Patents

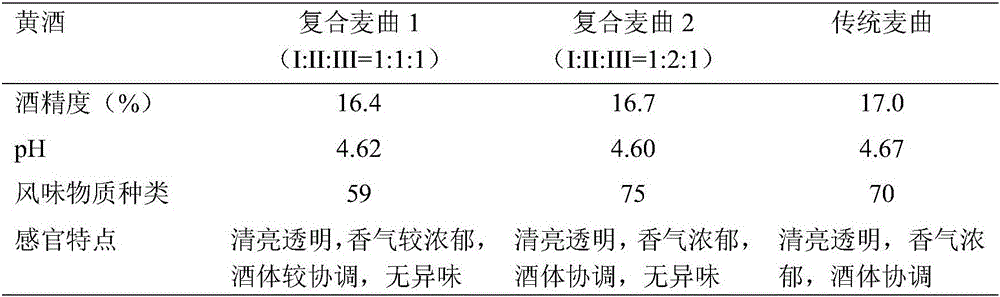

Literature

51results about How to "Easy to implement mechanically" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

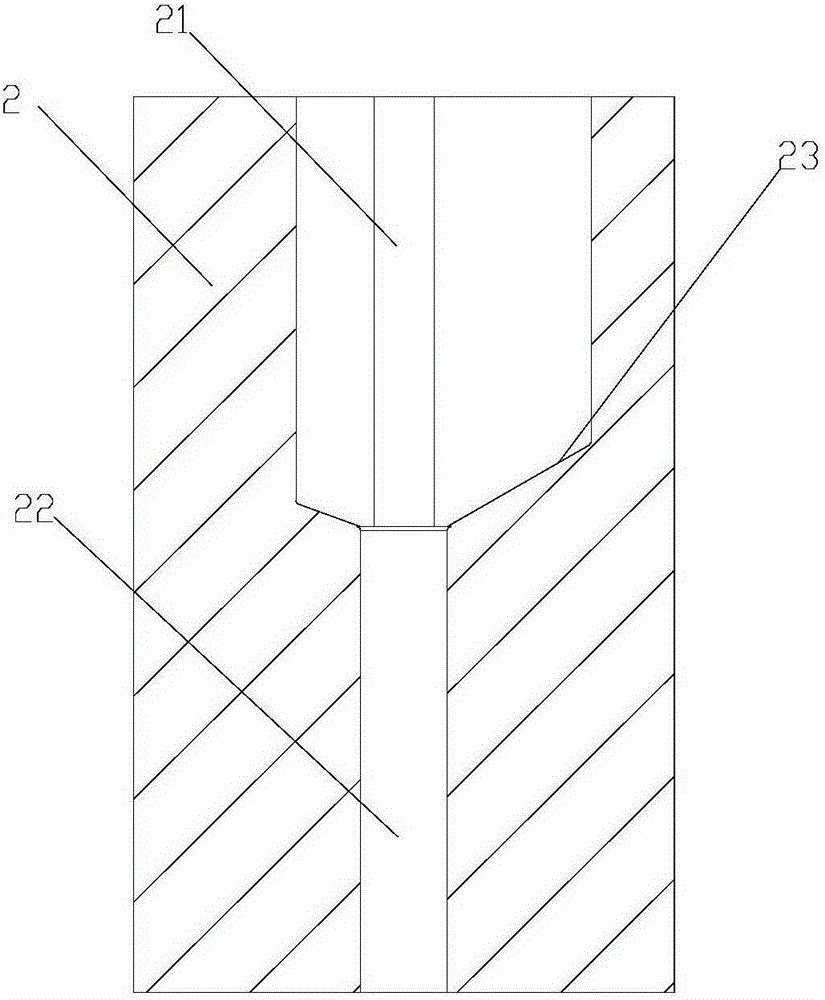

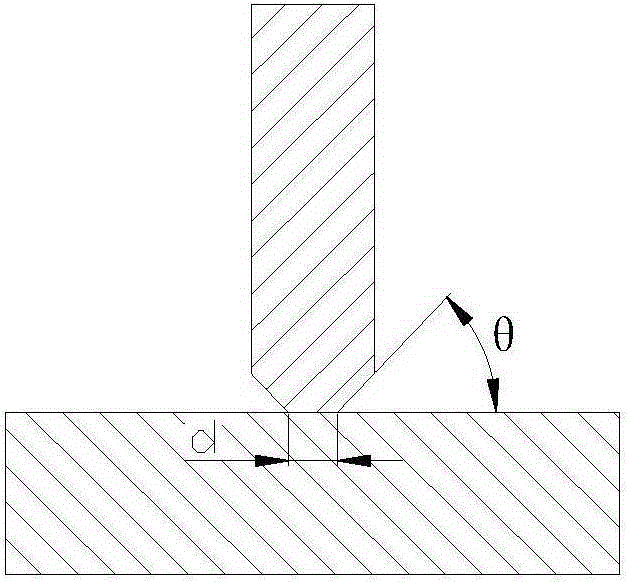

Welding method of deck structure of stainless steel compound plate for railway steel bridge

ActiveCN101797667AGuaranteed weld thicknessGuaranteed uncertaintyArc welding apparatusWelding/soldering/cutting articlesAusteniteTransition layer

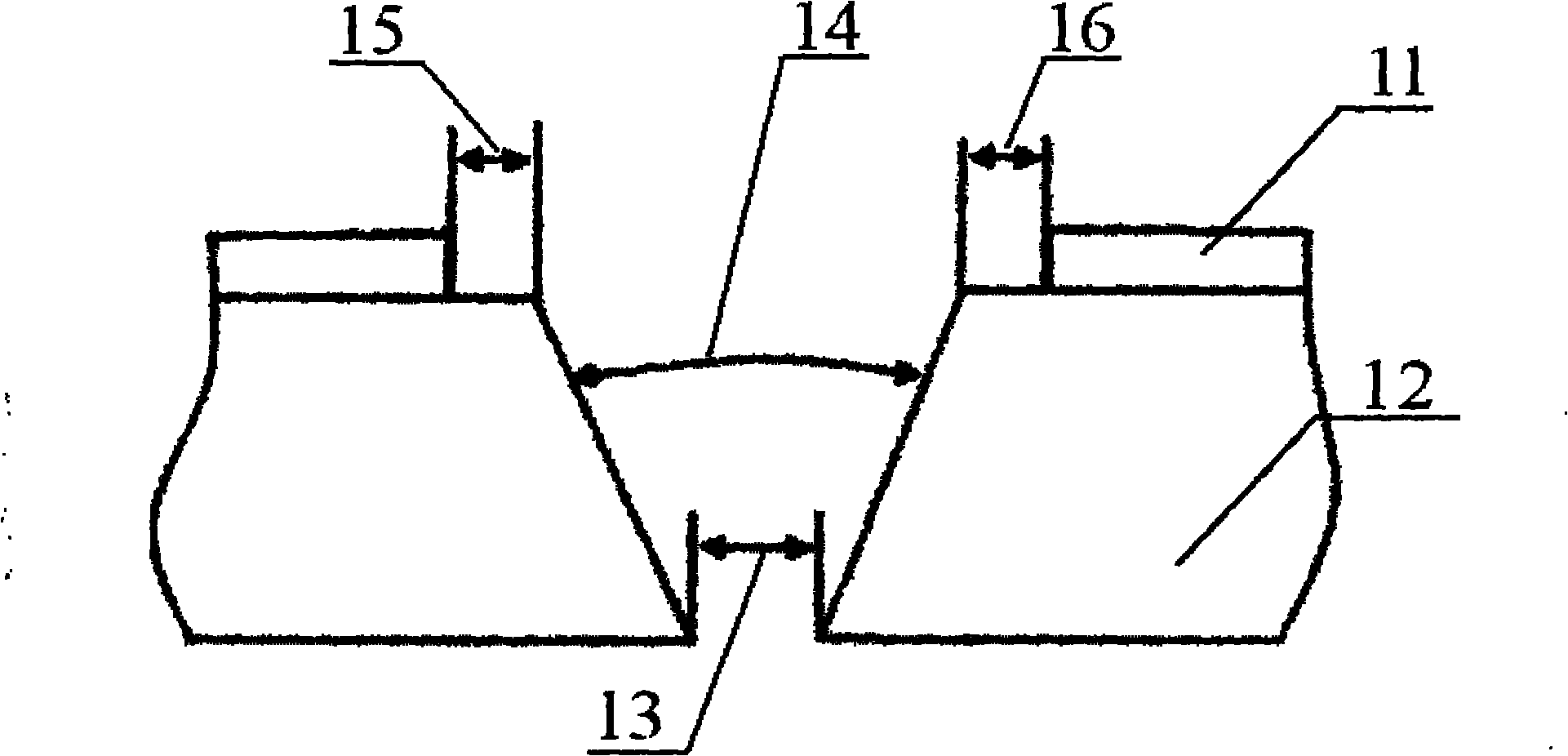

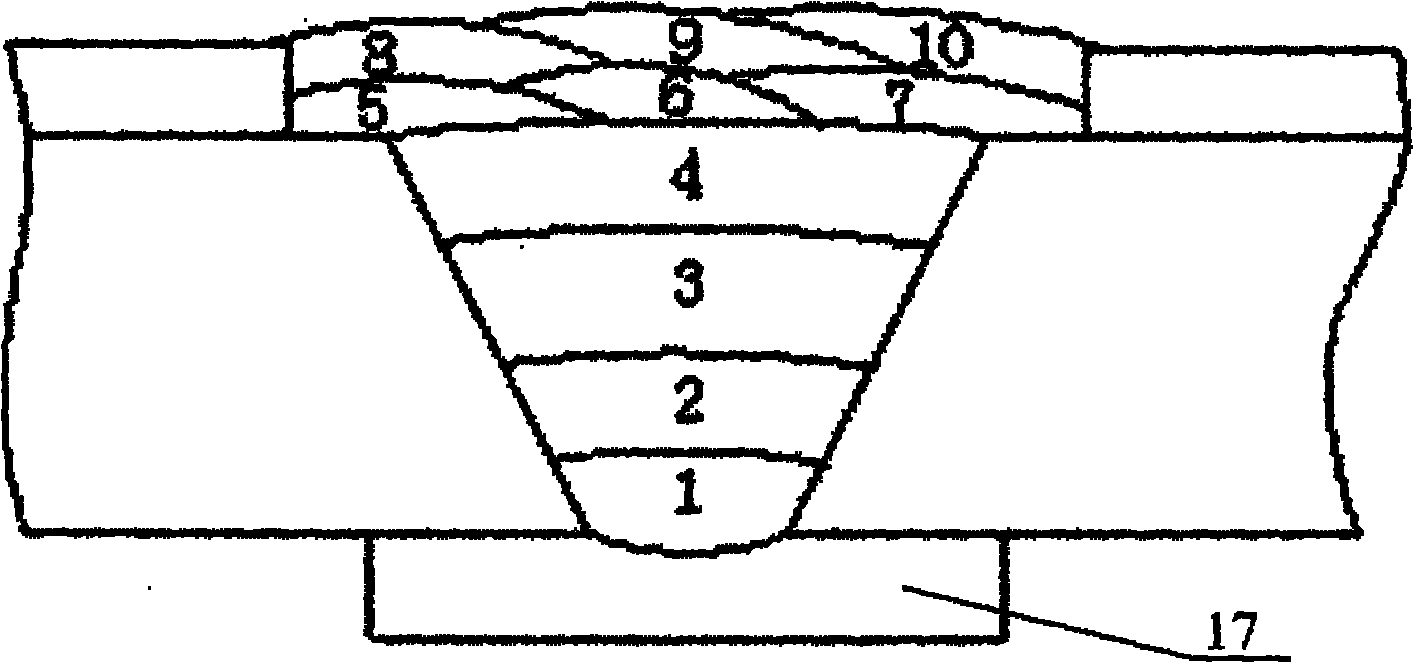

The invention discloses a welding method of a deck structure of a stainless steel compound plate of a railway steel bridge, which comprises the following steps: selecting structural steel for a bridge with thickness of 16-20mm as a base layer, selecting austenitic stainless steel with thickness of 2-4mm as a multiple layer, and removing 3-6mm of cladding material materials at each of two edges of welding grooves in advance, wherein the groove angle is 45-65 degrees, and the groove spacing is 4-8mm; the method comprises the following steps: firstly, assembling positioned welding, and then, carrying out backing welding by CO2 gas shielded welding; then, carrying out welding of the base layer by submerged-arc welding; and finally, carrying out welding of a transition layer and the multiple layer by the CO2 gas shielded welding. By adopting a specific groove type, the invention eliminates uncertain human factors and solves the problems that the thickness of the deposited metal of the base layer is insufficient, the multiple layer can be molten by mistake when the substrate layer is welded, and the like; the reverse formation is good, so that the reverse back gouging process is omitted; and the invention has the advantages of good assembly quality and easy realization of mechanization and automation, improves the production efficiency, and is convenient for ensuring the corrosion resistance of the multiple layer.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

