Patents

Literature

158results about How to "Strong Amorphous Formation Ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

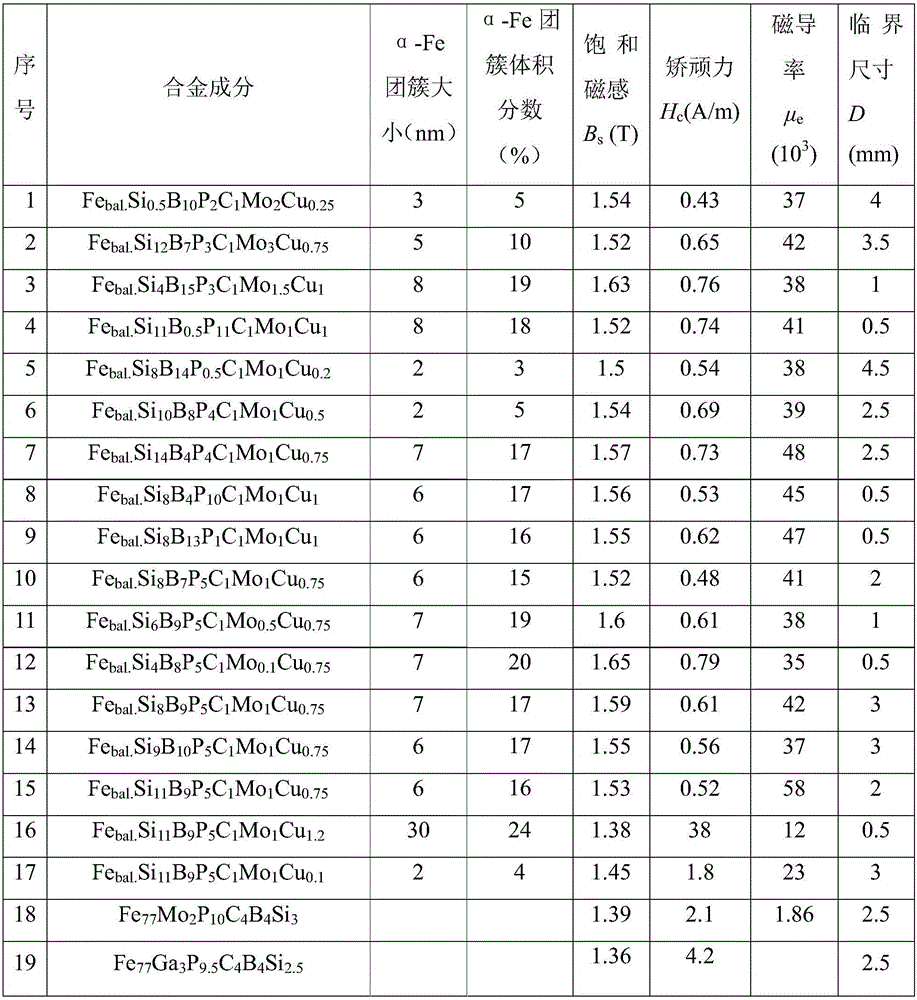

Iron-based nano-crystalline magnetically-soft alloy having high saturation magnetic induction intensity

InactiveCN101840763AReasonable design of ingredientsStrong Amorphous Formation AbilityMagnetic materialsAtomic compositionCoercivity

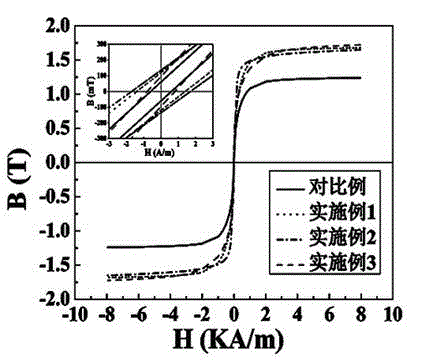

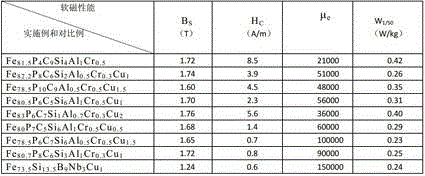

The invention provides an iron-based nano-crystalline magnetically-soft alloy having high saturation magnetic induction intensity. The iron-based nano-crystalline magnetically-soft alloy is characterized in that the atomic composition thereof by percentage (%) is shown in the following formula: FeTaBbCucCdMe, wherein T represents at least one selected from Zr, Ti, Ta, Hf, Nb, V, W, Mo and Cr; M represents at least one selected from P, Si, N, Sn, Ge, Ga and Al; the subscripts, i.e., a to e in the formula, indicate the atomic percentage (%) and meet the following conditions: a is larger than or equal to 0.002 and less than or equal to 5, b is larger than or equal to 2 and less than or equal to 18, c is larger than or equal to 0.02 and less than or equal to 5, d is larger than or equal to 0.002 and less than or equal to 3, and e is larger than or equal to 0.02 and less than or equal to 20; and Fe and other unavoidable impurities constitute the balancing amount. The magnetically-soft alloy of the invention has the characteristics of high glass-forming ability, high saturation magnetic induction intensity and good soft magnetic performance; and particularly, the saturation magnetic induction intensity of the annealed alloy is higher than 1.5T, and the coercive force thereof is lower than 15A / m.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Low-cost high-saturation magnetic induction intensity iron-based amorphous soft magnetism alloy

ActiveCN101840764AStrong Amorphous Formation AbilityHigh saturation magnetic inductionMagnetic materialsIron basedMagnetism

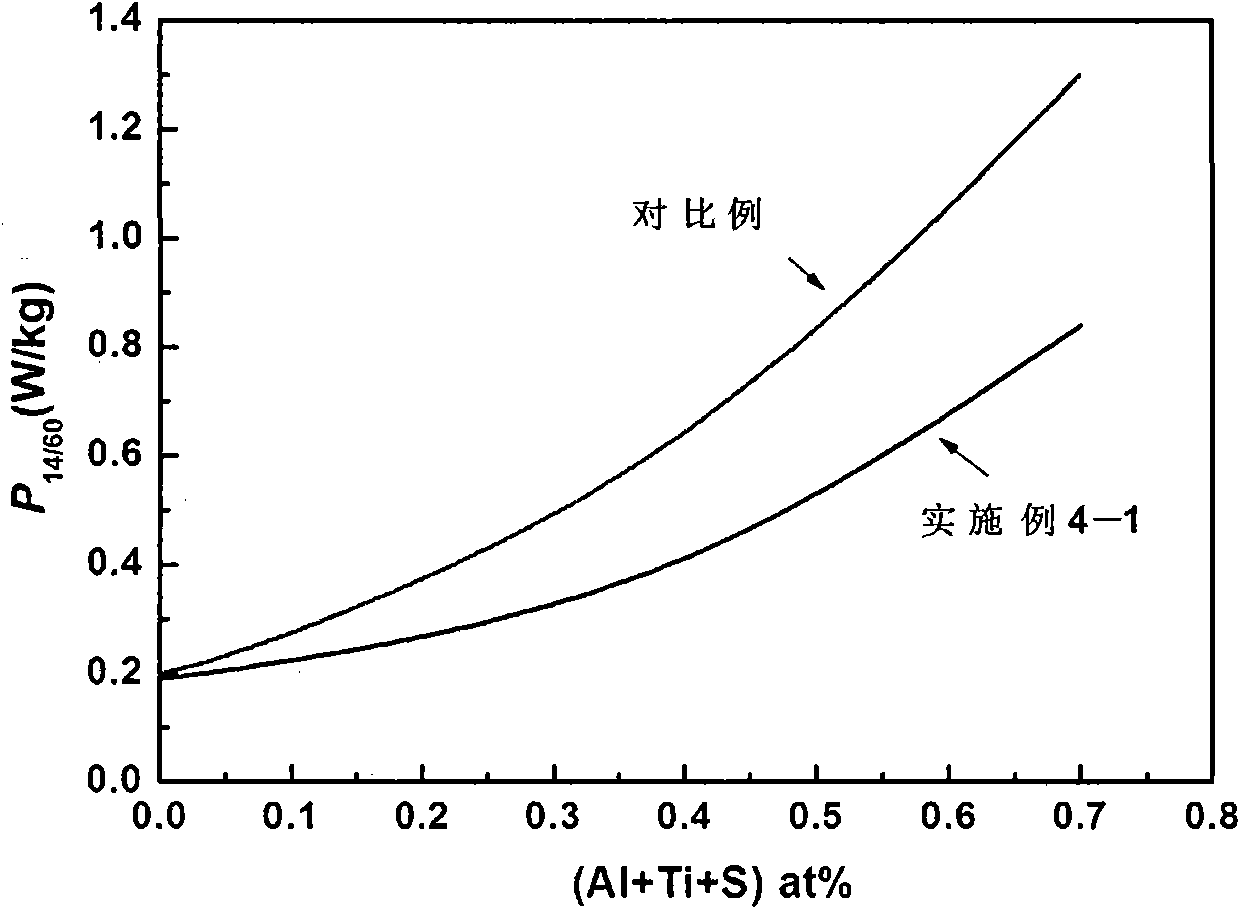

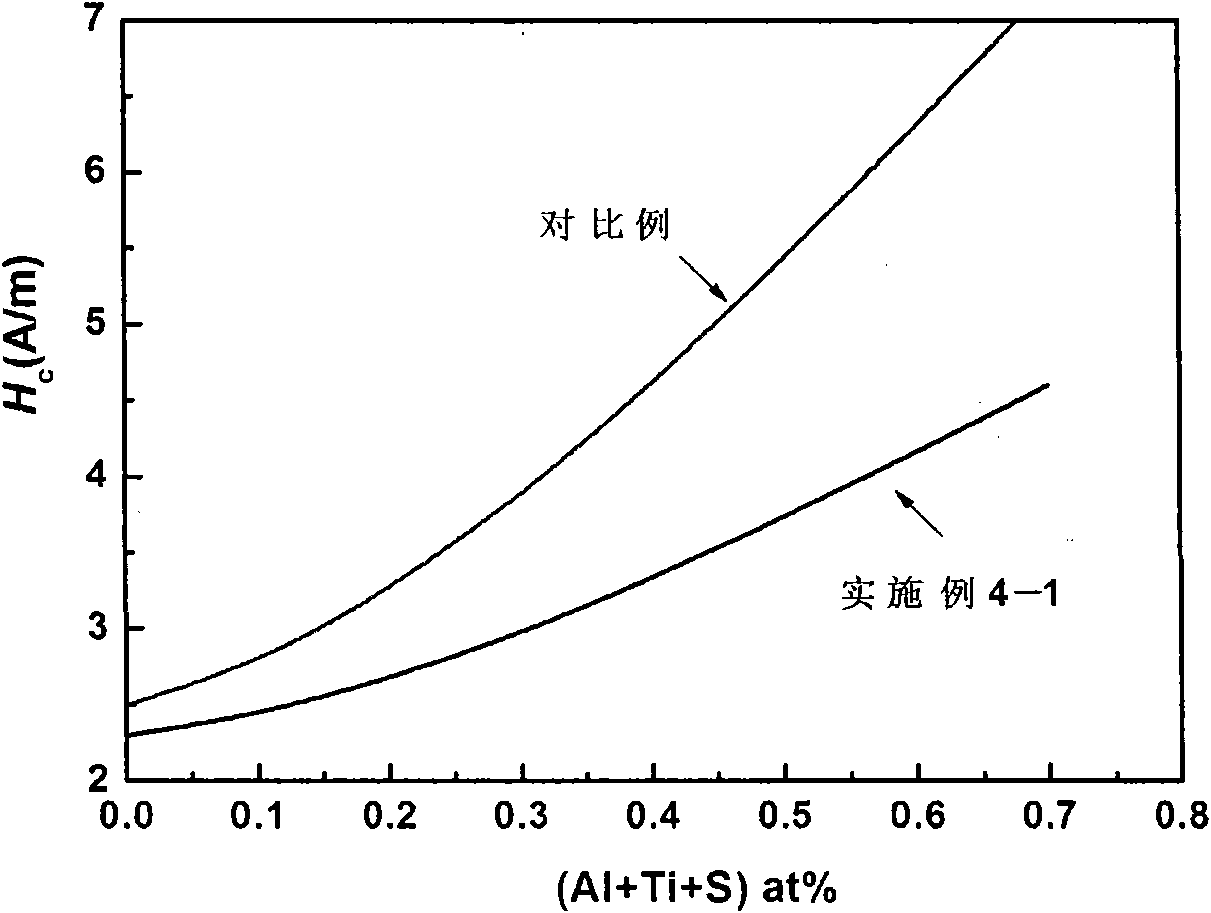

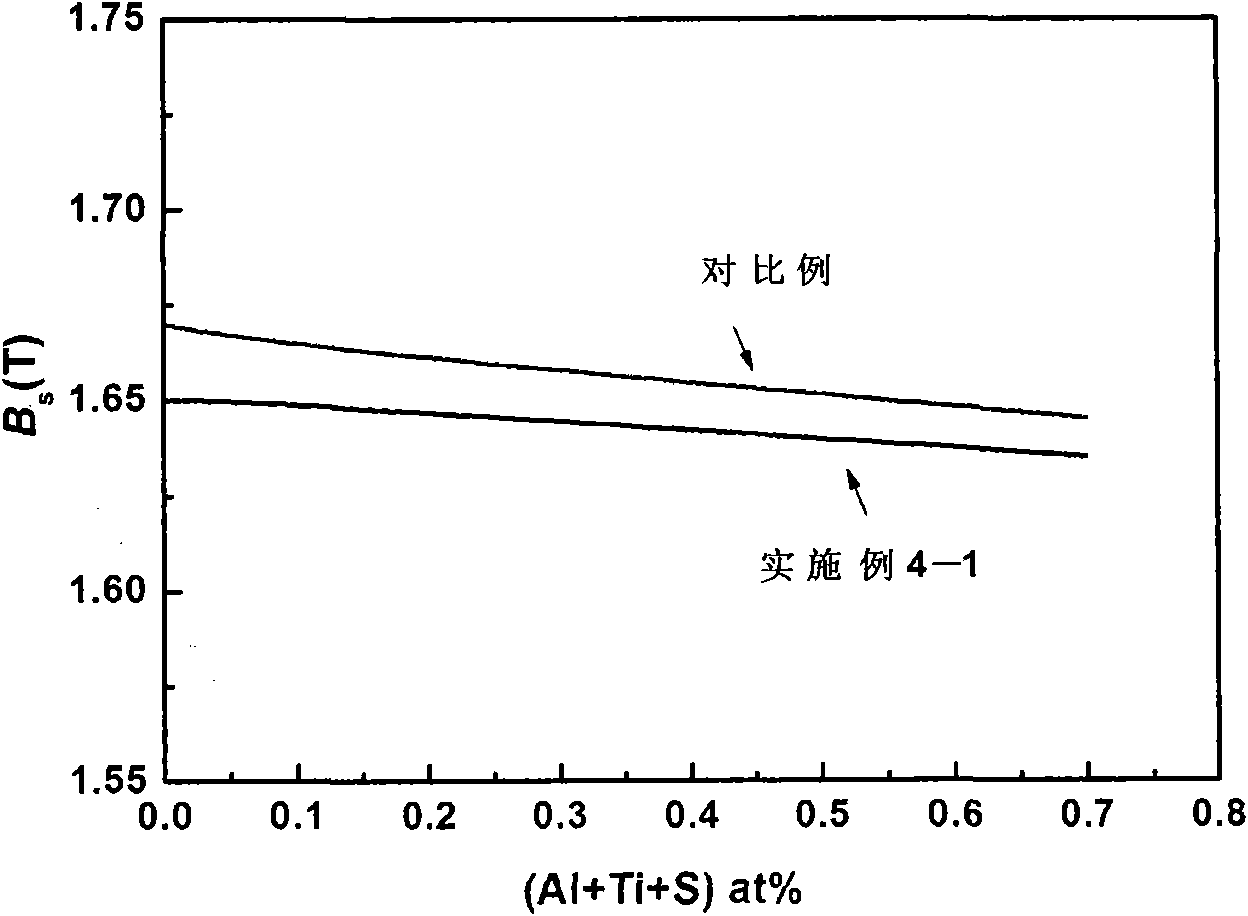

The invention provides a low-cost high-saturation magnetic induction intensity iron-based amorphous soft magnetism alloy. The alloy comprises the following ingredients in percentage by atoms: 0 to 15 of Si, 3 to 20 of B, 0.001 to 12 of P, 0.001 to 5 of C, 0.0001 to 0.1 of Al, 0.001 to 0.5 of Mn, 0.0001 to 0.5 of Sb, 0.0001 to 0.1 of Ti, 0.0001 to 0.5 of S, 0.0001 to 0.5 of Sn, 0.0003 to 0.2 of W and the balance of Fe and unavoidable impurities. The soft magnetism alloy of the invention has the characteristics of strong amorphous forming capability, high saturation magnetic induction intensity, low cost and the like. After the alloy is annealed, the saturation magnetic induction intensity is higher than 1.6 T, and the coercive force is lower than 5A / m.

Owner:AT&M AMORPHOUS TECH CO LTD

Iron-based amorphous magnetically soft alloy with uniform element distribution and preparation method thereof

ActiveCN104073749AImprove thermal stabilityHigh saturation magnetic inductionMagnetic materialsTransformerMaterials science

