H-shaped steel overturning, welding and forming device

A welding forming and H-beam technology, applied in the field of steel plate processing, can solve the problems of low work efficiency, low production efficiency, poor safety, etc., and achieve the effects of improving assembly accuracy, improving production efficiency and saving operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

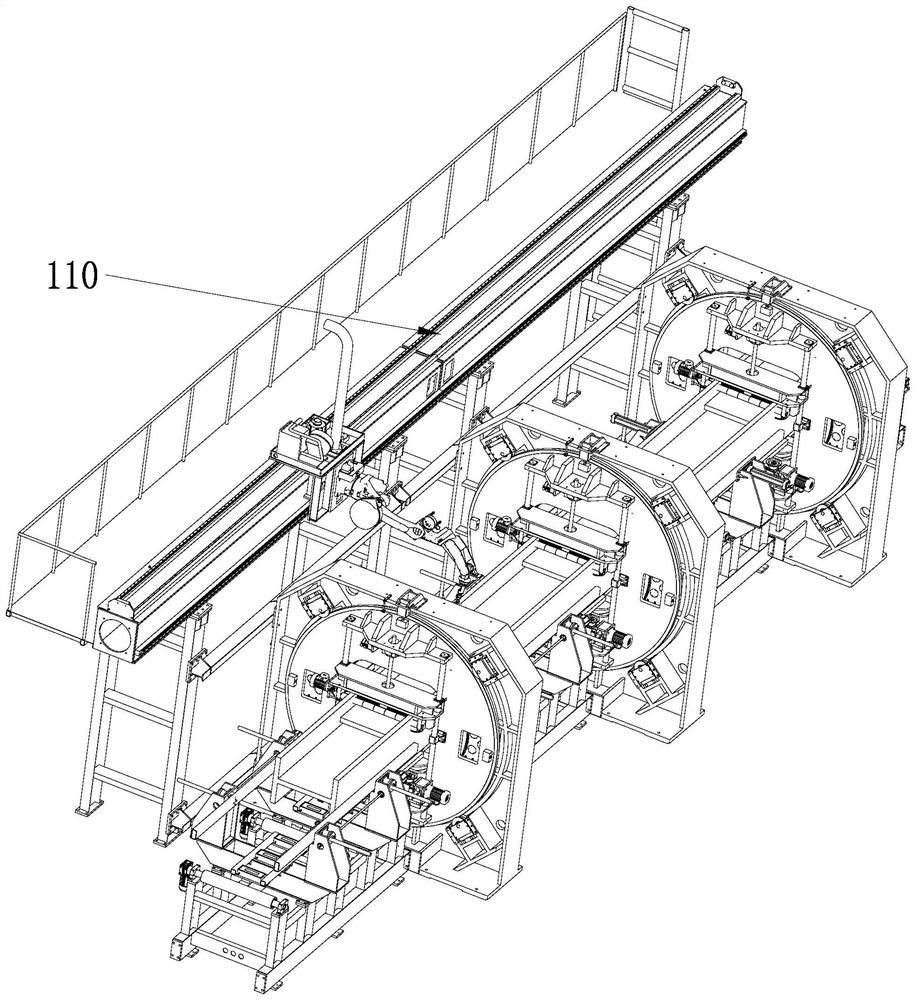

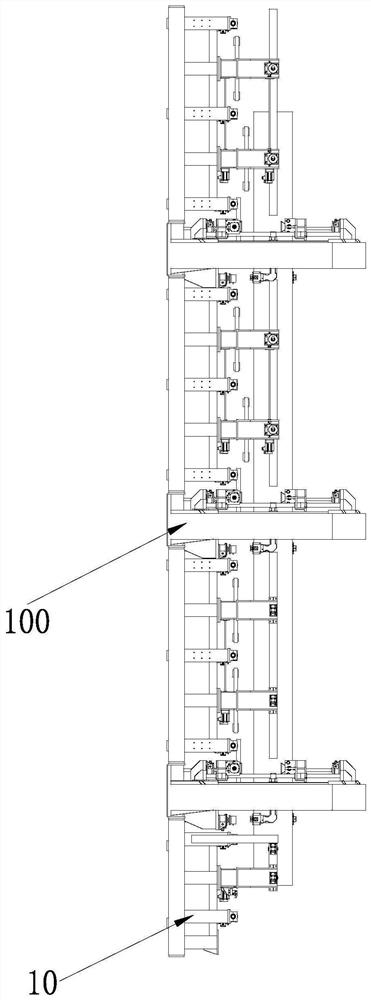

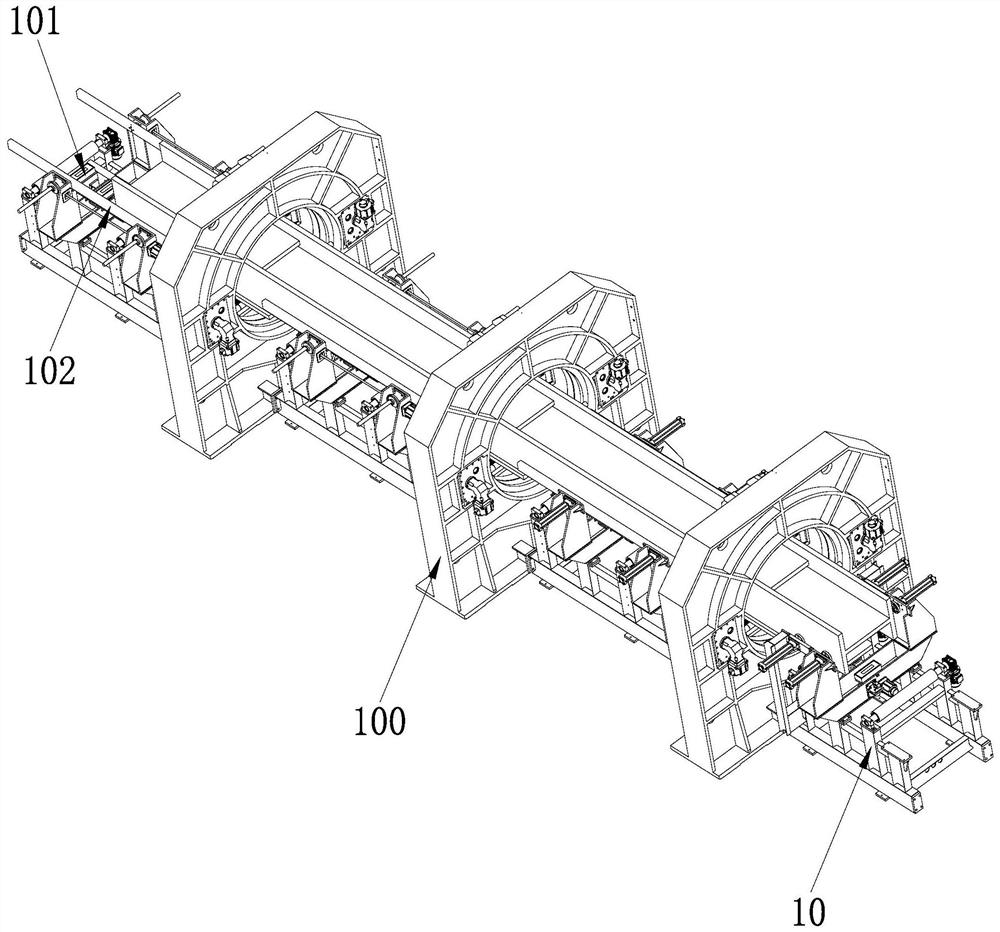

[0042] Example: such as Figure 1-24 As shown, a kind of H-shaped steel flipping welding forming device includes a welding robot moving mechanism 110, a steel plate conveying mechanism 10, and a plurality of clamping and turning mechanisms 100 arranged along the length direction of the steel plate conveying mechanism 10; the steel plate conveying mechanism 10 is also equipped with The web lifting mechanism 101 and the wing plate tightening mechanism 102; the welding robot moving mechanism 110 is arranged in parallel with the steel plate conveying mechanism 10; the welding robot moving mechanism 110 includes a support frame 9, and a beam 90 is fixed on the support frame 9, along which The longitudinal direction of the beam 90 is provided with a sliding mechanism 900; the robot support seat 910 is slidably assembled on the sliding mechanism 900, the welding robot 920 is assembled on the robot support seat 910, and the manipulator of the welding robot 920 is arranged corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com