Composite raw wheat kojis and production method thereof

A technology of wheat koji and wheat, applied in the field of compound raw wheat koji and its production, to achieve the effects of short fermentation time, improved production efficiency, and strong controllability of fermentation temperature and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The mechanized production of embodiment 1 composite raw wheat koji

[0037] (1) Select high-quality wheat: select wheat with complete and plump grains, no special smell, and moisture content ≤ 13%;

[0038](2) Screening and cleaning: remove dust, wheat husks, insect-corroded wheat and other impurities mixed in the wheat through a mechanical winnowing device;

[0039] (3) Crushing: Each grain of wheat is rolled into 3 to 5 pieces by a wheat rolling machine, so that the epidermis tissue of the wheat is broken, the starch in the endosperm leaks out, it is easy to absorb water, and the breeding area of microorganisms is increased;

[0040] (4) Add hydrating material: Add water to the weighed crushed wheat according to the mass ratio of wheat: water of 1:0.3, and stir quickly to make the wheat absorb water evenly and fully, and the moisture content reaches 22-24%. , and pile up moistening material for 1h;

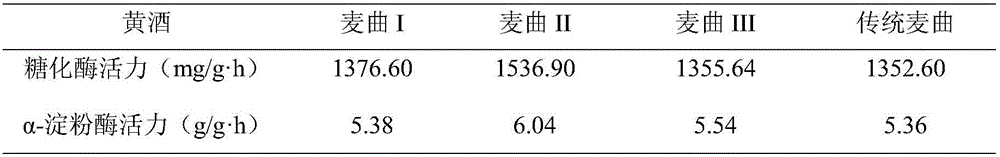

[0041] (5) Koji making separately: the wheat is divided into 3 e...

Embodiment 2

[0049] Example 2 Composite raw wheat koji is used for rice wine brewing

[0050] (1) Rice soaking: mix 5kg of glutinous rice and 6kg of water, keep warm at 39°C for 14h, and separate the rice and water;

[0051] (2) Steamed rice: steam the soaked glutinous rice until soft and rotten without white heart;

[0052] (3) Distiller's mother cultivation: add 50g of rice wine yeast into 500g of water, and keep it warm at 38°C for 1 hour; add it to the fermenter together with the glutinous rice cooked in step 2;

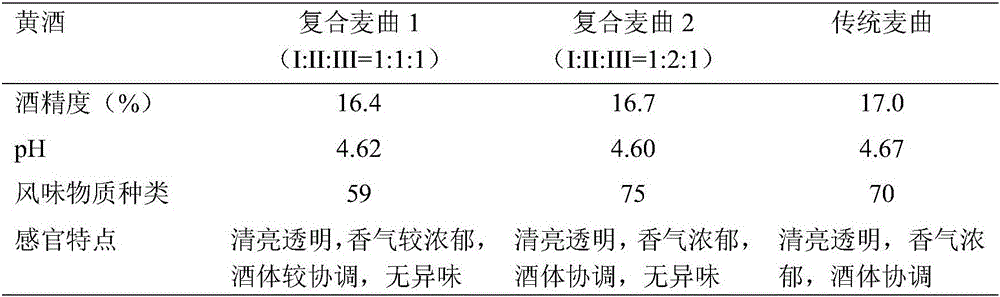

[0053] (4) compound wheat koji I, II and III according to the ratio of 1:1:1 and 1:2:1 respectively to obtain compound wheat koji 1 and compound wheat koji 2;

[0054] (5), respectively according to adding 4kg water, 500g pea compound wheat koji in fermenter, stir;

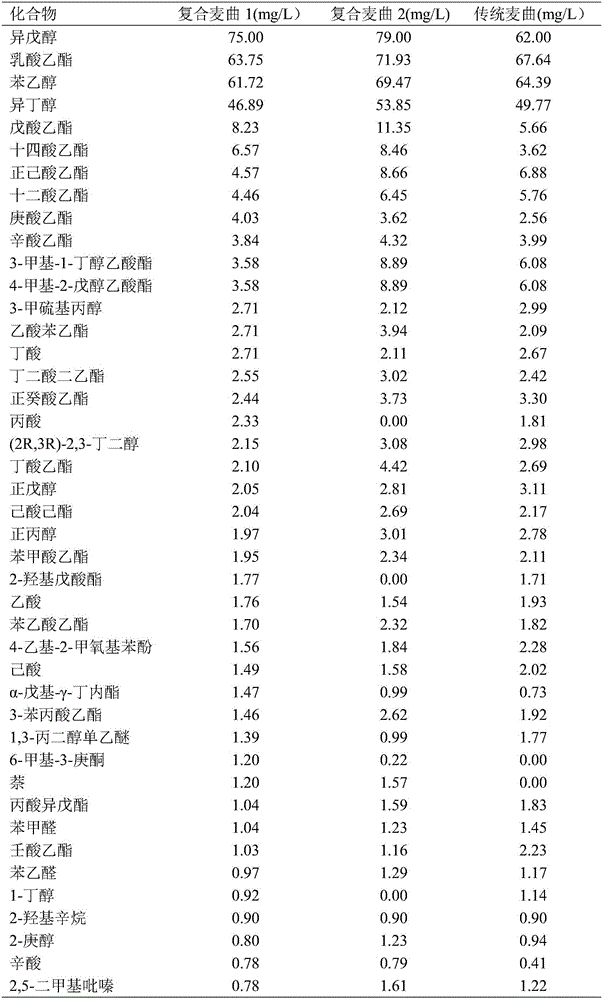

[0055] (6) Control the pre-fermentation temperature of rice wine to 24-26°C, and after 7 days of fermentation, lower the temperature to 16°C to enter the post-fermentation stage, and the fermentation will end a...

Embodiment 3

[0064] Example 3 Composite raw wheat koji is used for rice wine brewing

[0065] The specific implementation method is the same as in Example 2, except that the compound wheat koji I, II, and III are compounded according to the ratio of 1:3:1 to obtain the compound wheat koji 3.

[0066] The physical and chemical indicators of the rice wine after fermentation were measured, and the sensory evaluation of the rice wine was carried out. The results showed that the rice wine after the fermentation of compound wheat koji 3 was clear and transparent, with rich aroma, harmonious body and no peculiar smell. The types of flavor substances were higher than those of traditional wheat Yellow rice wine prepared from koji, and the total content of flavor substances is more than 400mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com