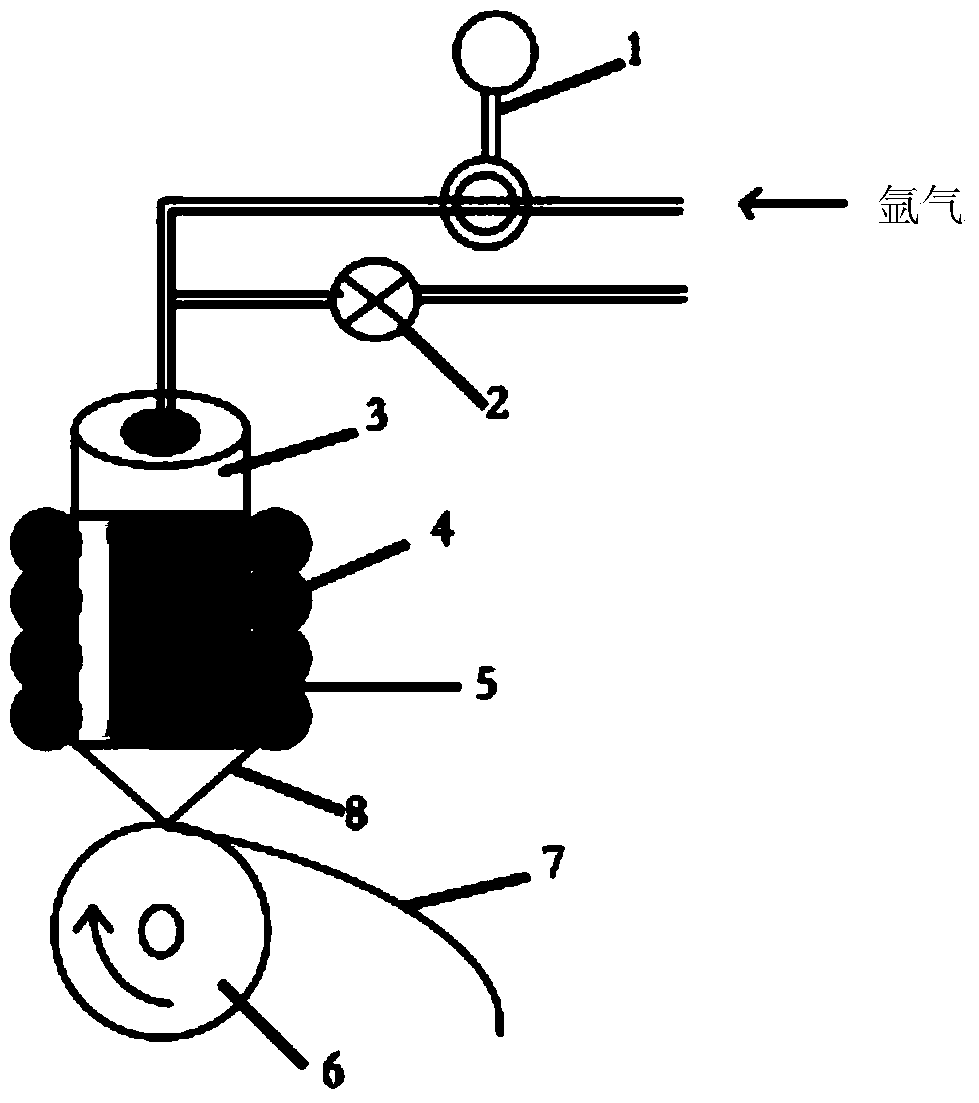

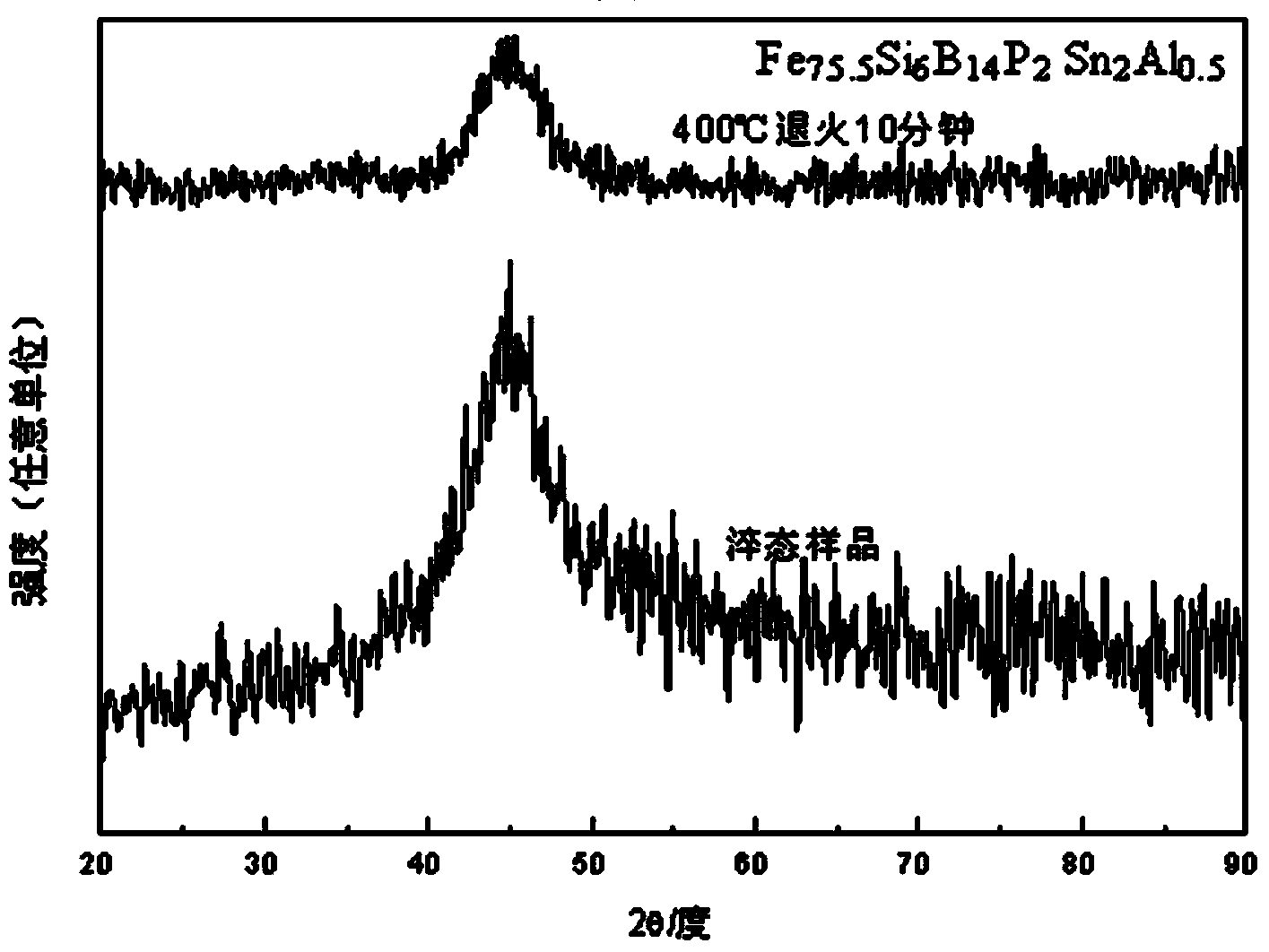

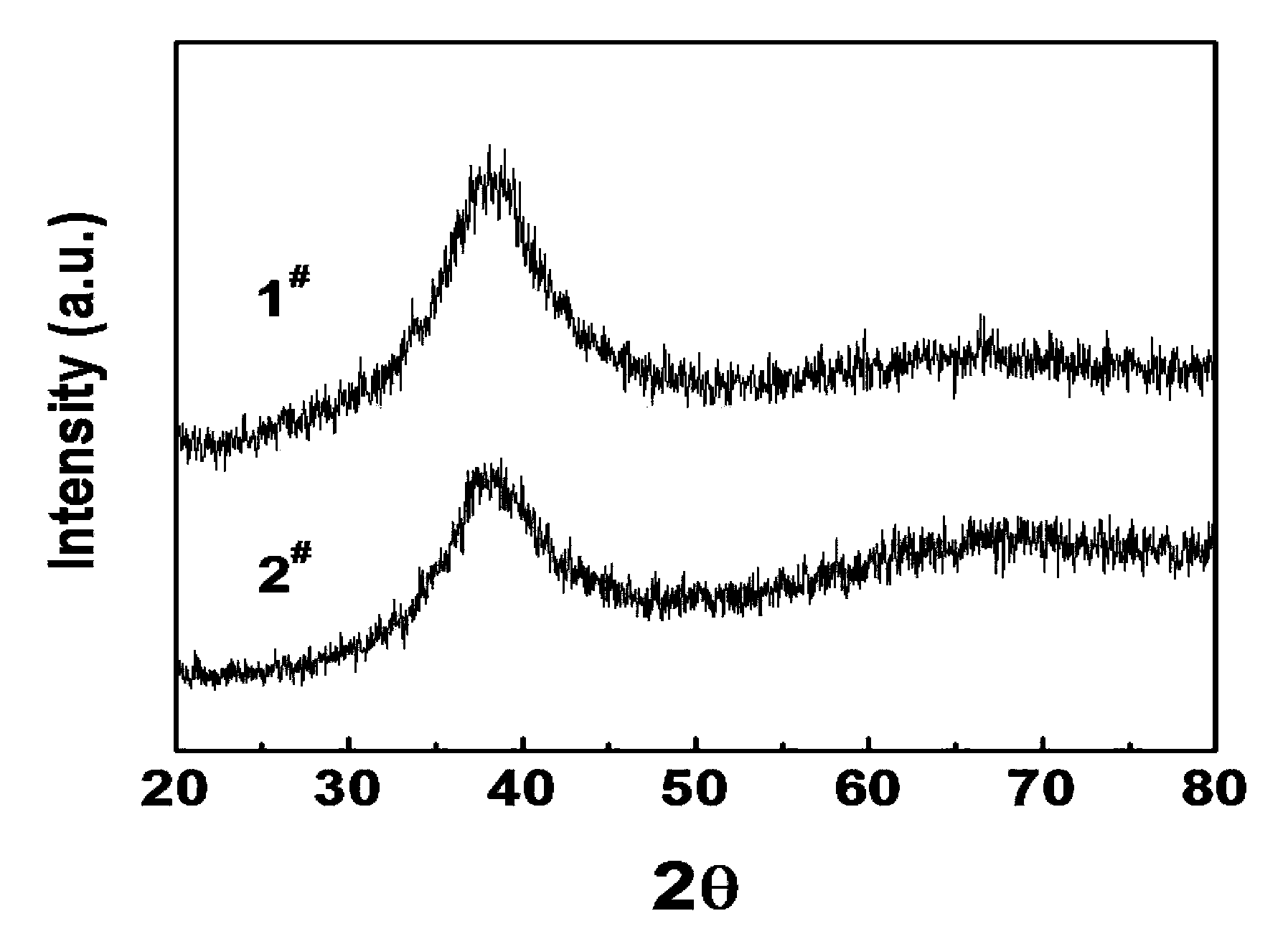

The invention discloses an iron-based amorphous magnetically soft alloy with uniform element distribution and a preparation method thereof. The expression of the alloy is FeaSibBcPdMe, a, b, c, d and e in the expression represent the atomic percent contents of corresponding components respectively, and meet the following conditions: a is not less than 70 and not greater than 84, b is not less than 2 and not greater than 10, c is not less than 5 and not greater than 18, d is not less than 0.001 and not greater than 8, e is not less than 0.0001 and not greater than 2.5, a+b+c+d+e=100%, and M is one or more of C, N, Sn, Ge, Ga, Al, S, Te, Be, Pb, Mg and Cu. The amorphous strip prepared from the alloy under a high vacuum and argon shield has the characteristic of uniform element distribution, particularly solves the problem of non-uniform distribution of element P in the amorphous alloy, has excellent magnetically soft performance, and is suitable for transformers, engines, power generators, magnetic sensors and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

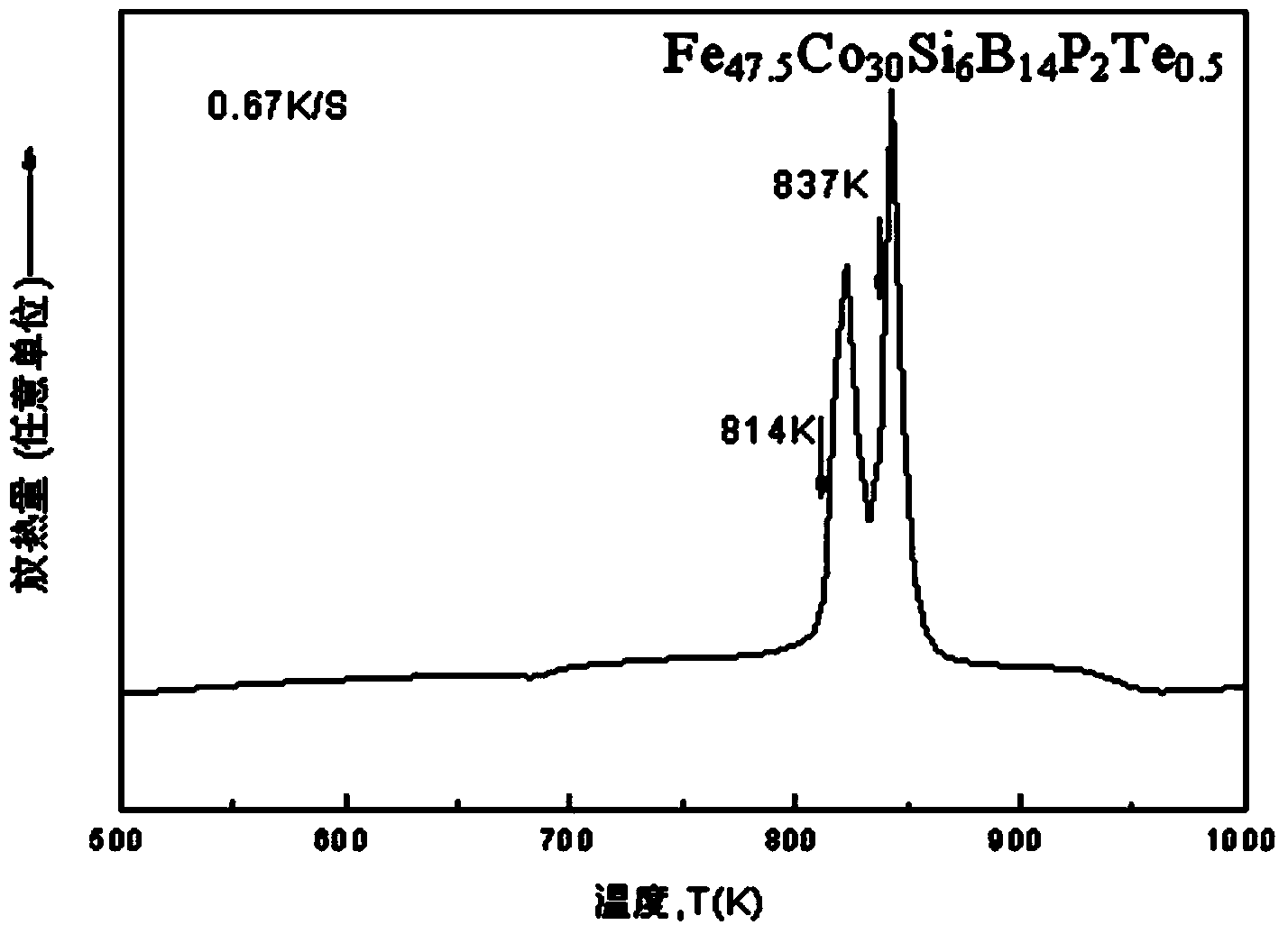

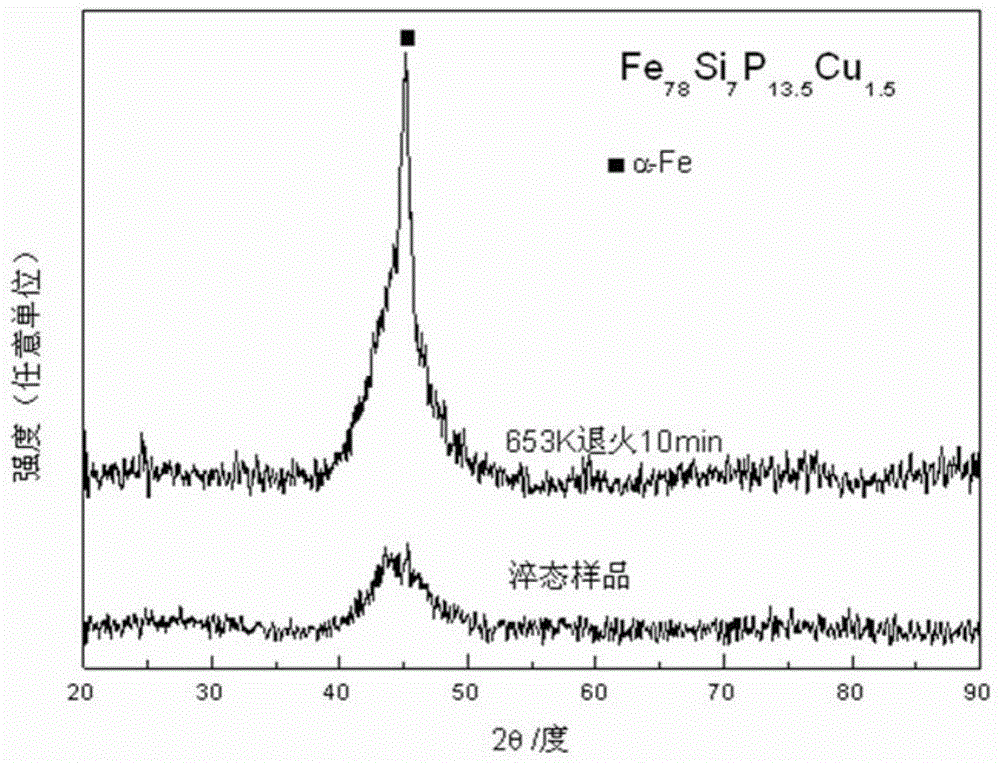

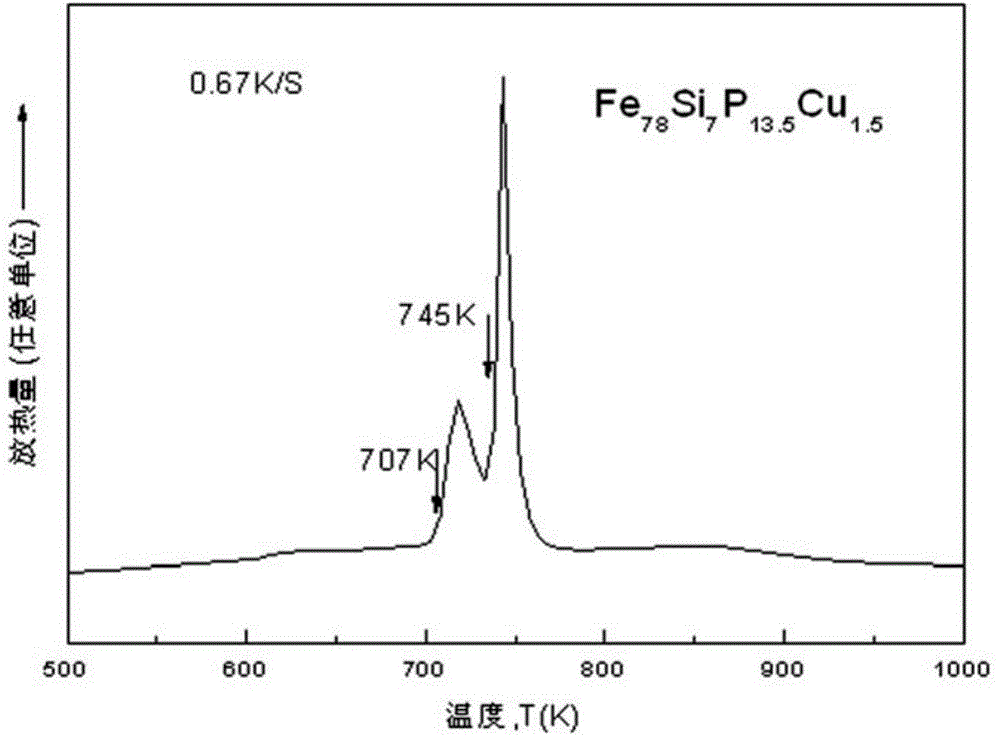

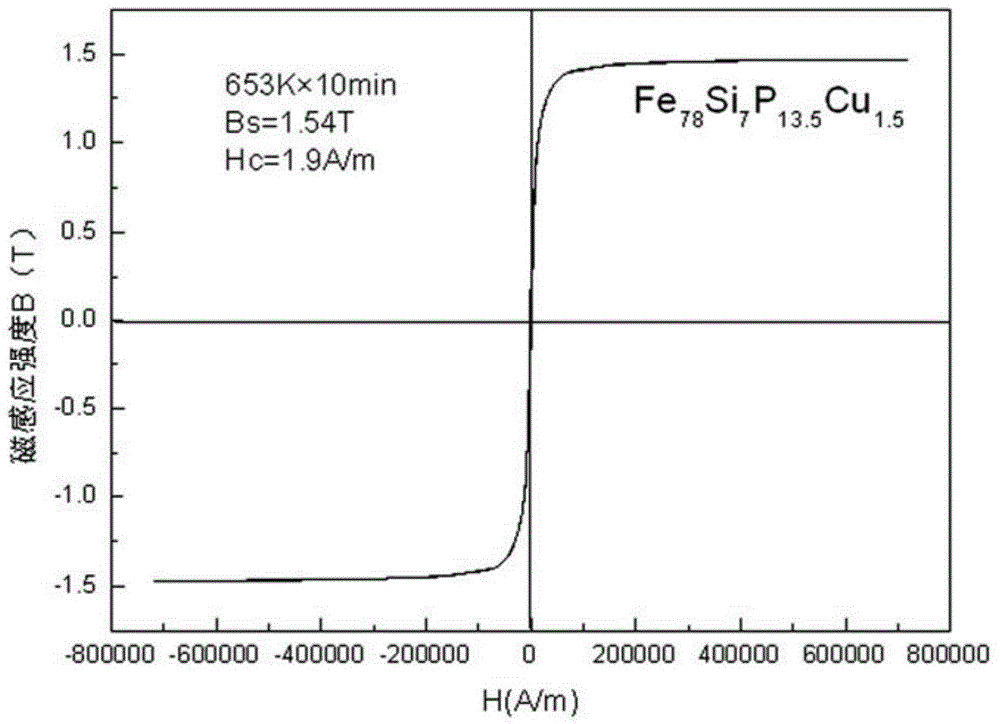

Iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and preparation method thereof

ActiveCN104087833AHigh saturation magnetic inductionImprove thermal stabilityMagnetic materialsRare-earth elementNanocrystalline silicon

The invention discloses iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and a preparation method thereof. The expression of the alloy is FeaSibPcCuxMy, wherein a, b, c, x and y respectively represent the atomic percent content of corresponding compositions and satisfy the following conditions: 70<=a<=85, 5<=b<=15, 5<=c<=18, 0.0001<=x<=3, 0<=y<=5, a+b+c+x+y=100%, and M is one or more of Zr, Ti, Ta, Hf, Nb, V, W, Mo, Mn, Cr, Re, Zn, In, As, Sb, Bi, Ca, platinum group elements, rare earth elements, N, Sn, Ge, Ga and Al. The alloy is a nanocrystalline soft-magnetic alloy band prepared by employing a single-roller quick-cooling method under the conditions of high vacuum and argon protection. The alloy does not contain B elements, is good in soft magnetic property, high in thermal stability, low in high-frequency loss and low in magnetostriction coefficient.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

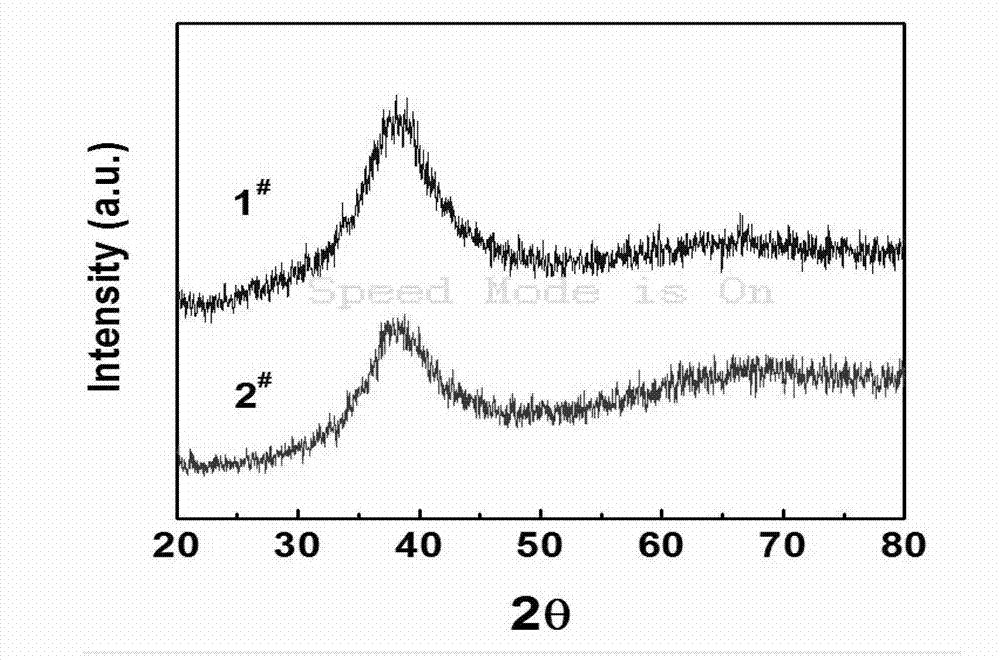

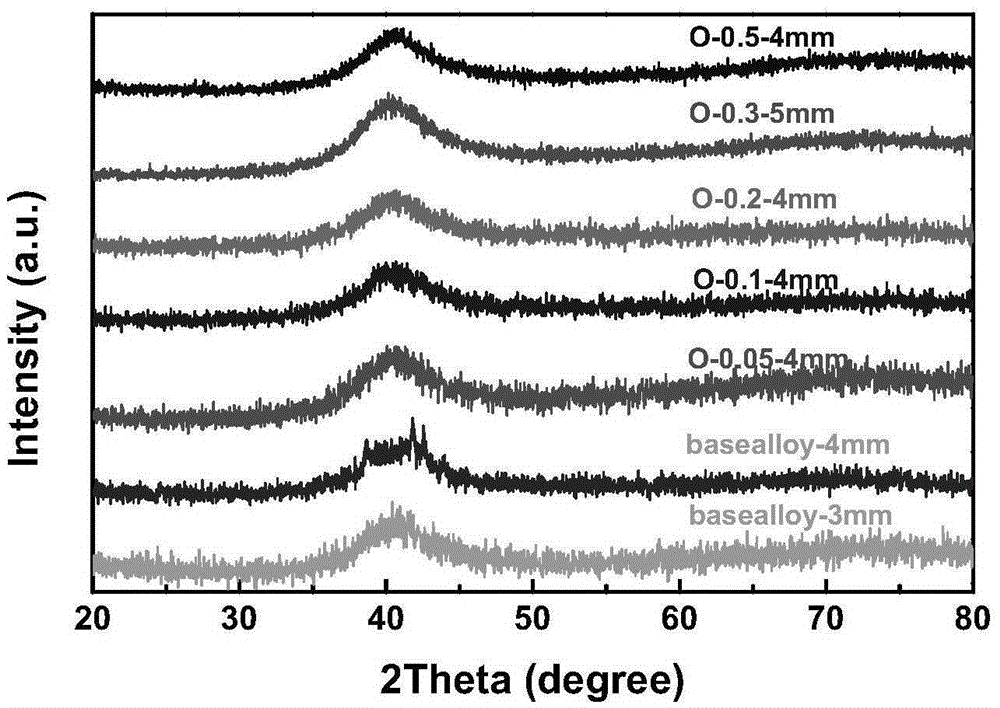

Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and preparing method of Fe-based nanocrystalline soft magnetic alloy

