Patents

Literature

259results about How to "Guaranteed quality and accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Added material manufacturing device and method

ActiveCN107671288AImprove yieldEliminate defectsAdditive manufacturing apparatusIncreasing energy efficiencyOptical measurementsEngineering

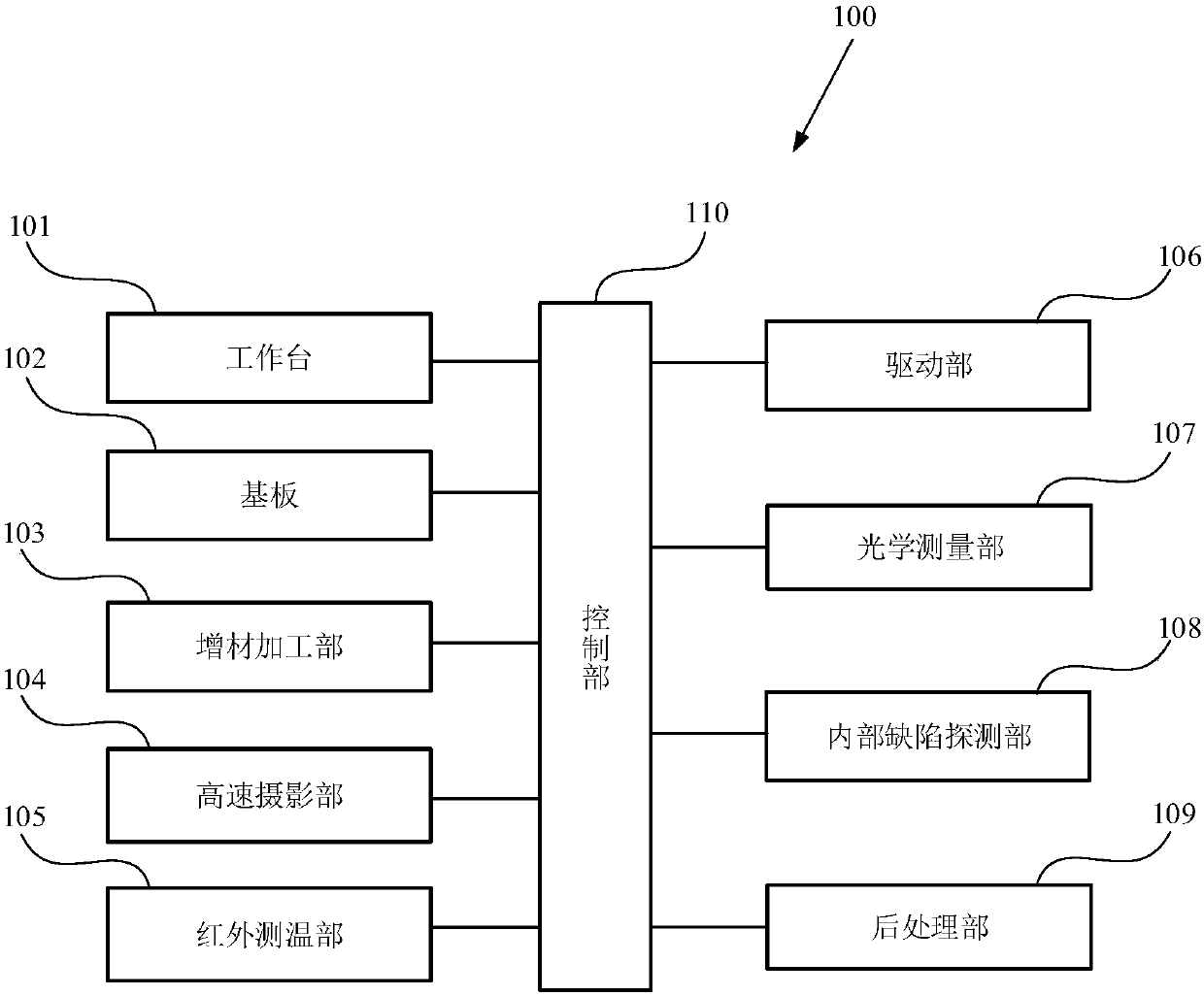

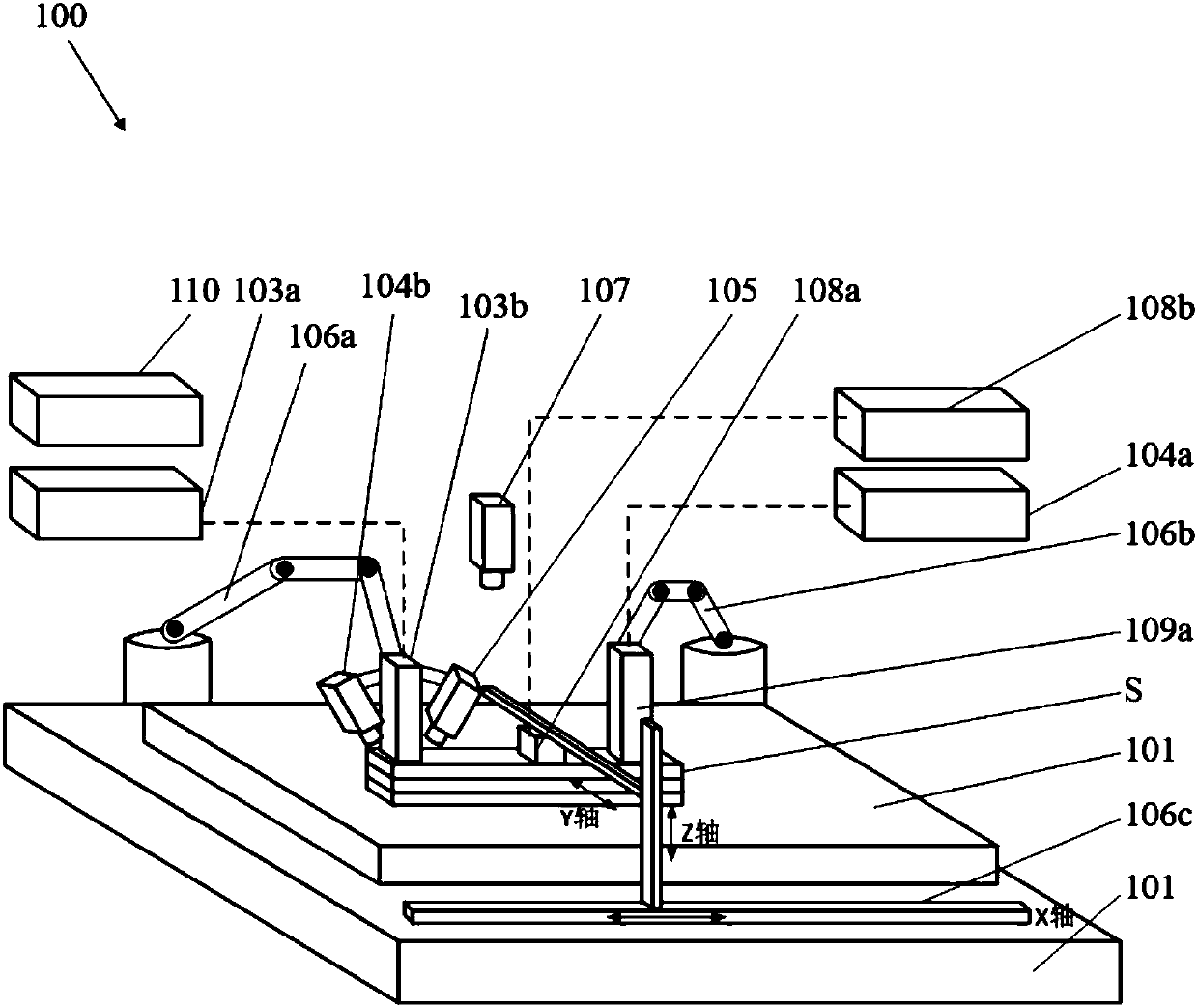

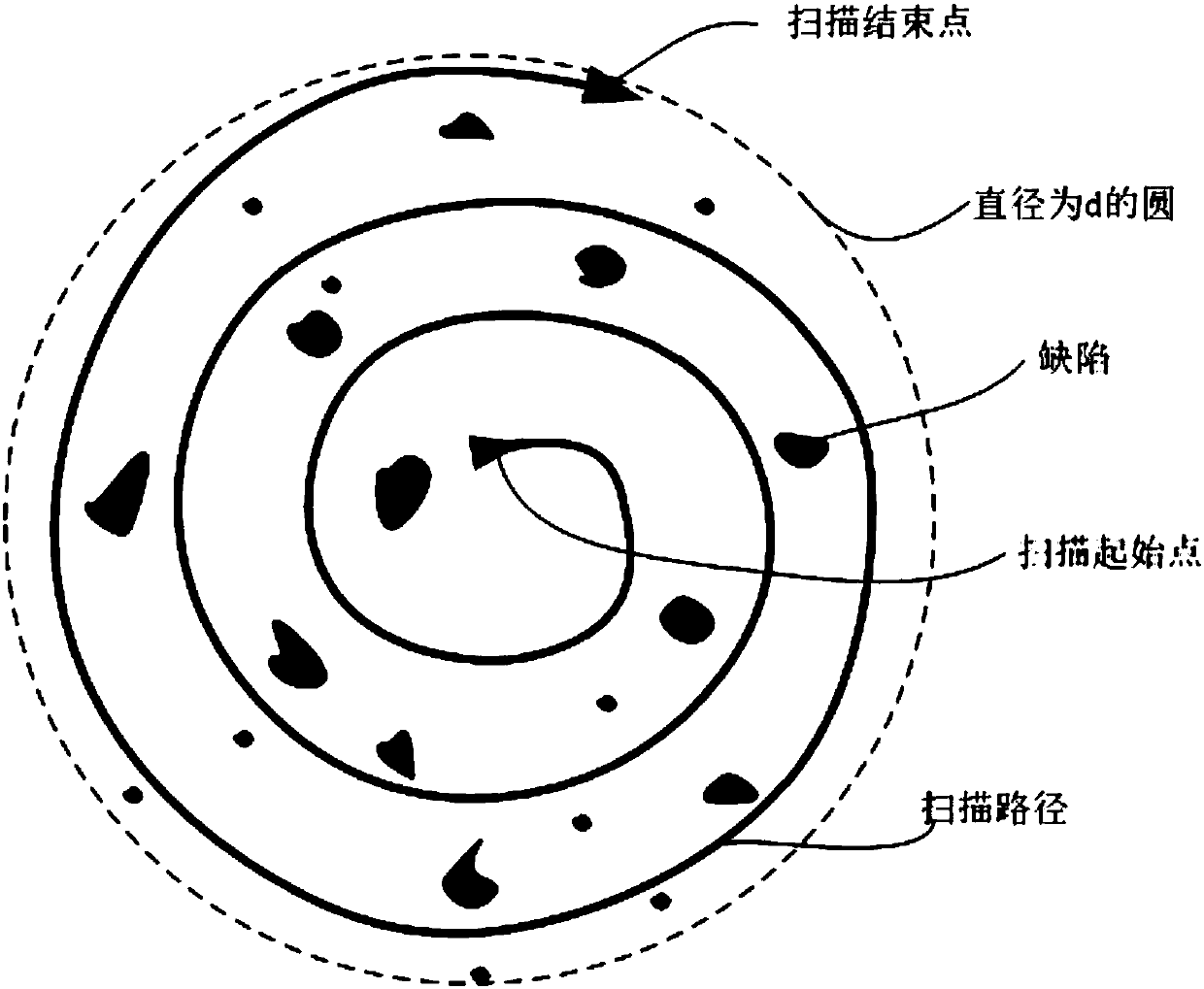

The invention provides an added material manufacturing device and a method. The device is characterized by comprising an added material machining part, a high-speed camera part, an infrared temperature measuring part, an optical measuring part, an internal defect detecting part, an aftertreatment part and a control part, wherein the high-speed camera part comprises a camera head, which moves withthe added material machining head at the same time to obtain material image information; the infrared temperature measuring part comprises a temperature measuring head, which moves with the added material machining head at the same time to obtain material temperature distribution information; the optical measuring part detects surface defects and forming sizes of materials to obtain detecting information; the internal defect detecting part comprises a detecting head and a detecting analyzer; the aftertreatment part treats material defect areas to eliminate defects by adopting corresponding aftertreatment modes; the aftertreatment modes comprise at least one of mechanical rolling treatment, laser shock reinforcement treatment and friction stir treatment; and the control part controls all the parts to operate to obtain various information, determines the defect treatment areas, aftertreatment paths and the aftertreatment modes based on the information, and controls the aftertreatment part to perform corresponding aftertreatments.

Owner:岳阳珞佳智能科技有限公司

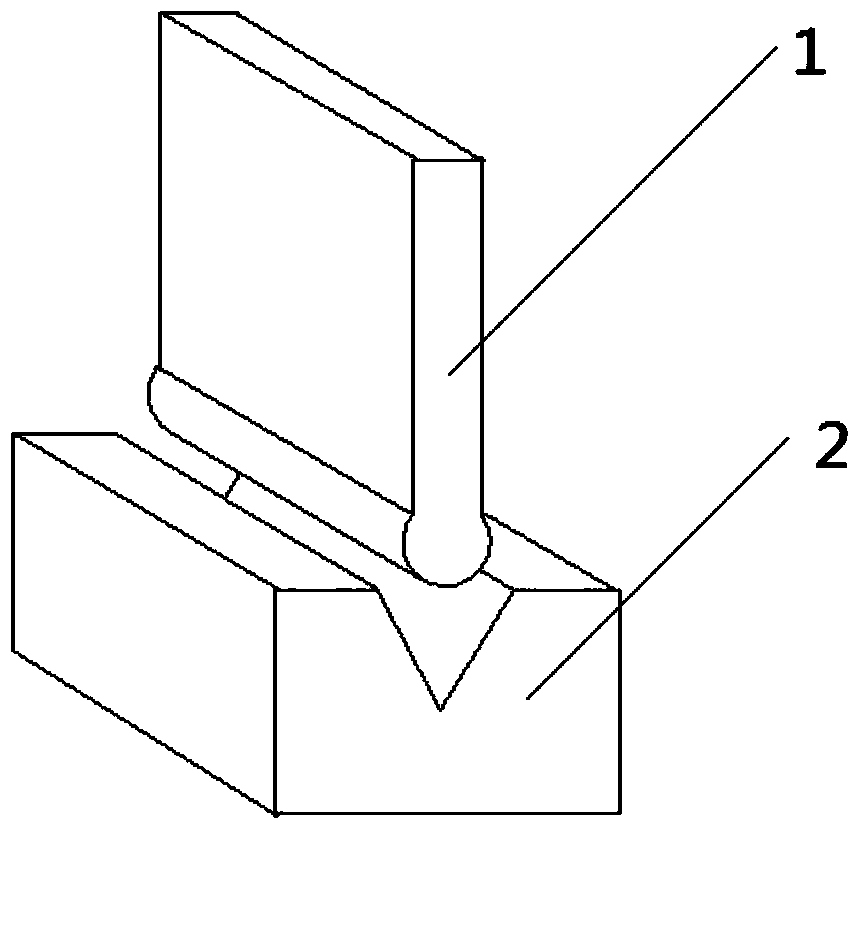

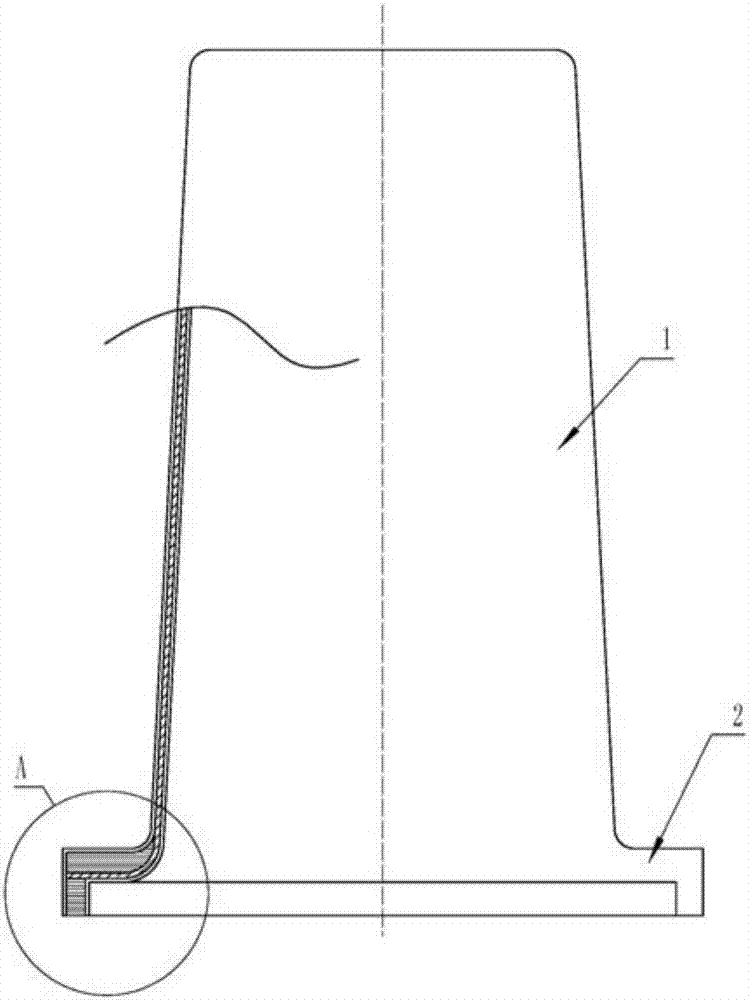

Incremental bending and forming method of hat-shaped member

InactiveCN103480704AHigh quality and precisionHigh forming precisionShaping toolsPunchingEngineering

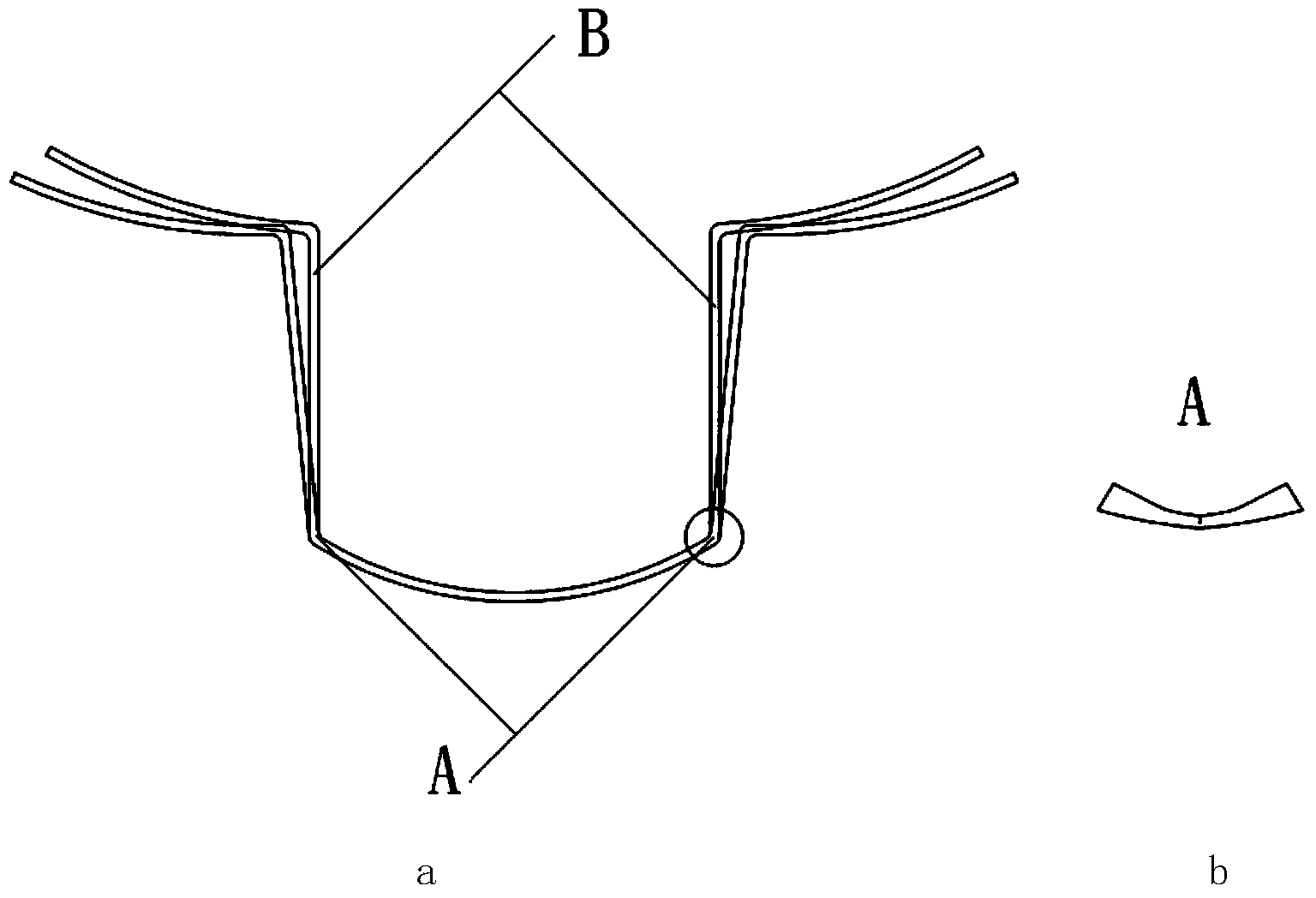

Disclosed is an incremental bending and forming method of a hat-shaped member. Complex hat-shaped member with multi-arcs is formed through a simple mold matching with a plant bending machine. The method includes unfolding each arc of the complex hat-shaped member with the multi-arcs into a plane to determine the size of the plane blank; establishing a three-dimensional model according to the size of the plane blank, and dividing areas by adopting arcs as standards; performing numerical simulation on the forming process complex hat-shaped member with the multi-arcs, incremental bending arcs on two sides, then bending a central arcs, and finally bending boundaries of the areas; determining feeding amount of the plate blanks and downward punching amount of each step during the bending process according to the simulation result. By the aid of the method, the thickness of each part of a formed hat-shaped member is consistent basically, and surface quality and forming accuracy of the formed member can be guaranteed well; the process of controlling deformation is simple, and the method has the advantages of low cost and short period.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Austenitic stainless steel thin-walled pipe machining method

InactiveCN105522341AGuaranteed quality and accuracyGuaranteed dimensional accuracyThin walledAustenitic stainless steel

The invention relates to the field of machining, in particular to an austenitic stainless steel thin-walled pipe machining method. The method comprises the following steps: rough turning, including turning excircles and step end surfaces with machining allowances 2 mm, and erecting a central frame at a right end; clamping, including machining a left end screw hole, which is matched with a left end choke plug, in a workpiece; heat treatment and aging treatment, wherein a right end choke plug rather than the left end choke plug needs to be demounted during aging heat treatment; and semi-fine turning, including clamping the excircle of the left end choke plug with a four-jaw chuck, supporting a right end inner hole with a four-jaw chuck tool on a tailstock with alignment within 0.05 mm, dismounting the four-jaw chuck tool of the tail stock, turning the right end inner hole with an allowance 0.4-0.5 mm, propping the tail stock, dismounting the central frame, and turning all the excircles and end surfaces, with the excircles remaining machining allowances 0.4-0.5 mm; heat treatment and aging treatment; secondary semi-fine turning; fine milling; fine turning; and grinding. The method is simple in machining process, facilitates manufacturing, can ensure the machining quality and dimensional precision of the workpiece, reduces the machining difficulty and the production cost and improves the machining efficiency.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

Additive and subtractive manufacturing based metal part repair method

ActiveCN107097036AImprove surface qualityAvoid interferenceElectron beam welding apparatusMulti platformHigh surface

The invention discloses an additive and subtractive manufacturing based metal part repair method. The additive and subtractive manufacturing based metal part repair method is used for solving the technical problem of the low material utilization rate of an existing metal part repair method. According to the technical scheme, firstly, after to-be-repaired model three-dimensional data are obtained through three-dimensional scanning, subtractive machining is carried out on the worn part of a part, that is, the part is worn through dry high-speed cutting, and a regular surface is obtained; and then additive manufacturing is carried out through an electron beam fuse wire additive process, the deposition additive repair process of the part is completed, meanwhile, the part surface is machined through dry high-speed cutting machining, and a repair part with high surface quality is obtained. According to the additive and subtractive manufacturing based metal part repair method, error accumulation brought by workpiece clamping, taking and placing during original multi-platform machining is avoided, meanwhile, the interference problem happening in the subtractive process of parts of complex structures is solved, and the mechanical performance of the damaged part achieves the level of normal parts. According to the method, the repair process is carried out in a vacuum environment, workpiece clamping only needs to be carried out once, and the material utilization rate is high.

Owner:西安博恩生物科技有限公司

Method for paving and sticking stone materials or ceramic tiles

The invention provides a construction method for paving and sticking stone materials or ceramic tiles on a wall or floor. The construction method comprises the following steps: sticking an extruded sheet on the back of a plate to be paved and stuck in advance and mounting stainless steel back bolts; sticking and hanging materials to be paved and stuck on the wall by using adhesive and hanging pieces so as to achieve a firm paving and sticking effect.