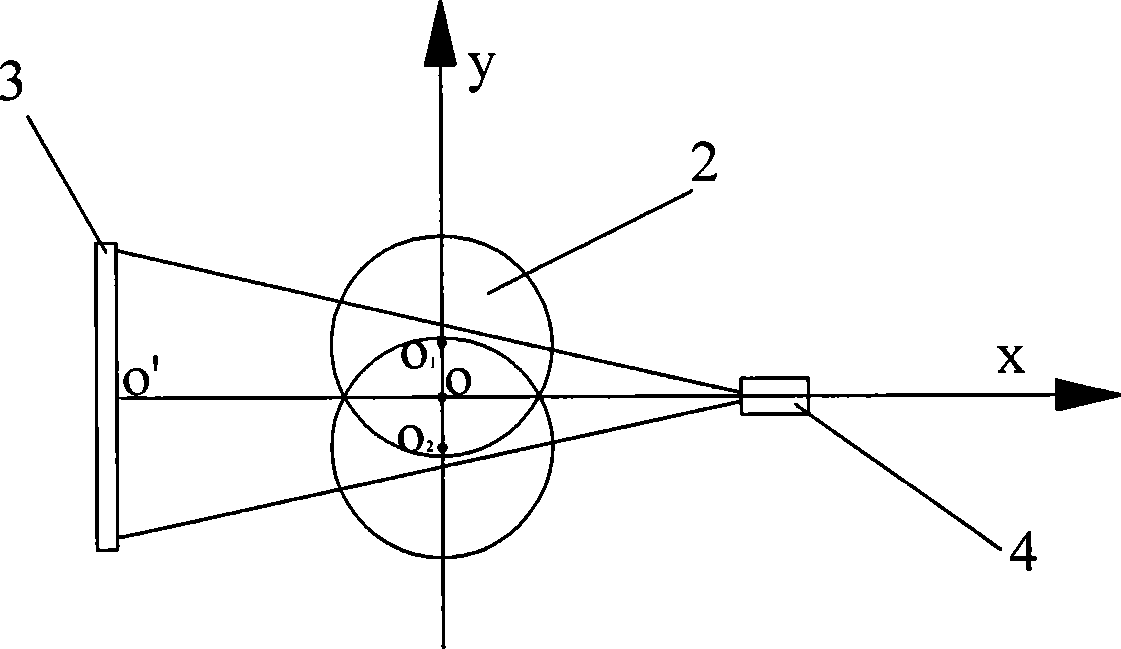

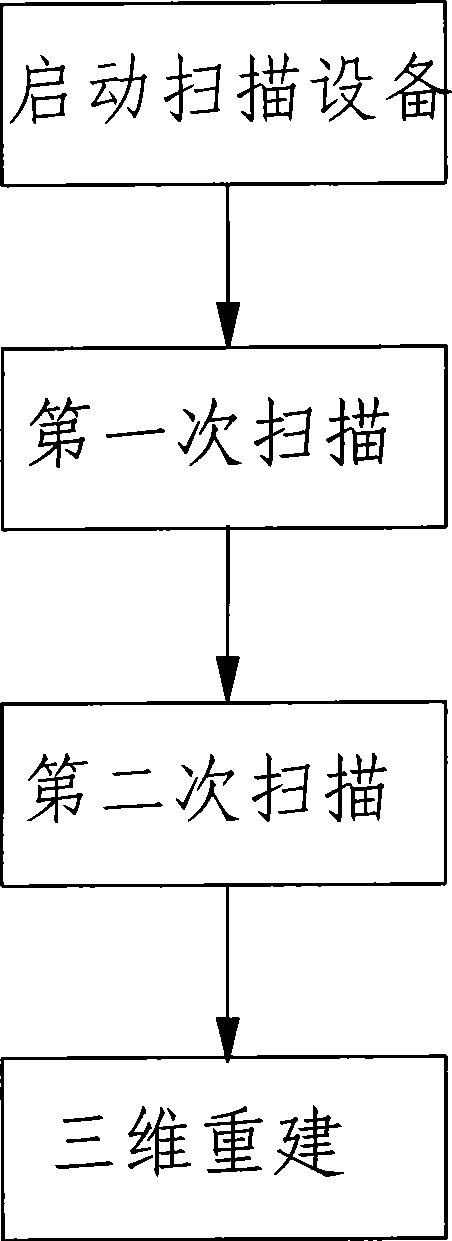

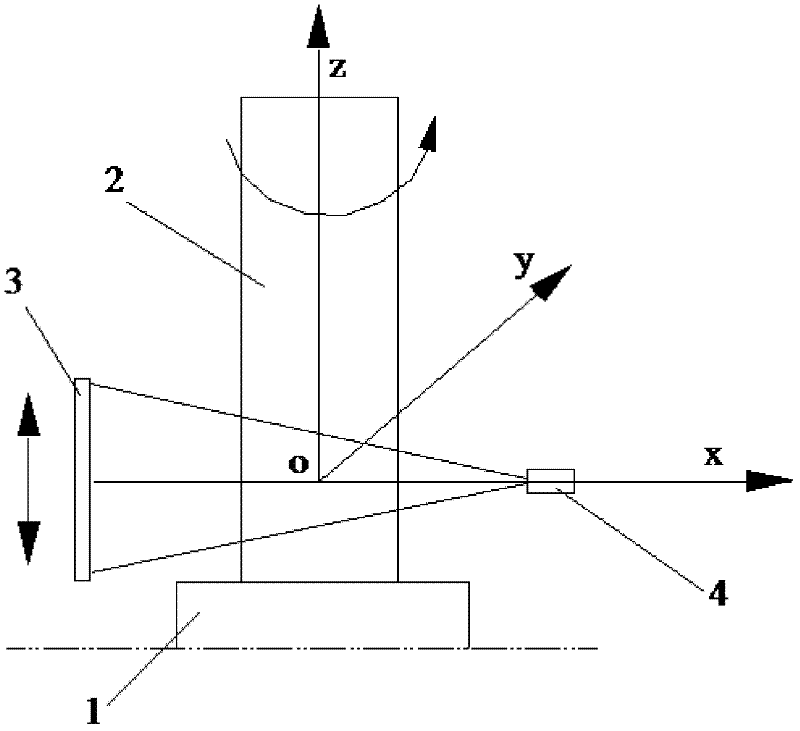

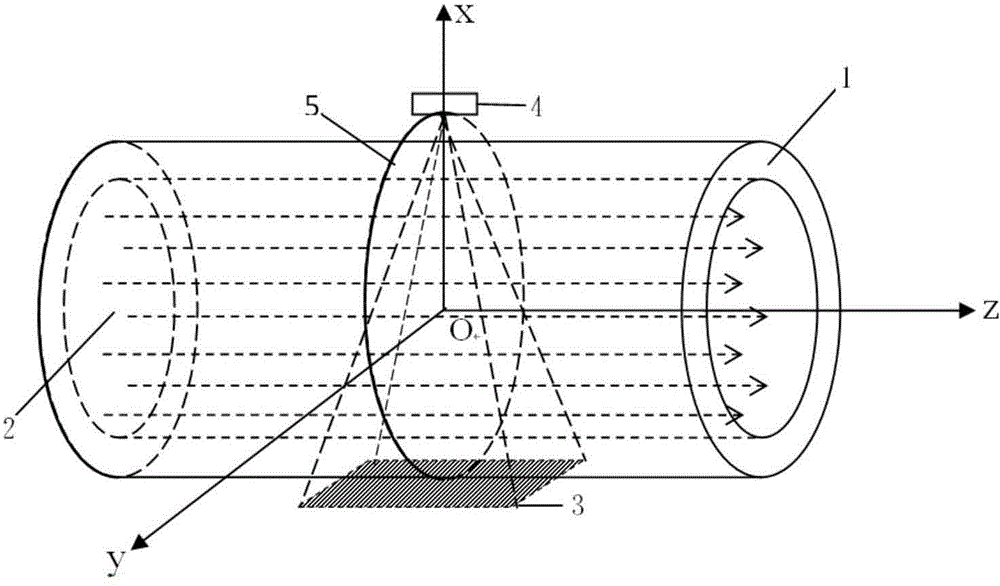

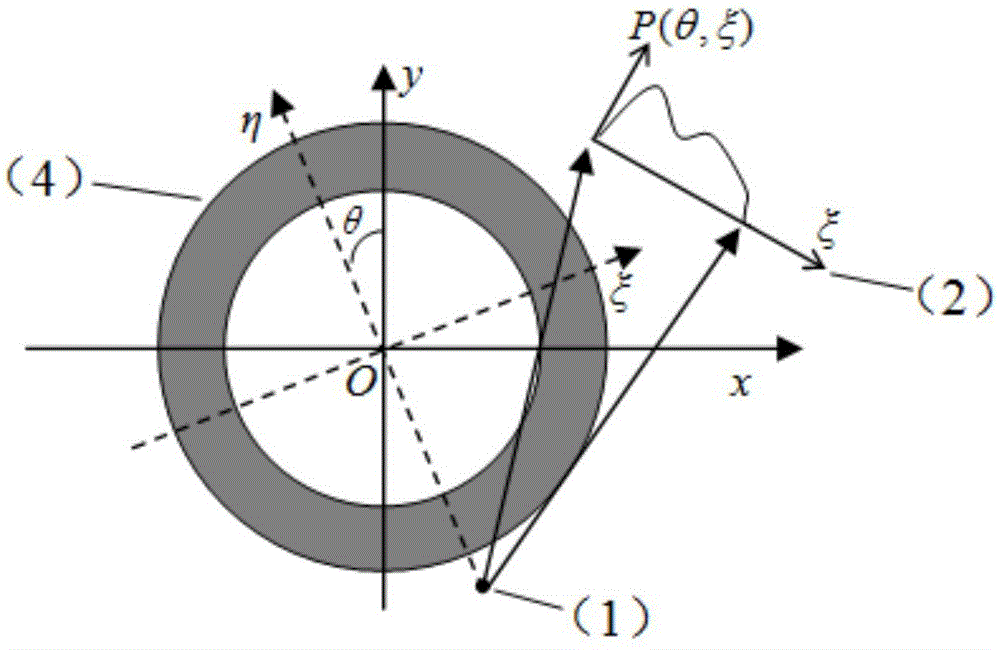

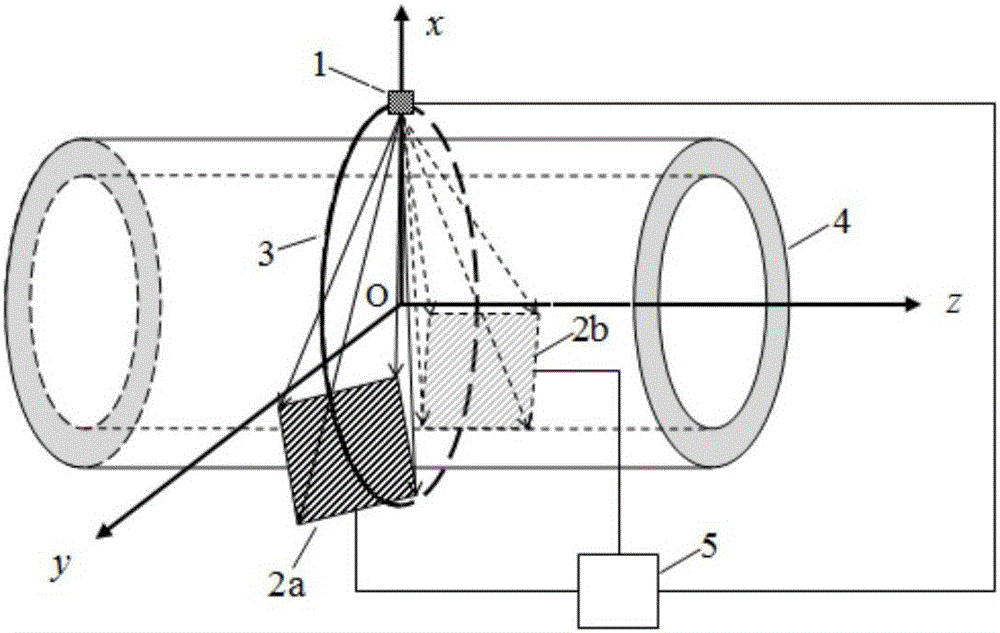

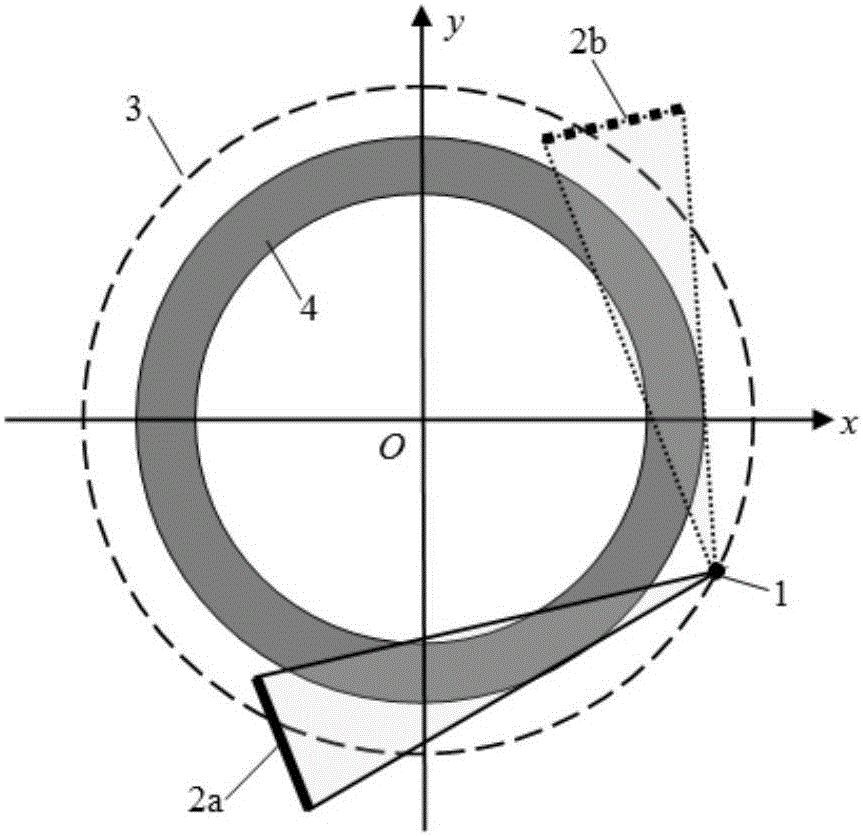

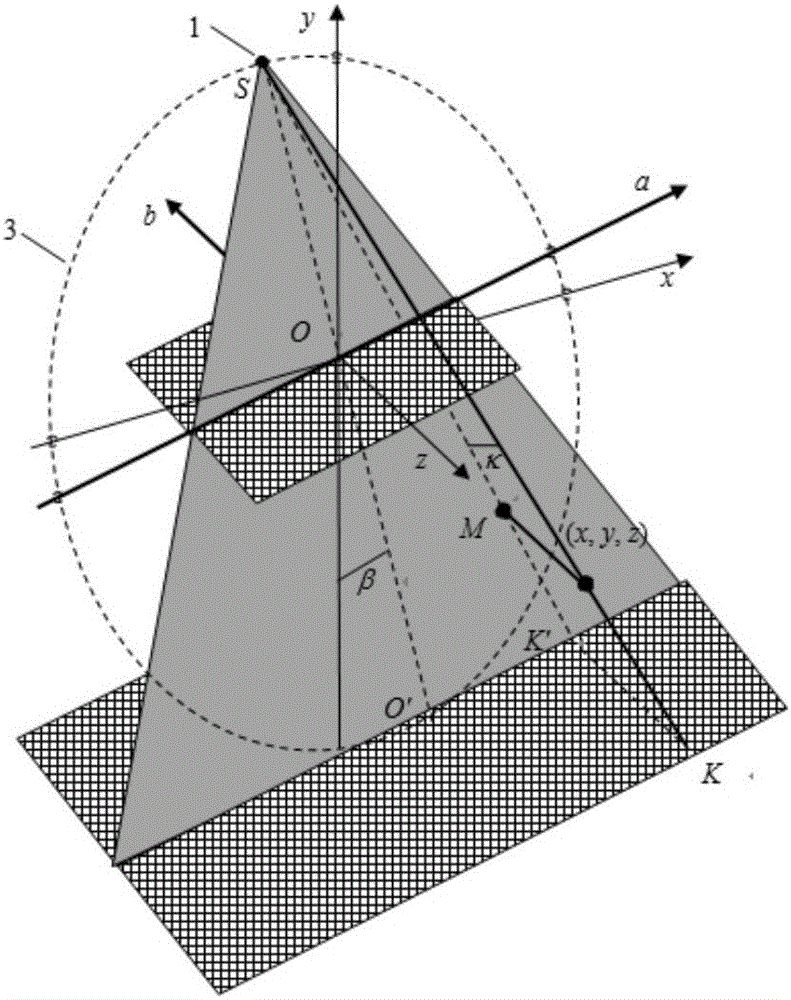

Cone beam double-helix CT Scanning and imaging method for large sized object

InactiveCN101393145AEasy to implement mechanicallyImprove detection accuracyMaterial analysis by transmitting radiationPhotographyPhysicsSpiral scanning

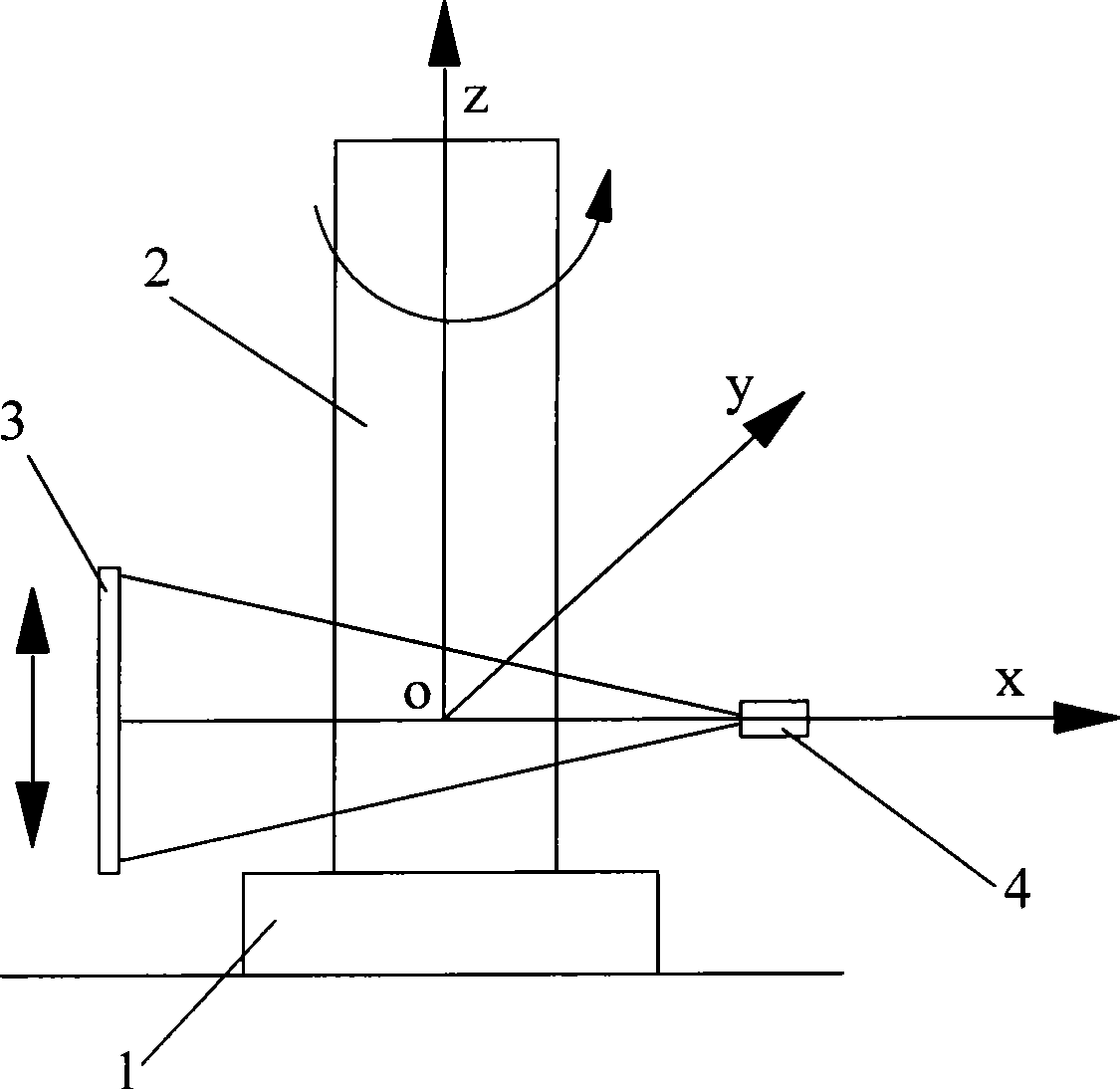

The invention discloses a cone-beam double-spiral CT scanning and imaging method for a large-sized object. The method comprises the following steps: after a turntable provided with a work piece to be detected translates twice along the direction vertical to a central ray, and the work piece and the turntable rotate around a rotating shaft; meanwhile, a ray source and a detector lift and scan along the direction of the rotating shaft to form parallel double-spiral scanning tracks and acquire a three-dimensional image of an area to be detected through a three-dimensional reconstruction method improved by the invention. The method realizes the detection of large objects by using the structure of the prior CT machine, the ray source and the detector do not need to deflect, and the turntable and the work piece to be detected do not need to translate along the radial direction (in the direction parallel to the central ray), so the scanning process is easy to realize mechanically, the transverse size of the detected object doubles that of the prior single-spiral CT, complete projection data of the object can be acquired, and the detection for long objects with large transverse sizes can be realized; and the method does not need to rearrange and interpolate projection data, has high detection precision, only scans the spiral track twice, and has high detection efficiency.