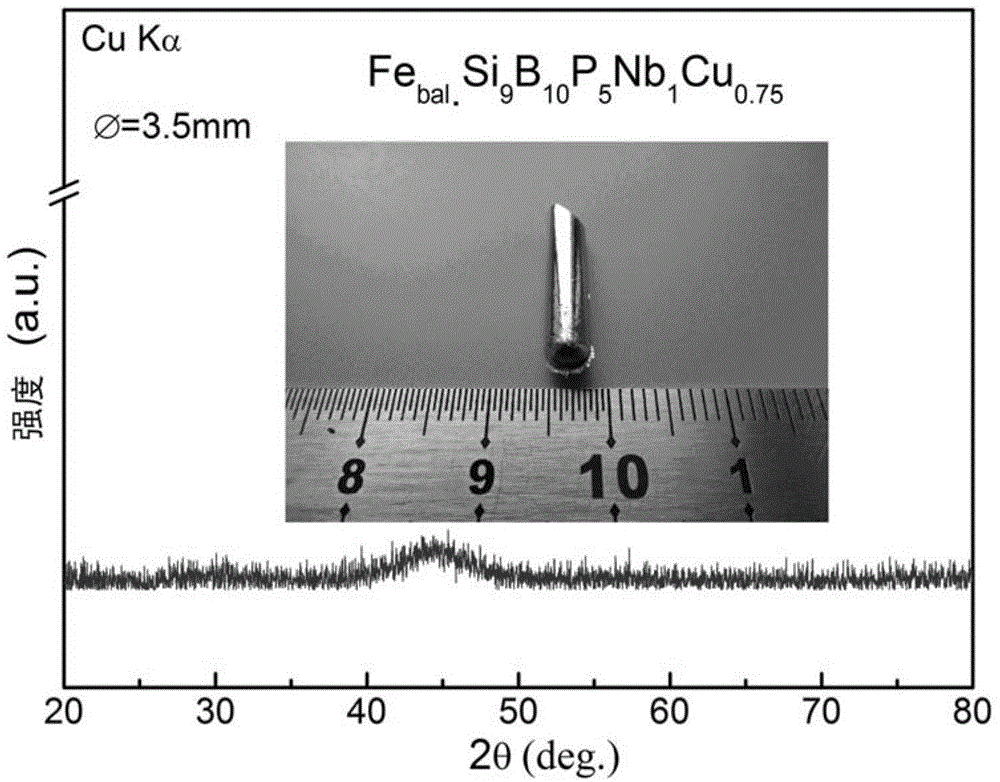

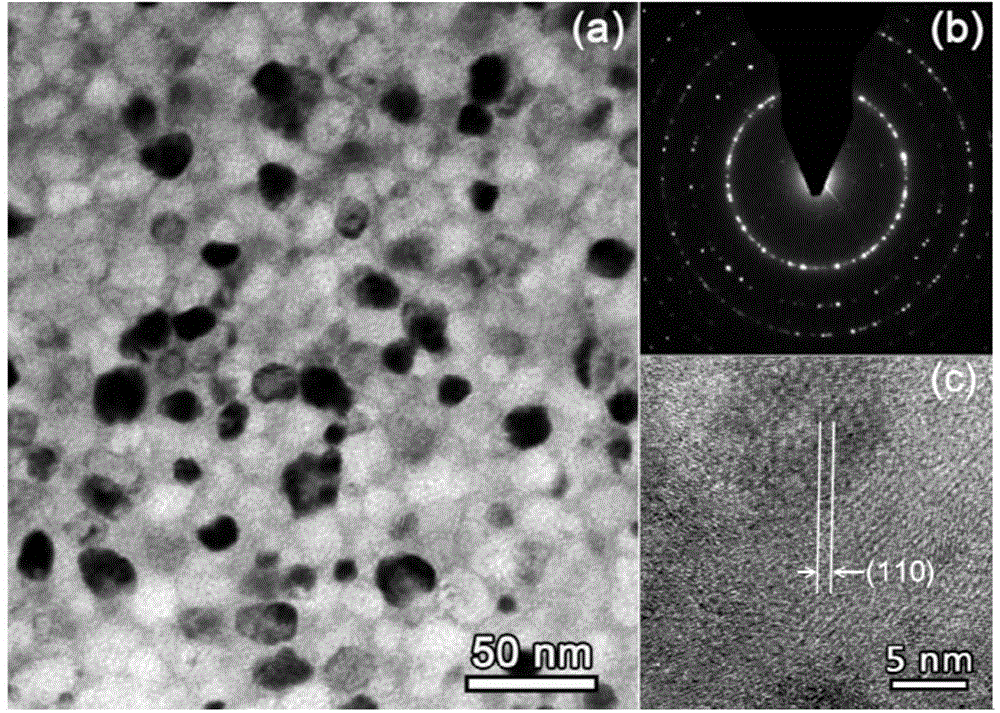

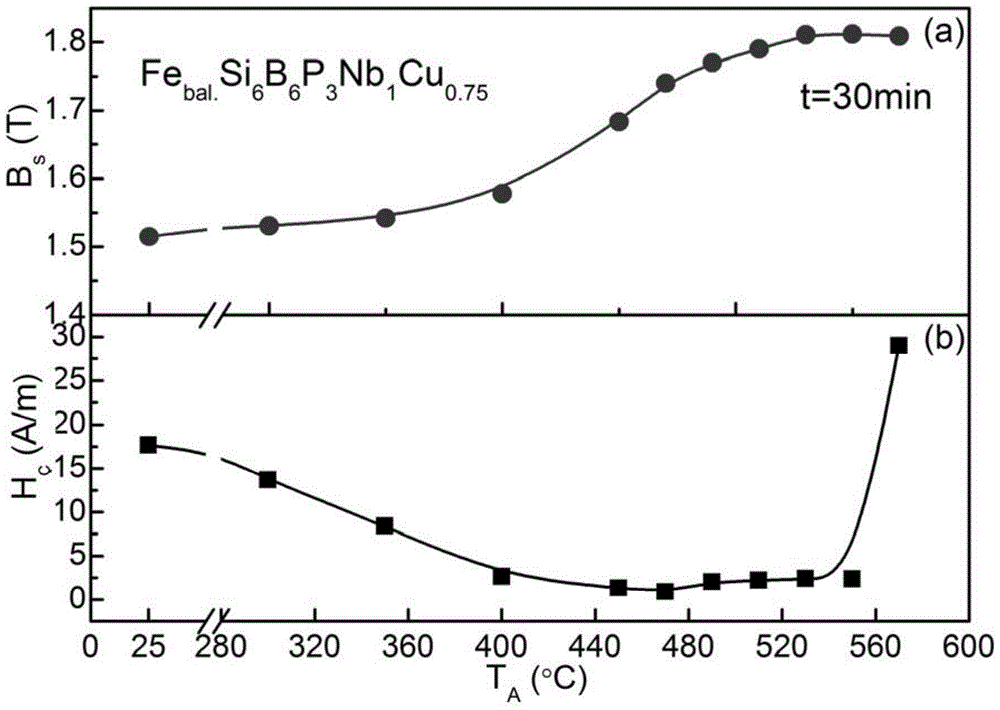

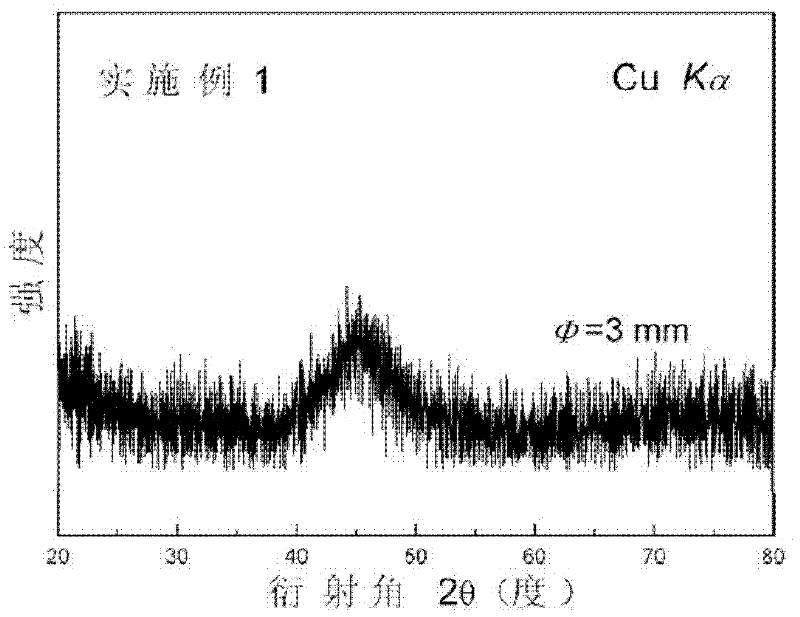

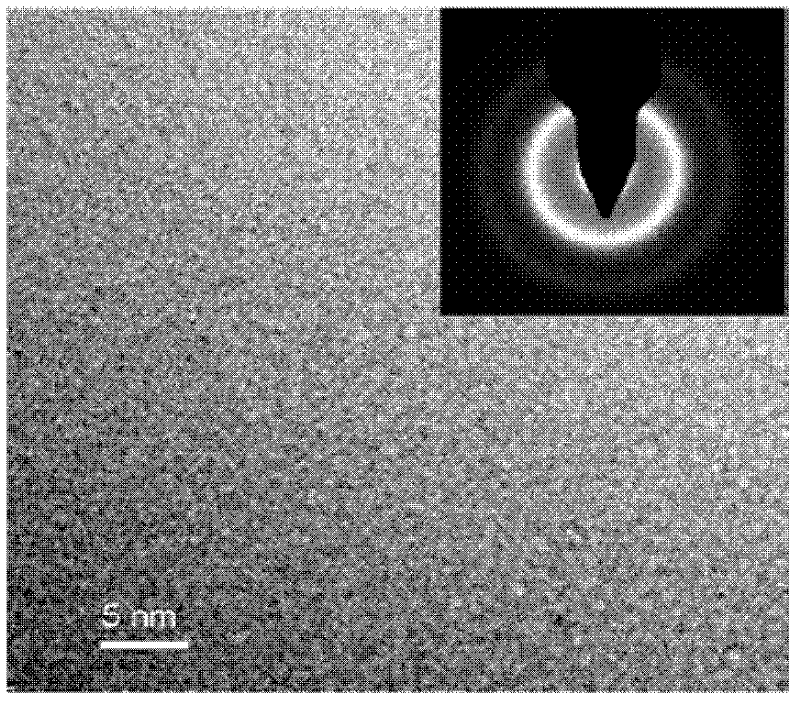

ActiveCN104934179AHigh saturation magnetic inductionLow coercivityMagnetic materialsCopper moldMagnetic alloy

The invention discloses a Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and a preparing method of the Fe-based nanocrystalline soft magnetic alloy. The alloy has an expression of Fe<x>SiBP<c>Nb<d>Cu<e>, wherein in the expression, each of the x, the a, the b, the c, the d and the e shows the atomic percentage content of the corresponding ingredient, and meets the following conditions that the a is greater than or equal to 0.5 but smaller than or equal to 12; the b is greater than or equal to 0.5 but is smaller than or equal to 15; the c is greater than or equal to 0.5 but smaller than or equal to 12; the d is greater than or equal to 0.1 but smaller than or equal to 3; the e is greater than or equal to 0.1 but smaller than or equal to 3; the x is greater than or equal 70 but smaller than or equal to 85; and the sum of the x, the a, the b, the c, the d and the e is 100 percent. The soft magnetic alloy has the advantages that an ordinary copper mold casting method can be used for preparing a Fe-based amorphous alloy with the critical dimension being 3.5mm; after the annealing; the saturation flux density is greater than 1.5T; and the coercive force value is smaller than 1A / m.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

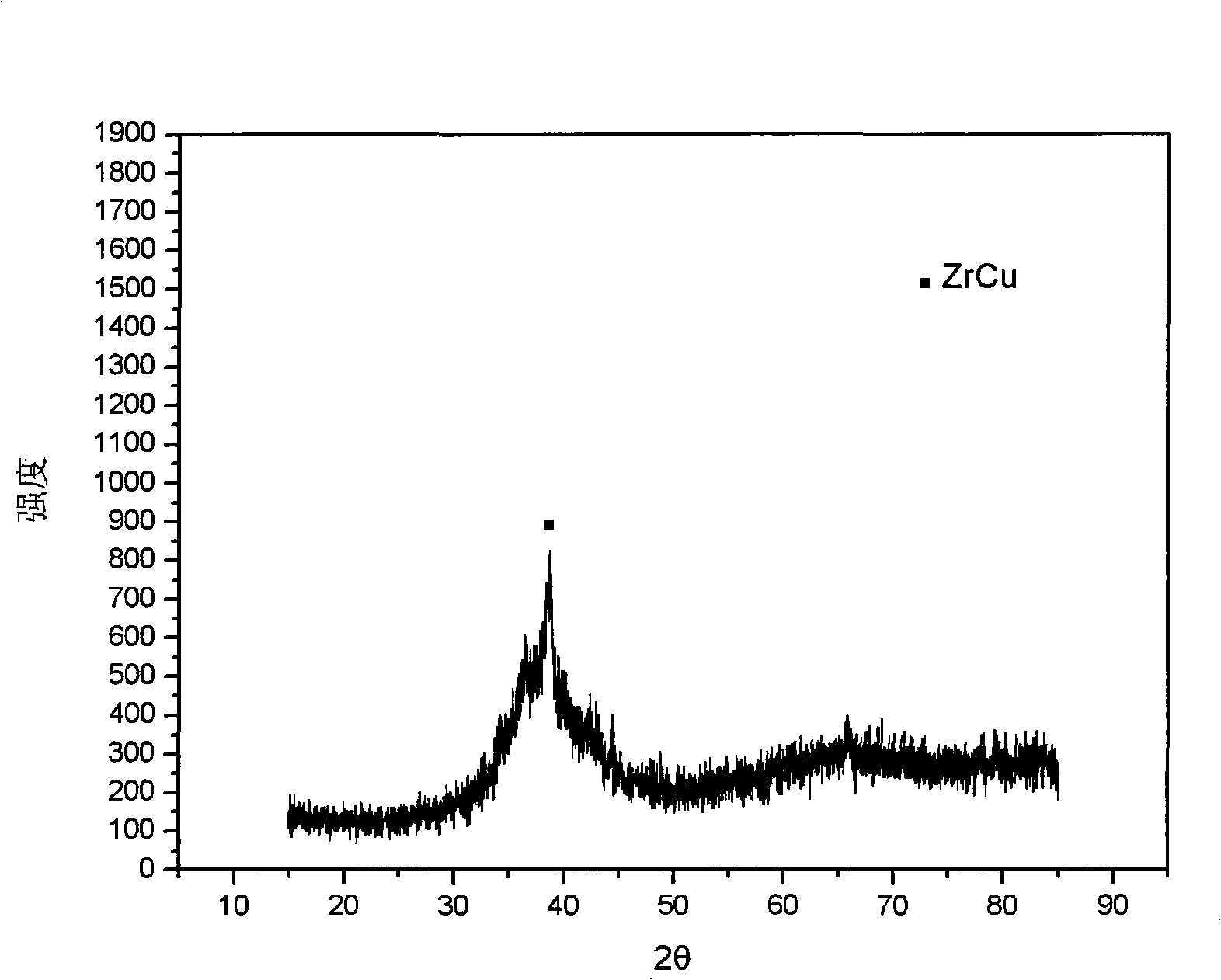

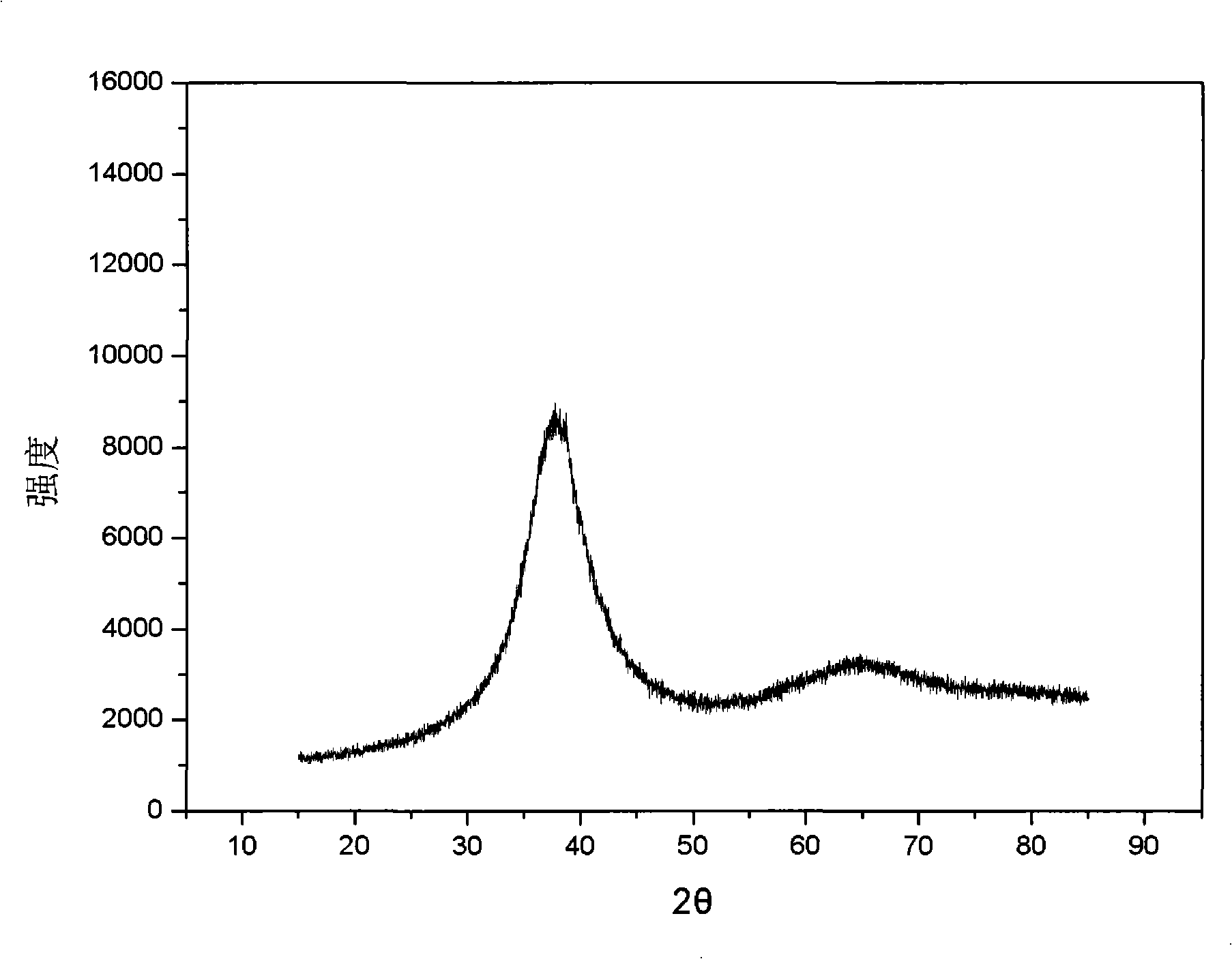

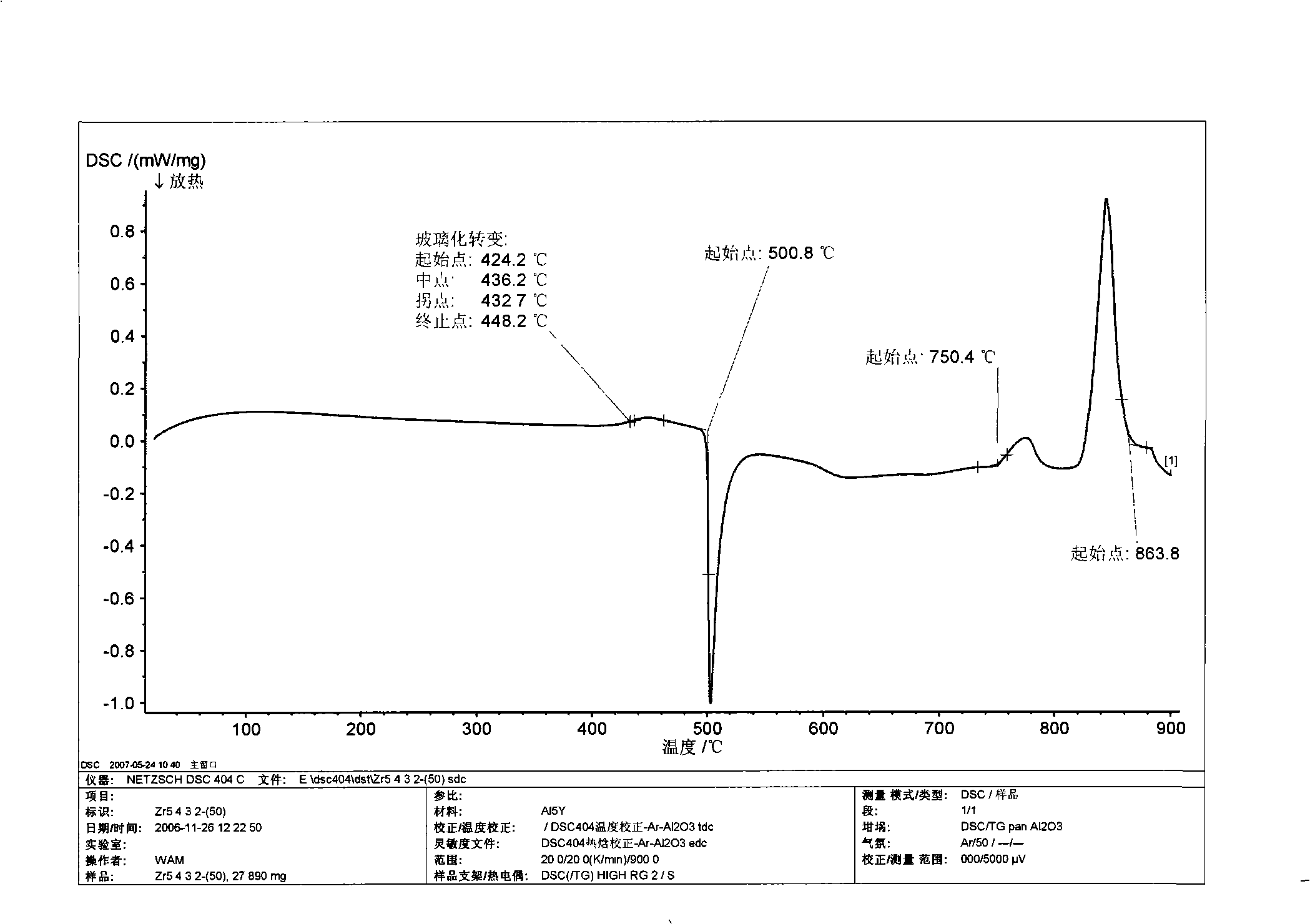

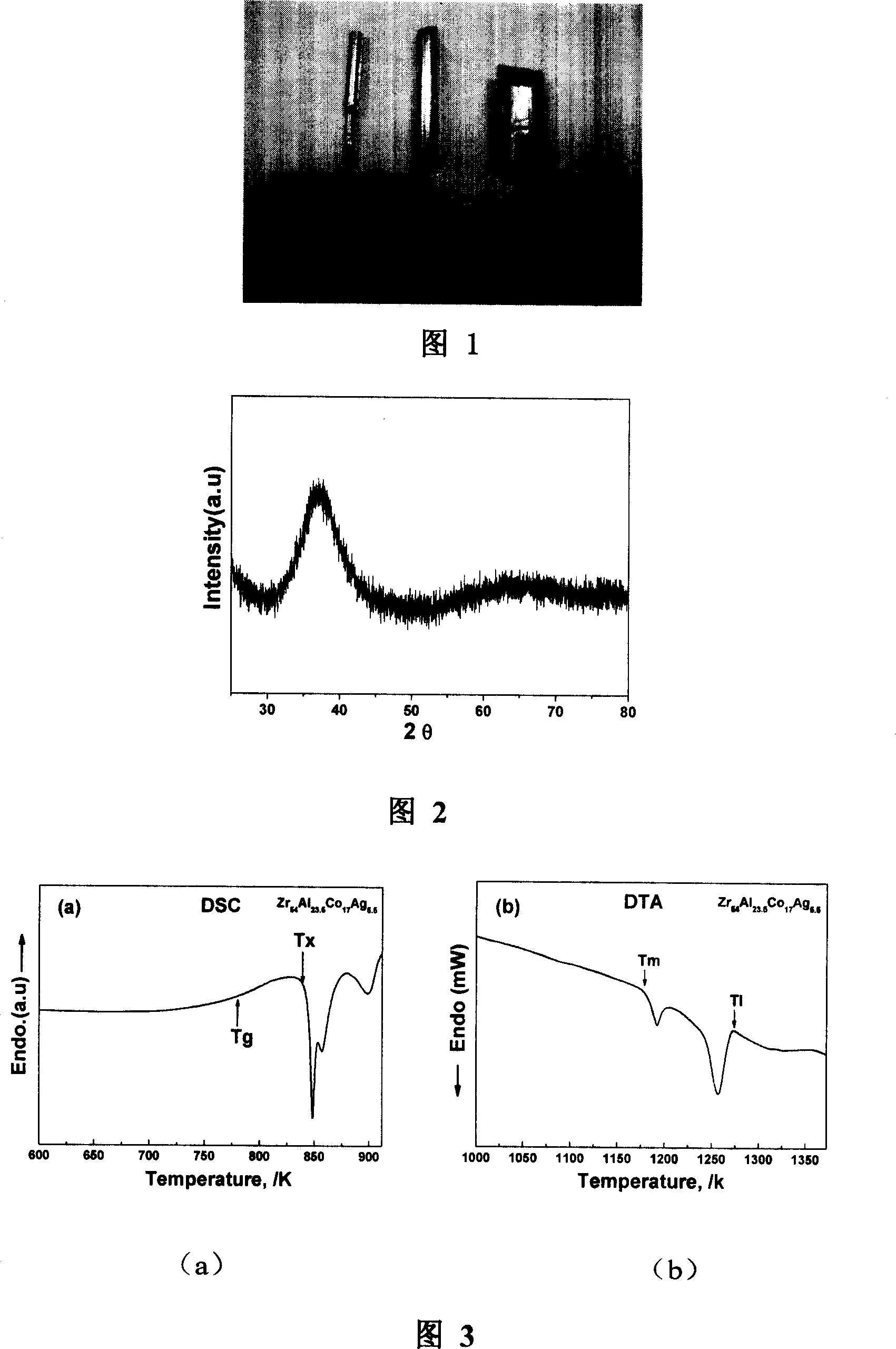

Zr-Cu-Ni-Al-Ag alloy with higher amorphous forming ability and production method thereof

The invention relates to a preparation technology of a block zirconium-base amorphous alloy, in particular to a Zr-Cu-Ni-Al-Ag alloy with higher glass-forming ability and a preparation method thereof, and the characteristic thermodynamics parameter and the mechanical property of the alloy are characterized and tested at the same time. The alloy system is the Zr-Cu-Ni-Al-Ag alloy, which has the component ranges (by atom percentage) that Zr is 41 to 63, Cu is 18 to 46, Al is 4 to 15, Ni is 1.5 to 12.5, and Ag is 1.5 to 26. Based on a Zr-Cu-Ni-Al quaternary alloy, the forming ability of the amorphous alloy is increased through inhibiting the precipitation of a crystalline state phase. The preparation technology adopts an electric arc melting method to prepare a master alloy ingot, then adopts a copper mold casting method to prepare amorphous alloy rods with different diameters, and the alloy in the system can easily prepare amorphous round bars, the diameter of which can reach 2cm. Due to stronger amorphous forming ability and good mechanical property, the alloy has good application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Zirconium-based amorphous alloy

The invention relates to a zirconium-based amorphous alloy. Composition of the zirconium-based amorphous alloy is (Zr, Hf, Nb)aCubNicAldRee, wherein a, b, c, d and e are corresponding contents in atomic percent of each element in the zirconium-based amorphous alloy, a is more than or equal to 45 and less than or equal to 65, b is more than or equal to 15 and less than or equal to 40, c is more than or equal to 0.1 and less than or equal to 15, d is more than or equal to 5 and less than or equal to 15, e is more than or equal to 0.05 and less than or equal to 5, the sum of a, b, c, d and e is less than or equal to 100, Re is one or combination of more than one of La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb and Lu elements, or Re is one or combination of Y with more than one of La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb and Lu elements.

