Patents

Literature

355results about How to "Guaranteed welding accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

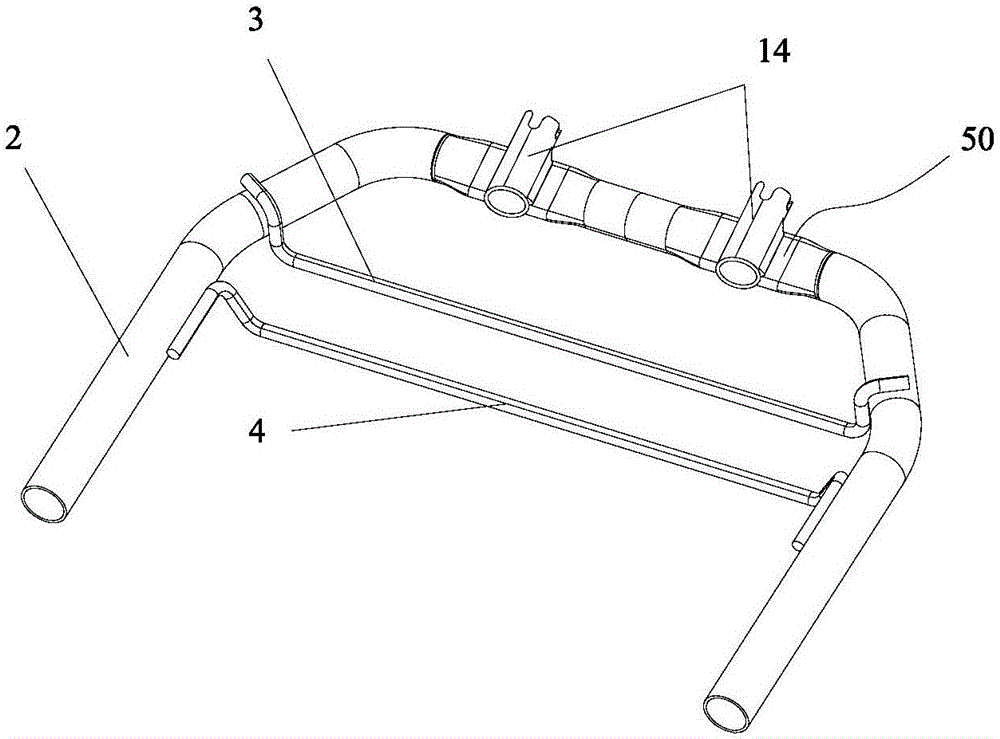

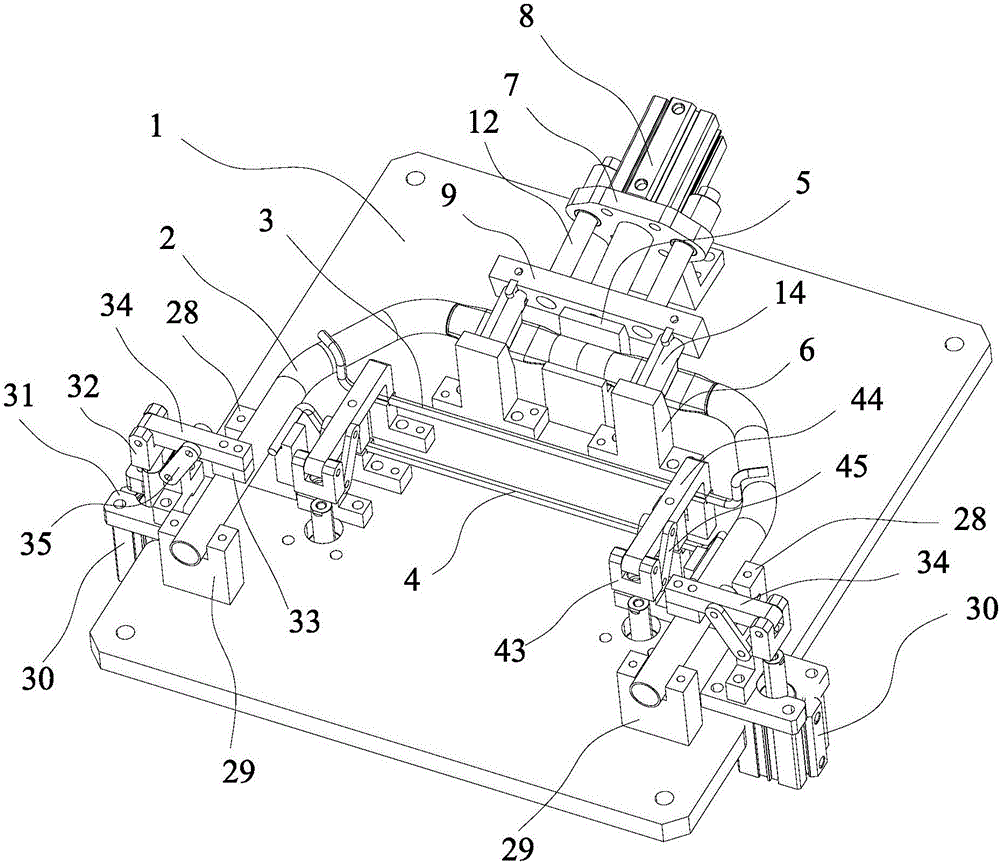

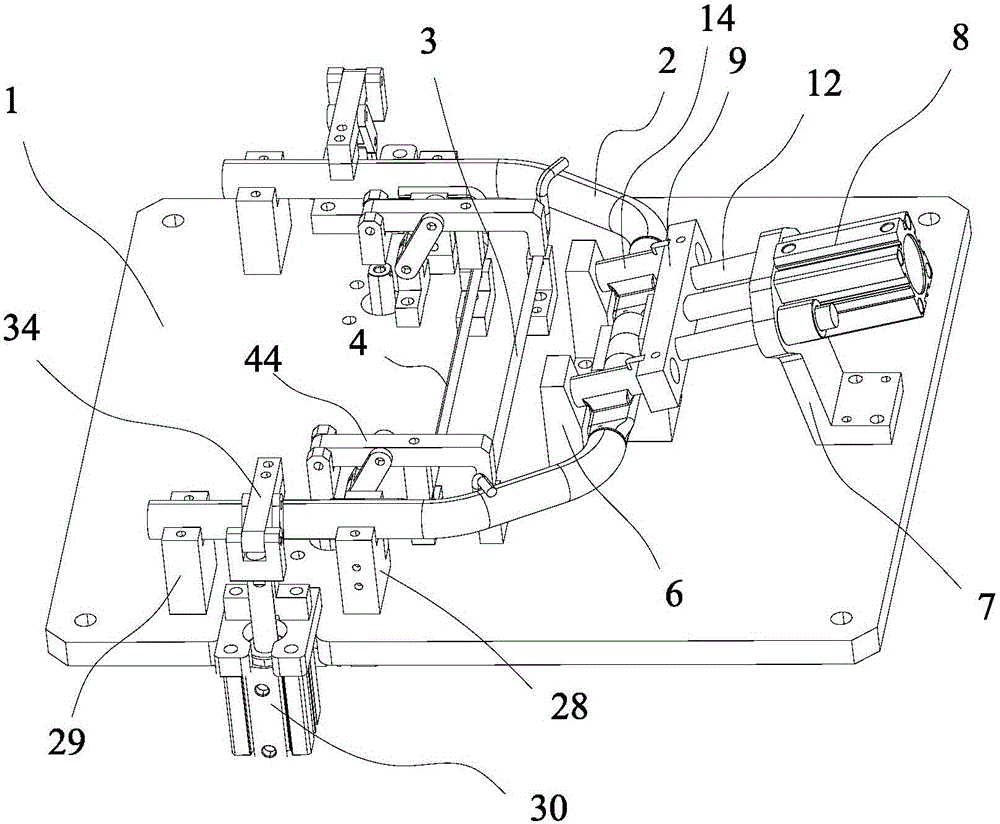

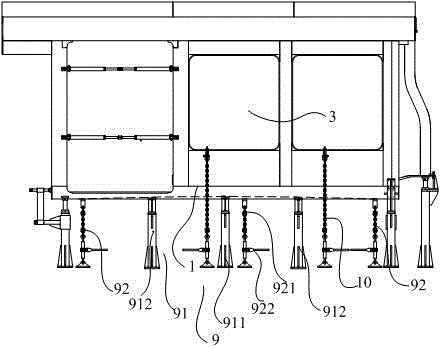

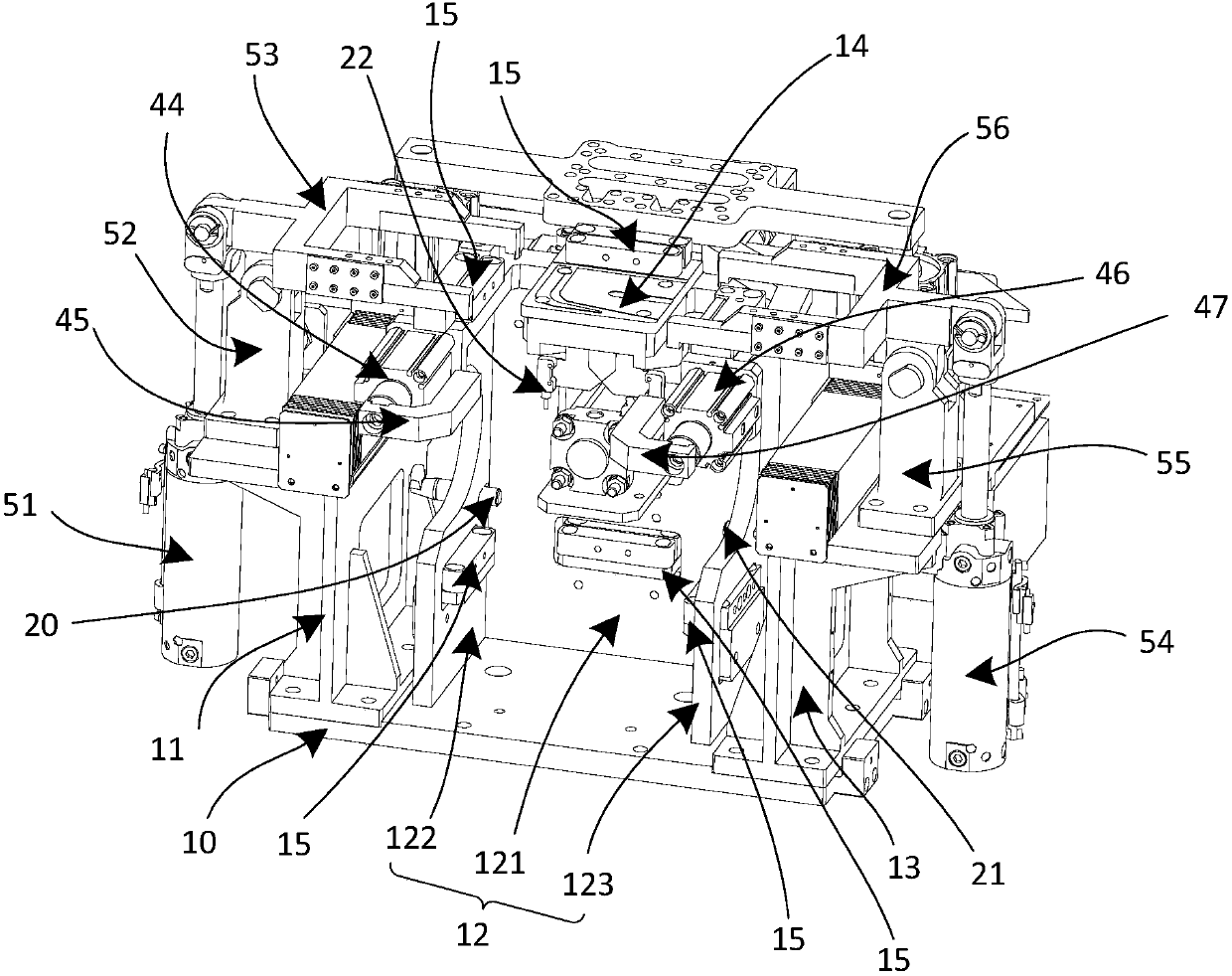

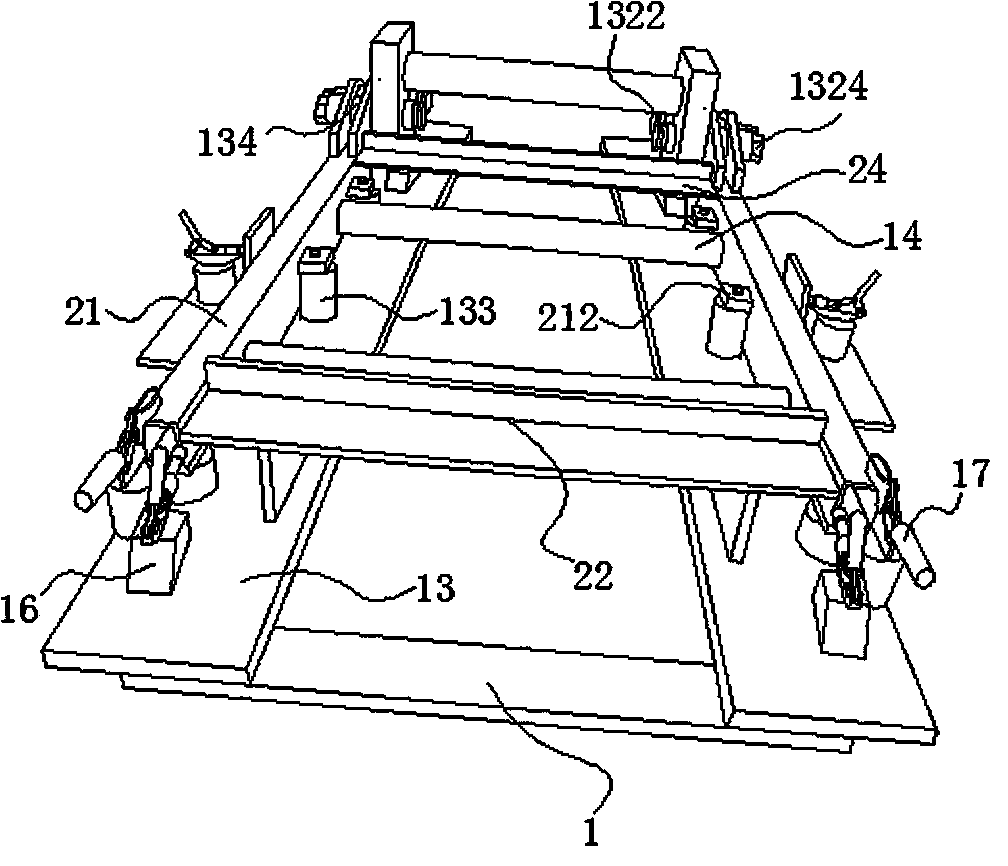

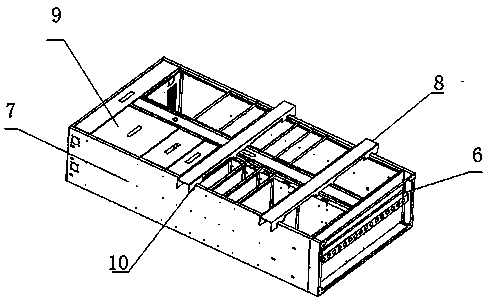

Welding tool for production of automobile seat framework

ActiveCN106112371AEnsure consistencyGuaranteed accuracyWelding/cutting auxillary devicesAuxillary welding devicesLap jointEngineering

The invention discloses a welding tool for production of an automobile seat framework. The welding tool for production of the automobile seat framework comprises a base (1), a feed clamping device, two side section clamping devices and a supporting bar clamping device, wherein the feed clamping device is provided with a sleeve (14) in advance and pushes the sleeve to the position above a slope (50) of the bottom section of a U-shaped bent pipe (2) in the automobile seat framework, the two side section clamping devices are used for fixedly clamping two side sections of the U-shaped bent pipe (2), and the supporting bar clamping device is used for fixedly clamping a first supporting bar (3) and a second supporting bar (4) so that the two ends of the first supporting bar (3) and the two ends of the second supporting bar (4) can be in fixed lap joint to the two side sections of the U-shaped bent pipe (2) correspondingly. By the adoption of the structure, the U-shaped bent pipe, the first supporting bar and the second supporting bar can be fixedly clamped, and therefore the welding tool for production of the automobile seat framework can guarantee fixed clamping of the U-shaped bent pipe and the welding precision and the product consistency of the first supporting bar and the second supporting bar during automatic welding.

Owner:宁波明望汽车饰件有限公司

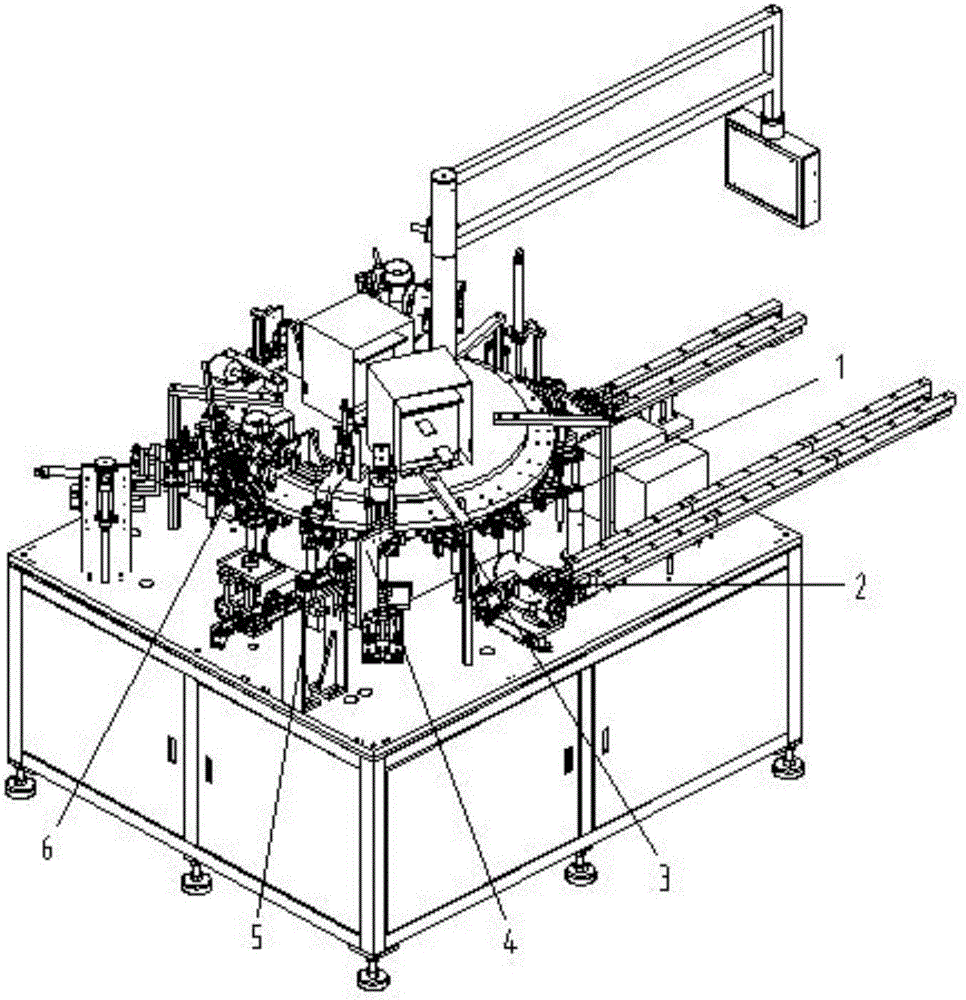

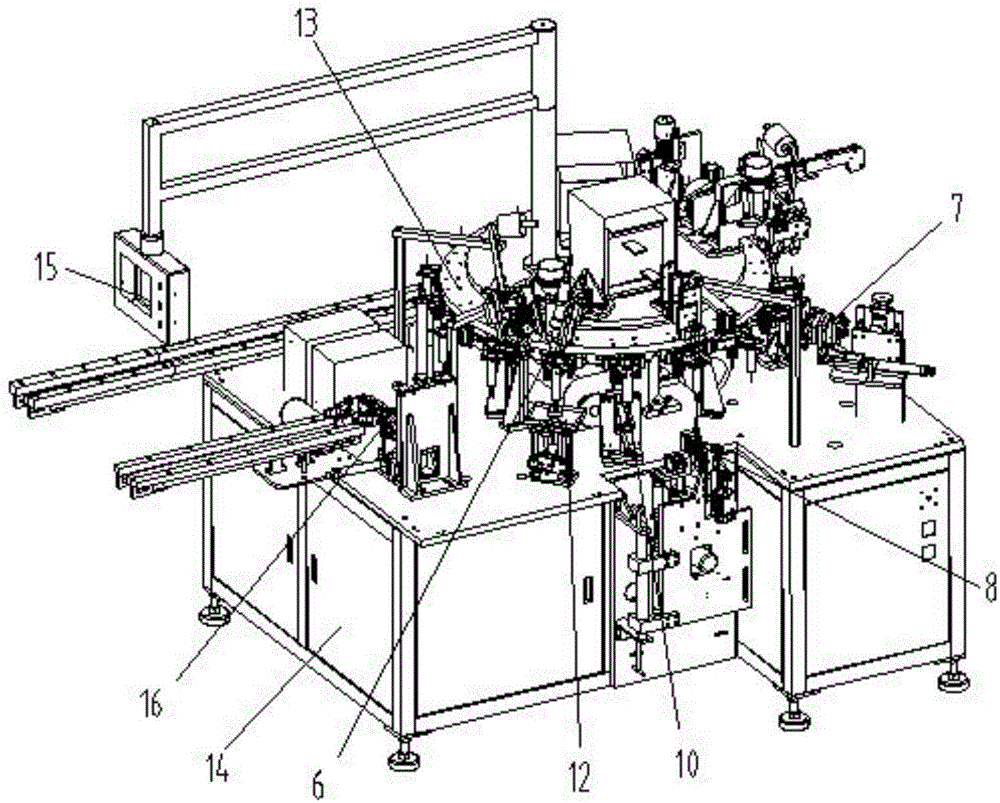

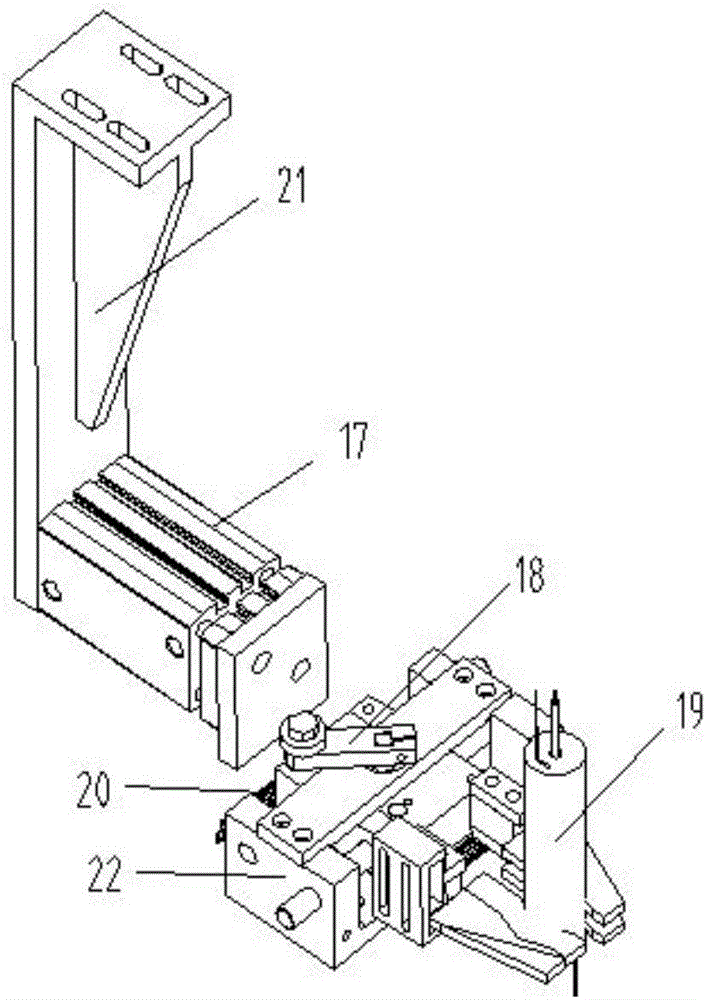

Automatic assembly machine of round capacitor

ActiveCN106847558ARealize automatic flipImprove welding efficiencyTerminal applying apparatusCapacitanceDistribution control

The invention relates to the field of capacitor processing equipment, in particular to an automatic assembly machine of a round capacitor. The machine includes a power distribution control box, a rotary plate and an operation screen, wherein the rotary plate and the operation screen are arranged above the power distribution control box through a bracket and communicated with the power distribution control box; clamps are uniformly arranged along a circle under the rotary plate; a feeding device, a positioning detection device, an upper tin-wire feeding device, a polarity detection device, a first tin-wire welding device, a capacitor turnover device, a lower tin-wire feeding device, a second tin-wire welding device and a discharging device are arranged in sequence on the outer side of the rotary plate in the clockwise direction and connected with the power distribution control box. The automatic assembly machine of the round capacitor has the advantages that automatic operation is adopted from feeding to discharging, the processing accuracy and processing efficiency of the round capacitor are greatly improved, and a large amount of working time is saved.

