Semi-automatic welding device for circumferential welds

A semi-automatic welding and annular welding technology, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high cost, low efficiency, low welding quality, etc., achieve uniform feeding, ensure voltage, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

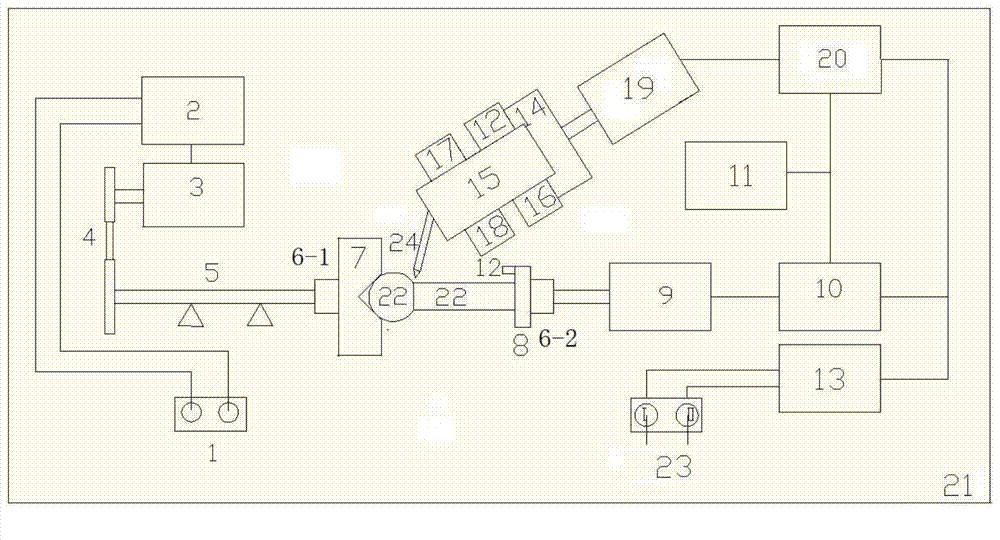

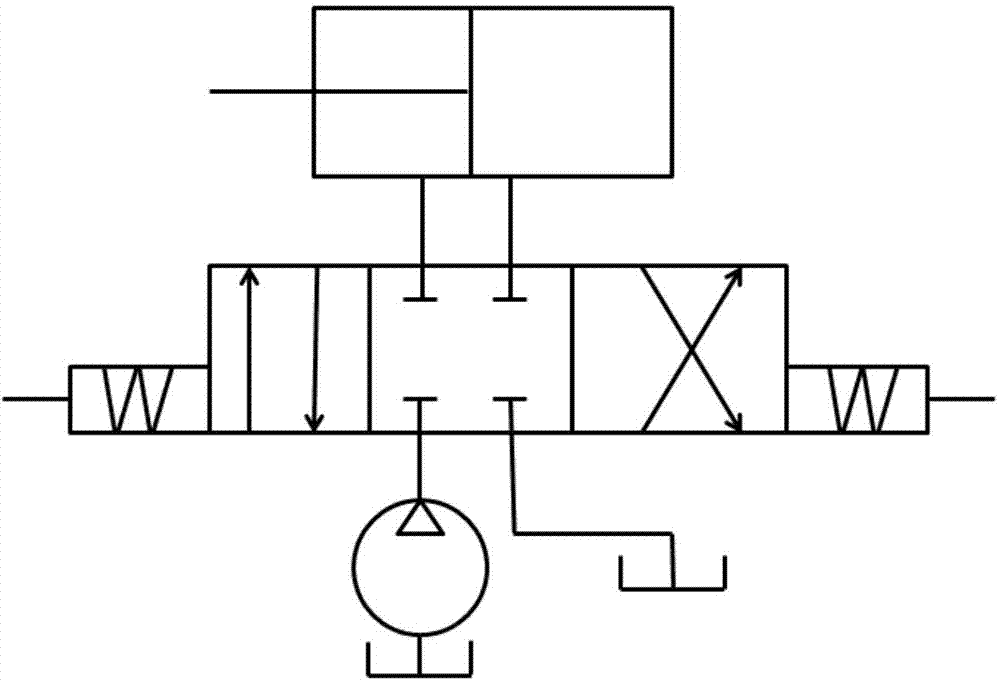

[0025] Such as figure 1 As shown, the present invention consists of a motor controller 2, an electromagnetic speed regulating motor 3, a transmission device 4, a main shaft 5, a first turntable mechanism, a second turntable mechanism, a positioning mechanism 7, a clamping mechanism 8, a No. 1 cylinder 9, and a No. 1 cylinder. Electromagnetic control valve 10, air pump 11, travel switch 12, control mechanism 13, clamping sleeve 14, welding torch 15, limit block 16, wire feeding mechanism 17, time relay 18, No. 2 cylinder 19, No. 2 electromagnetic control valve 20, And frame 21 forms.

[0026] The working process of this system is as follows:

[0027] (1) Position the spherical workpiece 22 to be processed on the positioning mechanism 7, adjust the position of the limit block 16 according to the specifications of the workpiece to be processed, pull the wrench I of the switch 23 of the control device to turn to the left, and the control device 13 passes through No. The electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com