Owner:HUAWEI TECH CO LTD

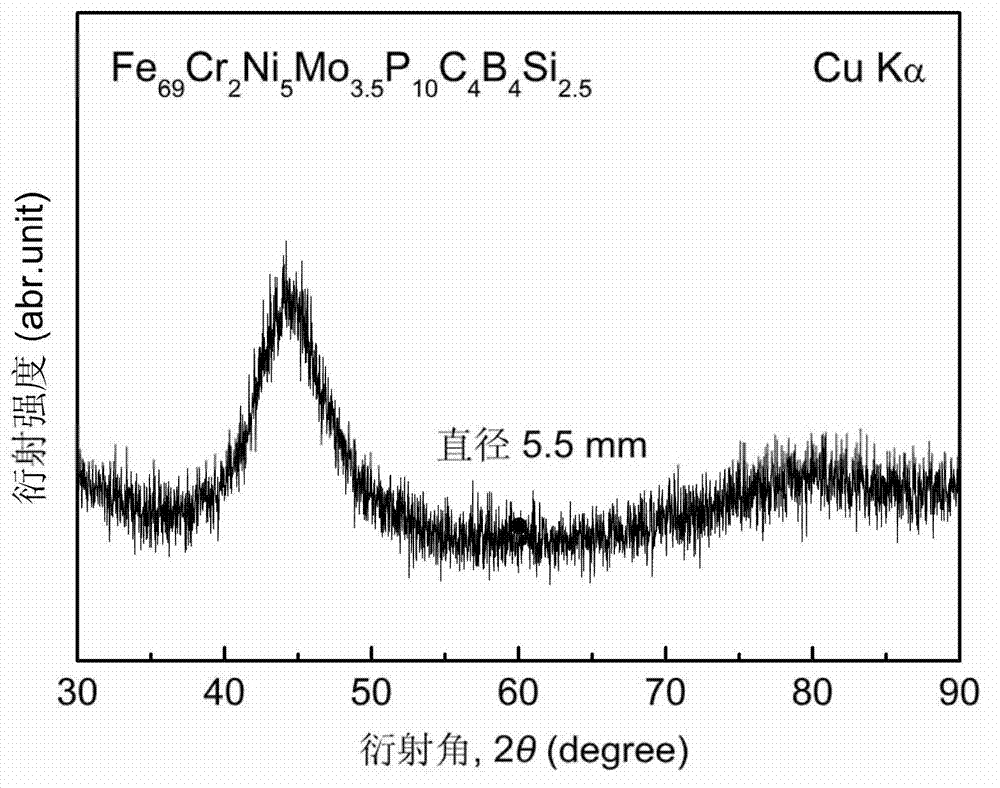

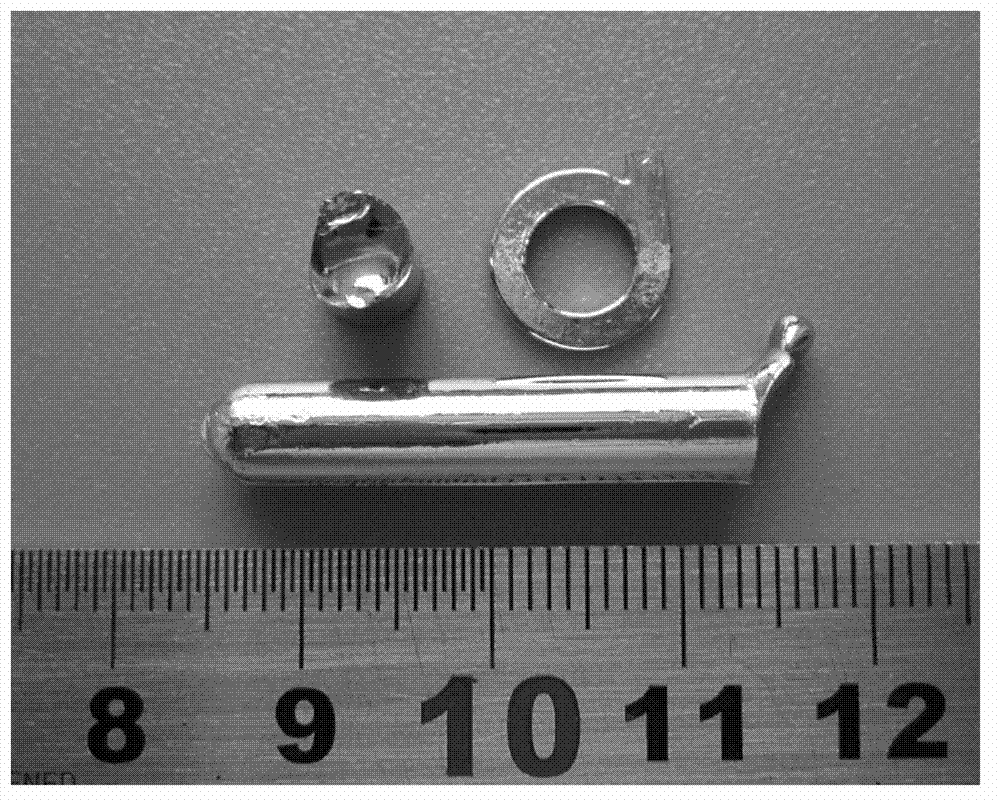

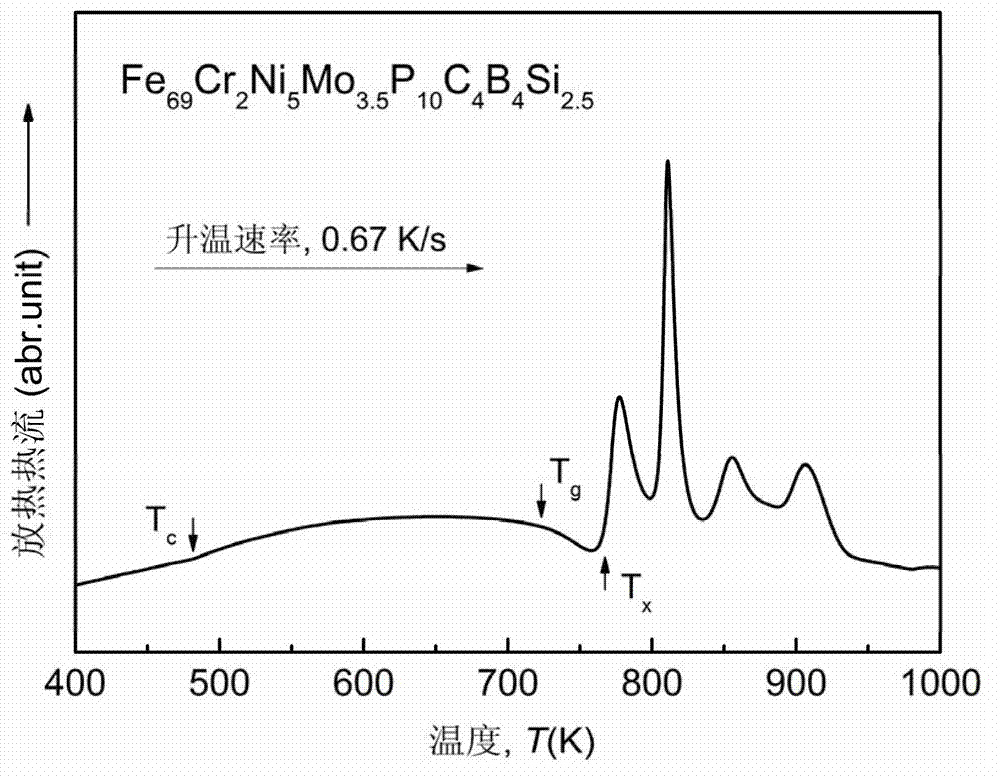

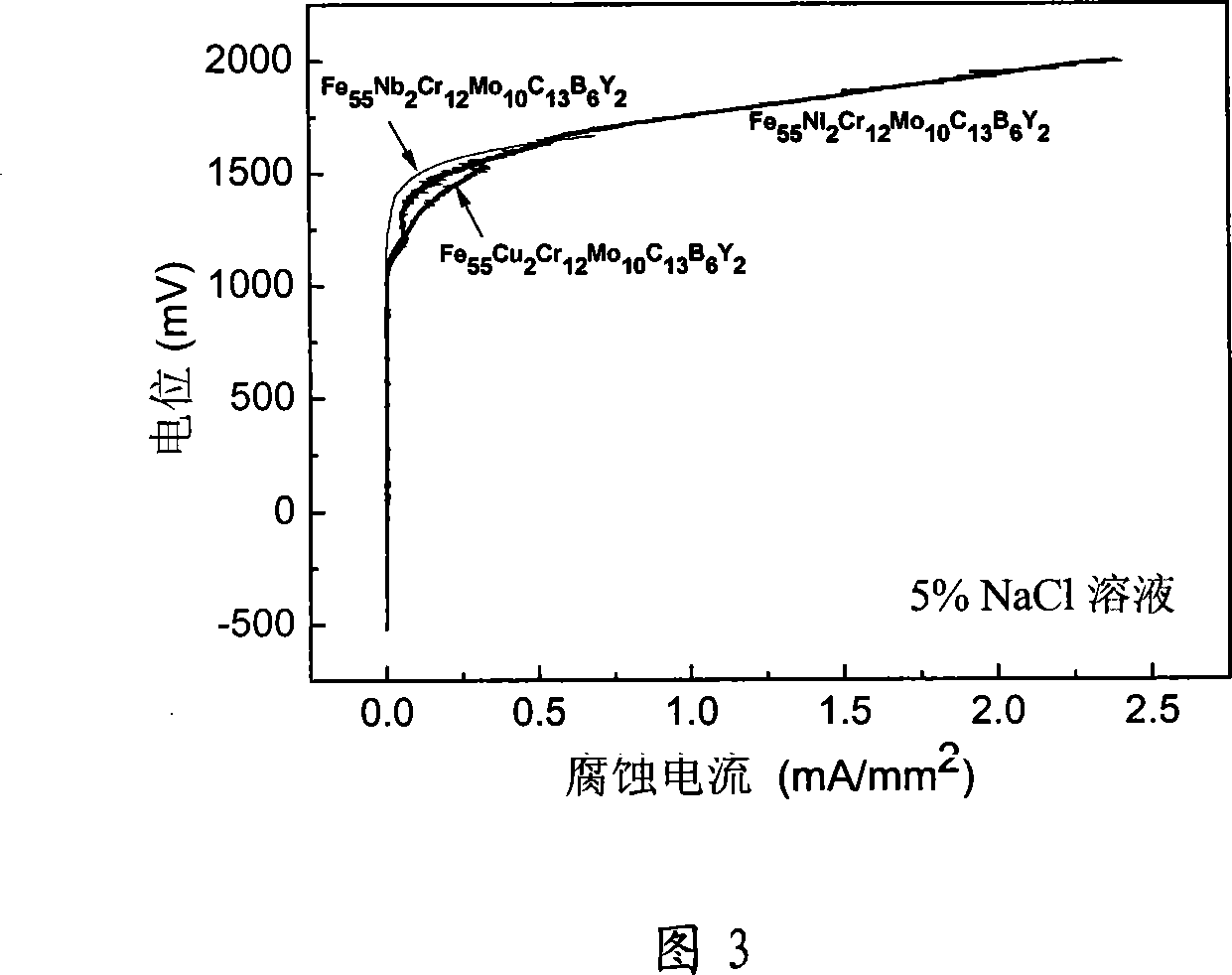

Fe-based soft magnetic amorphous alloy with high corrosion resistance and preparation method thereof

The invention discloses a preparation method of a Fe-based soft magnetic amorphous alloy with high corrosion resistance and a preparation method thereof. The Fe-based soft magnetic amorphous alloy has a molecular formula of FeaCrbNicModPeCfBgSih; and a, b, c, d, e, f, g and h represent the molar percentage of corresponding atoms and satisfy the following relations: 60<=a<=80; 0.5<=b<=4; 2<=c<=12; 2.5<=d<=4.5; 8.5<=e<=11.5; 2.5<=f<=5.5; 3<=g<=6; 1<=h<=4; and a+b+c+d+e+f+g+h=100. Compared with existing Fe-based soft magnetic amorphous alloy, the amorphous alloy has high corrosion resistance, high amorphous forming ability and excellent magnetic properties, and can be used as an electromagnetic device material in harsh environments, such as corrosive media comprising hot and humid salt spray, ammonia or various acids, sea water and sewage.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

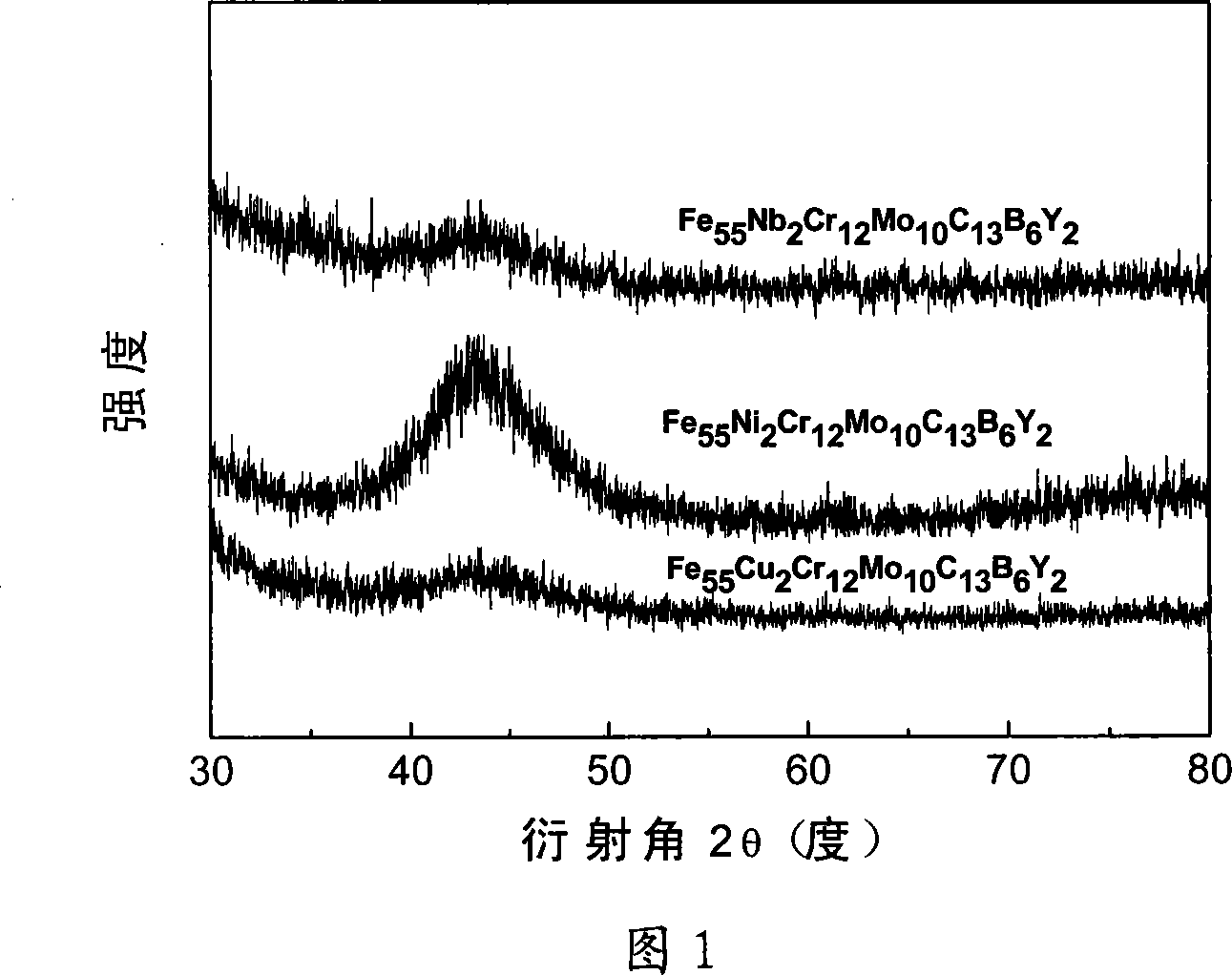

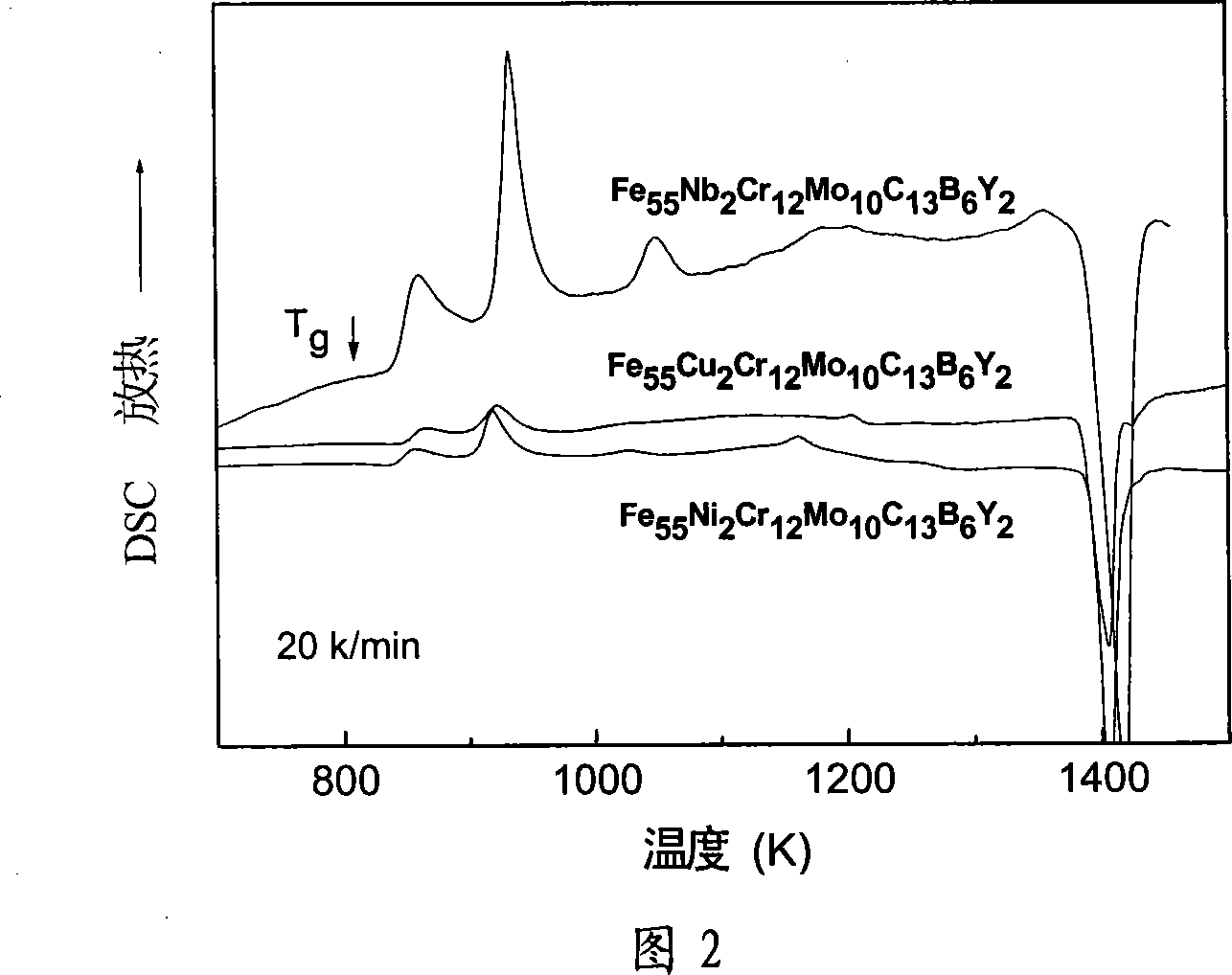

Ferrum-base block non-crystalline alloy material

This invention relates to a Fe based bulk non-crystal alloy material with the following chemical formula: FeaMbCrcModCeBfYg, and a is greater than 45 and smaller than 60, b is greater than 1 and smaller than 5, c is greater than 5 and smaller than 20, d is greater than 5 and smaller than 15, e is greater than 5 and smaller than 15, f is greater than 0.5 but smaller than 10 and g is greater than 0.5 and smaller han 3, in which, a, b, c, d, e, f and g are atomic percentages, the the weight percentage of the content sum of unavoidable impurities Si, S, P and O is less than 0.5%, and M in the formula is Ni, Cu or Nb.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

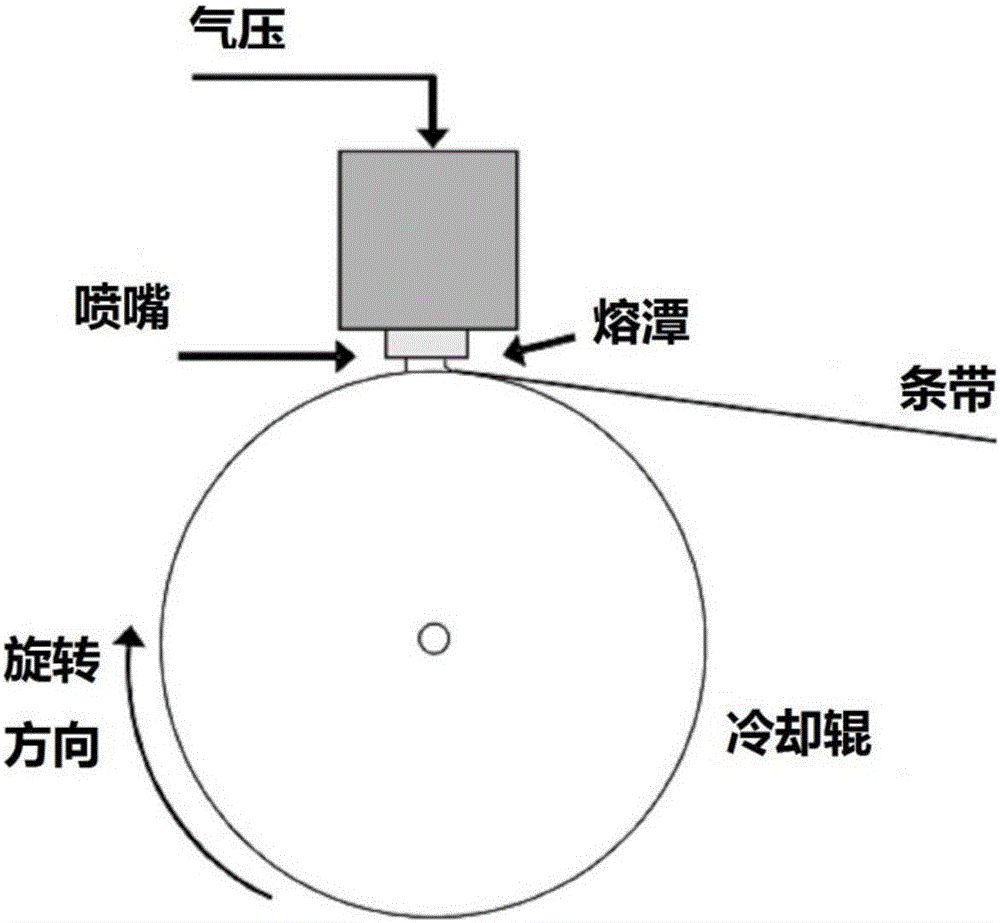

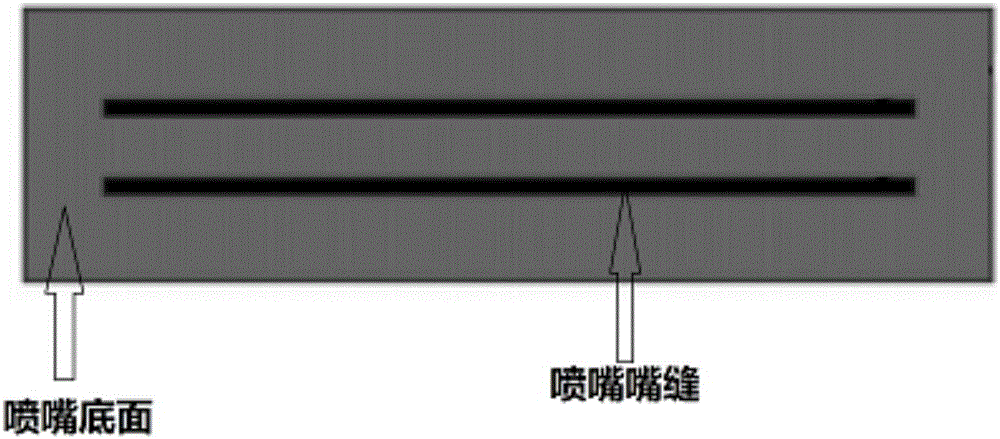

Rare-earth-doped iron-based amorphous thick strip and preparing method thereof

The invention relates to a rare-earth-doped iron-based amorphous thick strip and a preparing method thereof. The component expression of the iron-based amorphous thick strip is FexSiaBbPcYd, wherein x, a, b, c and d are atomic percents of corresponding elements, wherein a is larger than or equal to 0.5 and smaller than or equal to 10, b is larger than or equal to 0.5 and smaller than or equal to 12, c is larger than or equal to 0.5 and smaller than or equal to 8, d is larger than or equal to 0.001 and smaller than or equal to 0.5, and x+a+b+c+d is equal to 100. A plane flow casting method is adopted for manufacturing the strip, during strip manufacturing, a double-line nozzle is adopted, the thickness of the prepared amorphous thick strip ranges from 50 micrometers to 100 micrometers, the lamination coefficient is larger than 0.92, the saturated magnetic induction density is larger than 1.67T. Micro rare earth yttrium is contained in an alloy, the content of impurities of oxygen, sulphur and the like is greatly reduced, and the molten steel mobility is improved; meanwhile the rare earth yttrium improves the amorphous forming capacity of an alloy system, and the amorphous alloy strip with the thickness ranging from 50 micrometers to 100 micrometers can be prepared through the technology method.