Owner:CHONGQING UNIV

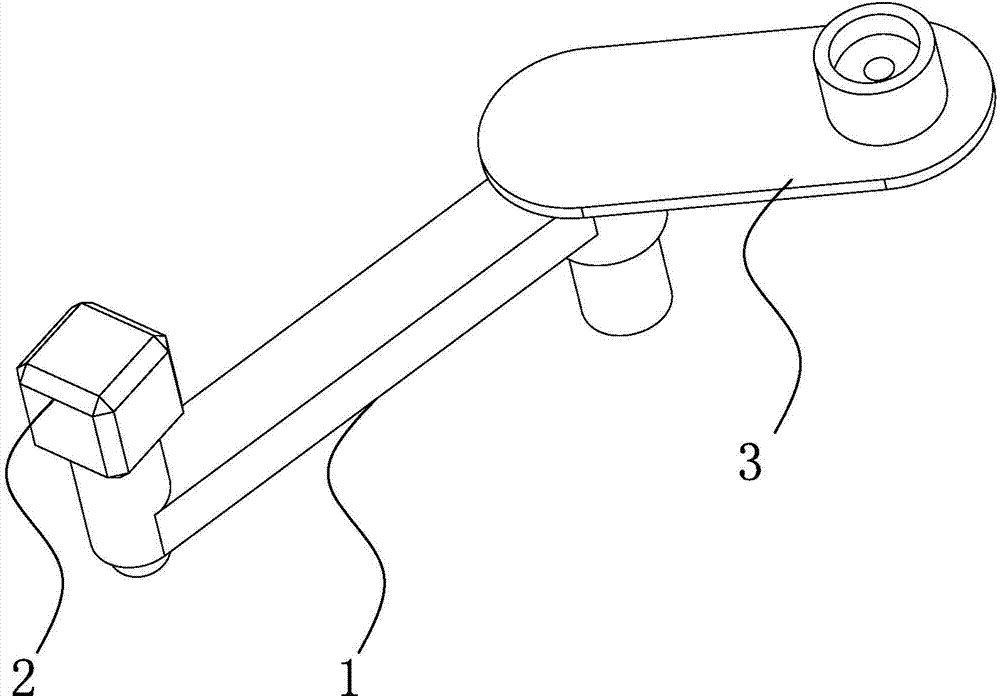

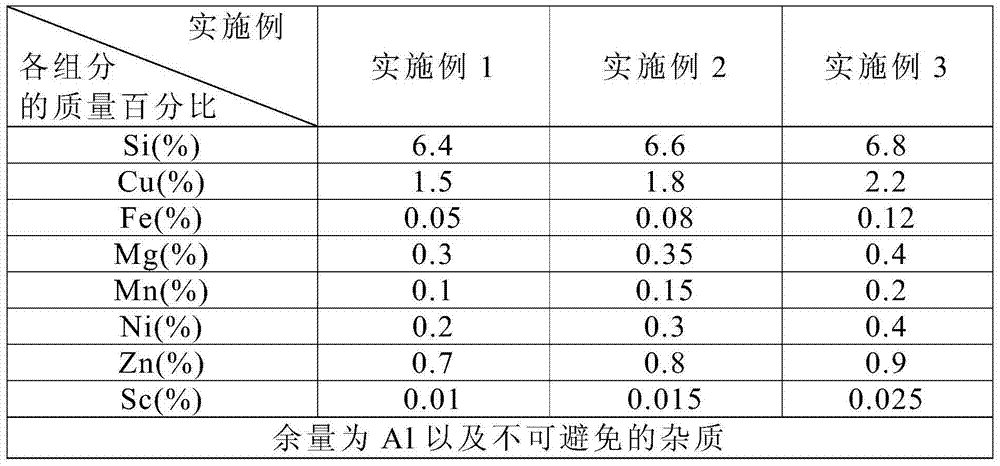

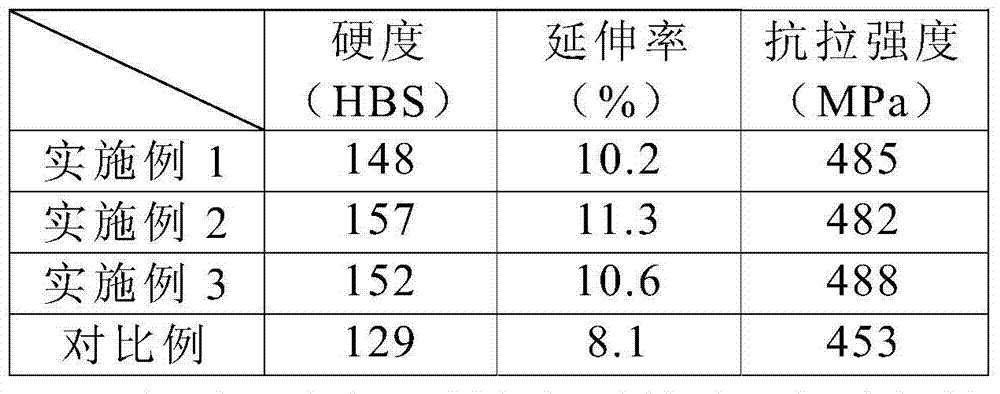

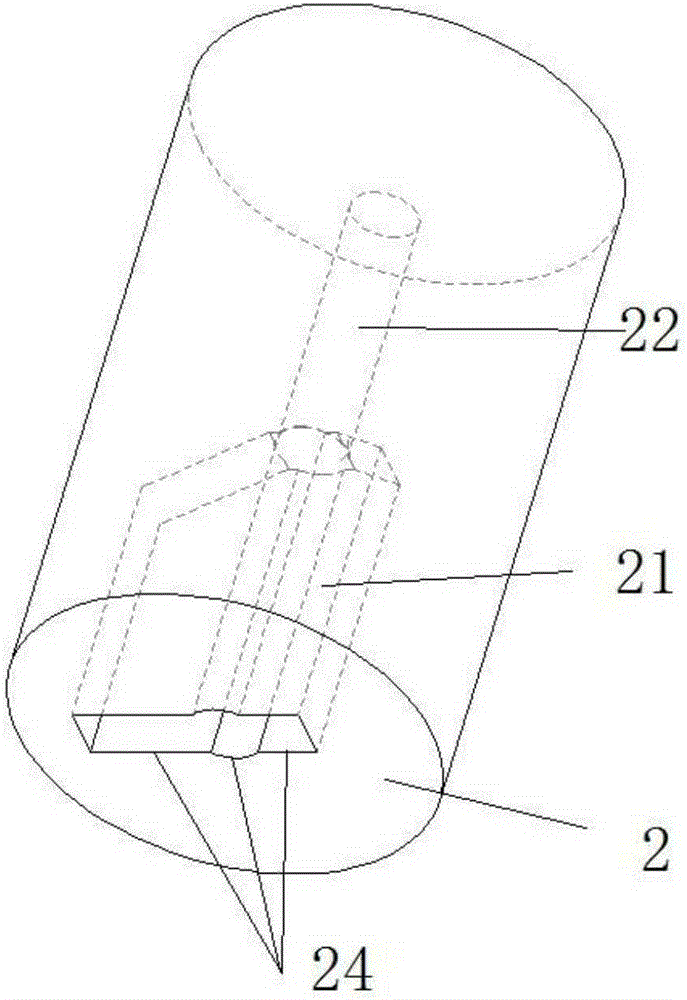

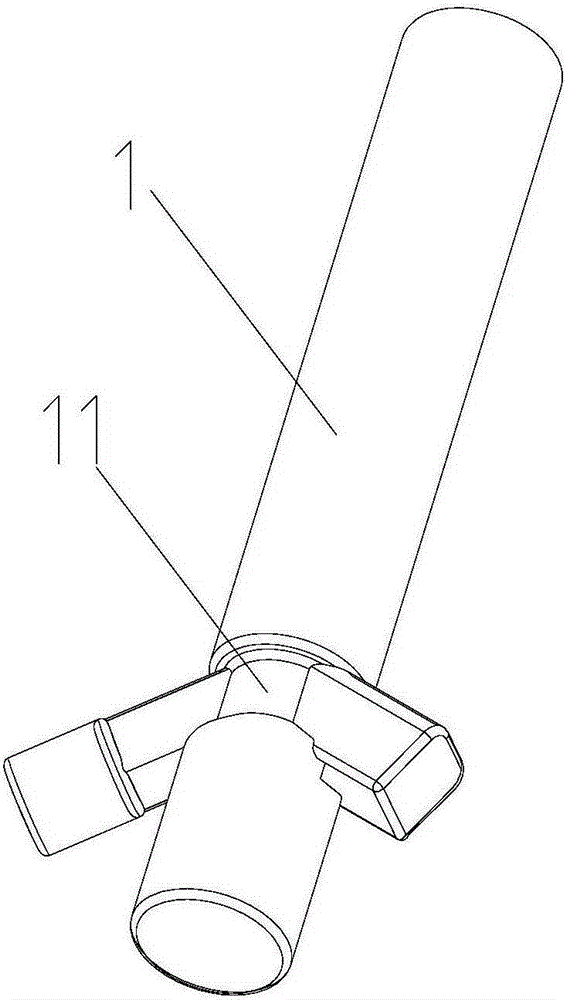

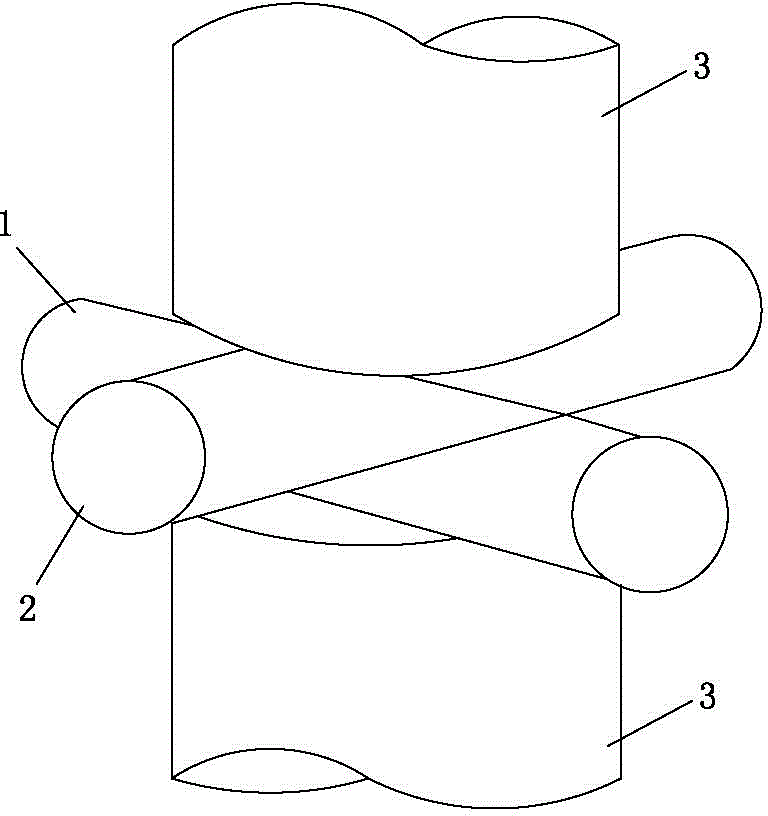

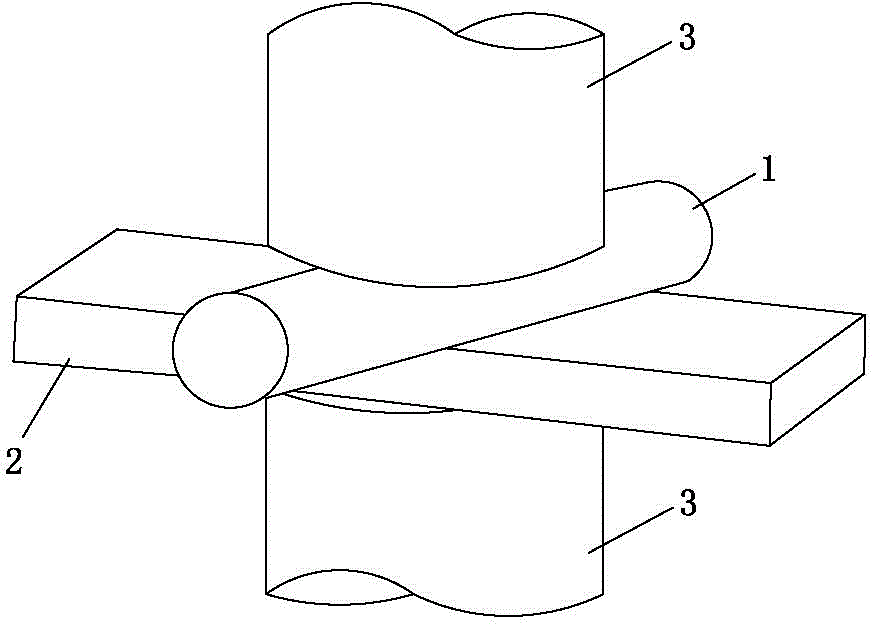

Connecting rod of sewing machine and preparation method thereof

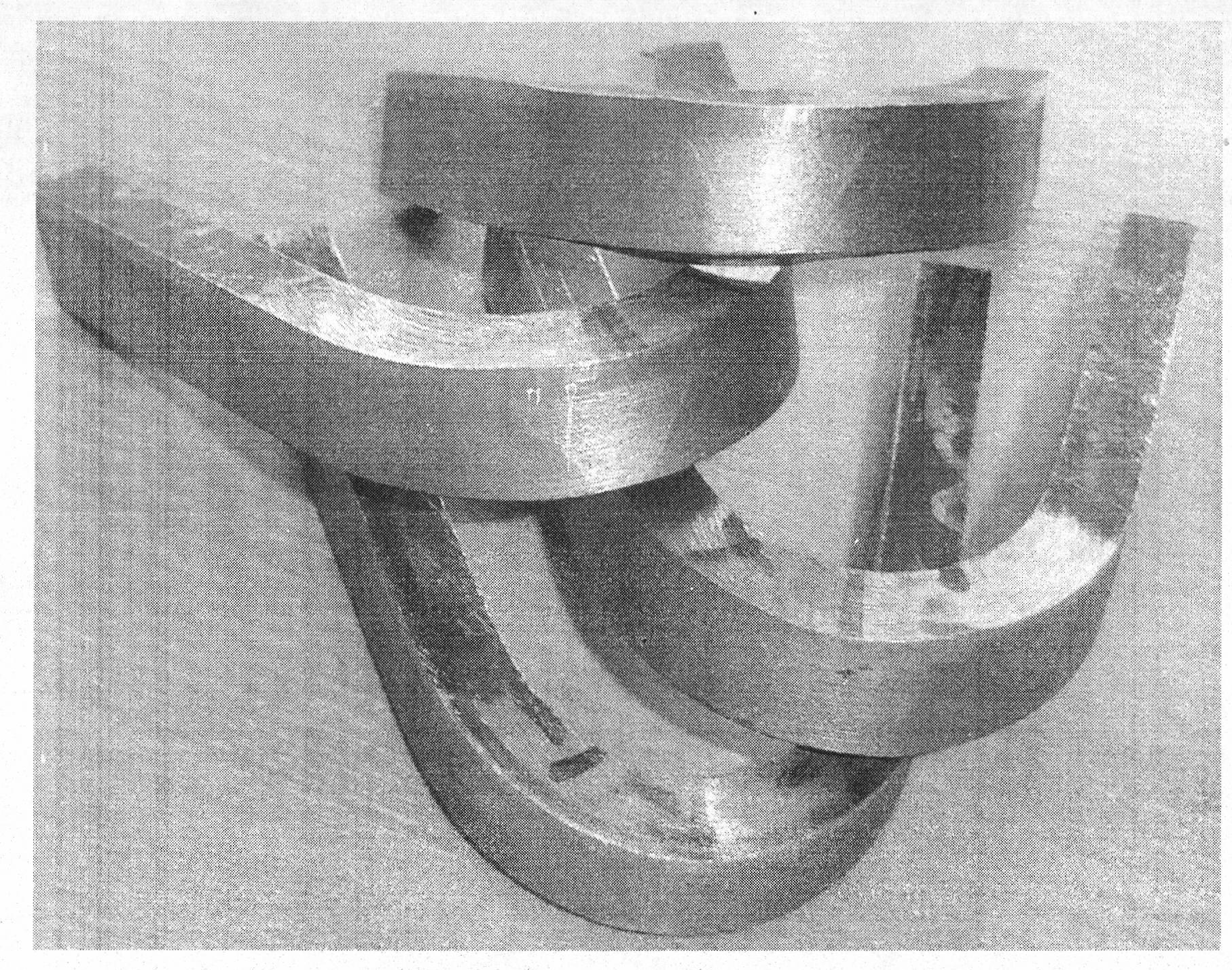

The invention relates to a connecting rod of a sewing machine and a preparation method thereof. The connecting rod is composed of a needle stem crankshaft bar, a needle bar column and a needle bar holding part and made of an aluminum alloy, wherein the aluminum alloy comprises, by weight, 6.2 to 7.0% of Si, 1.0 to 2.5% of Cu, 0.05 to 0.15% of Fe, 0.3 to 0.4% of Mg, 0.1 to 0.2% of Mn, 0.1 to 0.5% of Ni, 0.7 to 1.0% of Zn and 0.01 to 0.025% of Sc, with the balance being Al and unavoidable impurities. The preparation method comprises the following steps: fusing the above-mentioned metals and carrying out stirring and slag removal; then carrying out stamping and die casting so as to obtain blanks of the needle stem crankshaft bar, the needle bar column and the needle bar holding part; and finally, subjecting the blanks to post-treatment and carrying out assembling to obtain the connecting rod of the sewing machine. The connecting rod of the sewing machine has good strength, hardness, plasticity, toughness, wear resistance, elongation, tensile strength, etc. and high quality.

Owner:NINGBO RUIMING MACHINERY

Low-alloy bainite ductile iron abrading-ball

InactiveCN101200789AImprove impact resistancePromote formationFurnace typesHeat treatment furnacesChemical compositionHigh surface

A low alloy bainite ductile iron grinding ball is provided. The chemical compositions of the grinding ball (weight percentage) are as follows: 3.5 to 3.8 percent of C, 2.8 to 3.8 percent of Si, 0.1 to 0.5 percent of Mn, 0.15 to 0.35 percent of Cr, 0.35 to 0.5 percent of Mo, less than or equal to 0.03 percent of S, less than or equal to 0.1 percent of P, 0.03 to 0.08 percent of Mg, 0.5 to 1.5 percent of Cu, 0.01 to 0.03 percent of Bi and 0.02 to 0.07 percent of Re, and the rest is Fe. The ball is made through the following heat treatment steps: (1) heating the grinding ball to be at 880-960 DEG C; (2) quenching in mechanical oil; (3) taking the ball out when the surface temperature is 150-230 DEG C; (4) implementing the sands burying and the insulation tempering rapidly with temperature for 6-8h or taking the ball out for the air cooling after the sands burying and the insulation tempering for 1-3h. The obtained grinding ball has the advantages of reasonable organization structure, high surface strength, high hardness, good wear resistance, high inner toughness and perfect comprehensive property and is especially applied to crushing materials.

Owner:GUILIN UNIV OF ELECTRONIC TECH

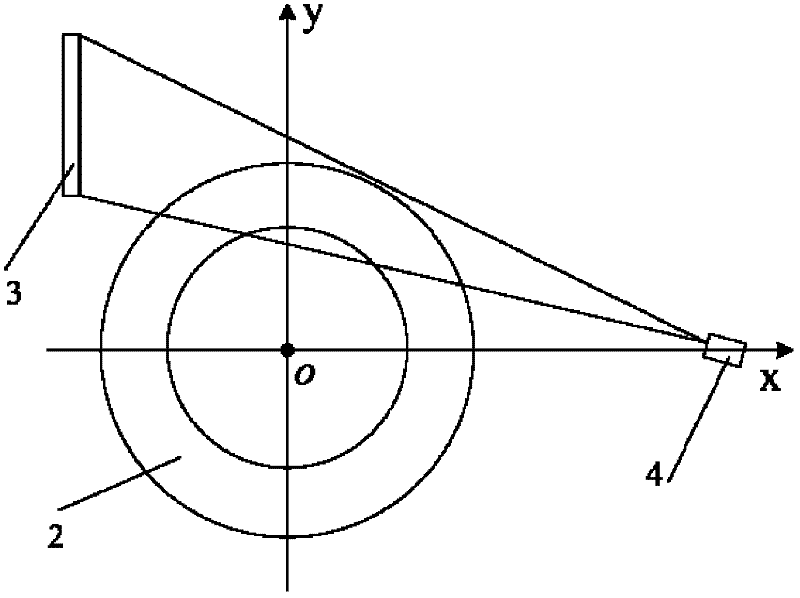

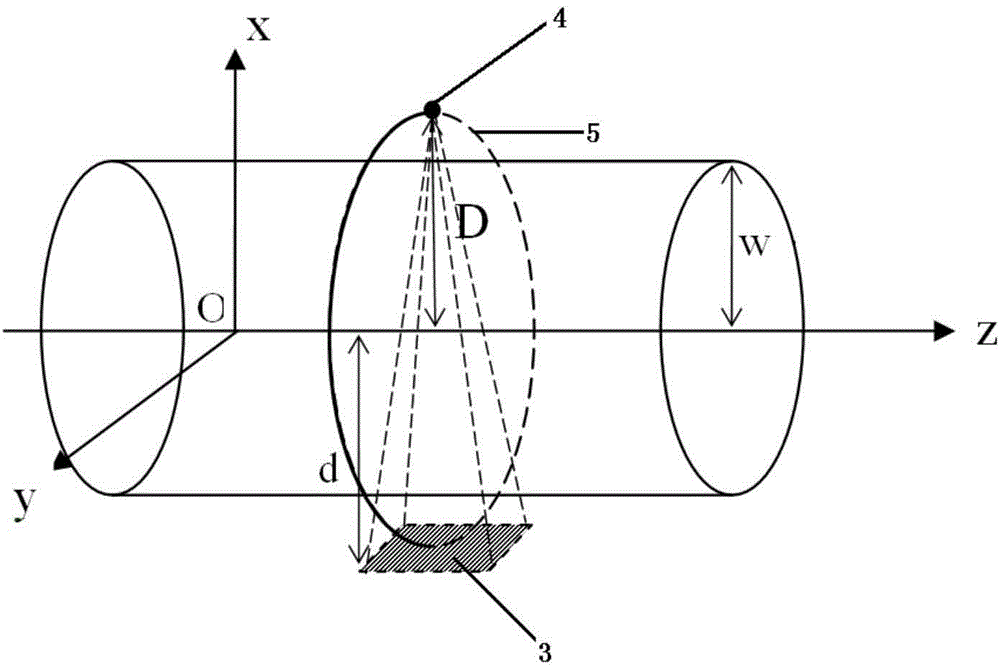

External spiral cone beam CT (computed tomography) scanning imaging method of large-size industrial long pipeline pipe wall

ActiveCN102331433ASolve the horizontal truncation problemQuality improvementMaterial analysis by transmitting radiationSpiral Cone-Beam CTComputed tomography

The invention discloses an external spiral cone beam CT (computed tomography) scanning imaging method of a large-size industrial long pipeline pipe wall, and relates to an external spiral cone beam CT scanning imaging method. Before scanning, a radial source is deflected and a plane array detector is offset to make conical radial beams cover the pipe wall area of one side of the cross section of a pipeline; in scanning, the pipeline is driven by a rotary table to rotate around a rotary shaft, and simultaneously the radial source and the detector are synchronously ascended and descended for scanning along the direction of the rotary shaft so as to obtain external spiral cone beam CT projection data of the pipe wall area; and a three-dimensional image of the pipe wall area to be detected isobtained in an improved external spiral cone beam CT iterative reconstruction algorithm provided by the invention. In the method disclosed by the invention, the detection of the large-size industriallong pipeline pipe wall is realized by a small-size plane array detector and the existing CT machine structure, the scanning process is easy to realize mechanically, one-step spiral cone beam scanning is adopted, and the detection speed is high. The reconstructed image of the pipe wall has good quality and high resolution, and nondestructive evaluation on the pipeline is easy to carry out.

Owner:CHONGQING UNIV

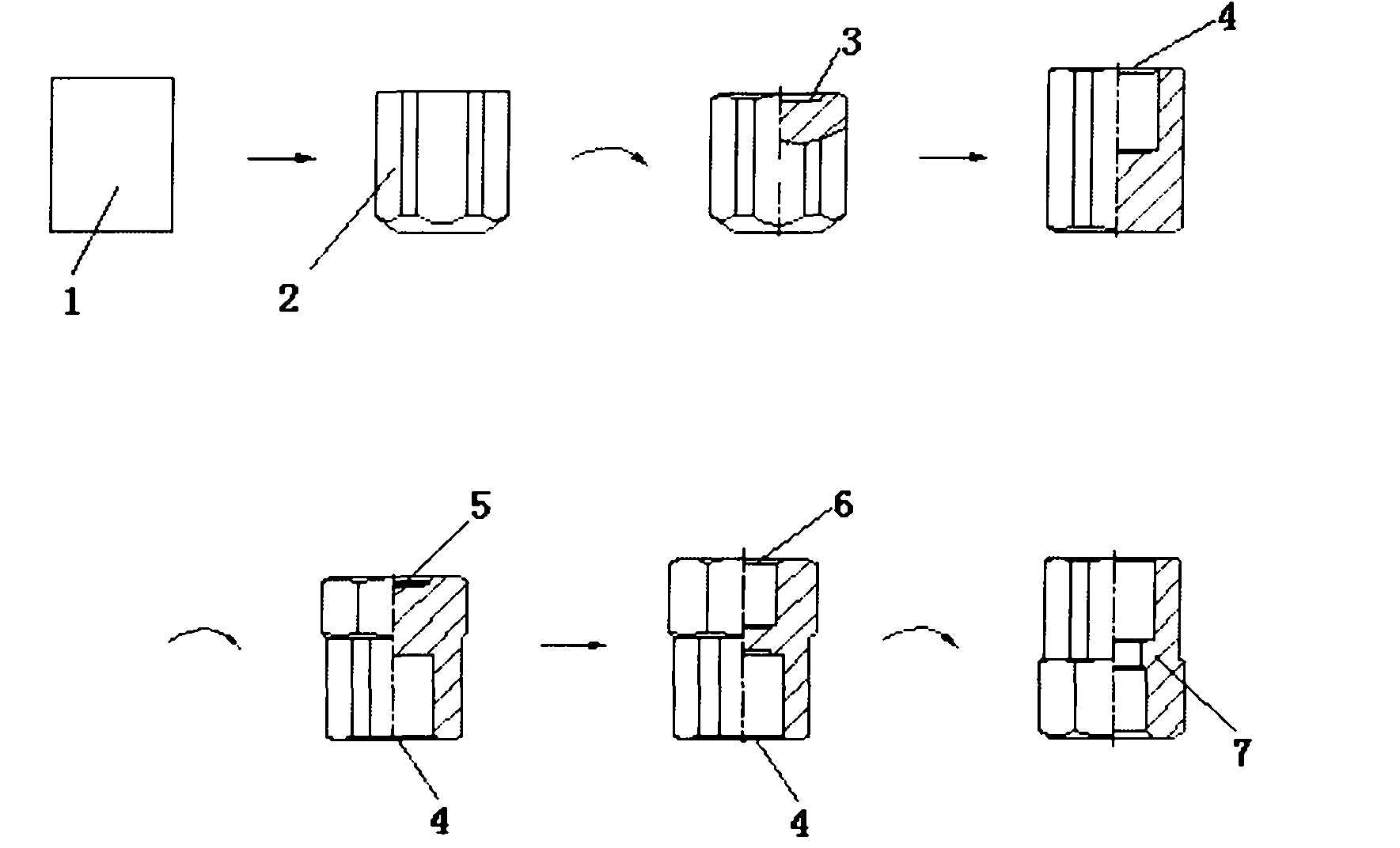

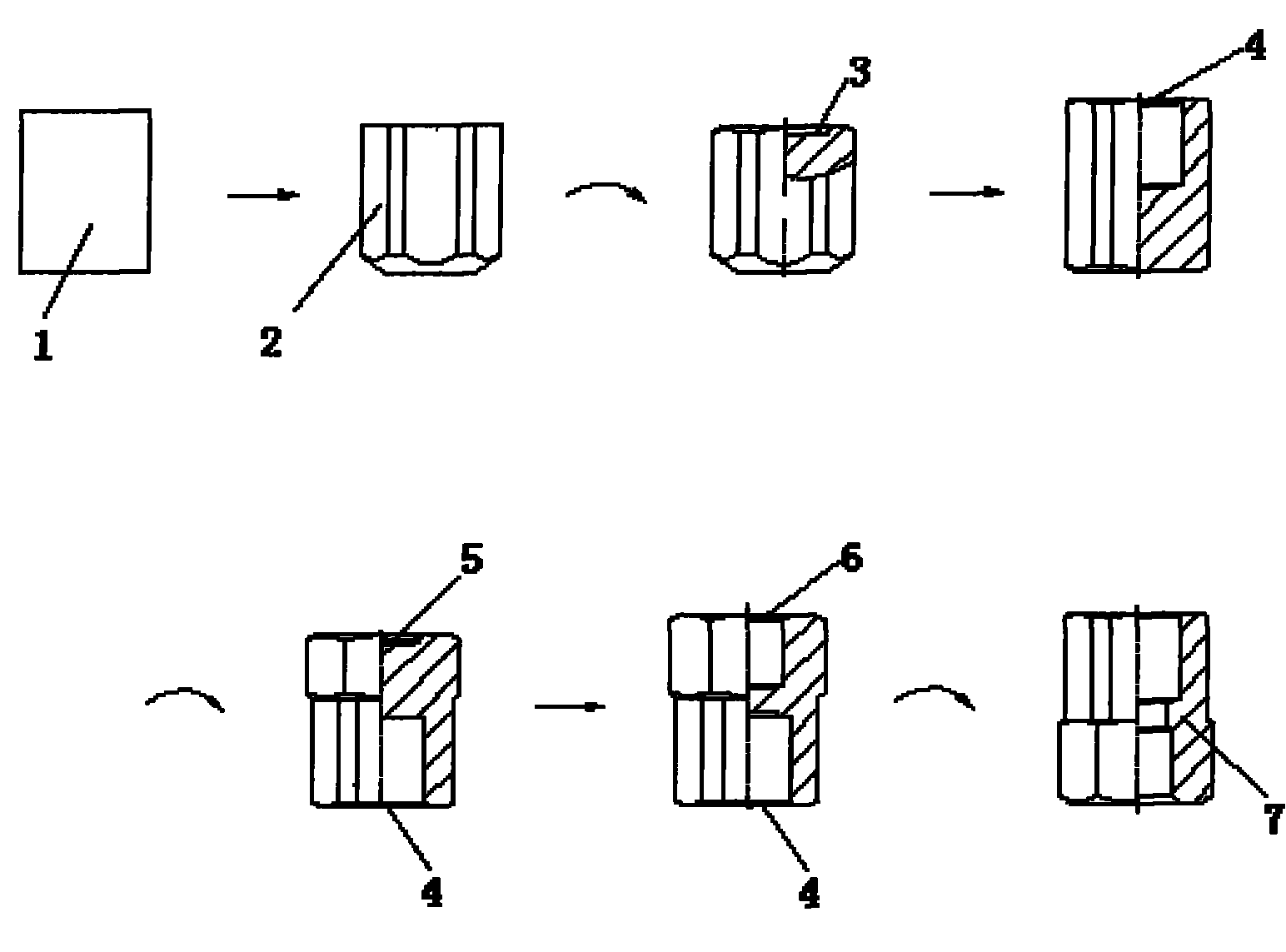

Process for manufacturing pneumatic inner and outer tooth joint blank

InactiveCN102152062AEasy to implement mechanicallyEasy to achieve productivityEngine componentsMaterials scienceRaw material

The invention discloses a process for manufacturing a pneumatic inner and outer tooth joint blank. The process comprises the following steps of: making a round disc material from a steel blank raw material, performing phosphate surface treatment on the round disc material, performing spheroidizing annealing, phosphate coating treatment and fine extraction and diameter fixing treatment on the round disc material subjected to rough extraction, and finally performing a forming procedure of the pneumatic inner and outer tooth joint blank in a cold forming header. The forming procedure of the pneumatic inner and outer tooth joint blank comprises the specific steps of: breaking the material; forming and heading the material into a hexagonal shape with circular beads; turning the material, forming and heading a first location hole at the upper end and an inner chamfer at the lower end; translating the material and heading a first counter bore at the front end; heading the other end of the turned material into a hexagonal shape with inclination angles, and heading a second location hole; translating the material and heading a second counter bore at the front end; and removing residual scrap iron in a middle hole so as to manufacture the final blank. The cold header is used for forming at one time, so the production efficiency and the quality of the pneumatic inner and outer tooth joint blank are improved, the raw materials are saved, and the production cost is reduced.