Owner:陈晓通

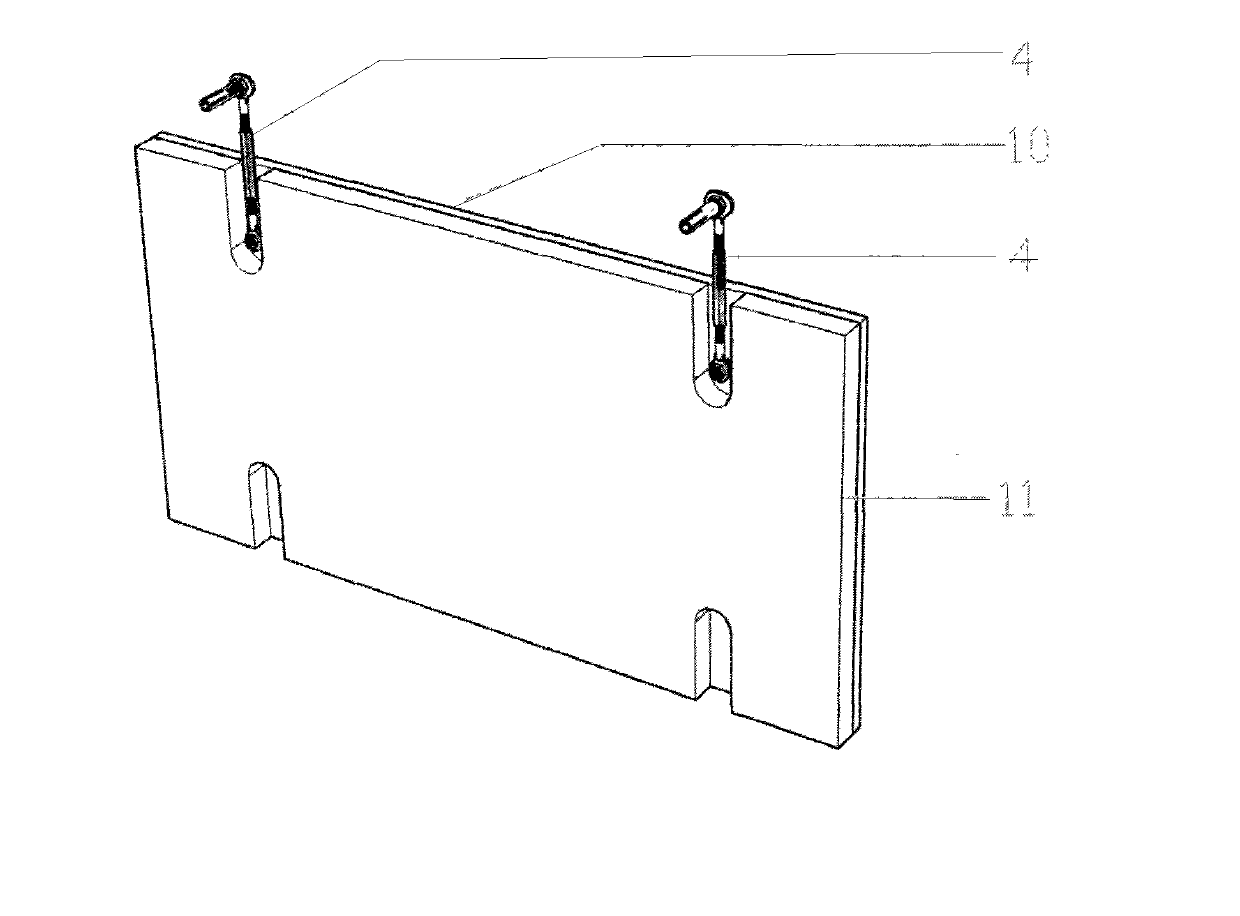

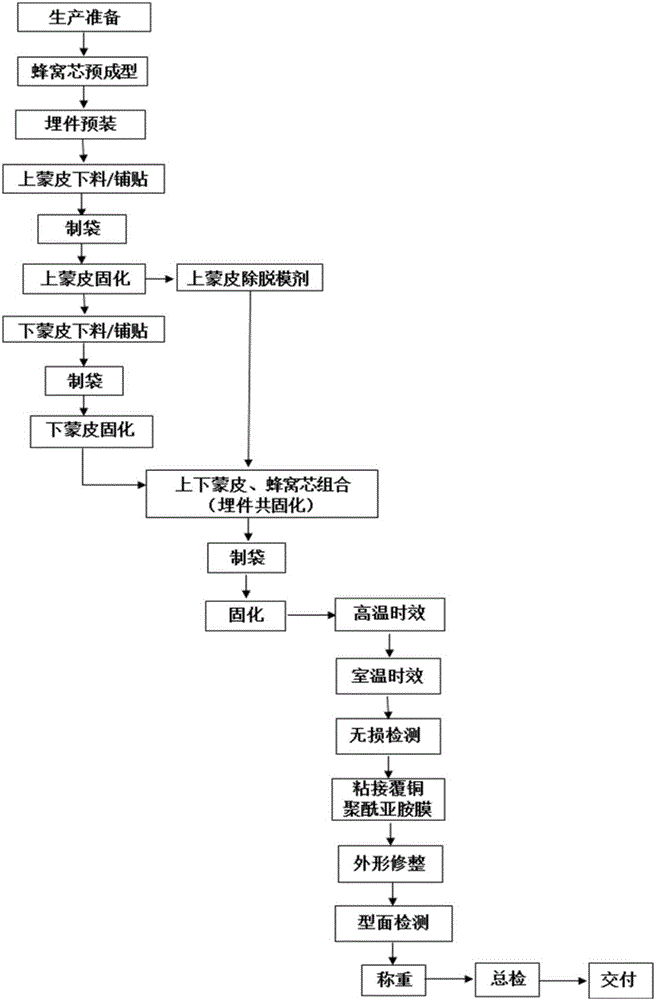

Molding method of aramid fiber composite material frequency selection surface reflector

ActiveCN106671557AAvoid deformationGuaranteed quality and accuracyLamination ancillary operationsCosmonautic vehiclesNomex honeycombRoom temperature

The invention provides a molding method of an aramid fiber composite material frequency selection surface reflector. The problems of profile accuracy control of the aramid fiber composite material frequency selection surface reflector and molding of a surface metal array are mainly solved by adopting a multi-step molding method, thermal cycle ageing and room-temperature aging treatment on a solidified reflector, a method of bonding a copper-coated polyimide membrane on the surface of a reflector substrate by using an adhesive film through a procured NOMEX honeycomb core and a reflector at a 'B' stage.