Owner:天长市中发电子有限公司

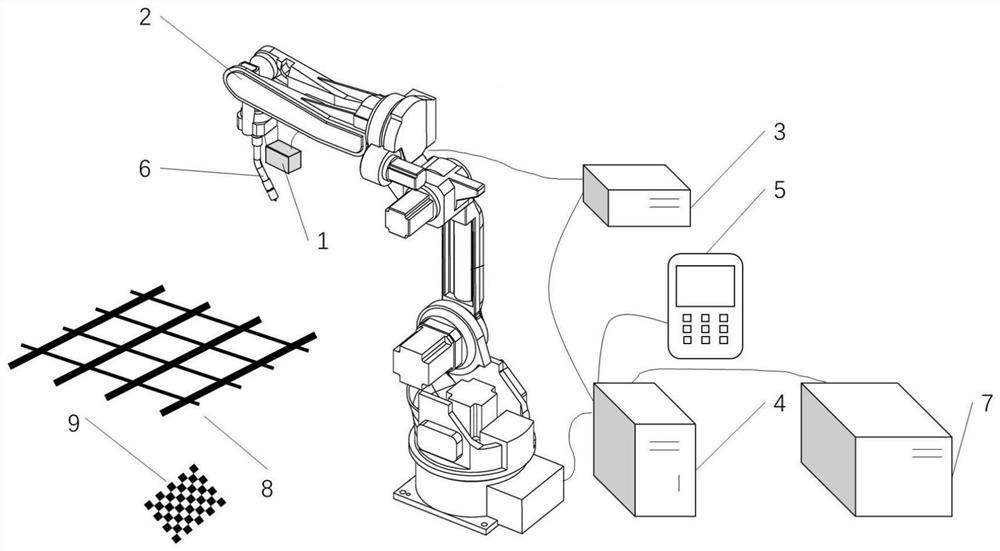

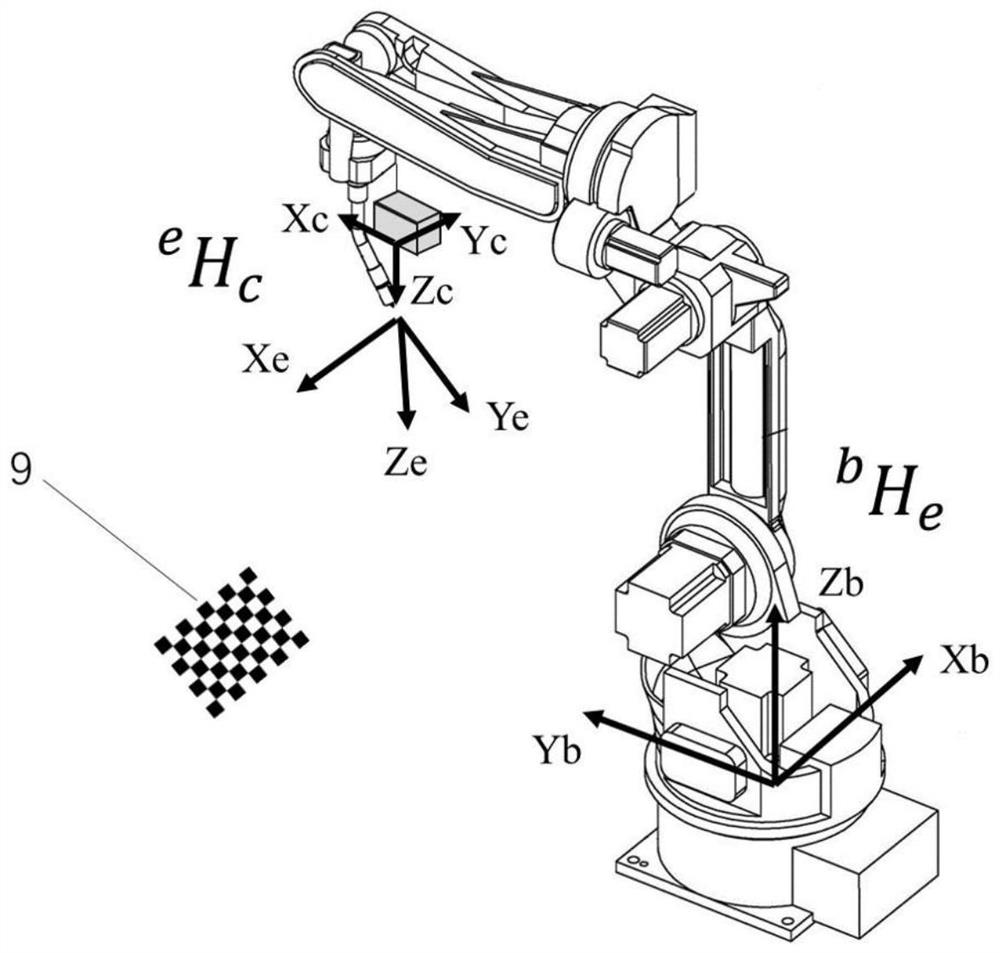

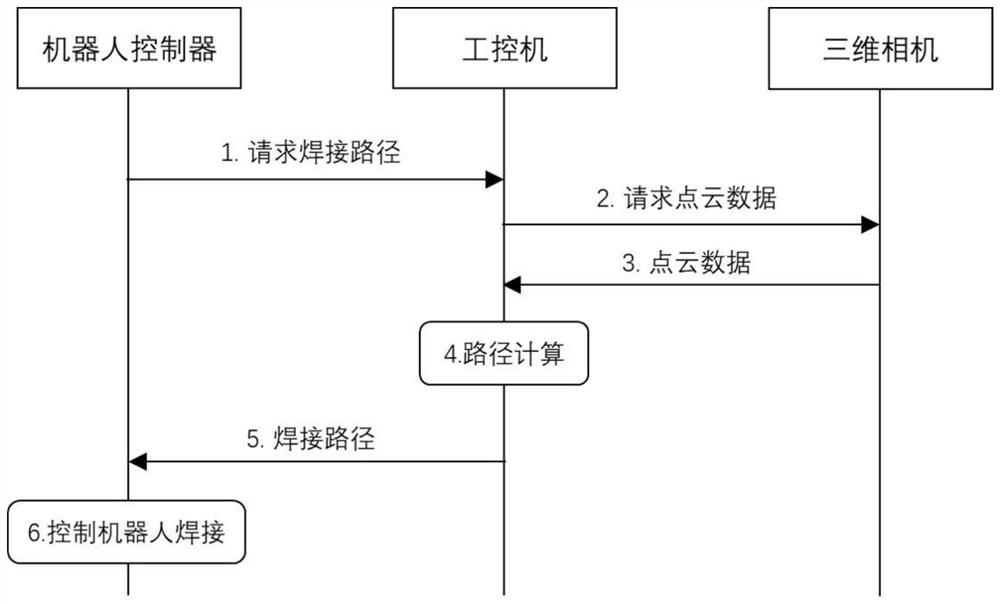

Visual location welding system and method based on robot welding

ActiveCN112122840ASimplify the teaching processFully automatedWelding/cutting auxillary devicesAuxillary welding devicesPoint cloudEngineering

The invention provides a visual location welding system and method based on robot welding. The visual location welding system is composed of a hand-eye calibration module, a photographing point location recording module and a welding execution module. The hand-eye calibration module is used for calculating a position and pose conversion relationship between a camera coordinate system and a robot coordinate system; three-dimensional information of crossed steel bars is acquired through the photographing point location recording module, and welding paths of the crossed steel bars are calculatedthrough a steel bar point cloud welding line extraction algorithm; and the welding paths are sent to the welding execution module, and the welding operation of steel bar crossing points is completed through the welding execution module . Through visual location of the crossed steel bars, the problem of poor precision of a workpiece and a clamp is solved, flexible and accurate welding is achieved,and the welding quality is guaranteed. According to the welding system, automatic calculation of the welding paths is achieved, and the demonstration of the welding paths is omitted; the robot demonstration process is simplified, and the requirement for operators is reduced; and the welding automation of the steel bars is achieved, and the welding effect and the production efficiency are improved.

Owner:XIAN CHISHINE OPTOELECTRONICS TECH CO LTD

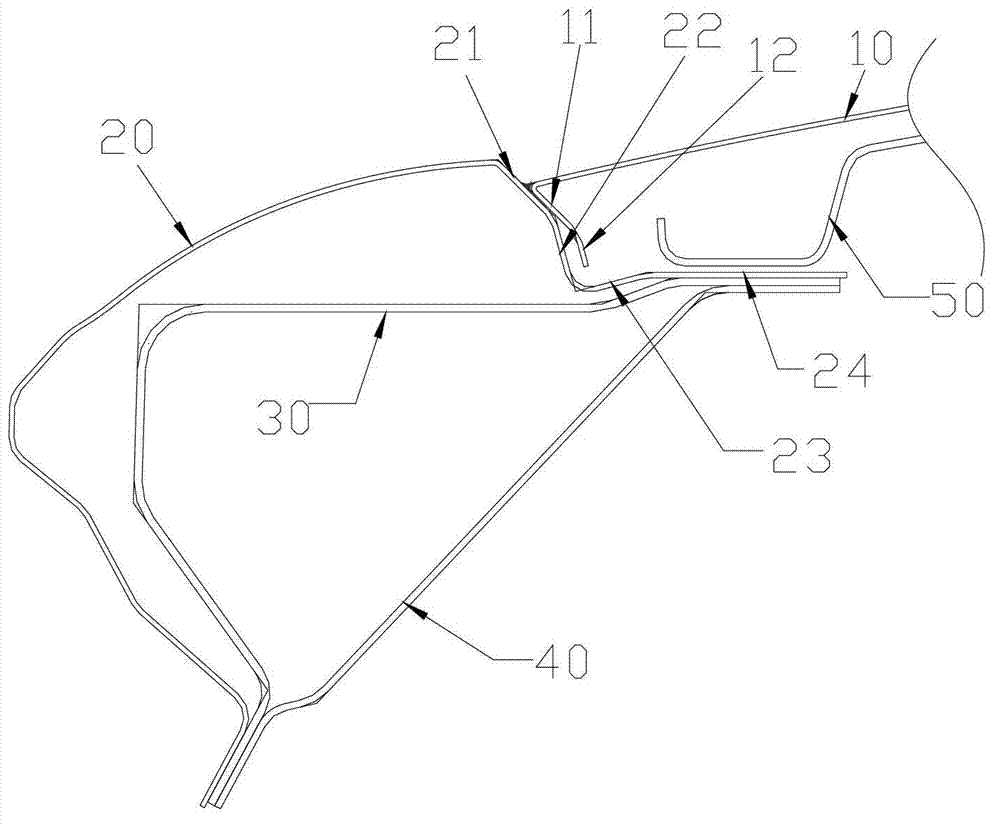

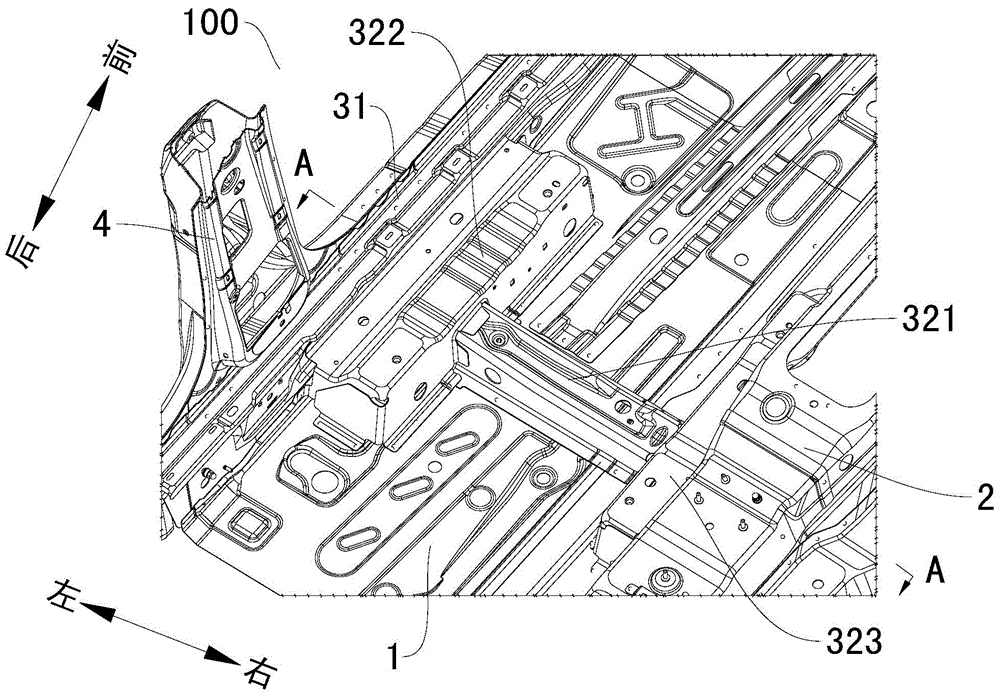

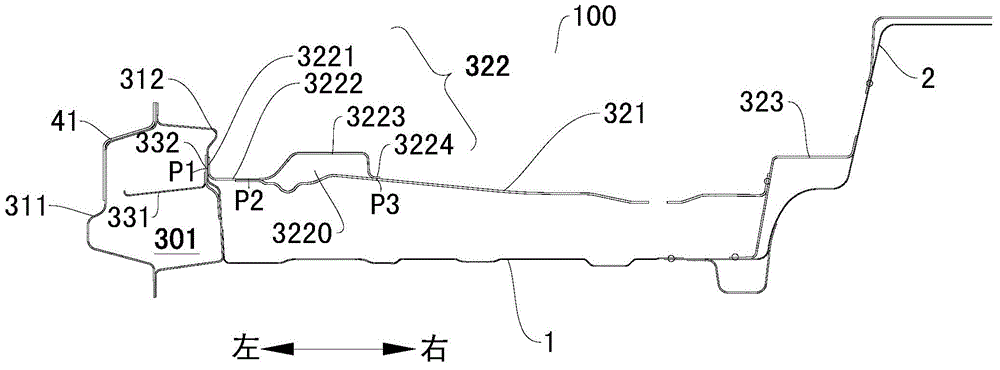

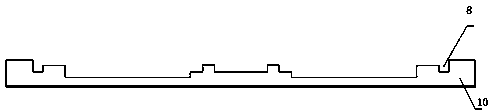

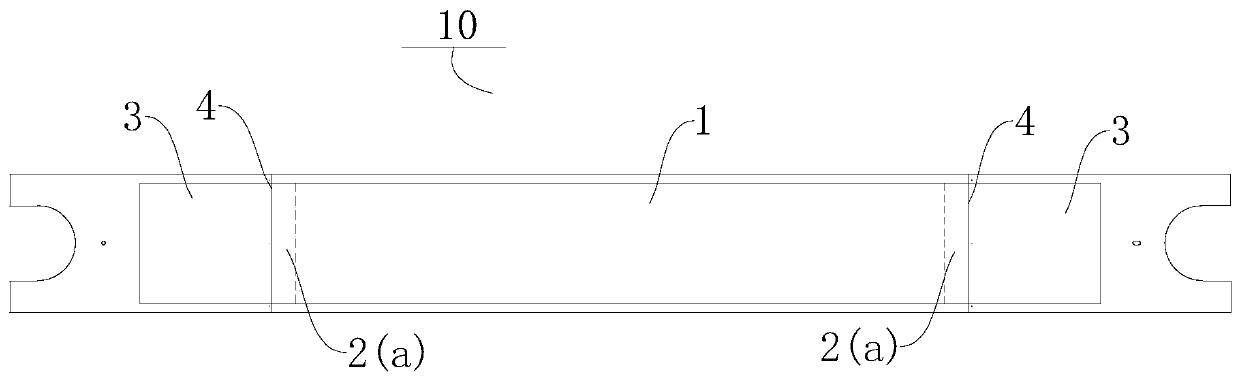

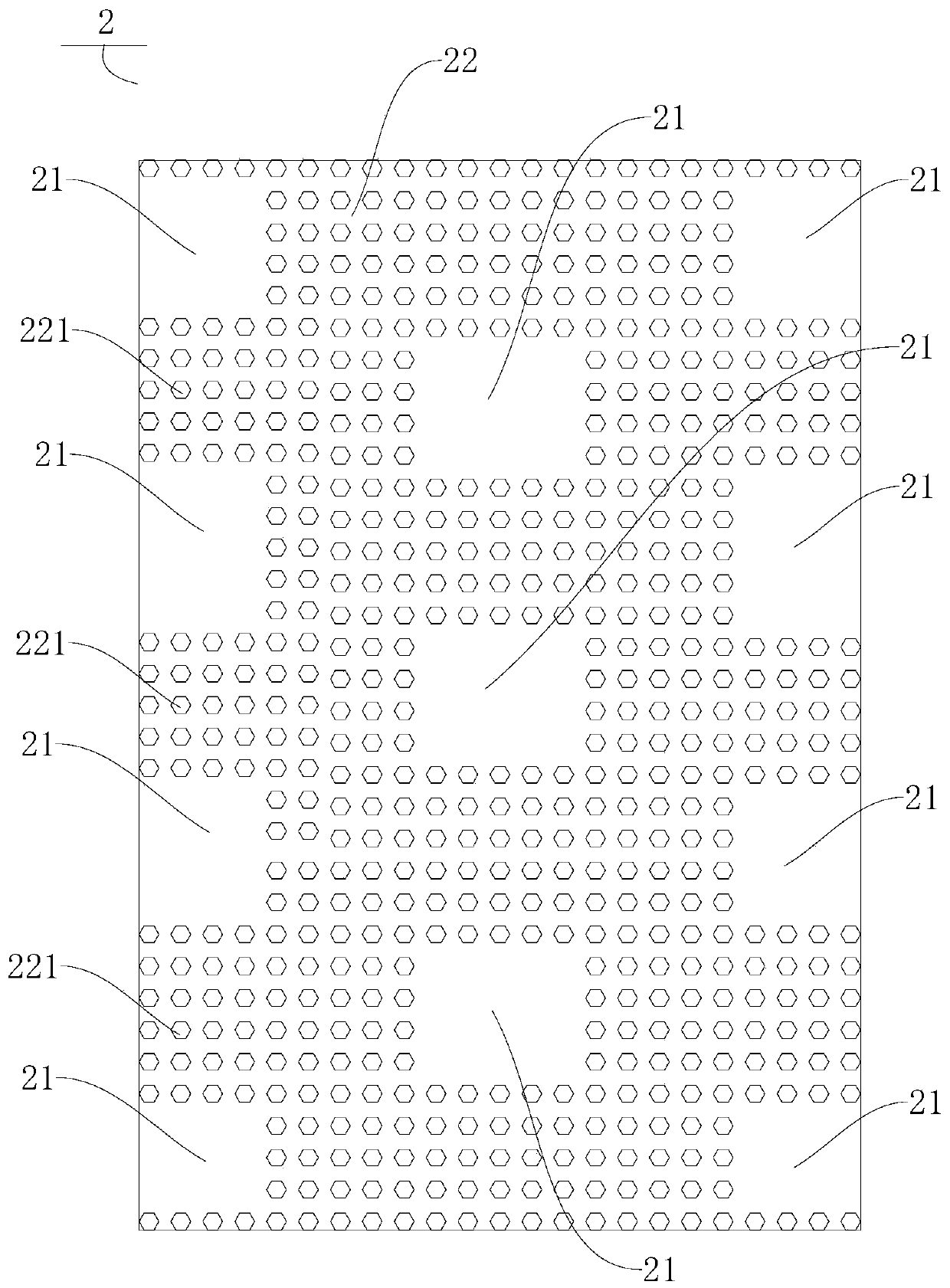

Connecting structure for automotive top cover plate and side panel and automobile

InactiveCN103587586APrecise positioningAccurate connectionSuperstructure subunitsFlangingProduction quality

The invention discloses a connecting structure for an automotive top cover plate and a side panel. The side panel is provided with a side panel first flanging (21) which extends from edges of a side panel main body(20); the top cover plate is provided with a top cover plate first flanging (11) which extends from edges of a top cover plate main body (10); the side panel first flanging (21) which extends towards the top cover plate downward inclines to support the top cover plate first flanging; the top cover plate first flanging is fixedly connected with the side panel first flanging. The invention also discloses an automobile comprising same. According to the above technical scheme, the top cover plate and the side panel can be positioned and connected due to the structure which is provided with the flanging, so that the top cover plate and the side panel can be accurately connected through the simple structure, welding accuracy between the top cover plate and the side panel is guaranteed, connecting quality is improved, appearance quality of the automobile is improved, and the production quality is reduced.

Owner:BEIQI FOTON MOTOR CO LTD

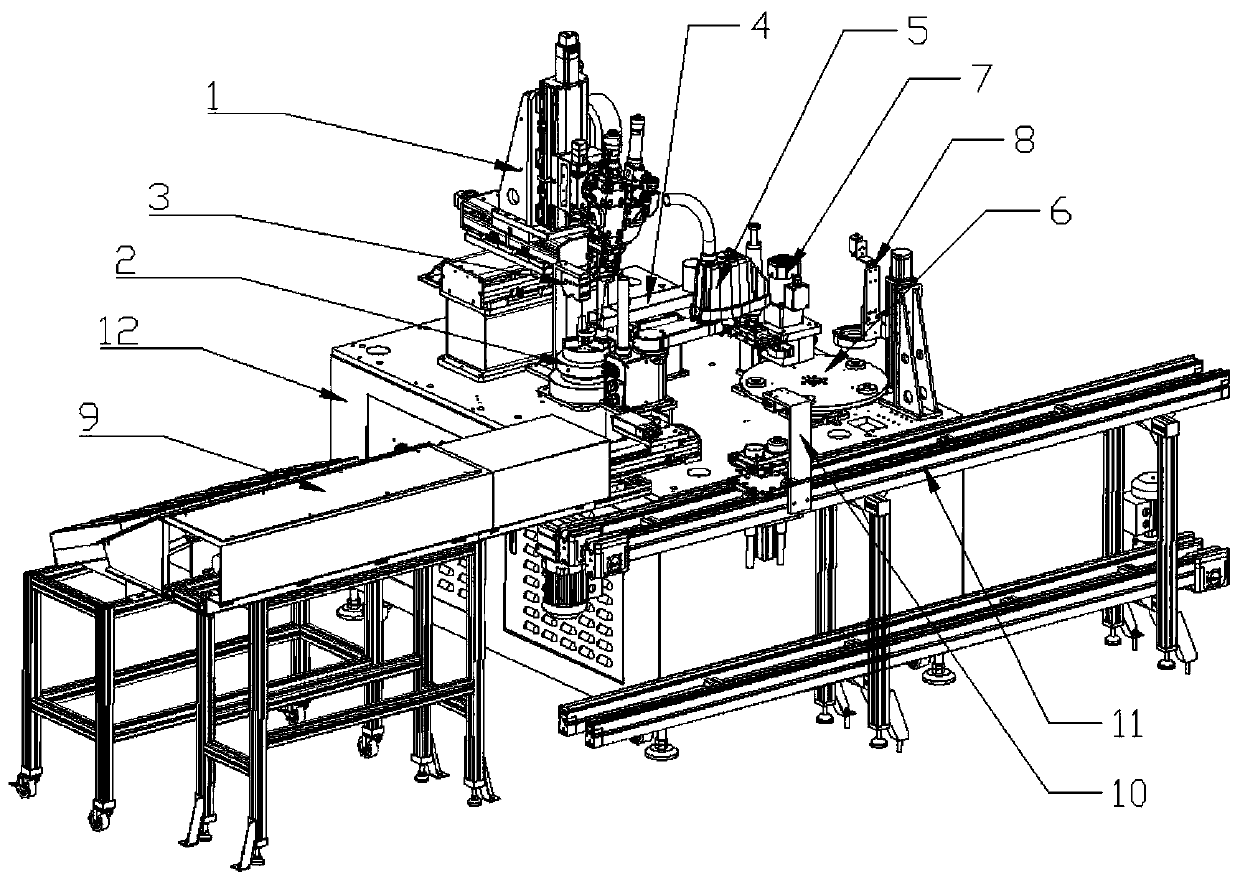

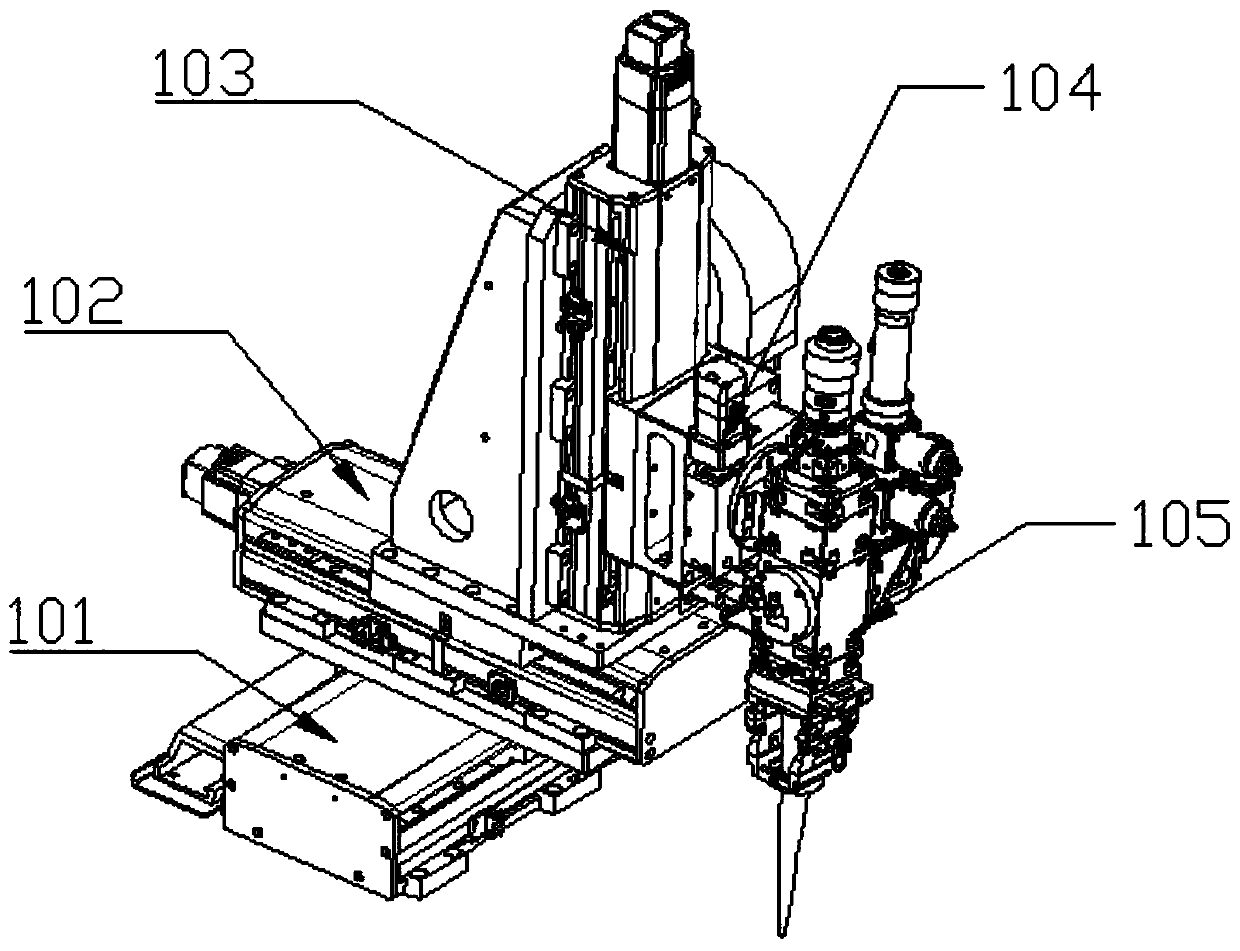

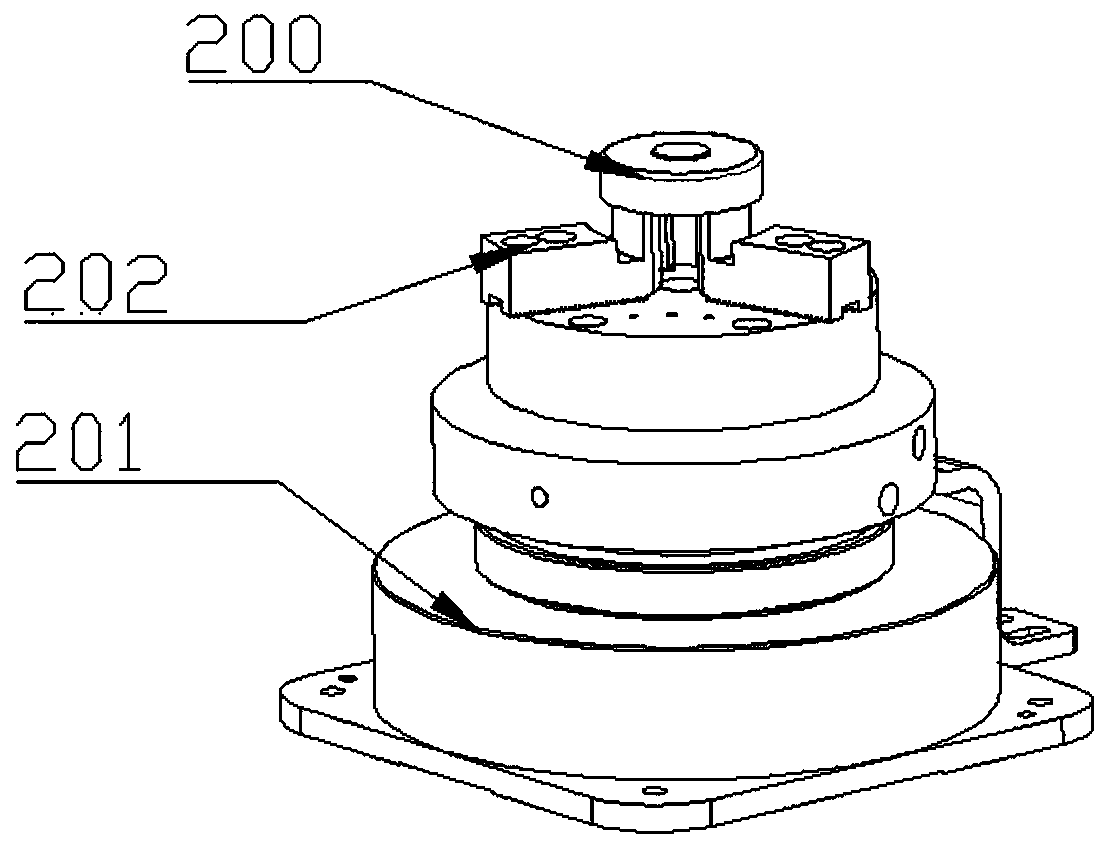

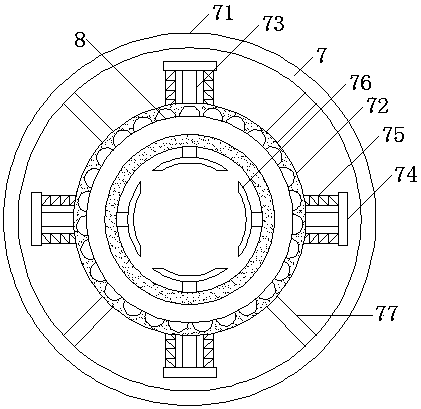

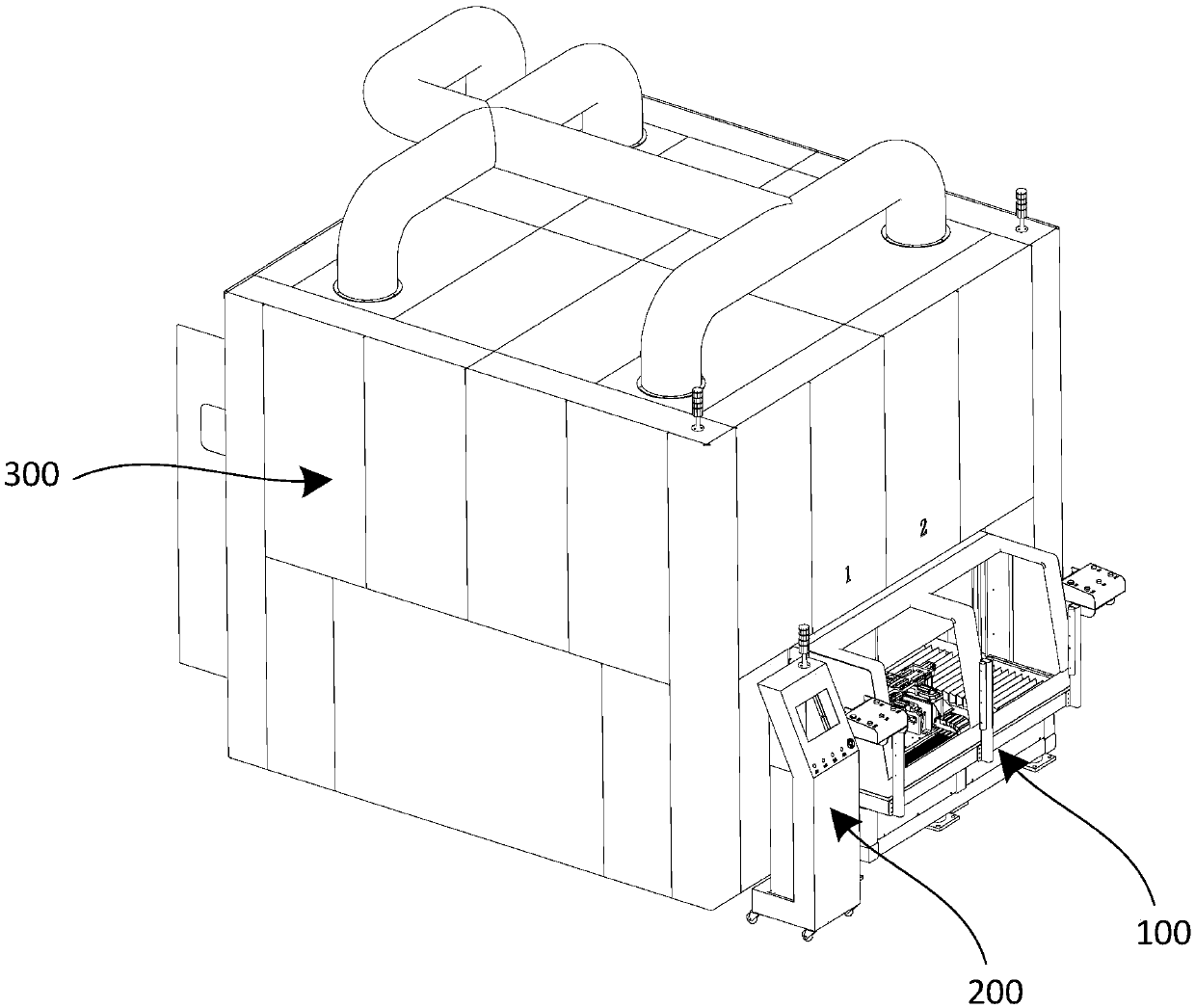

Automatic laser welding system

ActiveCN109822217AAdjustable angleAchieve precision clampingLaser beam welding apparatusThree dimensional shapeEngineering

The invention provides an automatic laser welding system. The automatic laser welding system comprises a machine table, a laser welding head drive device, a tool clamp, a 3D detecting device, a smoke-extraction and dust-removal device, a mechanical hand loading and unloading device, a material rotary disc device, a wiping device, a 2D detecting device, a sorting device, a workpiece conveyor line and a code scanning device, wherein the welding head drive device drives the laser welding head to move or deflect; the tool clamp realizes clamping and rotating of the workpiece; the 3D detecting device detects a three-dimensional shape of a welding seam; the mechanical hand loading and unloading device is used for grabbing the workpiece to realize loading and unloading; the material rotary disc device is used for sequentially rotating the welded workpiece to a wiping station, a detecting station and an unloading station; the 2D detecting device is used for detecting a quality state of the surface of the welding seam; and the code scanning device is used for reading bar codes or two-dimensional codes which are matched with welding parameters to store. The automatic laser welding system hasthe characteristics of being capable of performing circumferential welding on the welding seam workpiece, automatically loading and unloading, welding, 3D / 2D detecting, sorting and the like, does notneed manual operation, is high in efficiency, and enables welding parameters to be corresponding to bar codes.