Owner:NINGBO ANCHOR FASTENERS INDAL

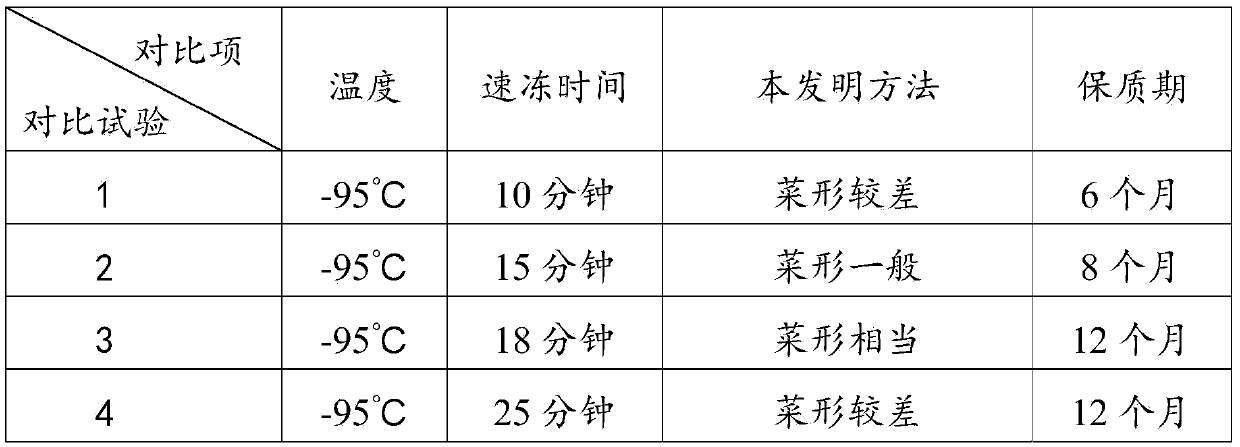

Quick-frozen chicken with lentinus edodes and manufacturing method thereof

InactiveCN105360980AEasy to implement mechanicallyImprove automationFood scienceComing outMonosodium glutamate

The invention discloses quick-frozen chicken with lentinus edodes and a manufacturing method thereof. The main materials comprise thawed frozen chicken breast, which is in the weight of 59 g / serving, cut into bevel shape, and in the size of 3cm*1cm*0.4cm, and dried letinous edodes, which is soaked, in the weight of 34 g / serving, cut into flaky shape with the specifications of 1cm wide and 0.4 cm thick. The main processing steps are as below: 1, removing the letinous edodes stalks and blanching in hot water to shrink the size; slicing and pickling the chicken breast, and cutting peppers into segments for standby; 2, heating the oil in a pot to 70% cooked, frying the pickled chicken breast to white color, taking out the chicken breast, filtering the oil, and stir-frying garlic, ginger, oyster sauce with hot oil in another pot until fragrance comes out; 3, adding the fried chicken breast, stir-frying for 1 min, adding letinous edodes, blending evenly, adding water, and then adding chicken essence and monosodium glutamate in turn, mixing well, and adding soy sauce 2 min later. The quick-frozen chicken with lentinus edodes produced by the method has the characteristics of nutrition, convenience, fast, popularity, and applicability to mass production.

Owner:WUHAN NEWSTAR FOOD

Cone beam CT local scanning imagery for fluid in pipelines

InactiveCN104614376AHigh resolutionFix truncationOptically investigating flaws/contaminationField conditionsImage resolution

The invention discloses a cone beam CT (Computed Tomography) local scanning imagery for fluid in pipelines, and relates to a nondestructive examination technology for pipelines in use. The method comprises the following steps: mounting a radiation source and an area-array detector on a round track coiled on a pipe wall before scanning, while scanning, making the radiation source and the area-array detector perform circular motion along the track around the pipeline during scanning, simultaneously, by flowing of fluid, obtaining equivalent spiral cone beam projection data of inclusions-containing fluid, and then, obtaining a three-dimensional image of the fluid inclusions in the to-be-detected pipeline by means of combining a spiral cone beam FDK (Feldkamp) image reconstruction algorithm with a local filter. Mechanical motion of such scanning mode is simple and easy to implement, and can easily adapt to field conditions of pipeline field in-use detection; local reconstruction image of the inclusions-containing fluid in the pipeline has good quality and high resolution.

Owner:CHONGQING UNIV

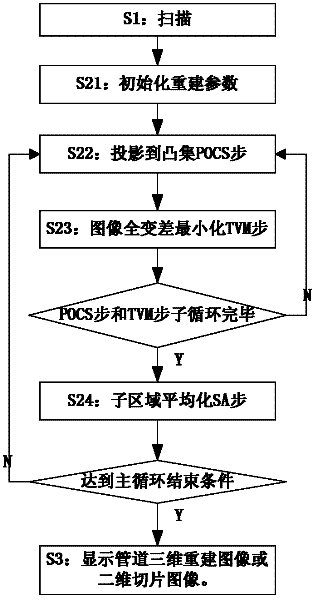

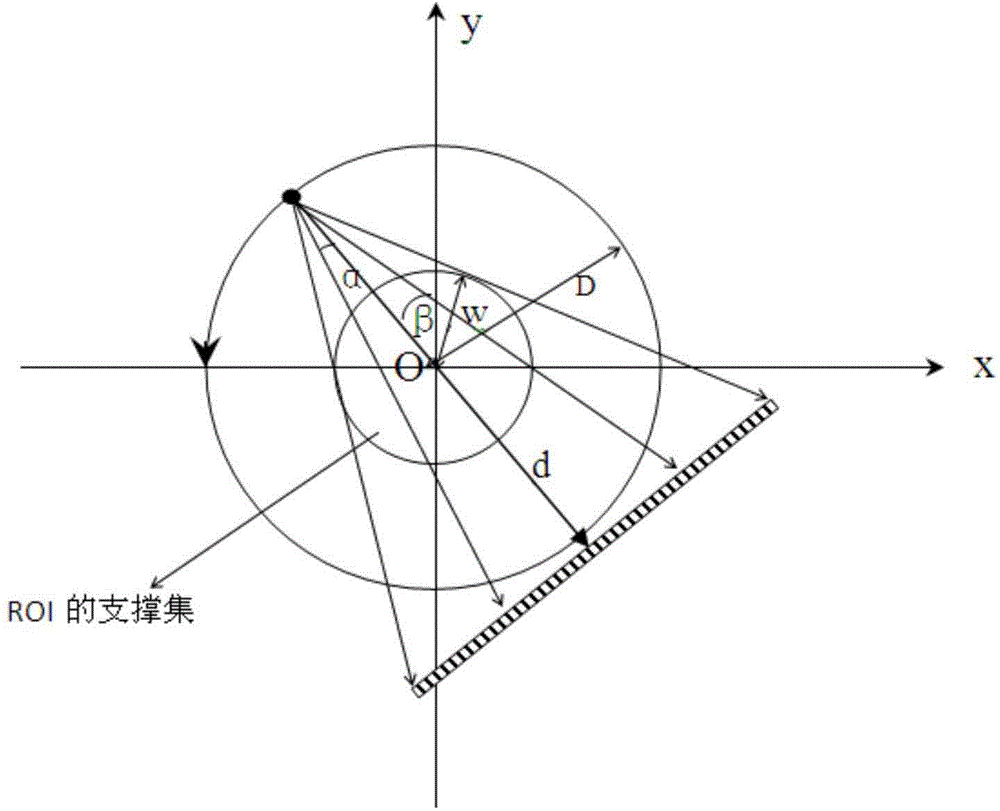

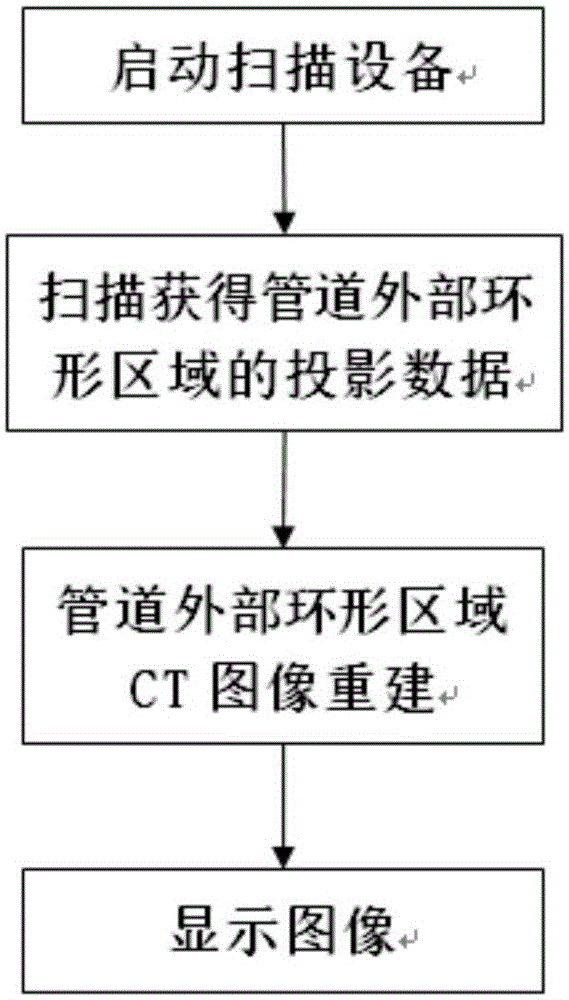

Large diameter pipeline wall outside CT local scanning imaging method

ActiveCN105136823AEasy to handleQuality improvement2D-image generationMaterial analysis by transmitting radiationCross cutBeam hardening

The invention relates to a large diameter pipeline wall outside CT local scanning imaging method, and belongs to the technical field of CT scanning imaging. The method comprises the following steps: a radiation source and a detector are arranged in a circular track surrounding the center of a pipeline to be detected, and the detector is arranged in an offset manner; the radiation source and the detector circularly move along the circular track to scan in order to obtain the projection data of the annular region outside the pipeline to be detected; and a TVM-POCS reconstruction algorithm and a region scale fitting segmentation technology are combined to reconstruct the image of the annular region outside the pipeline according to the projection data. The large diameter pipeline wall outside CT local scanning imaging method has the advantages of simple and easy scanning mode, short scanning time, low radiation dose, satisfactory solving of the cross cutting problem of the projection data, great reduction of the reconstruction artifact, satisfactory solving of the problem of reconstructed image gray scale unevenness caused by ray beam hardening, and good quality of the finally displayed local reconstruction image of the annular region outside the pipeline.