Owner:XI'AN AIRCRAFT INTERNATIONAL

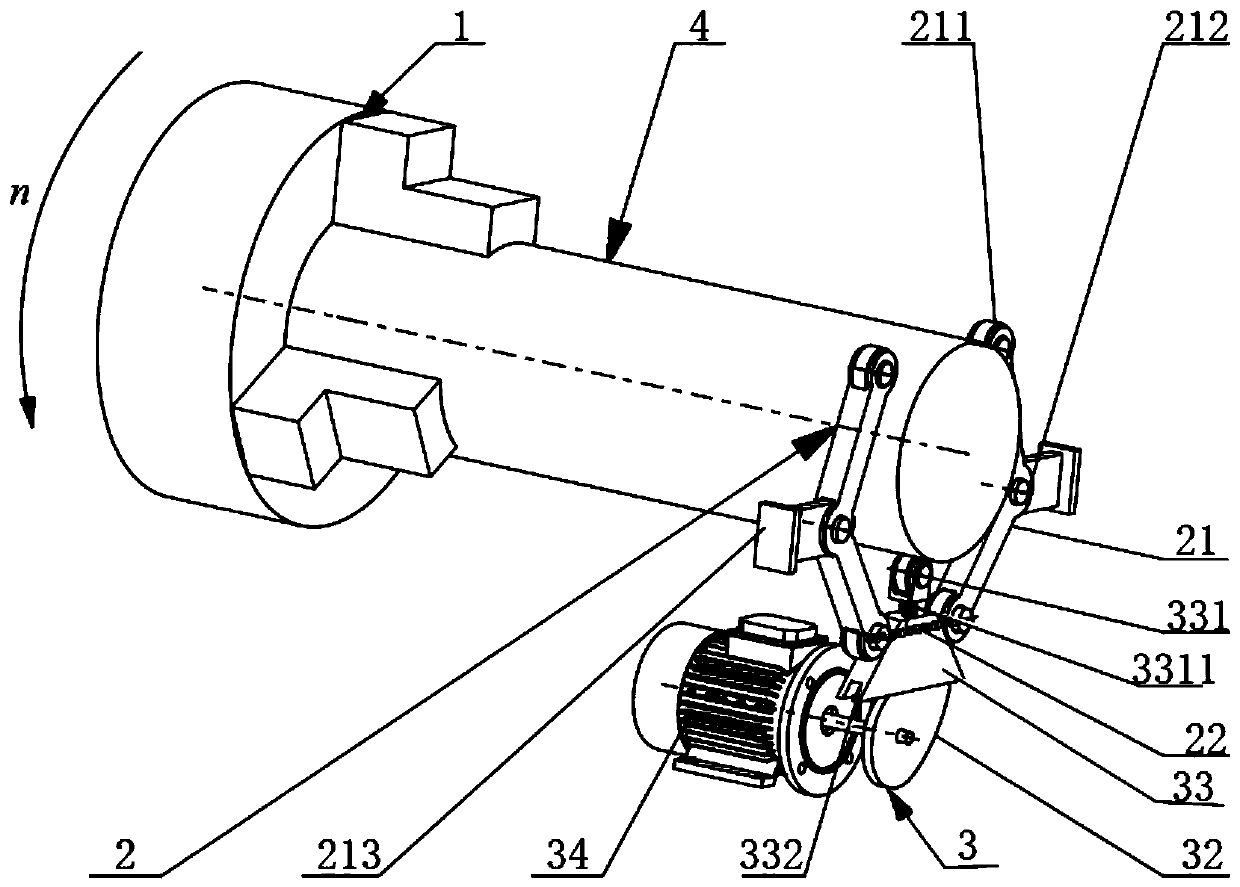

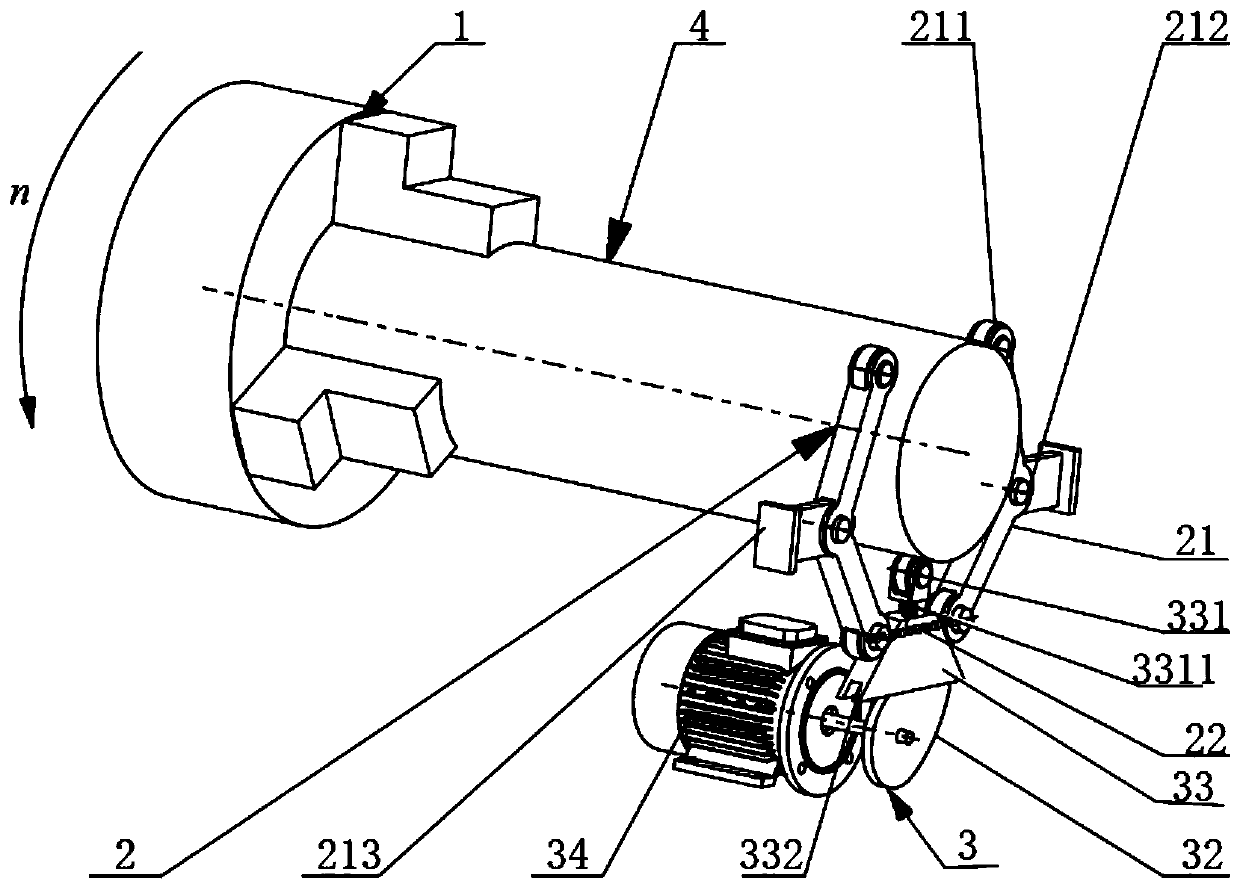

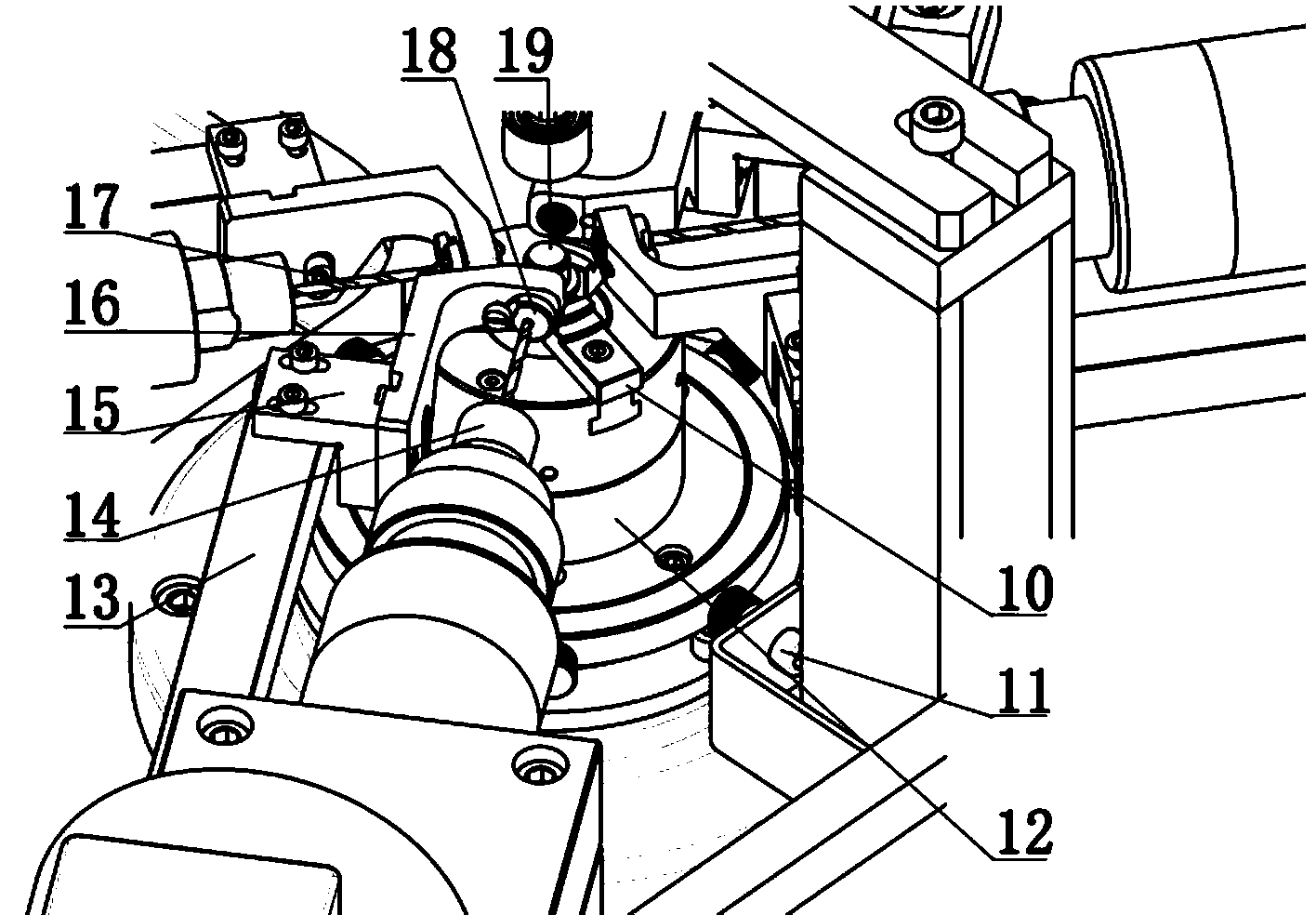

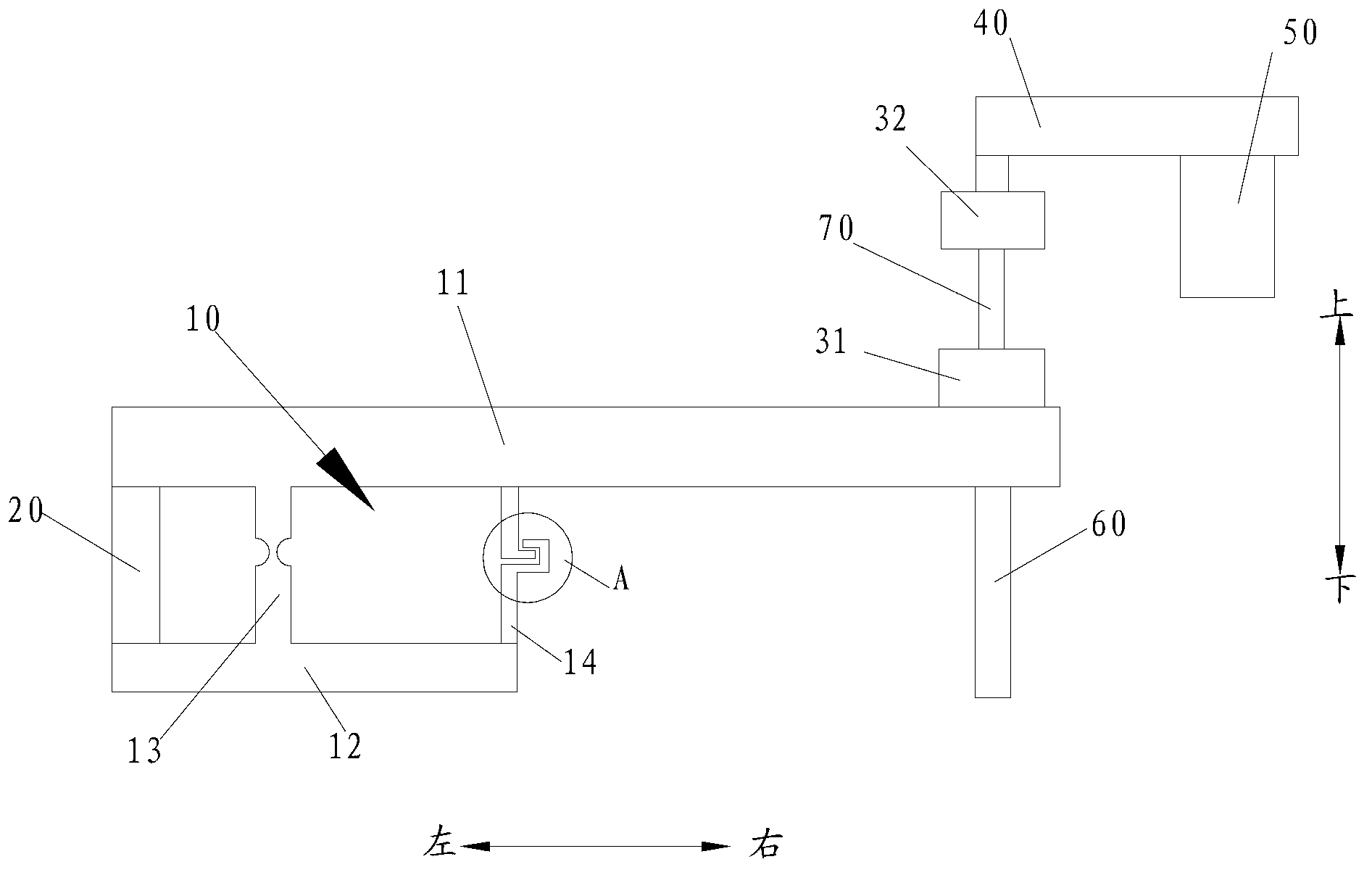

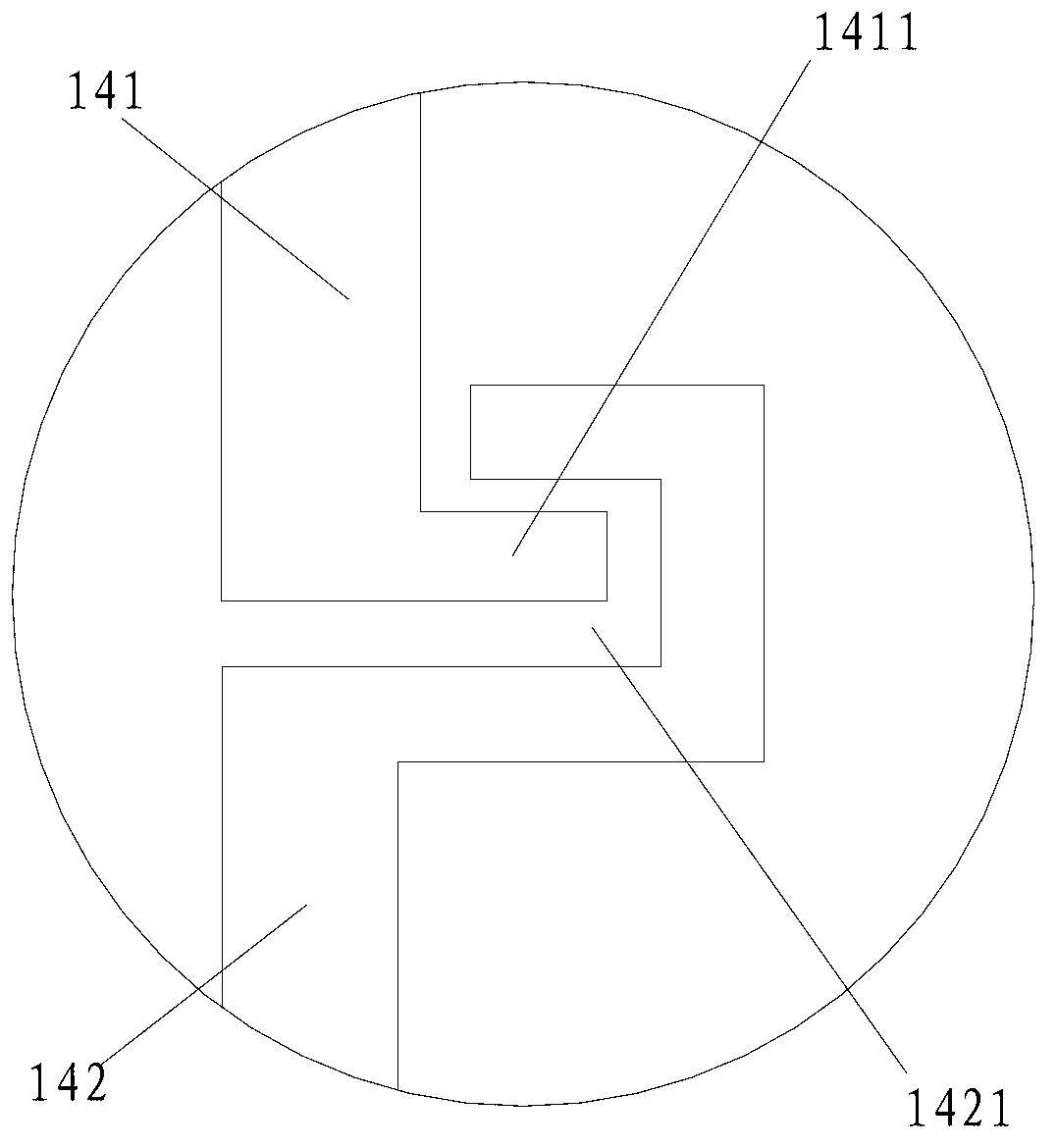

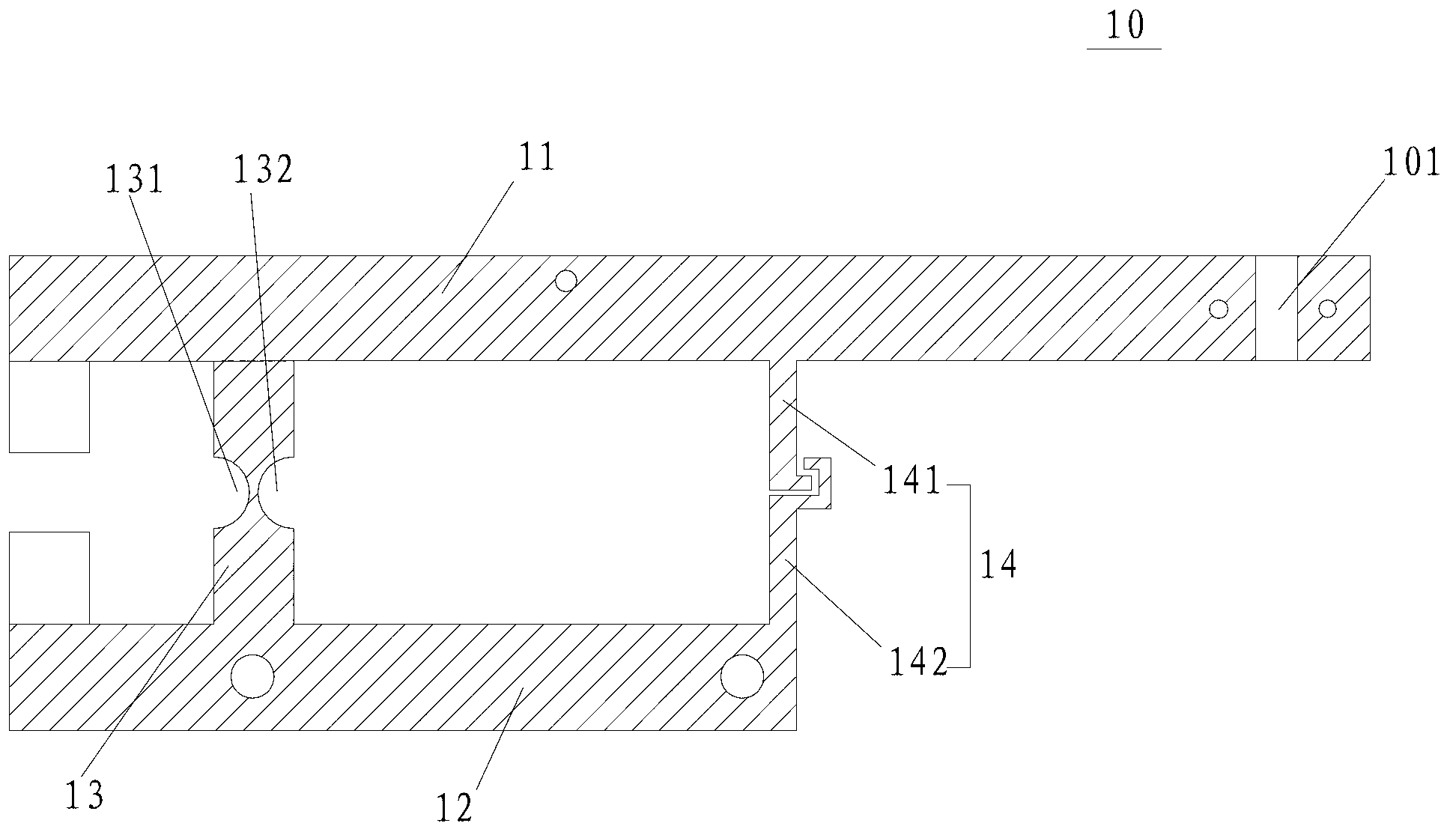

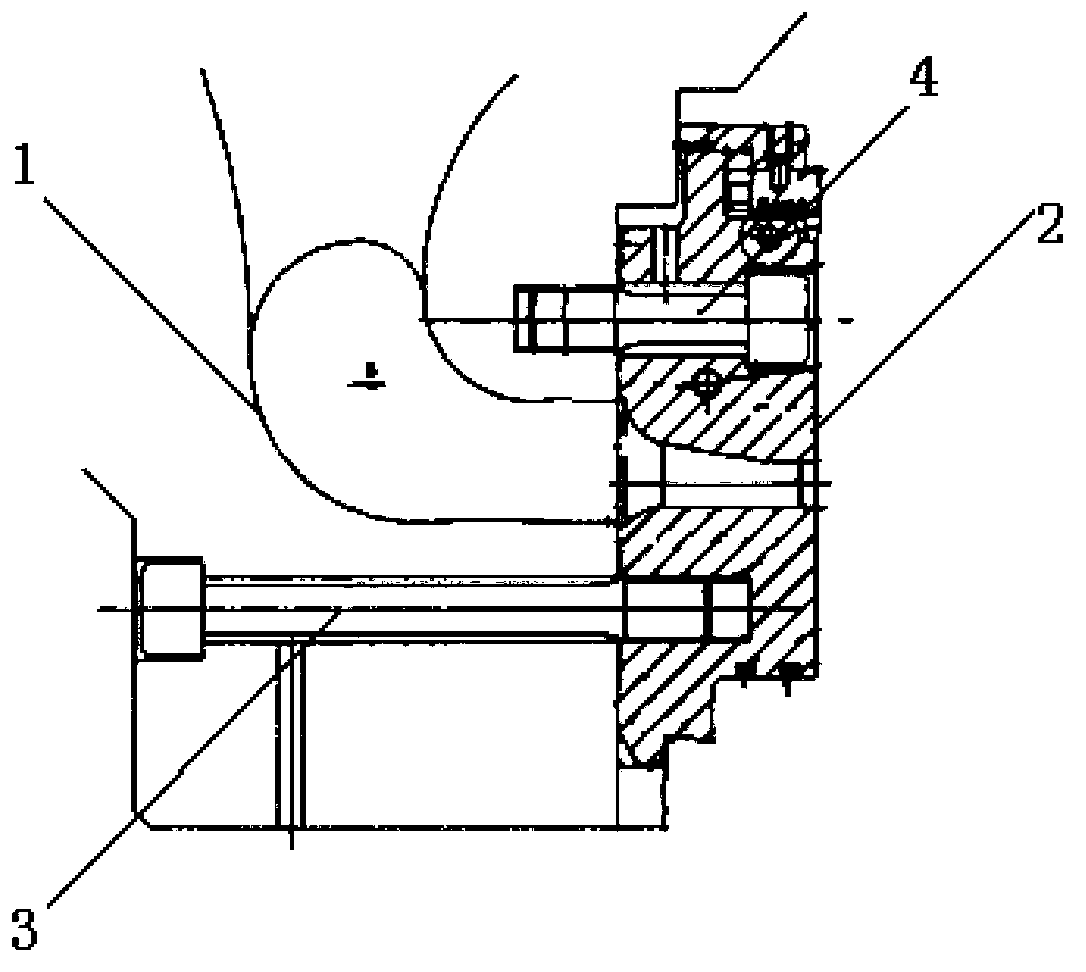

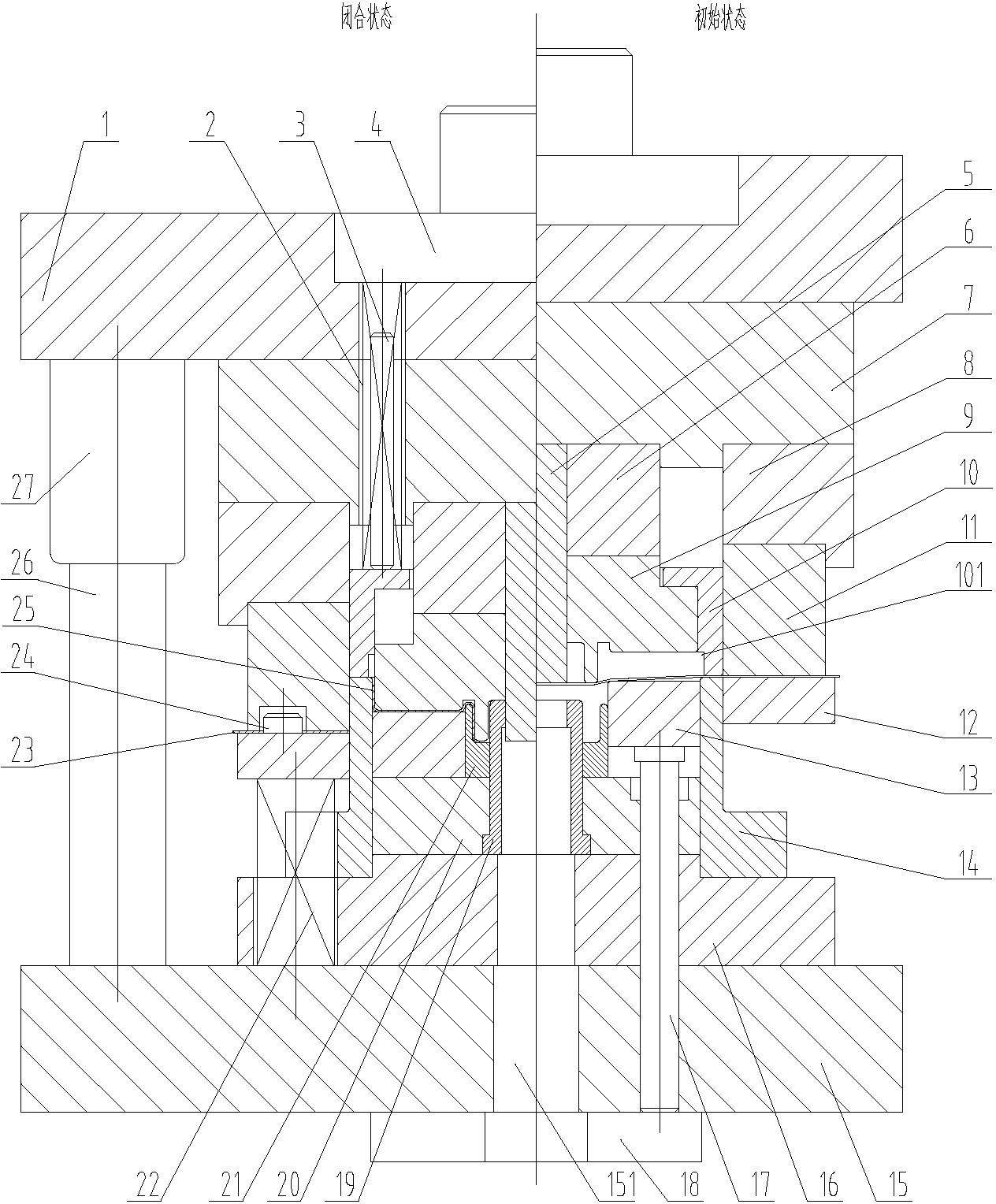

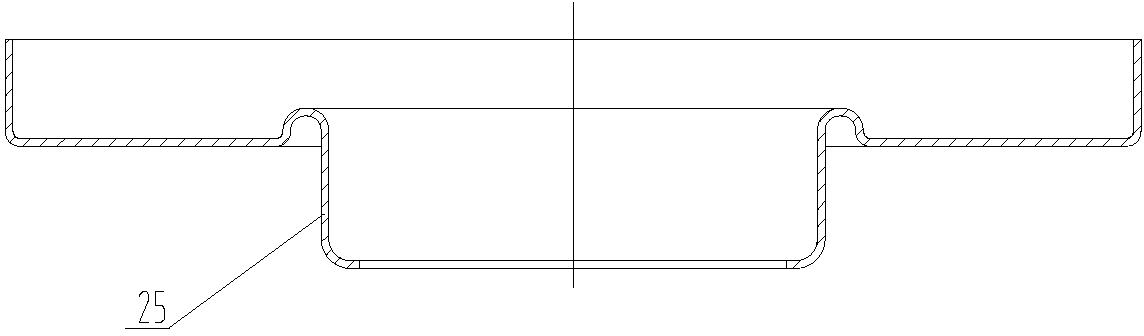

Long shaft part center adjustable quick clamping and machining device and operation method thereof

PendingCN109848735AGood supportReduce processing size and shape errorsChucksPositioning apparatusDrive motorCam

The invention provides a long shaft part center adjustable quick clamping and machining device and an operation method thereof. The device comprises a chuck, a fixture and a force applying device. Thechuck is used for fixing one end of a shaft part. The fixture comprises two V-shaped rods used for clamping the other end of the shaft part. The V-shaped rods are fixedly connected through a spring.The tail ends of the V-shaped rods are provided with rolling wheels. The force applying device comprises a cam, a bevel push block and a driving motor. The two bevels of the bevel push block are arranged in an inverted-V shape. The upper end of the bevel push block is arranged in the space formed by connecting the spring and the V-shaped rods. The lower end of the bevel push block is connected with one side of the cam. The driving motor is arranged on the other side of the cam. The long shaft part center adjustable quick clamping and machining device provided by the invention can implement quick clamping and dynamic clamping and machining on different diameters of shaft parts, is fast and convenient to operate, firm in clamping, integrates the functions of centers and follow-rest devices during traditional shaft part machining, saves the cost and optimizes the machining process.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

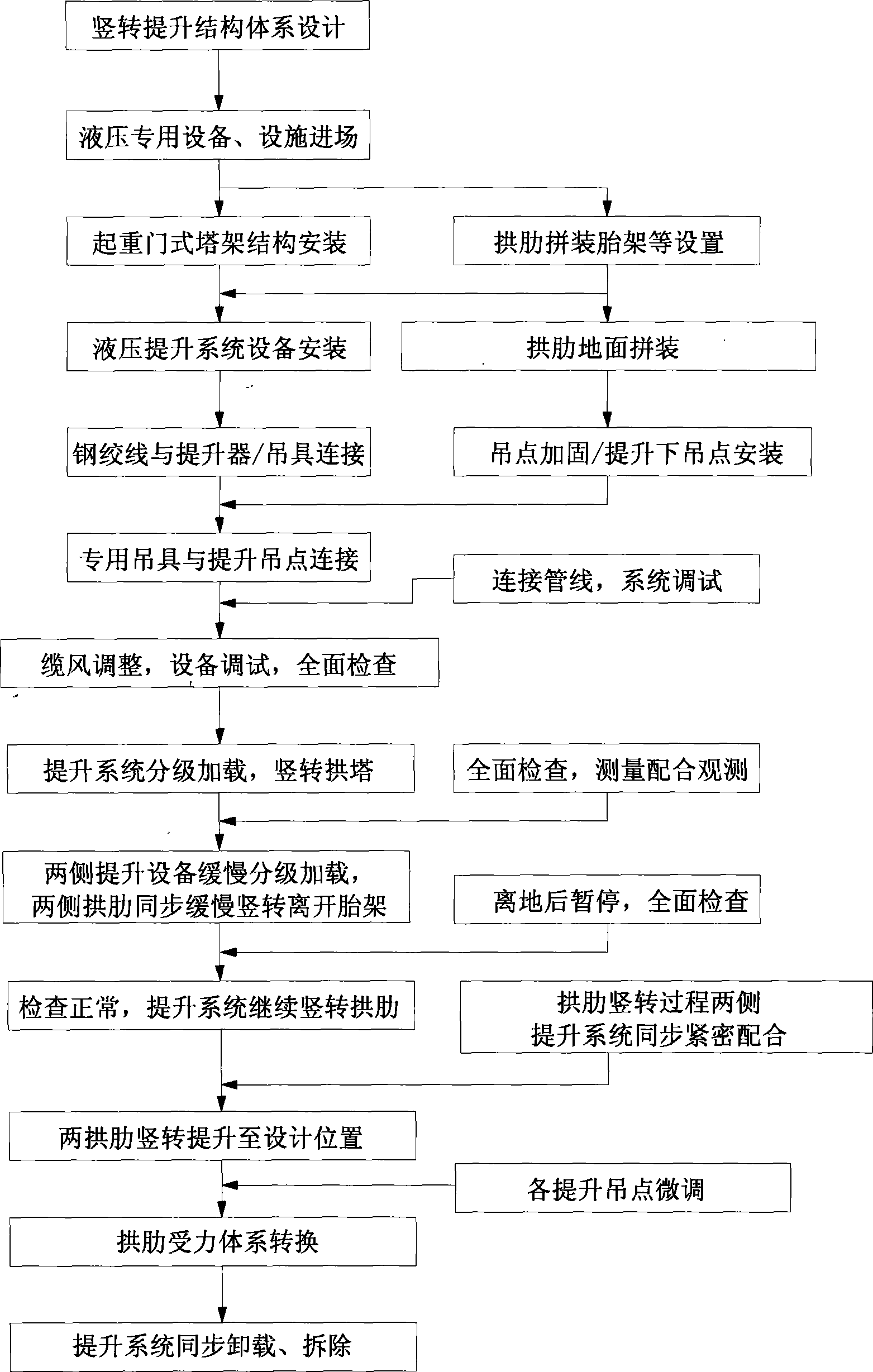

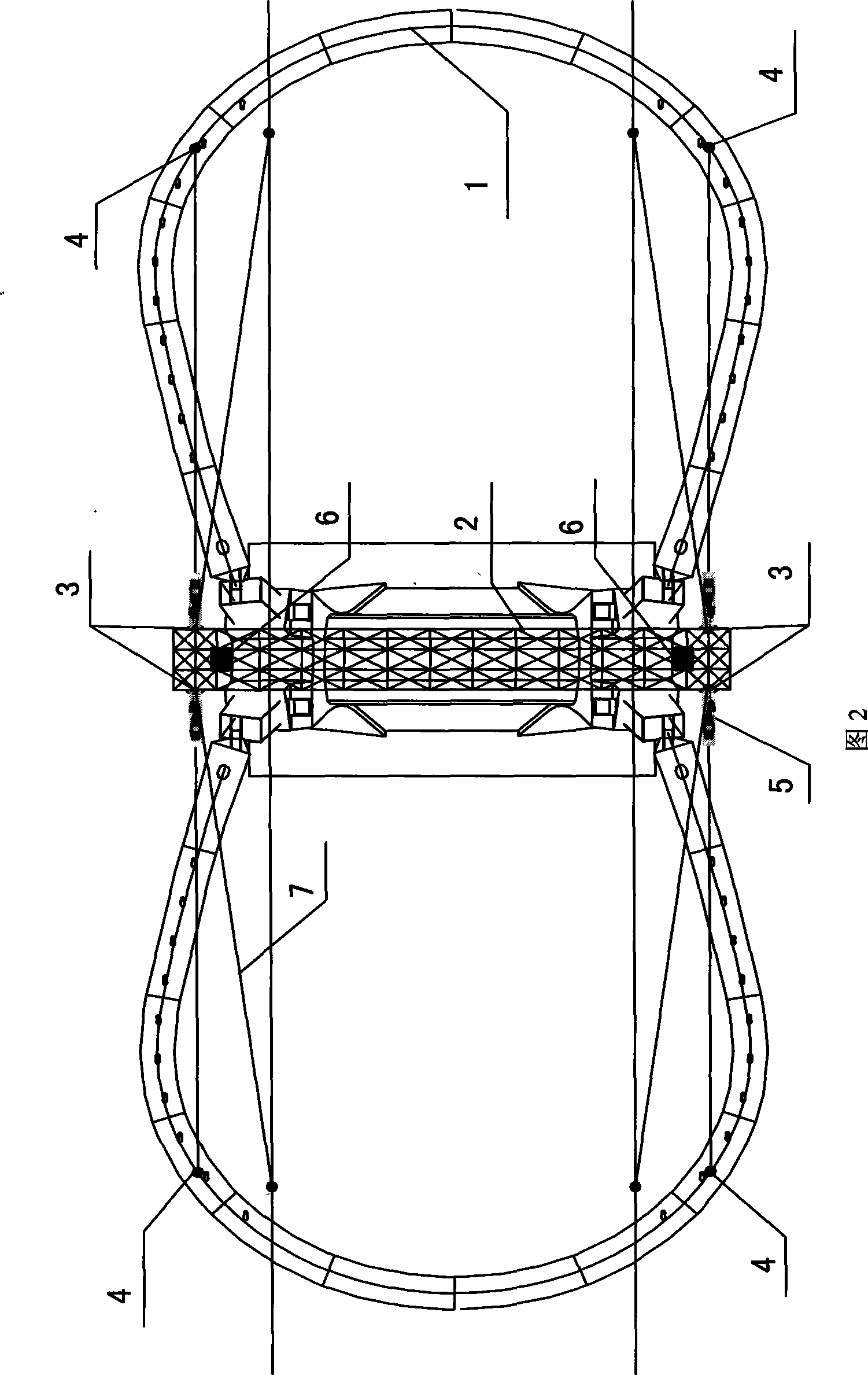

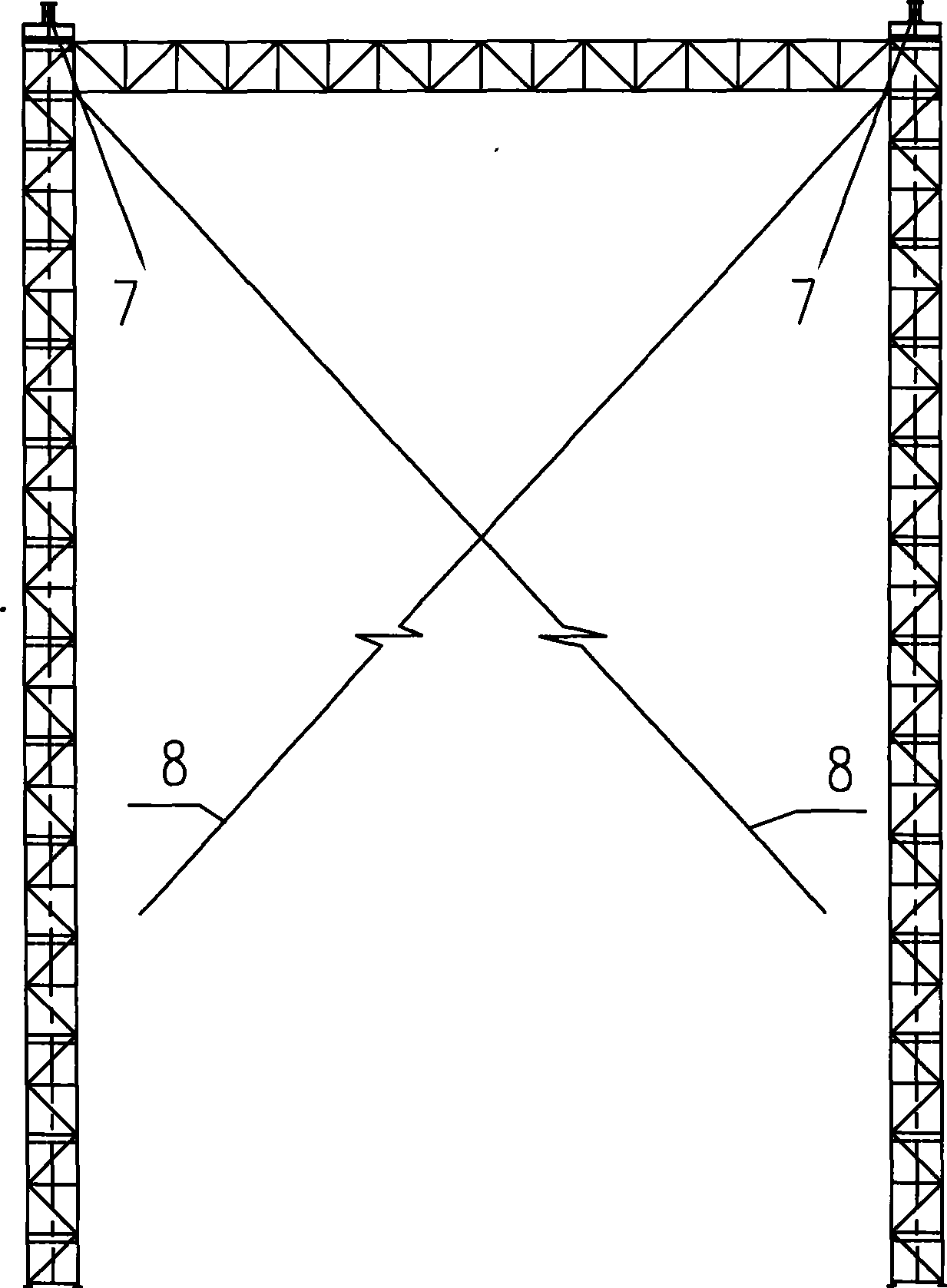

Synchronous vertical swing lift construction method for double inclination arc tower

ActiveCN101446075AIncrease the volume of the facilityReduce weightBridge erection/assemblyReinforced concreteCentral line placement

The invention discloses a synchronous vertical swing lift construction method for a double inclination arc tower. The method comprises the following steps: arranging a vertical swing winch at the combination of two gate-shaped arch ribs and reinforced concrete, arranging a bearing gate type lifting tower at the position of the symmetrical central line of the arch ribs, arranging an upper lifting sustained center and a lower lifting sustained center at the top of the tower and on the arch ribs respectively, and performing symmetrical synchronous vertical swing lift through two pairs of hydraulic lifters by utilizing the symmetry character of the double arch ribs, so as to achieve the purpose of vertically swinging the arch ribs from the planimetric position to the mounting position. The construction method has the advantages that the arc tower construction difficulty is reduced, tools and materials are saved, the construction period is shortened, and the installation of two mammoth arch rib structures can be completed with high precision and high quality; aloft work of the arch ribs is converted into ground integral assembly work, the construction efficiency is high, the safety protection work is easy to organize, and the construction quality is easy to guarantee; machines and equipment required for the construction are in a small quantity, the process is simple, and the operation is safe; the construction speed is high, the manufacture cost is low, and the investment is saved.