Owner:南京腾元软磁有限公司 +3

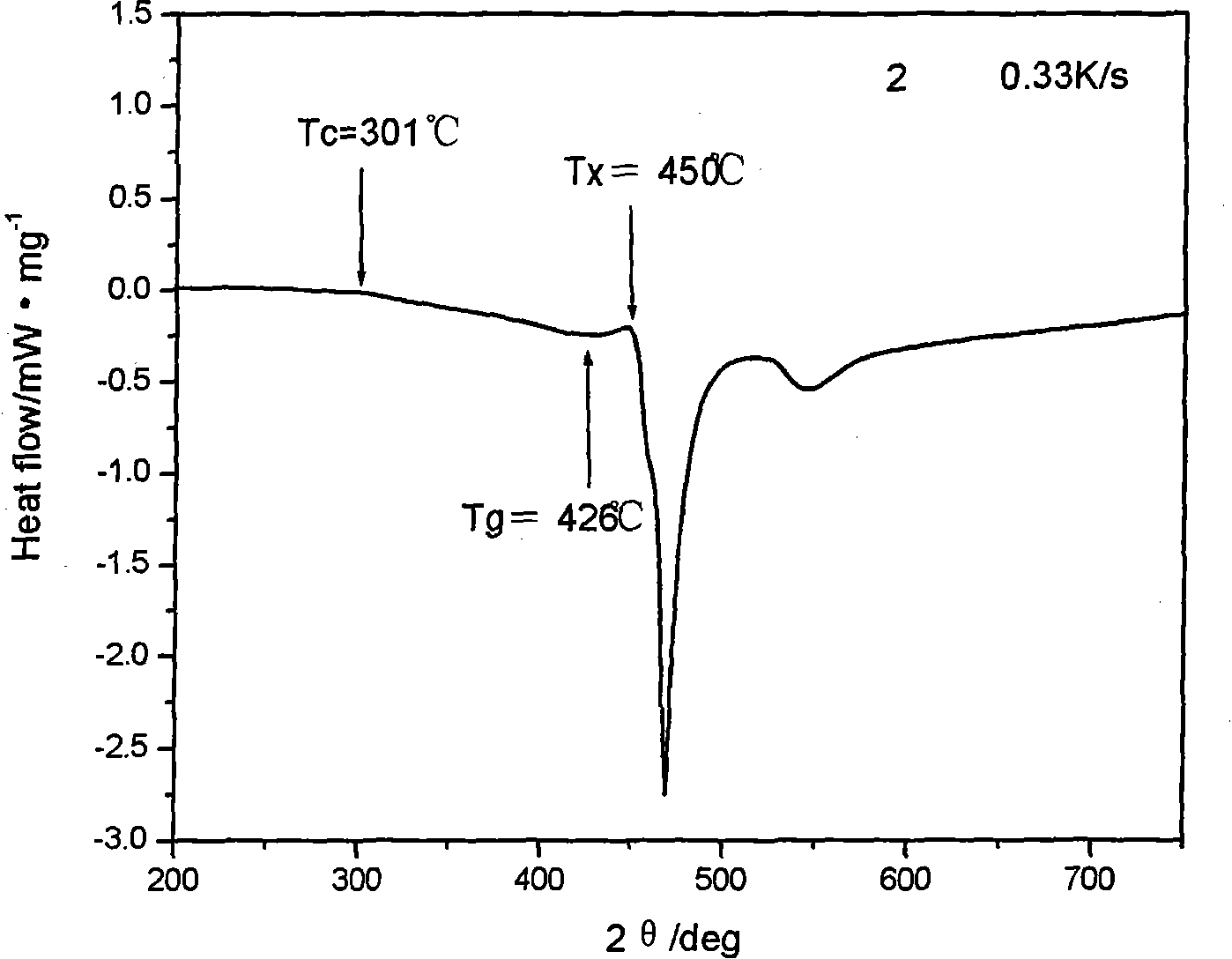

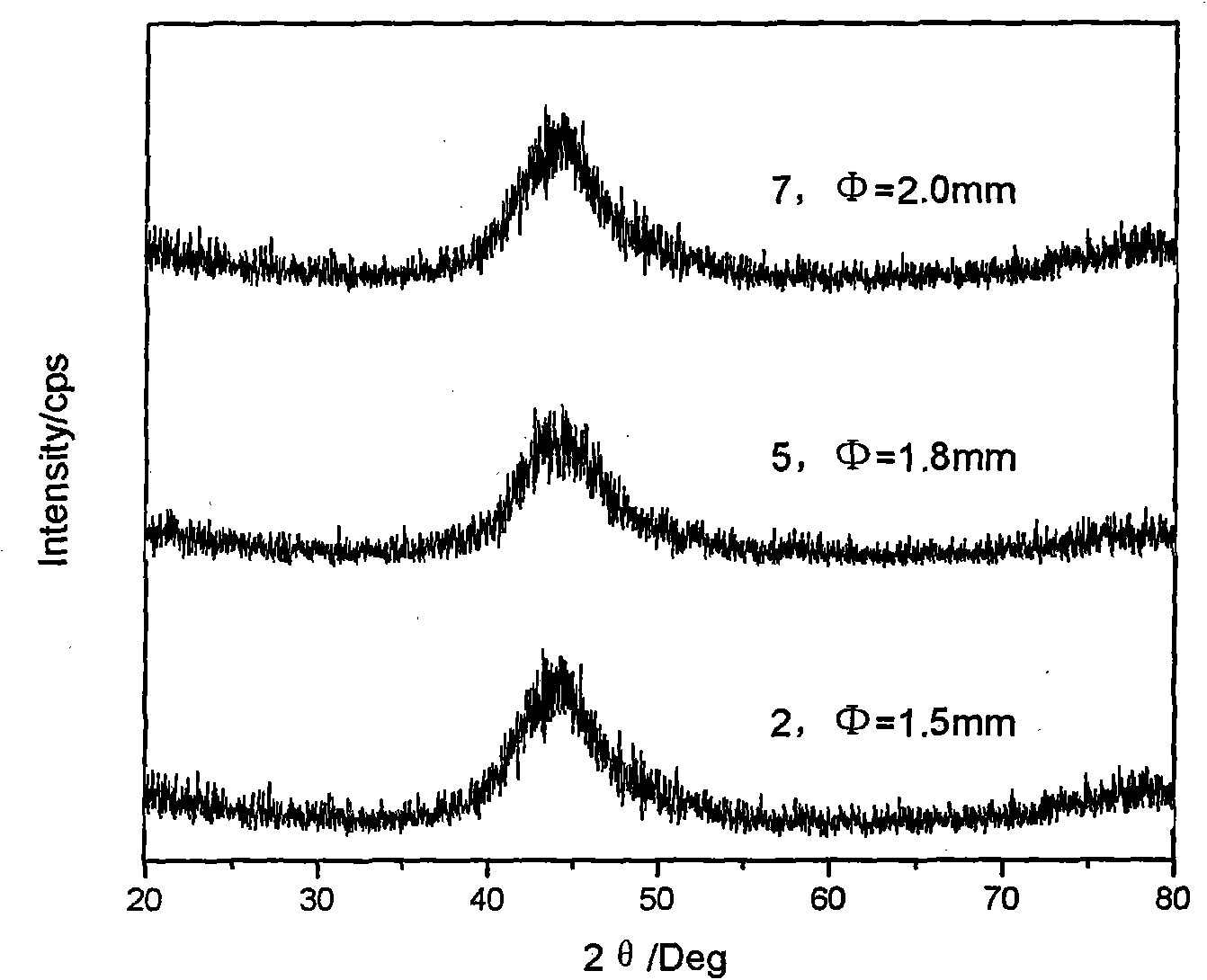

Beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and preparation method thereof

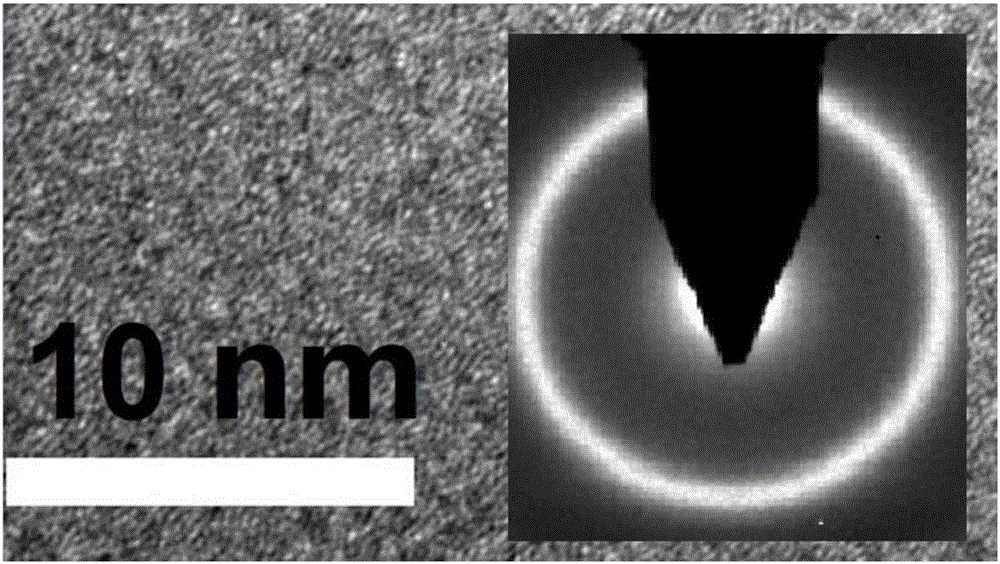

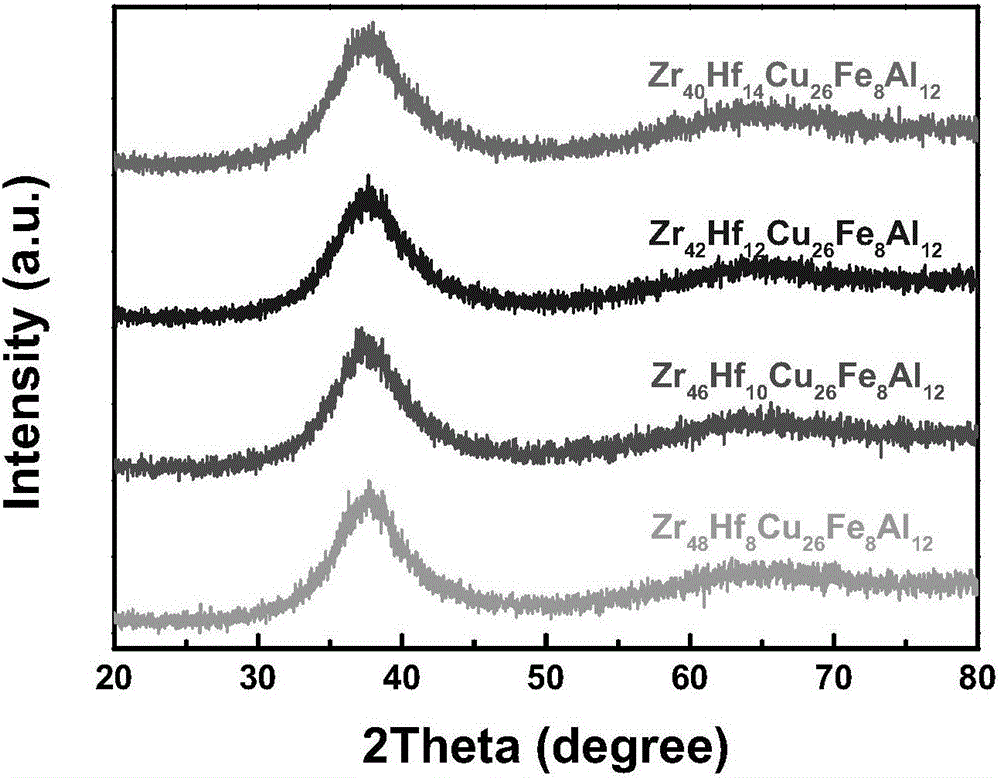

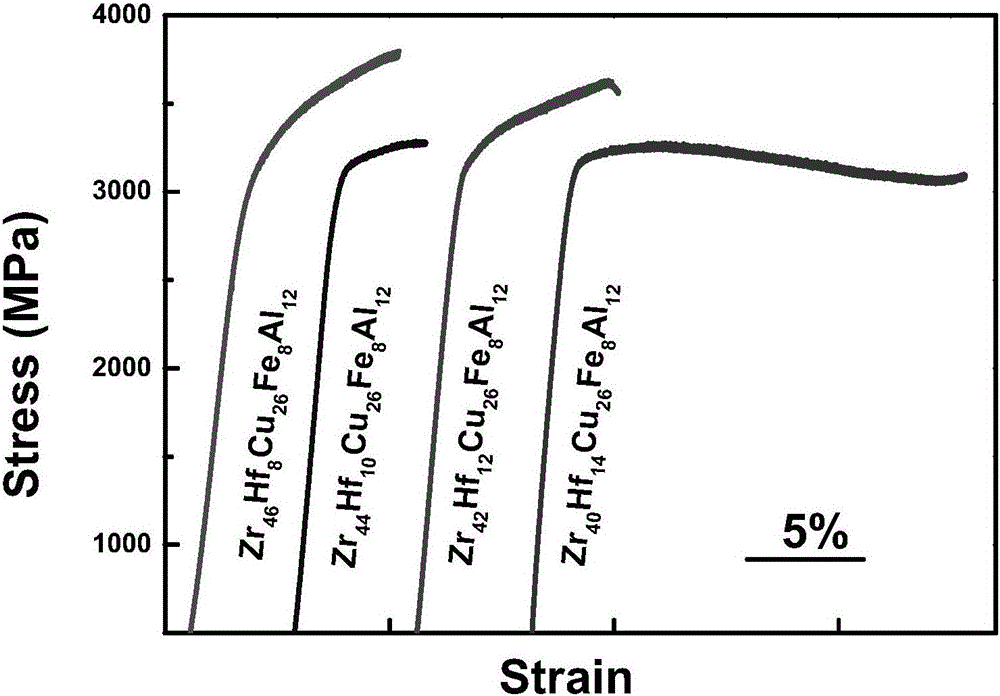

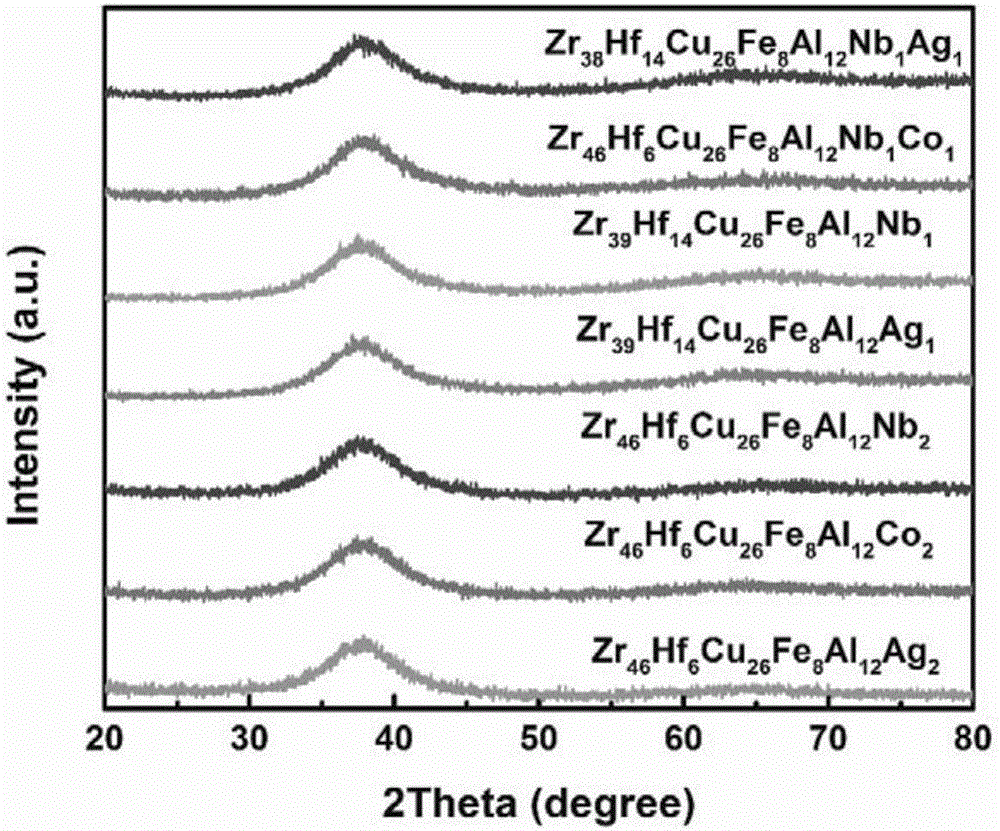

ActiveCN106756647AGood biocompatibilityWide temperature range of subcooled liquid phase regionBiocompatibility TestingNickel free

The invention provides a beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and a preparation method thereof. The alloy comprises, by atom, 38-50% of Zr, 2-15% of Hf, 20-30% of Cu, 5-10% of Fe, 10-15% of Al, 0-5% of Co, 0-5% of Ag and 0-5% of Nb. The electric arc melting copper mould casting method is adopted for preparation. The amorphous alloy is free of metal elements such as Be and Ni, and biocompatibility of the zirconium-base alloy is improved. The high amorphous forming capacity is achieved, and the zirconium-base block body amorphous alloy with the critical size being no less than 5 mm can be prepared through the copper mould casting method. According to the beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy, high hardness is achieved, and vickers hardness is larger than 540 Hv; the plastic deformation capacity being larger than 3% is achieved; and the super-cooled liquid phase region range is wide and reaches 92 K at most. The beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and the preparation method thereof has very wide application prospects in the fields of biomedical materials such as a precise complex medical component, a joint prosthesis and a human skeleton.

Owner:UNIV OF SCI & TECH BEIJING

High heat stability block ferromagnetic metal glas synthetic method

InactiveCN1552940ARational Ingredient DesignStrong Amorphous Formation AbilityMagnetic materialsCopperFerromagnetism

This invention relates to high thermally stable ferromagnetic metal glass blocks and their synthesis. The constituent of the said blocks comprises Co 35 - 45 at%, Fe 12 - 35 at%, Hf 2 - 10 at%, Mo 0 - 8 at%, Ti 2 - 8 at%, B 22 - 35 at%, and V 0 - 3 at%. The blocks can be prepared in copper molds, with excellent amorphization at >650 deg.C and the constituent designed more reasonable than the present materials, and used widely at higher temperature.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High energy gasification/atomization of Fe#-[3]B/R#-[2]Fe#-[14]B nanometer composite permanent magnet powder and its preparation method

InactiveCN1593820AHigh B contentStrong Amorphous Formation AbilityMagnetic materialsHigh energyAlloy

The invention makes public a kind of composite nanometer Fe3B / R2Fe14B permanent magnetism powder by high-energy gas atomizing and the method of making it. Transform the alloy fluid, whose atomic composition formulary is Rx(Fel-wCow)100-x-y-xByTz, into ball powder by high-energy gas atomizing. Then dispose it and get composite nanometer Fe3B / R2Fe14B powder based on Fe3B by hot crystallization. The R is at least one component as following: Nd, Pr, Dy, and Tb. The T is at least one of the following components: Zr, Nb, Cr, Ga, Ti, V and Si. And the proportion should be:3.0<=x<=6.0,8<=y<=22,0<=z<=5,0<=w<=0.5. The powder made by this method has advantages such as glaze, ball shape, good fluidity and low cost, and is especially fit for adhesive binding magnet by injection molding.

Owner:ZHEJIANG UNIV

High-performance ferric-based nano-crystalline soft magnetic alloy and preparation method thereof

InactiveCN102945719AGood soft magneticSuitable for mass productionMagnetic materialsChemical compositionChemical element

The invention provides a high-performance ferric-based nano-crystalline soft magnetic alloy and a preparation method thereof, and belongs to the field of preparation of soft magnetic alloy of functional materials. Chemical elements of the nano-crystalline soft magnetic alloy can be represented by FeaPbCcSidAleCrfCug, wherein a, b, c, d, e and f are the atomic percentage of corresponding elements, which are in a range as follows: b is 4-10, c is 5-9, c is 0-6, e is 0.5-1, f is 0.3-0.5, g is 0-2, and a is (100-b-c-d-e-f-g). A soft magnetic amorphous alloy ribbon made by a rotary quenching method according to an ingredient proportion requirement of the invention is provided with good amorphous forming ability and annealing process performance, and particularly can keep a rather low coercive force within a rather wide annealing temperature range. And the nano-crystalline soft magnetic alloy provided by the invention has a great potential application prospect because of relatively low cost and excellent soft magnetic performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Zirconium base amorphous alloy

The invention relates to a zirconium base amorphous alloy, wherein the composition of the zirconium base amorphous alloy is (Zr, Hf, Nb)CuTiAlRe, a, b, c, d and e are the percentage contents of the corresponding atoms in the zirconium base amorphous alloy, a is more than or equal to 40 and is less than or equal to 65, b is more than or equal to 20 and is less than or equal to 50, c is more than or equal to 0.1 and is less than or equal to 10, d is more than or equal to 5 and is less than or equal to 15, e is more than or equal to 0.05 and is less than or equal to 5, (a+b+c+d+e) is less than or equal to 100, Re is a combination comprising one or a plurality of materials selected from elements such as La , Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb and Lu, or is a combination comprising Y and one or a plurality of materials selected from elements such as La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb and Lu.