Owner:深圳市华天世纪激光科技有限公司

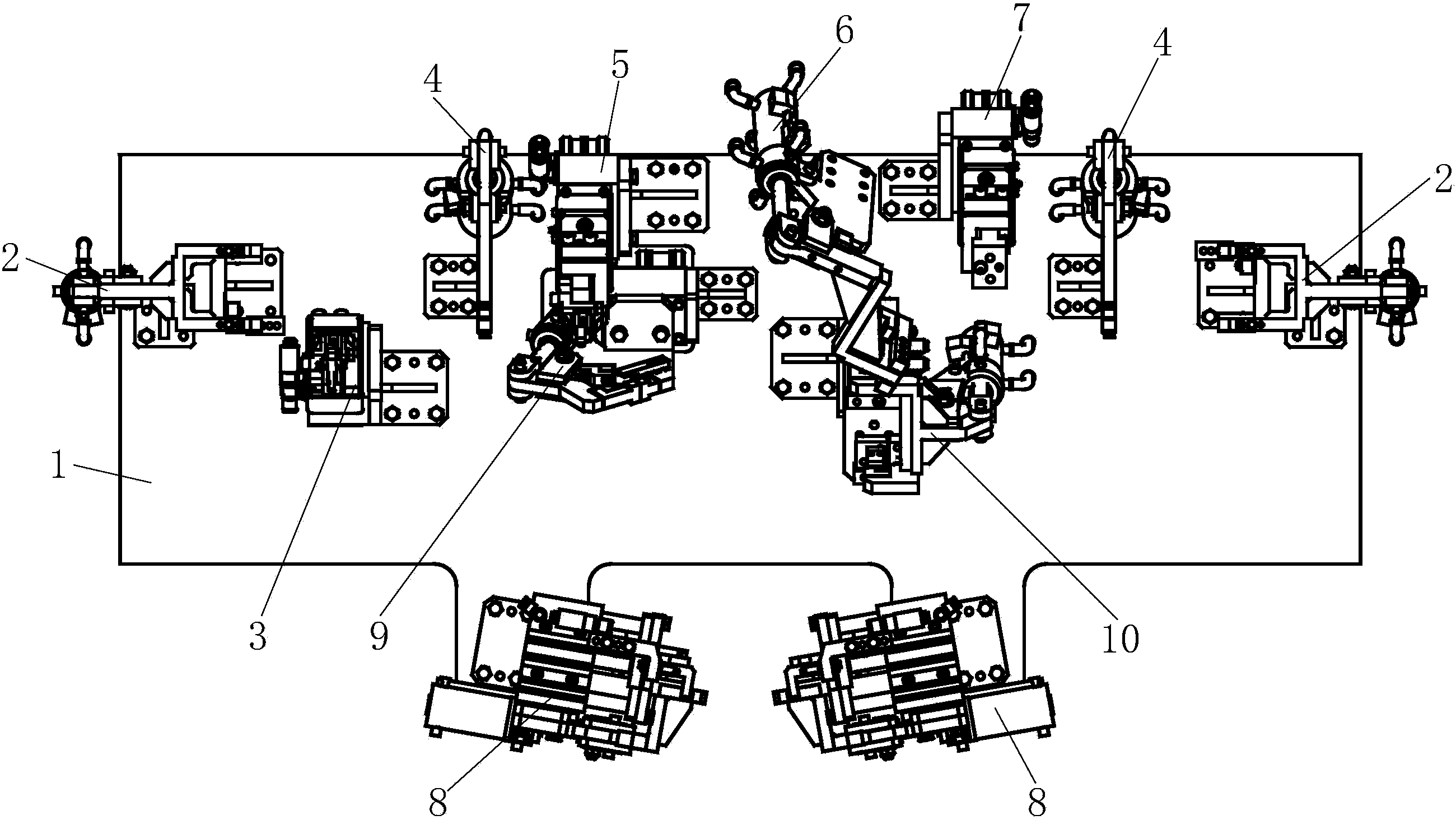

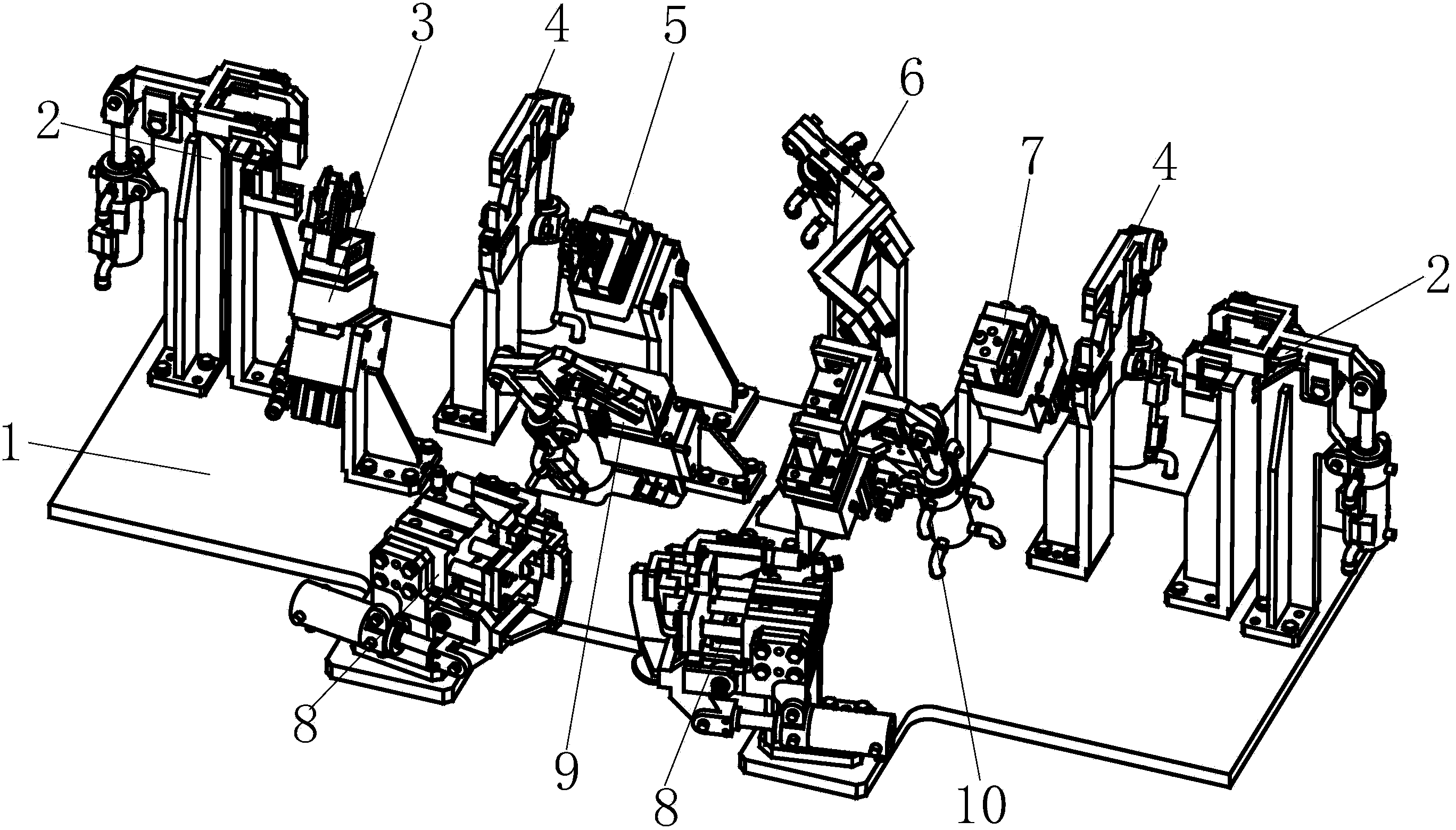

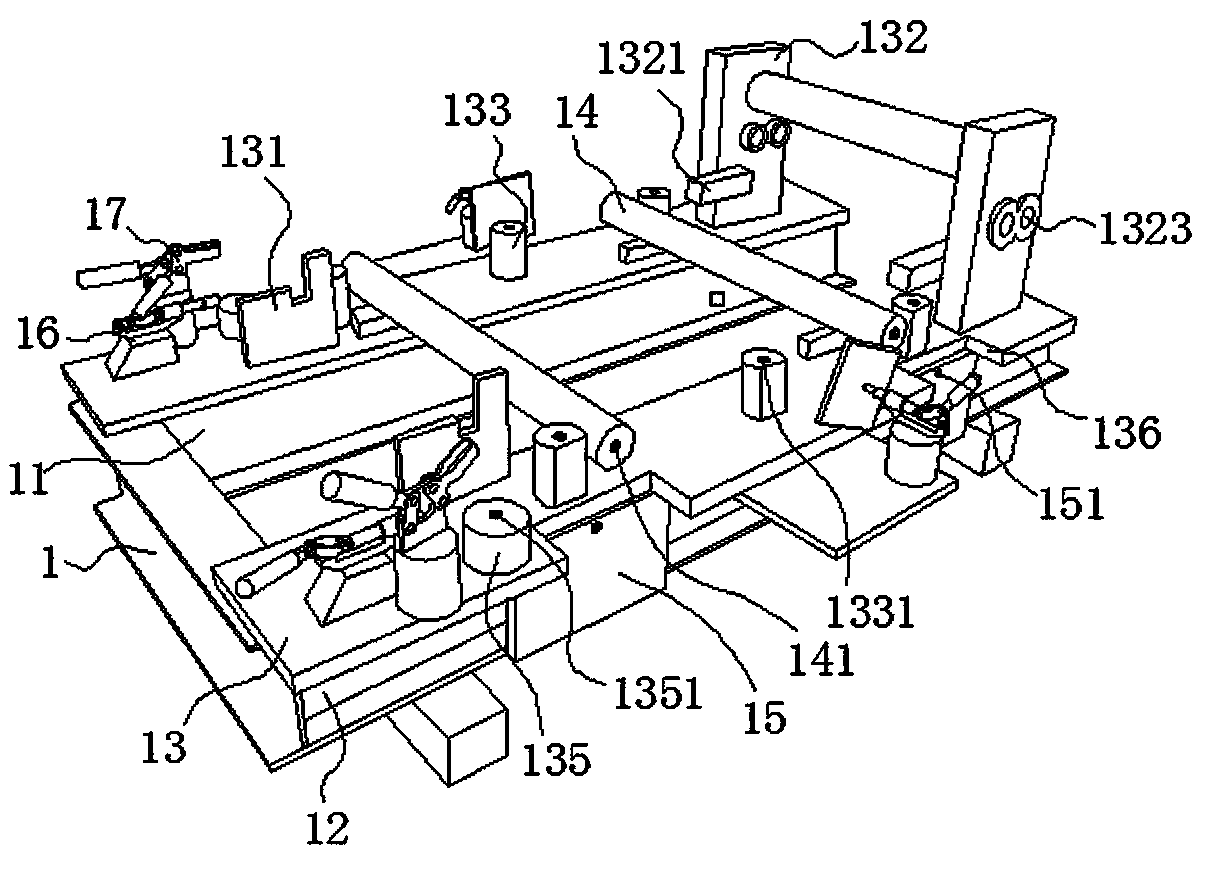

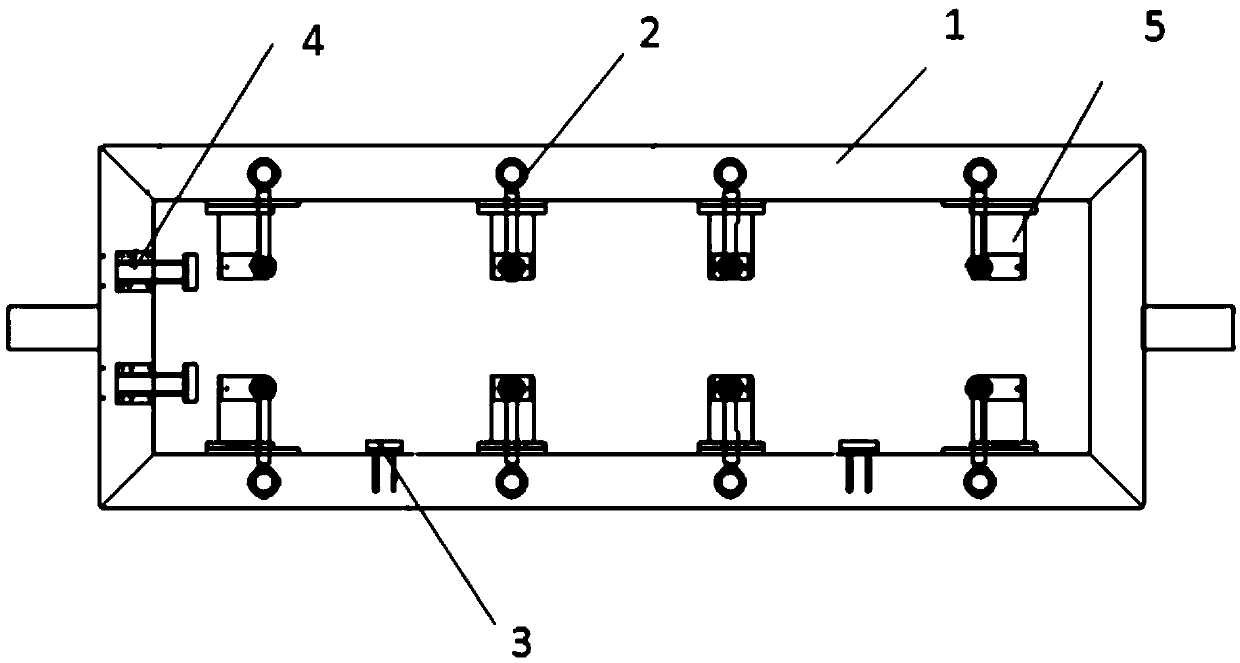

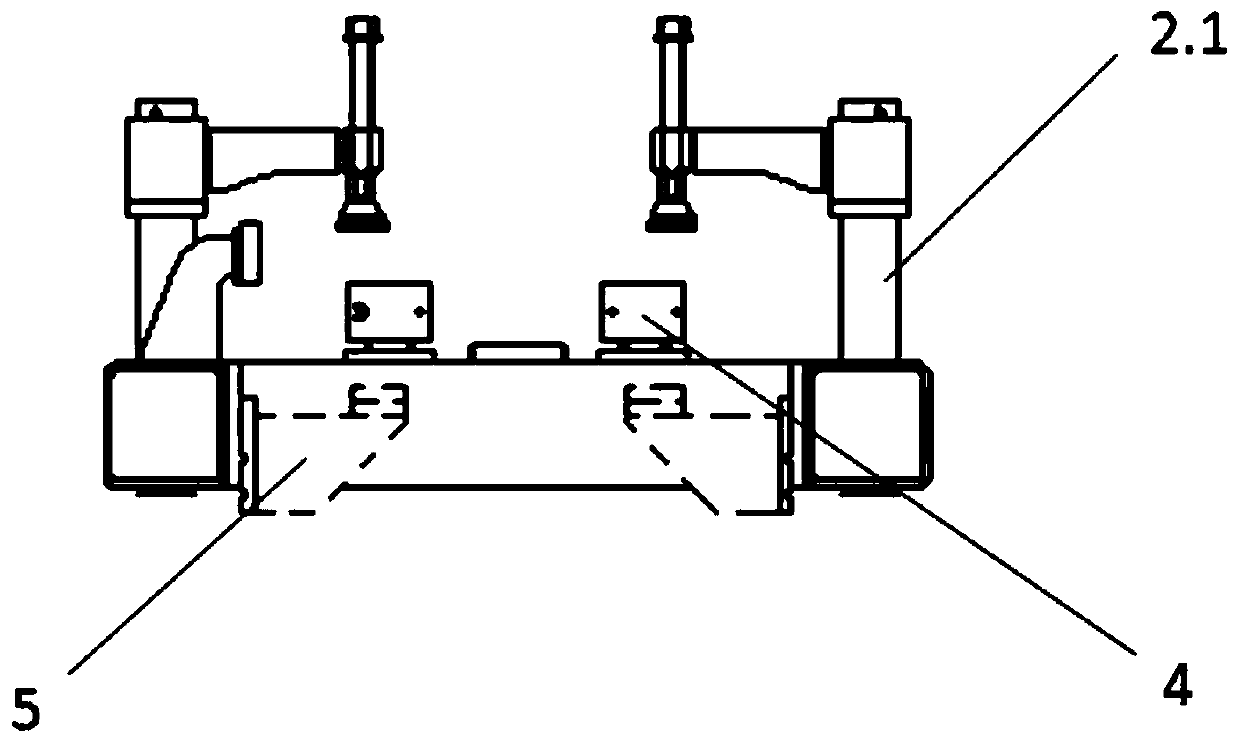

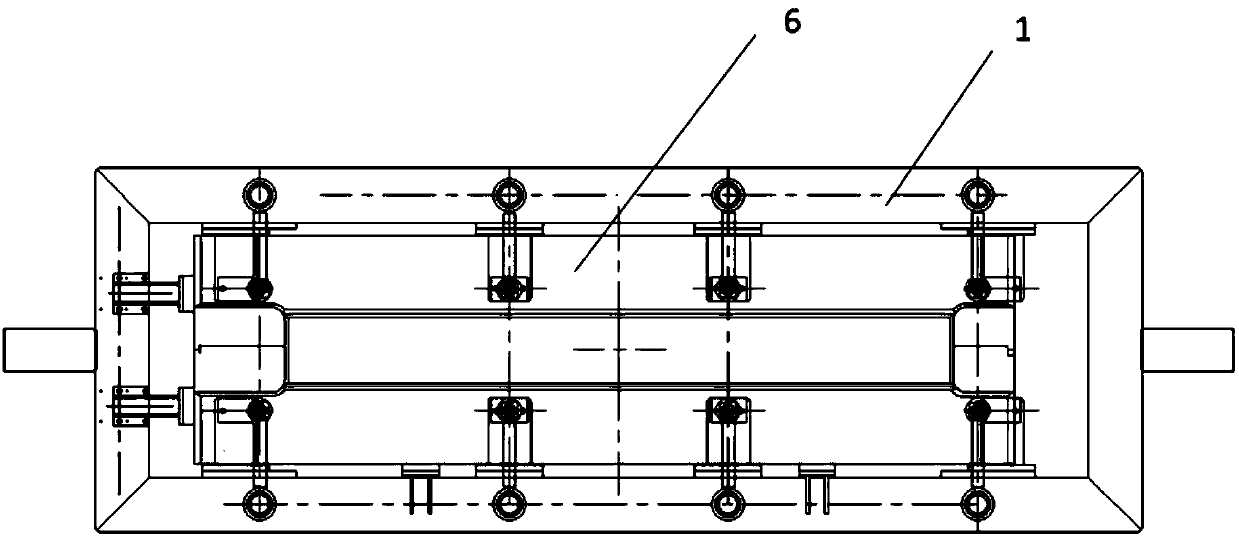

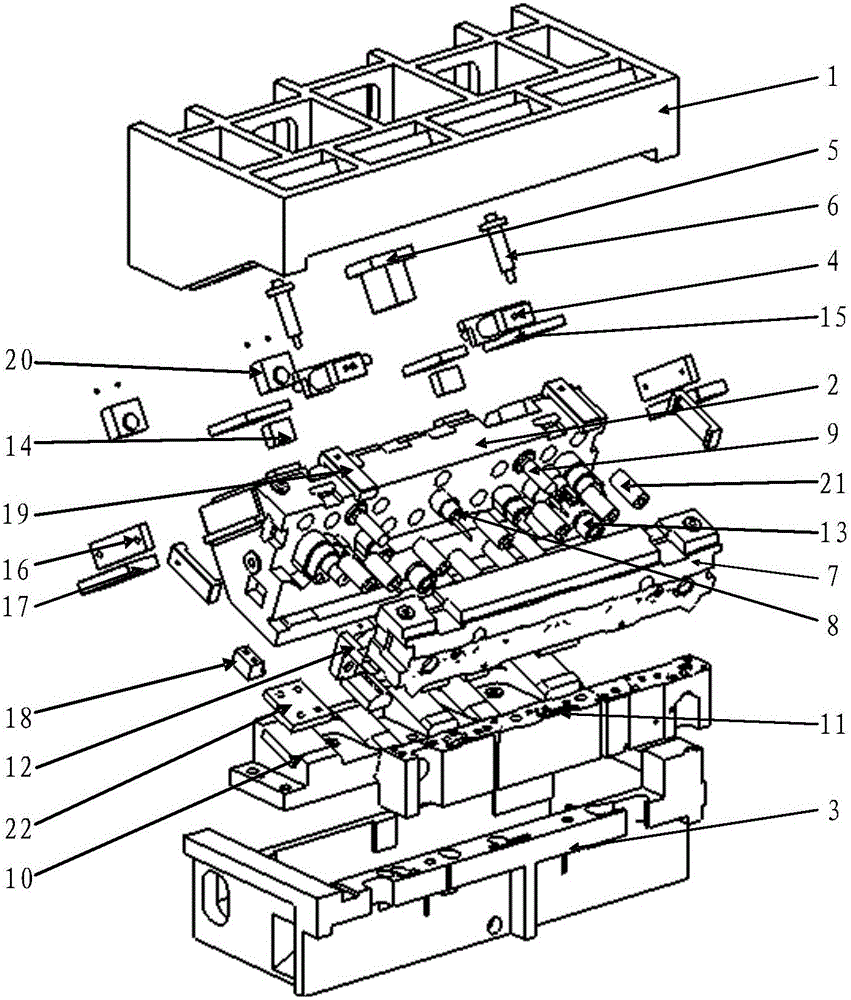

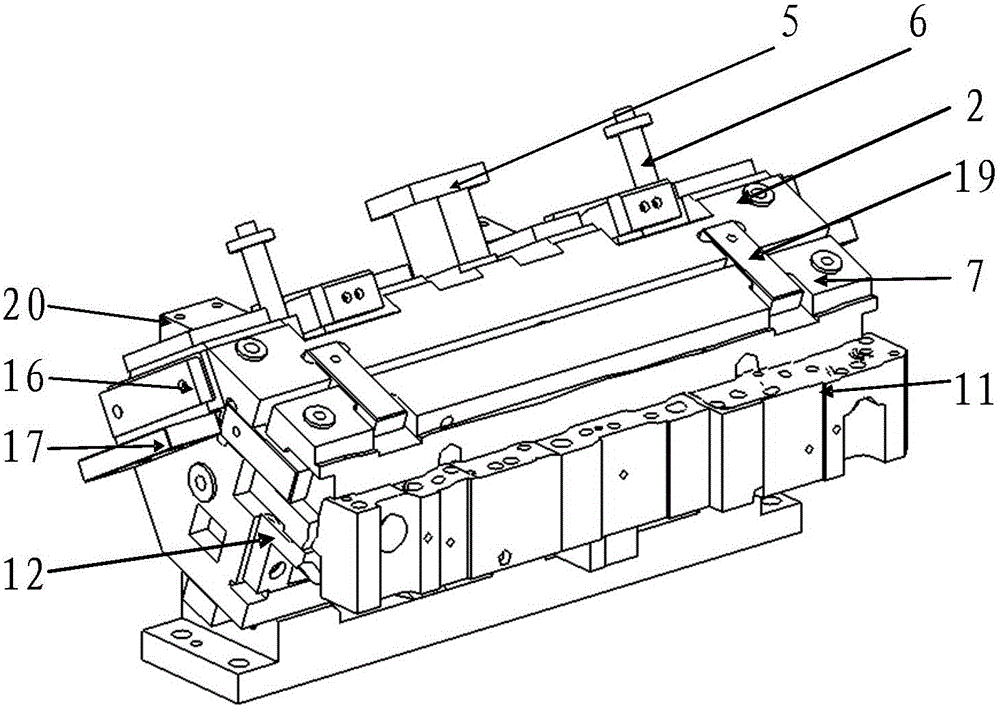

Welding fixture for instrument panel beam attached part group

InactiveCN103949830AReasonable structural designHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBody positions

The invention relates to a welding fixture for an instrument panel beam attached part group. The welding fixture comprises a base, wherein beam end part bracket assembly clamping devices are symmetrically mounted at the left end and the right end of the base, a first positioning clamping device is mounted in the middle of the base, positioning clamping racks are symmetrically mounted in the middle of the base, a second positioning clamping device is arranged in front of the positioning clamping rack positioned on the left side, a left reinforcing bracket positioning clamping device and an IP body positioning bracket assembly clamping device are arranged between the positioning clamping rack positioned on the right side and the first positioning clamping device, and a middle bracket assembly front end clamping device is arranged at the front end of the base. The welding fixture for the instrument panel beam attached part group has the advantages that the structural design is reasonable, the automation degree is high, and the control is convenient; the manual operation is replaced with automation, so that the efficiency of the positioning clamping is improved, and the welding precision is guaranteed; meanwhile, the self-positioning size can be adjusted, so that the welding fixture can adapt to the positioning clamping of the attached part group with different sizes and types, and the welding fixture has a wide application range.