Owner:JIANGSU HUNING STEEL MECHANISM

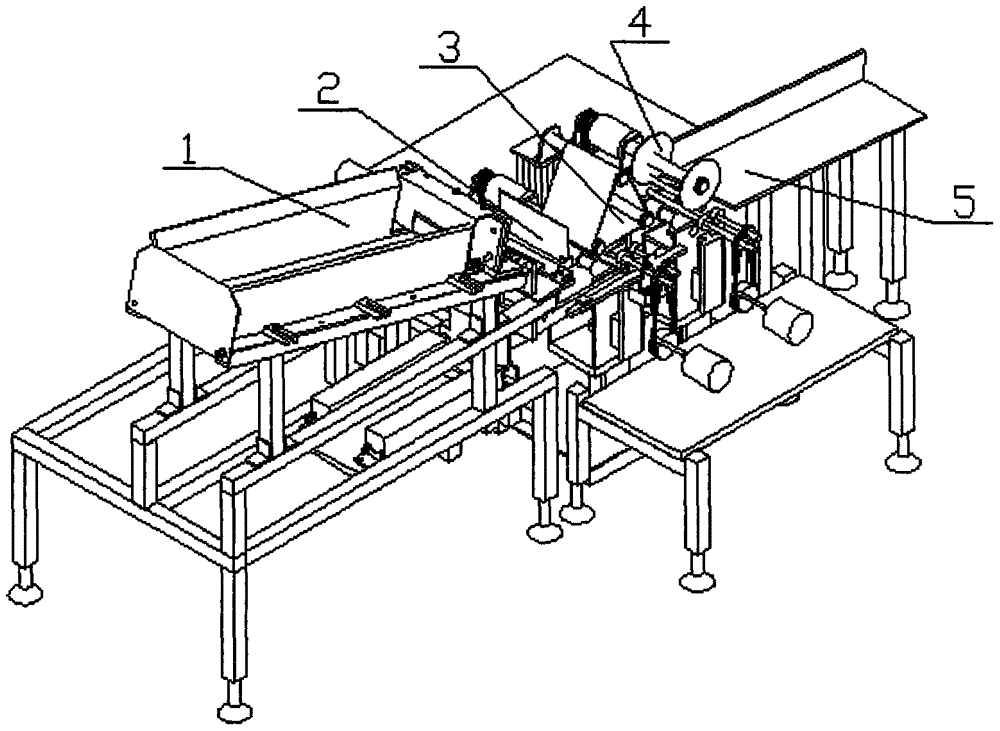

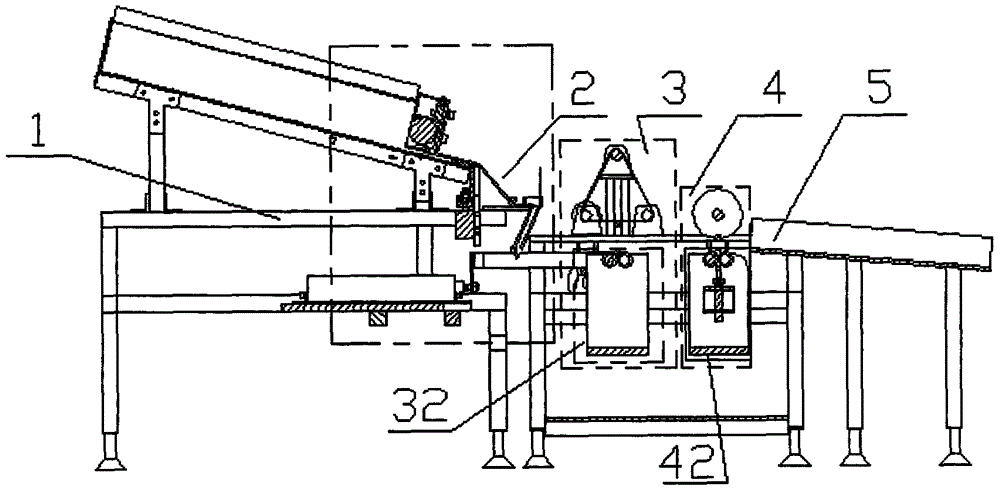

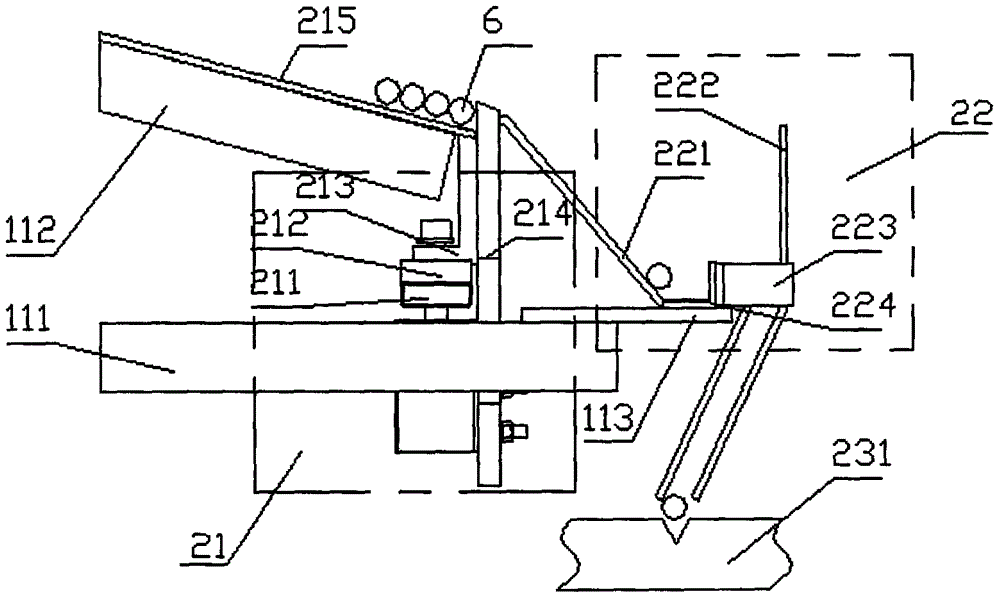

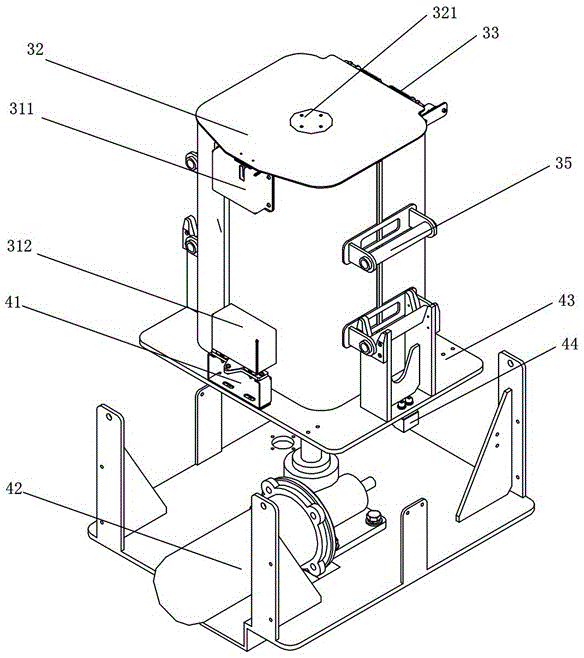

Double-station automatic grinding and cutting machine for ceramic green body tubes

InactiveCN106625132ASave land areaAccurate locationGrinding carriagesBelt grinding machinesSurface grindingSilo

The invention provides a double-station automatic grinding and cutting machine for ceramic green body tubes. The machine includes a machine frame, a storage silo, a feeding mechanism, a delivery mechanism, a ceramic green body tube grinding station and a ceramic green body tube cutting station; the ceramic green body tube grinding station is on the left side of the cutting station; the left side of the feeding mechanism is provided with the storage silo, a feeding air cylinder is located at the tail end of the storage silo, and the tail end of a storage silo supporting beam is fixedly provided with a guide plate for ceramic green body tube dropping; the delivery mechanism includes a delivery bracket driving air cylinder and a double-V-shaped groove delivery bracket which are fixed together, and the side of the double-V-shaped groove delivery bracket is fixedly provided with a guide slider; the grinding station includes a core-free supporting wheel, a magnetic-driving device and an abrasive belt grinding device; the cutting station includes a core-free supporting wheel, a magnetic-driving device and a cutting device and further includes a workpiece discharging mechanism. The machine has the advantage that ceramic green body tube surface grinding and ceramic green body tube two-end excess material cutting can be achieved with one machine.

Owner:ZHEJIANG UNIV

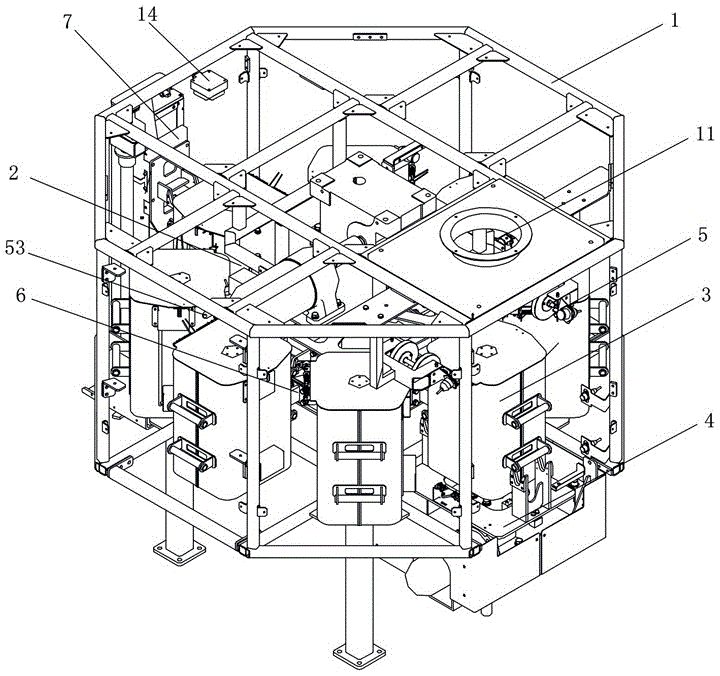

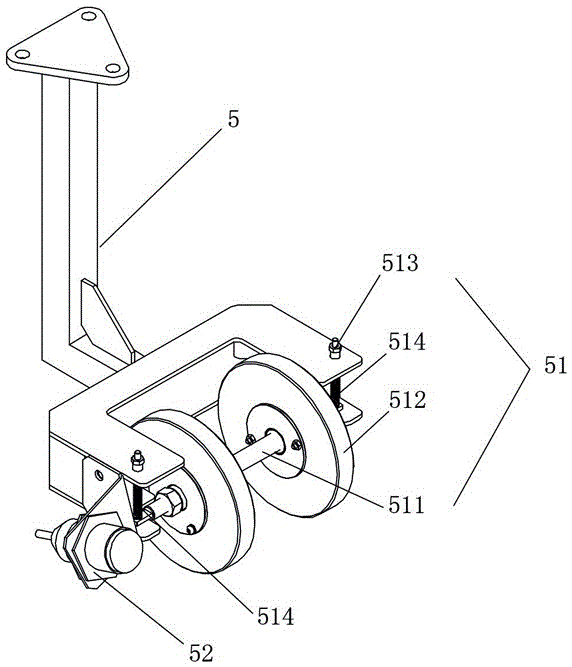

Intelligent sample collecting device

ActiveCN105752470ARisks Affecting Mass AccuracyHigh security for collection and transferLidsNon-removalbe lids/coversLocking mechanismEngineering

The invention discloses an intelligent sample collecting device which comprises a machine frame. The machine frame is provided with a feed inlet. A rotatable rotating disc mechanism and multiple sample storage barrels used for collecting samples are arranged in a collecting cavity formed by the machine frame. The sample storage barrels are hung on the rotating disc mechanism. Each sample storage barrel is provided with a hinged barrel cover and an induction locking mechanism used for locking the barrel cover. The hinged position of the barrel cover is provided with an elastic part so that the barrel cover can bounce upwards to be opened when not locked. The feed inlet is provided with a liftable weighing mechanism. The weighing mechanism is provided with an induction unlocking assembly matched with the induction locking mechanism. When the rotating disc mechanism drives the sample storage barrels to rotate to the position below the feed inlet, the weighing mechanism raises to lift up the sample storage barrels, so that the induction locking mechanism induces an unlocking signal of the induction unlocking assembly to open the barrel covers for sample connection and weighing operation. The intelligent sample collecting device has the advantages that the structure is simple and compact, the intelligence degree is high, sample collection and transfer safety is high, sample collection quality precision is high, working efficiency is high, and the production cost is low.

Owner:HUNAN SUNDY SCI & TECH DEV

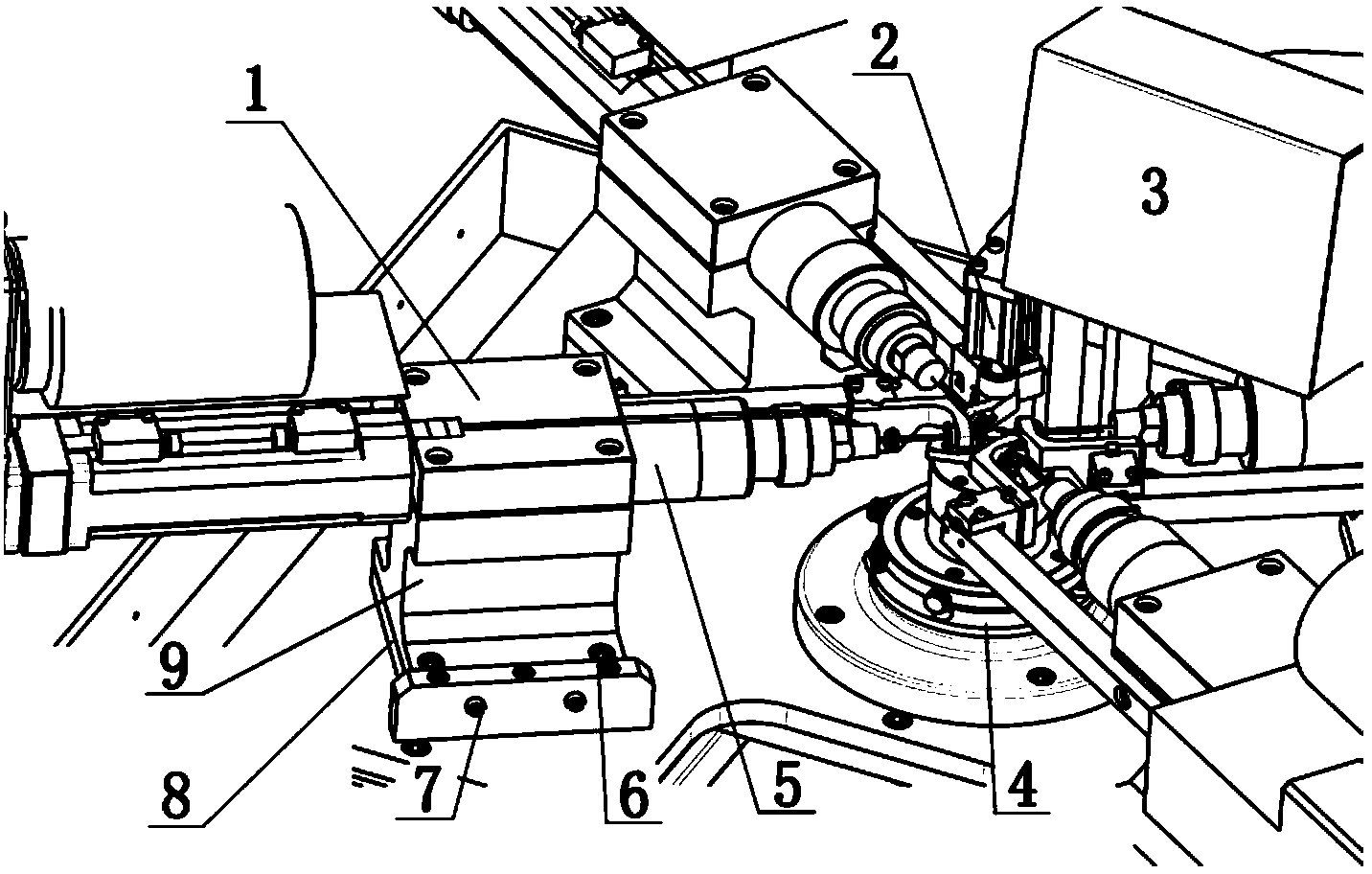

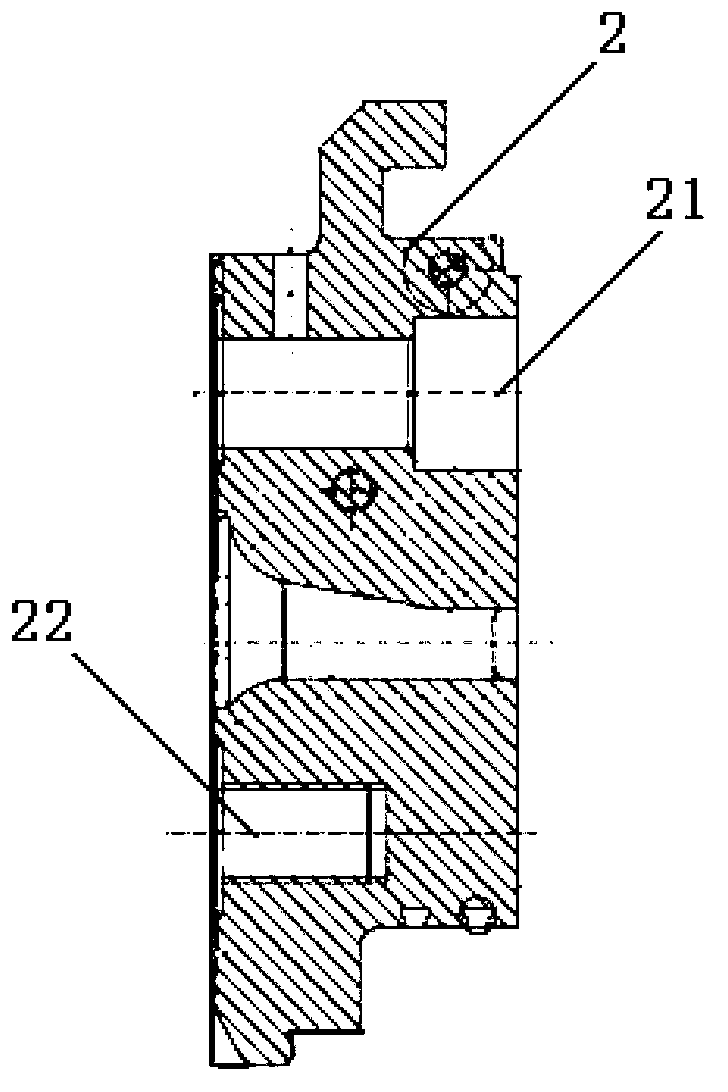

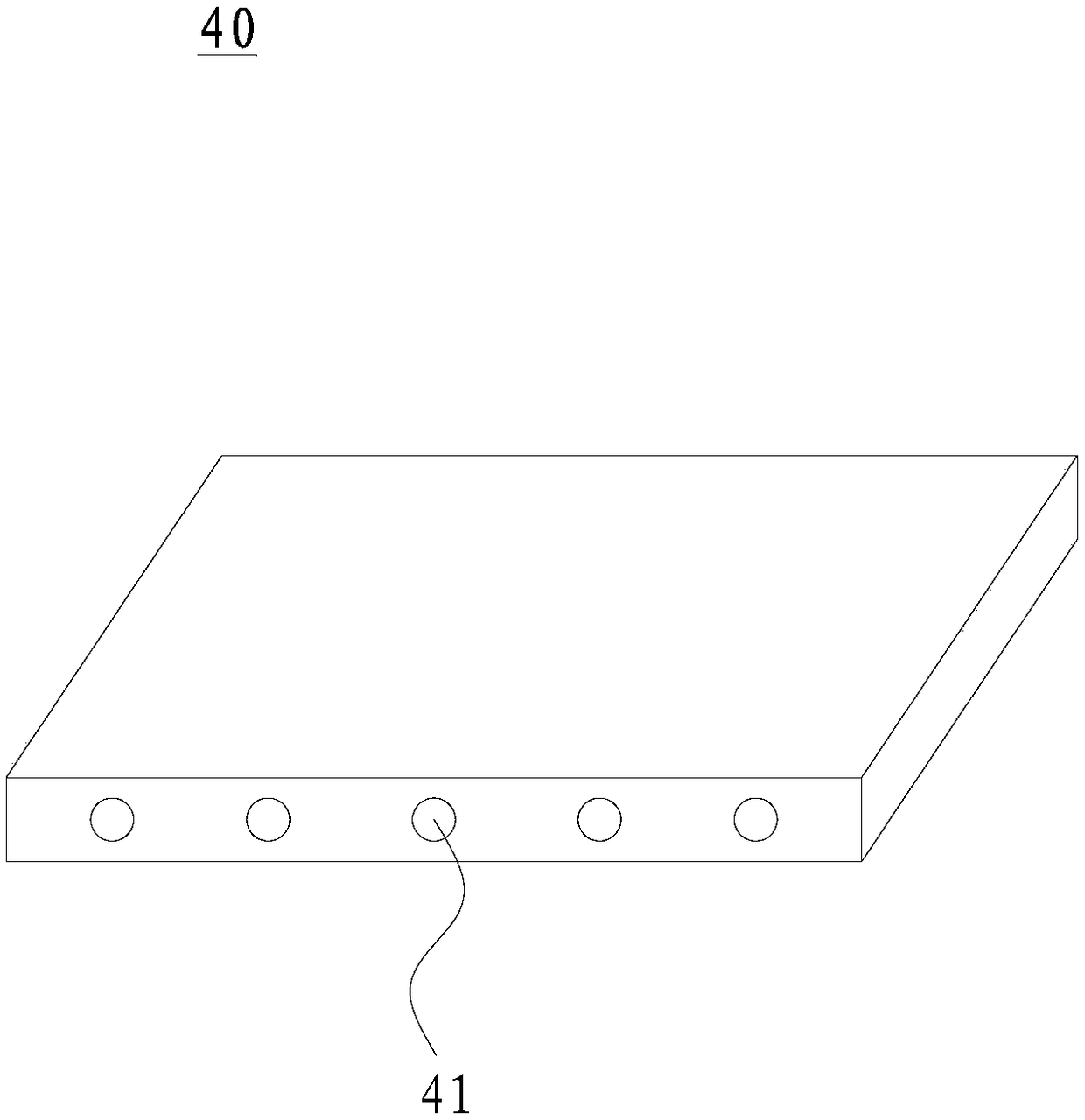

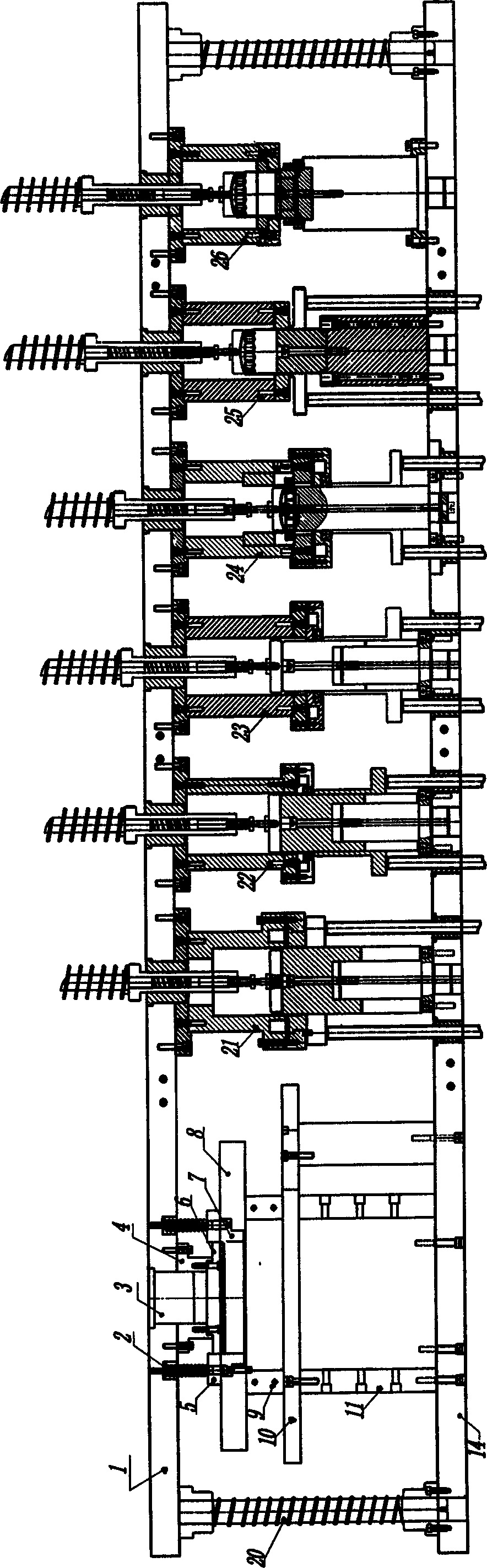

Multi-shaft precision drilling machine tool

InactiveCN103586503ARealize adaptive intelligent controlGuaranteed quality and accuracyPositioning apparatusMetal-working holdersCantileverMachine tool

A multi-shaft precision drilling machine tool comprises a machine frame and a working platform on the machine frame. The multi-shaft precision drilling machine tool is characterized in that the multi-shaft precision drilling machine tool further comprises two to six supports (9), two to six power heads (5), a dividing plate (4), a workpiece clamping mechanism and a drilling and covering clamping mechanism, wherein the supports (9) are fixed on the side portion of the working platform and are provided with sliding grooves, the power heads (5) are installed on the supports, and the dividing plate (4) is installed on the working platform; the workpiece clamping mechanism comprises a chuck (12) and a pressing air cylinder (2), wherein the chuck (12) is installed on the dividing plate (4) and rotates along with the dividing plate (4), and the pressing air cylinder (2) is used for pressing a workpiece (19); the drilling and covering clamping mechanism comprises a cantilever (13), a first holder (15) and a second holder (16), wherein the cantilever (13) can be adjusted in the horizontal direction of the sliding grooves of the supports (9), the first holder (15) is installed at one end of the cantilever (13) and can be adjusted in the transverse direction of the cantilever (13), and the second holder (16) is installed on the first holder (15) and can be adjusted in the vertical direction. The multi-shaft precision drilling machine tool has the advantages of being efficient, strong in rigidity, high in stability and machining precision, wide in application range and the like.

