Processing and forming method of double-layer type cellular shade

A processing forming and heating forming technology, applied in the direction of curtains, curtains, household appliances, etc., can solve the problems of easy deformation, single function, weak expansion function, etc., to improve the function expansion and enhance the effect of structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

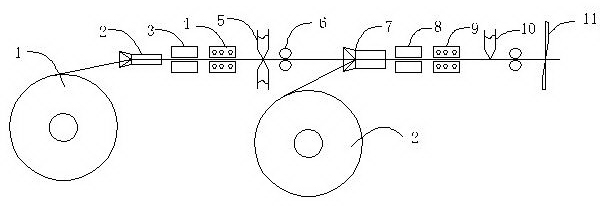

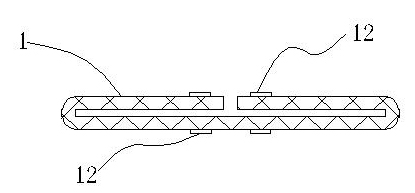

[0034] Embodiment: the double-layer type honeycomb curtain processing forming method of the present embodiment is as figure 1 shown, including the following steps:

[0035] (1) Feeding and preforming of the first base material belt: the bundled first base material belt 1 is driven horizontally in one direction by the belt roller 7, and firstly enters the first forming sleeve 3, and the first base material belt 1 Form two folded edges turned inward;

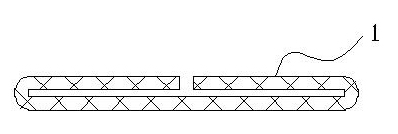

[0036] (2) Heating and forming of the first base material belt: the belt roll 7 drives the preformed first base material belt 1 into the first heating and forming device 4 with adjustable pressure to form the first base material belt 1 as shown in figure 2 Flat through tubular shown;

[0037] (3) Cooling and shaping of the first base material belt: After heating and forming, the first base material belt 1 immediately enters the first cooling and shaping device 5 with adjustable pressure, so that the first base material belt 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com