Owner:ANHUI DACHANG TECH

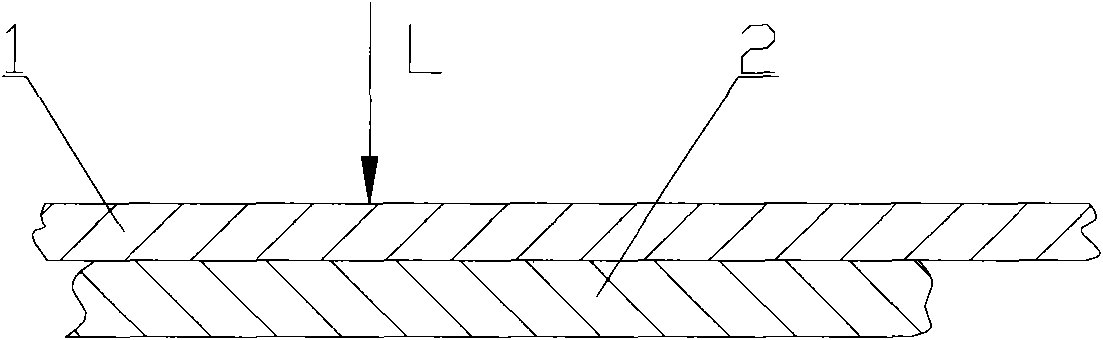

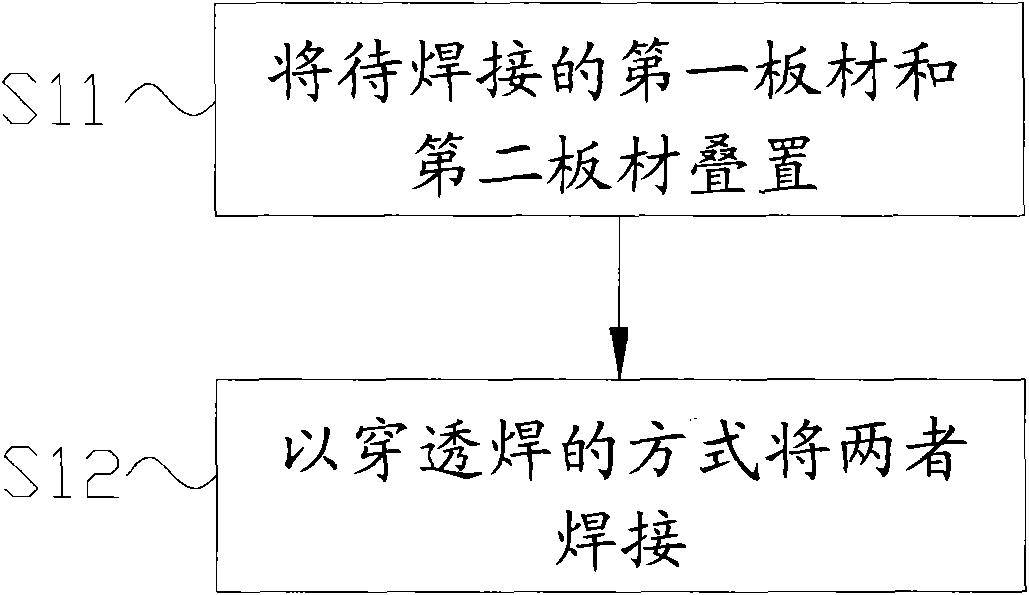

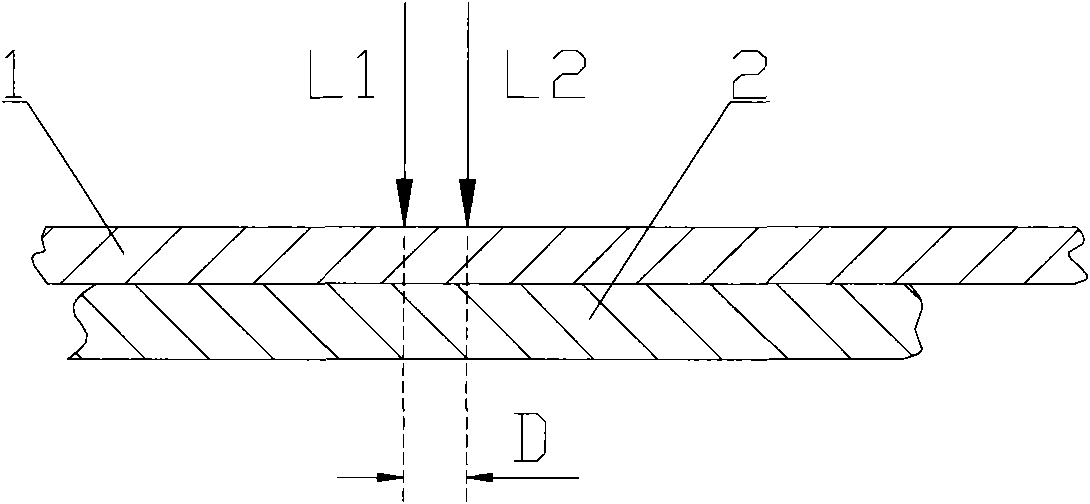

Method for welding plate material of seat of vehicle by laser

ActiveCN101676060AImprove welding effectWelding width widenedWelding/soldering/cutting articlesMetal working apparatusAbsorption rateWeld seam

The invention discloses a method for welding a plate material of a seat of a vehicle by laser, which comprises primary welding and secondary welding which is carried out by the afterheat of the primary welding. The welding seams of the primary welding and the secondary welding are close and have the same extension direction. In the process of the primary welding, a position close to the welding seam of the primary welding is heated, and the temperature of the position is greatly enhanced; then, the secondary welding is carried out on the position with the enhanced temperature, the laser absorption rate of the secondary welding is greatly enhanced, and the welding effect of the secondary welding is surely enhanced obviously. Furthermore, the welding width of the welding operation is remarkably widened due to the existence of the two close welding seams, and the welding effect is further enhanced.

Owner:HUBEI AVIATION PRECISION MASCH TECH CO LTD

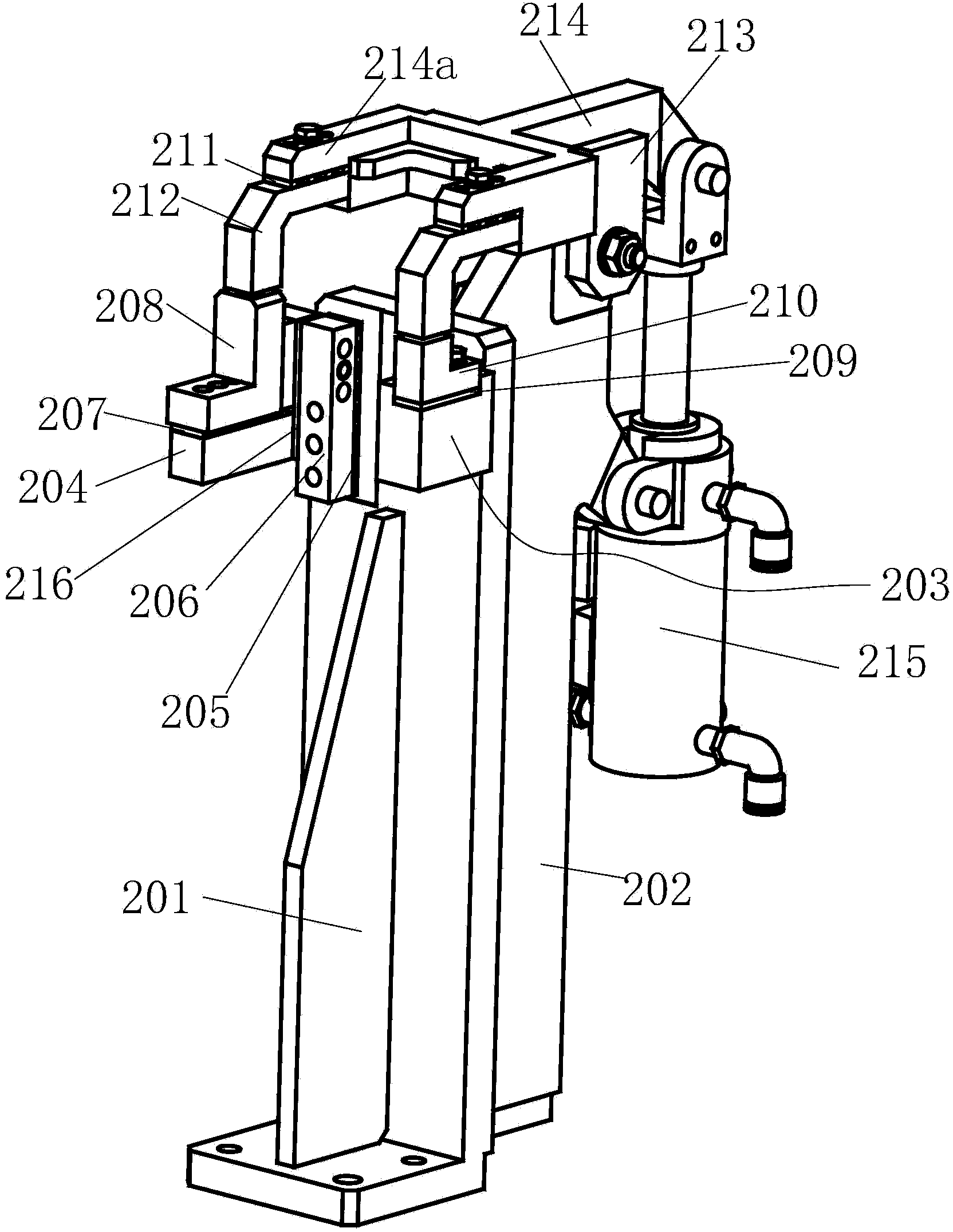

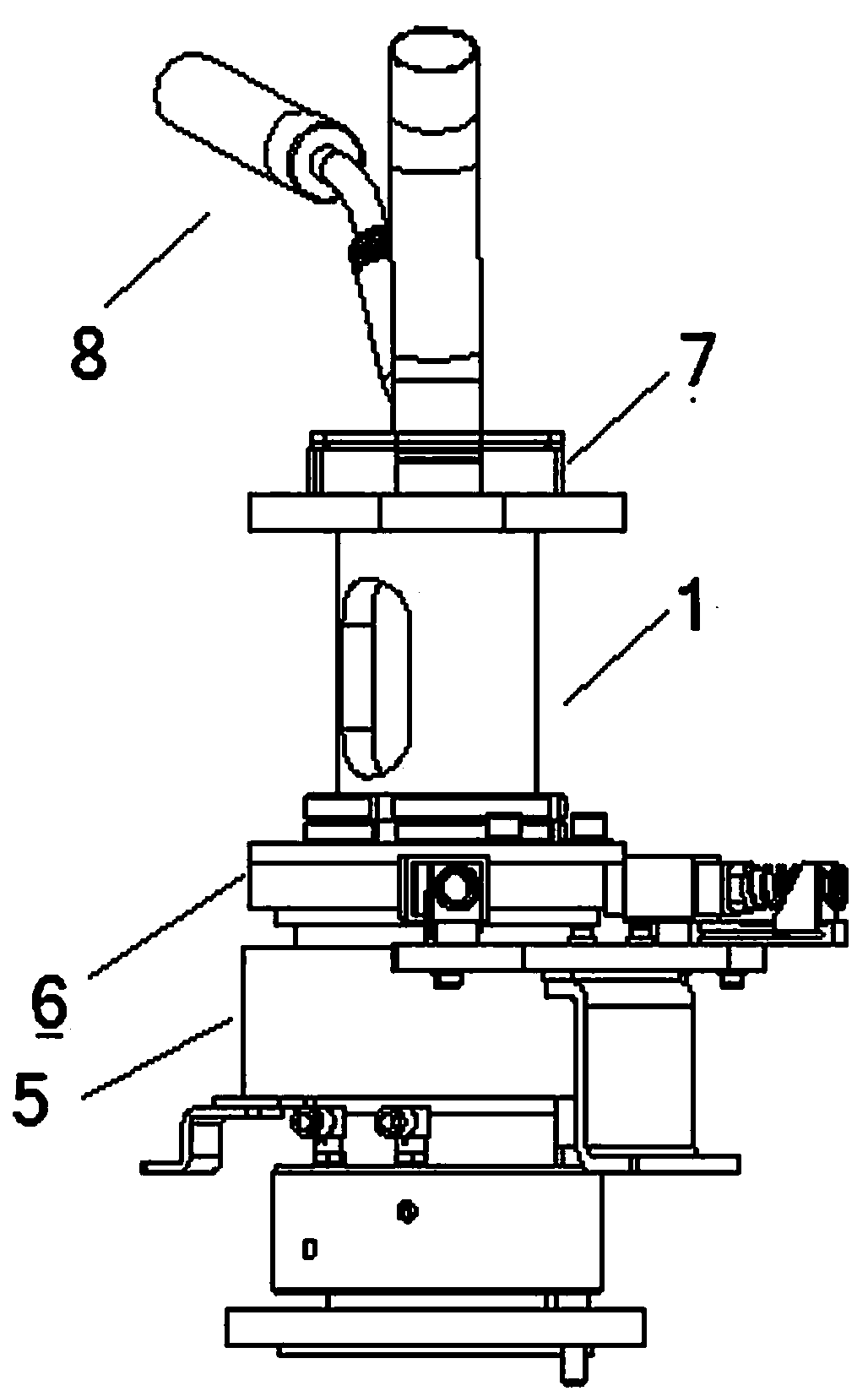

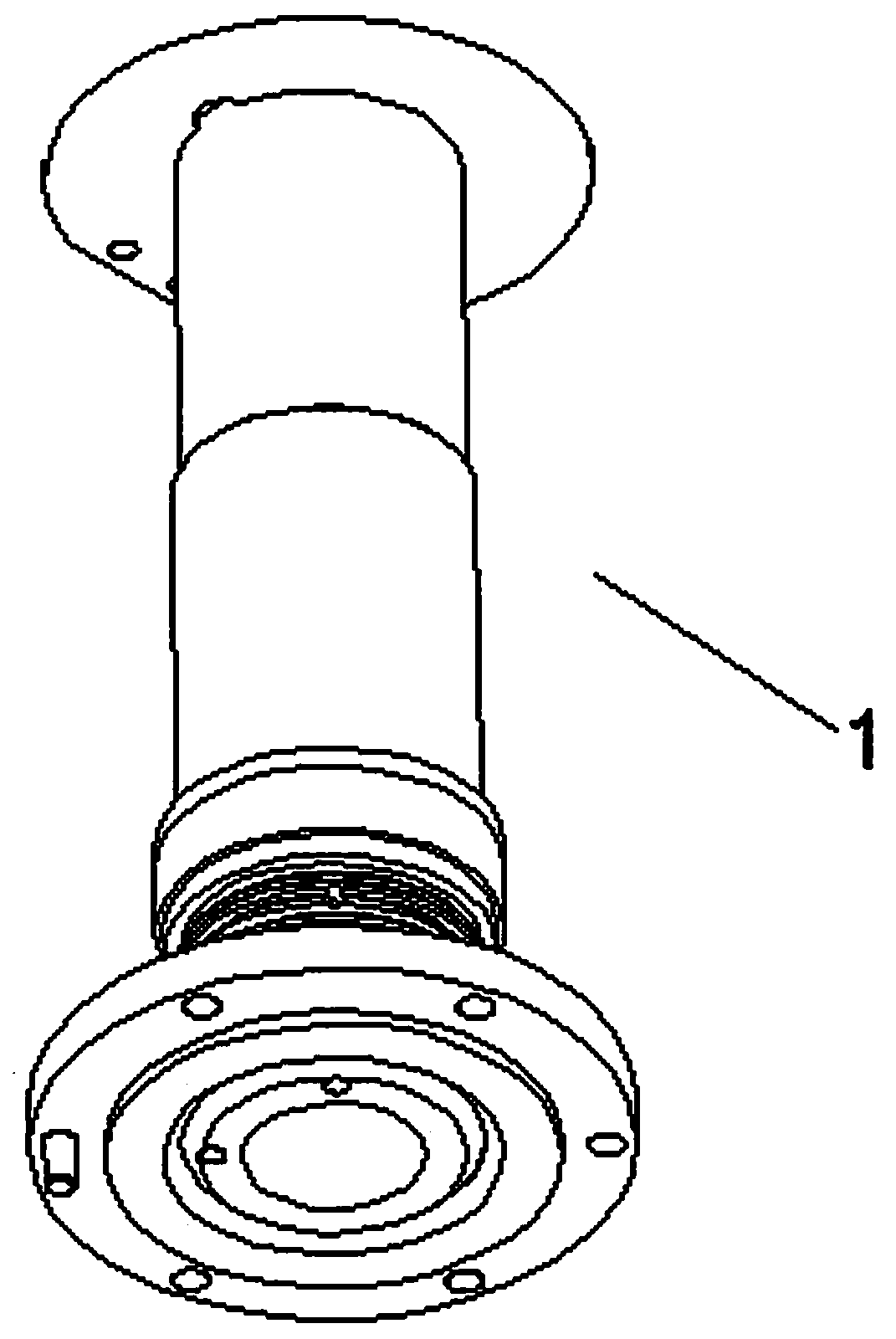

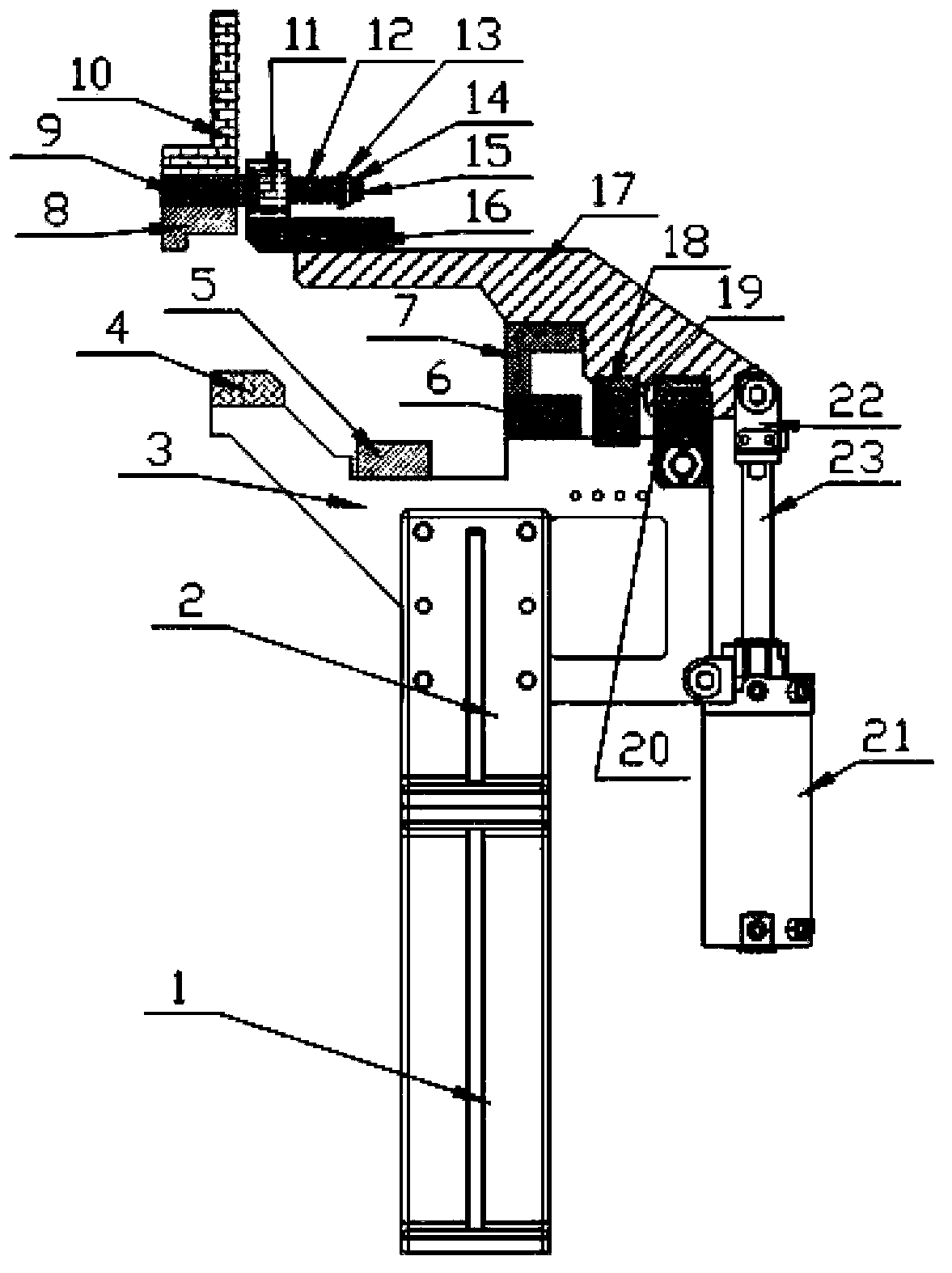

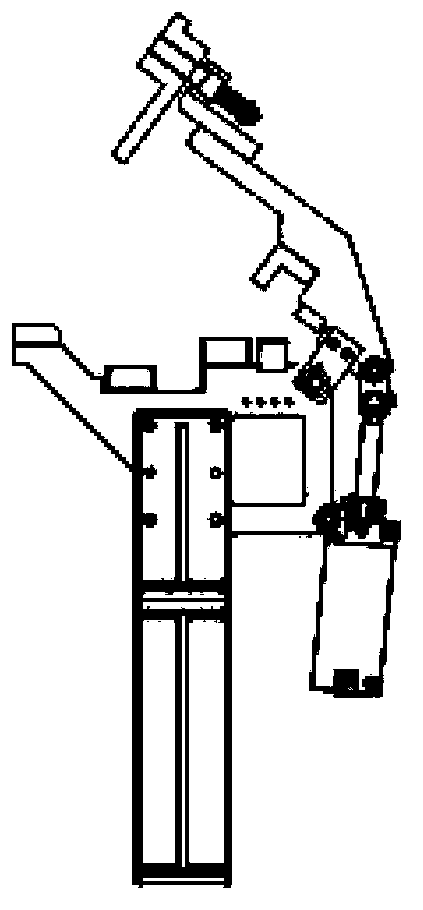

Vertical annular welding tool

ActiveCN104028884AImprove welding qualitySolve the entanglementWelding/cutting auxillary devicesElectrode holder supportersEngineeringStructural engineering

The invention discloses a vertical annular welding tool. The vertical annular welding tool comprises a rotatable platform and a hollow upright column, wherein the hollow upright column is perpendicular to the rotatable platform and sleeves the rotatable platform via a clearance; a gas guiding ring, a conductive ring and a ground wire grounding copper ring sleeve the upright column; a gas circuit, an electric control circuit and a welding ground wire are arranged in a hollow cavity of the upright column; a workpiece positioning mechanism is fixed on the upper portion of the upright column; and a wire feeding machine and a welding gun mechanism are fixed on the rotatable platform. Rotating power is provided by using a speed reducer; circuit transmission is carried out by using the conductive ring; and gas is turned on, turned off and changed over via the gas guiding ring, the welding gun can be adjusted multi-dimensionally in space, namely, the welding gun can be adjusted in the up-down direction and the left-right direction at an angle, annular welding between tubes, annular welding between a tube and a flange and annular welding between a tube and a plane can be performed, the product differentiation switching efficiency and the welding quality are improved, the welding angle and the welding speed can be freely adjusted, annular welding can be performed rotatably without limitation, workpieces do not need to rotate, and the time can be greatly saved. The vertical annular welding tool is suitable for annular welding between the tubes, annular welding between the tube and the flange and annular welding between the tube and the plane, or is suitable for welding an arc.

Owner:GREAT WALL MOTOR CO LTD

Clamping device

ActiveCN103862218AReduce in quantityReduce the impactWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to the field of a welding fixture and particularly discloses a clamping device. The clamping device comprises a supporting seat, a lower supporting plate, an upper supporting plate and a telescopic driving mechanism; the lower supporting plate is fixed on the supporting seat; one end of the lower supporting plate is rotatably connected with the upper supporting plate and the other end of the lower supporting plate is provided with a first lower clamping block; both ends of the telescopic driving mechanism are respectively connected with the lower supporting plate and the upper supporting plate; the upper supporting plate is provided with a spin chuck; the spin chuck is provided with a plurality of upper clamping blocks with different sizes; and the positions of the upper clamping blocks correspond to the positions of the first lower clamping blocks. According to the invention, universality of the clamping device on clamping and welding of parts with different heights; on the premise of ensuring part welding accuracy and part welding quality, the clamping device has a simple structure and is convenient to operate, the number of tools is reduced, an occupied space is small, influence on soldering plier operation is low, the welding repair operation is carried out a little, production cost is greatly reduced and production efficiency is effectively improved.

Owner:BEIQI FOTON MOTOR CO LTD

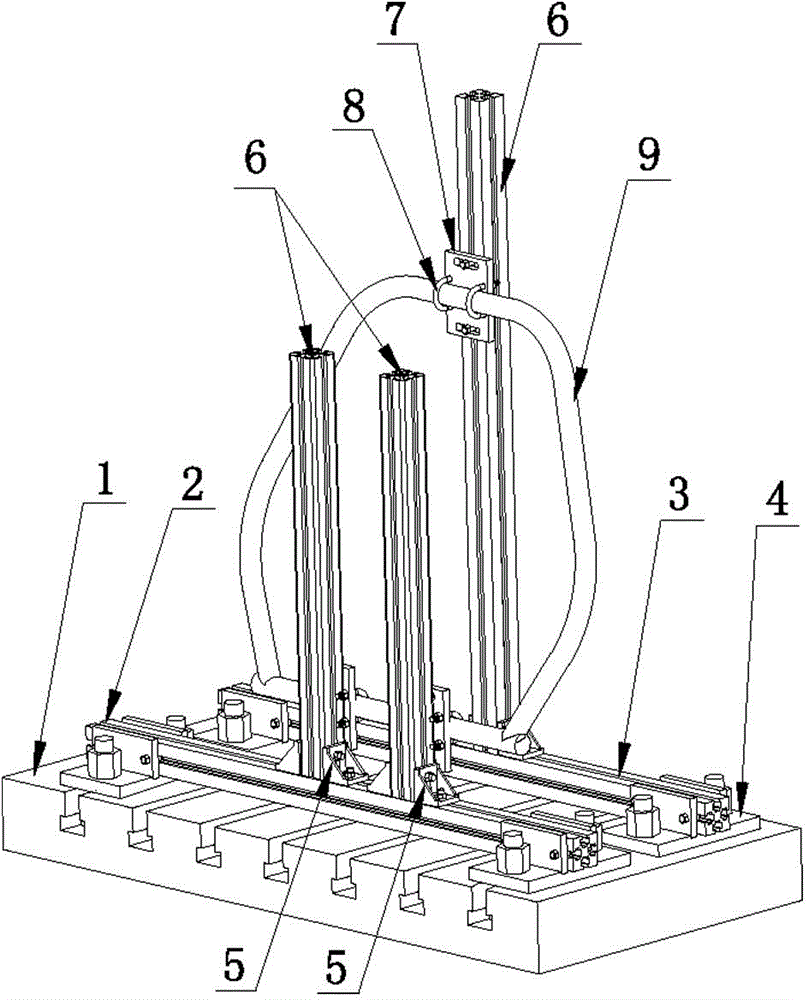

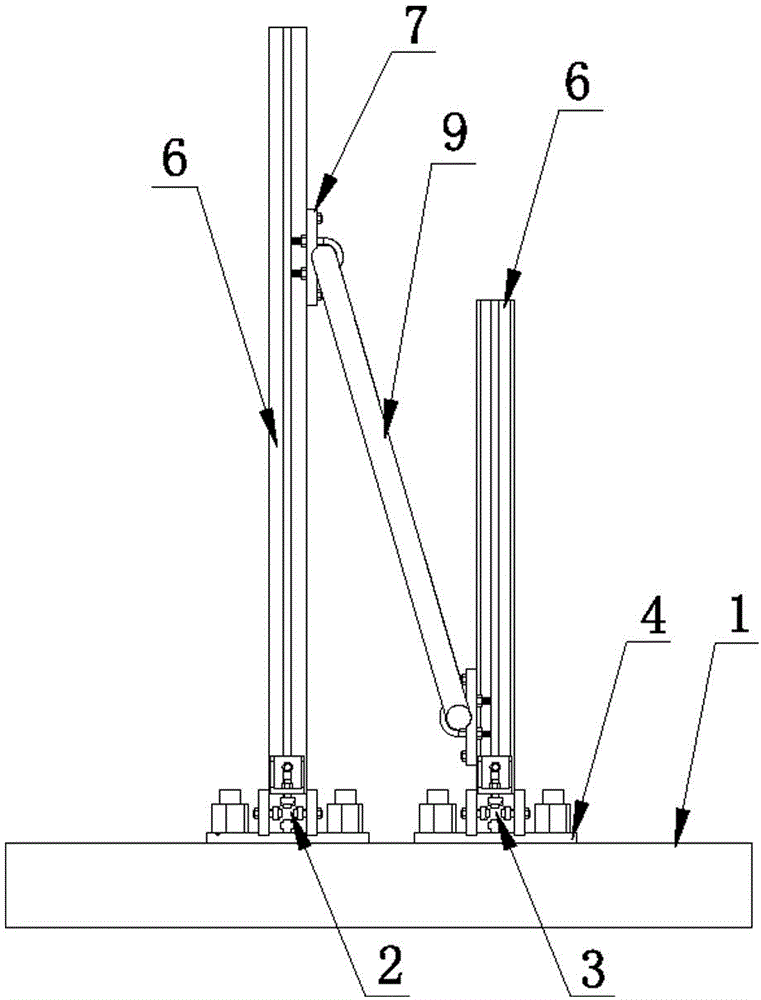

Racing automobile frame welding jig

InactiveCN104439851AAvoid deformationEasy to buildWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention provides a racing automobile frame welding jig which comprises a platform. Inverted T-shaped grooves are formed in the platform. Horizontal 4040 aluminum profiles are arranged on the faces of the inverted T-shaped grooves of the platform. The two ends of each horizontal 4040 aluminum profile are fixedly connected with the platform through T-shaped fixing clamping plates respectively. L-shaped corner joint plates are oppositely arranged on each horizontal 4040 aluminum profile. A vertical 4040 aluminum profile is vertically clamped between every two opposite L-shaped corner joint plates. An arc-shaped groove fixing clamping plate is arranged on one vertical 4040 aluminum profile and is composed of an arc-shaped groove fixing plate and U-shaped bolts. In the use process, a frame steel pipe is clamped and fixed through the arc-shaped groove fixing clamping plate. By means of the jig, all parts of a frame can be fixed and welded independently, overall welding is conducted after residual stress is eliminated, and therefore the stability of the frame is ensured, and the racing automobile machining and manufacturing are smoothly achieved; meanwhile, all the components of the jig are low in price, and the jig is convenient to detach, capable of being repeatedly used, long in service life and capable of greatly reducing the competition cost.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