Owner:DALIAN MIX FLUID ENG & TECH

Integrated manufacturing method of composite material cavity member

InactiveCN104742383AGuaranteed quality and accuracyGuaranteed dimensional accuracyWater solubleTheoretical models

The invention discloses an integrated manufacturing method of a composite material cavity part. The integrated manufacturing method comprises the following steps: manufacturing a standard mould according to a theoretical model of the part, wherein a cavity of the standard mould is coincident to that of the part; coating the surface in the cavity with one layer of water-soluble surface filling material and then injecting a water-soluble core material, compacting, closing, curing an upper mould and a lower mould, removing the standard mould after curing to form a water-soluble core mould of the part; spreading a composite material prepreg on the surface of the water-soluble core mould and curing; and finally, washing the water-soluble core mould by using water to form the composite material cavity part.

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

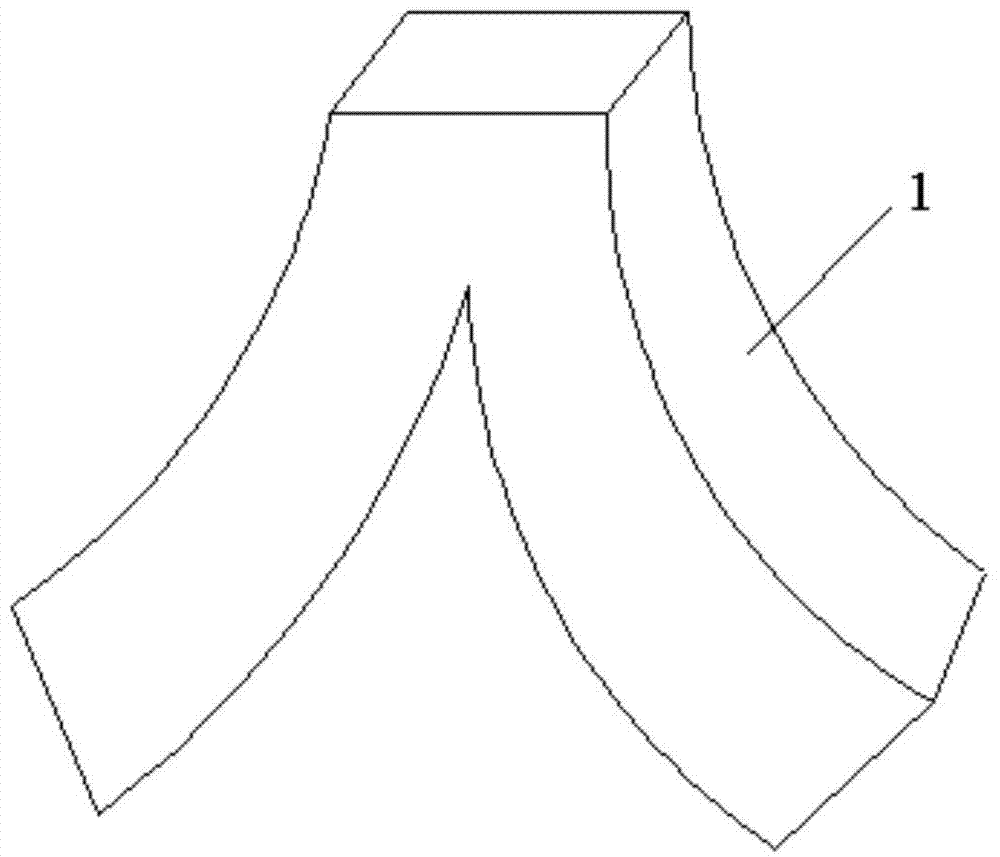

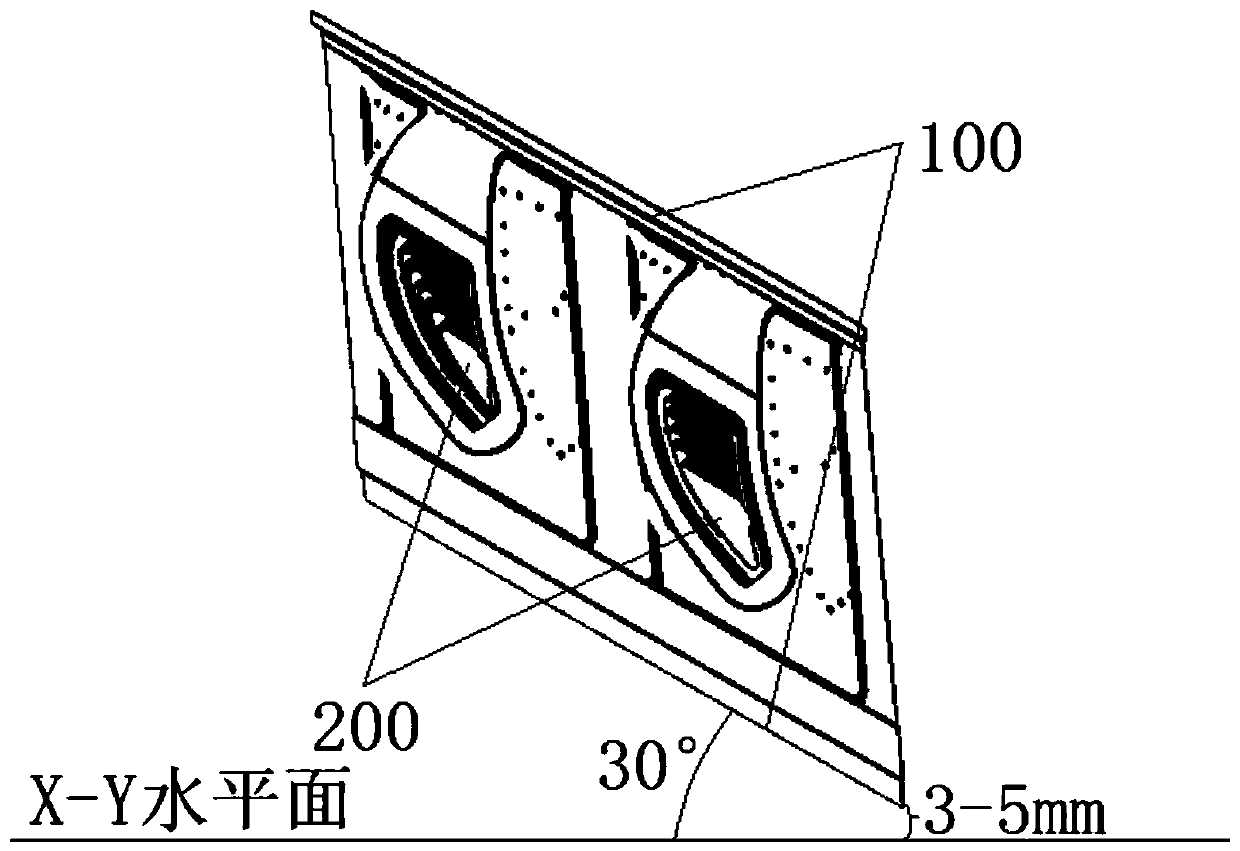

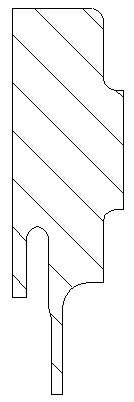

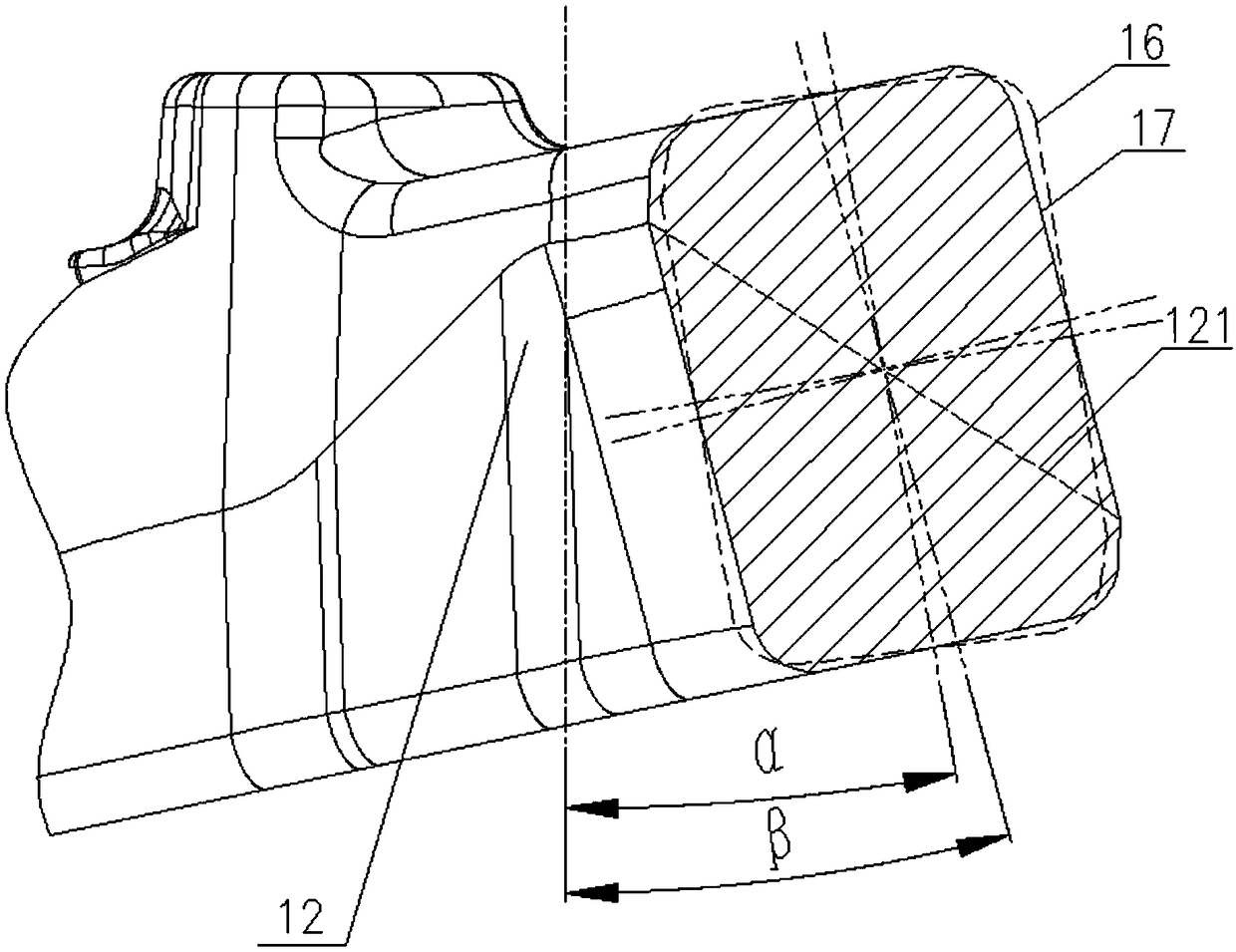

Process for preparing guide vane by selective laser melting

InactiveCN110523985AGuaranteed mechanical propertiesGuaranteed quality and accuracyTurbinesAdditive manufacturing apparatusSelective laser meltingSelective laser sintering

The invention discloses a process for preparing a guide vane by selective laser melting. The process comprises the following steps that S1, when a guide blade is placed, the powder laying direction ofa scraper is selected, the included angle between the upper end face and the lower end face of the guide blade and the X-Y horizontal plane is larger than 30 degrees, the distance between the guide blade and a base plate is kept 3-5 mm, a part is suspended in the air in a supporting mode, and after printing forming, the part is separated from the base plate through linear cutting; S2, model processing is performed on the guide vane by adopting a mode of combining blocky support and conical support; S3, a scanning strategy in a checkerboard mode is adopted, and regional bounce sintering is carried out; S4, process parameters are set; and S5, heat treatment is conducted, specifically, under the high-vacuum-degree condition, the temperature is increased to 1180 DEG C, heat preservation is conducted for one hour, and argon rapid cooling is conducted; and S6, surface treatment is conducted, specifically, after the part is printed and formed, the supporting part is removed. According to theinvention, the high-quality 3D printing high-temperature alloy guide blade formed through selective laser melting can be prepared, and the mechanical property, the surface quality and the forming precision are guaranteed.

Owner:航发优材(镇江)增材制造有限公司

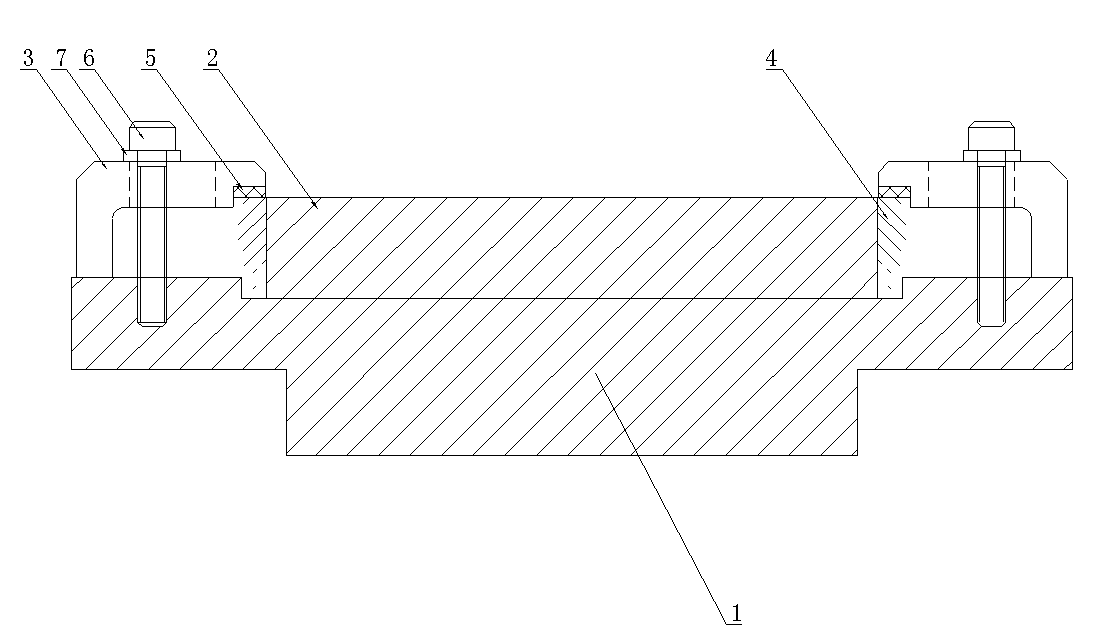

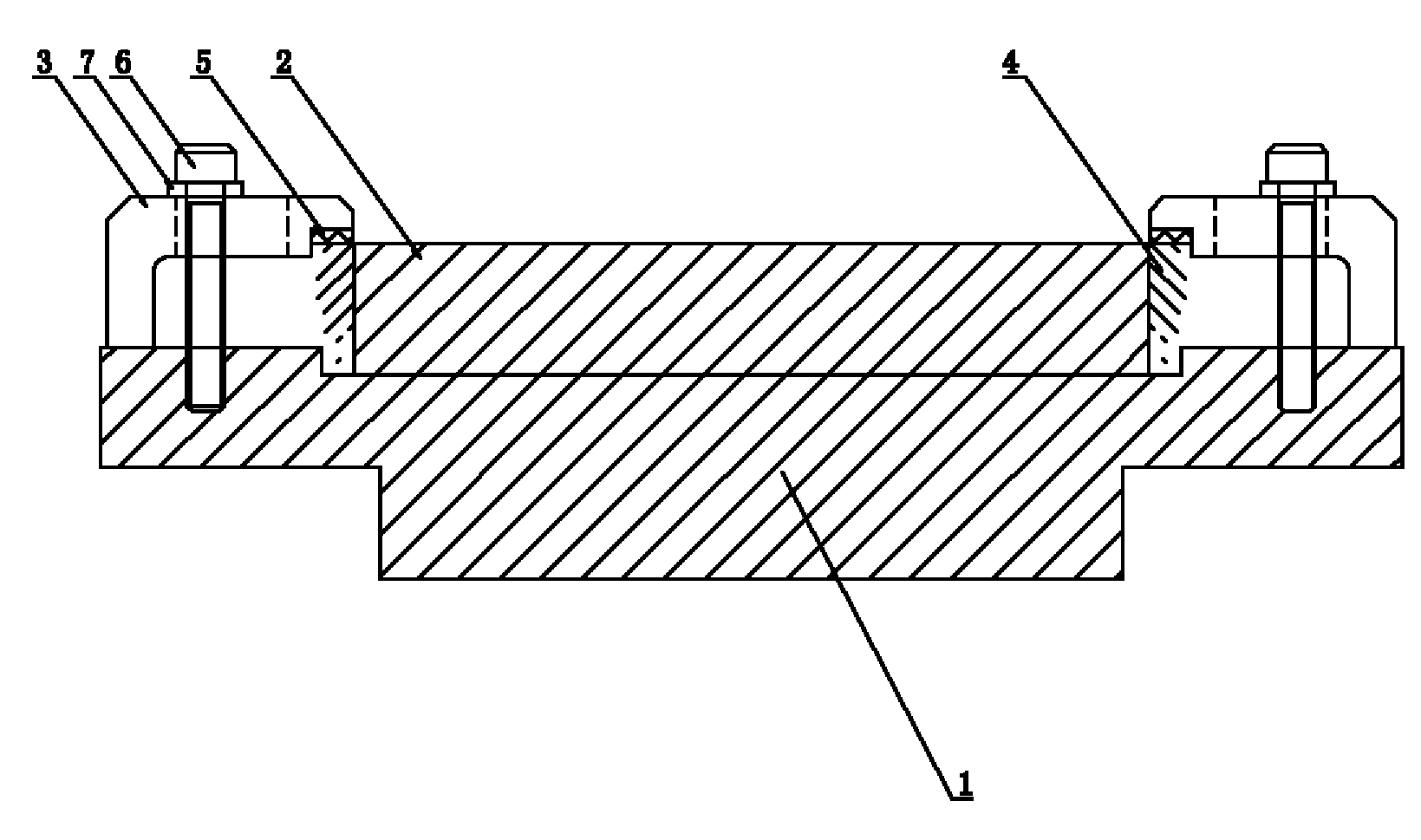

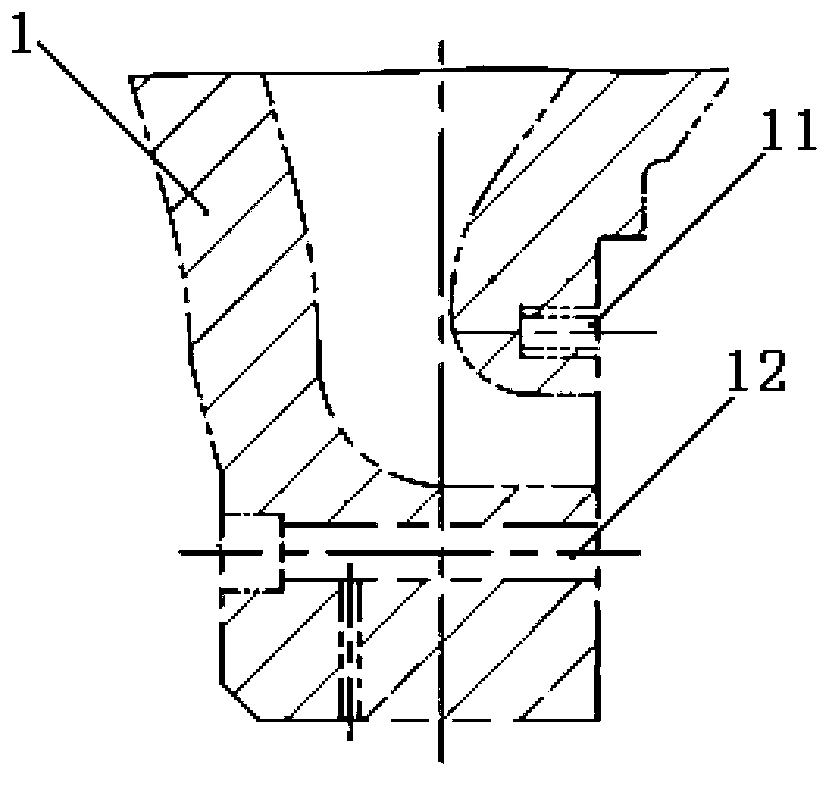

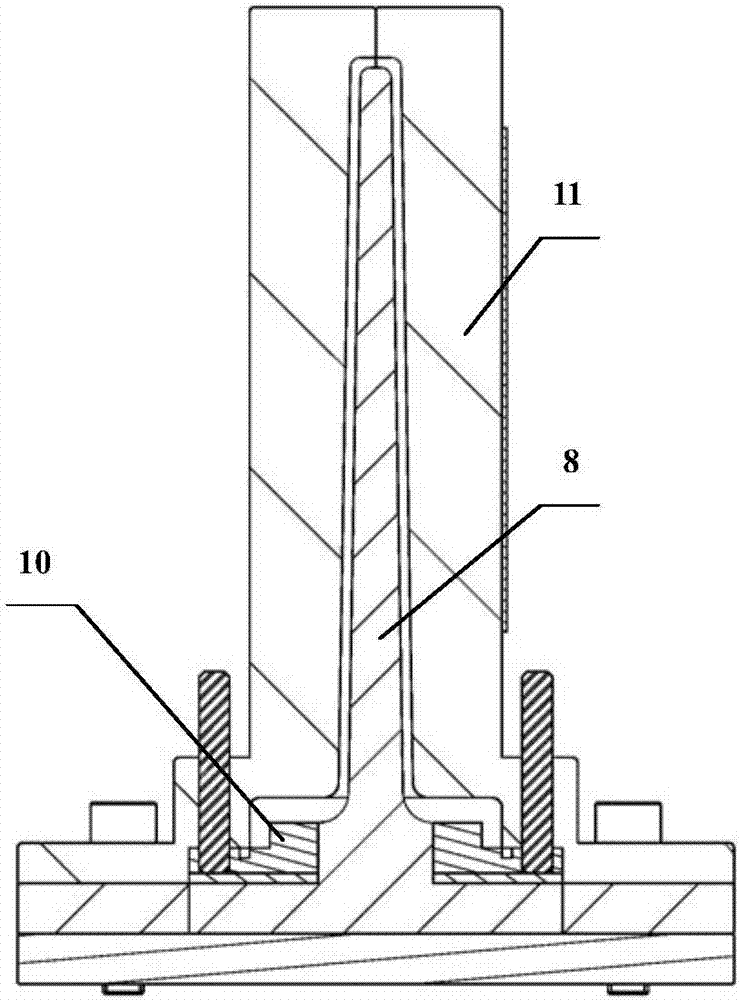

Fixture structure for machining large thin-wall annular part

InactiveCN102139454AGuaranteed quality and accuracyGuaranteed machining accuracyPositioning apparatusMetal-working holdersThin walledEngineering

The invention provides a fixture structure for machining a large thin-wall annular part, which can solve the problem that fixture structure of a traditional annular part is easy to deform after clamping the thin-wall annular part . The fixture structure for machining the large thin-wall annular part can effectively clamp parts and also ensure the machining quality and precision of the parts. The fixture structure for machining the large thin-wall annular part comprises a fixture body and is characterized in that the center of the fixture body is provided with a circular boss, the fixture body is provided with a pressing plate along the circumference, and the pressing plate is sleeved on the upper surface of an annular part to be machined outside the circular boss from the upper part in a compacting manner.

Owner:WUXI DAWN DIE & STAMPING

High-precision titanium-alloy thin-walled ring gear machining method

InactiveCN104668918AEliminate deformationGuaranteed quality and accuracyEngineeringMachining process

The invention relates to the field of machining, in particular to a high-precision titanium-alloy thin-walled ring gear machining method. The method includes the following steps: blank forging, rough turning of a blank, annealing, rough turning of a gear blank, heat treatment, half-finish turning, heat treatment, finish machining and heat treatment. For finish machining, a special clamp is used on a machine tool to clamp a workpiece, the gear blank is subjected to finish machining, and ring process bosses are removed layer by layer; for the last heat treatment, thermocycling is performed twice to further stabilize the structure, stabilize workpiece dimension and eliminate tooth surface stress. The machining process is simple, deformation of parts in machining is eliminated in the machining process, machining quality and dimensional accuracy of the workpiece can be guaranteed, and the dimension and quality of the workpiece are further stabilized by repeated heat treatment.

