Semiconductor device

a technology of semiconductors and devices, applied in the association of printed circuit non-printed electric components, solid-state devices, basic electric elements, etc., can solve the problems of increasing the cost of chips, the requirement to be met by media apparatuses such as short delivery time and low cost cannot be currently met, and the cost of conventional technology is increased. , the problem of longer processing tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

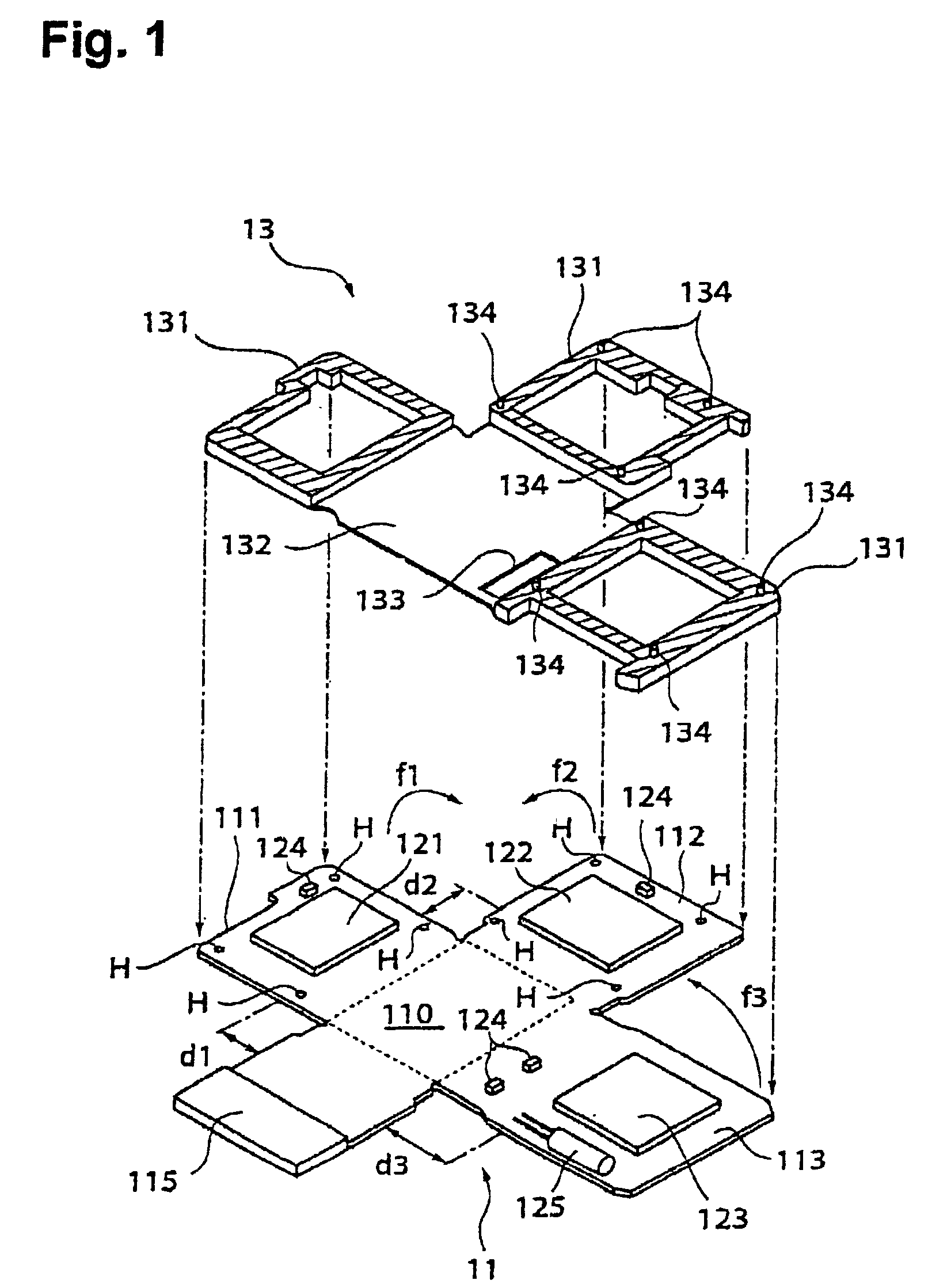

[0012] FIG. 1 shows a prospective view of a structure of a semiconductor device in accordance with the present invention.

