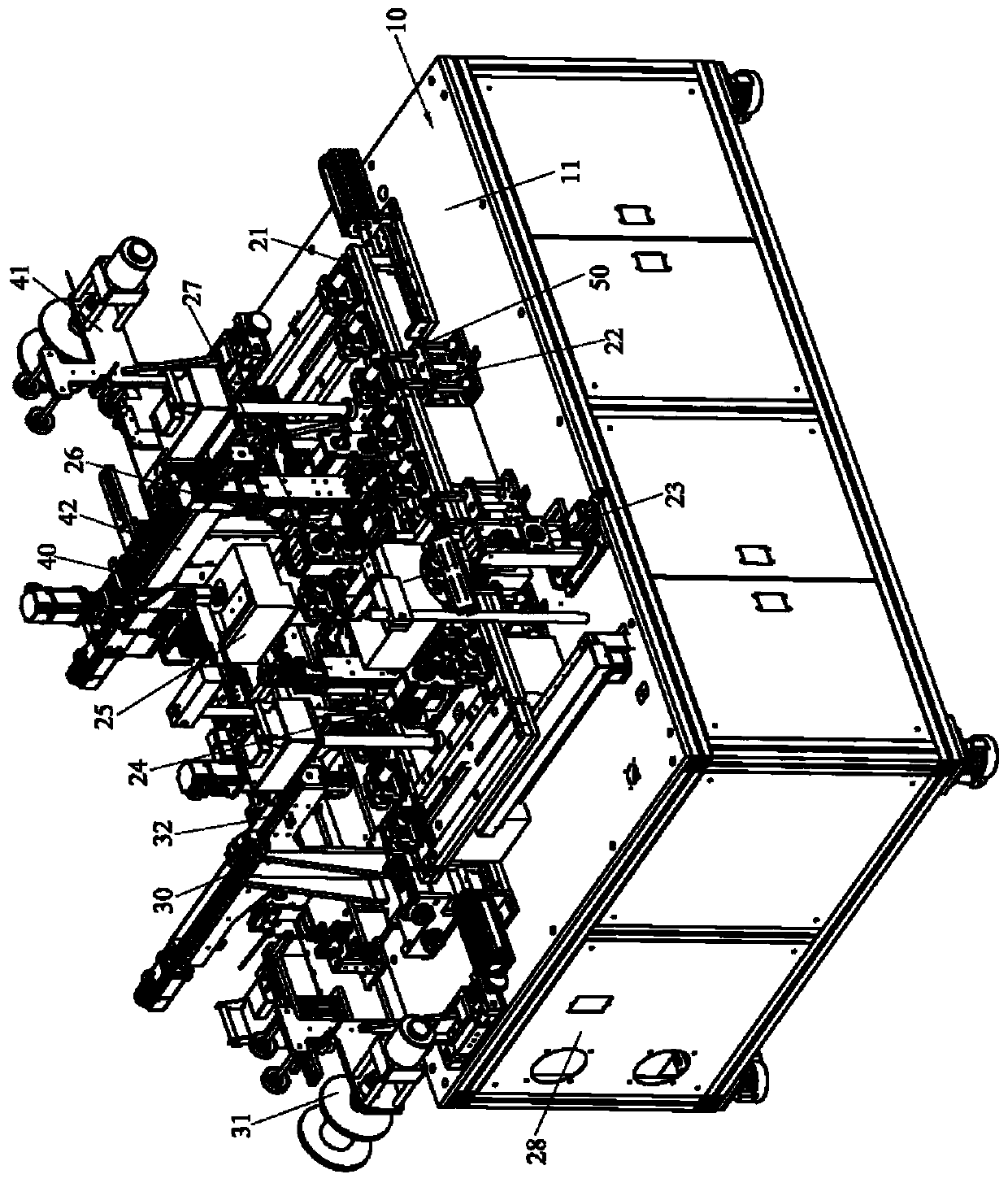

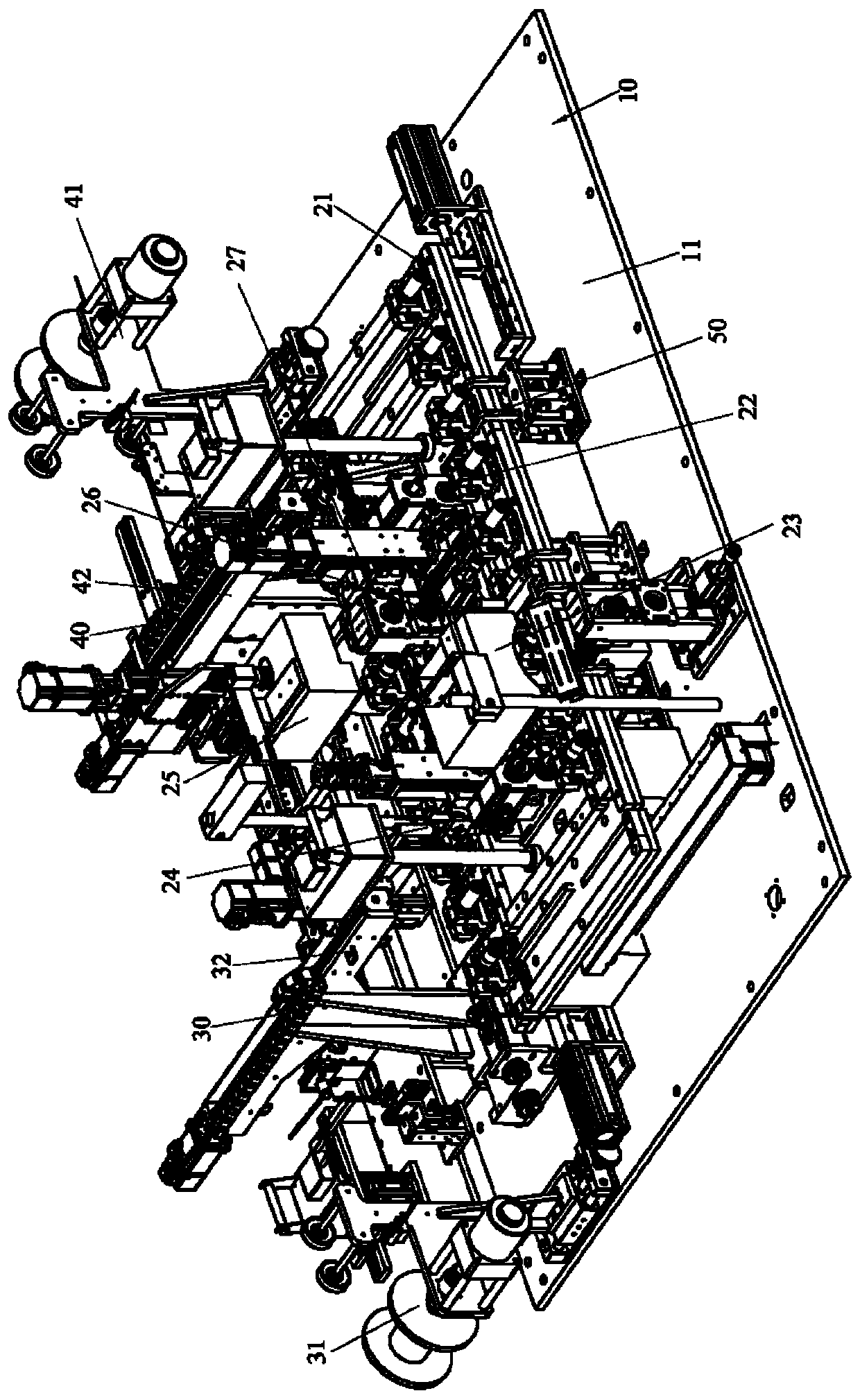

[0027] Please refer to figure 1 and figure 2 As shown, it shows the specific structure of the preferred embodiment of the present invention, including frame 10, circulation line 21, carrier 22, first visual inspection device 23, first high frequency welding device 24, second visual The detection device 25 , the rotating device 26 , the second high-frequency welding device 27 , the first braided wire feeding device 30 and the second braided wire feeding device 40 .

[0028] This circulation line 21 is arranged on the frame 10, and the specific structure and working principle of the circulation line 21 are prior art, the concrete structure and the working principle of the circulation line 21 are not described in detail here; the carrier 22 is arranged on the circulation line 21 and driven by the circulation line 21 to circulate.

[0029] The first visual detection device 23, the first high-frequency welding device 24, the second visual detection device 25, the rotating device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com