Owner:吴明铂

Film loading device

InactiveCN103163024AImprove practicalityAvoid backhaul errorsMaterial strength using tensile/compressive forcesMechanical engineeringCeramic

The invention discloses a film loading device which comprise a bracket, a lever assembly, piezoelectric ceramic, a first clamping piece, a second clamping piece and a sensor, wherein the lever assembly comprises a movable rod which is rotatably arranged on the bracket around a preset point; the piezoelectric ceramic is connected with the movable rod for inputting initial displacement to the movable rod; the first clamping piece is connected with the movable rod; the first clamping piece is used for clamping the first end of a film and the second clamping piece is used for clamping the second of the film; the distance from the joint of the first clamping piece and the movable rod to the preset point is longer than the distance from the joint of the piezoelectric ceramic and the movable rod to the preset joint; and the sensor is used for measuring tensile force applied to the film, is arranged on the bracket and is connected with the second clamping piece. The film loading device provided by the invention is high in loading placement accuracy, rapid to respond, large in output displacement and simple in structure.

Owner:TSINGHUA UNIV

Machining method of DCMP aluminium alloy vacuum soldering machine case

InactiveCN105563018AGuaranteed quality and accuracyGuaranteed dimensional accuracySolderingMachining process

The invention relates to the field of machining, in particular to a machining method of a DCMP aluminium alloy vacuum soldering machine case. The method comprises the following steps: blanking, wherein a workblank material is selected, and enough machining allowance is reserved; thermal treatment; rough machining, wherein a finishing allowance of 0.5mm needs to be reserved between soldering fitting surfaces of left and right side plates and a rear side plate and a front frame, a finishing allowance of 0.5mm is reserved between the soldering fitting surfaces of the left and right side plates and cooling fins, and the rear side plate and the front frame are clamped and machined together according to a ganged manner in finish machining by respectively reserving a finishing allowance of 0.5mm at a single side in the length direction; finish machining; preparation before soldering; soldering; turning after soldering; removing redundant soldering material after welding; milling to remove technical allowance and technical bosses on a workpiece; drilling according to requirements; and carrying out surface treatment on the surface of the workpiece.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

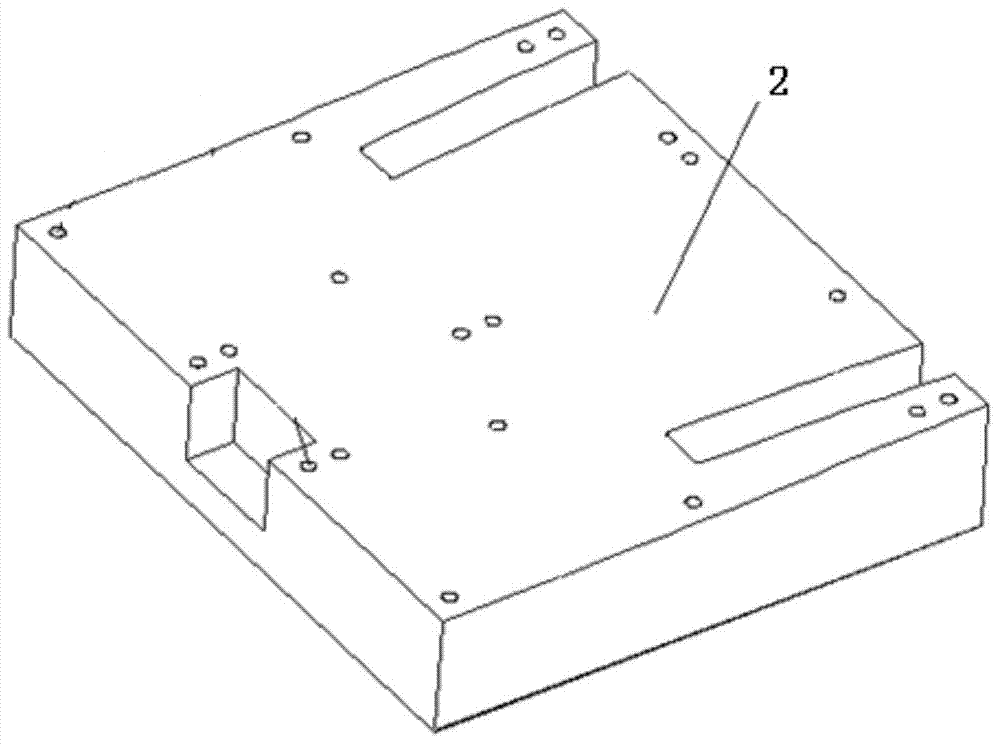

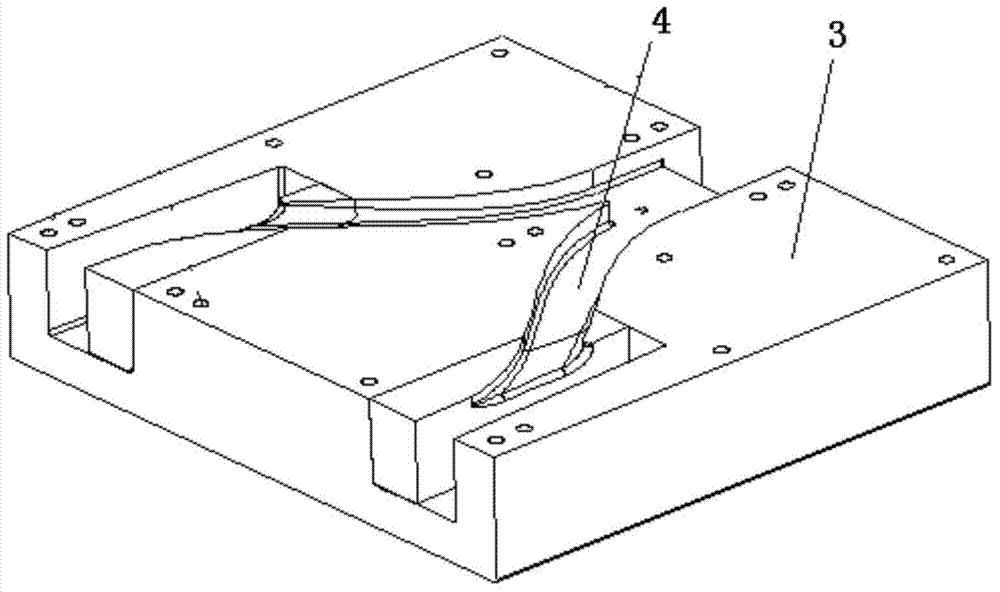

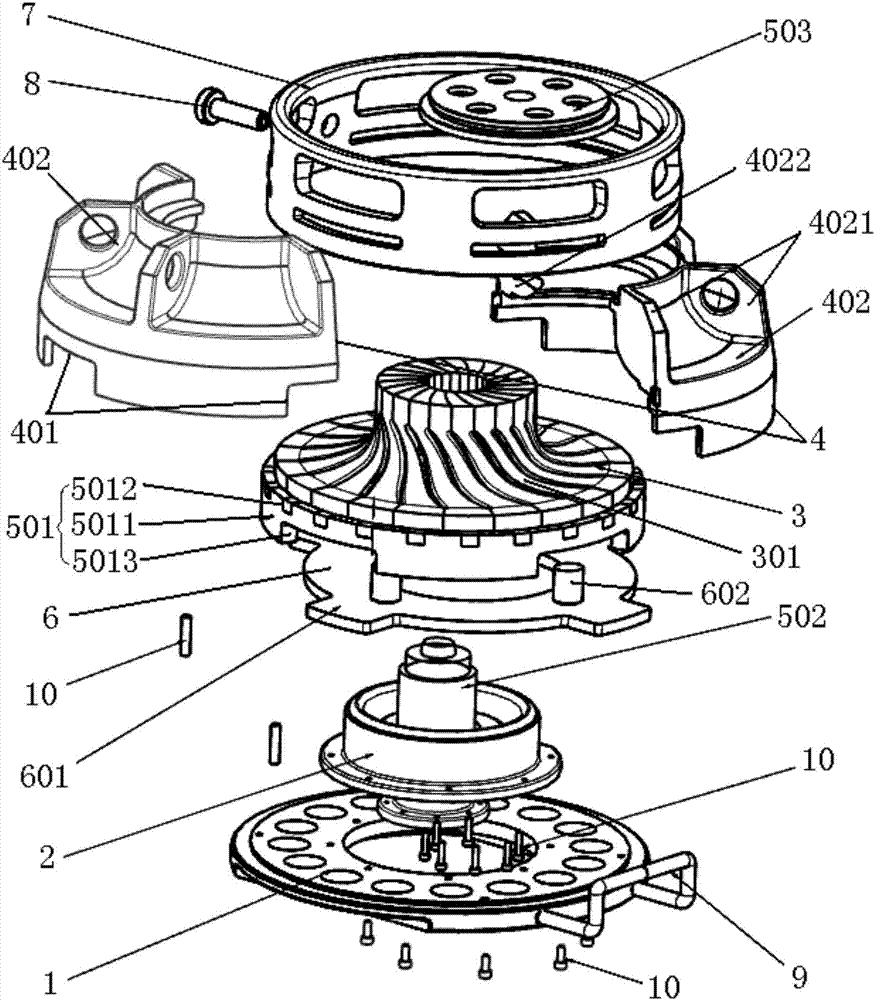

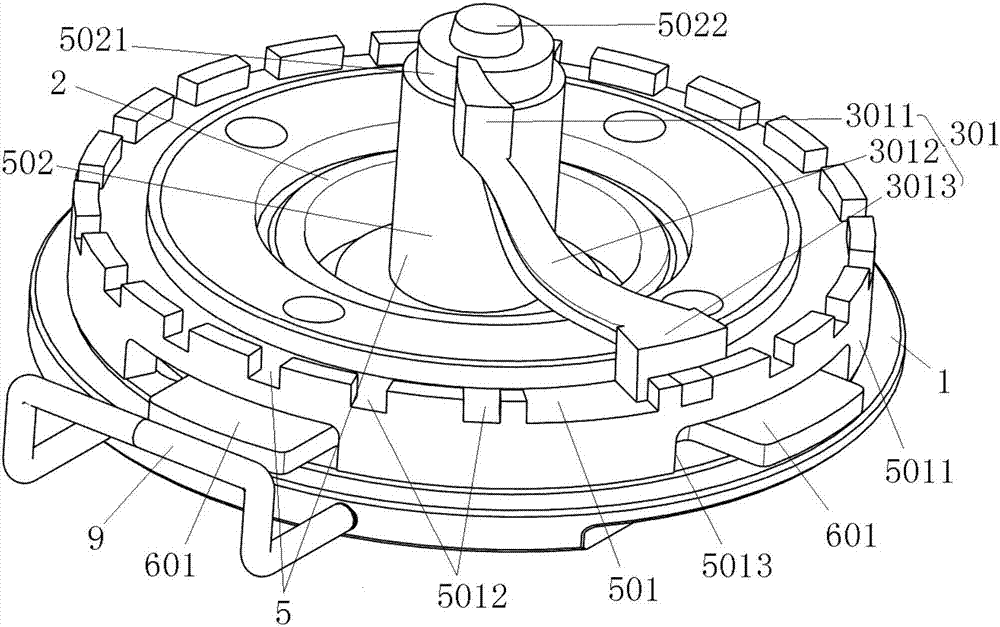

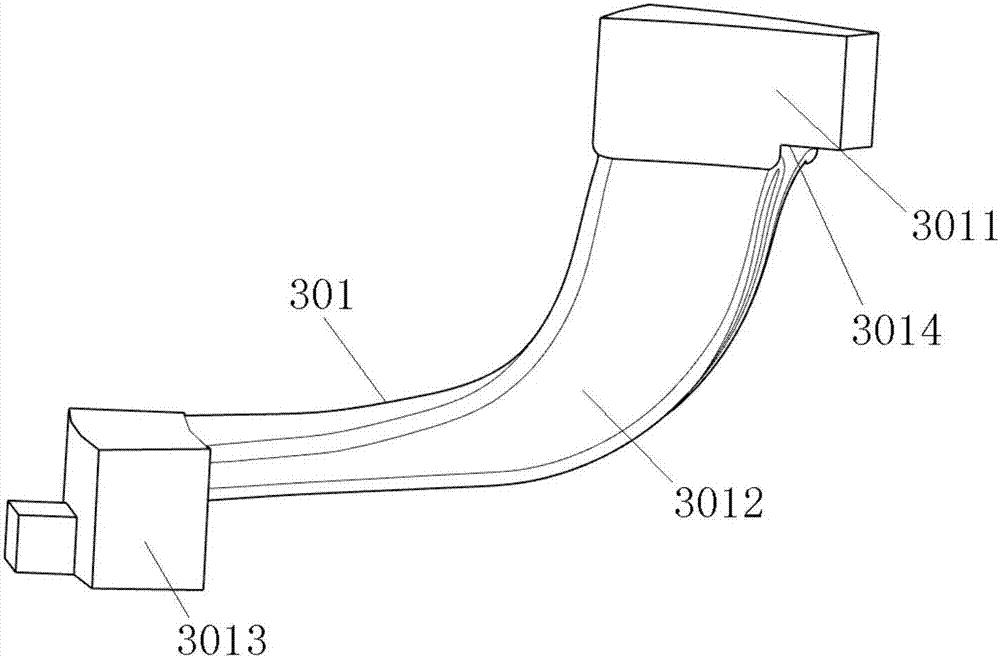

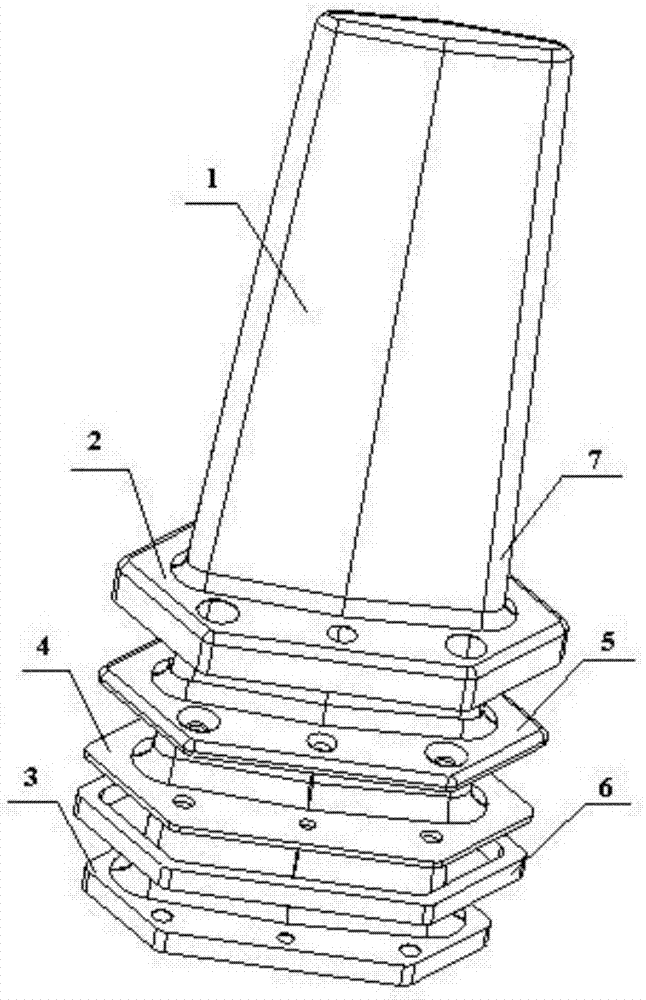

Wax mold for precision casting of closed centrifugal vane wheel and wax mold manufacturing method

ActiveCN107243596ASimple manufacturing processGuaranteed quality and accuracyFoundry mouldsFoundry coresManufacturing technologyMold filling

The invention discloses a wax mold for precision casting of a closed centrifugal vane wheel. The wax mold comprises a base plate used for supporting and positioning of the whole mold, the base plate is provided with a lower mold used for forming of a bottom wax mold, a combined mold core used for overall mold filling of all air current channels and a combined upper mold used for forming of an upper wax mold and a lateral wax mold, and a wax mold containing cavity used for enabling the wax mold to be injected and forming the wax mold is formed by the lower mold, the combined mold core and the combined upper mold in an enclosing manner; and the combined mold core is of a complete ring-shaped structure which is formed by closely splicing multiple mold core units used for mold filling of single air current channels in the ring circumferential direction, and the combined mold core is formed by splicing the mold core units through a centering and positioning mechanism used for centering and positioning of the mold core units. Assembling, inspecting and replacing of the whole wax mold and the pressing technology and positioning of the wax mold are reliable, replacing operation of the mold core units is simple and easy to carry out, the difficulty of the wax mold manufacturing technology is greatly reduced, the technological steps of additionally making a mold core positioning fixture and integrally moving the mold core are omitted, and the technological efficiency is improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