Owner:HUAWEI TECH CO LTD

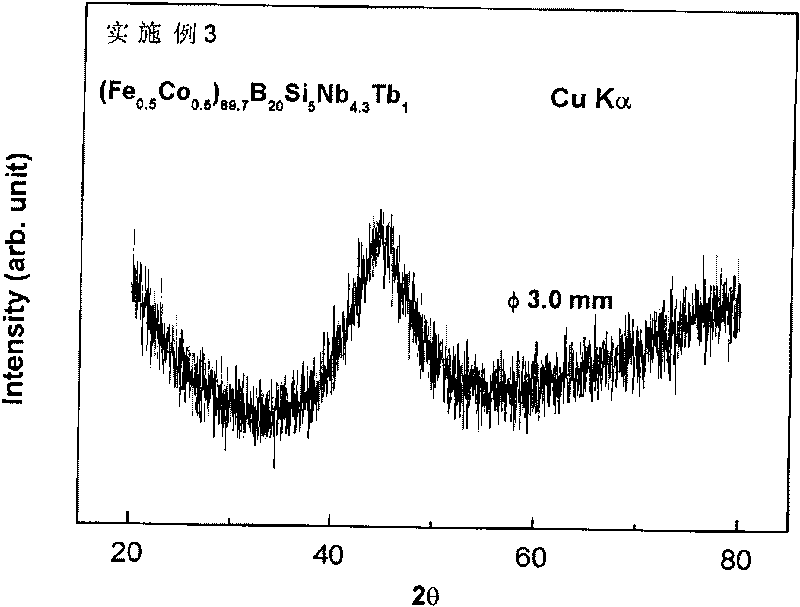

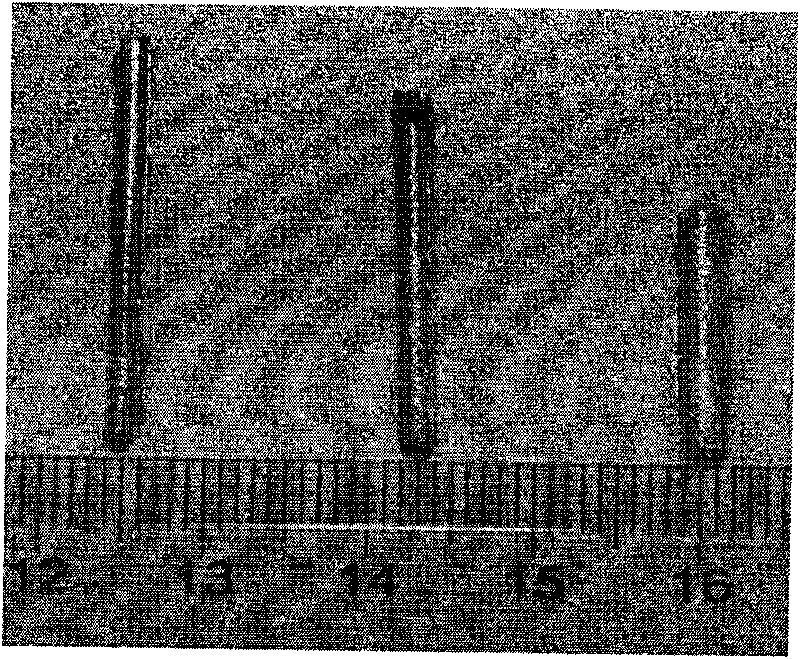

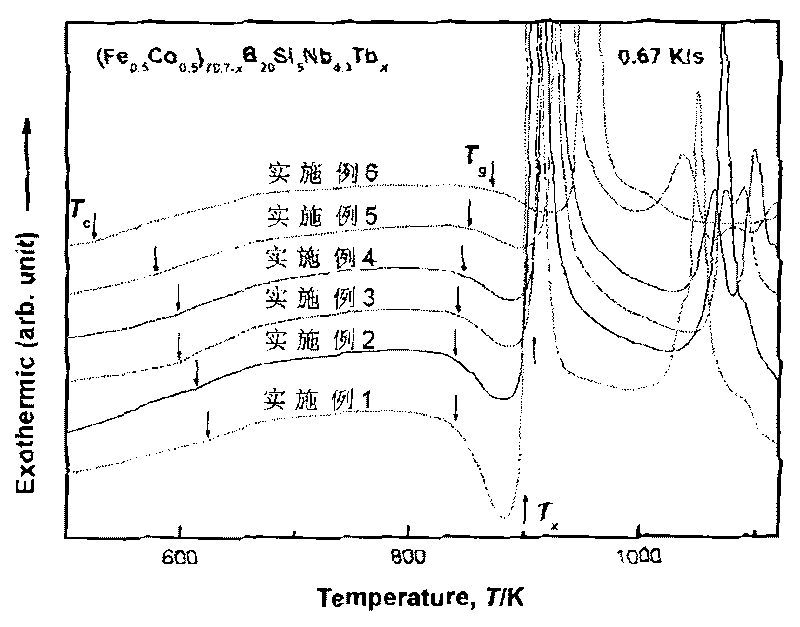

Iron-based bulk amorphous soft magnetic alloy and preparation method thereof

The invention discloses an iron-based bulk amorphous soft magnetic alloy and a preparation method thereof; the molecular formula of the amorphous alloy is (Fe 0.5Co0.5) 70.7-xB20Si5Nb4.3Tbx; wherein the numeric range of x is x larger than or equal to 0 and less than or equal to 2.5; the amorphous alloy is obtained by adding a rare earth element Tb into FeCo BSiNb system. Compared with the prior art, the iron-based bulk amorphous soft magnetic alloy prepared by industrial material has bigger amorphous formation capability and excellent soft magnetic performance; the diameter of the prepared amorphous bar material is 2mm-3mm, the saturation magnetization strength is 0.69 T-0.92 T, and the coercive force is 2.1A / m-3.8 A / m, which are relatively row compared with other doped rare-earth element systems. The preparation method is simple and has lower cost. The iron-based bulk amorphous soft magnetic alloy can be used as a core of a magnetic sensor and is applied to fields such as information, communication and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

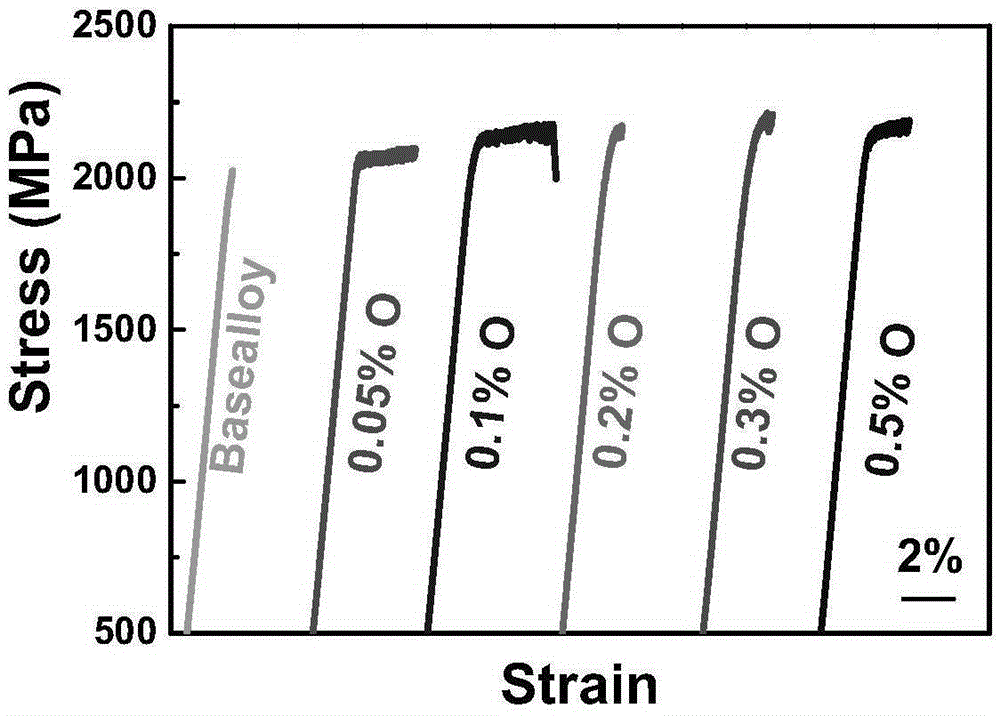

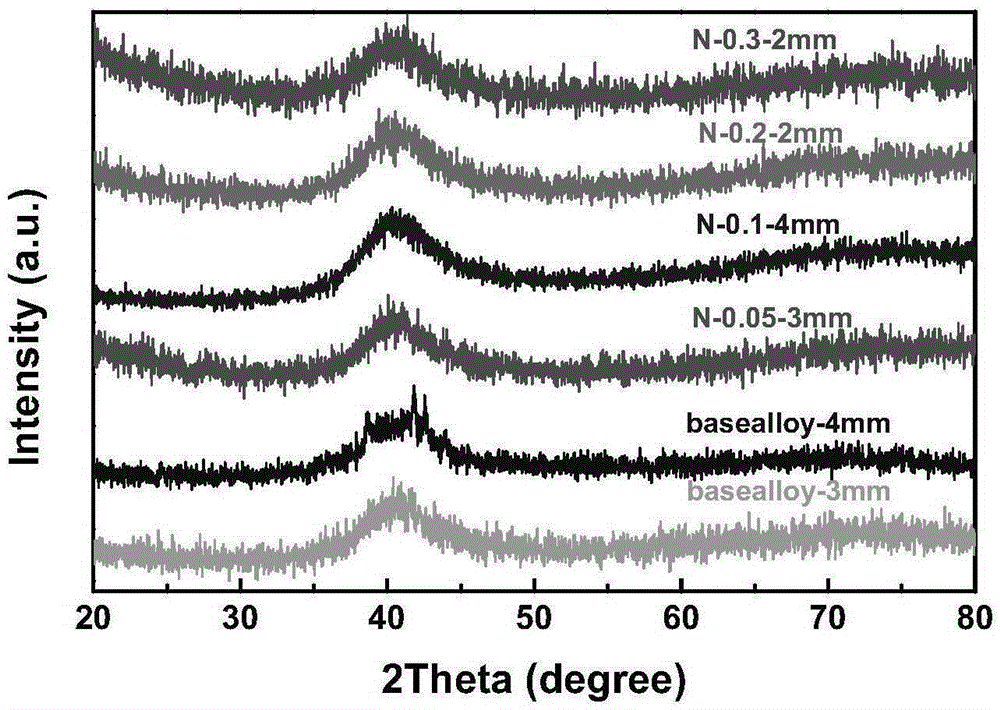

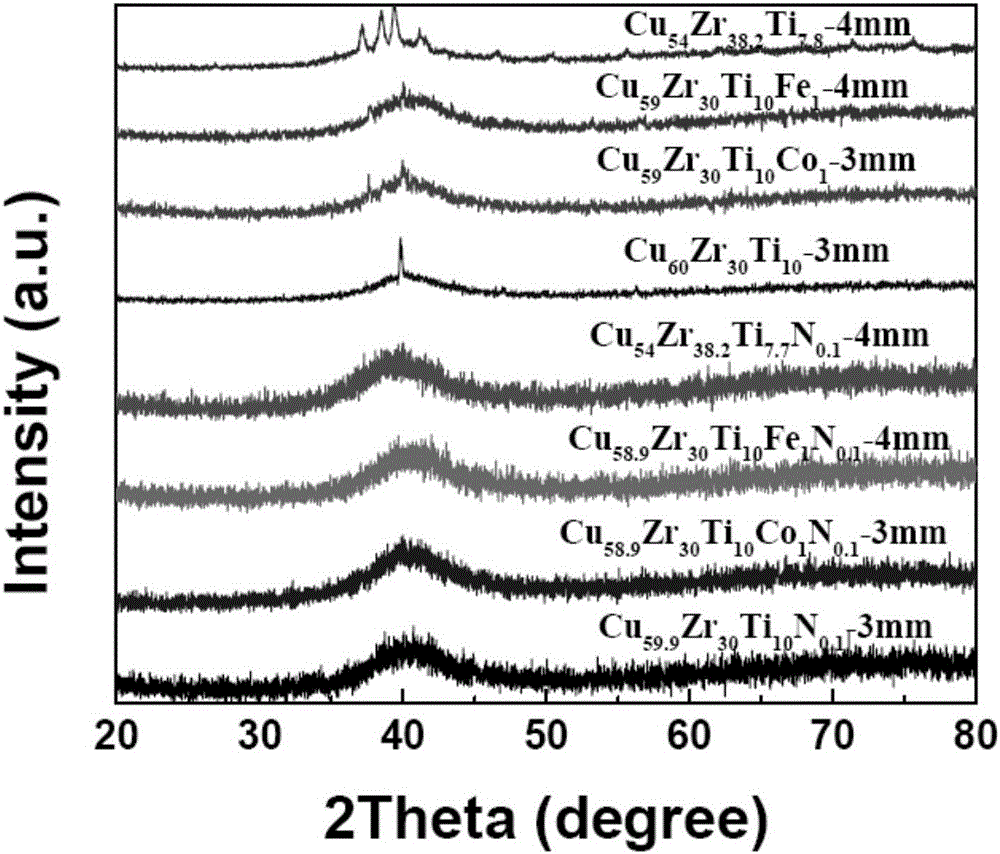

Nitrogen-oxygen alloying ti-based amorphous alloy and preparation method thereof

The invention discloses nitrogen-oxygen alloying ti-based amorphous alloy and a preparation method thereof. The atomic percentage expression of the amorphous alloy is (TiaCubZrcNidSne) nNpOq, and the components of the amorphous alloy meet the conditions that a is greater than 20 and less than or equal to 60, b is greater than 0 and less than or equal to 60, c is greater than 0 and less than or equal to 50, d is greater than 0 and less than or equal to 50, e is greater than 0 and less than or equal to 50, n is greater than or equal to 90 and less than 100, p is greater than or equal to 0 and less than or equal to 5, q is greater than or equal to 0 and less than or equal to 5, a+b+c+d+e=100, and n+p+q=100. The preparation method comprises the steps that raw metal materials Ti, Cu, Zr, Ni and Sn are weighed according to the molar ratio; after nitride and oxide are added simultaneously, smelting is carried out in a non-self-consuming vacuum arc furnace or a cold crucible shower furnace; the alloy is obtained through suction casting or pouring. According to the nitrogen-oxygen alloying ti-based amorphous alloy and the preparation method thereof, by adding one or two elements of N and O, the amorphous forming ability and compressive plasticity of the amorphous alloy is improved; the maximum critical dimension is 5 mm, the compressive strength is over 2000 MPa, and the breaking strain is more than 5.7%.

Owner:UNIV OF SCI & TECH BEIJING

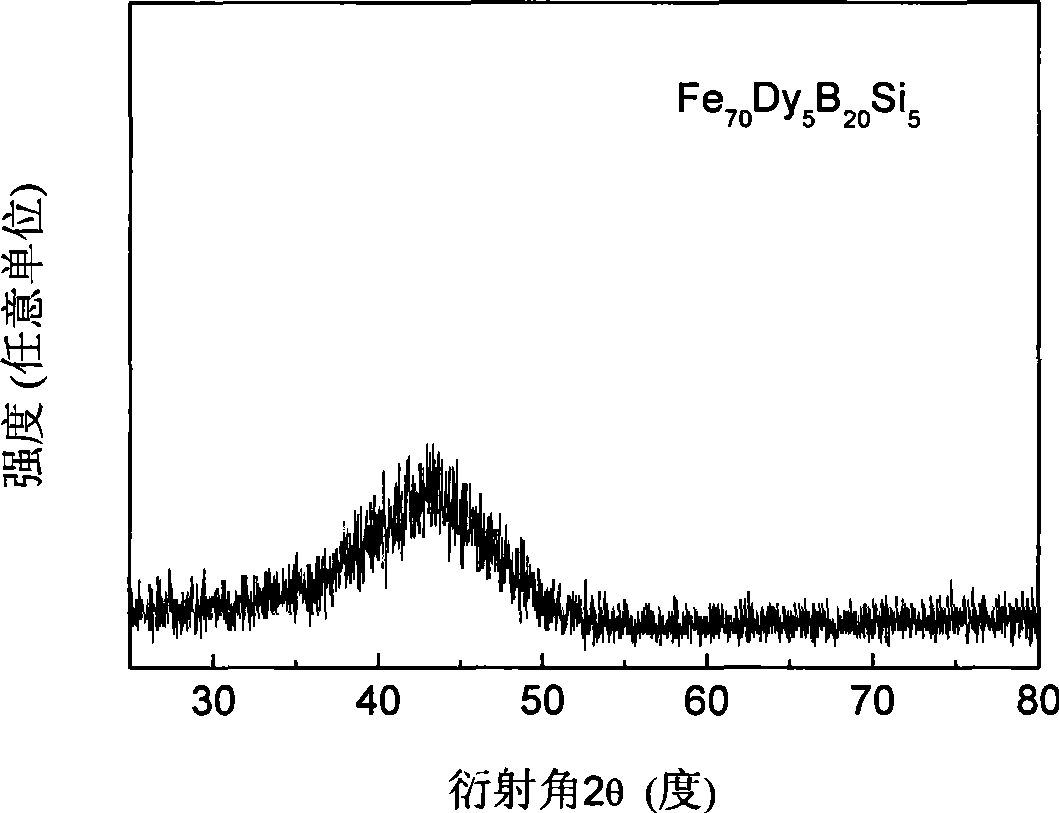

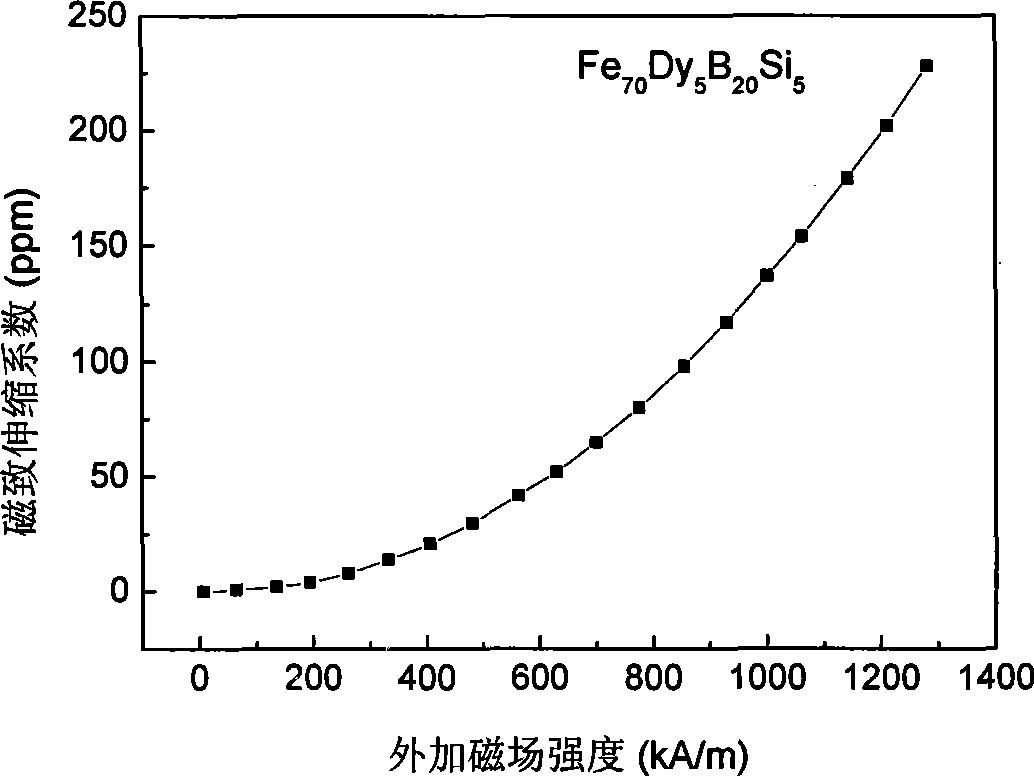

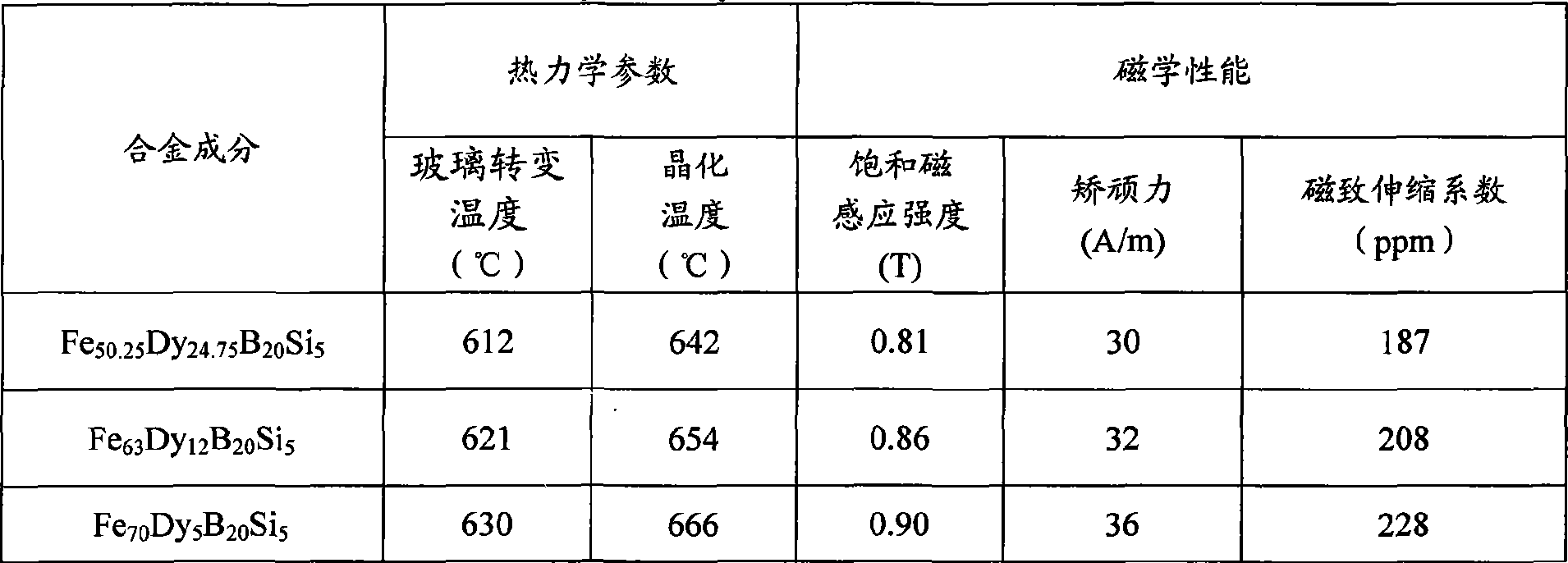

High magnetostriction iron based amorphous alloy and preparation thereof

InactiveCN101503784AHigh magnetostriction coefficientImprove thermal stabilityMagnetizationThermal stability

The invention discloses a high magnetostriction iron base amorphous alloy and a preparation method thereof. The high magnetostriction iron base amorphous alloy has the following chemical molecular formula: Fe100-x-y-zDyxBySiz, wherein x, y and z are the atom percent of a Dy element, a B element and a Si element respectively, 100-x-y-z is the atom percent of a Fe element, x is more than or equal to 5 and less than or equal to 25, y is more than or equal to 20 and less than or equal to 25, and z is more than or equal to 0 and less than or equal to 10. The preparation method comprises the following steps: mixing industrial pure metal raw materials and an FeB alloy according to an alloy formulation, carrying out the magnetic suspension induction smelting on the raw materials and the FeB alloy to obtain a mother alloy, and then preparing an amorphous thin belt through a single roller melt-spun method. The iron base amorphous alloy material has a high magnetostriction coefficient of 228 ppm, excellent soft magnetization performance, high thermal stability, and a good amorphous formation capability. Simultaneously, the alloy material has simple preparation method and can be widely applied to the aspects of soft magnetization materials and structural materials in the fields of information, communication, computer, and the like.