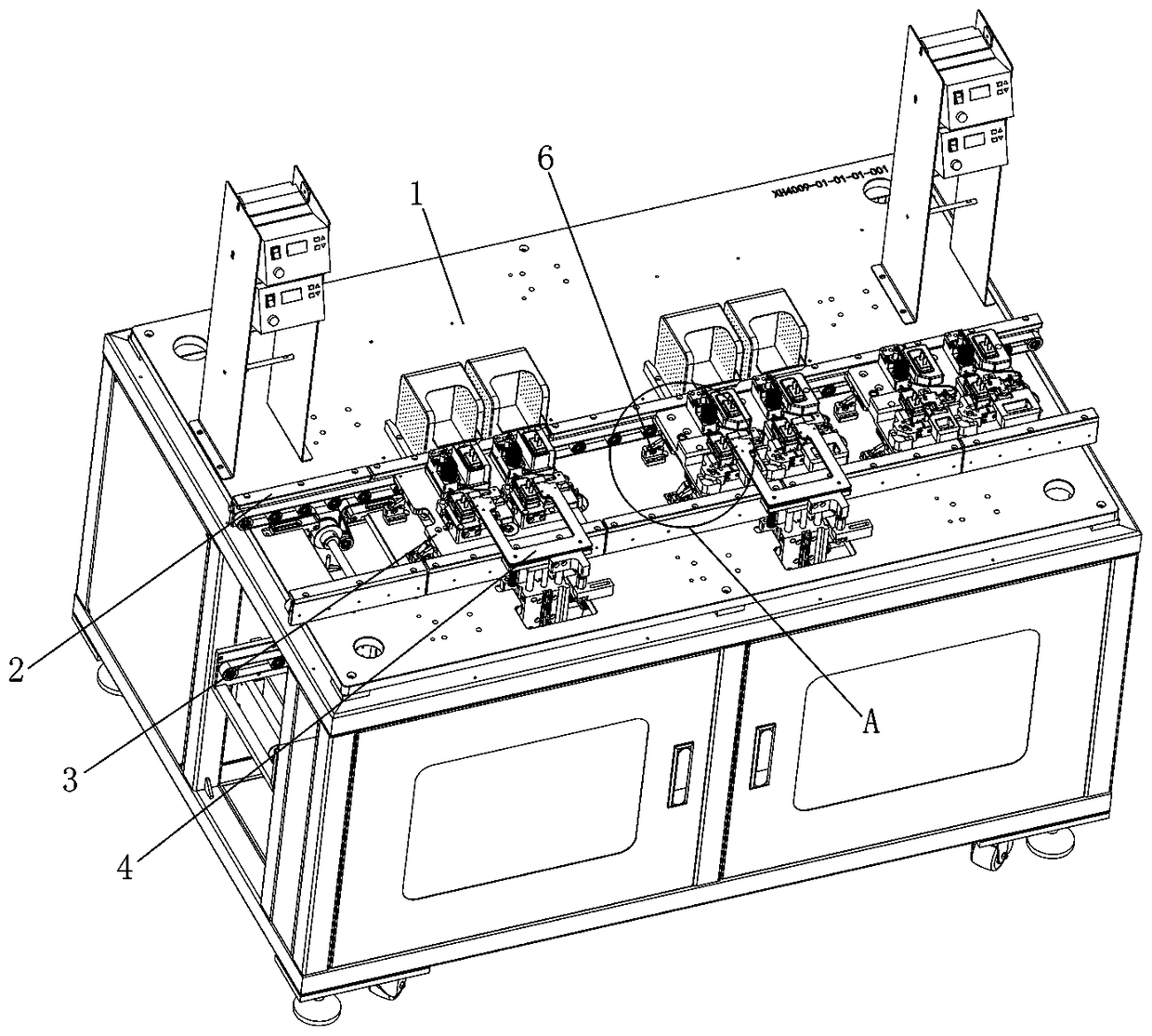

Automatic welder for DC wire of power supply

PendingCN108213645AImprove welding efficiencyPrecision weldingOther manufacturing equipments/toolsSoldering auxillary devicesFine-tuningWelding

The invention discloses an automatic welder for DC wires of a power supply. The automatic welder comprises a conveying pulling body, jigs, a jig positioning mechanism, a pressing mechanism and a welding mechanism, wherein the conveying pulling body is arranged on a rack along a left-right direction; the at least two jigs are arranged on the conveying pulling body; at least two PCBs of the power supply and DC wires of the power supply are placed on the jigs; a welding station is arranged on the side part of the conveying pulling body; the jig positioning mechanism is arranged at the welding station; the pressing mechanism is arranged on the front side of the jig positioning mechanism; the welding mechanism bestrides the upper side of the conveying pulling body and is arranged correspondingto the jig positioning mechanism, and the welding mechanism solders and fixes the connecting parts of the DC wires of the power supply and the PCBs of the power supply; and the jig positioning mechanism loosens the jigs after being soldered. The PCBs and the DC wires which are automatically conveyed and welded are effectively jointed, the PCBs and the DC wires are clamped stably; and the welding mechanism with a flexible fine tuning function achieves precise welding and automatic smoke exhaust and is high in welding efficiency.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Steel pipe positioned-welding device for industrial machinery and welding method

InactiveCN108772665AGuaranteed welding accuracyWeld firmlyEdge grinding machinesWelding/cutting auxillary devicesSteel tubePipe welding

The invention discloses a steel pipe positioned-welding device for industrial machinery and relates to the technical field of industrial machinery. The steel pipe positioned-welding device comprises afixing shell, wherein a fixing bracket is arranged at the bottom of an inner cavity of the fixing shell; a welding tank is connected with the opposite end surfaces of the fixing bracket; motors are arranged on the inner walls of both the left and right sides of the welding tank; rotating shafts are connected with the output ends of the motors; driving gears are connected with the other ends of the rotating shafts; two groups of fastening devices are movably connected with an inner cavity of the welding tank; driven gears are connected with the ends, close to the inner walls of the left and right sides of the welding tank, of the fastening devices; a hydraulic telescopic rod is arranged at the top of the inner cavity of the fixing shell; a welding gun is connected with the output end of the hydraulic telescopic rod; and a protective shell is arranged at the top of the inner cavity of the fixing shell. By adoption of the steel pipe positioned-welding device, the steel pipe welding precision can be guaranteed; furthermore, the stability of a steel pipe can be improved when the steel pipe is welded; the joint can be flatter during the steel pipe welding process; the grinding work andthe welding work can be completed by using one device; the operation procedure can be simplified; and the working efficiency can be improved.

Owner:CHENGDU PUJIANG KEXIAN TECH

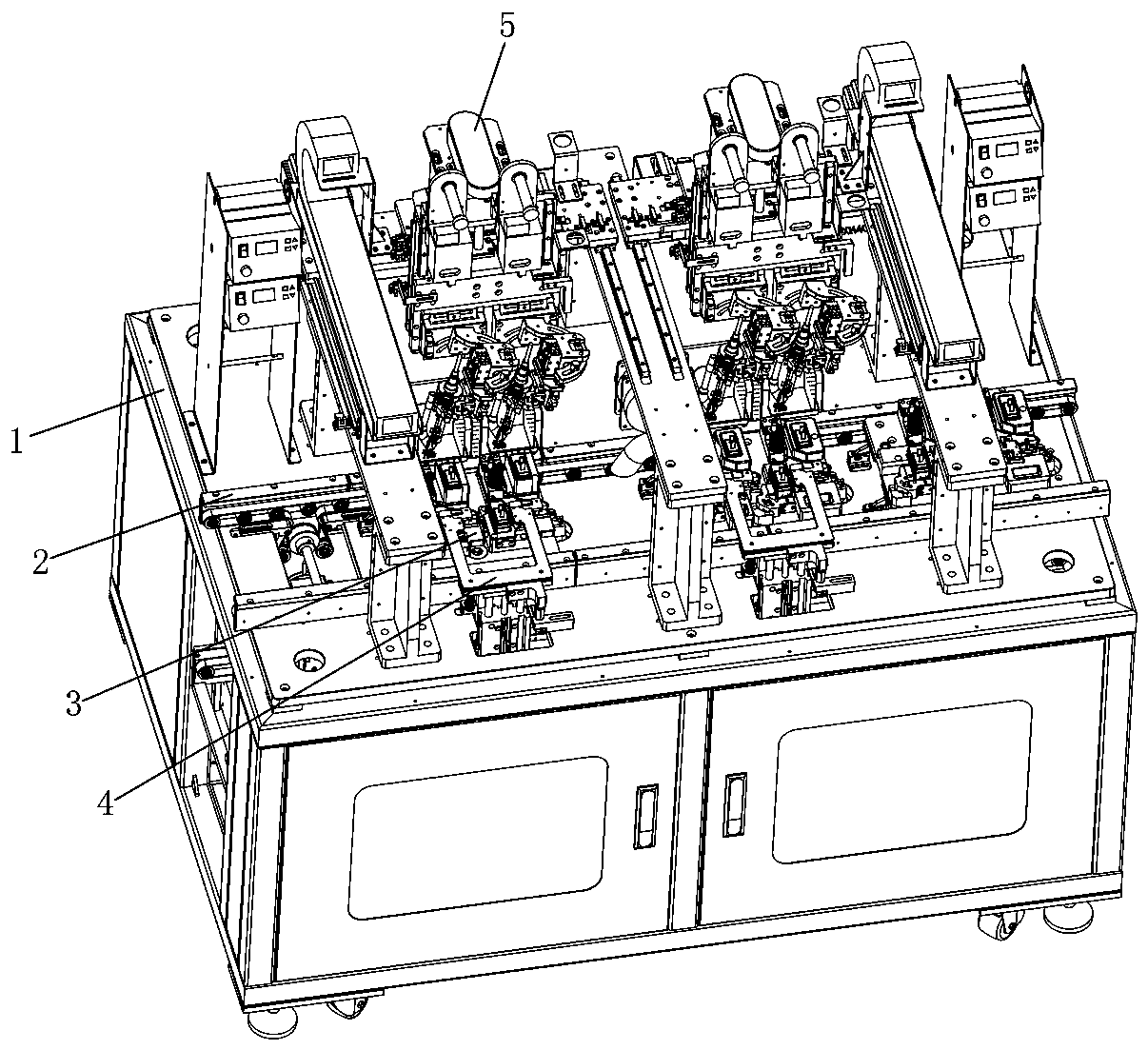

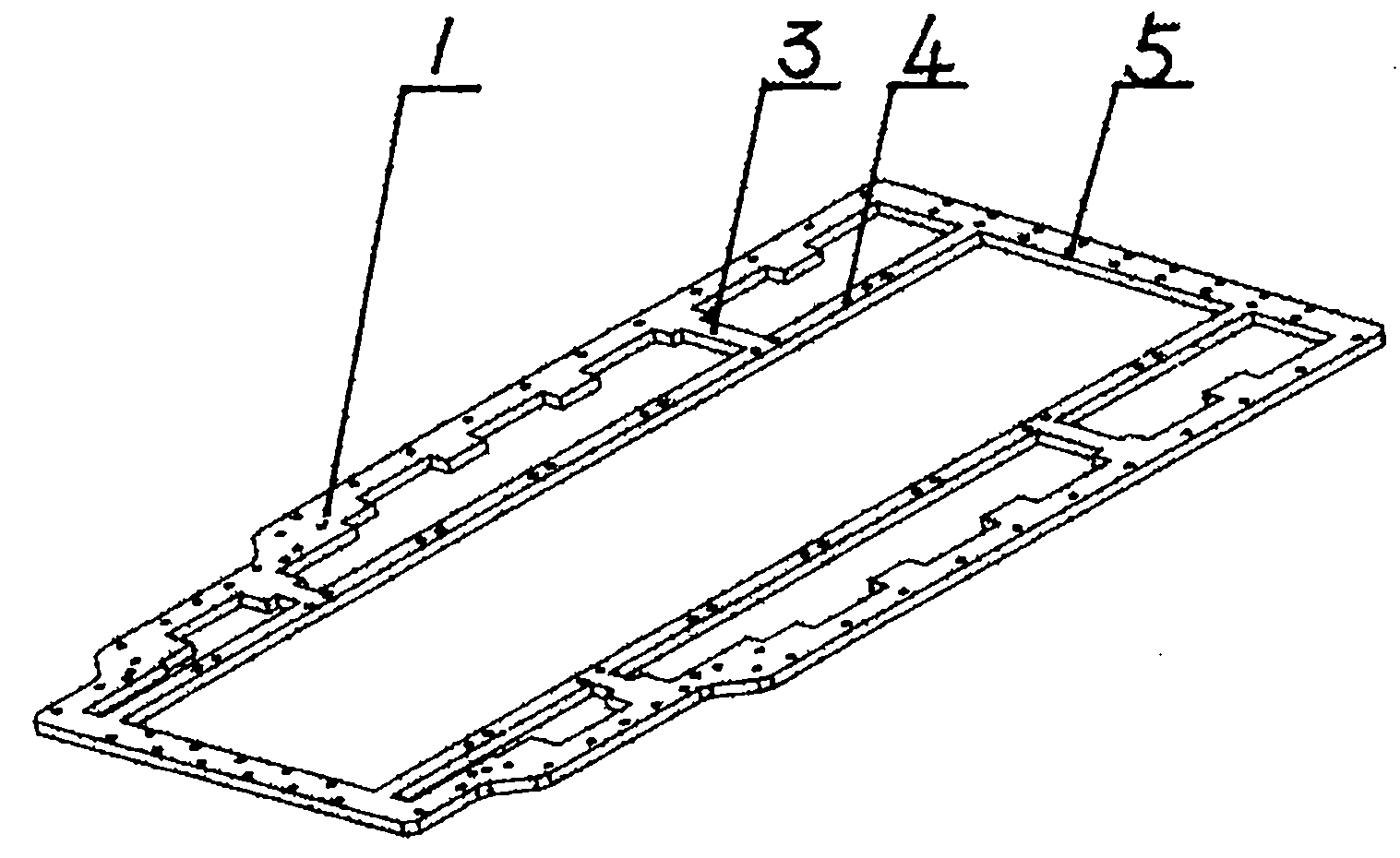

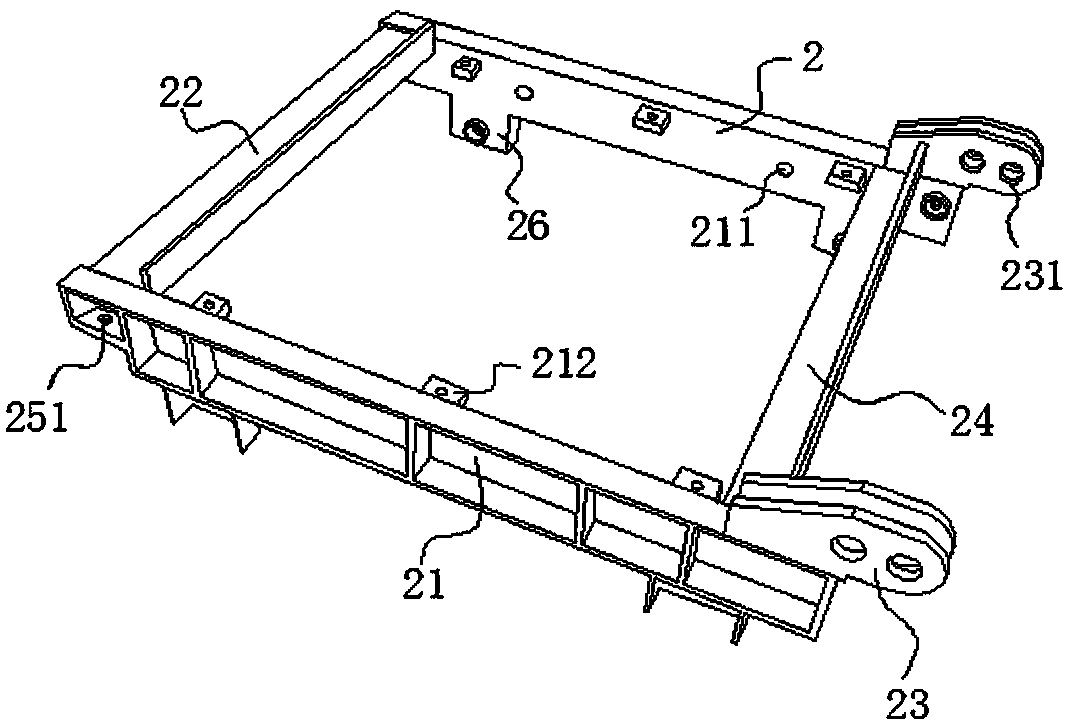

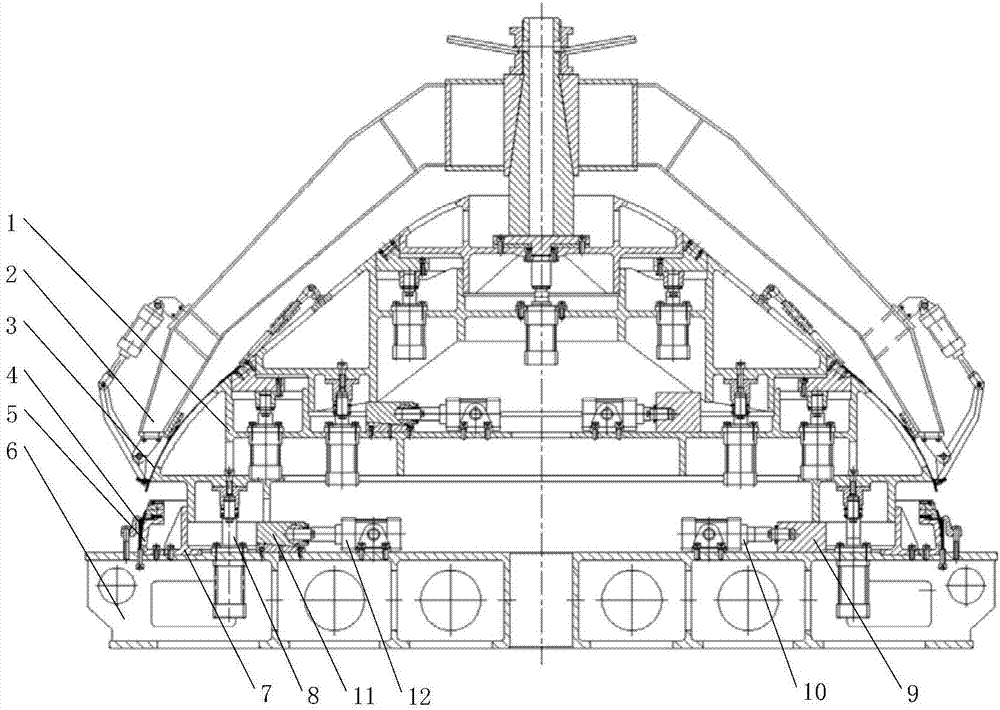

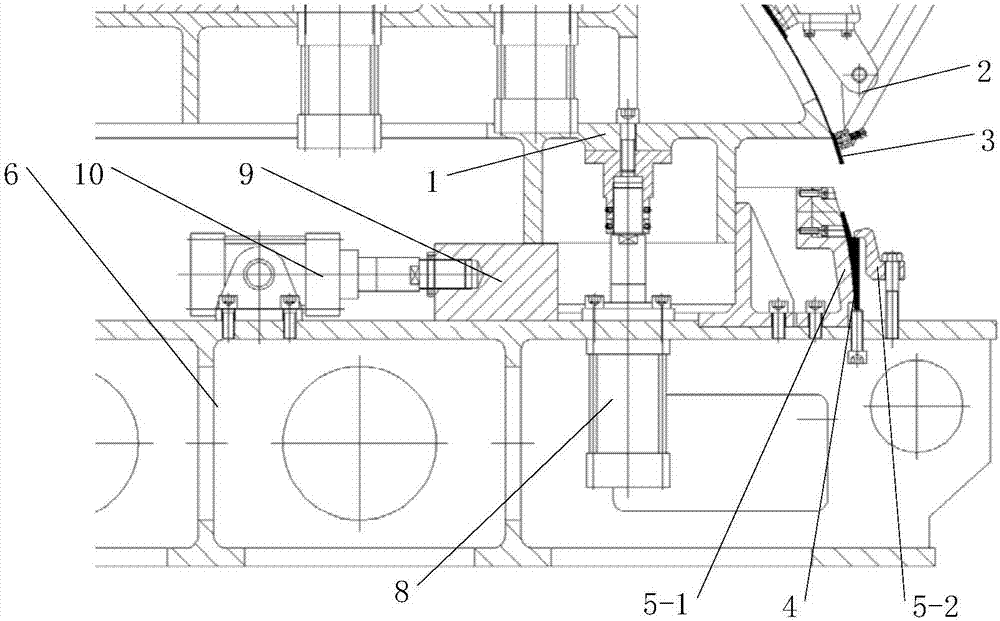

Aluminum alloy car body welding assembly tool

InactiveCN106808131AGuarantee welding qualityGuaranteed welding accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAlloy

The present invention proposes a welding assembly tool for an aluminum alloy car body, the aluminum alloy car body includes a chassis, a roof, a side wall and an end wall, side beams are arranged on both sides of the roof, including a fixing device for the chassis, and It is used to realize the fixed support and positioning of the underframe; the underframe deflection pull-down device is used to realize the prefabricated deflection curve of the underframe; the roof clamping and fixing device is used for clamping and positioning the roof during welding; the side wall assembly adjustment device , used to adjust the verticality and width of the side wall during the assembly process; the side beam assembly adjustment device is used to realize the tension and adjustment of the side beam; the roof clamping and fixing device includes a roof support frame, a setting On the roof supporting frame, an arc-shaped pressing device, a pressure block, an adjustable side clamping device for clamping the side beams on both sides of the roof, and A clamping device that clamps the roof up and down. The invention solves the problems of various types and poor versatility of aluminum alloy vehicle body welding tooling in the prior art.

Owner:CRRC SIFANG CO LTD

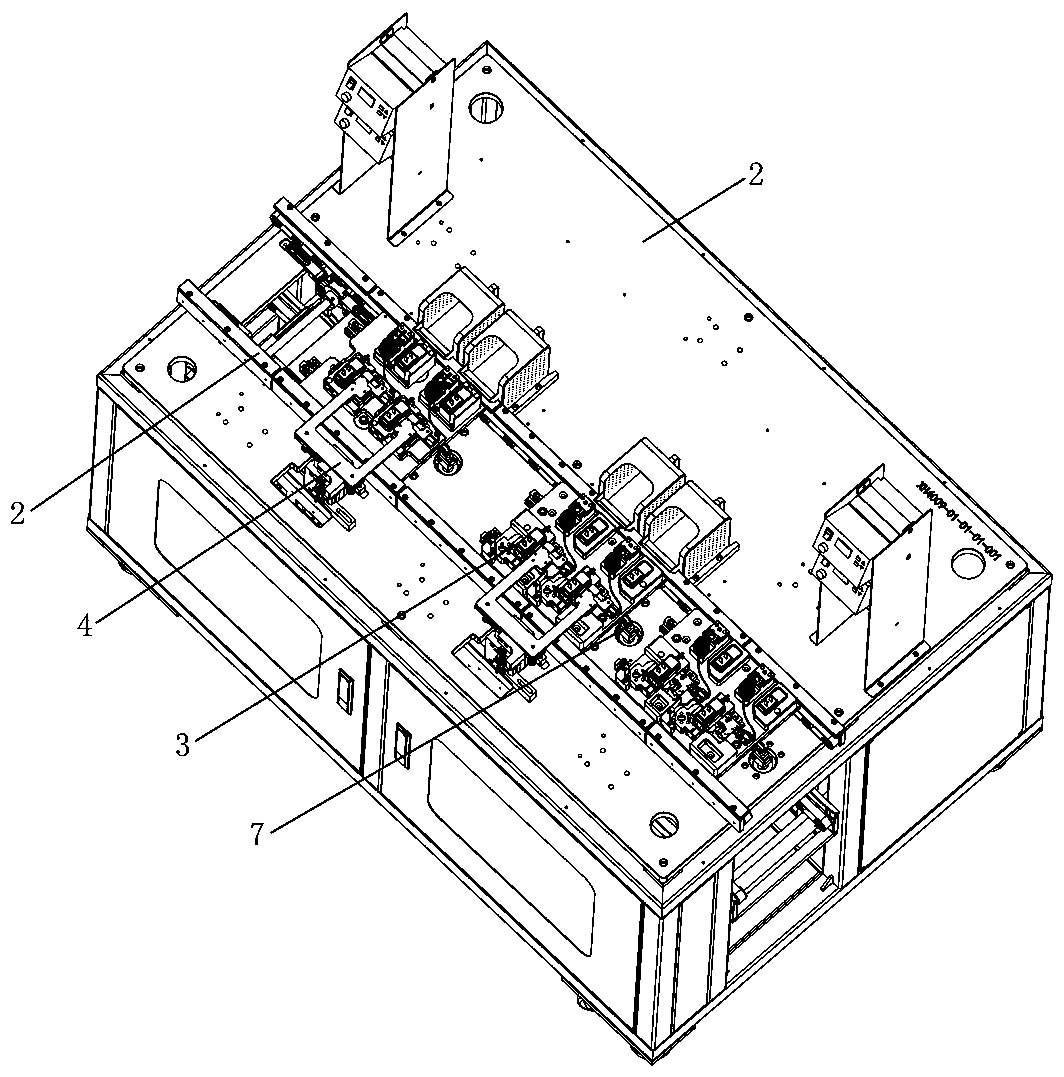

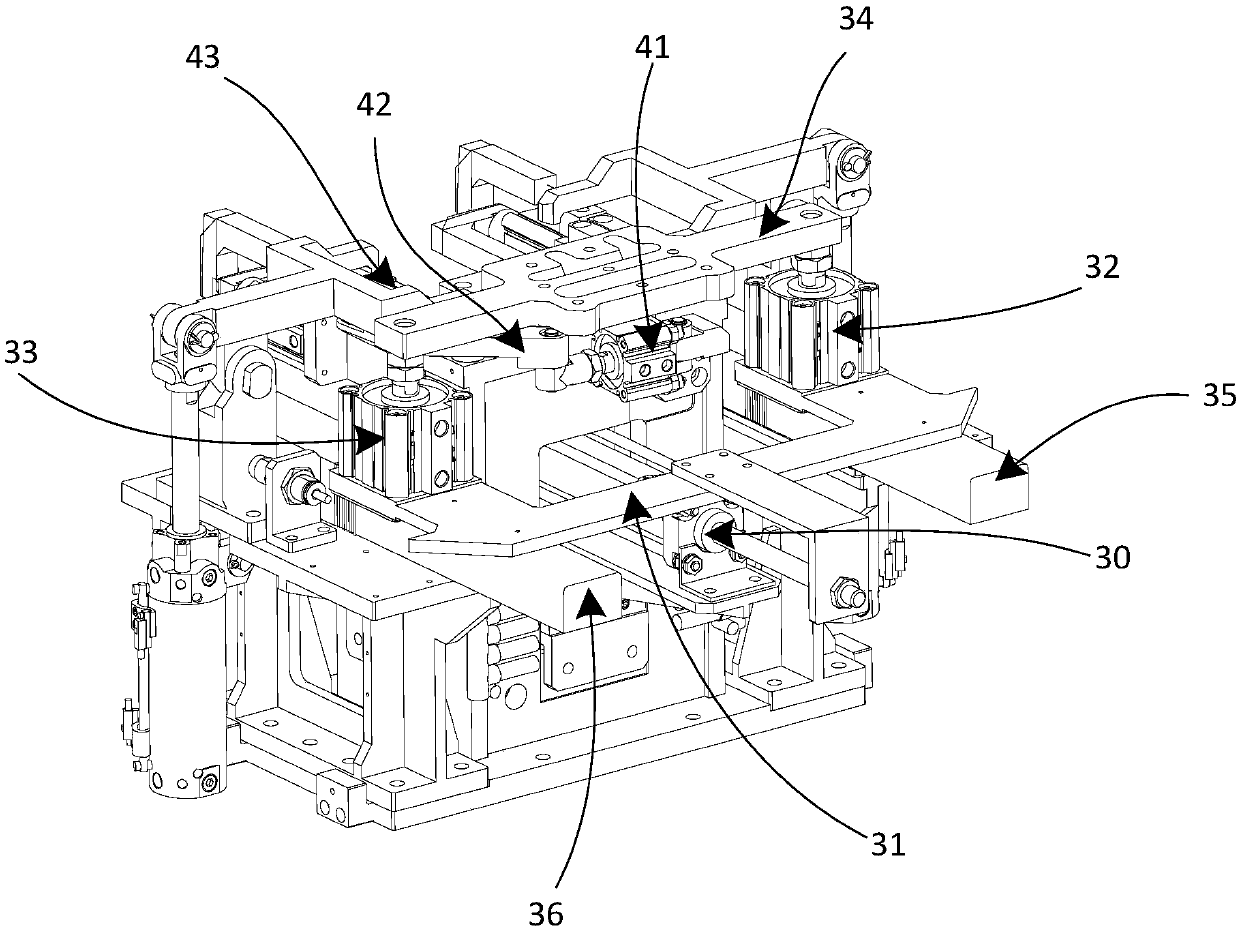

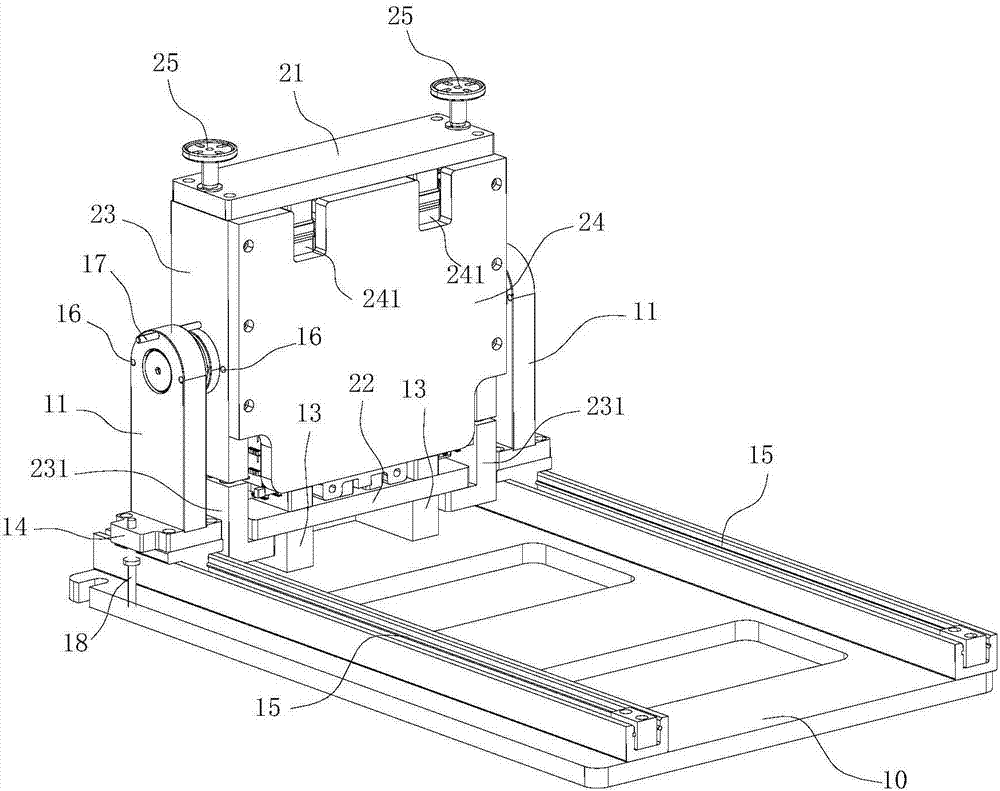

Laser welding fixture and laser welding workstation

ActiveCN109940326AGuaranteed positioningGuaranteed fixed effectWelding/cutting auxillary devicesAuxillary welding devicesGratingControl system

The invention belongs to the technical field of laser welding, and relates to a laser welding fixture and a laser welding workstation. The laser welding fixture comprises a support module, an upper pressing module, a first side pressing module, a second side pressing module and a clamping jaw module; and the support module, the upper pressing module, the first side pressing module, the second sidepressing module and the clamping jaw module are matched to fix machined workpieces in accommodating space. The laser welding workstation comprises a laser, a water cooler, a voltage stabilizing powersupply, an air circuit integration cabinet, a welding main machine and an operation control system, wherein the welding main machine comprises a worktable, an inlet and outlet slide table, a safety optical grating, a welding robot, a welding head and the laser welding fixture. The laser welding fixture and the laser welding workstation can achieve high welding precision, and effectively improvesthe product yield.