Owner:CHONGQING UNIV +1

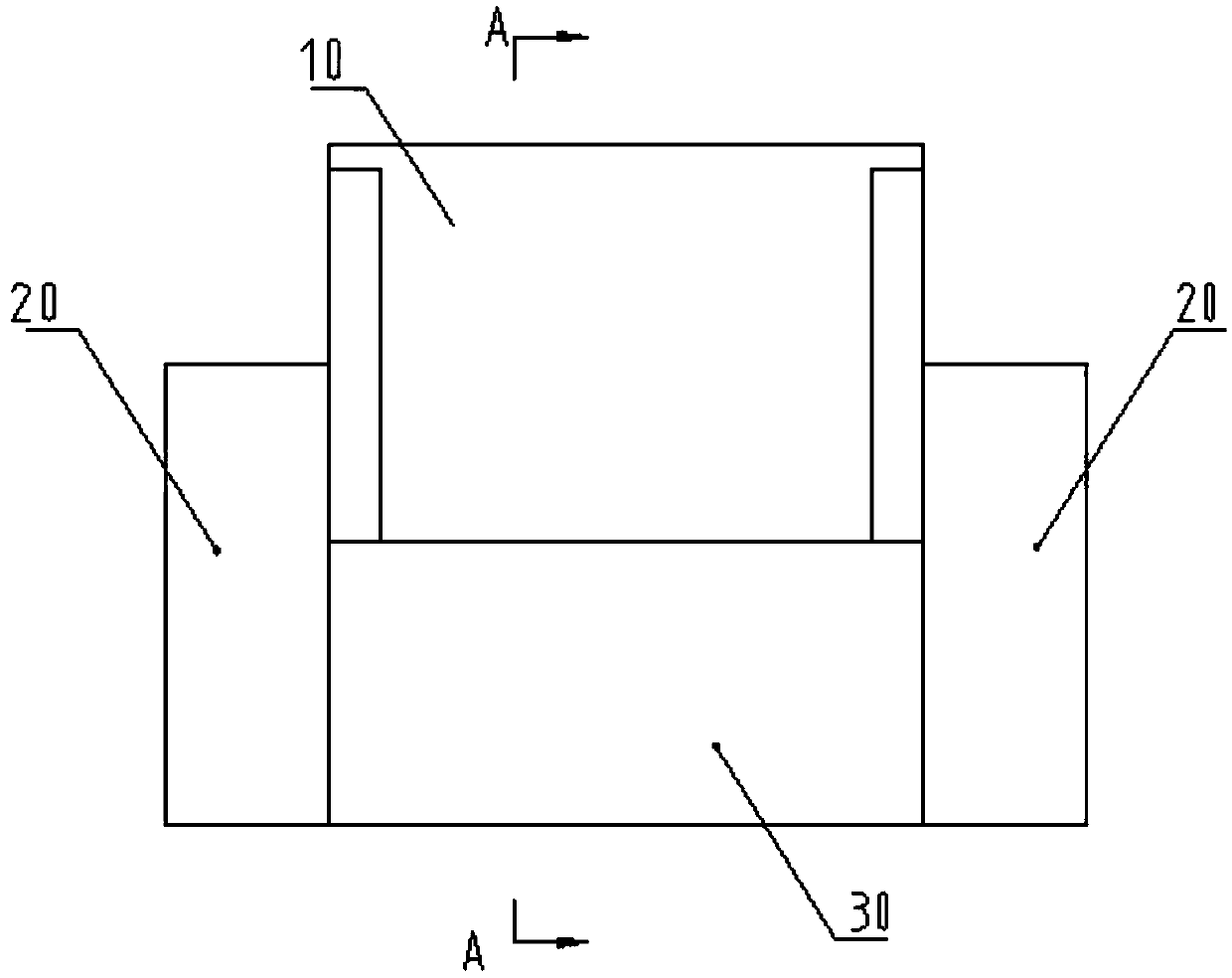

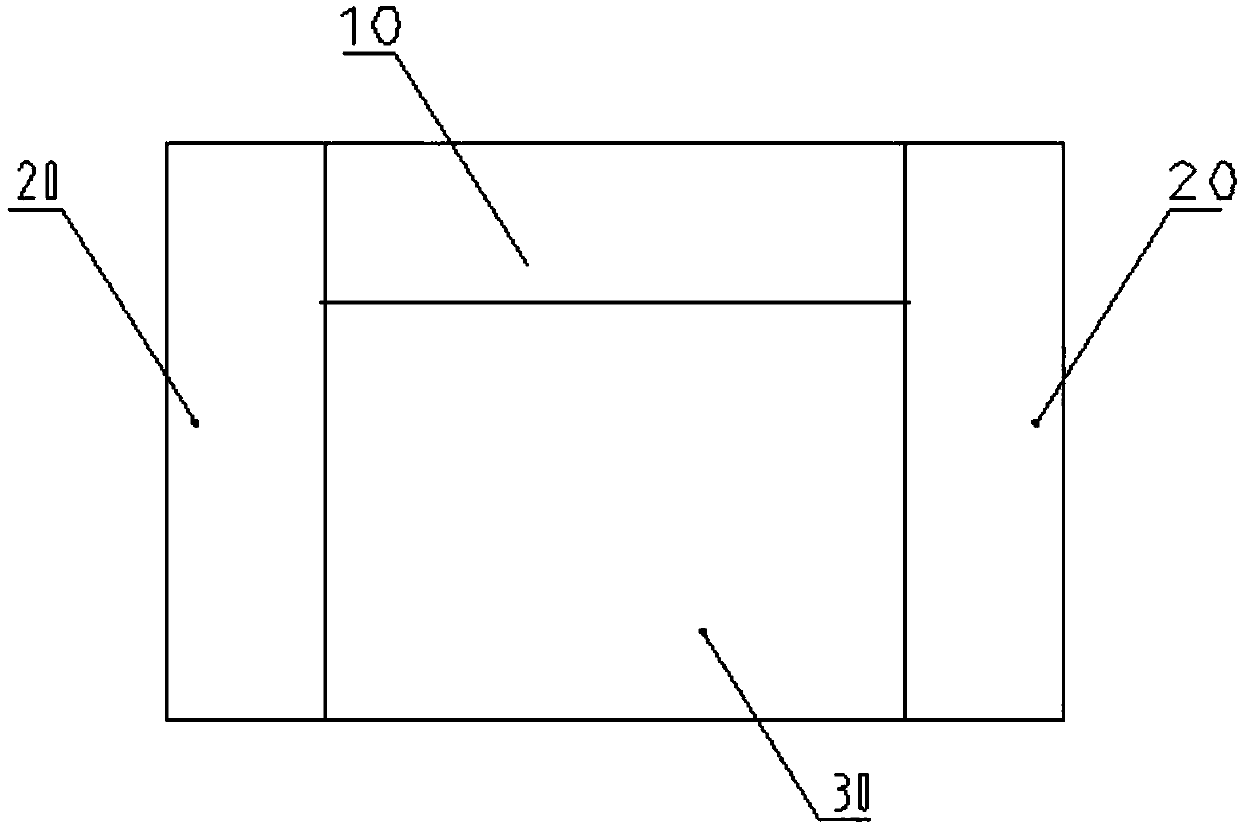

Filter case stretching material falling device

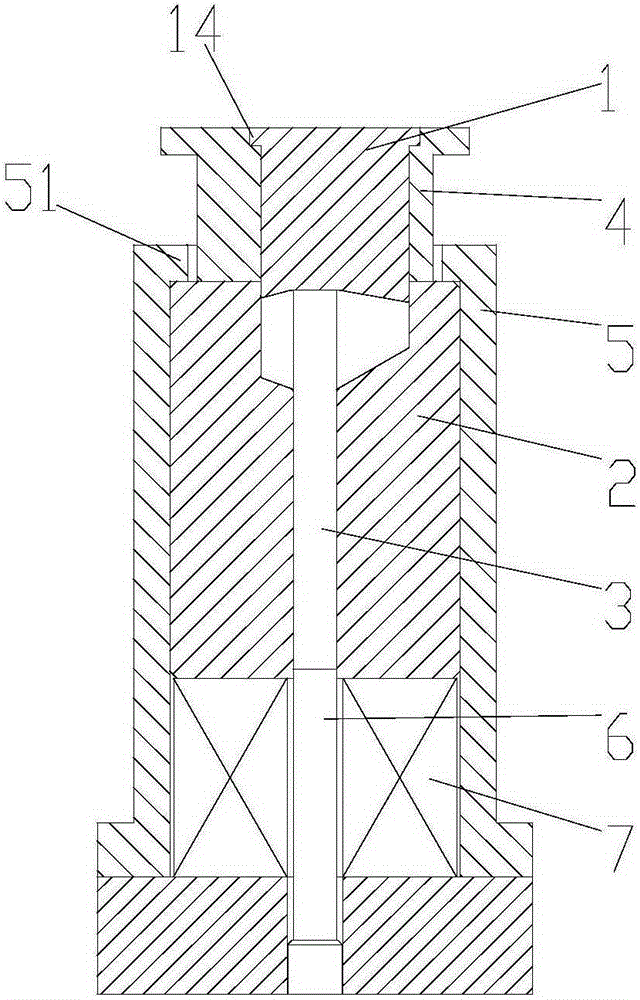

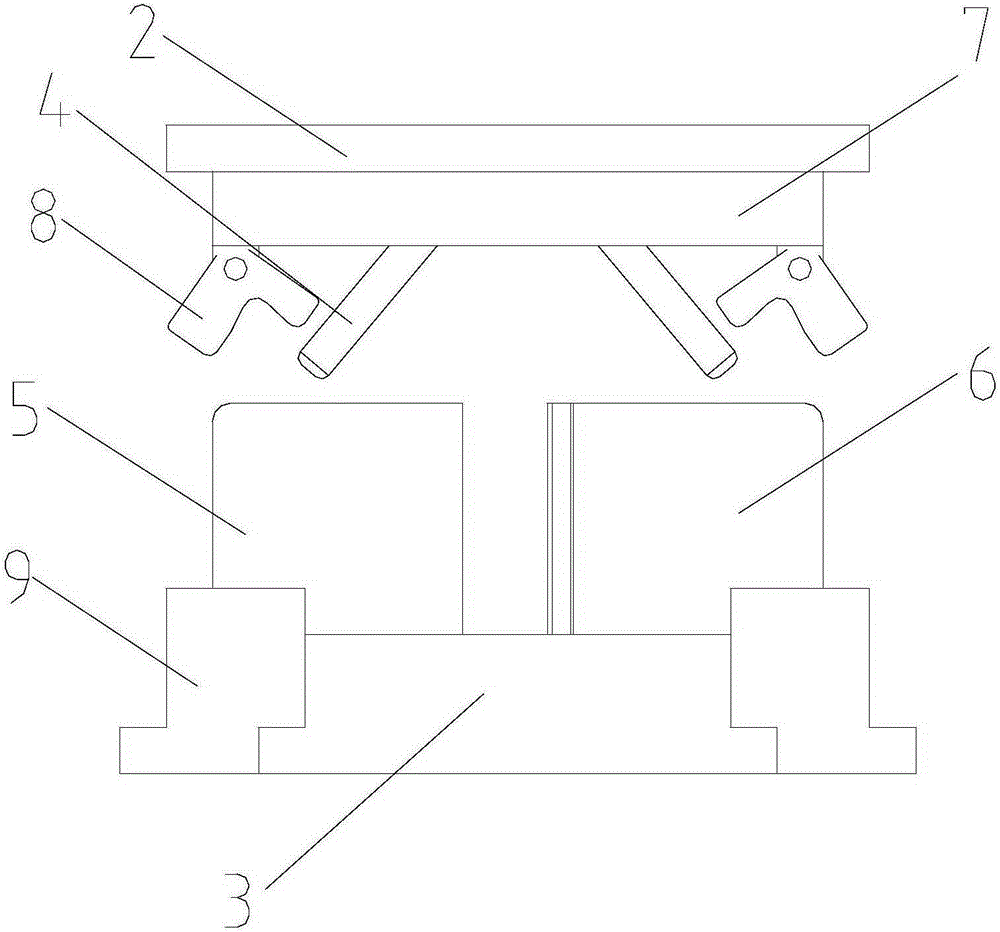

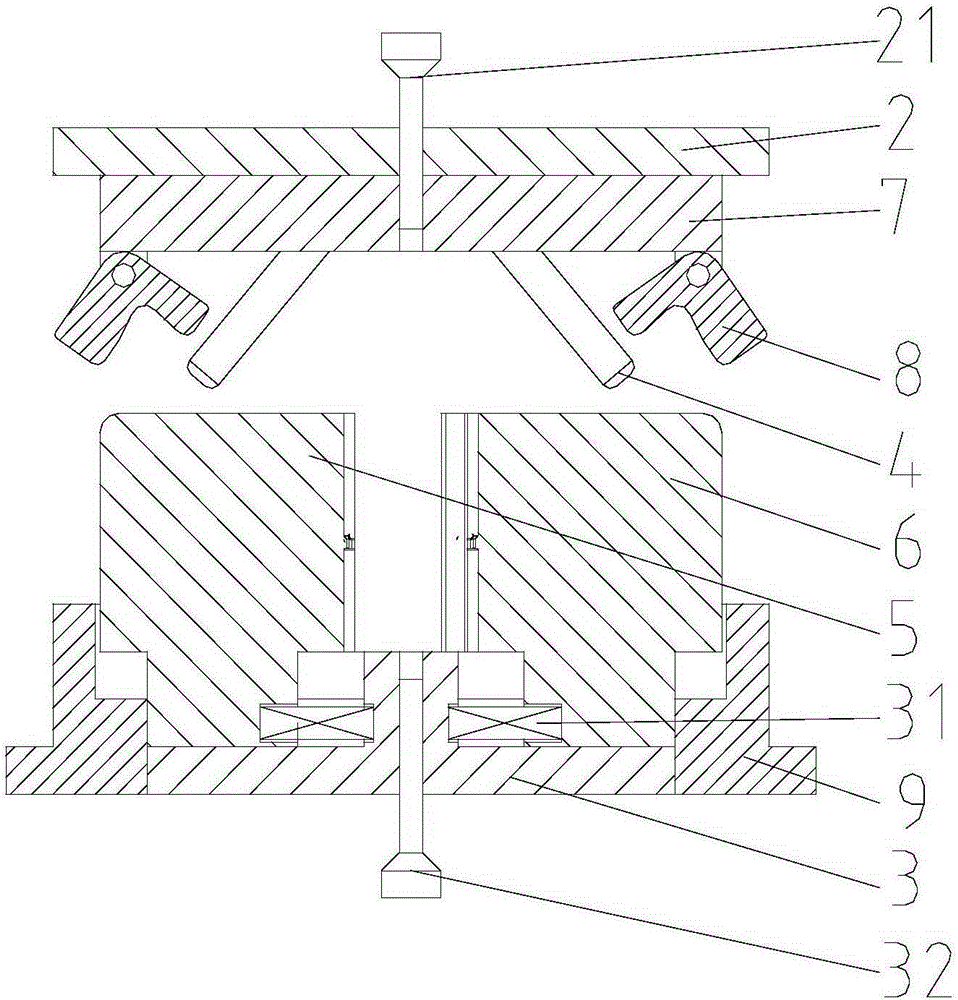

ActiveCN104226812AEasy to operateEasy to implement mechanicallyShaping toolsStripping-off devicesPunchingEngineering

The invention discloses a filter case stretching material falling device, which comprises an upper template (1) and a lower template (14), wherein a lower mold support frame (11) and a material pushing flat plate (10) are arranged on the lower template (14), a mold frame (9) is arranged on the material pushing flat plate (10), a material falling female mold (7) and a material falling male mold (6) are sequentially arranged on the mold frame (9) through a female mold positioning plate (8), the material falling male mold (6) is connected with the upper template (1) through a material falling connecting block (4), and material falling positioning blocks (3) are also arranged between the material falling male mold (6) and the upper template (1). The filter case stretching material falling device has the advantages that the operation is convenient, the mechanization and the automation can be easily realized, the filter case stretching material falling device is suitable for mass production of filter case parts, the production efficiency can be improved, the processing period can be shortened, the quality and the punching precision of products are ensured, in addition, the labor cost and the production cost are greatly reduced, a great amount of labor can be saved, and the rejection rate is reduced.

Owner:ZHEJIANG UNIVERSE FILTER

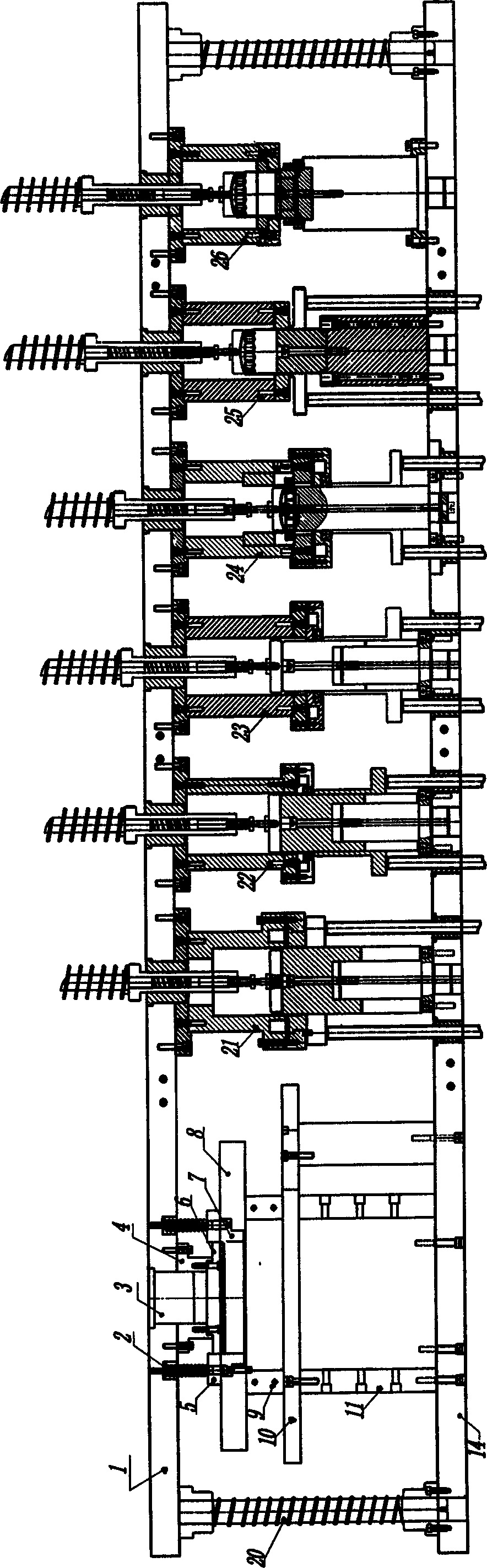

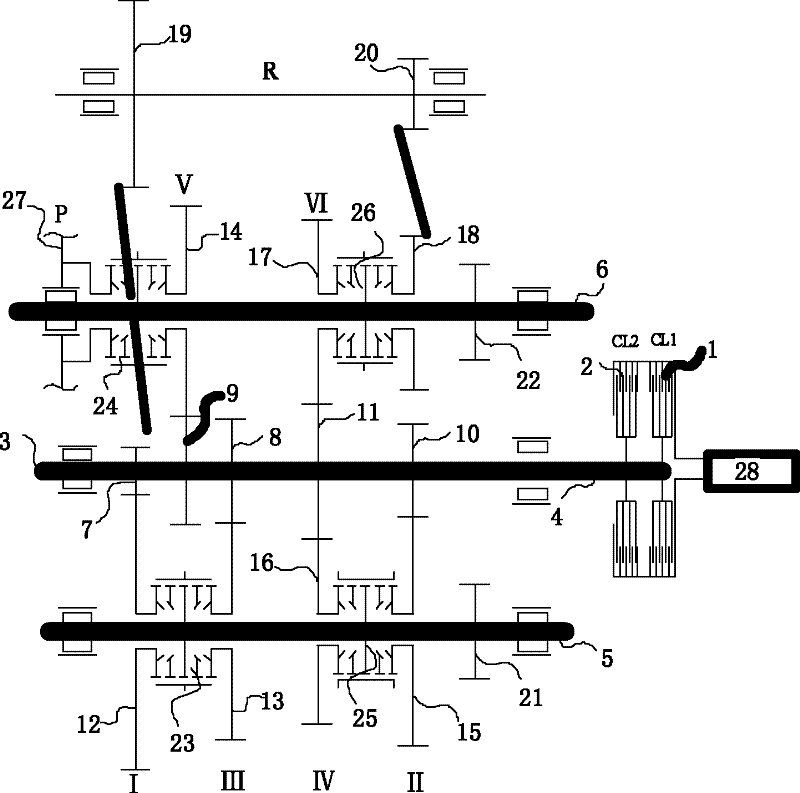

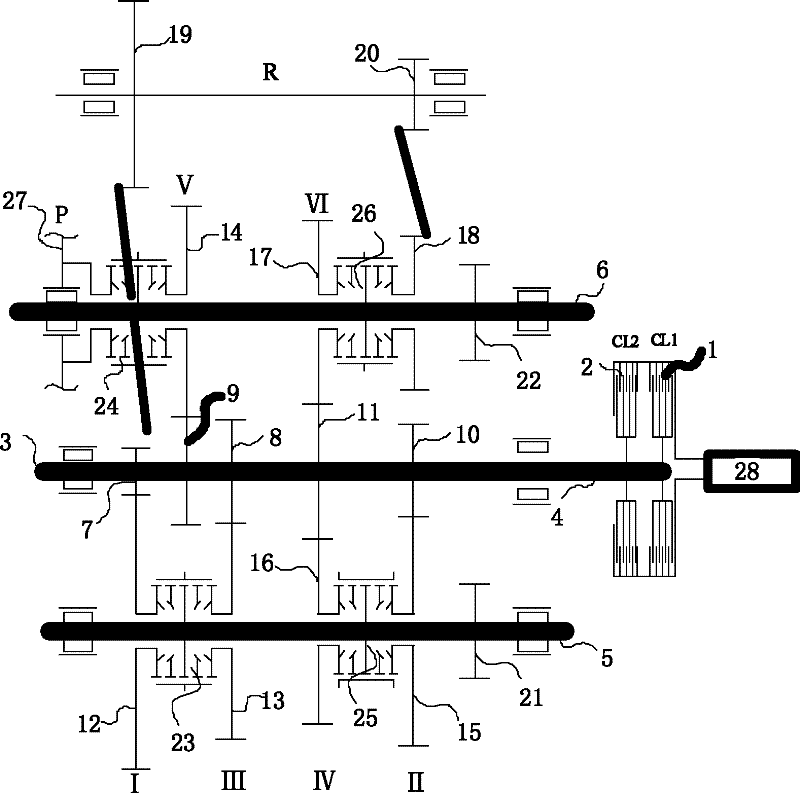

Double-clutch transmission with synchronizer parking device

The invention belongs to the field of transmissions, particularly relates to a double-clutch transmission with a synchronizer parking device, which is characterized in that: a double-clutch device which is integrated from two clutches is adopted, simultaneously a double-transmission input shaft which is combined from an inner shaft and an external sleeve shaft is arranged, an even number of stopping gear groups and an odd number of stopping gear groups are respectively connected with the two clutches respectively through the external sleeve shaft and the inner shaft, output driven gears are respectively arranged on two output shafts, wherein a synchronizer parking mechanism is arranged on one output shaft. According to the double-clutch transmission with the synchronizer parking device, the input shaft is a double-transmission input shaft which is combined from the inner shaft and the external sleeve shaft, the driving gears and the driven gears of all gears are meshed through the integration and the separation of the two clutches matched with a synchronizer, so that power is selectively transmitted to the output shafts in a certain conversion relationship, and is output discontinuously; and the special parking mechanism is omitted, so that the overall structure is the most compact, and an occupied space is small.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

Method for producing pineapple vinegar by utilizing full pineapple fruit

InactiveCN103789191AFruityMild sourMicroorganism based processesVinegar preparationBiotechnologyNutrition

The invention relates to a method for producing pineapple vinegar by utilizing full pineapple fruits. The method particularly comprises the following steps of washing fresh and mature pineapple fruits, and then crushing and squeezing the full pineapple fruits with peel residues and sarcocarp to obtain juice; filtering the pineapple juice; removing residues to obtain full fruit pineapple juice; adding sweet fermented glutinous rice fermented for 2-3 days to the pineapple juice according to the weight ratio of 1:(0.5-0.8) for alcoholic fermentation to improve the mouthfeel and quality of a finished product; carrying out acetic fermentation by mixing double acetic bacteria, fermenting at 30-35 DEG C for 6-8 days to obtain fermented original vinegar; filtering to remove sediments, and precipitating; indirectly heating the clarified fermented original vinegar to 50-55 DEG C, and keeping for 15-20 minutes; closely standing at ordinary temperature, and ageing for about 3 months. The pineapple fruit vinegar brewed through the method is strong in fruit flavour, gentle in sourness, mellow in mouthfeel and rich in nutrition, is easy and convenient to operate by obtaining the juice by crushing and squeezing the full pineapple fruits and can effectively increase the production efficiency and conveniently realize the large-scale production.

Owner:GUANGDONG OCEAN UNIVERSITY

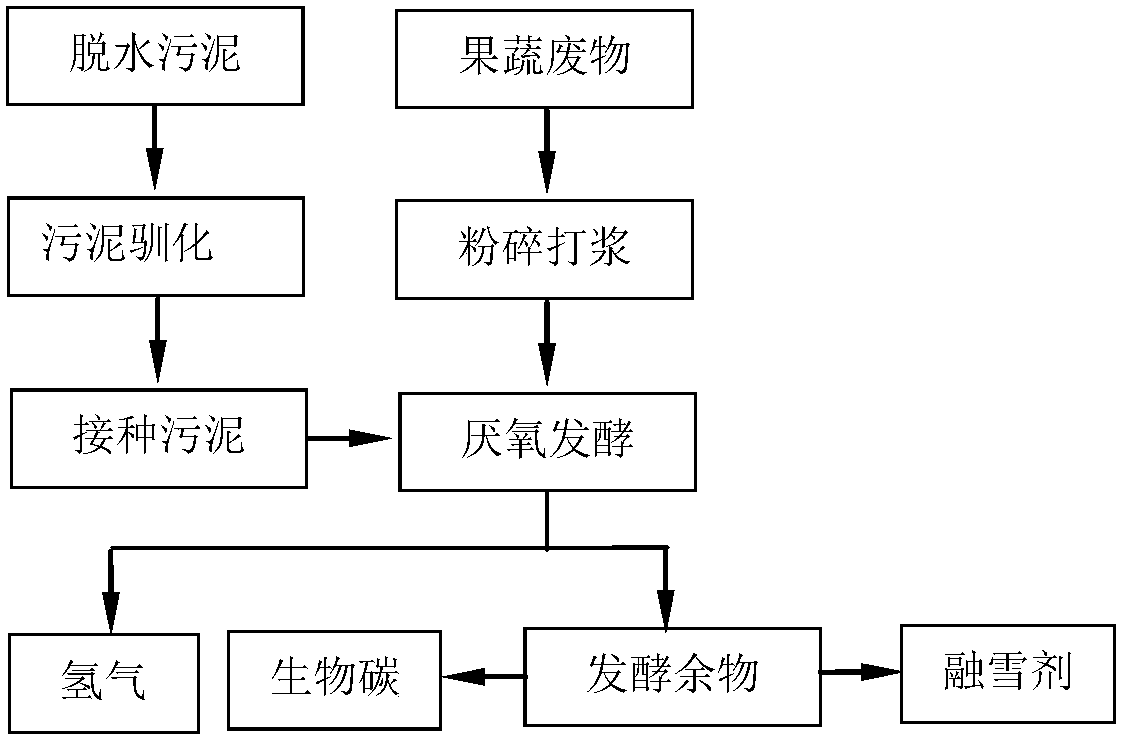

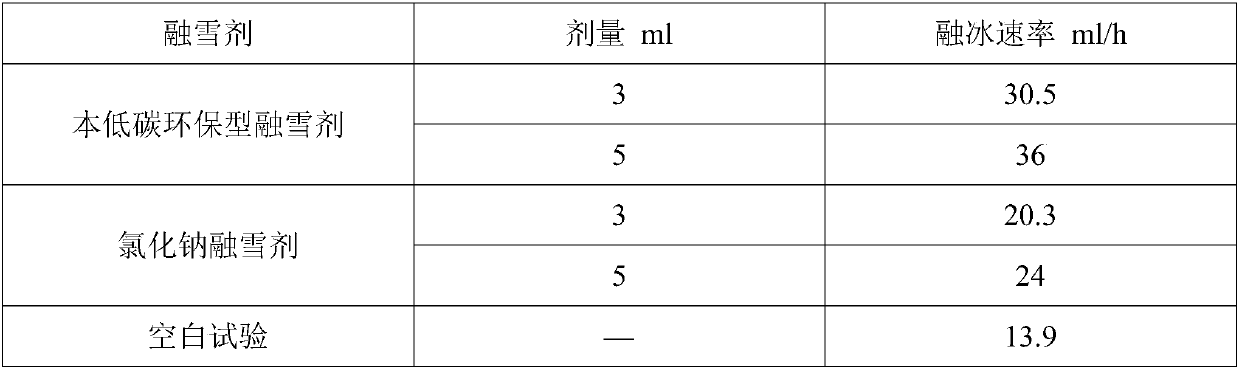

Preparation method of low-carbon environment-friendly snow melting agent

ActiveCN108018024ARealize high-value utilizationAvoid secondary pollutionOther chemical processesSolid componentLiquid product

The invention relates to a preparation method of a low-carbon environment-friendly snow melting agent, and relates to the field of fermentative hydrogen production and snow melting agents. The snow melting agent is generated through an acid-base neutralization reaction at suitable temperature with commercial calcium carbonate and metabolic products (organic mixed acid) generated when fruit and vegetable waste is subjected to anaerobic fermentative hydrogen production at medium temperature (35-38 DEG C) or high temperature (53-55 DEG C). The product is low in price, convenient to use, free of toxicity and corrosion and biodegradable, has no adverse effect on the growth of plants and is the efficient low-carbon environment-friendly snow melting agent. In addition, a liquid component generated after the operation of a solid-liquid separation unit is a liquid product of the low-carbon environment-friendly snow melting agent; a solid component is a substance containing cellulose, hemicellulose and lignin of calcium phosphate and other mineral fertilizer, serves as a raw material of biochar production and is used for soil improvement.