Owner:ZHEJIANG UNIV +1

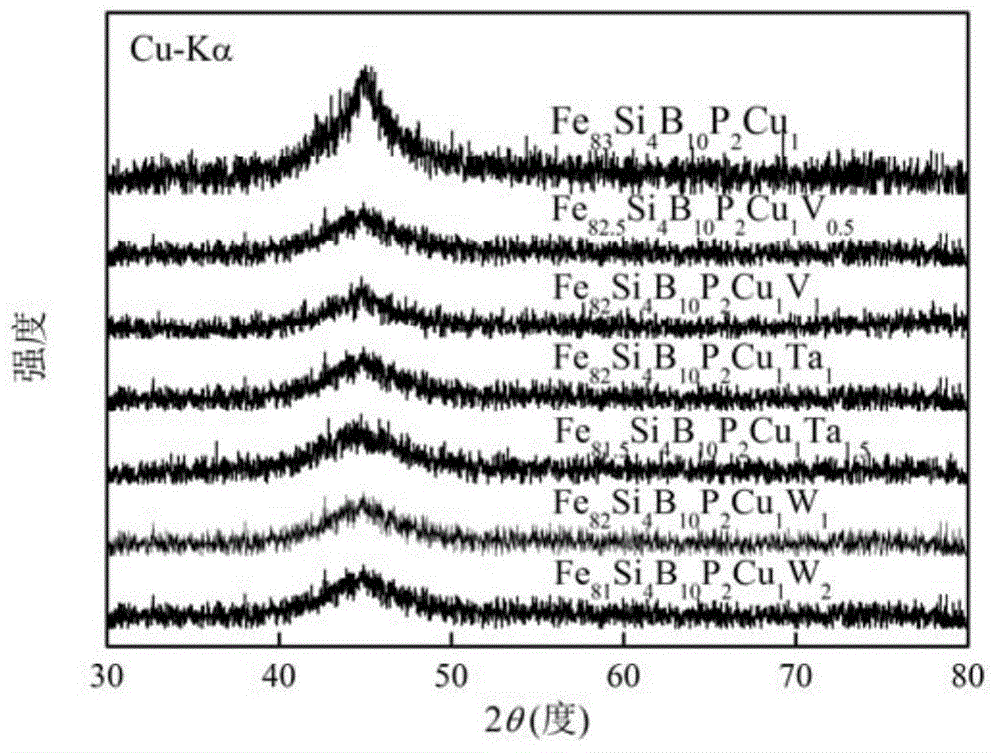

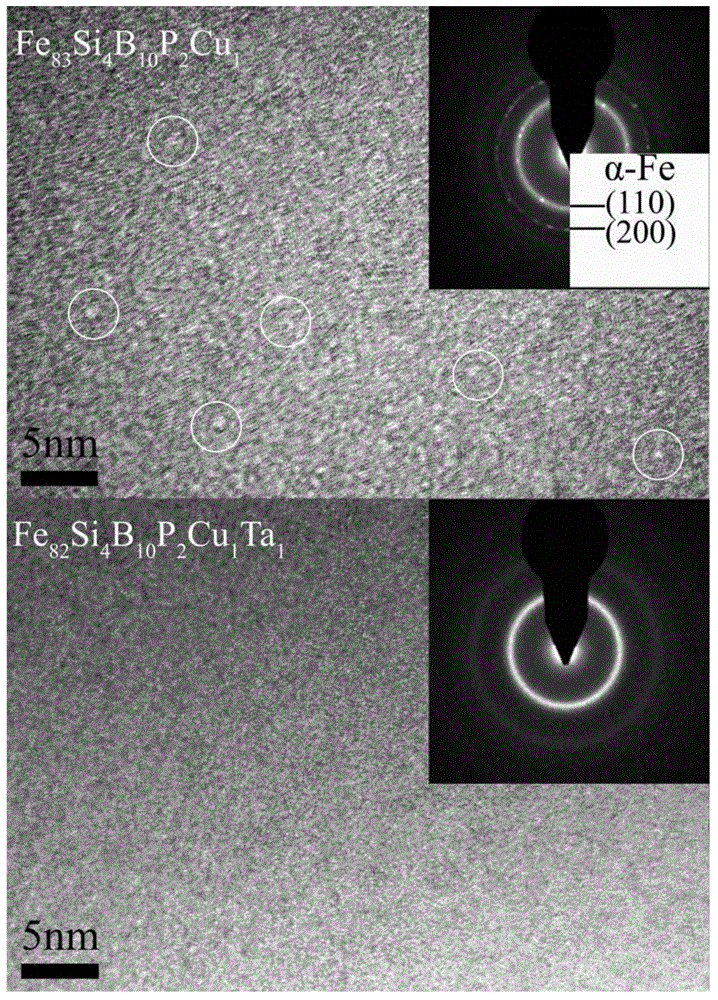

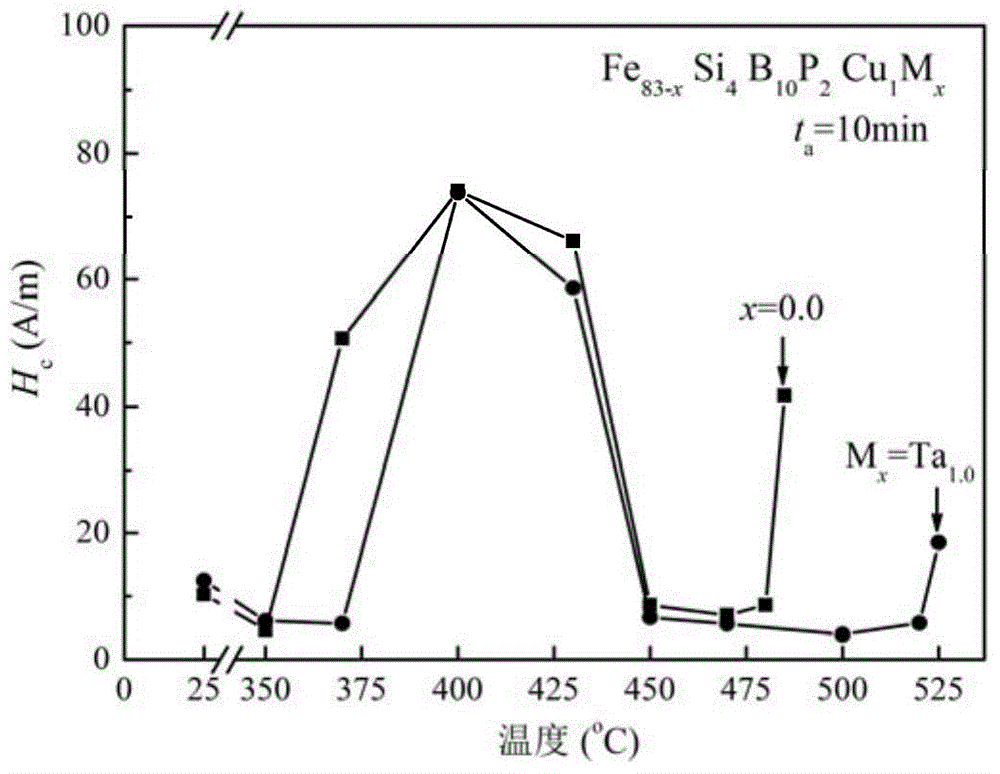

Iron-based nanocrystalline magnetically soft alloy and preparation method thereof

ActiveCN105448448AStrong Amorphous Formation AbilityExcellent soft magnetic propertiesFurnace typesMagnetic materialsThermal insulationAlloy

The invention provides an iron-based nanocrystalline magnetically soft alloy. The chemical formula of the components of the iron-based nanocrystalline magnetically soft alloy is FeaSibBcPdCueMf, wherein M is selected from at least one kind of transition metal elements V, Ta and W; the subscripts a, b, c, d, e and f represent atom percentage contents of each corresponding element; a is greater than 80 and less than 84; b is greater than 2 and less than 6; c is greater than 8 and less than 12; d is greater than 1 and less than 4; e is greater than 0 and less than 2; f is greater than 0 and less than 4; and a+b+c+d+e+f is equal to 100. Experiments prove that the alloy material has the advantages of high amorphous forming ability, excellent comprehensive soft magnetic property, and high thermal stability; when the alloy material is prepared from amorphous strips by thermal processing, when the thermal processing temperature reaches 100 DEG C, and when the thermal insulation time is extended to be 90 mins, the high comprehensive soft magnetic property of the alloy still can be kept; and therefore, the process conditions of the thermal processing are greatly lowered, the thermal processing process is simplified, and the industrial production is greatly promoted.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

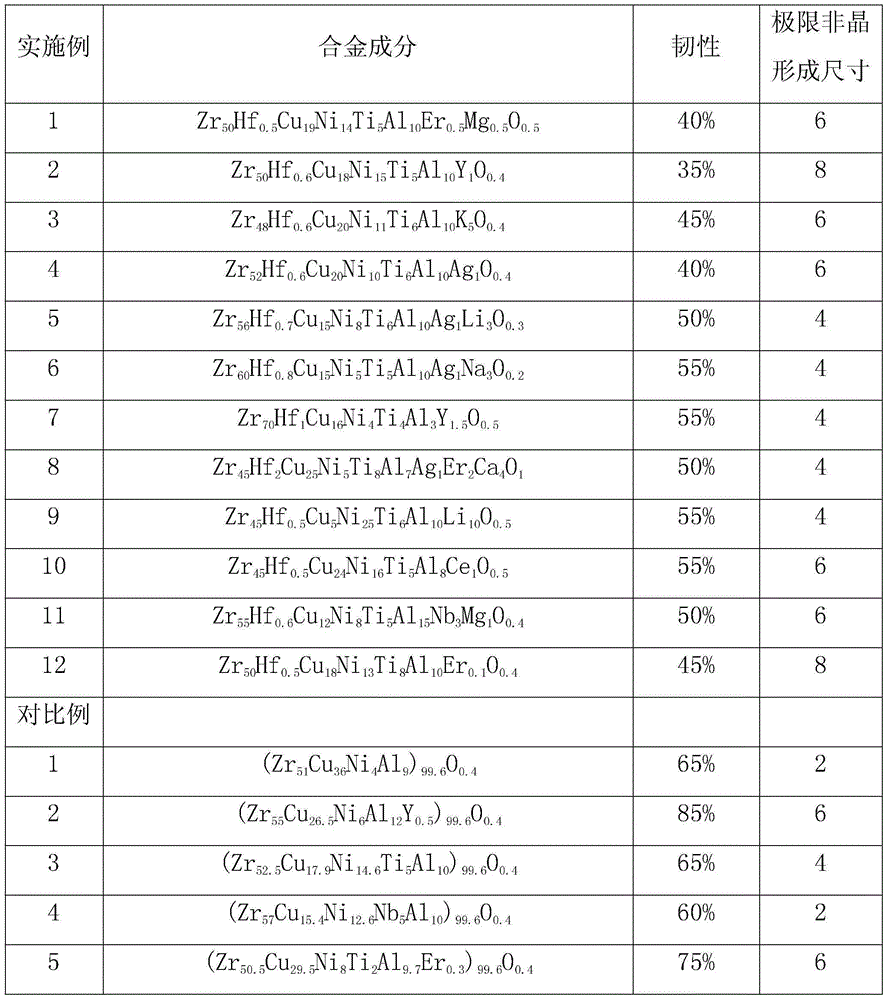

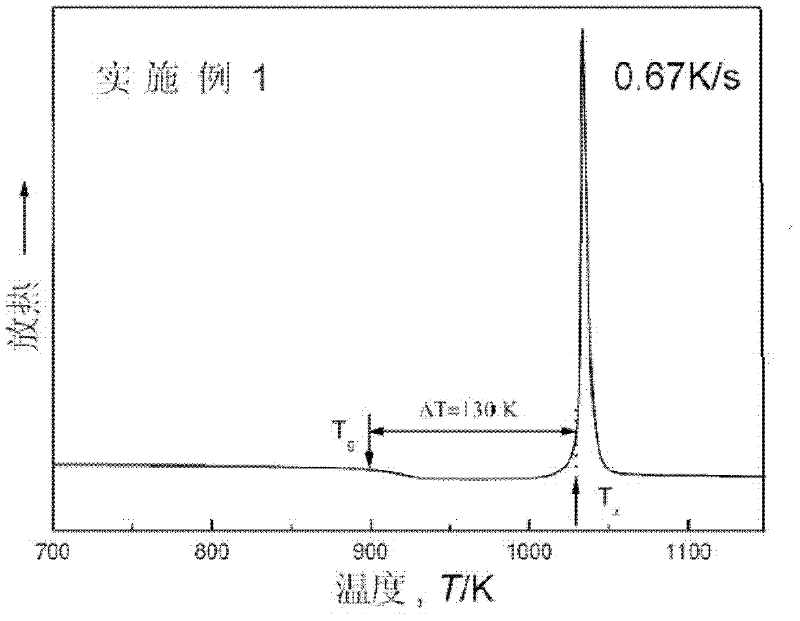

Low-cost bulk amorphous alloy

The invention relates to the technical field of manufacturing of bulk amorphous alloy, in particular to low-cost bulk amorphous alloy. The chemical formula of the low-cost bulk amorphous alloy is Zra(Hf,Ti)bAlc(CuxNiy)d(Ag,Re)e(Li,Na,K,Si,Mg,Ca)fOg, wherein a, b, c, d, e, f and g are the percentage contents of corresponding atoms of all the elements in the amorphous alloy, 45<=a<=70, 5<=b<=10, 3<=c<=15, 20<=d<=40, 0<=e<=3, 0<=f<=10, 0.05<=g<=1 0.2<=x / y<=5, 0.1<=e+f<=10, and Re is one or more of rare earth elements. According to the low-cost bulk amorphous alloy, the sensitivity of a formula to the oxygen content is greatly reduced, so that the large bulk amorphous alloy suitable for industrial application can still be formed under the high oxygen content condition.

Owner:CHANGZHOU STREAM LIQUID METAL CO LTD

Cobalt iron base block body metal glass with super-large super-cooling interval and preparation method thereof

The invention discloses cobalt iron base block body metal glass with a super-large super-cooling interval, which has a molecular formula of CoaFebNbcMdBe, wherein M is any one kind of elements from Dy, Y, Tb, Er and Gd, a, b, c, d and e are atom mol contents, a is greater than or equal to 24 but smaller than or equal to 56, b is greater than or equal to 6 but smaller than or equal to 38, c is greater than or equal to 4 but smaller than or equal to 8, d is greater than 0 but smaller than or equal to 5, e is greater than or equal to 6 but smaller than or equal to 31, and in addition, the sum of a, b, c, d and e is 100. The cobalt iron base block body metal glass has high glass forming capability and super-large super-cooling liquid phase interval width, the value can exceed 100K or even reach 130K, simultaneously, the ultra-high intensity and the excellent soft magnetic performance are realized, and in addition, the price of raw materials is relatively low, so the cobalt iron base block body metal glass belongs to the block body metal glass with the excellent integral performance, and wide application prospects are realized in the fields of miniature precise devices, magnetic function materials and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

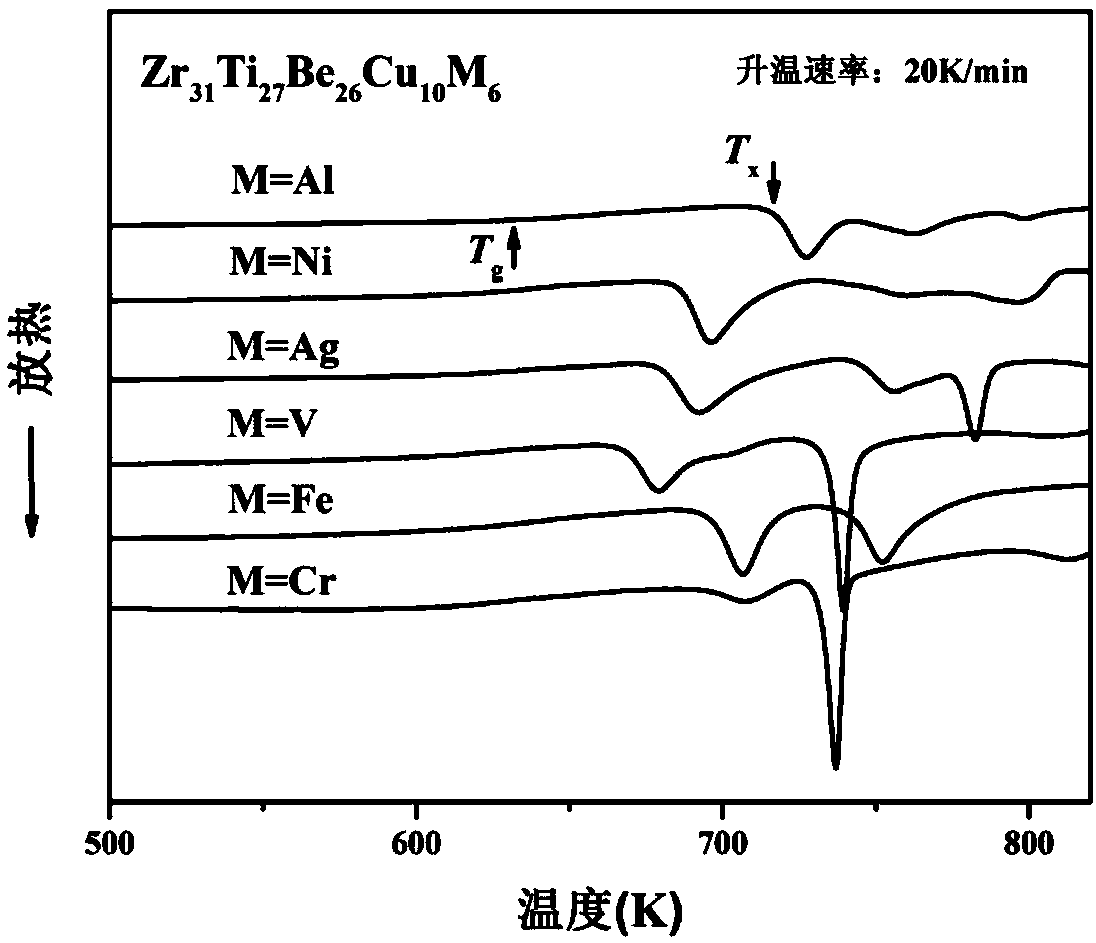

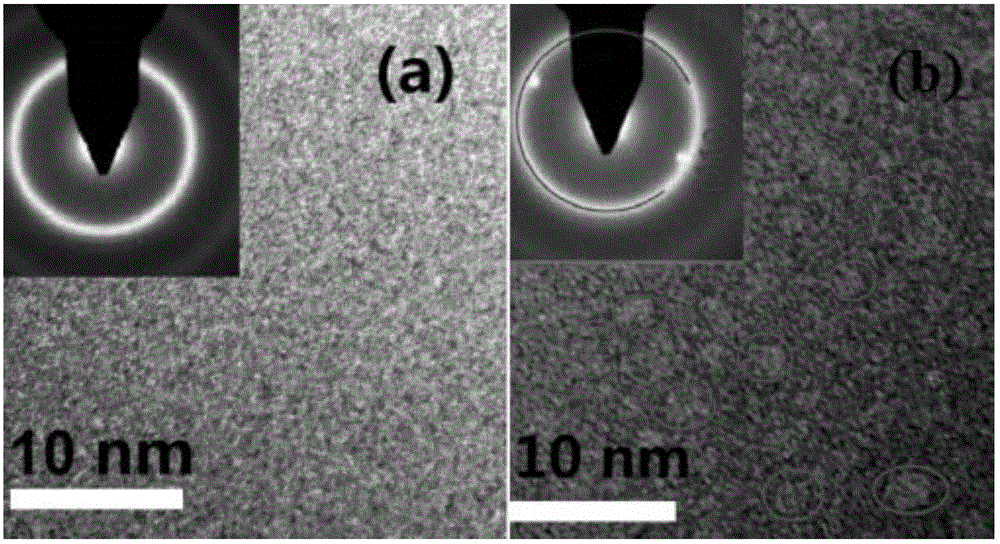

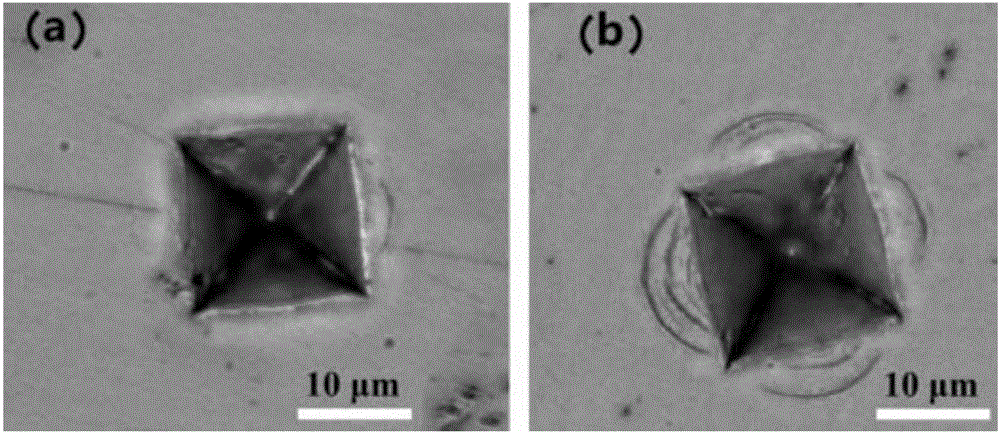

High-entropy bulk amorphous alloy and preparation method thereof

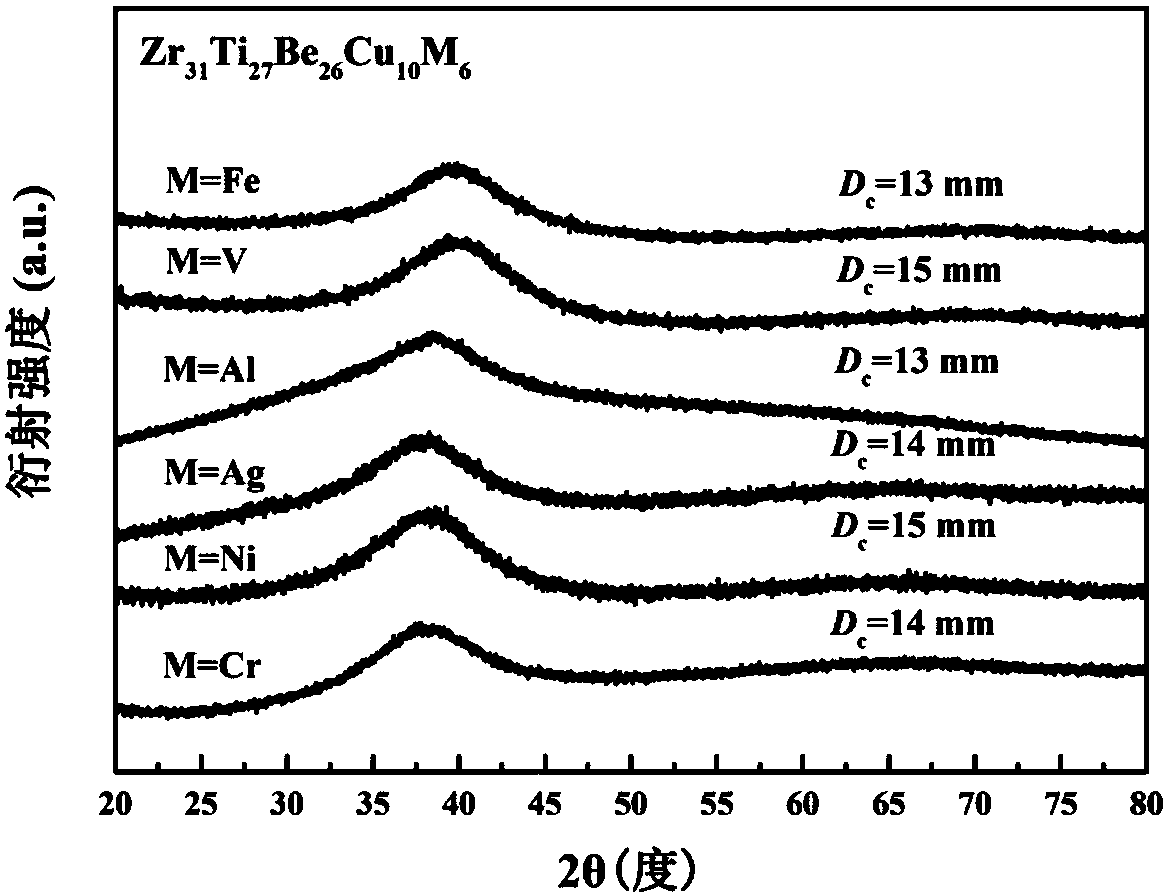

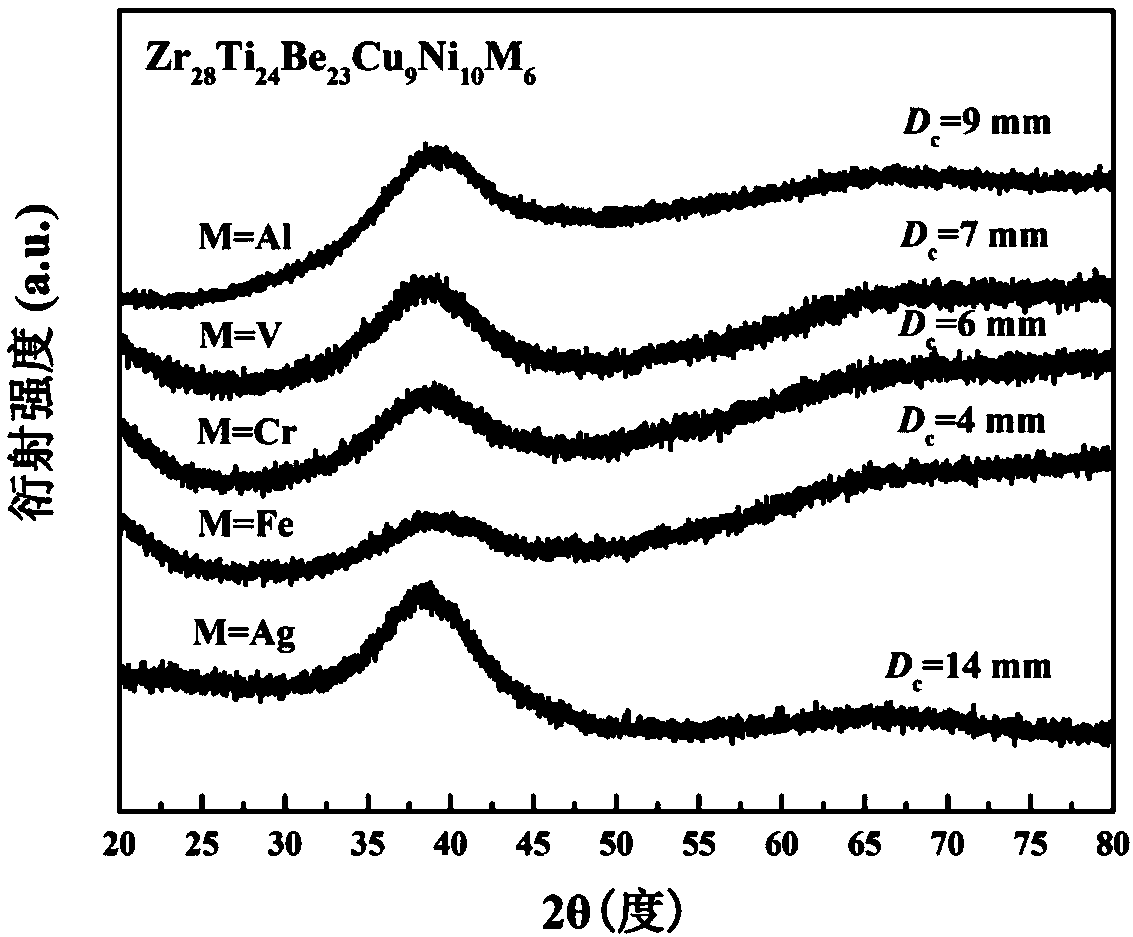

The invention belongs to the field of materials of amorphous alloys and high-entropy alloys and discloses a high-entropy bulk amorphous alloy and a preparation method thereof. The high-entropy bulk amorphous alloy comprises the components of, by atomic percent, 25-35% of Zr, 25-35% of Ti, 22-30% of Be, 5-15% of Cu and M, wherein M represents one or two of Al, Fe, Ag, Ni, V and Cr; and when M represents one element, the atomic percent of M is 5-8%, when M represents two elements, M comprises Ni and another element, the atomic percent of Ni is 5-15%, and the atomic percent of the other element is 5-8%. According to the preparation method, electric arc melting is conducted under an inert atmosphere to prepare a master alloy ingot, and then copper mould suction casting / spray casting / pouring forming is adopted. The high-entropy bulk amorphous alloy provided by the invention has the characteristics of being high in amorphous forming capacity, low in density, high in specific strength and thelike; and the application range is wide.