Owner:HANS LASER TECH IND GRP CO LTD +1

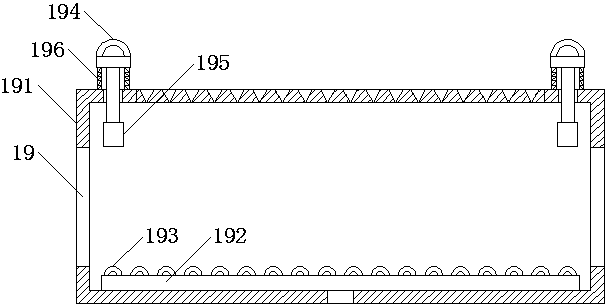

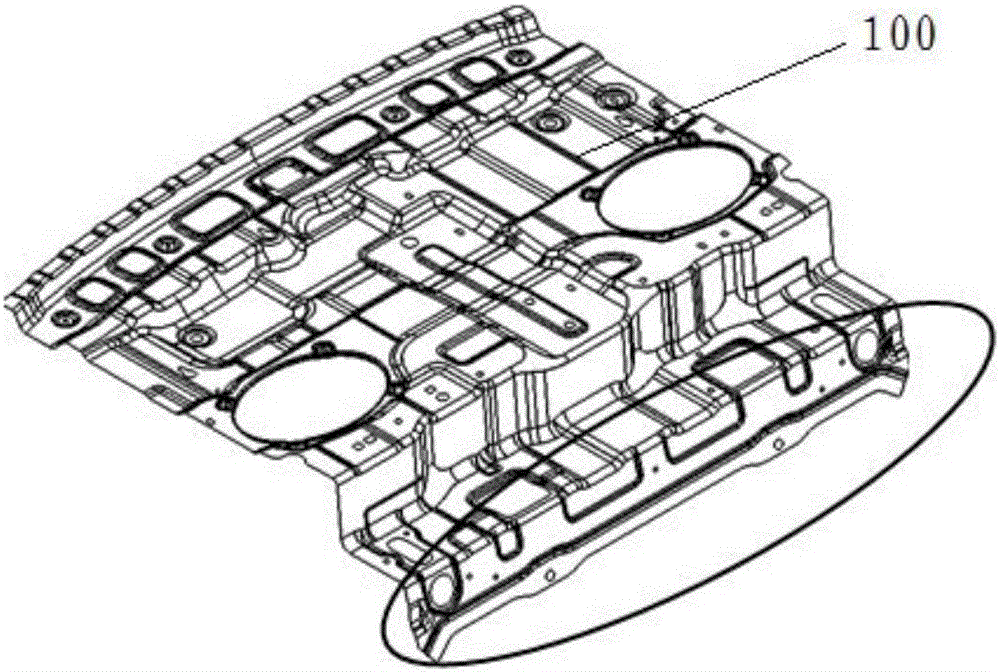

Welding fixture tool of aluminum alloy battery tank body for electric automobile

ActiveCN101862930AHigh positioning accuracyRealize in-line coolingWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryWater flow

The invention relates to a welding fixture tool of an aluminum alloy battery tank body for an electric automobile, comprising an upper fixture frame and a lower fixture frame, wherein a cross brace, a longitudinal beam and a thread hole A are arranged on the upper fixture frame, and the cross brace, the longitudinal beam and the upper fixture frame form a whole; an installing slot, a thread hole B, a cooling channel, a baffle plate, a cooling water inlet and a cooling water outlet are arranged on the lower fixture frame; the cooling channel formed by three cavities is arranged in the lower fixture frame; the annular cooling channel is divided into two parts by the baffle plate arranged at one side of the lower fixture frame, and both sides of the baffle plate are respectively provided with the cooling water inlet and the cooling water outlet which are respectively connected with a water inlet pipe and a water outlet pipe. The invention has the advantages that cooling water flows in the cooling channel to take away heat generated during welding so that the on-line cooling for a welded member and the fixture tool is realized, the deformations of the upper fixture frame, the lower fixture frame, the border of the welded member and a transverse partition wall are furthest reduced, and the welding precision and the quality of a product are ensured.

Owner:天津锐新昌科技股份有限公司

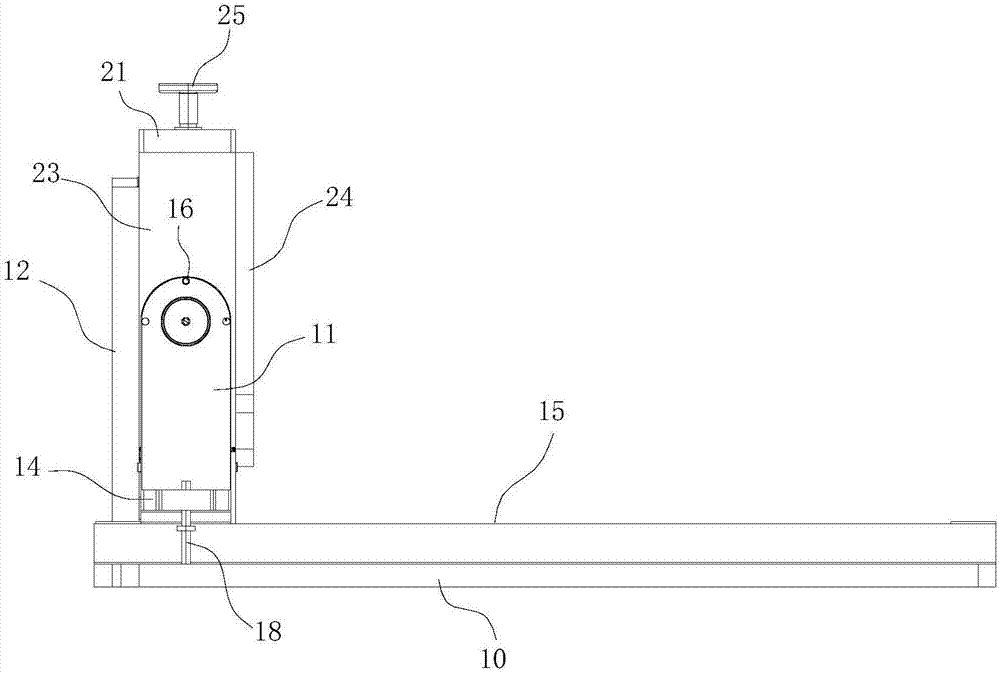

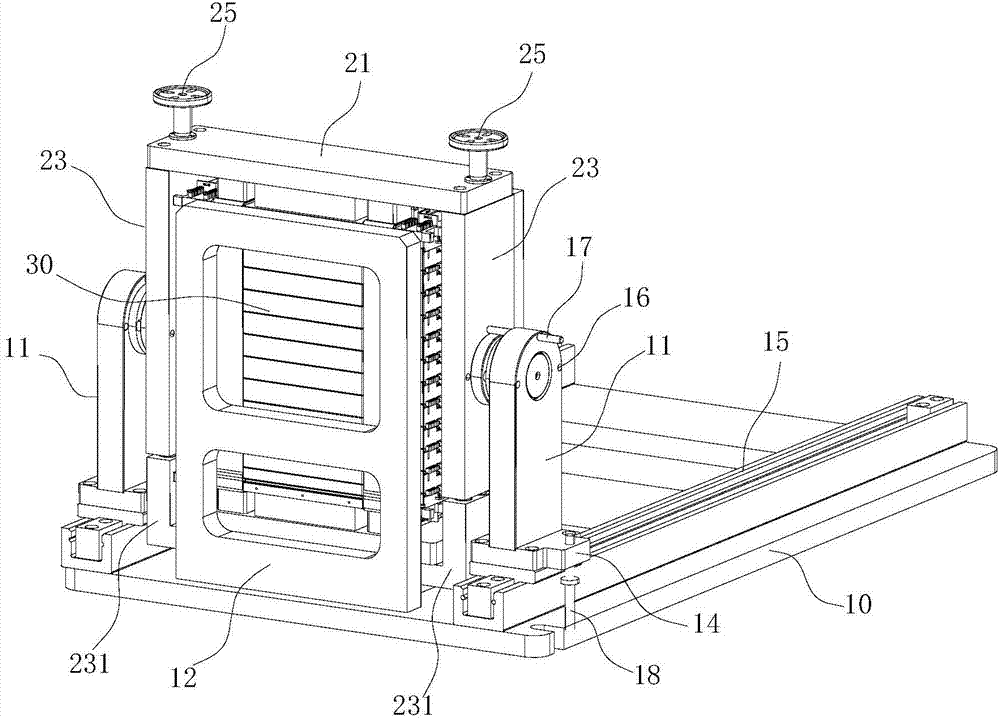

Erecting welding tool for soft package battery module

InactiveCN107030429AMake sure it fitsAssembly precisionWelding/cutting auxillary devicesAuxillary welding devicesHorizontal axisEngineering

The invention belongs to the technical field of electric car battery production and processing, and particularly relates to an erecting welding tool for a soft package battery module. The erecting welding tool for a soft package battery module comprises an overturn frame, a support and a base, wherein the overturn frame is rotationally arranged on the support along the horizontal axis, the support is installed on the base, a limiting device is arranged on the support, and the overturn frame can be locked to stay in the horizontal state or the vertical state by the limiting device. The overturn frame comprises a rectangular frame body and two end plates, wherein the rectangular frame body is formed by a bottom plate, two side plates and a top plate in an enclosure manner, each end plate is arranged at one end of the rectangular frame body, the distance between the top plate and the bottom plate is set to be adjustable, at least the end plate on one side is detachably connected with the rectangular frame body, a chamber for containing a battery module is formed inside the overturn frame, and notches for exposing the welding positions of the battery module are formed in each of the two end plates. With the erecting welding tool for a soft package battery module, the position of the battery module can be fixed, it is guaranteed that all the soft package batteries are aligned accurately, and meanwhile, the shell of the battery module can be tightly clamped, it is guaranteed the batteries inside the shell of the battery module are pressed tightly, and the accuracy of welding is guaranteed.

Owner:ANHUI OFFNENBACH NEW ENERGY TECH CO LTD

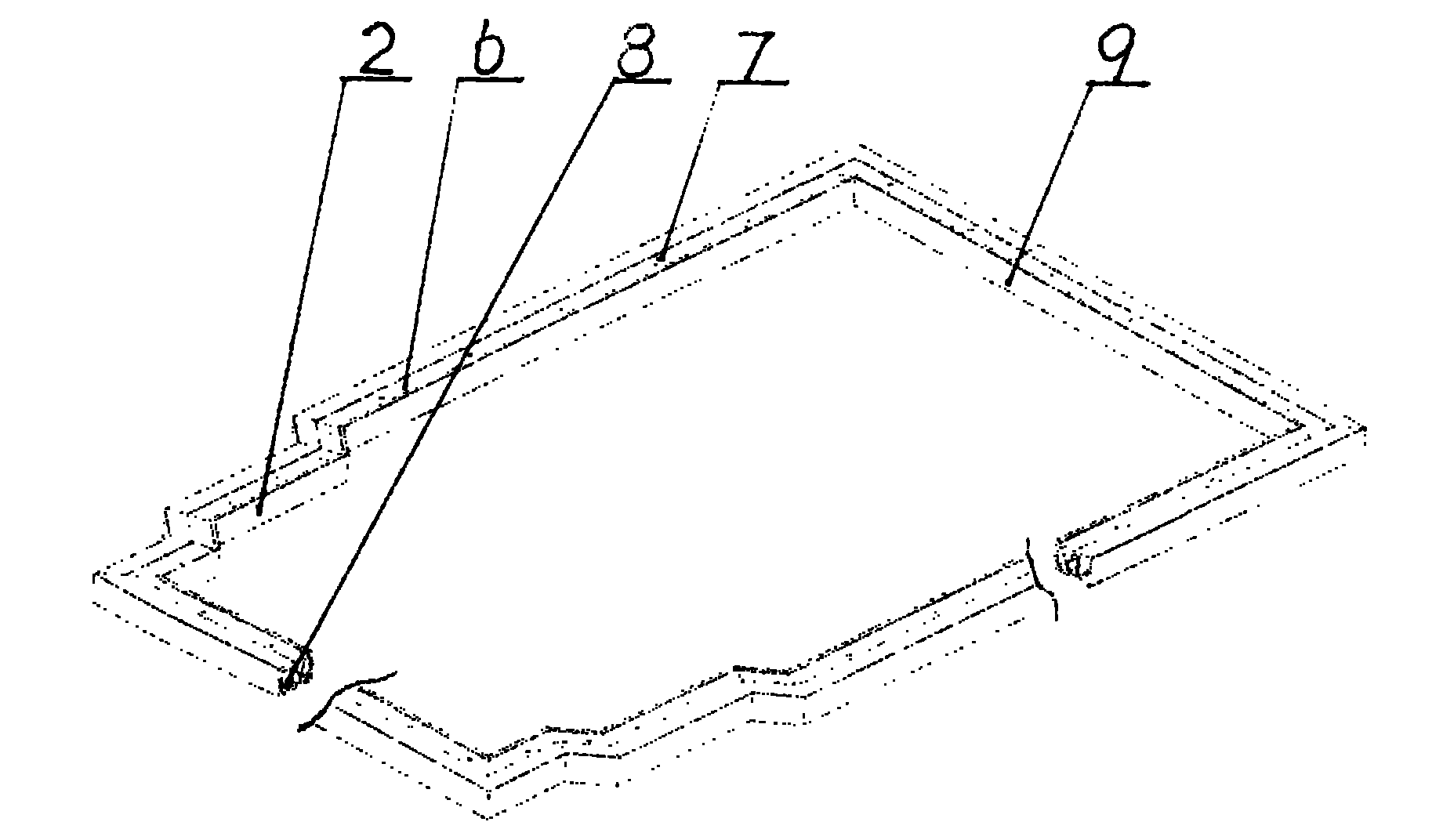

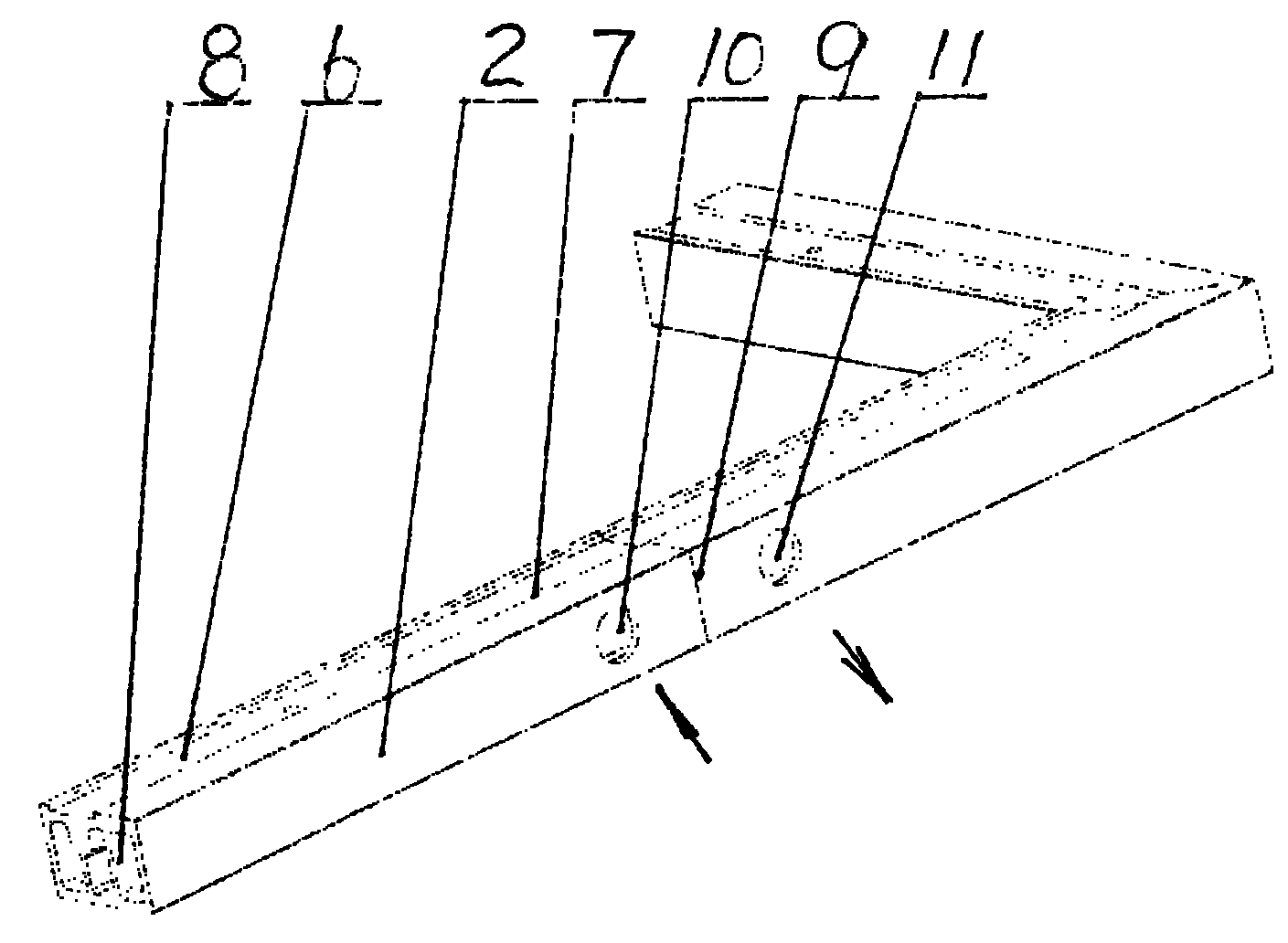

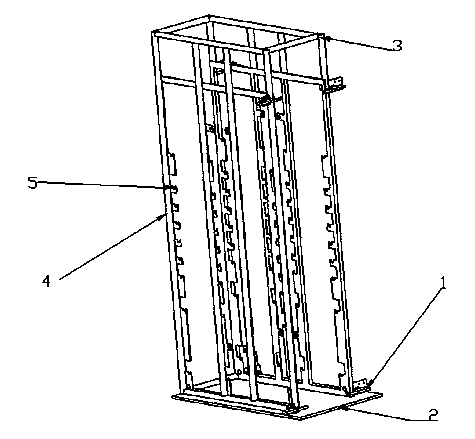

Elevator transmission frame welding and positioning device and welding method thereof

InactiveCN103753093AGuaranteed welding accuracyGuaranteed positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesFixed frameEngineering

The invention relates to an elevator transmission frame welding and positioning device. The elevator transmission frame welding and positioning device is characterized by comprising a welding machine base provided with a left side beam and a right side beam, the left side beam and the right side beam are parallel with each other, the upper surface of the left side beam and the upper surface of the right side beam are respectively and fixedly connected with a bottom plate, the bottom plates are located on the same plane, two cross rods are transversely arranged between the left side beam and the right side beam, the two end faces of each cross rod are respectively provided with threaded holes matched with bolt holes in fixed frames on the two sides of a transmission frame, the back side portion of each bottom plate is provided with an L-shaped supporting plate used for positioning back angle iron on the back side of the transmission frame, the front side portion of each bottom plate is provided with vertical fixing plates matched with the inner side faces of lugs on the front side of the transmission frame, the inner side of each fixing plate is fixedly connected with positioning blocks extending out of the back side face of a connecting plate, and the positioning blocks are perpendicular to the back side face of the connecting plate and are used for positioning front angle iron on the front side of the transmission frame. The invention further relates to a corresponding elevator transmission frame welding method.

Owner:FUJIAN YOUSHENGDA ELEVATOR

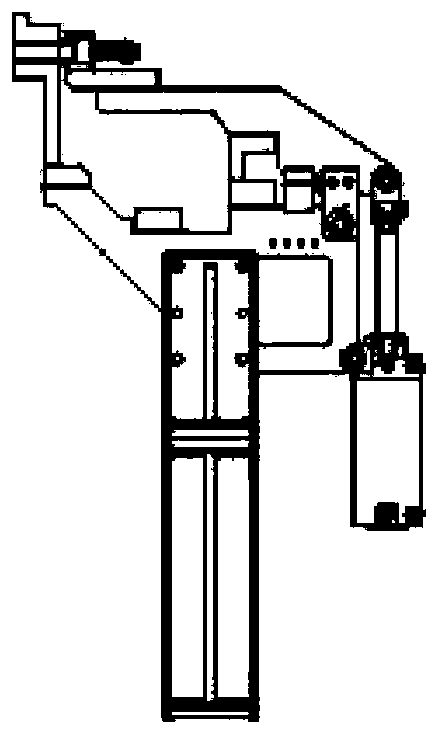

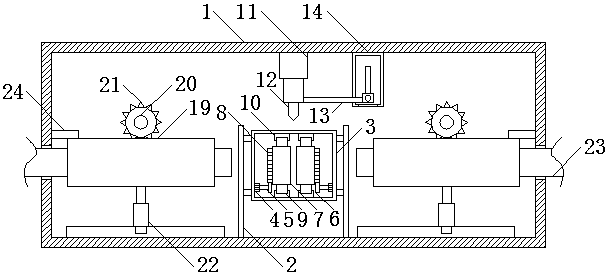

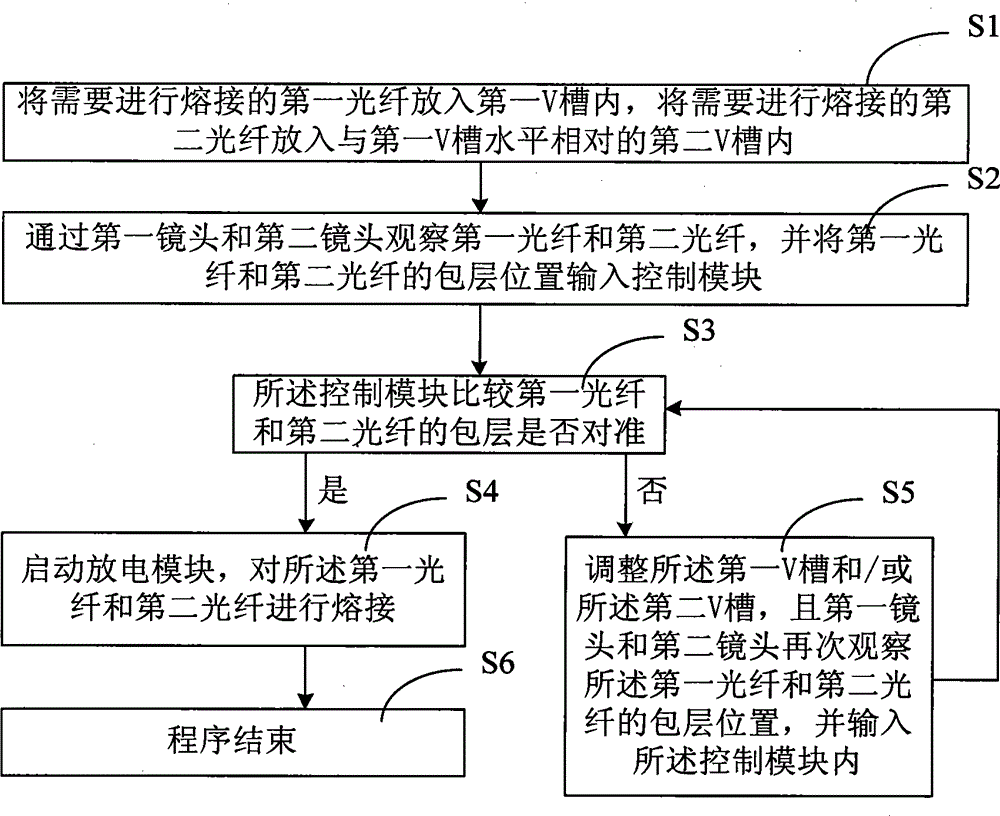

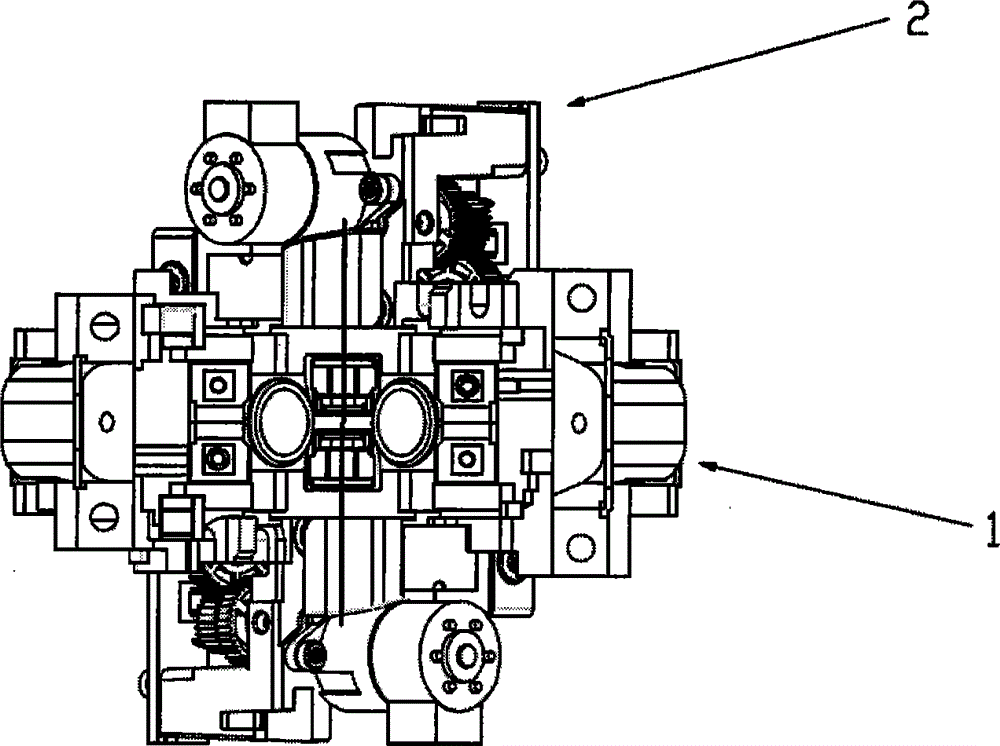

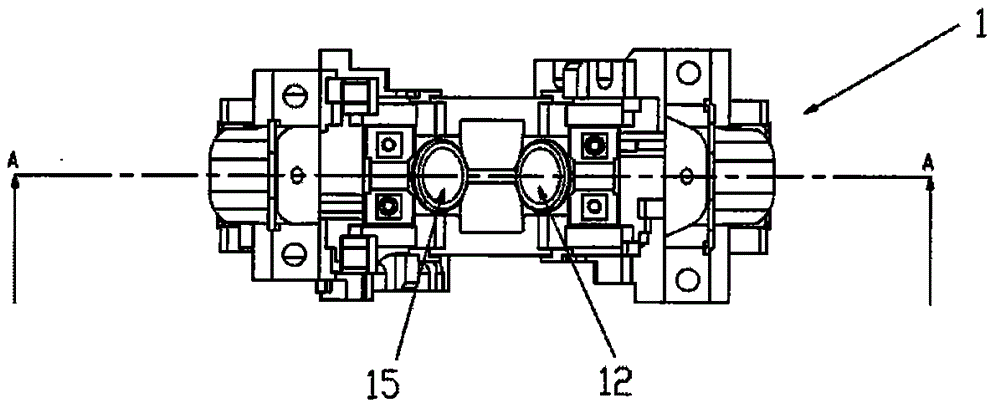

Fiber welding method and fusion splicer

The invention discloses an optical fiber fusion splicing method and an optical fiber fusion splicing machine. The first optical fiber and the second optical fiber are observed through the first lens and the second lens, and the cladding positions of the first optical fiber and the second optical fiber are input into a control module; the control module Comparing whether the claddings of the first optical fiber and the second optical fiber are aligned; and adjusting the first V-groove and / or the second V-groove according to the comparison result of the cladding, so as to align the cores. The present invention realizes the adjustment of the fiber core through the alignment of the cladding, completes the core adjustment of the fiber without focusing the lens, performs more accurate fiber docking and construction, and ensures fusion splicing accuracy and low splicing loss. At the same time, Since there is no need for a lens to focus, there is no need for a motor for focusing, which realizes the miniaturization of the fusion splicer and reduces the cost of the fusion splicer.

