Modular demolition method of sintering desulfurization plant

A modular and workshop technology, applied in construction, building maintenance, building construction, etc., can solve the problems of large amount of scaffolding and dismantling, easy safety accidents, cumbersome operation, etc., to reduce construction costs and safety risk factors, The effect of shortening the construction period and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

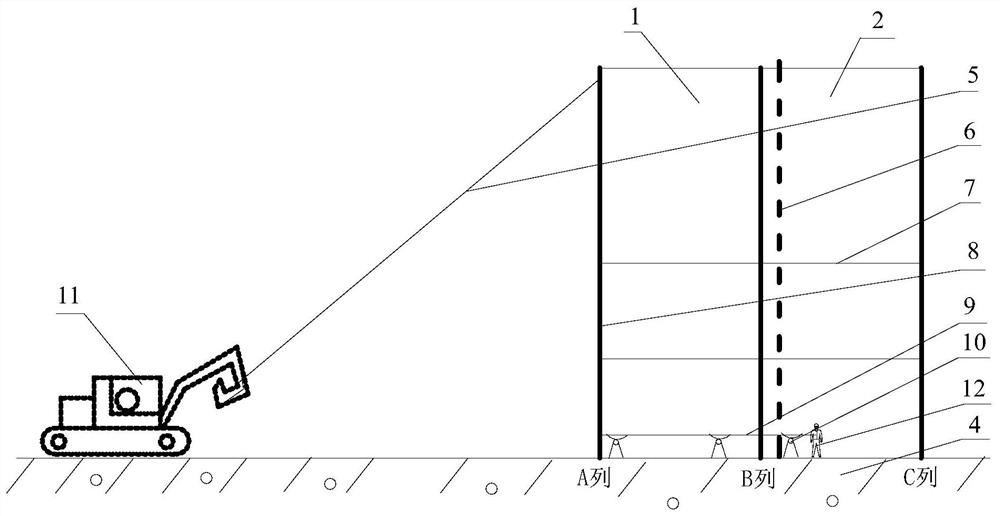

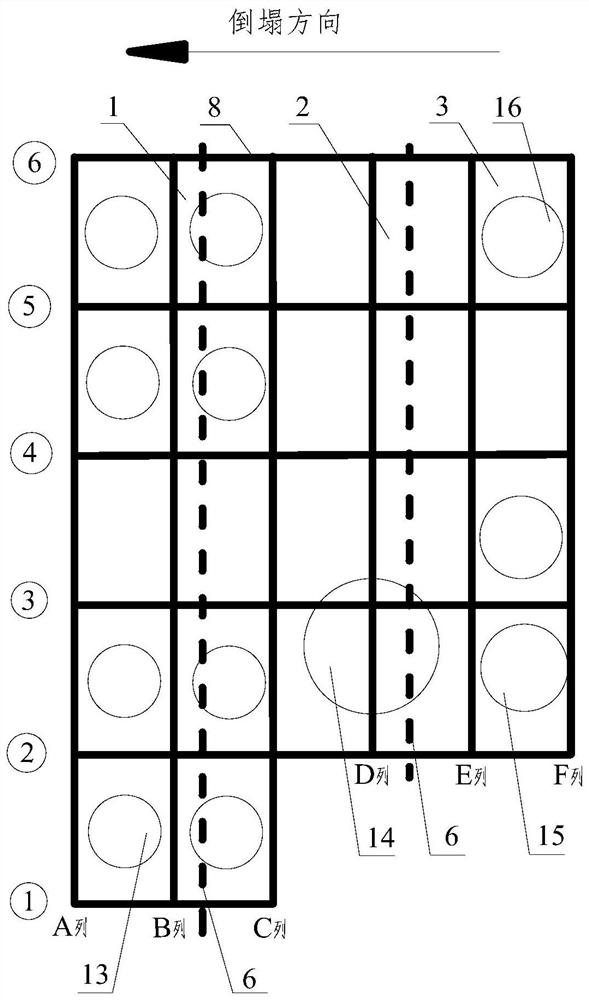

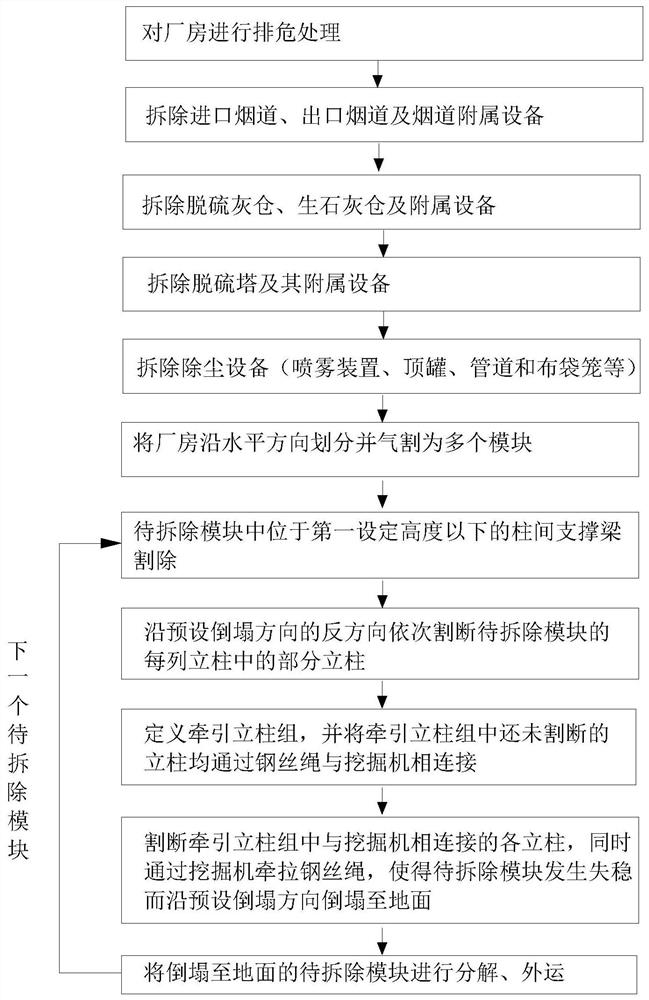

[0035] Such as Figure 1-Figure 3 As shown, a modular demolition method for a sintering desulfurization plant includes the following steps:

[0036] 1) if figure 2 As shown, the factory building is divided and gas-cut into multiple modules along the horizontal direction (from left to right), and the position of the gas-cut separation line 6 between each module is as follows figure 2 As shown, each module includes two rows of columns arranged in sequence, multiple rows of inter-column support beams are arranged between two adjacent columns of columns, and multiple rows of inter-column support beams are arranged from top to bottom between two adjacent columns of columns , multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com