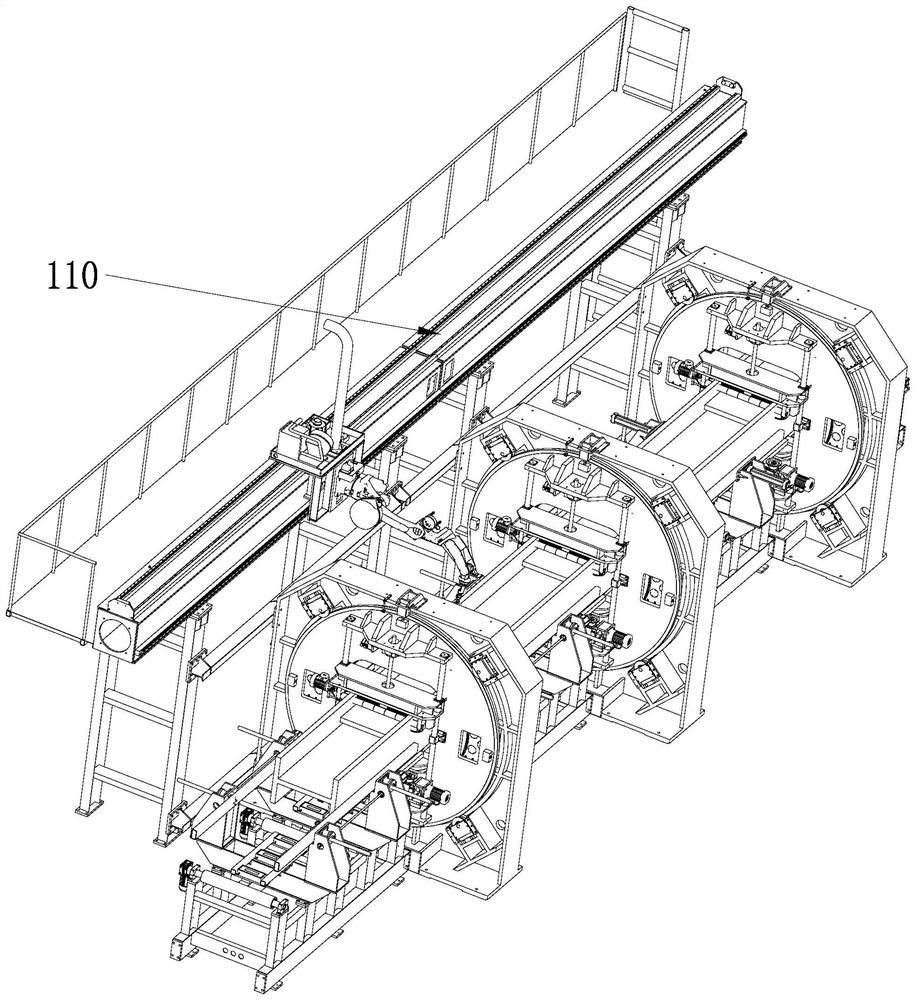

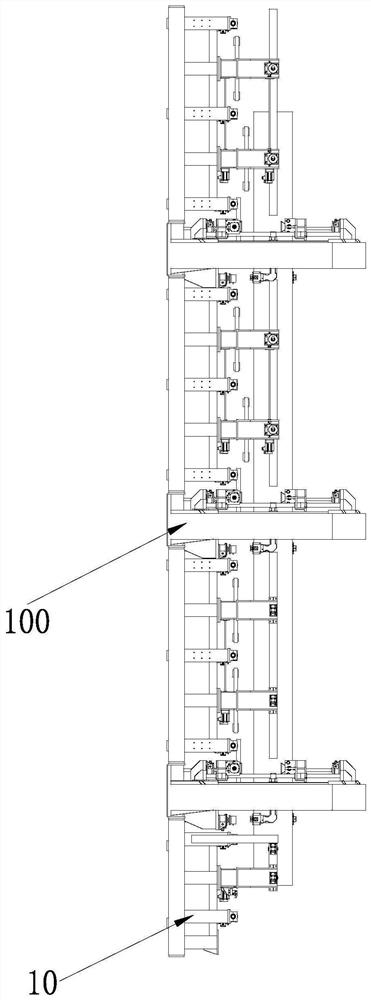

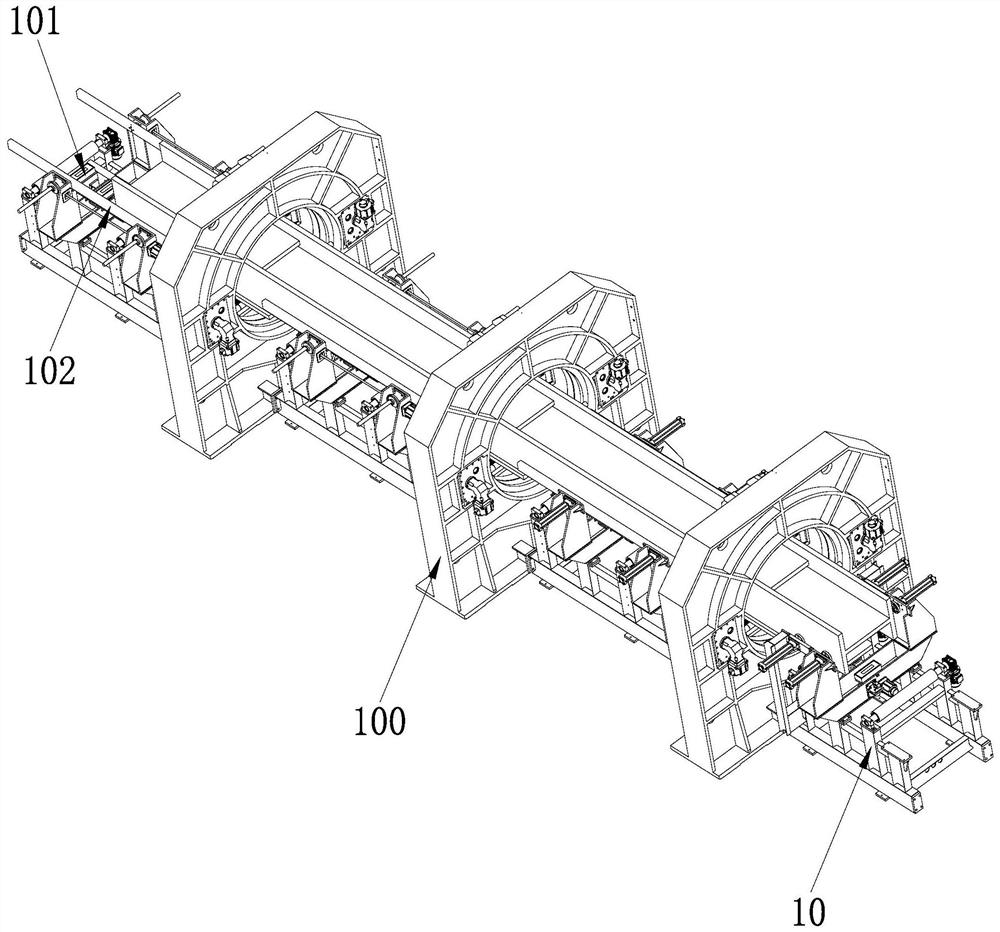

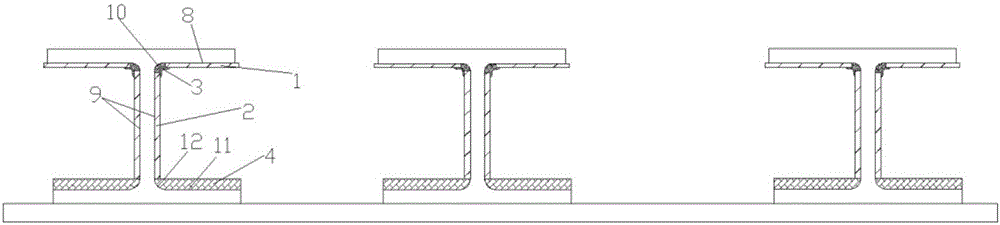

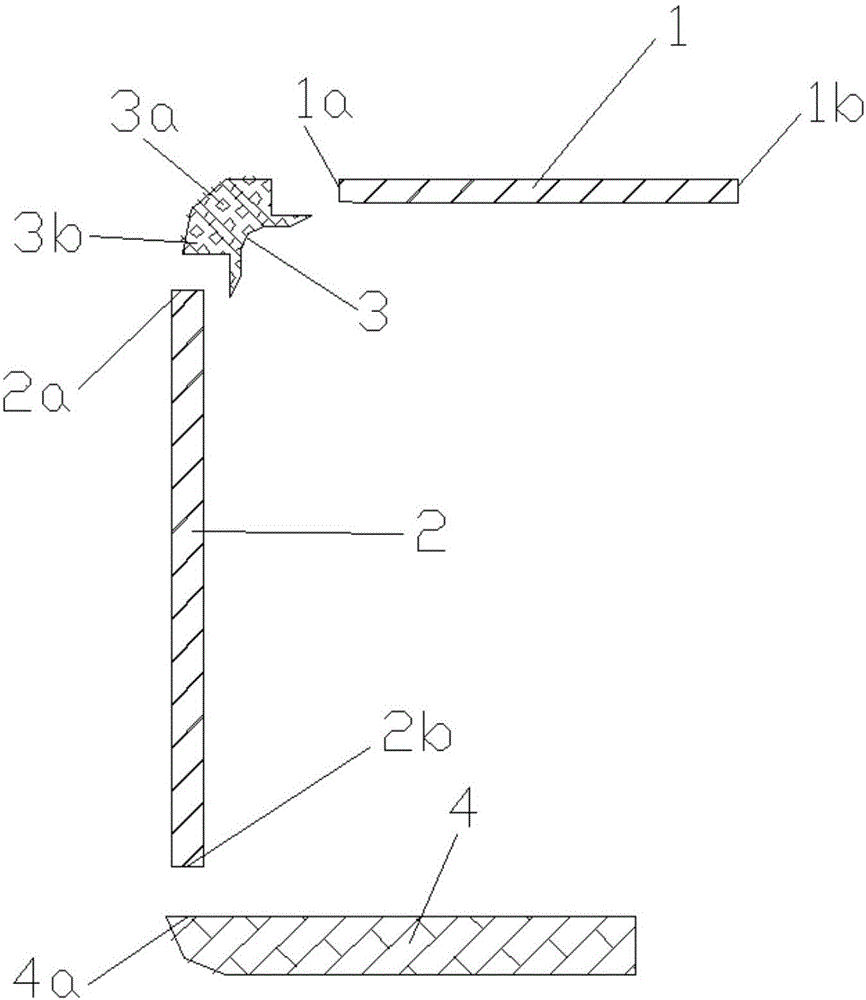

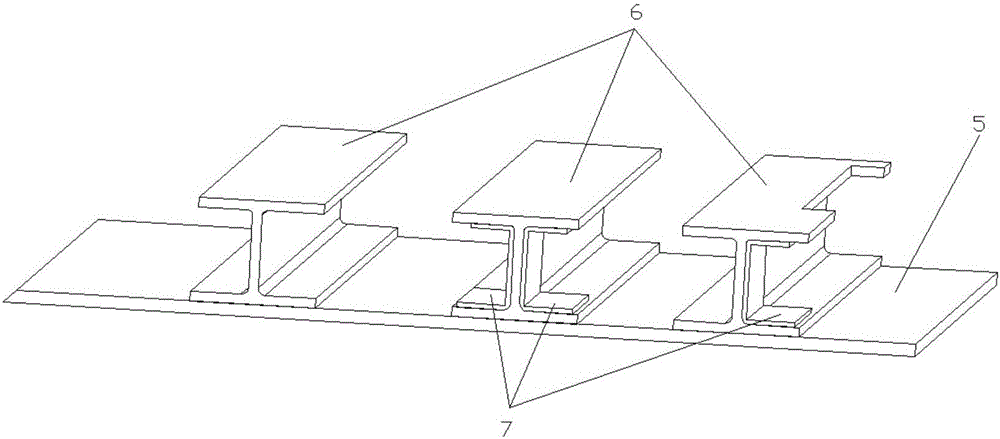

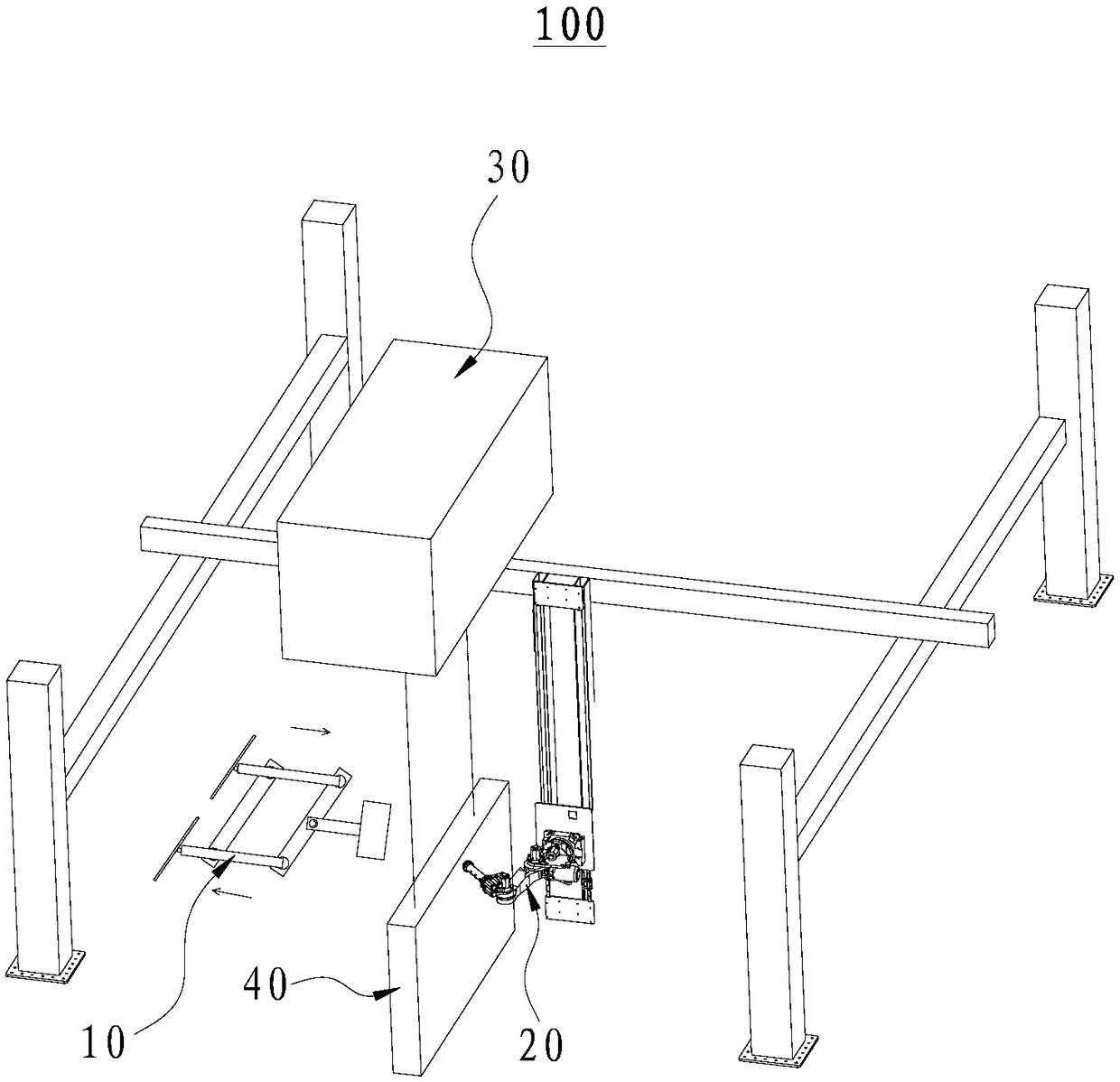

H-shaped steel overturning, welding and forming device

ActiveCN112059456AImprove assembly accuracyImprove processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention relates to an H-shaped steel overturning, welding and forming device. The H-shaped steel overturning, welding and forming device comprises a welding robot moving mechanism, a steel plateconveying mechanism, and a plurality of clamping and overturning mechanisms arranged in the length direction of the steel plate conveying mechanism, wherein a web jacking mechanism and a wing plate jacking mechanism are further arranged on the steel plate conveying mechanism. The H-shaped steel overturning, welding and forming device is simple in structure, ingenious in design and suitable for welding of H-shaped steel components of various types, and ensures the welding quality and the welding precision; spot welding is performed through an electric welding machine; and the assembling precision, machining efficiency and automation degree of the H-shaped steel are greatly improved; the H-shaped steel can be directly assembled through the H-shaped steel overturning, welding and forming device with no need for a traveling crane and a large amount of auxiliary manual work; and the the H-shaped steel overturning, welding and forming device has high assembling operation efficiency, saves labor force and operation time, is safe and convenient, and improves the production efficiency of products.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

Machining method for hollow transmission shafts

InactiveCN105522357AGuaranteed quality and accuracyGuaranteed dimensional accuracyShaftsVehicle componentsDrive shaftEngineering

The invention relates to the machining field, in particular to a machining method for hollow transmission shafts. The machining method for the hollow transmission shafts comprises the steps of preparing material, selecting seamless tubes, preserving the machining allowance of 10 mm in the length direction and cold-drawing the seamless tubes, wherein the hidden danger of cracks is avoided, the wall thickness tolerance is smaller than 0.3 mm, and the overall straightness error is smaller than 0.3 mm; forging and upsetting the outer diameters and the wall thickness of the two ends of tube blanks and carrying out chambering, upsetting and rolling formation; carrying out turning and one clamping and one supporting with outer turned circles as the locating basis, turning inner holes of the right ends of work-pieces and preserving the machining allowance of 1-2 mm in the length direction; carrying out turning and one clamping and one supporting with outer circles of the work-pieces as the locating basis, drilling and expanding the inner holes to D of the required size, adopting deep hole drilling, removing a carriage in a lathe, installing a drill stem fixing base on the large carriage and connecting a drill stem to a special reamer bit, wherein high pressure oil enters the drill stem from the tail part of the drill stem and is sprayed from a cutting edge of the bit. According to the invention, the machining process is simple, manufacturing is easy, the machining quality and the dimensional accuracy of the work-pieces can be guaranteed, the production efficiency can be improved, and the production cost can be lowered.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

Assembling and machining process for steam cabinet of steam turbine and nozzle group

ActiveCN103009002AGuaranteed quality and accuracyGuaranteed machining accuracyDrill jigsMachining processNozzle

The invention provides an assembling and machining process for a steam cabinet of a steam turbine and a nozzle group. A jig tool is arranged for the assembling and machining process for the steam cabinet of the steam turbine and the nozzle group. Concentric circular bump and circular shrinkage pool are respectively arranged on both sides of the jig tool. Assembling holes of the steam cabinet of the steam turbine and the nozzle group are respectively machined by using the circular bump and circular shrinkage pool as positioning reference, so that the steam cabinet of the steam turbine and the nozzle group can be precisely positioned in the vertical and horizontal directions. Therefore, the assembling holes of the steam cabinet of the steam turbine and the nozzle group are consistent in position, so that the quality and machining precision of assembly of the steam cabinet of the steam turbine and the nozzle group can be ensured. According to the method in the process, the assembling holes in the steam cabinet of the steam turbine and the nozzle group can be conveniently and precisely machined, so that the assembling requirement of the steam cabinet of the steam turbine and the nozzle group can be satisfied.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

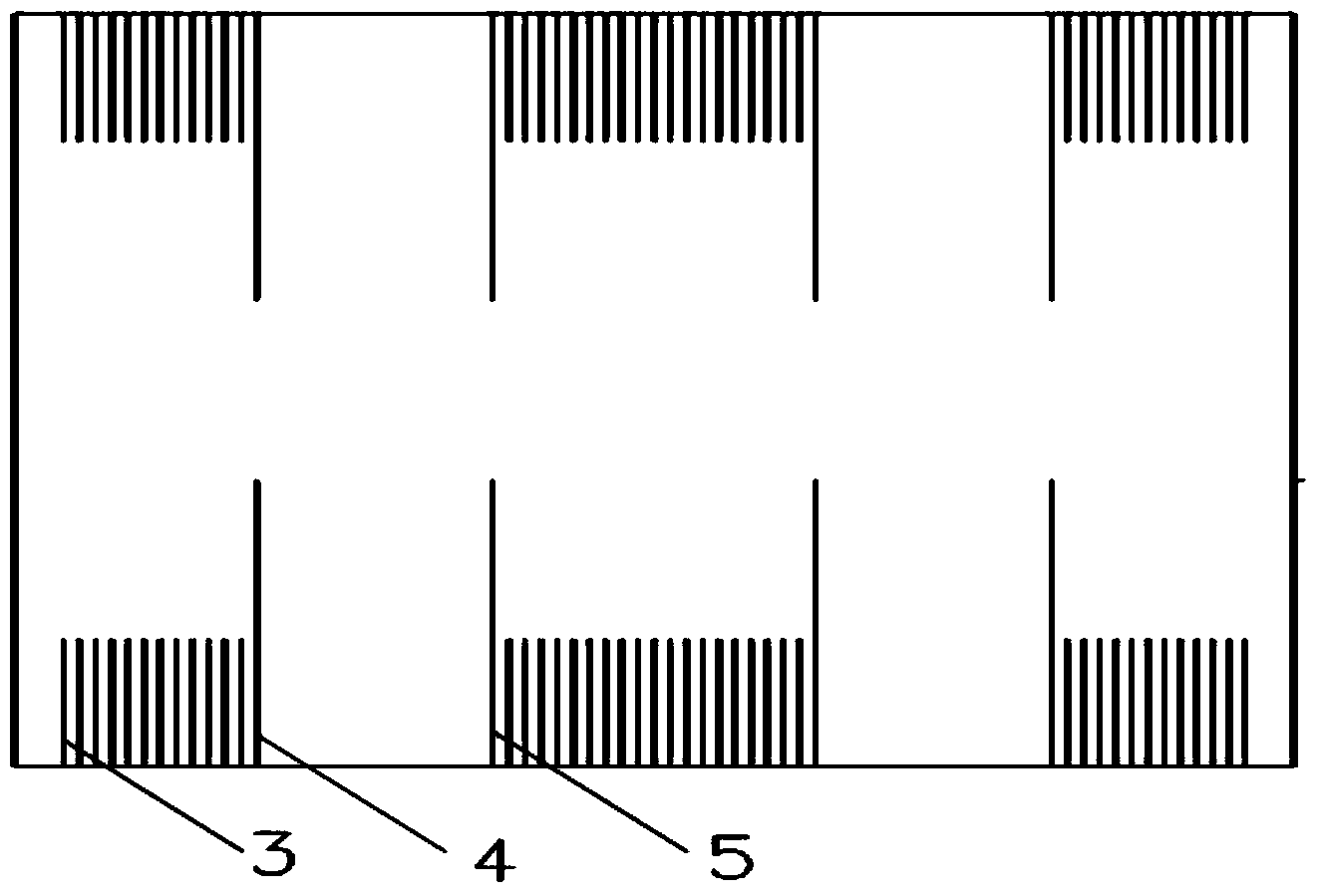

Composite mold for integrally molding inner profile of ribbed composite wall panel

The invention belongs to the polymer matrix composite molding technology, and relates to a composite mold for integrally molding an inner profile of a ribbed composite wall panel. The molding mold comprises an upper flange molding soft mold body, a web molding soft mold body, an upper R corner molding soft mold body and a lower flange and R corner molding soft mold body. The upper R corner molding soft mold body of the composite mold is made of a rigid and flexible blended and cured material, and therefore the rigidity of a soft mold upper R corner area is increased, the pressure in a tank is better transmitted to an upper R corner area of the ribbed composite wall panel, and the defects of upper R corner area hole concentration, layering, appearance deviation and the like can be effectively avoided. The lower flange and R corner molding soft mold body is utilized for guaranteeing the inner quality and appearance accuracy of a lower flange and a lower R corner area, especially a side profile of the lower flange and R corner molding soft mold body is chamfered according to the theoretical appearance of an inner profile of a lower R corner of each rib, the procedure of preparing a lower R corner molding soft mold body by entering the tank is omitted, the mold manufacturing cost is reduced, and the appearance accuracy of the lower R corner area is improved.

Owner:AVIC COMPOSITES

Preparing method for ceramic molding shell for casting high-temperature alloy orientation/single crystal blade

ActiveCN106311980AReduce and prevent transfersQuality improvementFoundry mouldsFoundry coresCeramic moldingSingle crystal

The invention discloses a preparing method for a ceramic molding shell for casting a high-temperature alloy orientation / single crystal blade and belongs to the technical field of the high-temperature alloy precision investment pattern casting technology. According to the method, a certain amount of a metal oxide mixture is absorbed from a coating of a face layer of the ceramic molding shell in advance, low-valence oxide in the ceramic molding shell can be prevented from reacting with chromium in a fused alloy, and therefore chromium in the fused alloy can be prevented from being transferred into the ceramic molding shell, the chromium transferred into the ceramic molding shell is reduced, the chemical sand burning tendency is eliminated, and the quality of the surface of a casting is improved. The prepared ceramic molding shell is good in chemical stability, high in surface density, capable of ensuring the surface quality and the size precision of a blade blank and capable of meeting the requirement for advanced orientation / single crystal blade production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

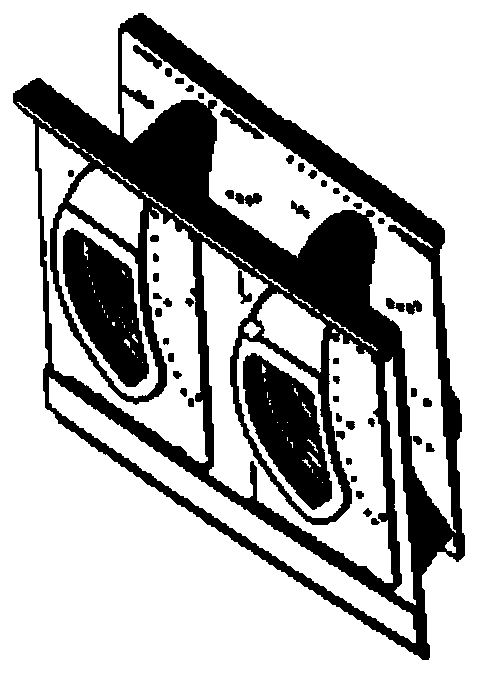

Punching composite die for filter element end cover

InactiveCN103317029AIncrease productivityReduce manufacturing costShaping toolsDimensional precisionEngineering

The invention relates to a punching composite die for a filter element end cover. The punching composite die comprises a guide column, an upper die base plate of a guide sleeve, a lower die base plate of the guide sleeve and a compositing device. The compositing device is mounted between the upper die base plate and the lower die base plate and comprises an upper die fixing plate, a punching male die fixing plate, a punching male die, a flanging male die, a guide pin, a pressing ring, a blanking female die fixing plate, a blanking female die, a flat-wire spiral spring, a guide post, a die shank, a lower die fixing plate, a punching female die, a punching female die fixing plate, a lower forming core, a punch-die, a circular wire spiral spring, a pressing plate, an ejector pin and an ejector plate. By the technical scheme, during a stroke of a punching machine, all punching procedures for forming the filter element end cover with a protrusion at the center, production efficiency can be increased, production cost can be lowered, and appearance quality and dimensional precision of products are guaranteed.