Owner:QILU UNIV OF TECH

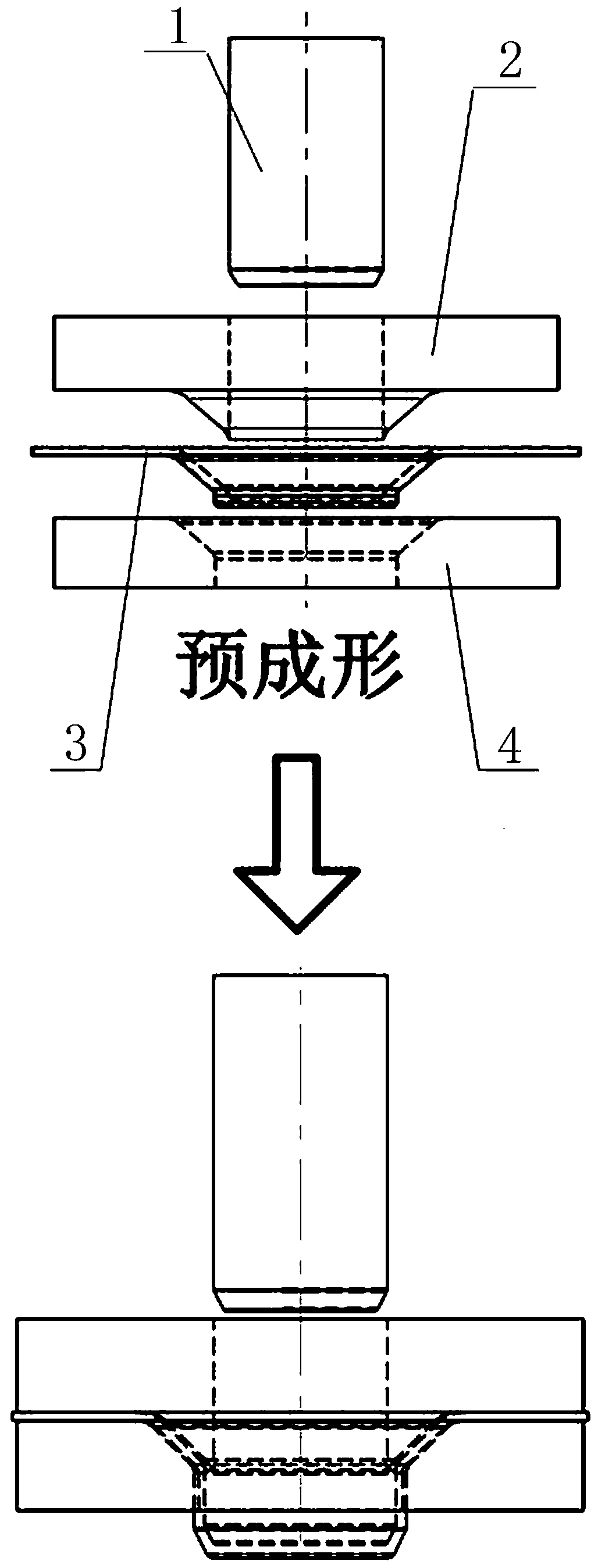

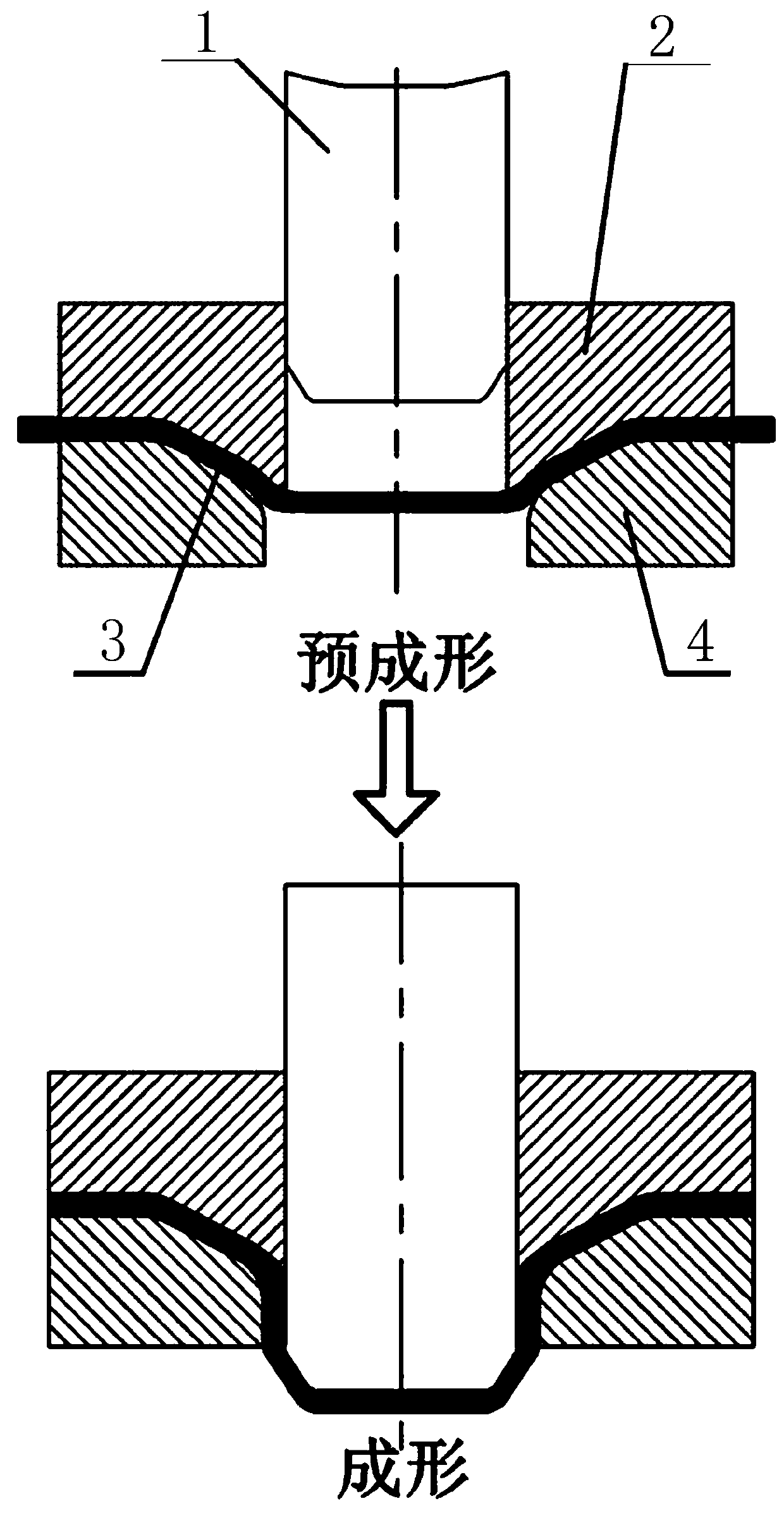

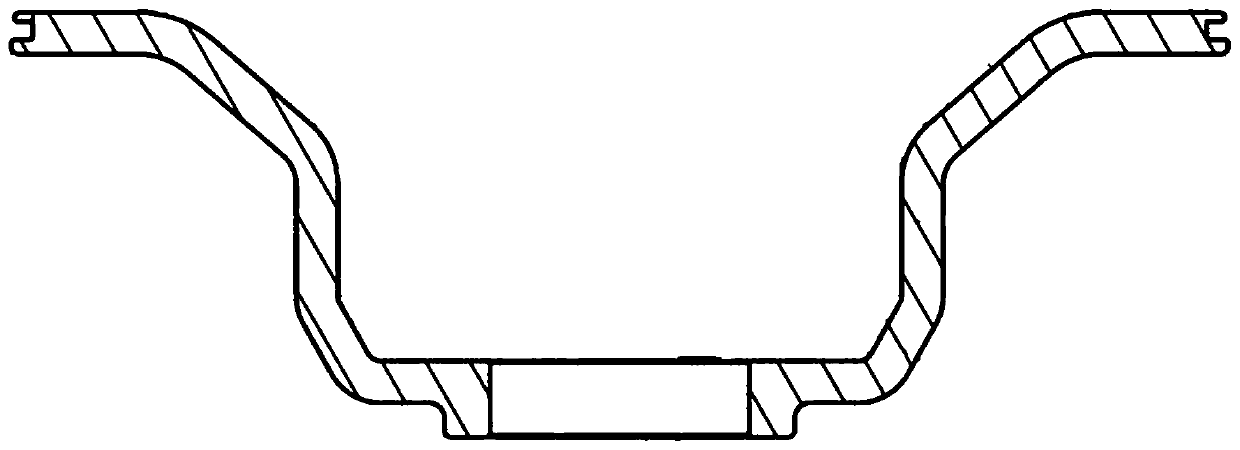

Hot stamping forming process for preparing vehicle driving belt wheel actuating cylinder

The invention discloses a hot stamping forming process for preparing a vehicle driving belt wheel actuating cylinder. The hot stamping forming process comprises the steps of blanking, specifically, aplate is put into a blanking die for blanking, and a blank obtained after blanking is cleaned to remove greasy dirt or dust; heating, specifically, the cleaned plate is heated in a heating furnace toan austenite state, and heat preservation is carried out; performing, specifically, after the plate is heated, the plate is quickly transferred to a female die of a thermoforming die, and an edge pressing slide block drives a conical edge pressing ring to press the plate for performing; forming, specifically, after preforming, a drawing slider drives a male die to press down for forming, the edgeof the plate or the semi-finished product is formed into a vertical edge according to a certain curvature along a certain curve, so that forming is completed; punching, specifically, the material is put into a flanging and punching die to be subjected to flanging and punching; heat treatment, specifically, heat treatment is carried out on the thermoforming piece; and trimming and shaping, specifically, the material is put into a trimming die for trimming, and put into a shaping die for shaping. The hot stamping forming process is simple in process steps and operation, easy for achieving mechanization and automation, and suitable for batch production.

Owner:TAIYUAN UNIV OF TECH

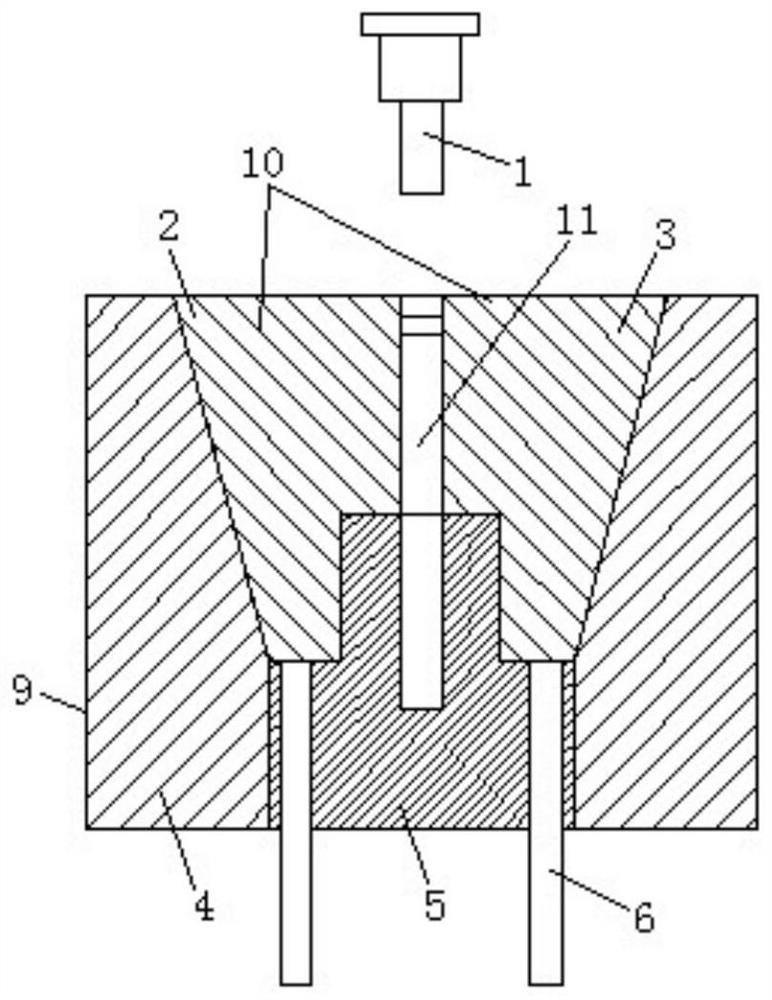

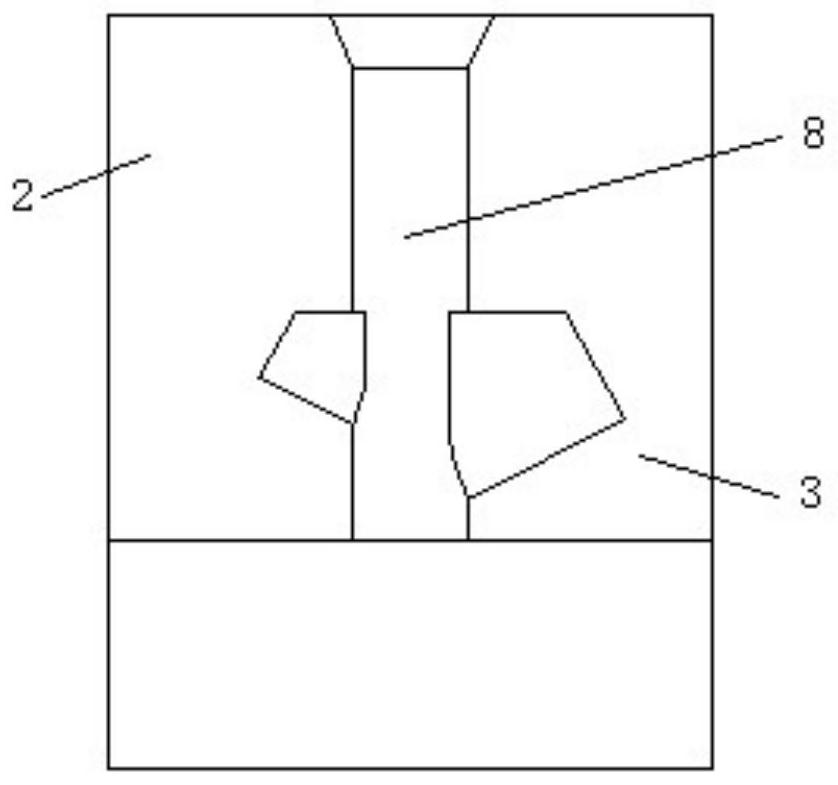

Closed pre-forging molding die for special-shaped oil spray device body workblank and process of closed pre-forging molding die

ActiveCN105290291ASmall free upsetting heightAvoid bending and foldingForging/hammering/pressing machinesFace shapeMaterials science

The invention belongs to the field of forging molding. A closed pre-forging molding die for a special-shaped oil spray device body workblank comprises an upper die body and a lower die body. A die cavity is formed in the lower die body. The die cavity comprises an upper die cavity corresponding to the head of the special-shaped oil spray device body workblank and a lower die cavity corresponding to the tail of the special-shaped oil spray device body workblank. The upper die cavity is defined by the side faces and the bottom face. The side face shape of the upper die body is matched with the shape of the upper die cavity. An ejector rod is arranged in the lower die cavity in a sliding manner. A process for molding the special-shaped oil spray device body workblank through the closed pre-forging molding die includes the following steps of blanking, heating, closed pre-forging, finish forging, trimming and post-processing, wherein in the closed pre-forging step, tag swaging is conducted under the support of the side faces of the upper die cavity of the closed pre-forging die. The closed pre-forging molding die and the process have the beneficial effects that in the closed pre-forging process, a special die structure is adopted, and a blank is supported laterally to be prevented from being bent and folded; and production efficiency is high, the material utilization rate is high, the forging streamline is good, quality is good, and mechanization and automation are easy to realize.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

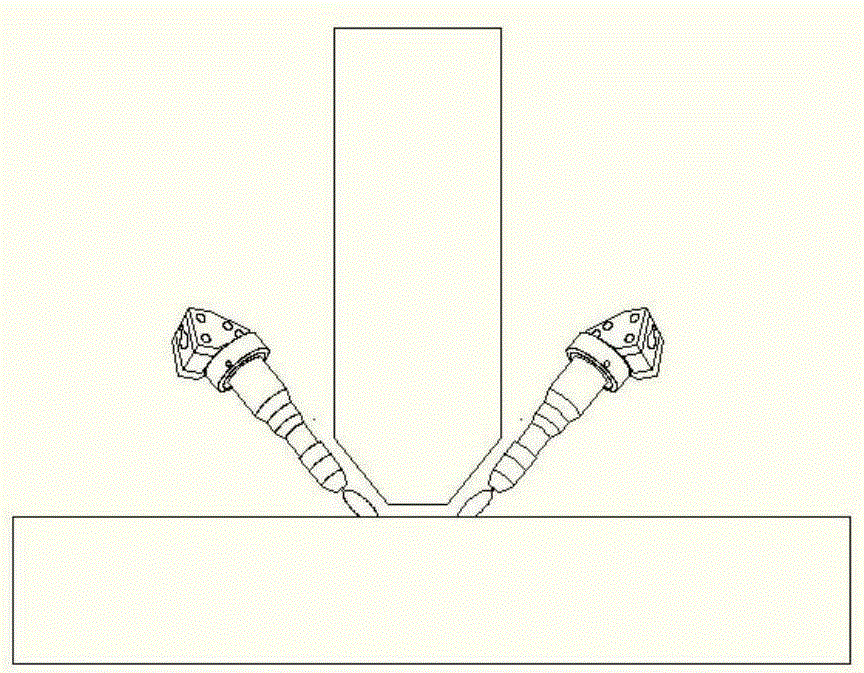

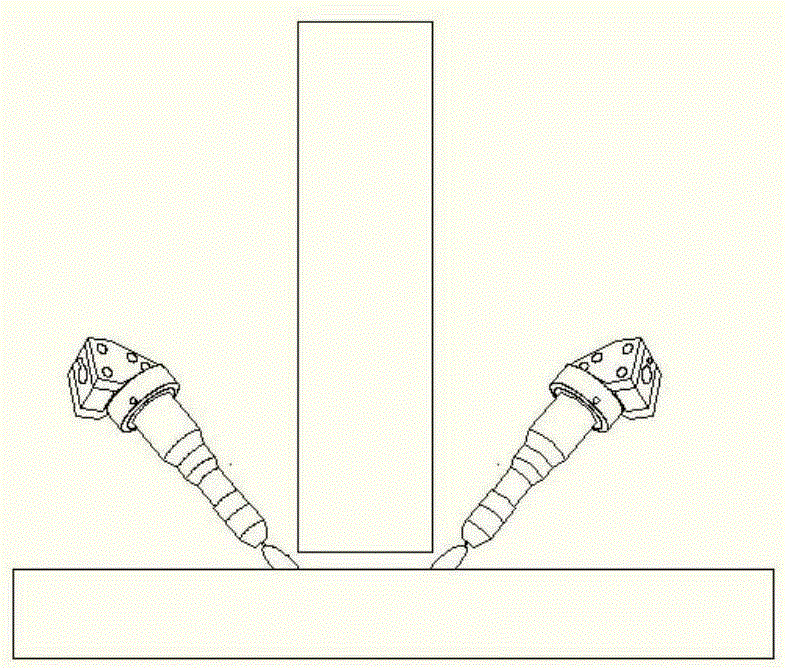

InFocus electric arc synchronous welding method for two sides of T-shaped connector

InactiveCN105149740AImprove protectionDesign scienceArc welding apparatusWelding/soldering/cutting articlesThick platePeak value

The invention relates to an InFocus electric arc synchronous welding method for the two sides of a T-shaped connector. The method comprises the steps that firstly, a workpiece is treated and fixed through a clamp; secondly, the included angle alpha between an InFocus welding gun and the longitudinal surface of a T-shaped connector faceplate is kept to be 30-45 degrees, and the included angle beta between the InFocus welding gun and a T-shaped base plate is kept to be 30 degrees; thirdly, technological parameters are set, the welding current is 300 A-900 A, the gas flow of the electric arc welding gun is 15 L / min-30 L / min, the welding speed is 0.6 m / min-3.0 m / min, and the wire feeding speed is 4.0 m / min-10.0 m / min; and fourthly, welding is conducted. Compared with the peak value of a traditional tungsten inert gas (TIG) electric arc 400A, the acting force and the energy density of the current are large; the welding of a keyhole can be achieved; the InFocus electric arc synchronous welding method is big in welding penetration and high in welding speed; the welding efficiency is greatly improved; a middle thick plate can be welded.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