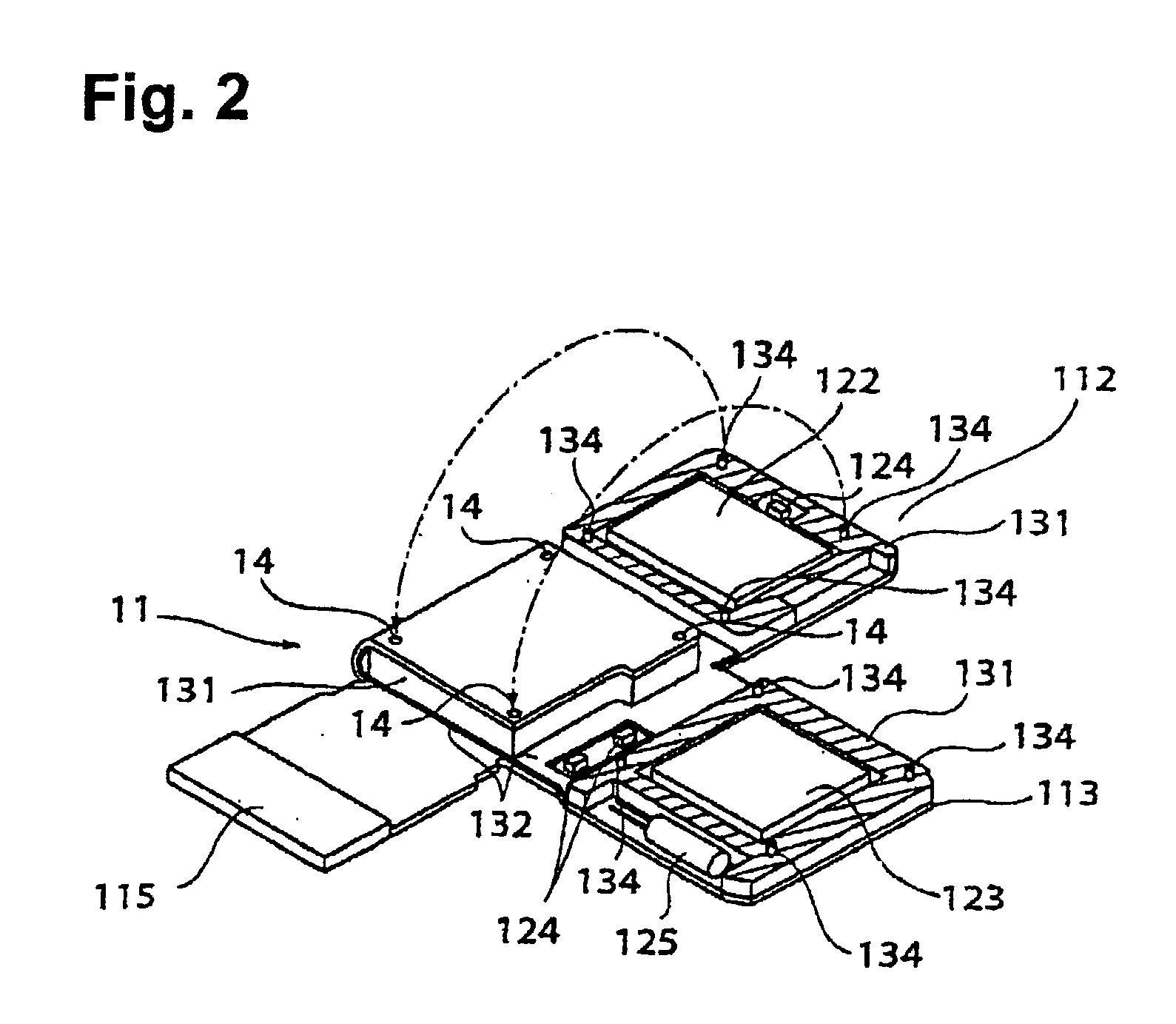

[0013] FIG. 2 shows a perspective view of a characteristic assembling configuration with the structure shown in FIG. 1.