Owner:INNO INSTR (CHINA) INC

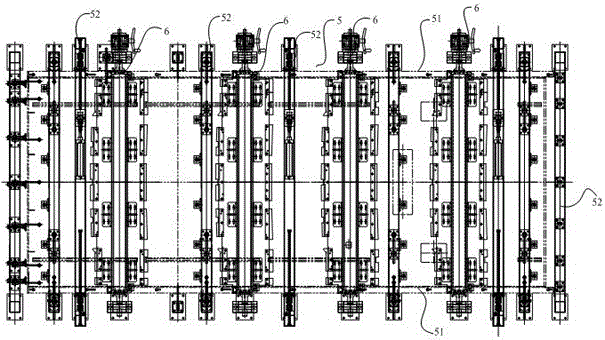

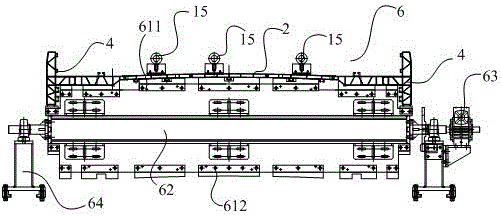

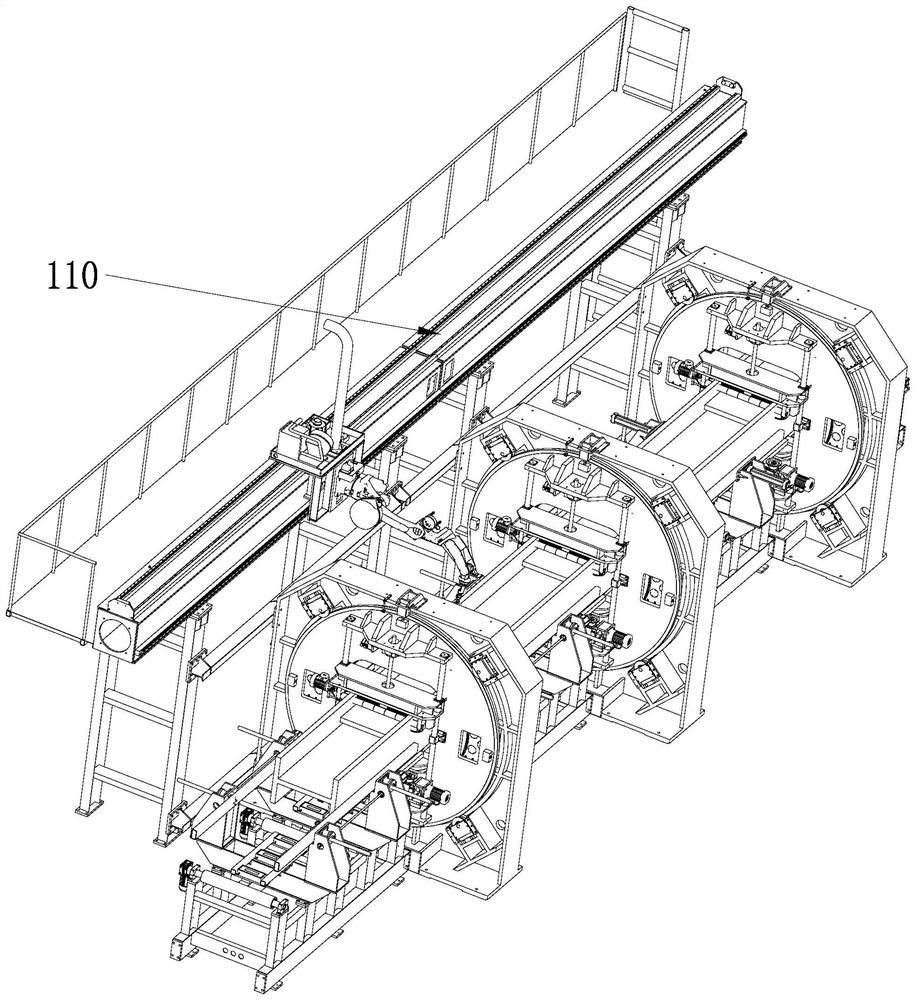

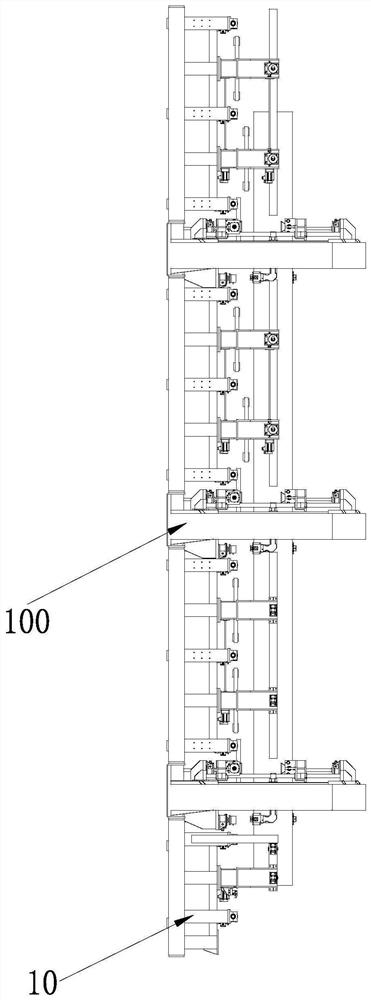

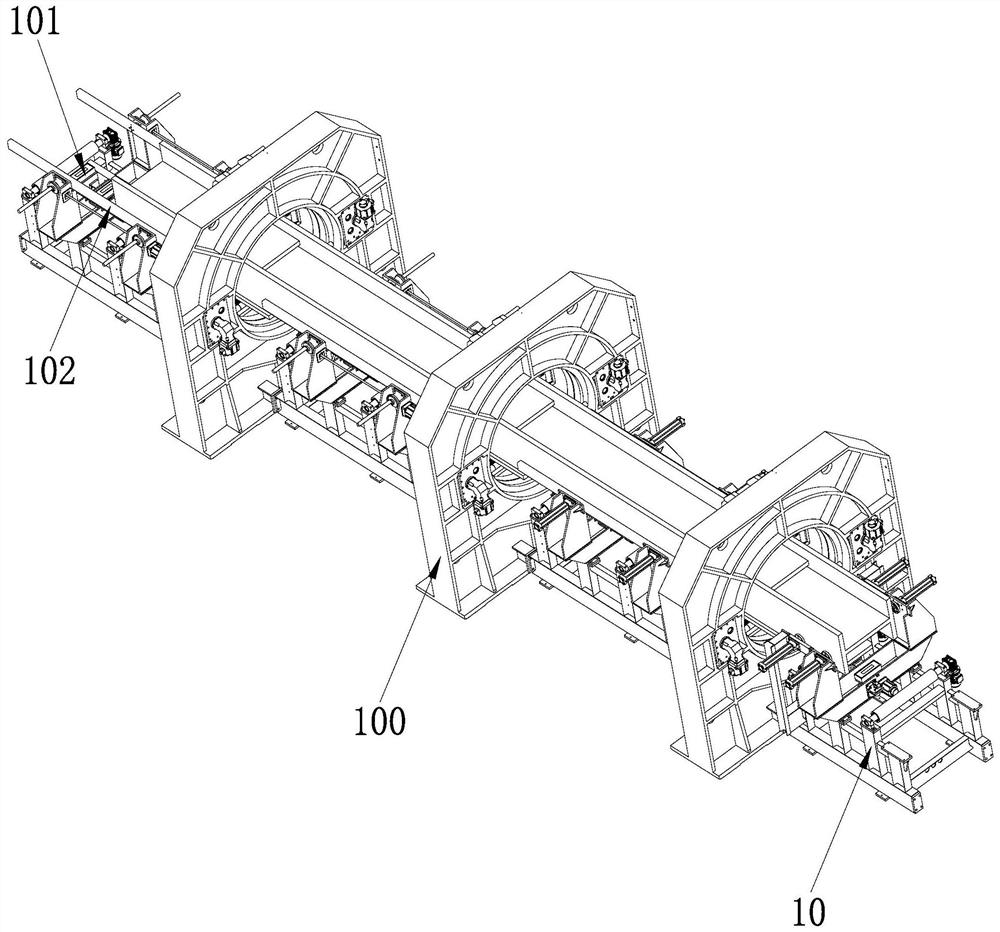

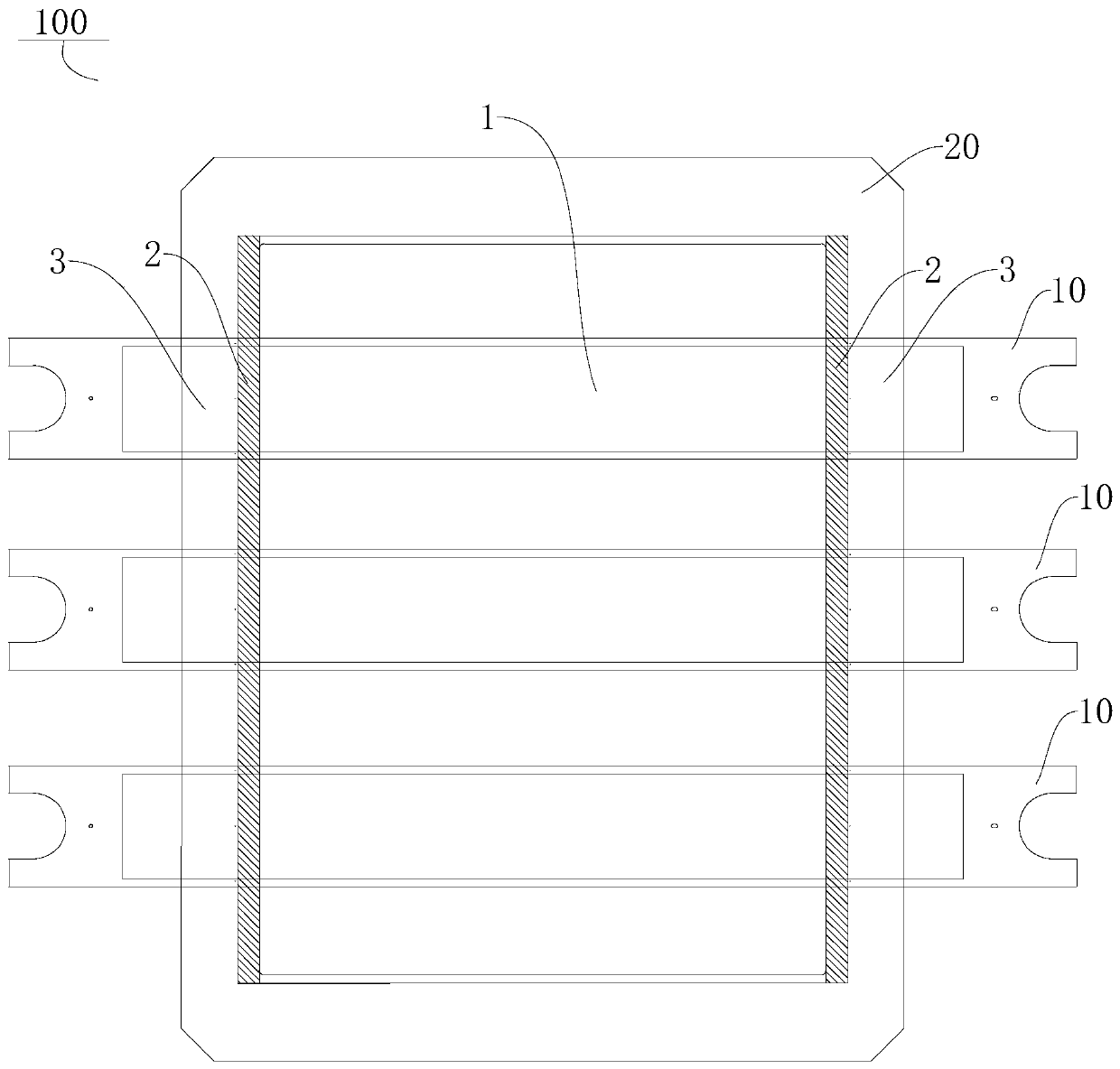

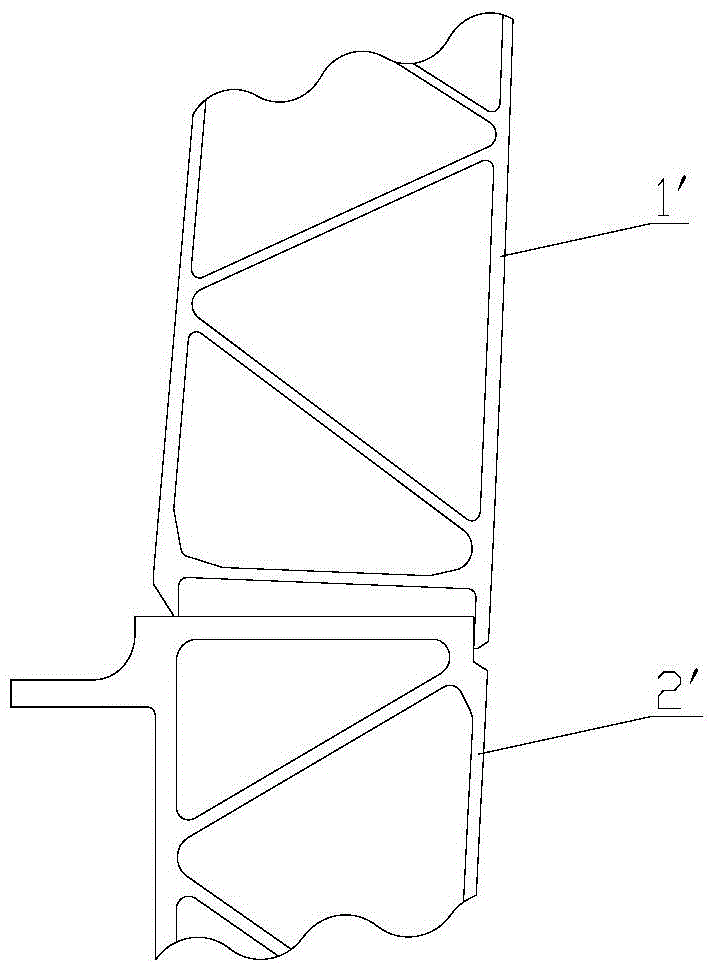

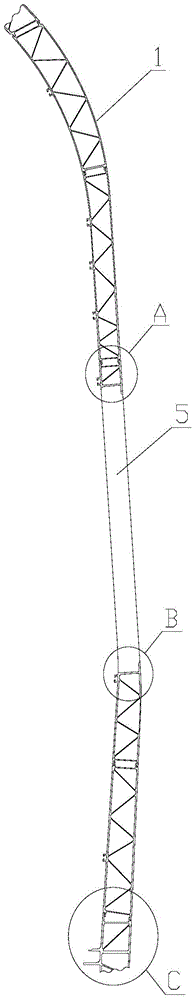

Universal welding tool for sleeper beam of subway rail vehicle and welding method thereof

PendingCN109676299ASave tuning timeImplement anti-morphingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention provides a universal welding tool for a sleeper beam of a subway rail vehicle, comprising a frame, a sleeper beam pressing device, a longitudinal limiting device, a transverse limiting device and a reference adjusting device; the sleeper beam pressing device is arranged on the frame to press the sleeper beam, the longitudinal limiting device is arranged on the frame to limit the sleeper beam in a longitudinal direction, the transverse limiting device is arranged on the frame to limit the sleeper beam in a transverse direction, the reference adjusting device is positioned on the inner side surface of the frame, and the reference adjusting device corresponds to the sleeper beam pressing device one by one to adjust the placing height of the sleeper beam. The invention relates toa welding method for a sleeper beam of a subway rail vehicle, which comprises the following steps of adjusting too before welding, welding and assembling the sleeper beam, and standing after weldingto eliminate stress. The welding tool provided by the invention has a simple structure, novel design, convenient operation and strong universality; double functions of workpiece positioning and welding deformation reduction are simultaneously realized by matching the welding method, and the production efficiency is greatly improved.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

H-shaped steel overturning, welding and forming device

ActiveCN112059456AImprove assembly accuracyImprove processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention relates to an H-shaped steel overturning, welding and forming device. The H-shaped steel overturning, welding and forming device comprises a welding robot moving mechanism, a steel plateconveying mechanism, and a plurality of clamping and overturning mechanisms arranged in the length direction of the steel plate conveying mechanism, wherein a web jacking mechanism and a wing plate jacking mechanism are further arranged on the steel plate conveying mechanism. The H-shaped steel overturning, welding and forming device is simple in structure, ingenious in design and suitable for welding of H-shaped steel components of various types, and ensures the welding quality and the welding precision; spot welding is performed through an electric welding machine; and the assembling precision, machining efficiency and automation degree of the H-shaped steel are greatly improved; the H-shaped steel can be directly assembled through the H-shaped steel overturning, welding and forming device with no need for a traveling crane and a large amount of auxiliary manual work; and the the H-shaped steel overturning, welding and forming device has high assembling operation efficiency, saves labor force and operation time, is safe and convenient, and improves the production efficiency of products.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

Inclined wedge mechanism with lateral material pressing function

InactiveCN105880372AImprove trimming and punching qualityEnsure lap qualityShaping toolsPerforating toolsPunchingWelding

The invention discloses an inclined wedge mechanism with a lateral material pressing function. The inclined wedge mechanism with the lateral material pressing function comprises an upper die seat, an inclined wedge body and a lower die seat, wherein the bottom of the upper die seat is provided with a nitrogen spring; a safety hook and a safety bolt penetrate through a through hole in the upper die seat, and then are fixedly connected with inclined wedge body; the inclined wedge body is provided with a material pressing core, a punching head upper die and a trimming knife; the material pressing core cooperates, in a sliding manner, with a guide post mounted on the inclined wedge body; the top of the lower die seat is provided with a driving block and a lower die; the driving block cooperates with the inclined wedge body in the sliding manner; and the lower die cooperates with the punching head upper die and the trimming knife. By using the inclined wedge mechanism with the lateral material pressing function, a material pressing problem that a position cannot be corrected and punched forwards can be solved; and a sheet metal component is prevented from generating profile change due to trimming and hole punching, so as to improve the welding and assembly precision of a whole car.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

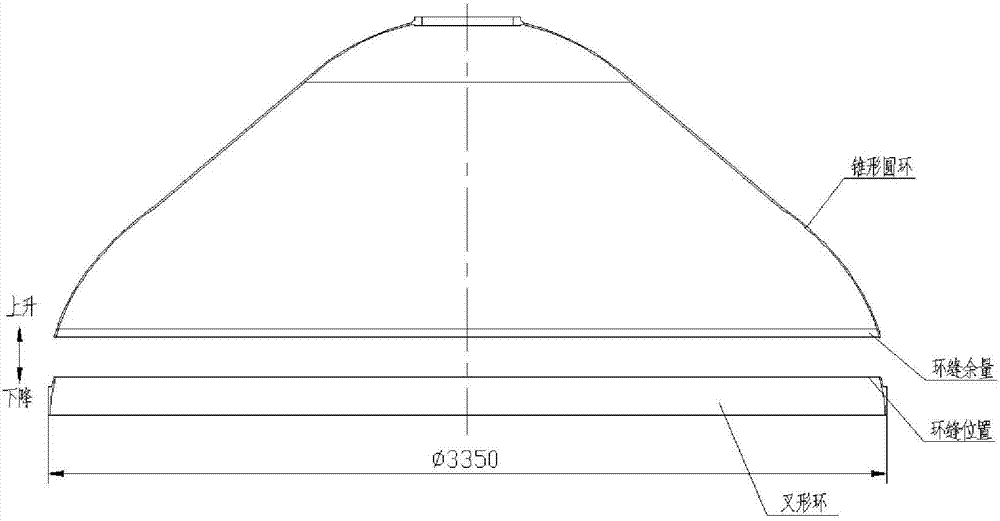

Precision lifting and positioning device for inner-support mold tire at conical bottom of storage box

ActiveCN107962418AGuaranteed accuracyPrecise positioningPositioning apparatusMetal-working holdersLarge sizeMechanical engineering

The invention relates to a precision lifting and positioning device for an inner-support mold base at the conical bottom of a storage box. The precision lifting and positioning device comprises the inner-support mold base, an external pressure system, a transition connecting ring positioning device, a base, an inner-support mold base guide seat, milling positioning blocks and welding positioning blocks. The external pressure system presses a large-size thin wall curved surface component to the inner support mold base. A transition connecting ring is fixed through the transition connecting ringpositioning device. When the milling positioning blocks are used for milling, the milling positioning blocks are clamped between the base and the inner-support mold base, and the relative height between the base and the inner-support mold base is kept; and when the welding positioning blocks are used for welding, the welding positioning blocks are clamped between the base and the inner-support mold base, and the relative height between the base and the inner-support mold base is kept. According to the precision lifting and positioning device, by arranging the milling positioning blocks, the precision of the ascent height of a conical circular ring is guaranteed in the milling process of the conical circular ring, and accordingly precision positioning of a milling device and the conical circular ring is guaranteed; and by arranging the welding positioning blocks, the descent displacement of the inner-support mold base can be precisely adjusted in the theoretical joint seam position.