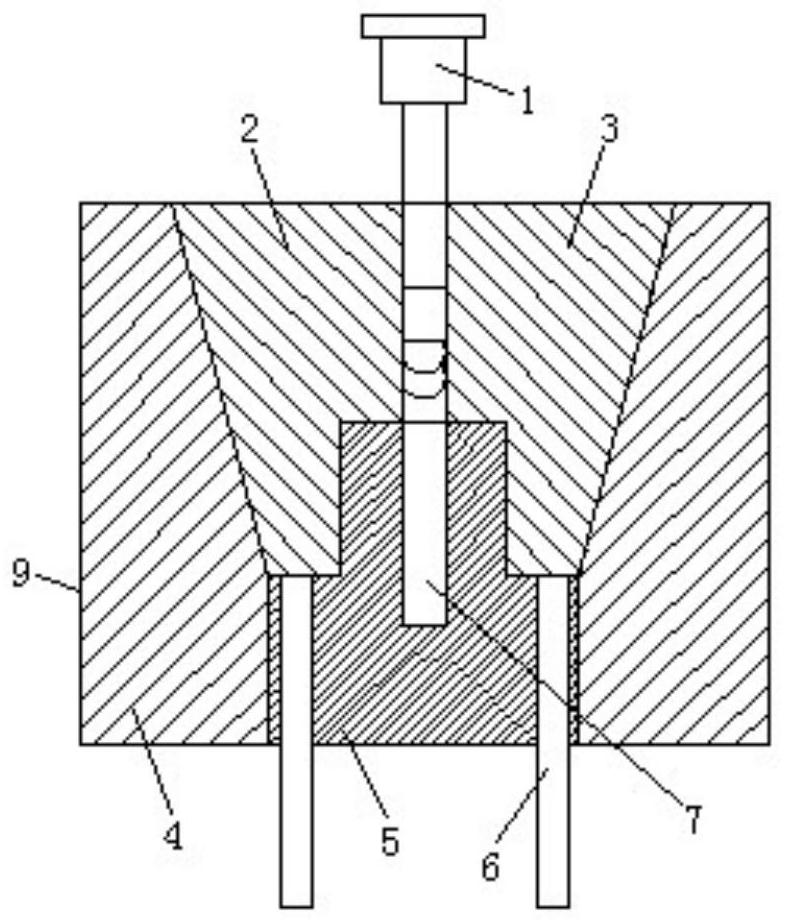

Guide-pin-based multidirectional closed forging device and technology for special-shaped oil sprayer body

ActiveCN105195659ASimplify the forging processIncrease productivityForging/hammering/pressing machinesSprayerMedium frequency

The invention belongs to the technical field of oil sprayer body forging, and discloses a guide-pin-based multidirectional closed forging technology and device for a special-shaped oil sprayer body. The technology includes the steps that a bar with the diameter slightly smaller than the minimum diameter of a forge piece is adopted to be fed, and the blank is heated to the forging temperature through a medium-frequency induction furnace and placed into the closed forging device; the device can perform lateral mold assembling under the effect of guide pins, the whole closed forging device moves downwards after a left female mold and a right female mold are locked through locking blocks, and the blank is molded under the effect of an upper male mold and a lower male mold; in the process that the closed forging device moves upwards after molding, the upper male mold is released, the left female mold and the right female mold are opened, and a workpiece is jacked out through the lower male mold. According to the technology and device, due to multidirectional parting, one-step closed forging molding of the special-shaped oil sprayer body is achieved, the forging technology is simplified, production efficiency and product performance are improved, and mechanization and automation can be easily achieved.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

Low-alloy bainite ductile iron oil quenching isothermal tempering heat treatment process

A low alloy bainite ductile iron oil quenching with temperature isothermal tempering heat treatment process includes: (1) heating a ductile iron work piece to be at 880 to 960 DEG C for the austenization; (2) quenching the work piece in machine oil; (3) taking out the ductile iron work piece when the surface temperature is 150 to 230 DEG C; (4) keeping the ductile iron work piece with temperature and rapidly burying sands for the heat preservation and the tempering for 6 to 8 hours; or burying sands for the heat preservation and the tempering for 1 to 3 hours and then taking the work piece out for the air cooling. Through refractory bricks and molding sands in an insulation packet or a ground pit, the process forms a reasonable temperature gradient from the inside of the ductile iron to the surface, a sands layer, the insulation packet or the ground pit. The slow and stable cooling speed which accords with the requirement is established. The isothermal tempering temperature is effectively controlled. The residue heat after the heat treatment on the ductile iron work piece is used to realize the isothermal transformation from austenite to bainite, which is more beneficial to the formation of bainite tissues. The obtained ductile iron work piece tissues have the advantages of reasonable structure and perfect comprehensive property and are especially applied to gears, crankshafts, grinding balls, etc.

Owner:GUILIN UNIV OF ELECTRONIC TECH

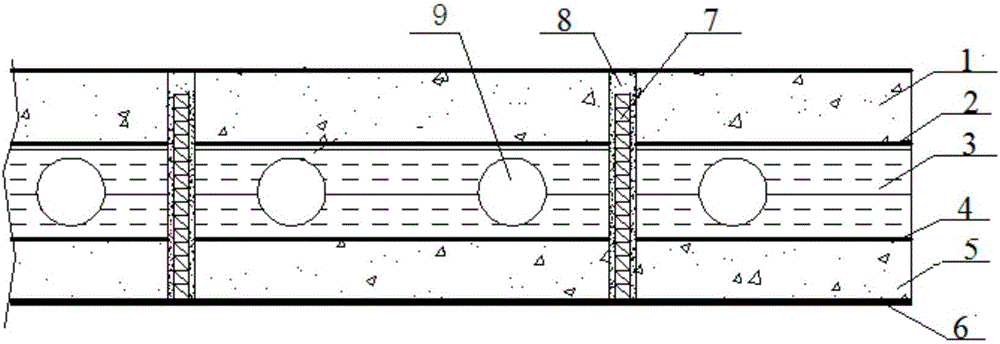

Production method of light composite board for floor separation and roof

InactiveCN105667005AImprove bending abilityImprove ductilityBuilding componentsConstructions elementsReinforced concreteAdhesive

The invention discloses a production method of a light composite board for floor separation and a roof. The upper surface of a reinforced concrete bottom plate is coated with a structural adhesive, galvanized steel wire netting is laid on the reinforced concrete bottom plate, an SIP core board is arranged on the galvanized steel wire netting, and the reinforced concrete bottom plate, the galvanized steel wire netting and the SIP core board are aligned in the longitudinal direction; the upper surface of the SIP core board is coated with the structural adhesive, galvanized steel wire netting is laid on the SIP core board, a reinforced concrete roof board is stacked on the galvanized steel wire netting, and the SIP core board, the galvanized steel wire netting and the reinforced concrete roof board are aligned in the longitudinal direction; compaction is performed under self-weight, and all the parts are bonded and composited to form a whole after the structural adhesive is naturally solidified. According to the produced light composite board, the structure self-weight is reduced under the condition that the bearing capacity of the structure is guaranteed, and impact load which is probably caused to a lower structure under a collapse work condition is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

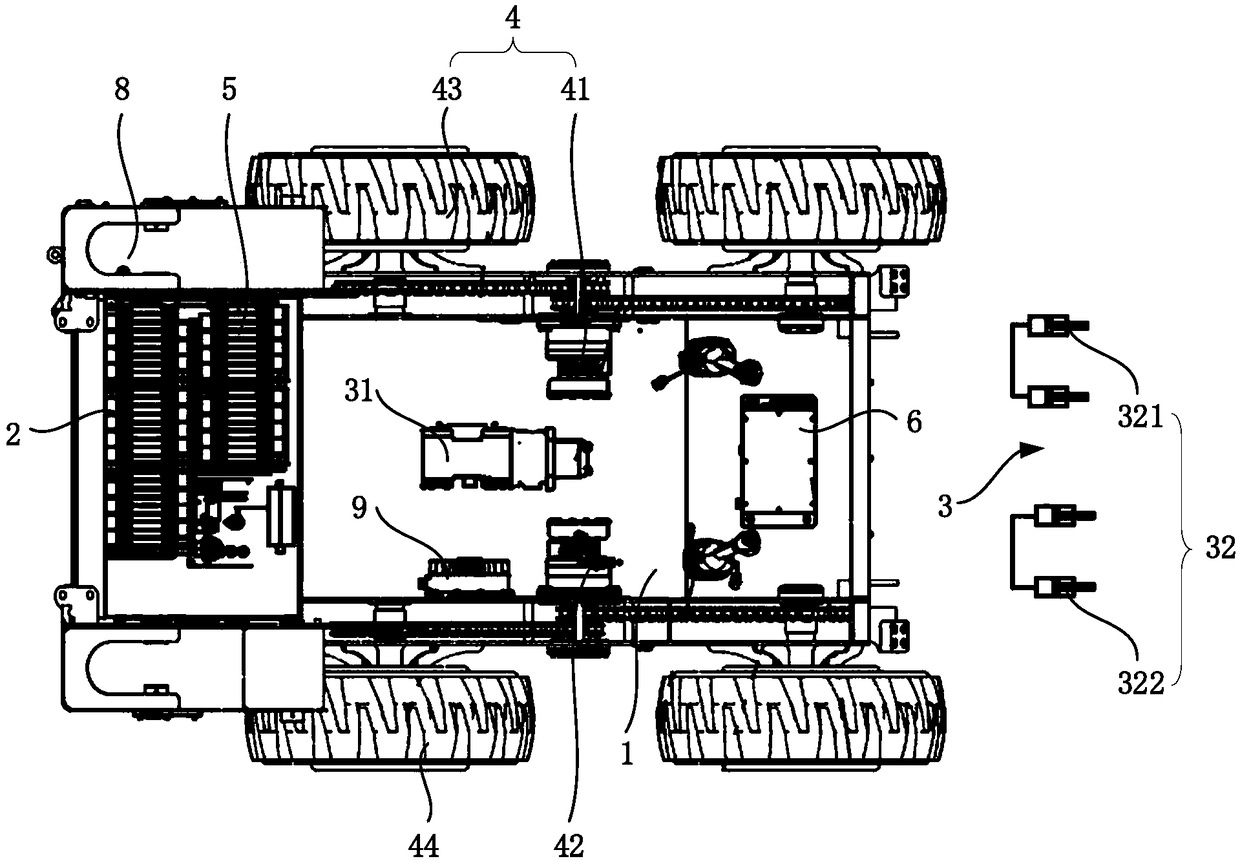

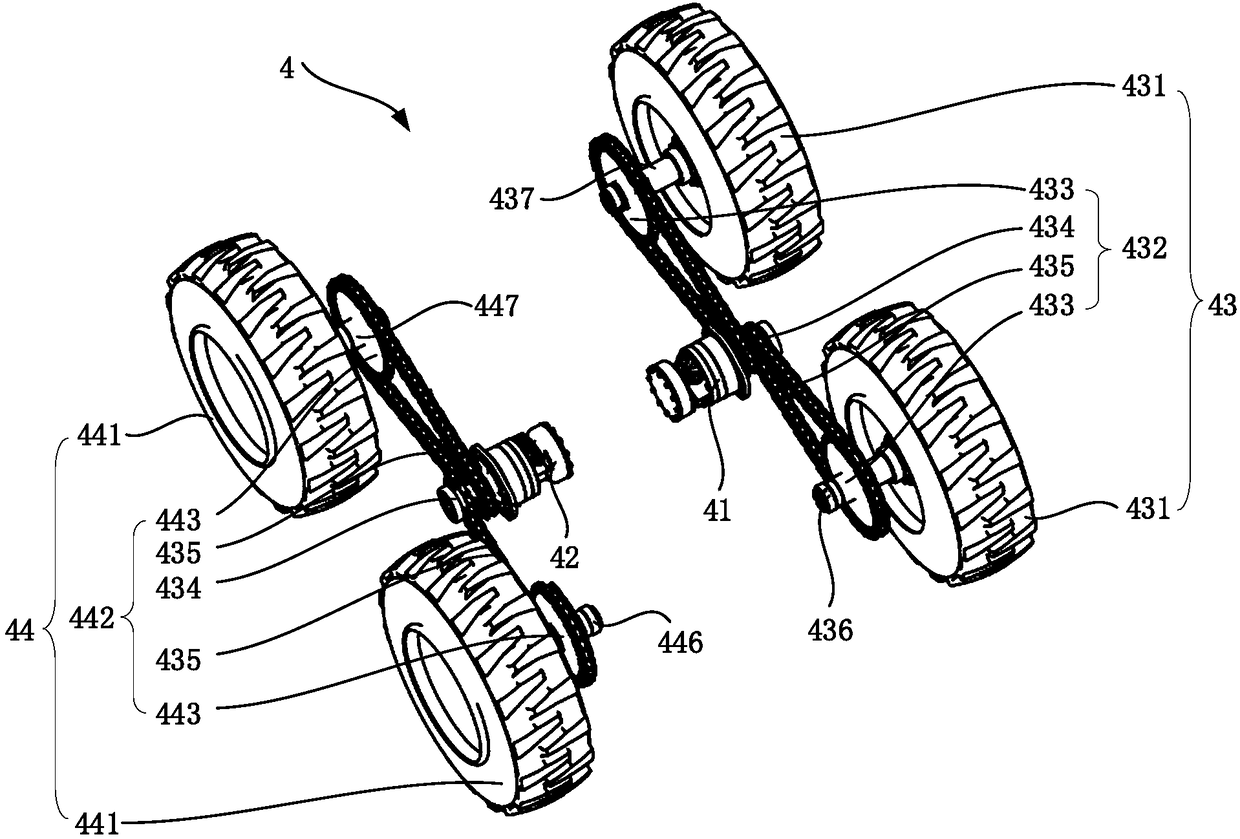

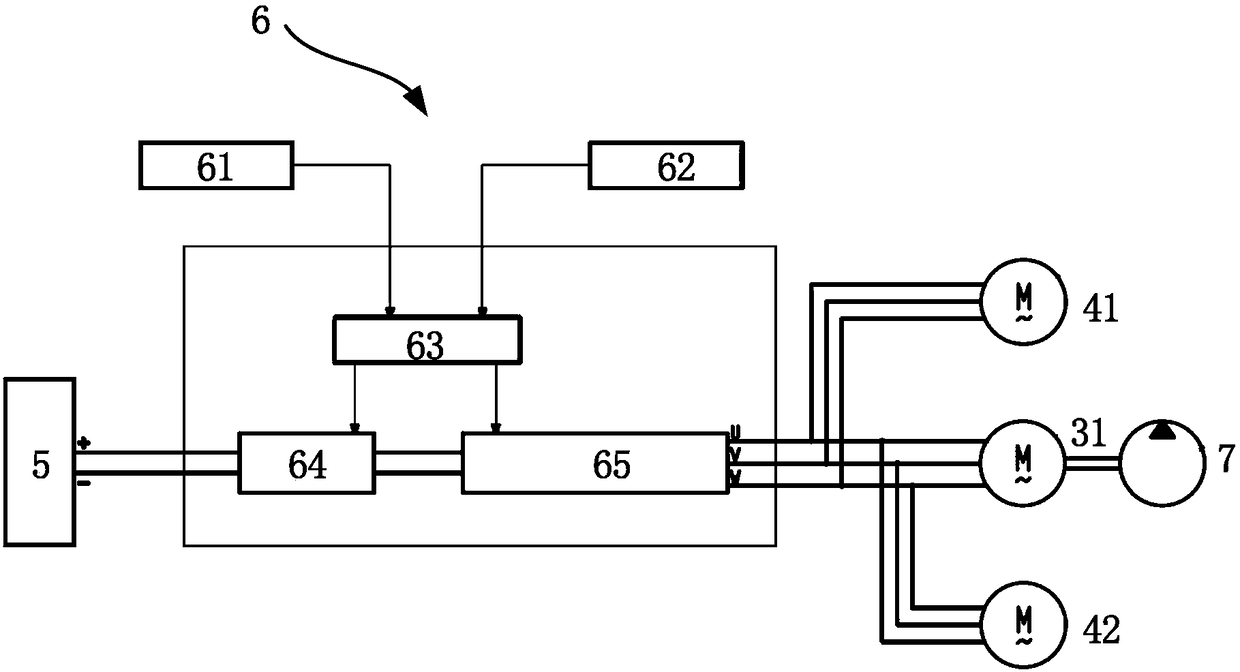

Skid-steer loader and control method thereof

PendingCN108385765AReduce working noiseAchieving zero emissionsSoil-shifting machines/dredgersVehicle frameRechargeable cell

The invention discloses a skid-steer loader, and relates to the field of engineering machinery and is used for optimizing the performance of the existing skid-steer loader. The skid loader comprises aframe, a rechargeable battery, a working system and a walking system. The working system comprises a working motor and an executing mechanism. The walking system comprises a first walking motor, a second walking motor, a first walking wheel assembly and a second walking wheel assembly. The frame supports the installation of other components. The rechargeable battery is arranged on the frame. Rechargeable batteries are used to power the working motors on skid steer loaders as well as the traveling motors. According to the technical scheme, the working noise of the skid-steer loader is reduced,the skid-steer loader is clean and environment-friendly, zero emission of pollutants is realized, and the cost is reduced.

Owner:XCMG CONSTR MACHINERY

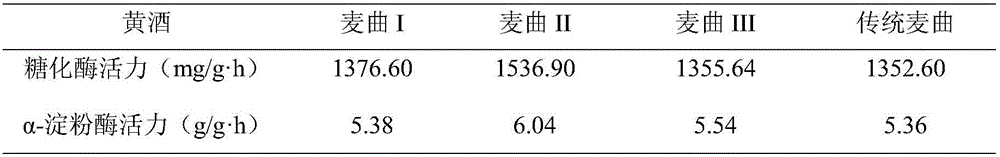

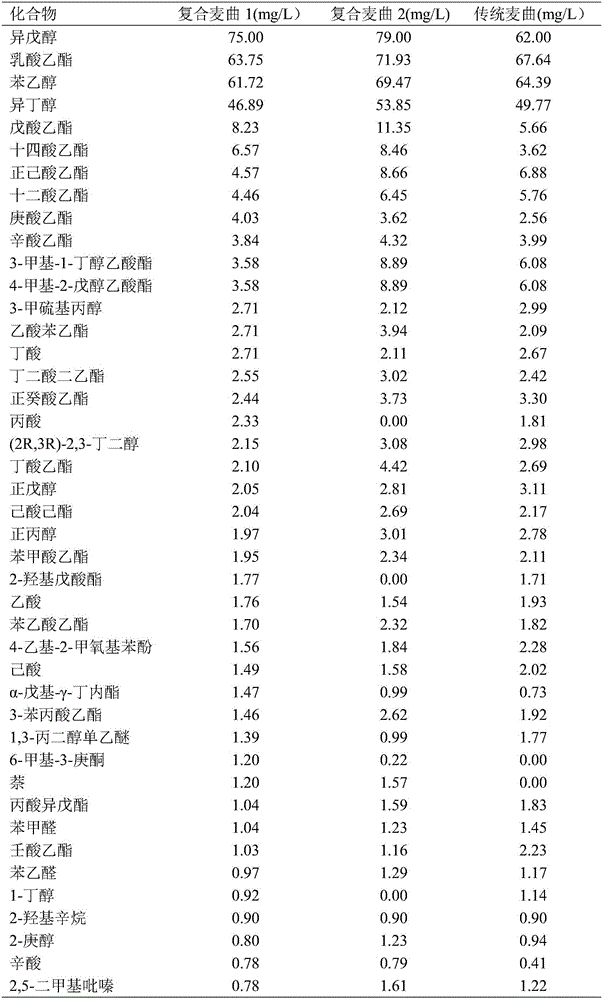

Composite raw wheat kojis and production method thereof

ActiveCN106591055AReasonable production process designEasy to operateAlcoholic beverage preparationBiotechnologyOxygen content

The invention discloses composite raw wheat kojis and a production method thereof, and belongs to the technical field of wine brewing. The production process comprises the steps of firstly, according to a traditional koji making method, rolling and crushing wheat, adding water, wetting the material, then dividing the wheat into 3 parts, respectively placing the 3 parts in drum fermenting devices, controlling the temperature, humidity and oxygen content by stages, and culturing to obtain the wheat kojis containing different microflora. The wheat kojis are mixed for use according to a certain proportion, and wine bodies with different flavors and tastes can be obtained. The method is easy to operate, saves manpower and is prone to realization of mechanized operation.

Owner:JIANGNAN UNIV

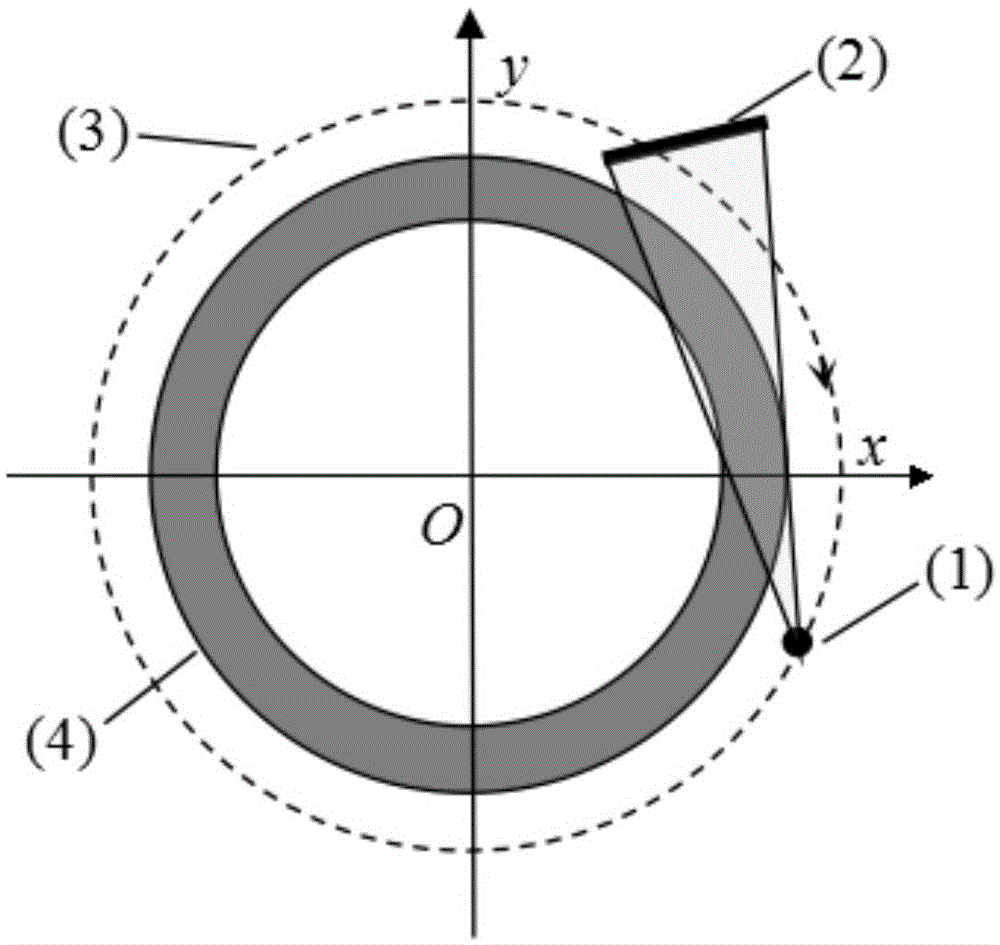

Double-periphery external CT detection device based method and system for on-line detection of large-diameter pipe wall

ActiveCN106066335AEasy to implement mechanicallyRay beam angle is smallMaterial analysis by transmitting radiationDetector arrayPhysics

The invention relates to a double-periphery external CT detection device based method and system for on-line detection of a large-diameter pipe wall. The system includes an X-ray source, an area array detector I and an area array detector II, and a control and image processing system. The signal lines of the X-ray source and area array detector are connected to the control and image processing system. A circular orbit is fixed in the pipeline, so that the center of the circular orbit superposes with the center of circle of a cross section of the pipeline and the overlap; the X-ray source, area array detector I and area array detector II are respectively fixed on the circular orbit; the area array detector array detectors I and II are symmetrically arranged on both sides of the pipeline in offset arrangement, so that a cone beam produced by the X-ray source covers the outer wall area of the pipeline. The invention can scan and reconstruct the image of the outer annular region of the larger-diameter pipeline by using low-energy ray and smaller size detector; the ray beam has smaller field angle, and good ray consistency; and the invention can be used for reconstruction of the three-dimensional image of external annular region of pipeline wall (including fixed pipe).