Owner:BENGBU JINWEI FILTERS

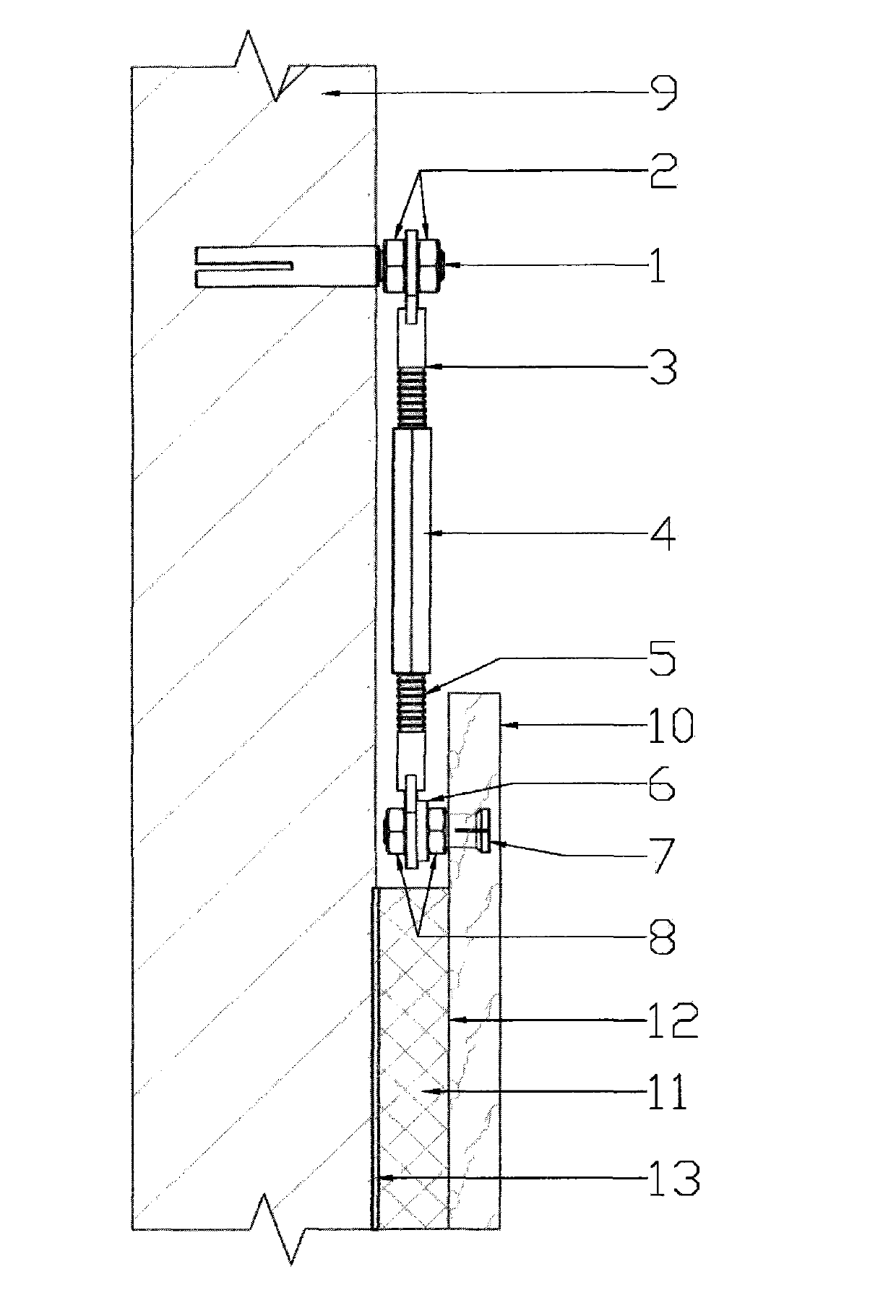

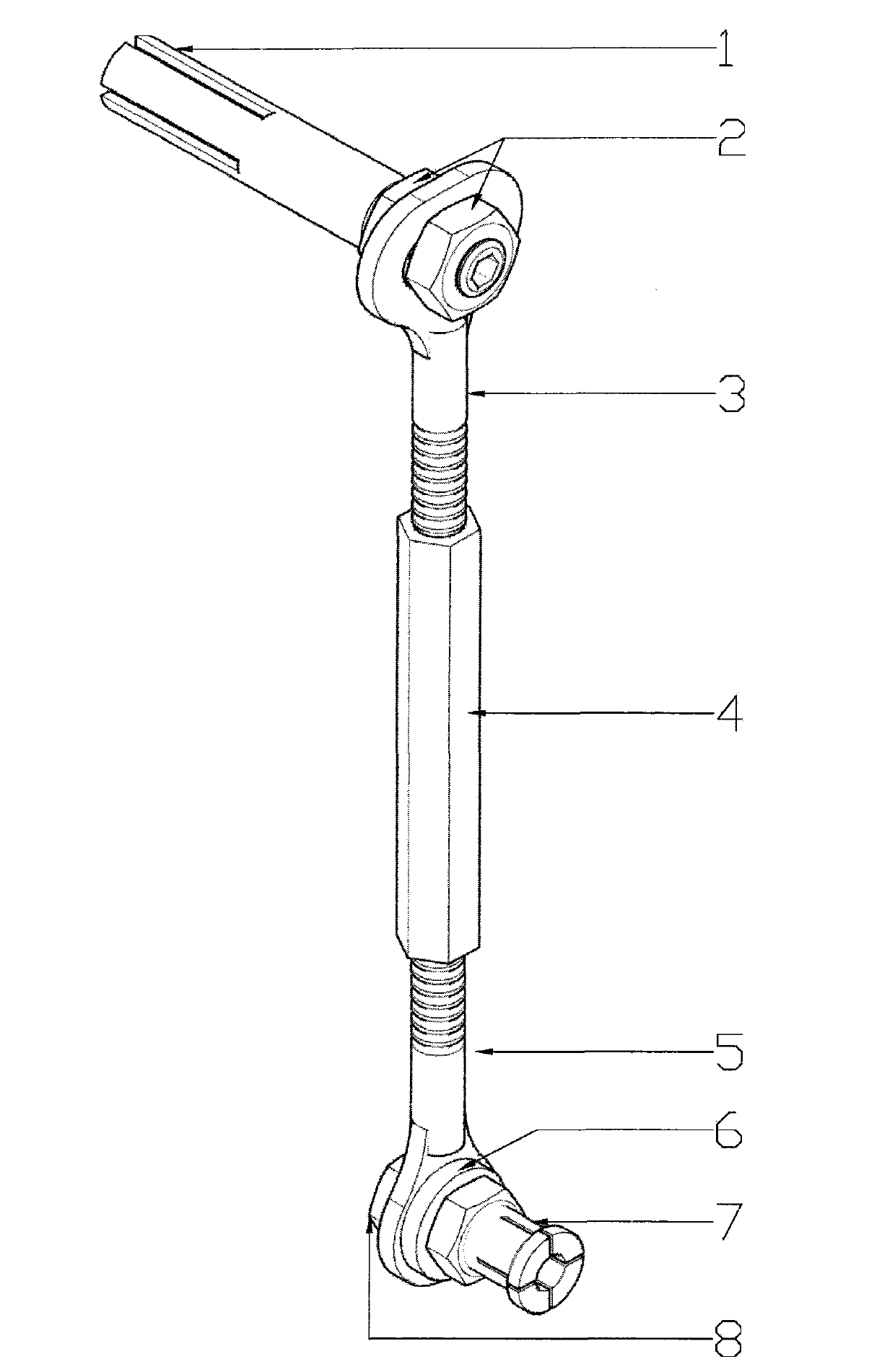

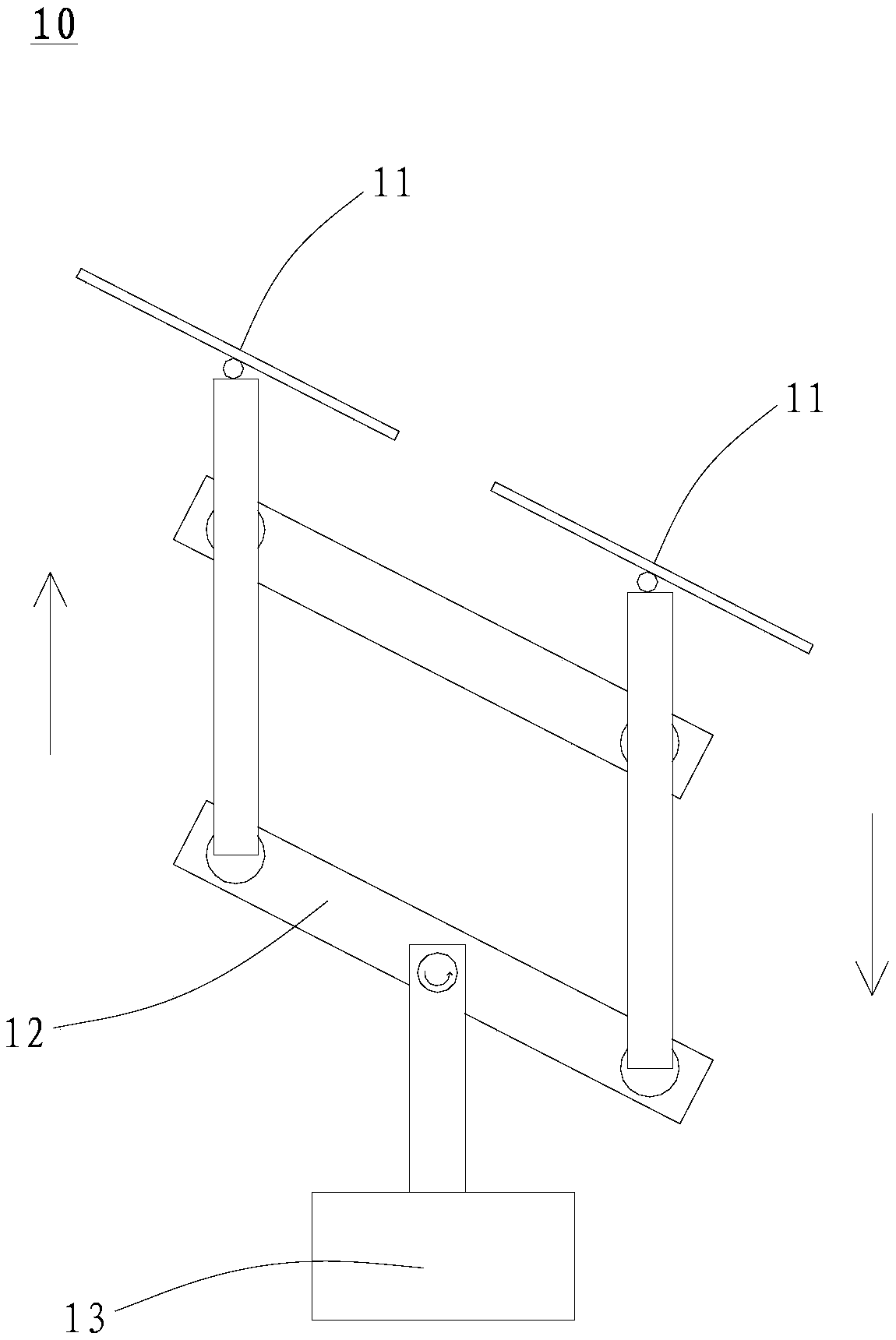

Auxiliary mounting mechanism and method

PendingCN109339461AAccurately grasp the installation accuracyImprove installation accuracyBuilding material handlingControl systemAgricultural engineering

The invention provides an auxiliary mounting mechanism and method. The auxiliary mounting mechanism comprises a control system, a hoisting system and an adjustment system. The auxiliary mounting method comprises the steps that firstly, the control system controls the hoisting system to hoist a prefabricated wall plate above positioning reinforcing steel bars corresponding to a floor to be constructed; secondly, suction cups of an adjustment device are attached to the prefabricated wall plate, the position of the prefabricated wall plate is detected through a detection device, and the control system correspondingly controls the suction cups of the adjustment device to push or pull the prefabricated wall plate to adjust the specific position of the prefabricated wall plate; and finally, after the position of the prefabricated wall plate is adjusted well, the control system controls the hoisting system to drive the prefabricated wall plate to descent in the vertical direction, until positioning holes of the prefabricated wall plate are inserted with the corresponding positioning reinforcing steel bars. The positioning and mounting of the prefabricated wall plate is carried out by using the auxiliary mounting mechanism, the construction efficiency is higher, and the mounting precision of the prefabricated wall plate can be accurately grasped through the adjustment device.

Owner:CHINA CONSTR SCI & TECH CO LTD +1

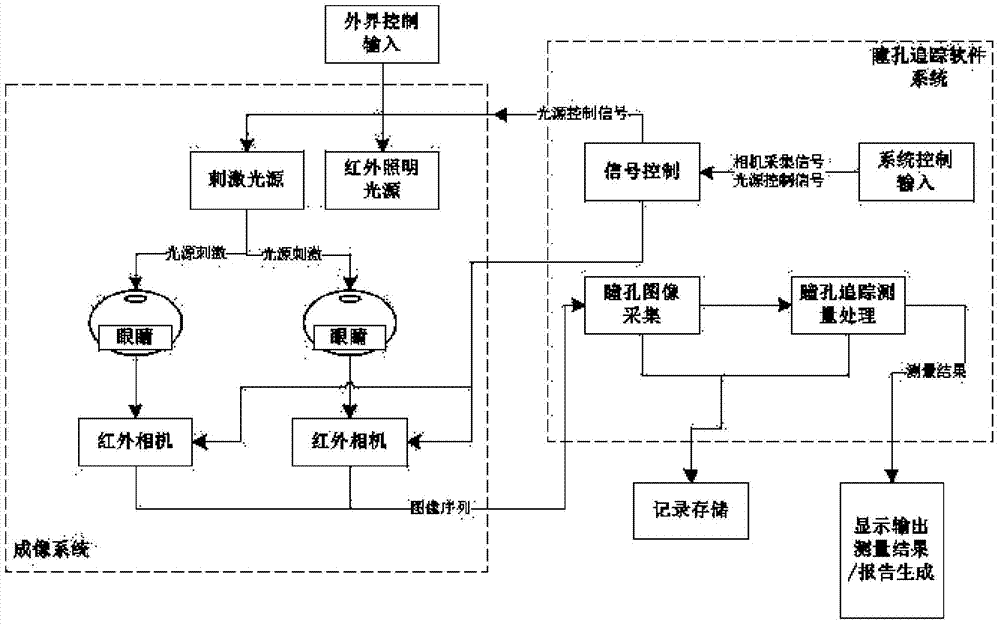

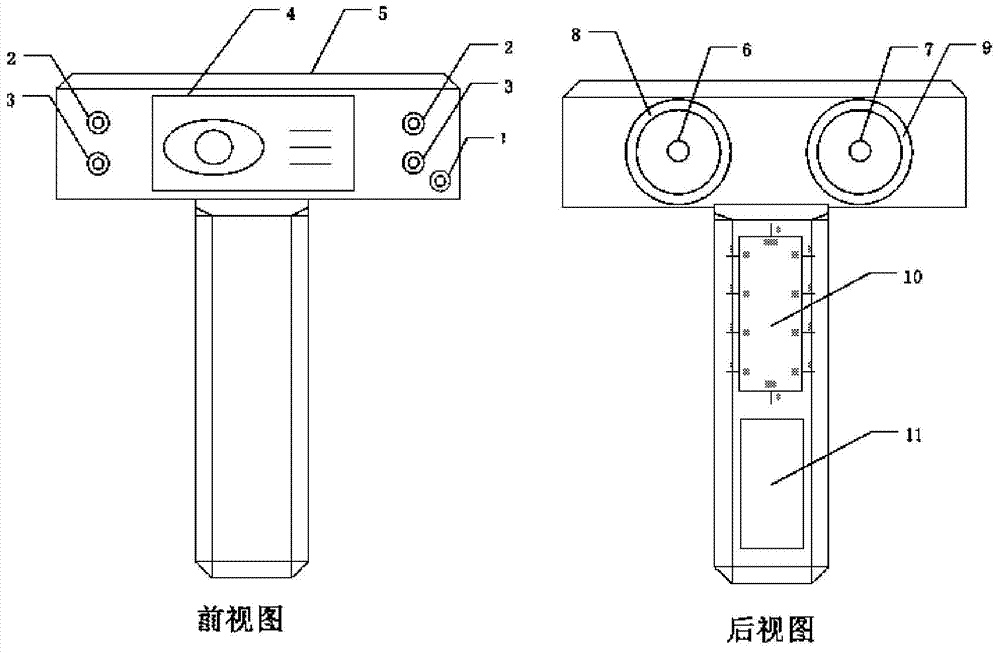

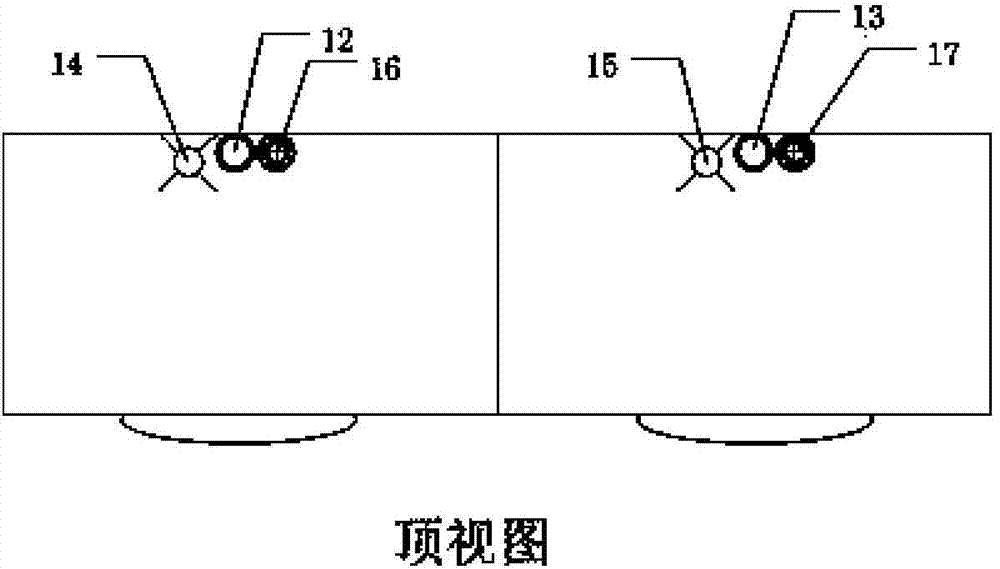

Binocular pupil light reflex tracking system

ActiveCN104739364AImprove portabilityAccurate measurementEye diagnosticsMicrocomputerMicrocontroller

The invention discloses a binocular pupil light reflex tracking system. The binocular pupil light reflex tracking system comprises a grabbing type binocular pupil detection device imaging system and a pupil tracking and measuring module. The imaging system comprises two infrared cameras, two infrared lighting light sources, two stimulation light sources, a grabbing type device and a single-chip microcomputer. The infrared cameras, the lighting light sources, the stimulation light sources and the single-chip microcomputer are integrated in the grabbing type device, the cameras and the light sources are connected with the single-chip microcomputer, and the single-chip microcomputer is in charge of signal control and data input and output. The pupil tracking and measuring module is integrated in the single-chip microcomputer, images collected by the single-chip microcomputer are tracked and measured, and the measuring result is analyzed. The system further comprises a movable seat matched with a handle, and a suspension assembly. The system is high in adaptability, capable of being applied to first-aid and field occasions and the like, and wide in application prospect.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Method for small-and-medium-size motor seat

InactiveCN104625612ASimple processingGuaranteed dimensional accuracy and processing qualitySupports/enclosures/casingsStatorMachining process

The invention relates to the field of machining, in particular to a method for a small-and-medium-size motor seat. The method includes the following steps of casting a workpiece; conducting heat treatment; conducting rough turning, wherein the non-wire-outlet end of the motor seat is clamped on a vertical lathe; conducting rough turning, wherein one-time turning stop opening seat mold positioning and clamping are conducted, and a stop opening, the end face and an iron core baffle of the non-wire-outlet end are roughly turned, the finish turning allowance of the stop opening and the iron core baffle is reserved to range from 2 mm to 3 mm, and the finish turning allowance of the end face is reserved to range from 1.5 mm to 2 mm; conducting finish turning on the iron core baffle, wherein tail end stop opening seat mold positioning and clamping are conducted, finish turning is conducted on the iron core baffle till the iron core baffle meets the drawing requirement to be matched with a stator iron core, and the mold matching clearance is smaller than 0.1 mm; pressing the stator iron core into the motor seat; conducting rough turning on the stop opening, wherein the internal diameter of the stator iron core serves as a reference, and upper and lower meter running alignment is conducted; conducting finish turning on the stop opening, wherein four-time turning stop opening seat mold positioning and clamping are conducted, meter running alignment is conducted on the iron core jump which is controlled within 0.06 mm, finish turning is conducted on a stop opening and the end face of the extension end, and the total length is controlled to meet the drawing requirement; conducting detection. The machining process is simple, the workpiece machining quality and dimensional accuracy can be guaranteed, production efficiency is improved, and production cost is reduced.

Owner:吴明铂

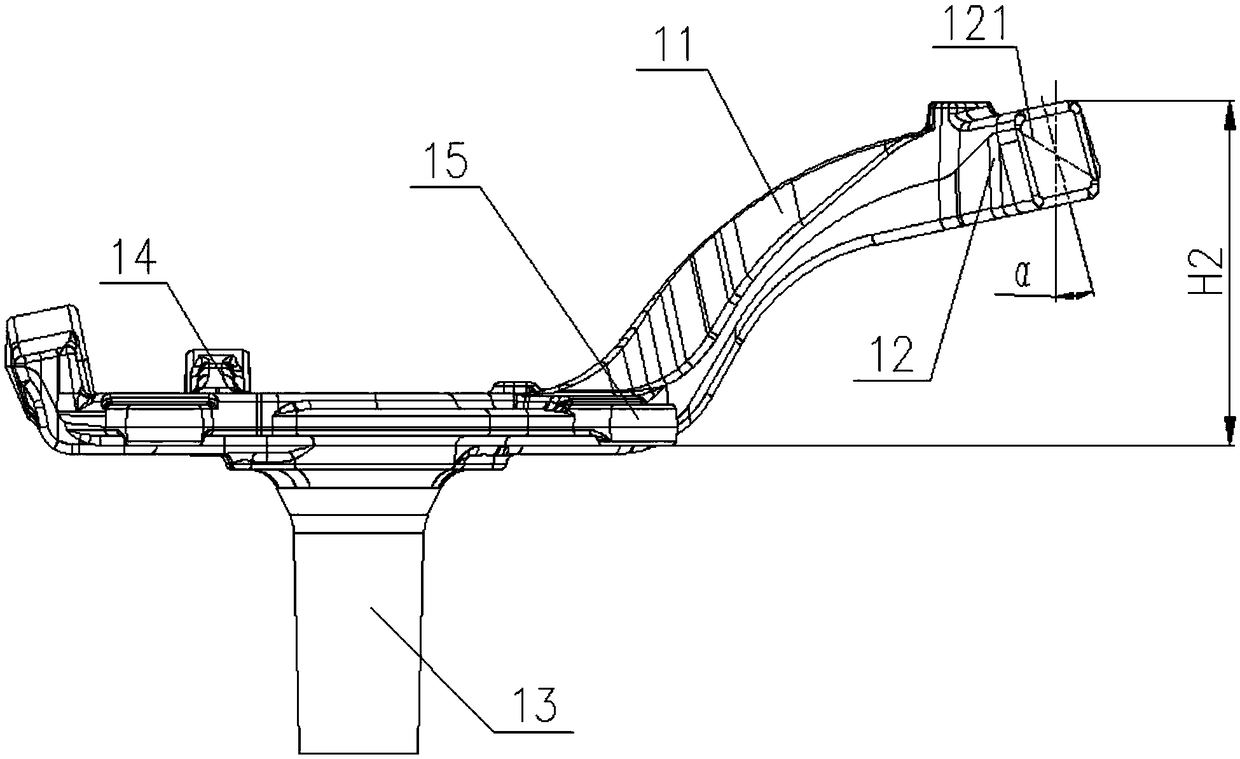

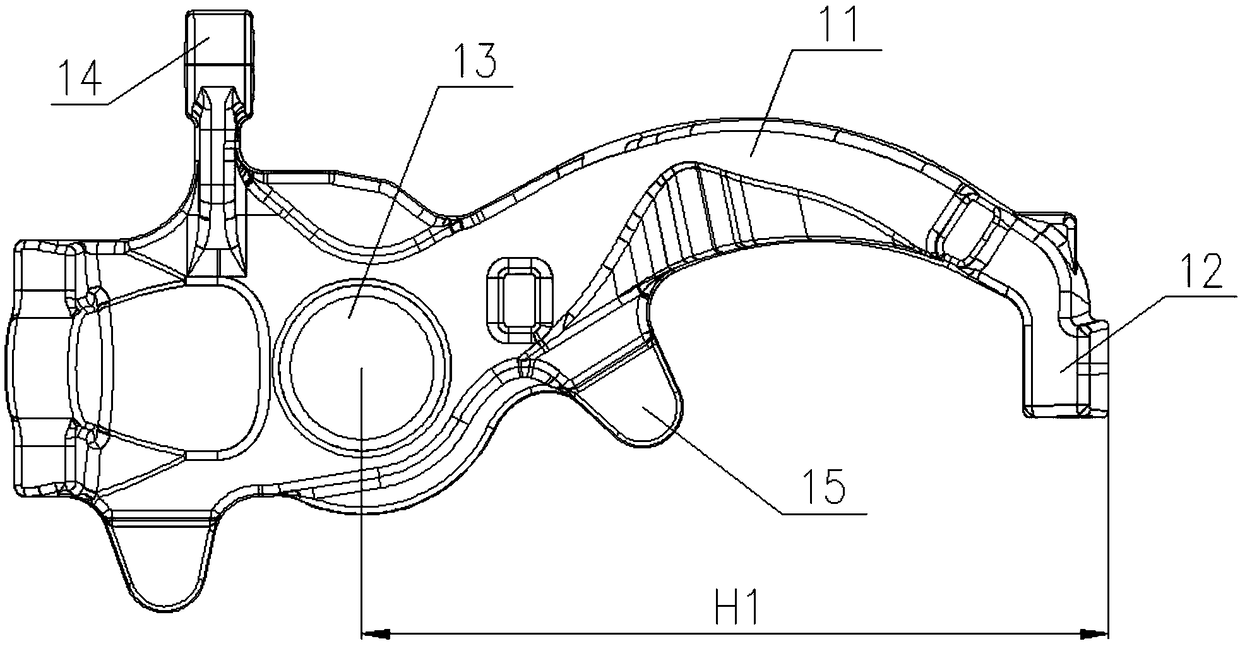

Knuckle composite mold and technology

ActiveCN109093041ASimple structureEasy to operateSteering linkagesRailway componentsManufacturing technologyTorsional deformation

The invention relates to the technical field of knuckle production and fabrication, in particular to a knuckle composite mold and technology. According to the composite technology, a forge piece is positioned in a calibration lower mold to drive an upper mold plate to move downwards. The forge piece is wrapped and compressed by a calibration upper mold and the calibration lower mold, and thereforea cube head of the forge piece is subjected to sustained torsional deformation until the cube head is formed. During the torsional deformation process of the cube head, edge cutting is conducted through cooperation of an edge cutting concave mold and an unloading plate. After edge cutting, the upper mold plate continuously moves downwards, the calibration upper mold and the calibration lower moldcontinuously wrap and compress the forge piece to complete overall fine forming of the forge piece. The knuckle composite mold and technology has the beneficial effects that the cube head of the knuckle is formed and positioned through torsional deformation, cutting machining is not required, processes are simplified, efficiency is improved, and the cost is lowered; and the edge cutting process is accomplished simultaneously during the knuckle wrapping compressing forming process, edge cutting deformation is avoided, and the product quality and size accuracy are guaranteed.

Owner:QINGLING MOTORS GRP +1

Filter case stretching material falling device

ActiveCN104226812AEasy to operateEasy to implement mechanicallyShaping toolsStripping-off devicesPunchingEngineering

The invention discloses a filter case stretching material falling device, which comprises an upper template (1) and a lower template (14), wherein a lower mold support frame (11) and a material pushing flat plate (10) are arranged on the lower template (14), a mold frame (9) is arranged on the material pushing flat plate (10), a material falling female mold (7) and a material falling male mold (6) are sequentially arranged on the mold frame (9) through a female mold positioning plate (8), the material falling male mold (6) is connected with the upper template (1) through a material falling connecting block (4), and material falling positioning blocks (3) are also arranged between the material falling male mold (6) and the upper template (1). The filter case stretching material falling device has the advantages that the operation is convenient, the mechanization and the automation can be easily realized, the filter case stretching material falling device is suitable for mass production of filter case parts, the production efficiency can be improved, the processing period can be shortened, the quality and the punching precision of products are ensured, in addition, the labor cost and the production cost are greatly reduced, a great amount of labor can be saved, and the rejection rate is reduced.

Owner:ZHEJIANG UNIVERSE FILTER

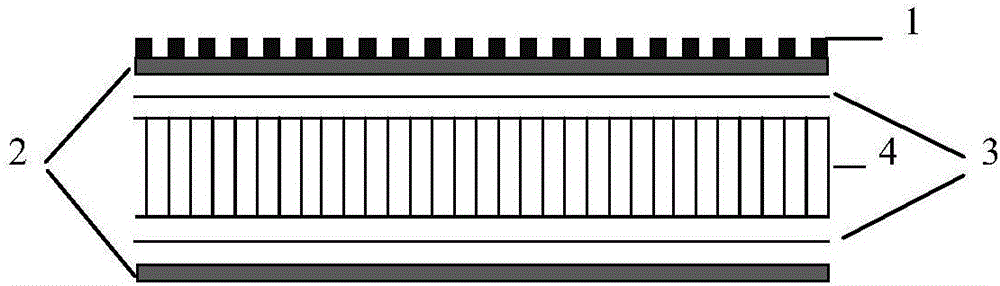

Vehicle-mounted knife-type antenna cover and precise manufacturing method thereof

ActiveCN106921031AAchieve broadband characteristicsImprove electrical performance indicatorsAntenna adaptation in movable bodiesRadiating element housingsGlass fiberSurface layer

The invention discloses a vehicle-mounted knife-type antenna cover and a precise manufacturing method thereof. The antenna cover is formed by combining an inner surface layer, a functional layer, a bottom plane layer, a stop opening layer and an outer surface layer. The inner surface layer, the bottom plane layer, the stop opening layer and the outer surface layer are made of different specifications of high-intensity glass fiber prepregs. The functional layer is made of different materials of high-intensity glass fiber prepreg, a metal array and a nomex honey comb, thereby satisfying different functions of wide frequency, high wave transparency and invisibility. The inner surface layer, the stop opening layer, the functional layer, the bottom plane layer and the outer surface layer are successively laid on a core die sequentially, an outer die is assembled and a vacuum bag is used for sealing, and through a vacuum system and an oven, heating and solidification are achieved to form a whole body. A layering method and laying sequence are set, so high speed discharging and precise prefabrication of different layers can be achieved. By combining a metal outer die and a silicone rubber core die, the size precision of the antenna cover is ensured and the technique cost is reduced.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com