Automatic assembling and tack welding system for U-shaped rib plate units

An automatic assembly and positioning welding technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of poor parallelism between U-shaped ribs, poor spacing accuracy of U-shaped ribs, and inability to ensure close adhesion of panels, etc. problems, to achieve the effects of improved production efficiency, high assembly precision, and high production efficiency of automatic assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

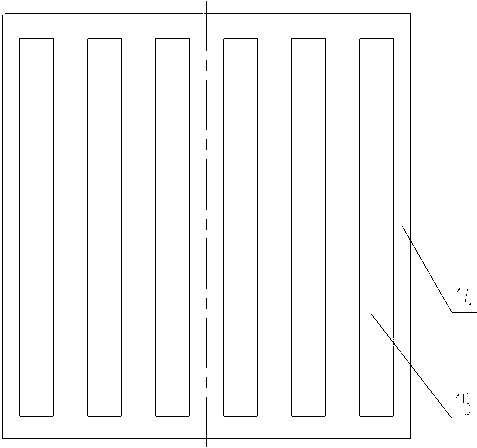

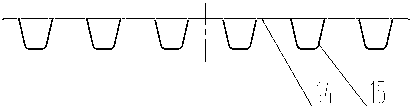

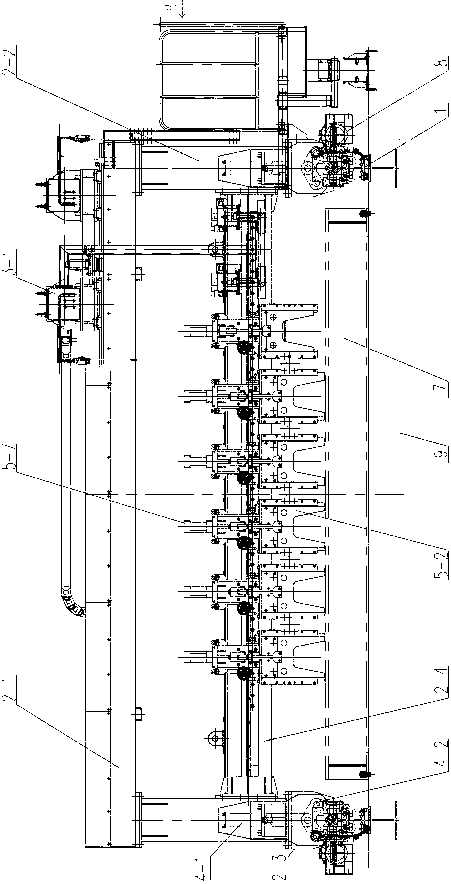

[0022] Such as Figure 3 to Figure 6 , the U-shaped rib plate unit automatic assembly positioning welding system of the present invention comprises a pair of parallel rails 1, a gantry frame moving on the rails 1, and an assembly platform 7 is laid between the two rails 1; The upper beam 2-1, the lower beam 2-4, four columns 2-2 and two running beams 2-3, the upper beam 2-1 and the lower beam 2-4 are respectively fixed on the front two columns 2-2 Between them, a gantry travel 8 is provided at the bottom of the two traveling beams 2-3; a movable welding system is provided on the upper beam 2-1; a rail clamping device 4 is provided between the traveling beam 2-3 and the rail 1, The lower beam 2-4 is provided with a movable two-dimensional adjustable positioning and pressing system; a grinding and dust removal system is provided betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com