Electromagnetic wave absorption particle with kieselguhr as template and preparation method thereof

A diatomite, electromagnetic wave technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of heavy metal powder specific gravity, and achieve the effects of reducing specific gravity, convenient material acquisition, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

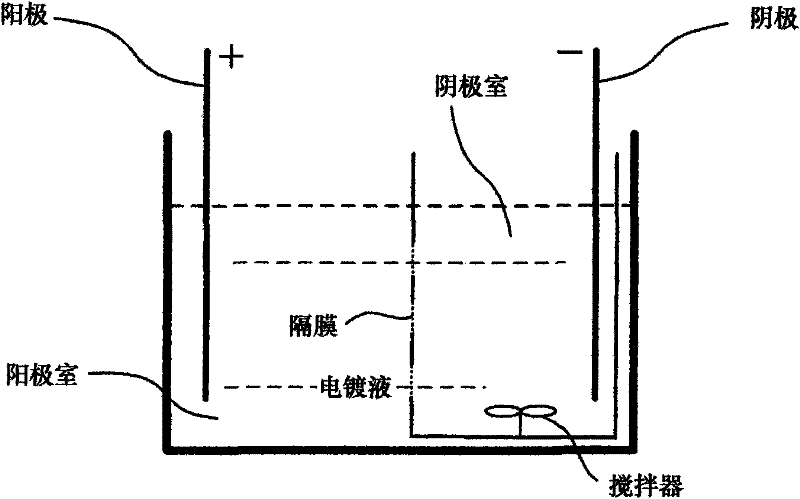

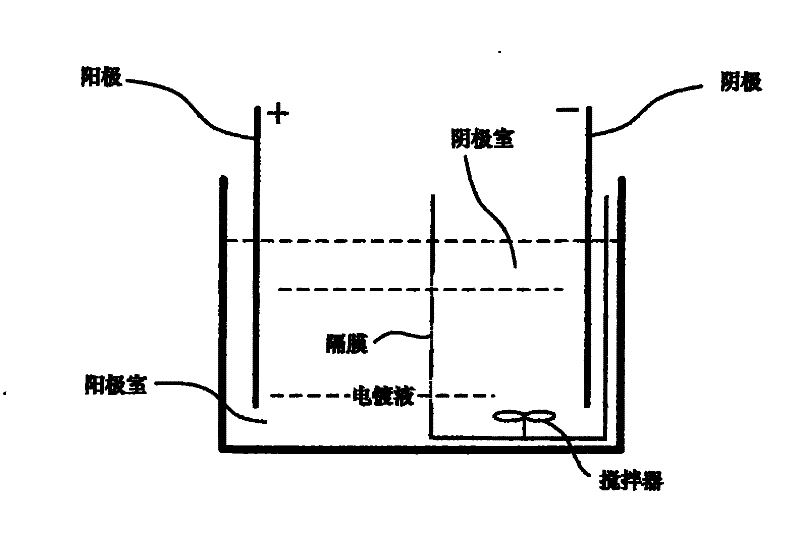

[0089] In the preparation process of step 4, the electroplating device is shown in Figure 4. In the figure, the anode and the cathode are connected to the positive and negative electrodes of the DC power supply respectively, and the cathode adopts a copper plate. In order to increase the particle density near the cathode, a perforated diaphragm is used to The electroplating tank is divided into a cathode chamber and an anode chamber, and a stirrer is arranged in the cathode chamber, and the aperture of the diaphragm with holes is 1 micron. The anode material is selected from copper, iron, nickel, cobalt, zinc and other metal single sheets (thickness 2 mm); or an alloy sheet of copper, iron, nickel, cobalt, zinc; or a graphite plate.

[0090] Step 5: Drying to obtain electromagnetic wave absorbing particles

[0091] Dry the metal-coated diatomite prepared in step 4 at a vacuum degree of -0.05MPa to -0.1MPa and 110 to 150°C for 2h to 4h to prepare electromagnetic wave absorbing ...

Embodiment 1

[0092] Example 1 : Preparation of iron metal particles using disc-shaped diatomaceous earth as a template.

[0093] Step 1: Pretreatment of diatomaceous earth

[0094] After grinding the diatomite to a particle size of 100 μm, the diatomite with organic matter removed is obtained after high-temperature treatment at 400°C for 50 minutes;

[0095] Put the diatomite and absolute ethanol solution (mass concentration of 95%) for removing organic matter into a glass container, and place the glass container in an ultrasonic cleaning machine, and ultrasonically clean it for 30 minutes under the conditions of power 800W and working frequency 28KHz , using filter paper with a pore size of 3 μm for separation, and filtering to obtain the supernatant of the filter paper; drying the supernatant at 110° C. for 6 hours to obtain dry diatomite;

[0096] The dosage of diatomite for removing organic matter and absolute ethanol solution is: add 3 g of diatomite for removing organic matter to ...

Embodiment 2

[0124] Example 2 : Preparation of nickel-iron metal particles with disc-shaped diatomite as template.

[0125] Step 1: Pretreatment of diatomaceous earth

[0126] After grinding the diatomite into a particle size of 50 μm, the diatomite with organic matter removed is obtained after high-temperature treatment at 400°C for 90 minutes;

[0127] Put the diatomite and absolute ethanol solution (mass concentration: 95%) to remove the organic matter into the glass container, and place the glass container in the ultrasonic cleaning machine, after ultrasonic cleaning for 40min under the conditions of power 800W and working frequency 28KHz , using filter paper with a pore size of 3 μm for separation, and filtering to obtain the supernatant of the filter paper; drying the supernatant at 120° C. for 6 hours to obtain dry diatomite;

[0128] The amount of diatomite and absolute ethanol solution for removing organic matter is: add 2 g of diatomite for removing organic matter to 100 ml of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com