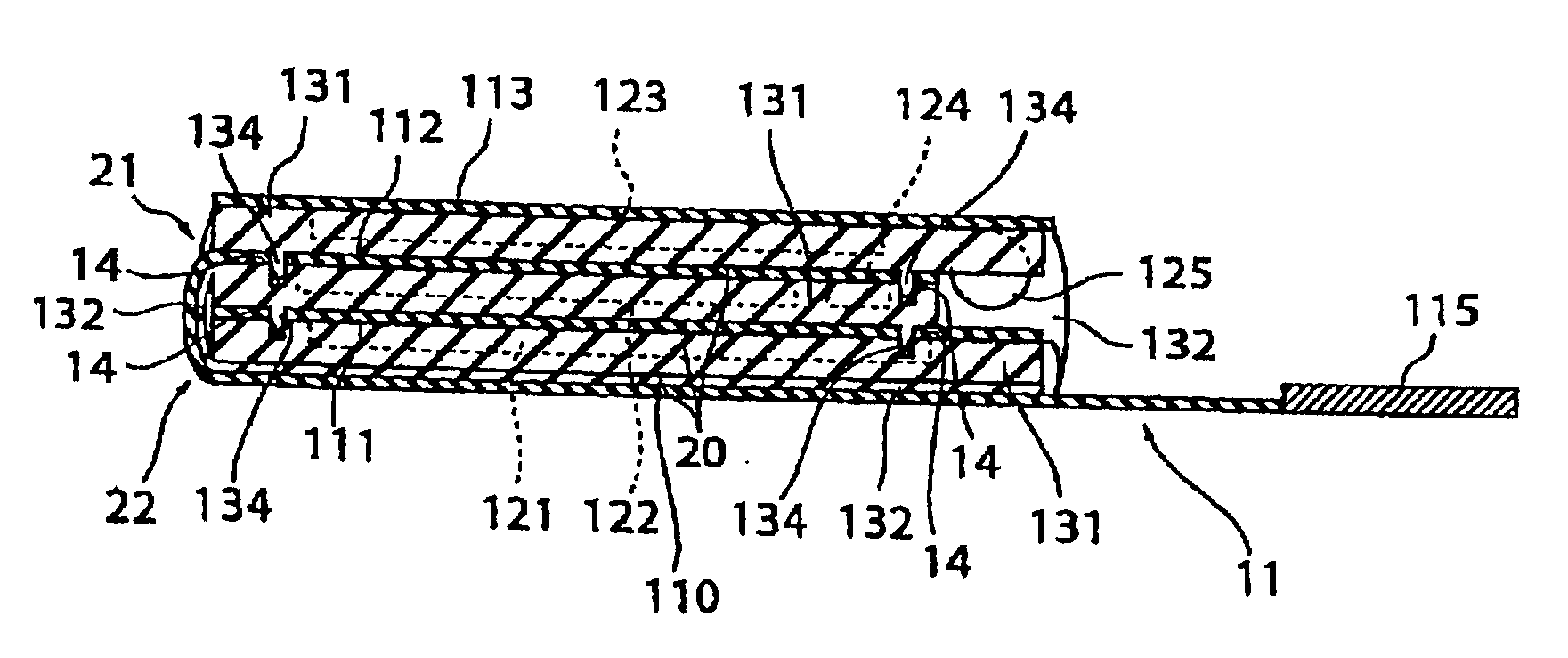

[0014] FIG. 3 shows a cross-sectional view of an assembled configuration of the semiconductor device of FIG. 1.

second embodiment

[0015] FIGS. 4(a) and (b) show a structure of a semiconductor device in accordance with the present invention, respectively, wherein FIG. 4(a) shows a plan view before assembly, and FIG. 4(b) schematically shows a cross-sectional view of a characteristic general structure of a three-dimensional mounting module after assembly.

third embodiment

[0016] FIGS. 5(a) and (b) show a structure of a semiconductor device in accordance with the present invention, wherein FIG. 5(a) shows a plan view before assembly, and FIG. 5(b) schematically shows a cross-sectional view of a characteristic general structure of a three-dimensional mounting module after assembly.

EMBODIMENTS OF THE PRESENT INVENTION IN BEST MODE

[0017] FIG. 1 shows a prospective view of a structure of a semiconductor device in accordance with a first embodiment of the present invention. FIG. 2 shows a perspective view of a characteristic assembly configuration with the structure shown in FIG. 1. As shown in FIG. 1, a flexible circuit substrate 11 has a generally square base region 110 indicated by broken lines, mounting regions 111, 112 and 113 that are continuously provided along the periphery of the base region 110, and predetermined conduction patterns (not shown) formed below a protection film. Also, an external terminal section 115 is provided at the periphery of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com