Owner:CHONGQING UNIV

One-step oil-removal rust-removal phosphatization technology of steel workpiece

InactiveCN104250780ANo heating requiredSave energyMetallic material coating processesThioureaPhosphate

The invention discloses a one-step oil-removal rust-removal phosphatization technology of a steel workpiece. A phosphatization liquid used by the one-step oil-removal rust-removal phosphatization technology comprises 165-175g / L of phosphoric acid having a concentration of 85%, 22-28g / L of nickel dihydrogen phosphate, 14-18g / L of zinc dihydrogen phosphate, 6-8g / L of cobalt dihydrogen phosphate, 6-8g / L of sodium chlorate, 2-4g / L of sodium 3-nitrobenzene sulfonate, 2-4g / L of potassium ferrocyanide, 1-3g / L of ammonium molybdate, 2-4g / L of thiourea, 11-15g / L of tartrate, 6-10g / L of OP-10 and the balance water. The one-step oil-removal rust-removal phosphatization technology comprises the following steps of preparing the phosphatization liquid from the above components, adjusting free acidity to 14-20 and total acidity to 200-240, keeping a temperature of the phosphatization liquid in a range of 15-35 DEG C, putting a steel workpiece into the phosphatization liquid for phosphatization treatment for 25-35min, taking out the treated steel workpiece and carrying out airing in a ventilated place.

Owner:WUXI LUOSHE TECH VENTURE

Blocking forging device and forging process for special-shaped fuel injector body

PendingCN111745107ASimple structureImprove reliabilityForging/hammering/pressing machinesEngineeringMold removal

The invention discloses a blocking forging device for a special-shaped fuel injector body. The device comprises an upper mold and a lower mold for blank forming, wherein the lower mold comprises a lower mold sleeve, and a base is arranged inside the lower mold sleeve; the upper end of the base is provided with a sliding mold which is in sliding connection with the inner side face of the lower moldsleeve, and the lower end of the base is provided with movable ejection rods capable of ejecting the sliding mold out; and the sliding mold is composed of a left half mold and a right mold half whichare oppositely arranged. Forming of a cavity is achieved by the oblique sliding of the left half mold and the right half mold, and under the action of self-locking angles, the space positions of thehalf molds are kept stable without additional mechanism maintenance; and a forged piece can be simultaneously demolded from a shape hole of the base and the cavity of the half molds during ejection, so that one-step blocking forging forming of the fuel injector body is achieved, the forging process and the mold structure are simplified, mold parts are reduced, the parting surface is flat and freeof step surfaces, the unbalance loading phenomenon does not exist during forging, and the forming force is lower. The invention further provides a blocking forging process for the special-shaped fuelinjector body, and the blocking forging device is included in the blocking forging process.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

Pressure casting process for bearing block

The invention discloses a pressure casting process for a bearing block, which includes the steps: mounting a die; preheating the die; cleaning the die; spraying coatings on the die; placing the die on a die assembly device for die assembly; selecting injection pressure and filling speed; injecting liquid metal into a cavity and leading the cavity to be filled with the liquid metal; continuing injection under the action of an injection plunger until the liquid metal filled to a flow gate of the cavity is completely solidified; taking out a casting by opening the cavity after maintaining pressure; and cleaning the casting. The pressure casting process has the advantages that fine product quality is ensured, precision, strength and hardness are high, machining amount is small, large quantities of machining equipment and machining time are reduced, metal utilization rate is increased, both assembly time and the metal are saved, production efficiency is high, and mechanization and automation are easy to realize.

Owner:南通新景华企业管理服务有限公司

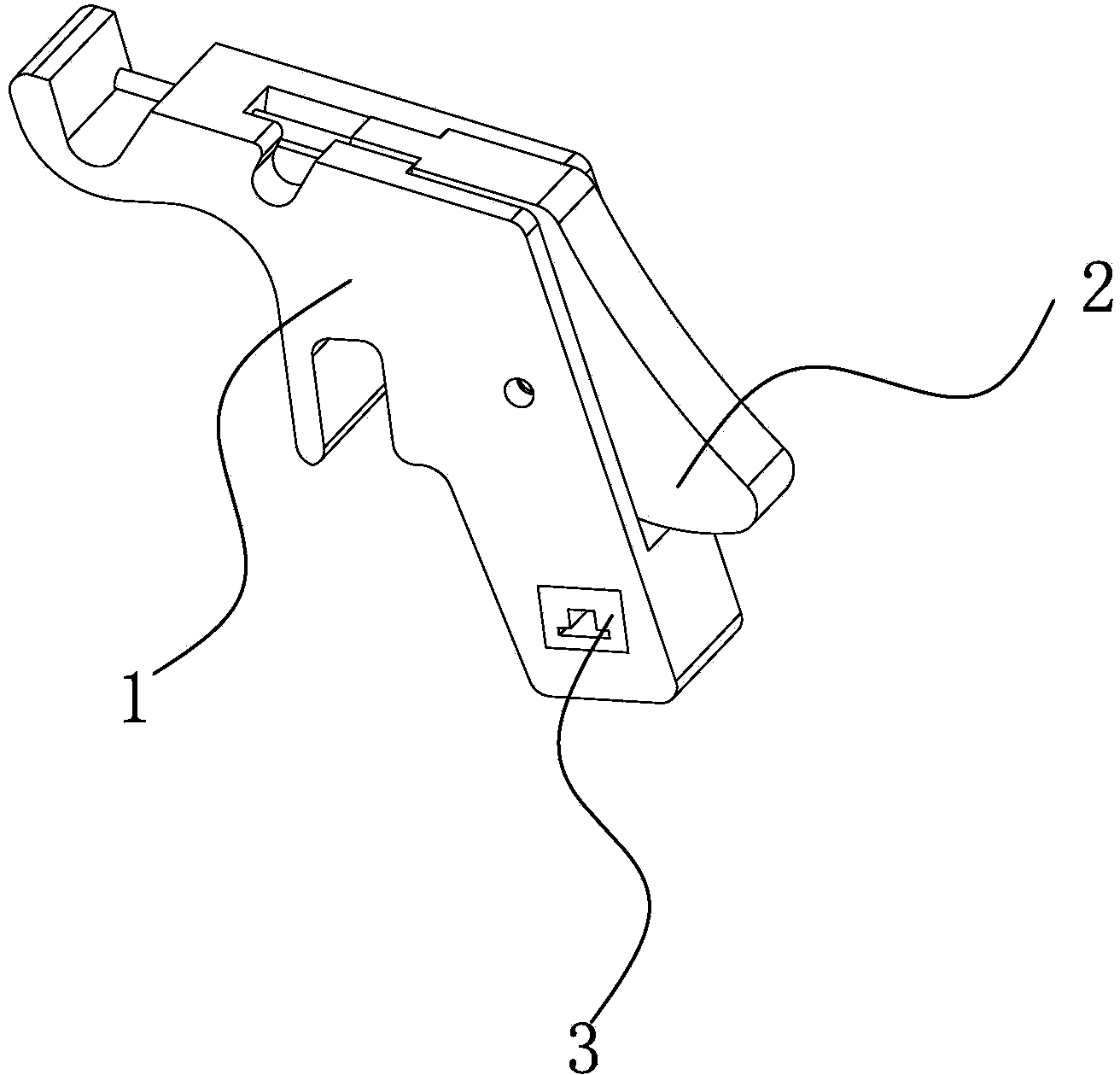

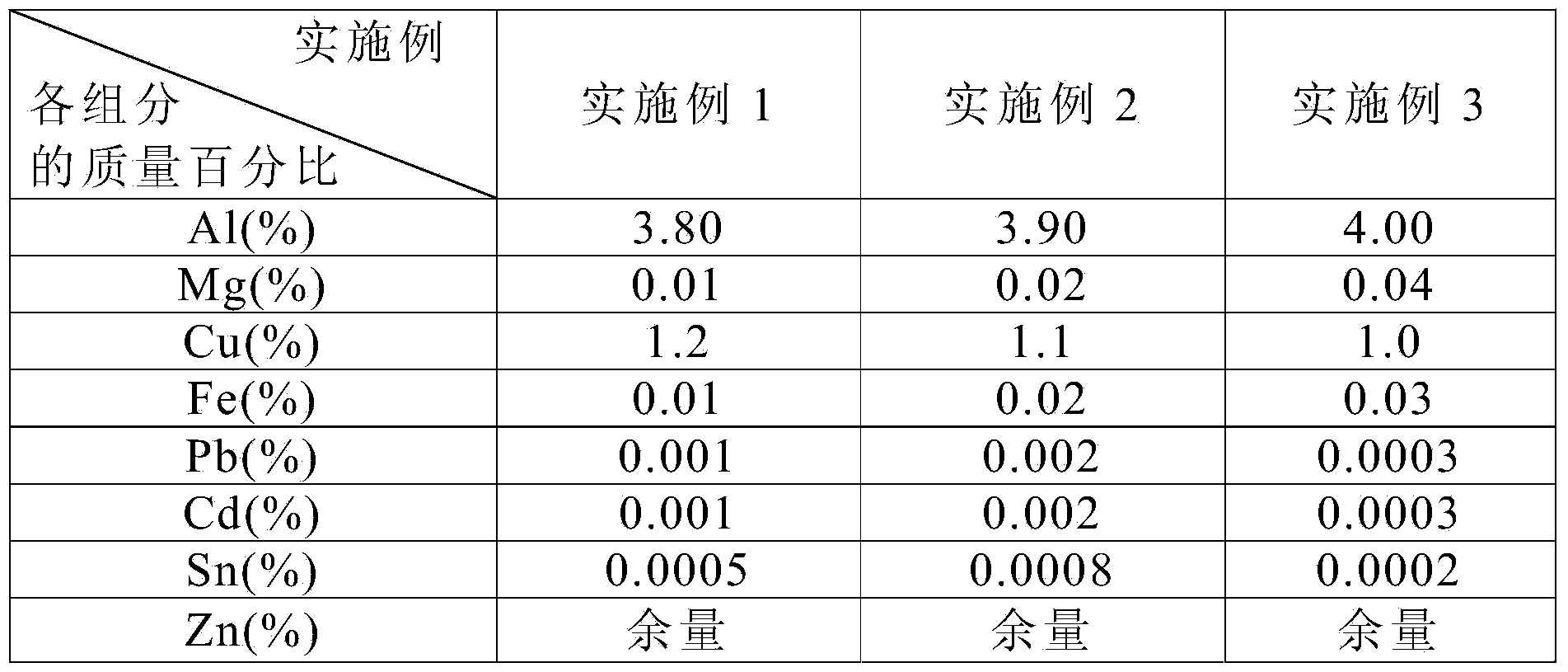

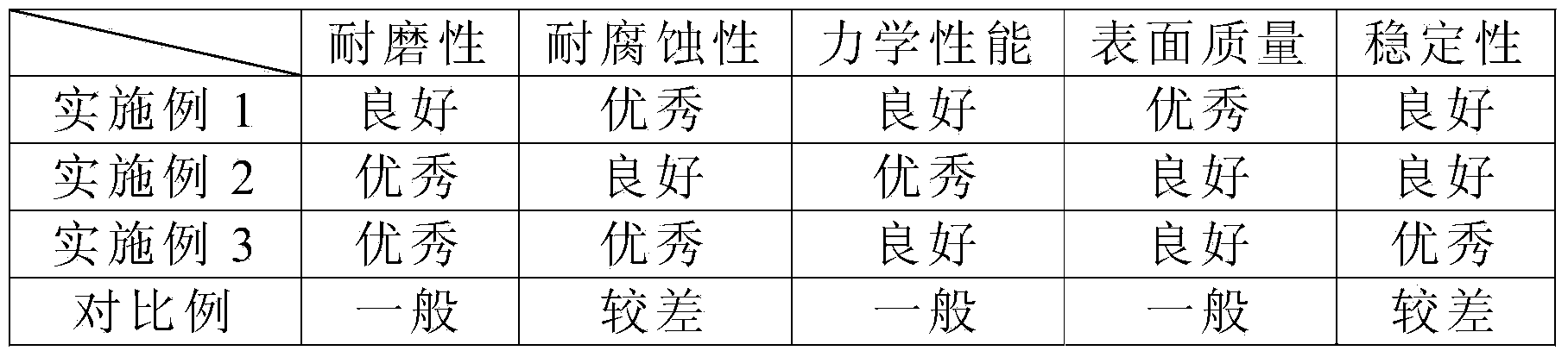

Presser foot fixer of sewing machine and preparation method thereof

InactiveCN103667791AImprove corrosion resistanceInhibit intergranular corrosionPressersMetal coatingDie casting

The invention relates to a presser foot fixer of a sewing machine and a preparation method thereof. The presser foot fixer is made of a zinc alloy, and a metal coating is plated on the surface of the zinc alloy. The zinc alloy comprises components in percentage by weight as follows: 3.80 %-4.00% of Al, 0.01%-0.04% of Mg, 1.0%-1.2% of Cu, smaller than or equal to 0.02% of Fe, smaller than or equal to 0.002% of Pb, smaller than or equal to 0.002% of Cd, smaller than or equal to 0.0008% of Sn and the balance of Zn. The preparation method comprises steps as follows: metal is melted into an alloy solution which is subjected to stirring, slagging off, stamping and die casting to obtain a presser foot fixer blank; then finish machining and vibration milling are performed, and metal Cu, Ni and Cr are electroplated in sequence on the blank surface; and finally, the blank, a button and a locating piece are assembled into the presser foot fixer of the sewing machine. The presser foot fixer of the sewing machine has the advantages of better mechanical property, abrasion resistance and corrosion resistance, higher surface quality and longer service life.

Owner:NINGBO RUIMING MACHINERY

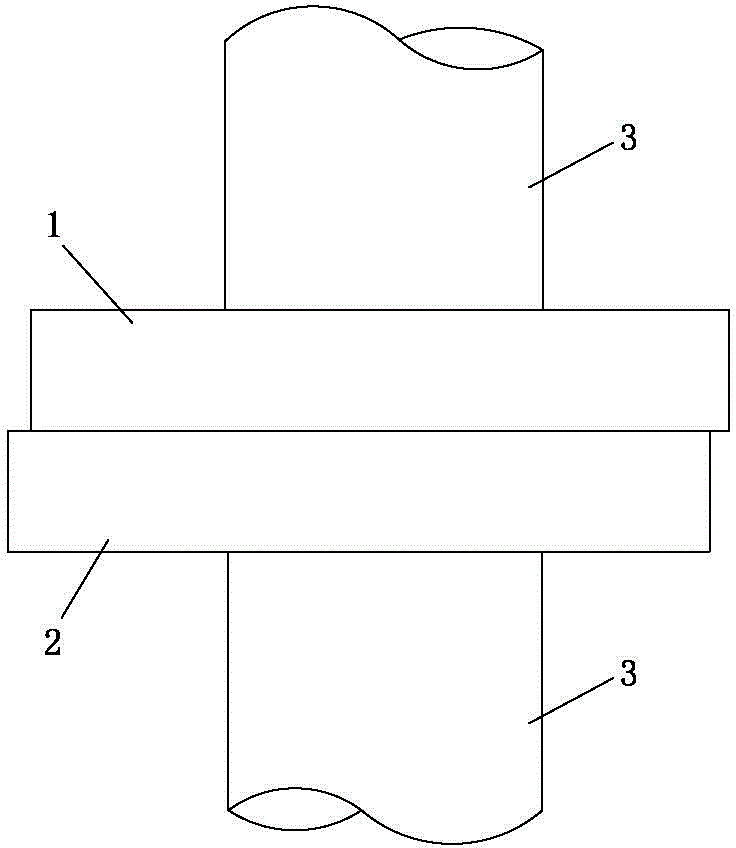

Resistance welding method for amorphous alloy

ActiveCN104139234ASolve difficult-to-tap problemsAchieve bondingResistance welding apparatusElectrical resistance and conductanceAlloy

The invention relates to the technical field welding of amorphous alloy, in particular to a resistance welding method for the amorphous alloy. The resistance welding method for the amorphous alloy comprises the steps that the base metal amorphous alloy and welding workpieces are welded, the amorphous alloy and the welding workpieces make contact with each other, after the amorphous alloy and the welding workpieces are connected with electrodes respectively, the electrodes apply pressure, resistance heat generated through currents is utilized for heating the amorphous alloy and the welding workpieces to exceed respective melting points or to reach respective supercooled liquid phase regions, a TTT drawing serves as a standard, and the welding workpieces and the amorphous alloy are welded under the condition that a crystallization reaction does not occur. The welding workpieces contain one or more elements contained in the amorphous alloy. The welding method solves the problem that tapping is hard to carry out on the amorphous alloy, achieves joint of the amorphous alloy and the welding workpieces quite well, the intensity of the welding positions between the amorphous alloy and the welding workpieces is made to be quite high, and the welded amorphous alloy still maintains an amorphous structure.

Owner:DONGGUAN PROMETAL TECH CO LTD

Flexible strip weaving sofa

PendingCN109008397AAchieving Pipeline OperationsIncrease productivitySofasCouchesEngineeringAssembly line

The invention discloses a flexible strip weaving sofa, which includes more than one independent flexible strip weaving sofa. Each independent flexible strip weaving sofa includes a back board, side plates, and a pedestal, wherein the back board is connected to the rear end of the pedestal and the side plates are connected to the sides of the pedestal. The improvement of the sofa is that at least one of the back board, the side plates and the pedestal is formed from a flexible strip weaving panel unit, which includes a flexible strip weaving panel and a framework assembly, wherein clamping boards are disposed on the ends of periphery of the flexible strip weaving panel and are used for clamping the flexible strips corresponding to the ends of periphery of the flexible strip weaving panel, thus drawing the flexible strip weaving panel to at least coat one end surface of the framework assembly and fixedly connecting the flexible strip weaving panel onto the framework assembly. In the invention, by means of the flexible strip weaving panel unit coated in large area, manual weaving can be replaced by mechanical weaving conveniently, so that assembly line work can be achieved and productivity can be significantly increased.

Owner:郑子钰

Connecting rod part processing method

InactiveCN105983821AEasy to implement mechanicallyEasy to achieve integrationFurnace typesHeat treatment furnacesPunchingWork in process

The invention discloses a connecting rod part processing method. A material is 40 Cr. The processing method is characterized by including following steps: (1), charging the material into a furnace, and heating; (2), blanking a rolled material to obtain needed specification, directly performing surface quenching after rough machining without tempering to form a semi-finished product; (3), carburizing and quenching to obtain a non-tempered connecting rod, wherein quenching temperature is 850-950 DEG C, quenching time is 60-90 min, and a quenching agent is water or oil; (4), punching and edge-cutting, wherein roughness Ra is less than 1.6 um; (5), polishing and refining, wherein roughness Ra is less than 0.4 um; (6), sequentially performing rust preventing, inspecting, packaging and warehousing. By using the connecting rod part processing method, process parameters of each stage are controlled strictly, and processes are reduced remarkably; the connecting rod part processing method is simple in process, convenient to operate and low in energy consumption.

Owner:CHONGQING JUNZHUO MACHINERY

Needle rod eccentric pin of sewing machine and manufacturing method thereof

The invention provides a needle rod eccentric pin of a sewing machine and a manufacturing method thereof. The needle rod guide eccentric pin is made of zinc alloy, wherein the zinc alloy comprises the following components in percentage by weight: 3.90%-4.30% of aluminum, 0.03%-0.06% of magnesium, 0.20%-0.50% of copper, not more than 0.035% of iron, not more than 0.004% of lead, not more than 0.003% of cadmium not more than 0.001% of tin, and the balance of zinc. The invention further provides the manufacturing method of the needle rod eccentric pin. The needle rod eccentric pin provided by the invention is convenient to machine and operate, less in processes, capable of improving the production efficiency, easy for realization of mechanization and automation, stable in quality and low in cost.

Owner:NINGBO RUIMING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com