Enormous-span steel tube house truss assembling construction method

A construction method and technology of roof trusses, applied to truss structures, girders, truss beams, etc., can solve the problems of large amount of measures, and achieve the effects of saving materials, ensuring consistency, and ensuring accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, exemplary embodiments of the present invention are described in detail with reference to the accompanying drawings.

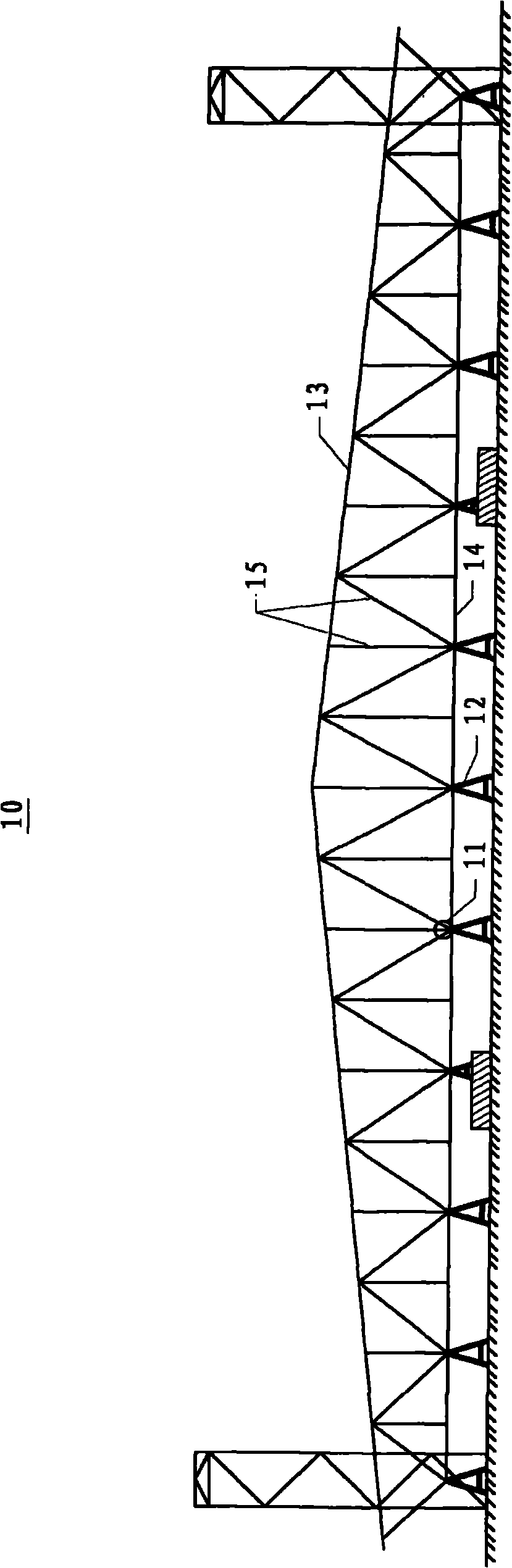

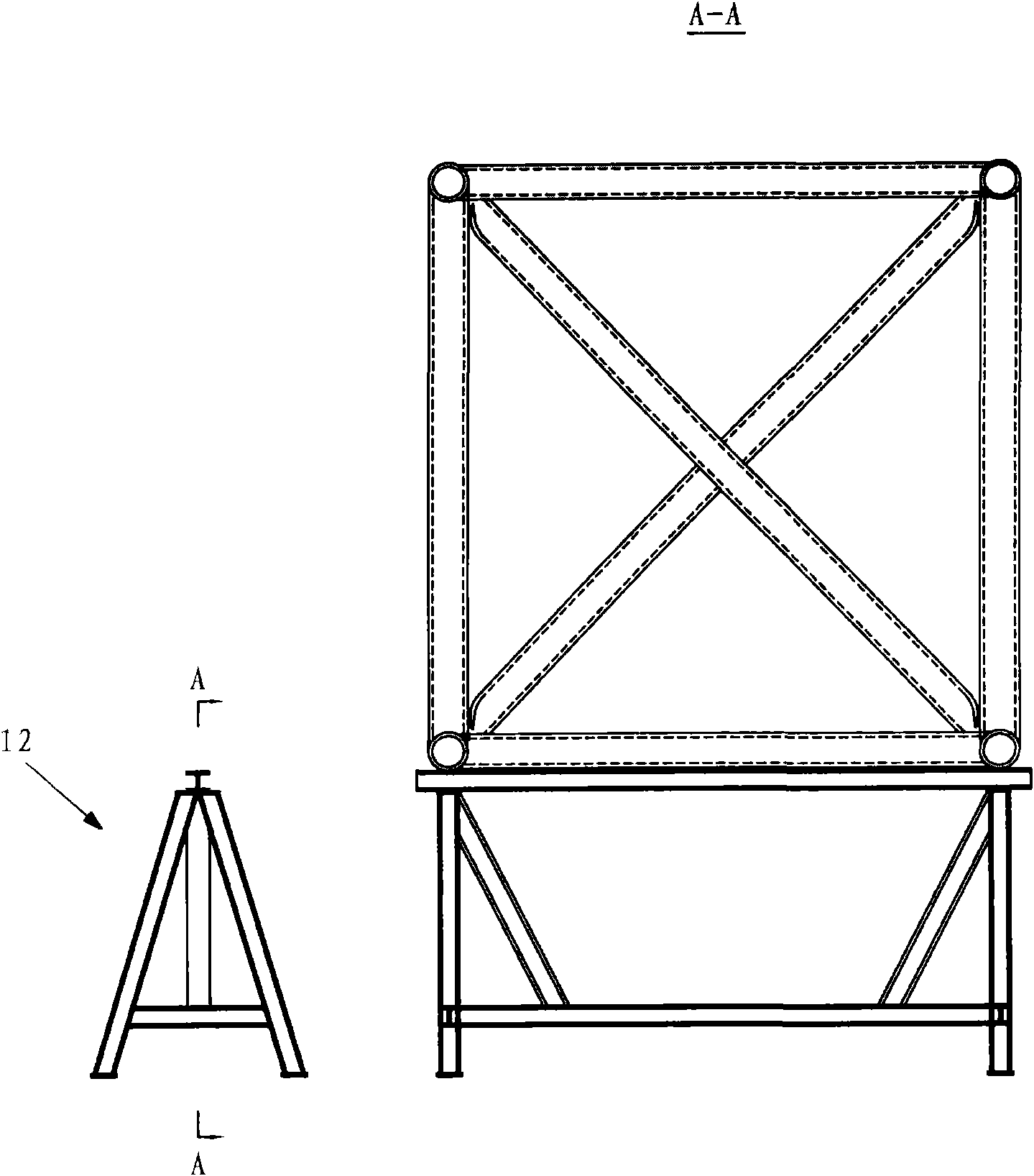

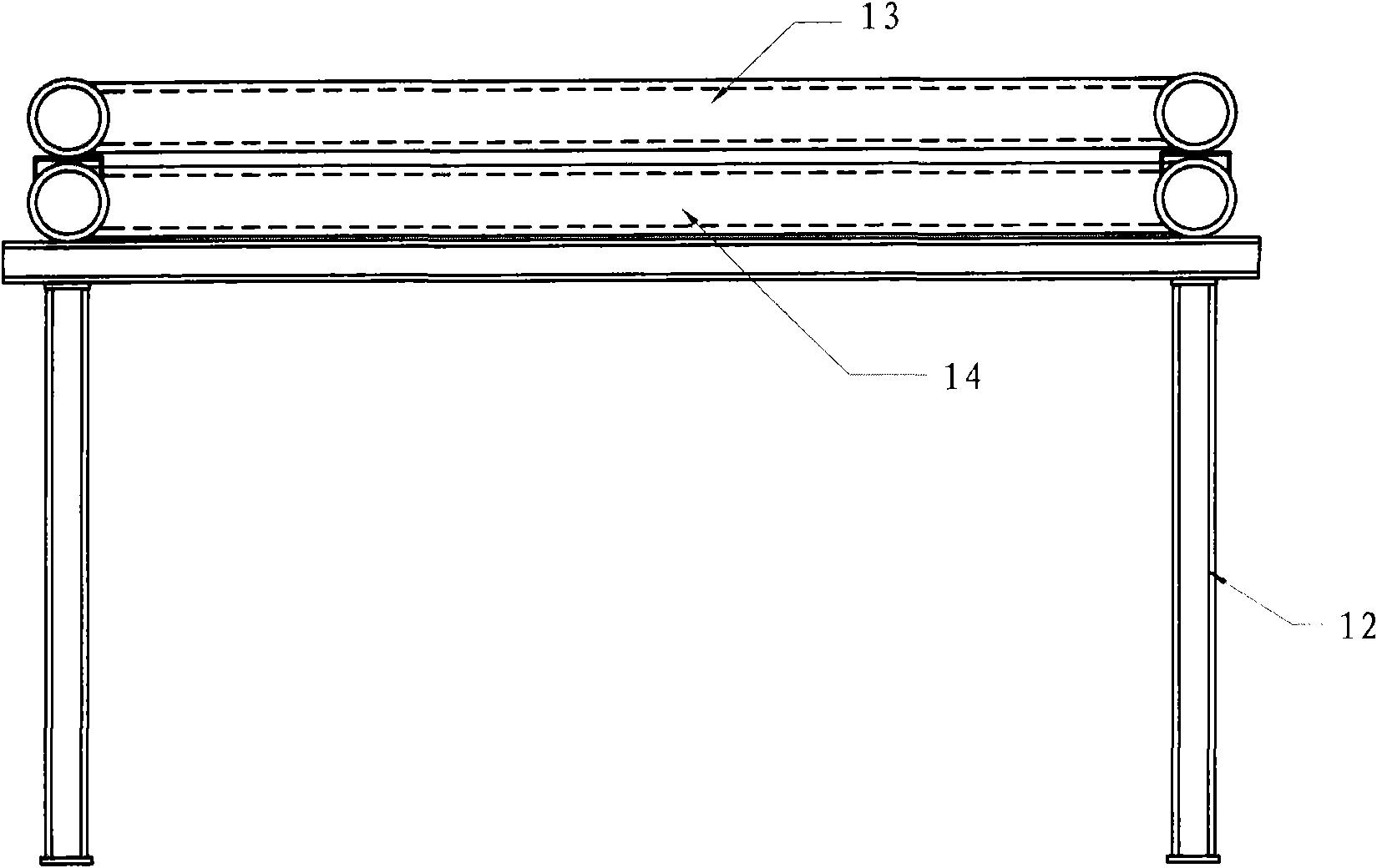

[0026] figure 1 is a structural schematic diagram of a steel pipe roof truss 10 according to an exemplary embodiment of the present invention.

[0027] Before the steel pipe roof truss is assembled, it is necessary to arrange the assembly sequence of the rods reasonably according to its structural characteristics. according to figure 1 The structural form of the steel pipe roof truss shown in , determine the assembly sequence as follows: lower chord plane truss assembly - upper chord plane truss assembly - upper chord plane truss lifting - lower chord plane truss arching - upper and lower chord plane truss member assembly.

[0028] The method for assembling the trusses of a huge-span steel pipe roof according to an exemplary embodiment of the present invention will now be described in detail, and the method mainly includes the following st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com