Preparation method of novel hollow sphere filled polyurethane-based composite material

A composite material and hollow sphere technology, which is applied in the field of preparation of new hollow sphere-filled polyurethane-based composite materials, can solve the problems of difficulty in controlling the foam size and the distribution of air bubbles, and little improvement in thermal and acoustic functions, and achieves composition Controllable structural design, excellent mechanical and acoustic properties, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

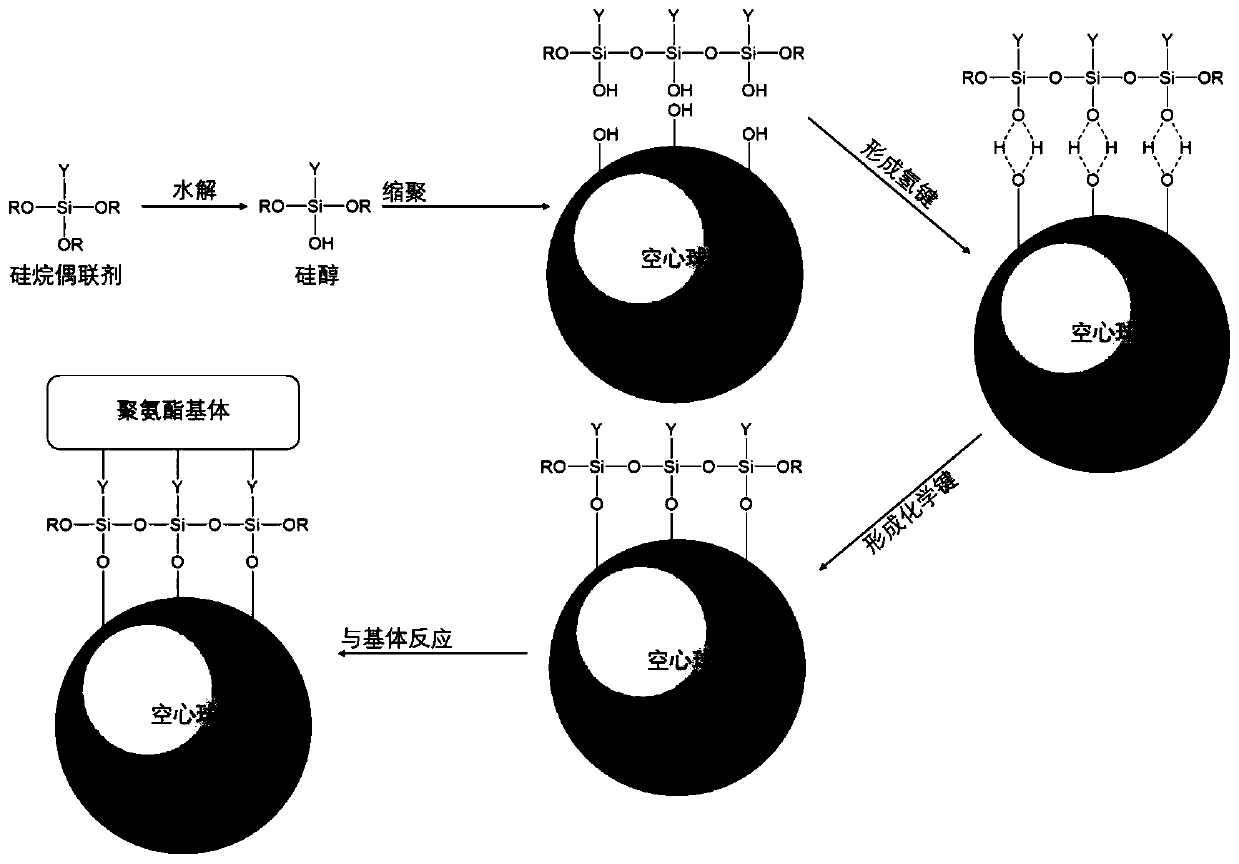

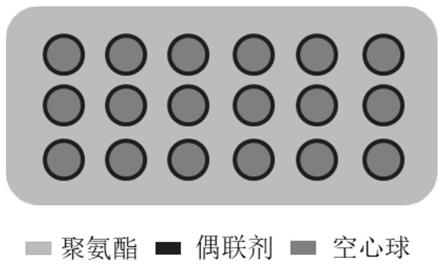

[0028] A method for modifying the surface of hollow spheres and a method for preparing polyurethane-based composite materials filled with hollow spheres. The specific method includes the following steps:

[0029] Step 1. Use absolute ethanol to clean the surface of the hollow ball for about 10 minutes to remove surface impurities and dirt, then put the hollow ball into an oven, dry it at 80°C for more than 6 hours, and take it out for later use.

[0030] Step 2, the surface modifier used in the present invention is a silane coupling agent, the amount of the coupling agent is 2% to 6% of the mass fraction of the hollow sphere, and the silane coupling agent needs to be hydrolyzed before the surface of the hollow sphere is hydrolyzed. modified.

[0031] Step 3: Add the hollow spheres to the hydrolyzed silane coupling agent solution, stir at an appropriate temperature for a period of time, then put the hollow spheres into an oven to dry, and take them out for later use.

[0032] ...

Embodiment 1

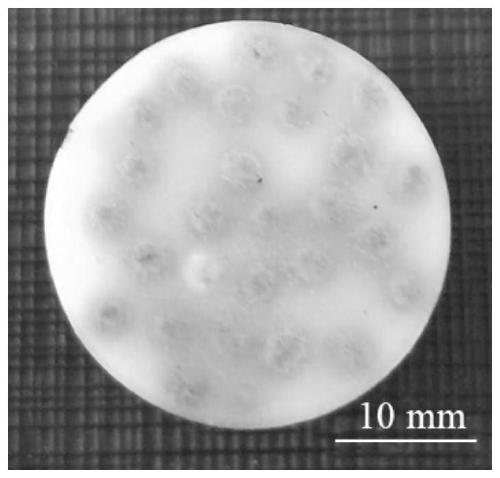

[0041] Step 1. Use absolute ethanol to clean the surface of the stainless steel hollow ball with a diameter of 2.5mm for 10 minutes to remove surface impurities and dirt, then put the stainless steel hollow ball into an oven, dry at 80°C for 6 hours, and take it out for use.

[0042] Step 2, the surface modifier used in the present invention is KH550 silane coupling agent, the amount of coupling agent is 3% of the mass fraction of stainless steel hollow spheres, and the KH550 silane coupling agent needs to be hydrolyzed before the stainless steel hollow spheres are hydrolyzed. surface modification. The hydrolysis process of KH550 is: volume fraction KH550 / ethanol / water=1 / 1 / 16, temperature 65°C, pH=6.0, hydrolysis for 45 minutes.

[0043] Step 3: Add stainless steel hollow spheres to the hydrolyzed KH550 silane coupling agent solution, stir at 65°C for 1 hour, then put the stainless steel hollow spheres in an oven to dry for 6 hours, take them out for later use.

[0044] Step ...

Embodiment 2

[0046] Step 1. Use absolute ethanol to clean the surface of the titanium alloy hollow sphere with a diameter of 2.5mm for 10 minutes to remove surface impurities and dirt, then put the stainless steel hollow sphere into an oven, dry at 80°C for 6 hours, and take it out for use.

[0047] Step 2, the surface modifier used in the present invention is KH550 silane coupling agent, the amount of coupling agent is 5% of the mass fraction of titanium alloy hollow spheres, and the KH550 silane coupling agent needs to be hydrolyzed before the titanium alloy hollow sphere Surface modification of balls. The hydrolysis process of KH550 is: volume fraction KH550 / ethanol / water=1 / 1 / 16, temperature 65°C, pH=6.0, hydrolysis for 45 minutes.

[0048] Step 3: Add the titanium alloy hollow spheres to the hydrolyzed KH550 silane coupling agent solution, stir at 65°C for 2 hours, then put the stainless steel hollow spheres in an oven to dry for 8 hours, take them out for later use.

[0049] Step 4: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com