Owner:CAPITAL AEROSPACE MACHINERY +1

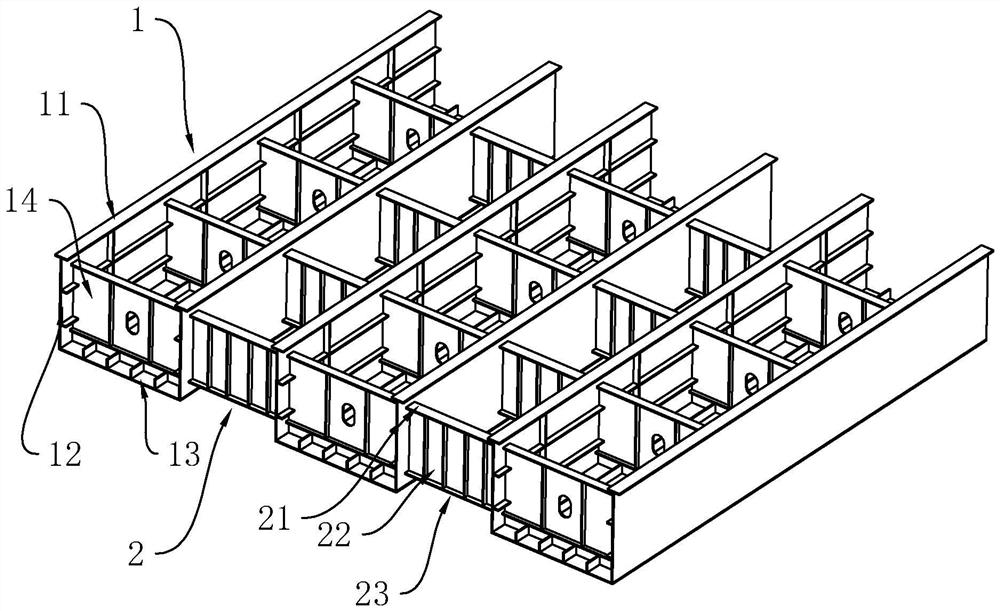

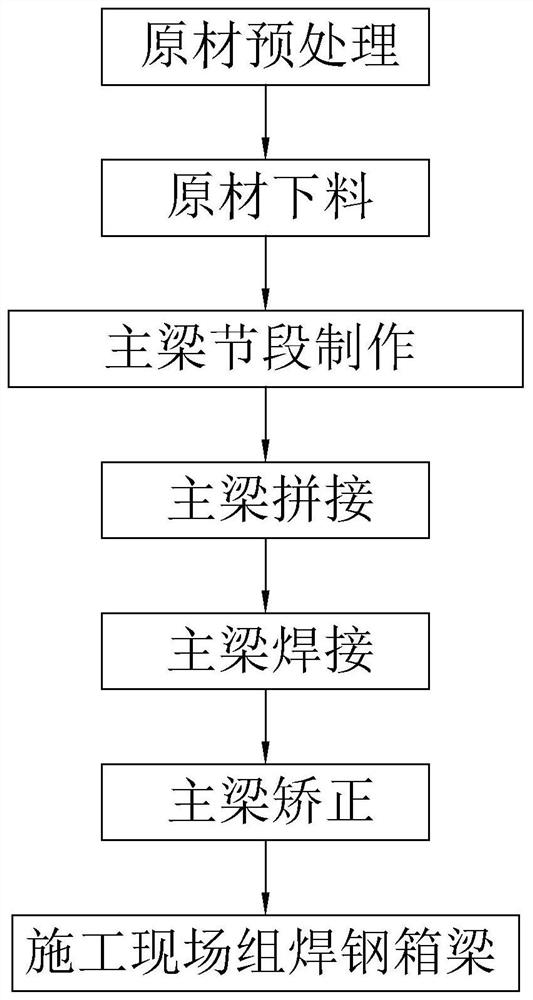

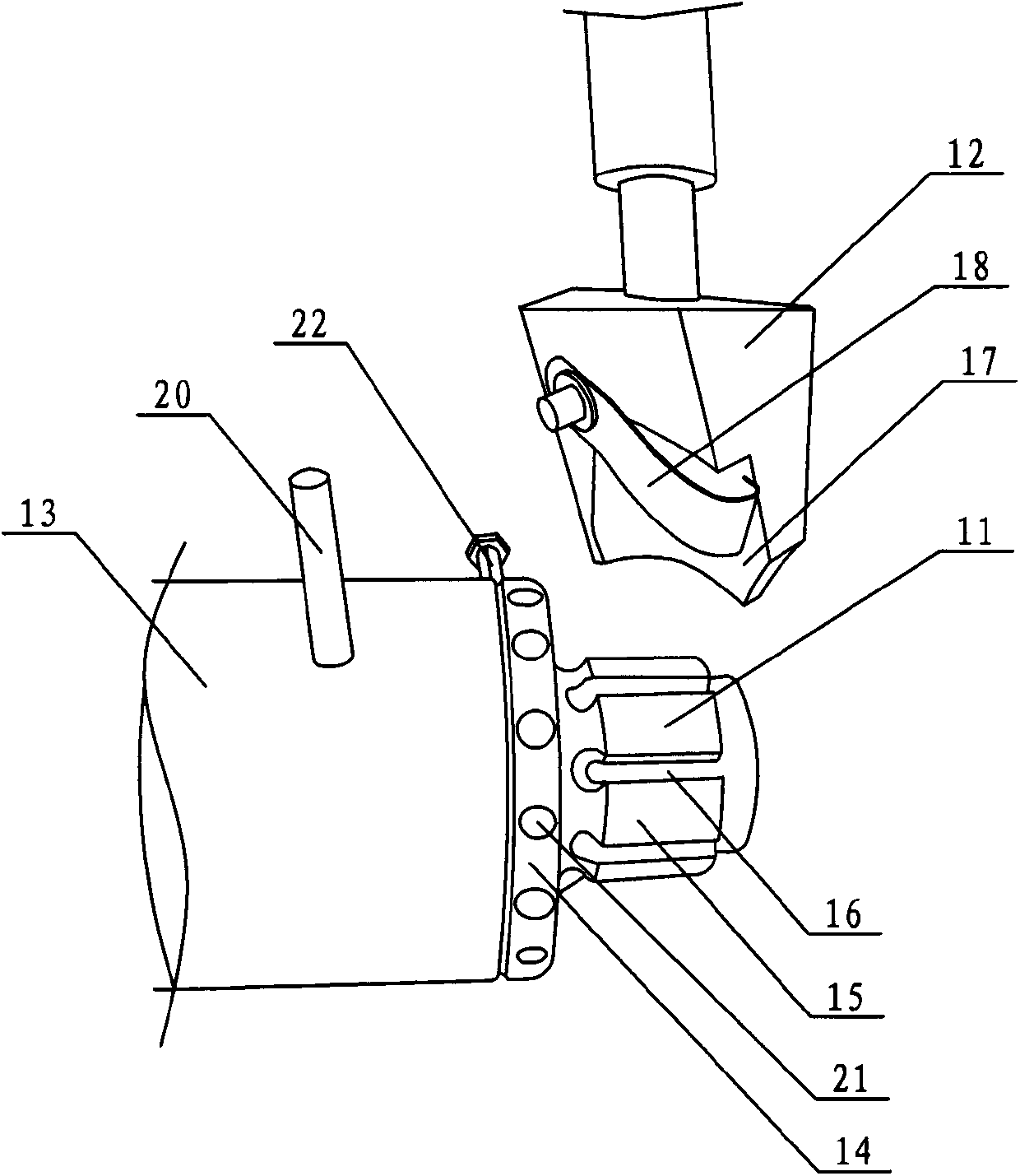

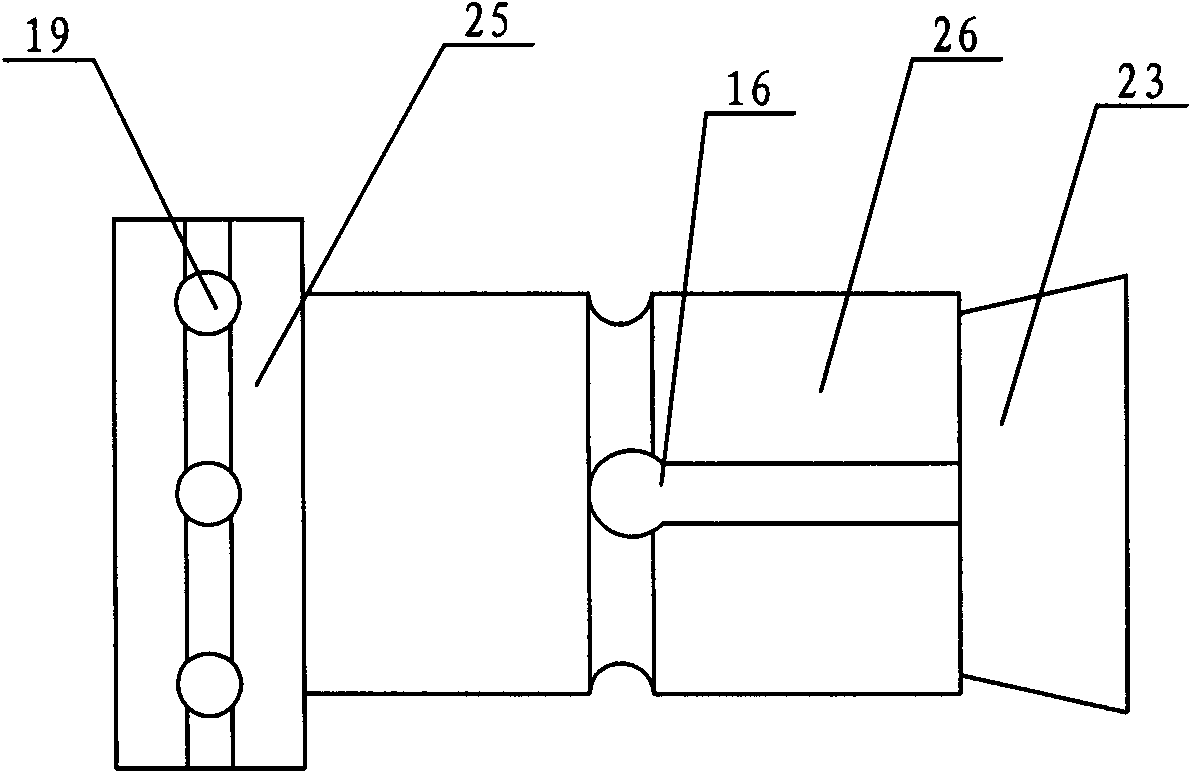

Steel box girder manufacturing and welding process

PendingCN112453831AQuality assuranceReduce distortionBridge materialsStressed stateMechanical engineering

The invention relates to a steel box girder manufacturing and welding process. The steel box girder manufacturing and welding process comprises the following steps that step 1, raw materials are pretreated; step 2, raw material blanking is carried out; step 3, steel box girder sections are manufactured; step 4, main beams are spliced; step 5, the main beams are welded; step 6, the main beams are corrected; and step 7, the steel box girder is assembled and welded on a construction site. The steel box girder manufacturing and welding process has the effects that welding deformation can be reduced, the part stress state is improved, and the box girder quality is guaranteed.

Owner:THE 5TH ENG CO LTD OF CHINA RAILWAY 25TH BUREAU GRP +1

Welding fixture for welding blade on rotor

ActiveCN103341687AGuaranteed welding accuracyShorten positioning timeElectrode featuresThermodynamicsCopper electrode

The invention discloses a welding fixture for welding a blade on a rotor. The welding fixture for welding the blade on the rotor comprises a first copper electrode and a second copper electrode. The first electrode comprises a fixing seat, a rotary plate and a rotor bearing seat, wherein the fixing seat, the rotary plate and the rotor bearing seat are sequentially arranged; the rotary plate is sleeved on the rotor bearing seat and is fixedly connected with the rotor bearing seat; a protruding block at the front end of the rotor bearing seat is inserted in the fixing seat; the rotor bearing seat rotates around the fixing seat; the diameter of a bearing end at the rear end of the rotor bearing seat is matched with the inner diameter of the rotor; a positioning groove for positioning the rotor is formed in the outer circle of the bearing end; an accommodating groove for bearing the blade is arranged on the second electrode; a compression sheet for pressing the blade in the accommodating groove is locked on the second electrode through a bolt. The welding fixture for welding the blade on the rotor achieves the purposes that the blade and the rotor are accurately positioned between the electrodes, the welding precision of the blade and the rotor is guarantees, and welding quality and production efficiency are improved.

Owner:苏州斯奥克微电机制造有限公司

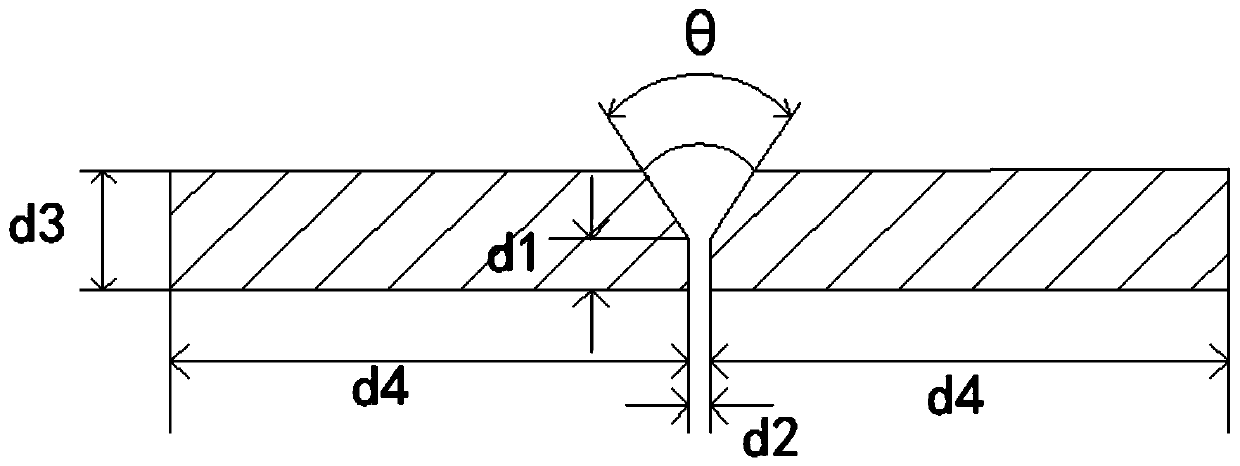

Laser and arc composite welding method of martensite precipitation-hardening stainless steel

InactiveCN110293322AUniform weld formationReduce distortionLaser beam welding apparatusButt jointMartensite

The invention relates to a laser and arc composite welding method of martensite precipitation-hardening stainless steel. The method includes the steps that butt joint connection ports of two to-be-welded workpieces are machined into grooves; the two to-be-welded workpieces are assembled and fixed, and a gap is reserved between the two to-be-welded workpieces; laser is adopted for performing backing welding on the bottoms of the grooves, and bottom weld joints are performed; and laser and arc composite welding is adopted for performing wire filling and face covering welding on the grooves, anda welding process is completed. According to the method, due to the fact that the laser backing welding is firstly performed on the bottoms of the grooves formed after machining of the to-be-welded workpieces, penetration fusion welding is achieved, through welding of the bottom of a truncated edge can be guaranteed, so that the weld joints at the bottoms of the grooves are uniform in forming, deformation is small, and the welding precision is guaranteed; then laser-arc composite welding is adopted for performing wire filling and face covering welding on the grooves, and therefore the high-quality weld joints are formed; and work procedures are simple, operation is easy, the process cost is low, and a good welding effect is achieved on the special material of the martensite precipitation-hardening stainless steel.

Owner:WUHAN JINDUN LASER TECH CO LTD

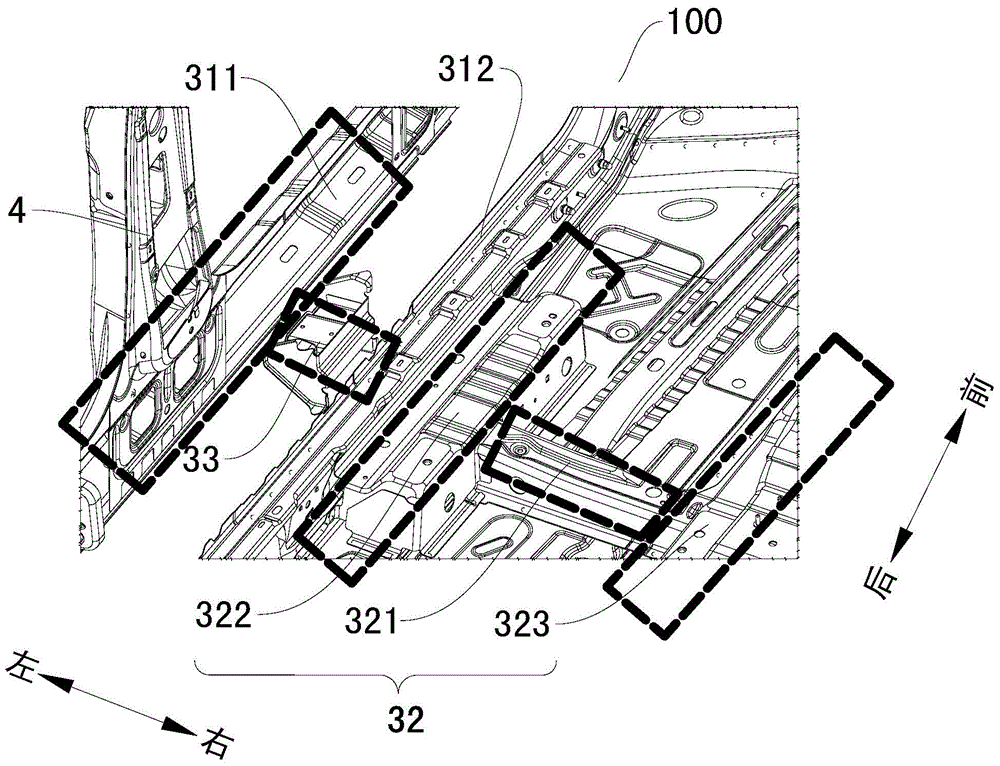

Vehicle body and vehicle with vehicle body

ActiveCN104802863AImproved side impact safety performanceImprove structural strengthSuperstructure subunitsEngineeringLiving space

The invention discloses a vehicle body and a vehicle with the vehicle body. The vehicle body comprises a left seat reinforcing component and a right seat reinforcing component, wherein at least one of the left seat reinforcing component and the right seat reinforcing component comprises a doorsill side beam, a front seat cross beam component and a doorsill reinforcing member; a cavity which extends longitudinally is arranged in the doorsill side beam; the outer end of the front seat cross beam component is connected with the doorsill side beam; the doorsill reinforcing member is transversely connected into the cavity; a part of the doorsill reinforcing member and the front seat cross beam component are welded to the corresponding doorsill side beam to form a three-layer welding structure. According to the vehicle body provided by the embodiment of the invention, the safety performance during collision of the side face of the vehicle body is high, and a living space is remained for passengers in the vehicle.

Owner:BEIQI FOTON MOTOR CO LTD

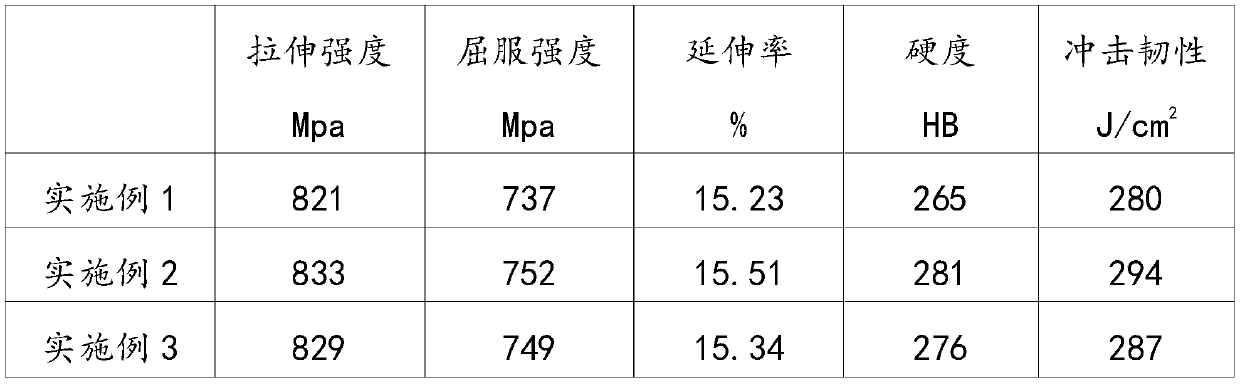

Assembling installing method for express cabinet

ActiveCN104384785AHigh welding technology requirementsLabor intensiveWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention discloses an assembling installing method for an express cabinet. According to the method, firstly, express cabinet plates are integrally assembled and spliced together, and then, connecting parts between the plates are welded. The assembling installing method has the advantages that the production and installing mode has low requirements on the welding skill of workers, the work intensity of the workers is reduced, the assembling and welding efficiency is improved under the condition of ensuring the assembling and welding precision, and further, the production efficiency of the finished product of the express cabinet is improved.

Owner:CHENGDU WOLAILA GRID INFORMATION TECH

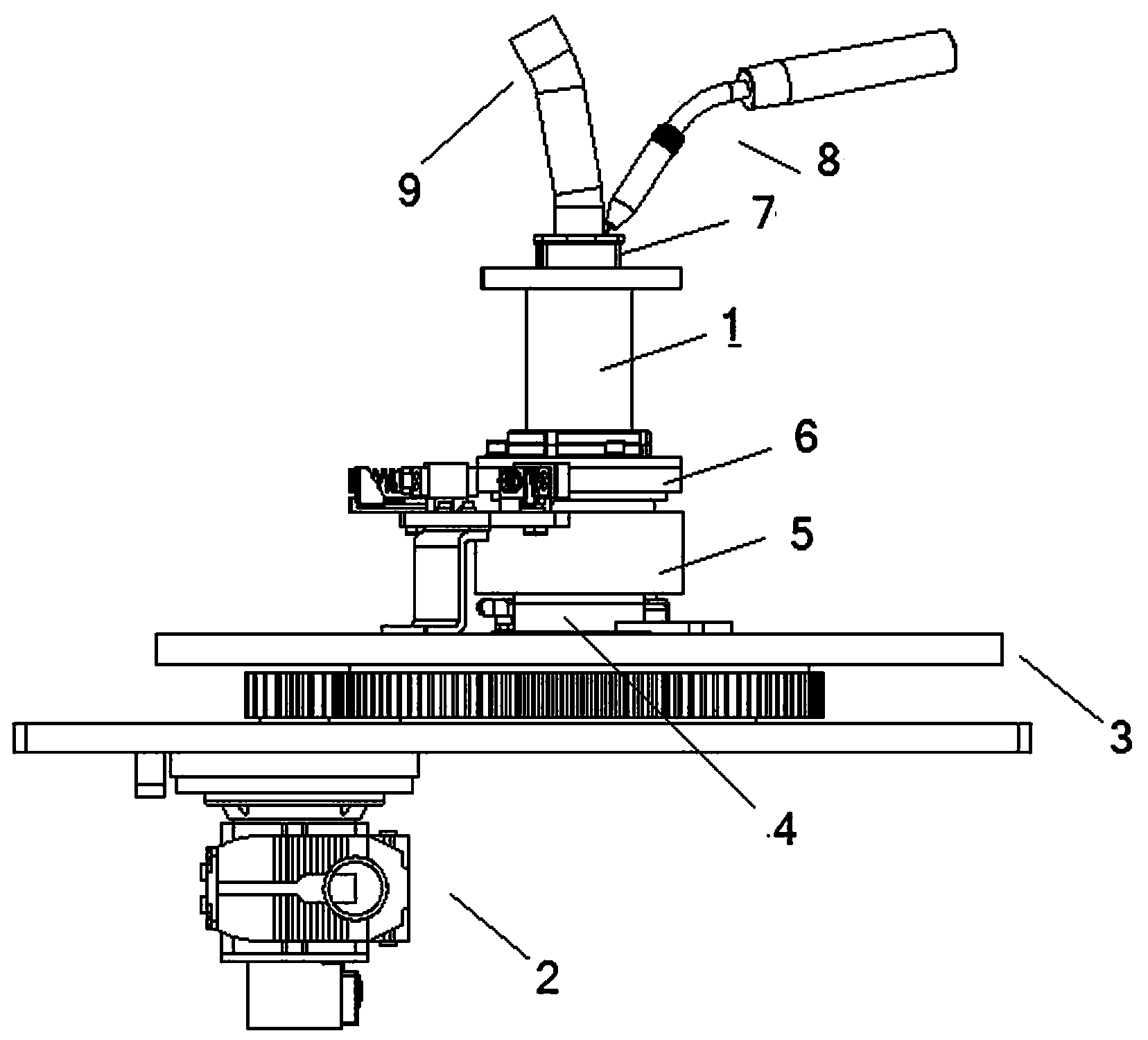

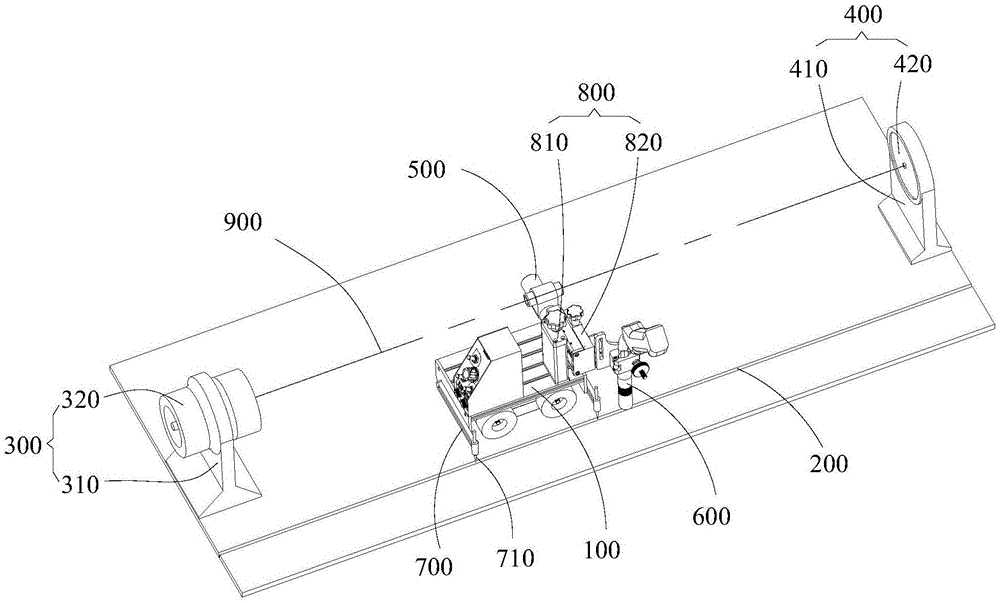

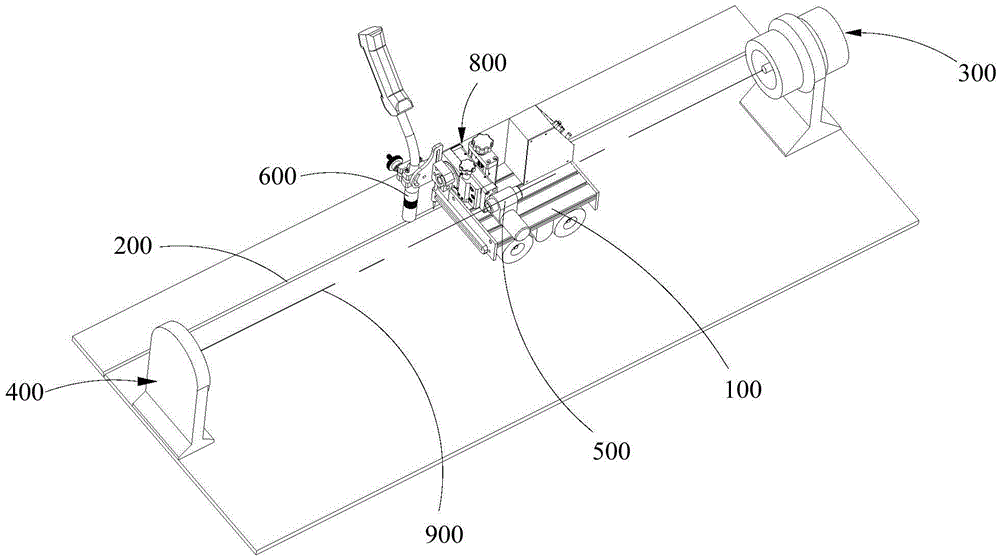

Automatic welding device and welding method

ActiveCN105479054AExtend welding distanceLow costWelding/cutting auxillary devicesArc welding apparatusLaser beamsPosition sensor

The invention discloses an automatic welding device and a welding method. The device and method are used for welding a long straight weld joint. The automatic welding device comprises a welding trolley. The welding trolley walks on one side of the weld joint. The automatic welding device is characterized by further comprising a laser beam transmitting device and a correction device, the laser beam transmitting device and the correction device are arranged at the two ends of the same side of the weld joint respectively, laser beams transmitted through the laser beam transmitting device are corrected through the correction device relative to the weld joint, the welding trolley is provided with a laser position sensor and a position adjusting mechanism, and the laser position sensor induces the laser beams and controls the position adjusting mechanism to adjust the welding route of the welding trolley. By the adoption of the automatic laser welding device, no walking mechanical rail needs to be additionally arranged for the welding trolley in the welding process of the long straight weld joint, the welding distance is prolonged, and welding cost is reduced.

Owner:SHENZHEN RILAND IND

Precision metal mask and mask assembly provided with same

ActiveCN111455314AImprove stress distributionReduced risk of creasesVacuum evaporation coatingSolid-state devicesEngineeringSoldering

The invention discloses a precision metal mask and a mask assembly provided with same. The precision metal mask comprises an effective display area and two welding areas, wherein the two welding areasare separately positioned at the two sides in the length direction of the effective display area; at least one welding area is a set welding area; and a first through hole is formed in the set welding area. According to the precision metal mask provided by the invention, the first through hole is formed in the set welding area, so that stress distribution, in an average trap net stretching process, of the precision metal mask is facilitated, and folding risk of the welding area is reduced, and therefore, welding precision is guaranteed, an insufficient soldering condition is reduced, and evaporating quality is improved.

Owner:BOE TECH GRP CO LTD

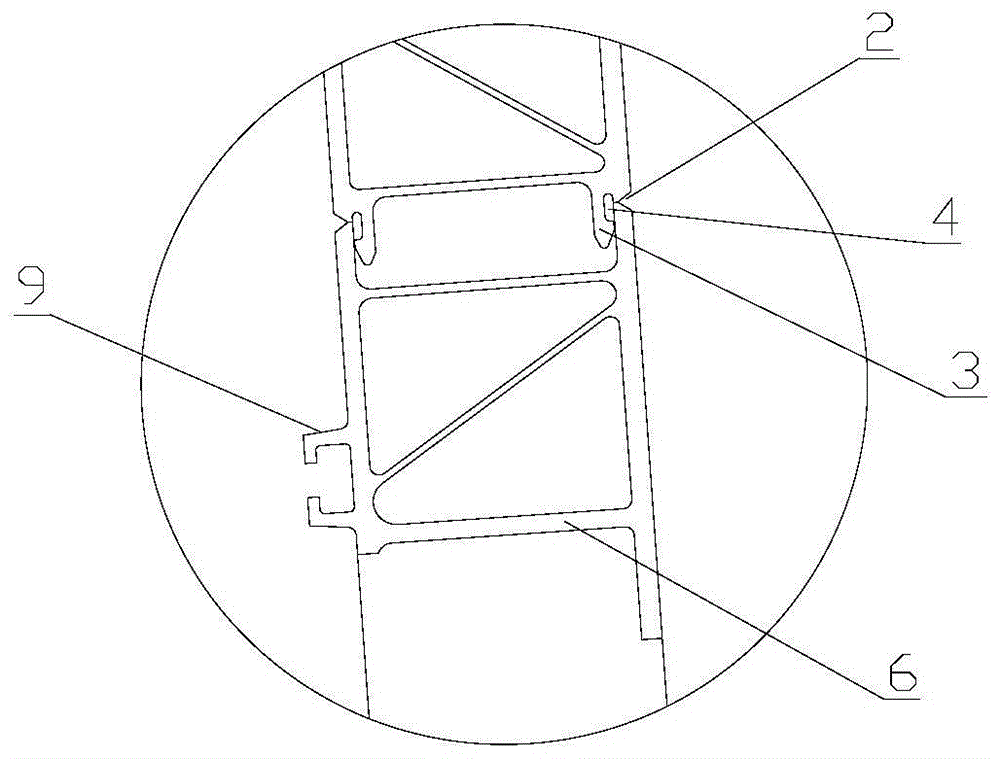

Rail car and side wall assembly thereof

ActiveCN105197031AImprove structural strengthImprove air tightnessAxle-box lubricationRailway bodies5005 aluminium alloyEngineering

The invention discloses a rail car and a side wall assembly thereof. The side wall assembly is formed by inserting and welding a plurality of aluminium alloy extruded sections (1); a car body accessory installation opening is formed in the body of the side wall assembly; a subplate (3) which is formed on one of the two adjacent aluminium alloy extruded sections (1) is arranged at the inner side of a joint of the two corresponding adjacent aluminium alloy extruded sections (1), the subplate (3) is in a hook shape on the section, the head of the subplate (3) is clung to the inner wall of the joint of the other aluminium alloy extruded section (1), and a hook groove between the root and the head of the subplate (3) forms a cavity (4) corresponding to the joint. The side wall assembly is used for optimizing a design of inserting structures and welding structures of the aluminium alloy extruded sections, a local structure of the installation opening, section shapes and the like, so that the structure strength and an air sealing performance of a side wall can be obviously improved, and the side wall assembly can be suitable for a car body structure that devices, such as sliding plug doors and air conditioners are installed onto of a car top.

Owner:CRRC QINGDAO SIFANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com