Owner:HUAZHONG UNIV OF SCI & TECH

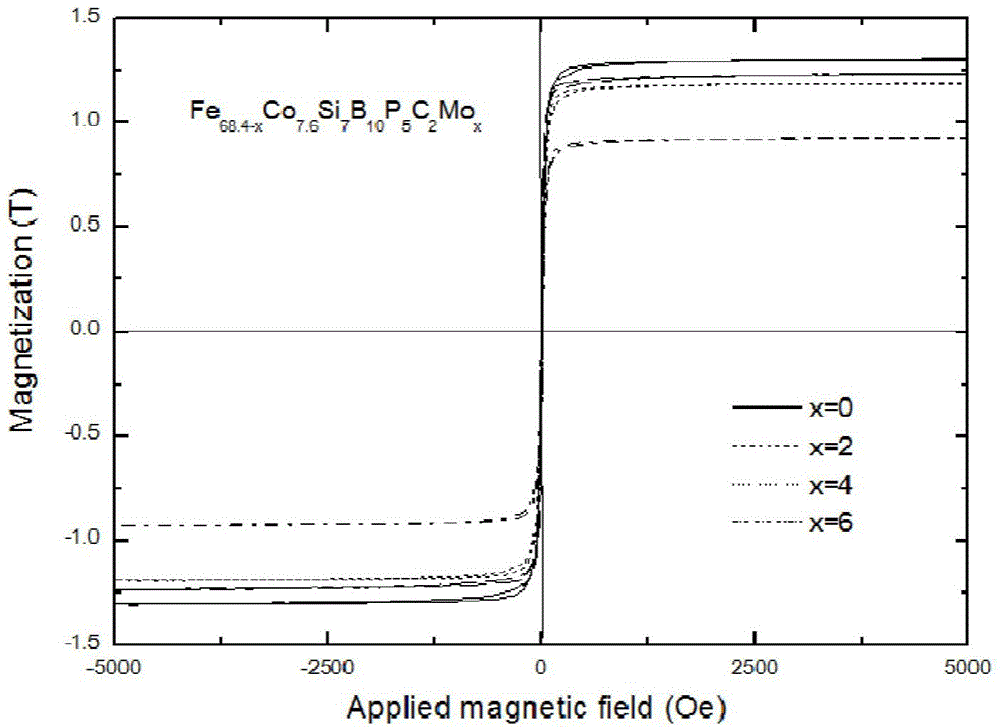

Toughness-enhanced iron-based bulk amorphous soft magnetic alloy and preparation method thereof

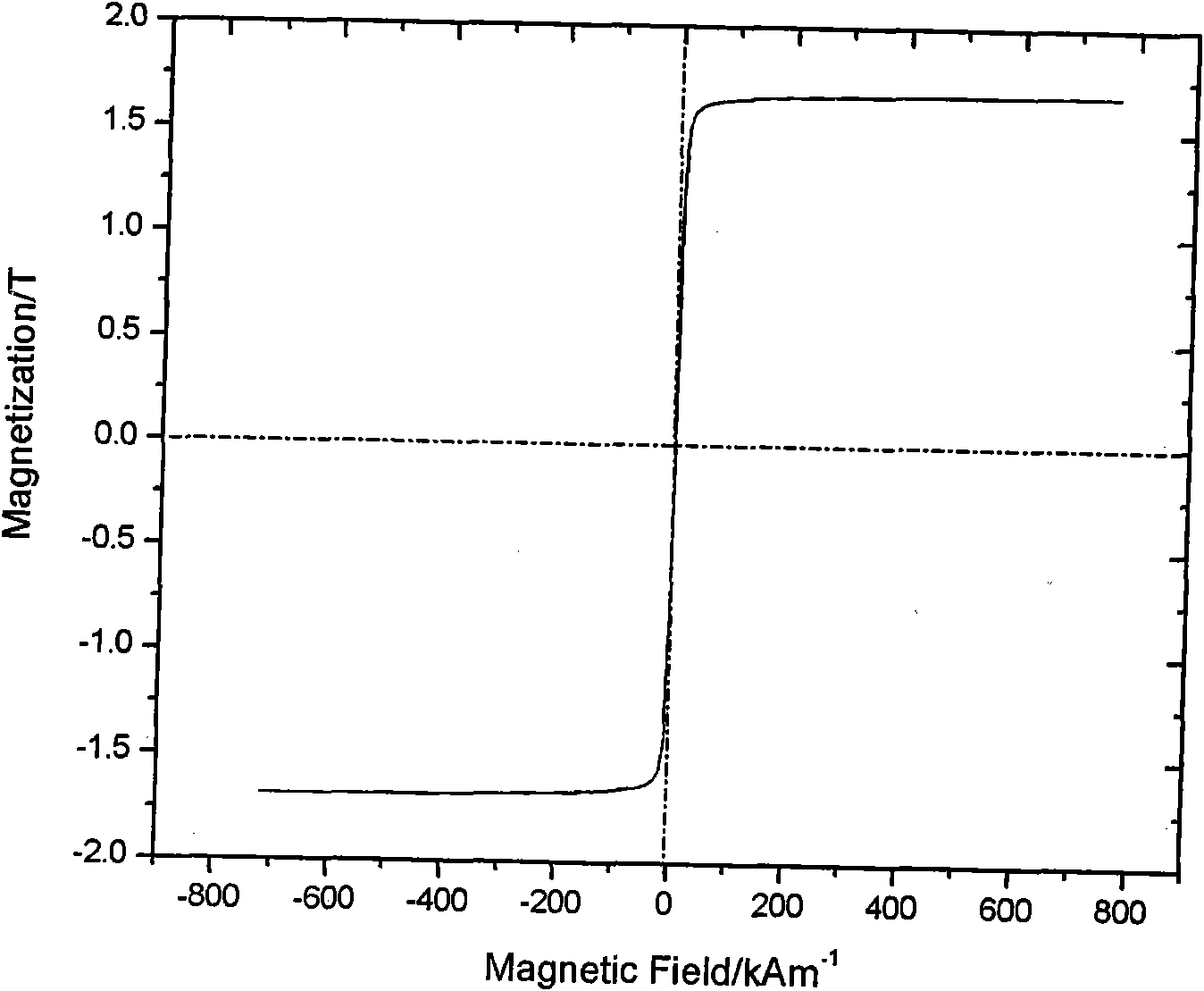

ActiveCN105741998AHigh saturation magnetic inductionLow coercivityMagnetic materialsToughnessElectron

The invention relates to toughness-enhanced iron-based bulk amorphous soft magnetic alloy and a preparation method thereof, belonging to the field of a magnetic functional material. The expression formula of the alloy is Fe<x>SiBP<c>C<d>Mo<e>M<f>, wherein M is at least one of Cu, Ag and Au, x, a, b, c, d, e and f respectively represent atomic percent content of each corresponding constituent, a is more than or equal to 0.5 but less than or equal to 14, b is more than or equal to 0.5 but less than or equal to 15, c is more than or equal to 0.5 but less than or equal to 14, d is more than or equal to 0.1 but less than or equal to 5, e is more than or equal to 0.1 but less than or equal to 5, f is more than or equal to 0.2 but less than or equal to 1, x is more than or equal to 72 but less than or equal to 85, and (x+a+b+c+d+e+f) is equal to 100%. With the preparation method provided by the invention, the saturation magnetic induction and the plastic deformation capability of iron-based bulk amorphous can be simultaneously improved; moreover, the production process is simple, is low in cost and is easy for industrialization; and the product has excellent soft magnetic performance and toughness, and can be taken as a structure and a functional soft magnetic material applied to the fields of power, electrons, information, communication and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

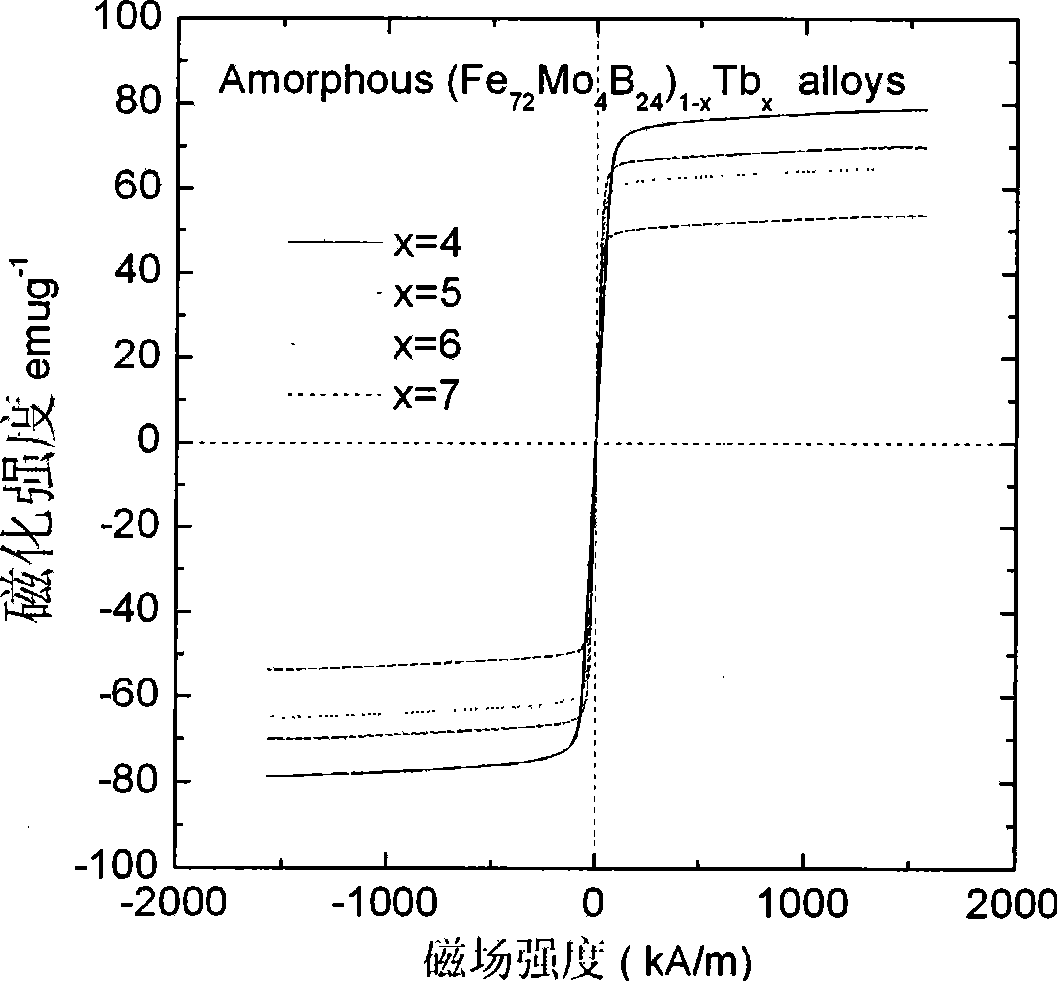

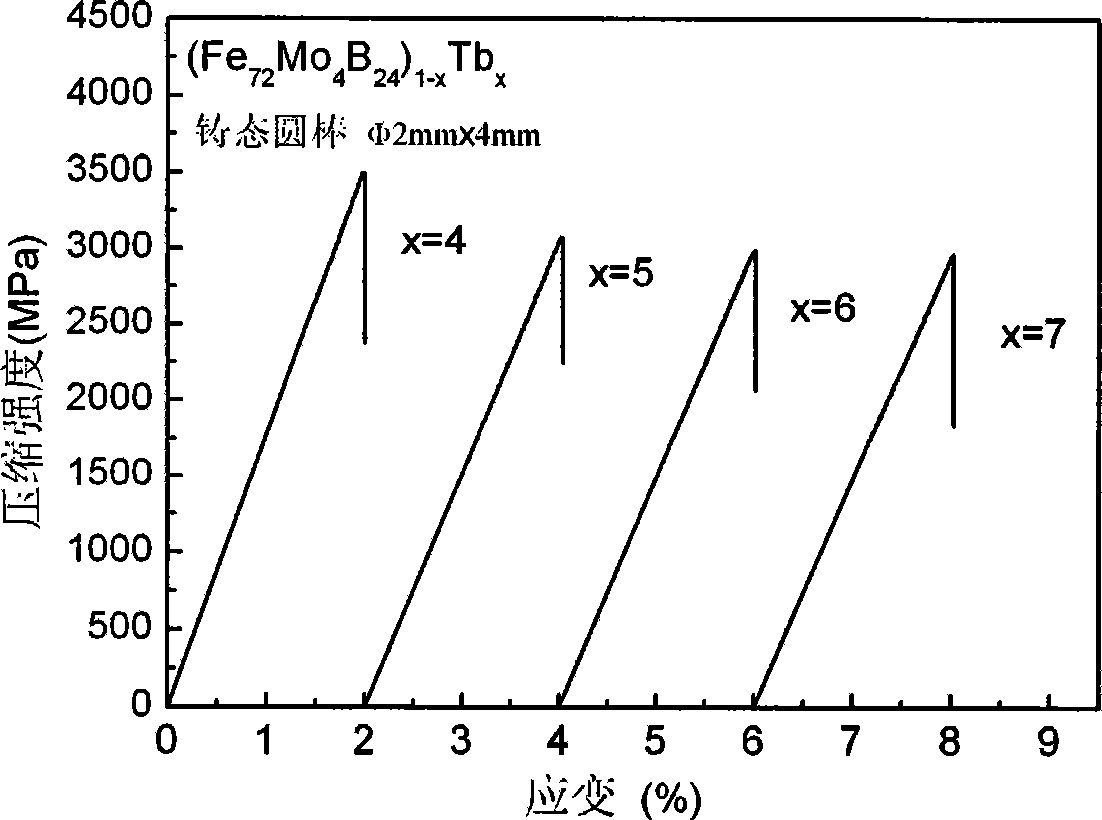

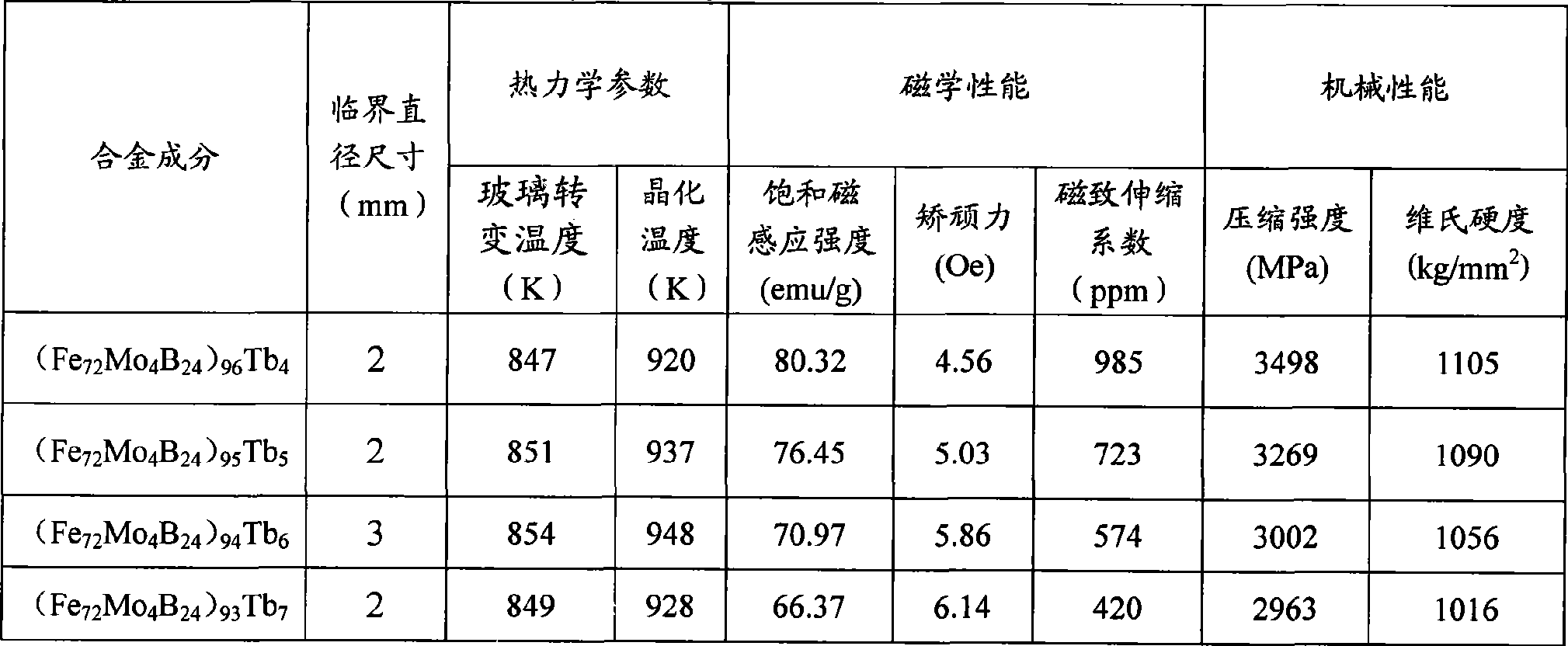

High magnetic striction iron based metallic glass magnetic material and preparation thereof

InactiveCN101487106APurity requirements are not very highHigh magnetostriction coefficientSimple componentTransducer

The invention discloses a high magnetostrictive Fe-based metal glass magnetic material and a preparation method thereof. The chemical formula of the high magnetostrictive Fe-based metal glass alloy is Fe100-x-y-zMozByTbx, wherein, x, y and z are respectively the atomic percents of Tb, B and Mo, 100-x-y-z is the atomic percent of Fe, x is more than 0 and less than or equal to 10, y is more than or equal to 20 and less than or equal to 25, z is more than 0 and less than or equal to 10. The preparation method of the alloy is as follows: the industrial pure metals Fe, Mo, Tb and FeB alloy are proportioned according to the alloy formula and melted repeatedly by induction-arc under the protection of argon to make master alloy, then the high magnetostrictive Fe-based metal glass magnetic material is obtained through casting by using the copper mold spray-casting method. The magnetostrictive coefficient of the magnetic material is 420 ppm to 985 ppm, and the magnetic material has simple components, high thermal stability, and good mechanical properties and amorphous forming ability. The high magnetostrictive Fe-based metal glass magnetic material can be widely applied to the fields of sonar transducer, sensor, ultrasonic technology, communication technology, and the like.

Owner:ZHEJIANG UNIV +1

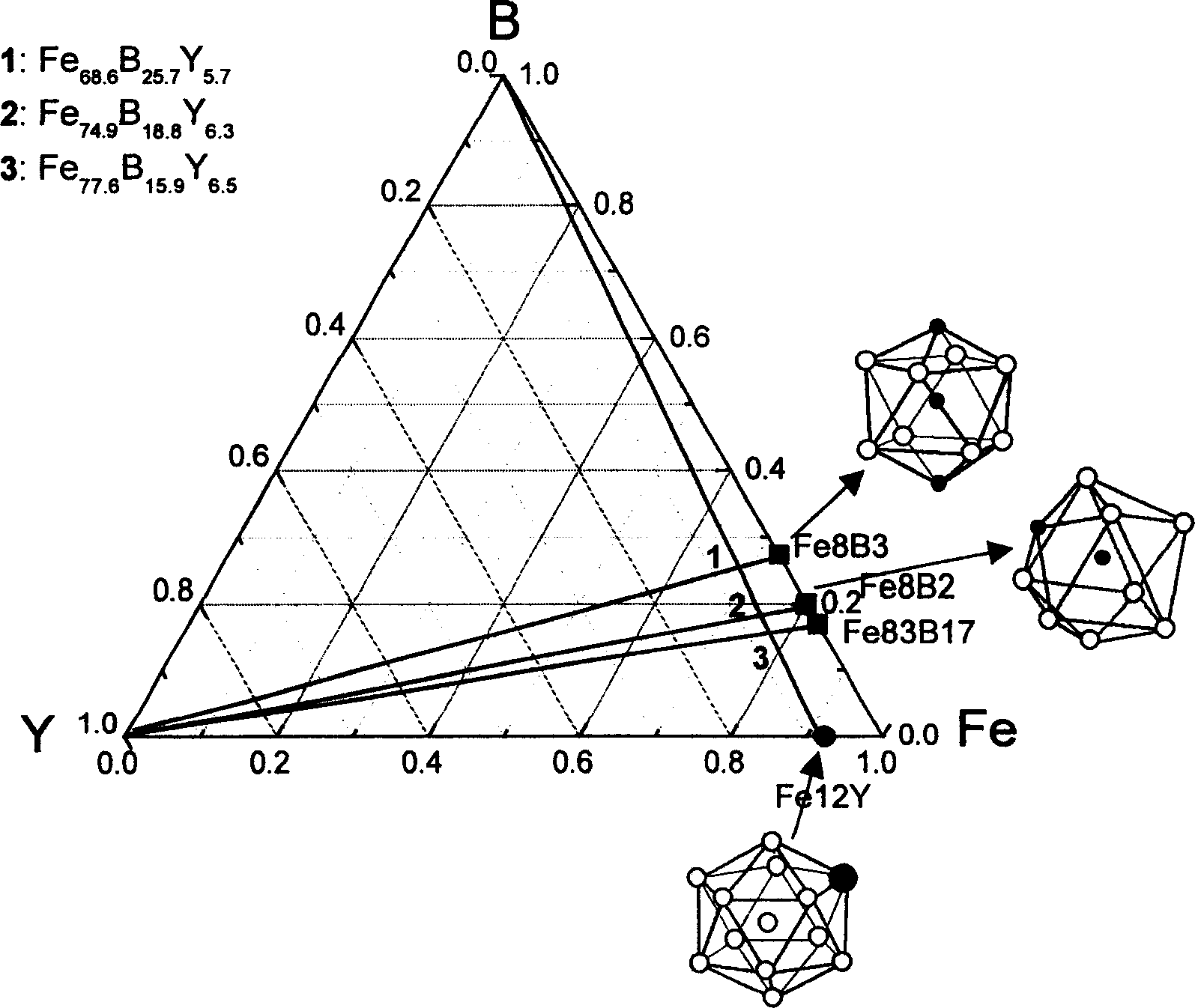

Fe base block amorphous alloy based on Fe-B-Y cluster

InactiveCN1869276AImprove thermal stabilityStrong Amorphous Formation AbilityPower flowPressure casting

The invention relates to Fe radical block non-crystal alloy based on F3-B-Y group cluster. It adds 2at.% Nb and 2at.% Zr or Hf or Ti or Mo or Ta on the base of Fe-B-Y ternary system to take micro alloying. The constituent interval is [(Fe12 / 13Y1 / 13)100-xBx]0.96Nb2M2, and x=15-26at.%. The method includes the following steps: mixing, melting in Fe-B internal alloy, taking negative pressure casting absorbing, the argon gas pressure is 0.06-0.08MPa, fusion melting current density is 180-220A / cm2, casting adsorbing current density is 280-310A / cm2, and draught head is 0.04+0.005MPa, the diameter of the block non-crystal is 3mm. The advantages of the invention are that it develops five Fe radical block non-crystal alloys. In the melting process, smelting Fe and B to form internal alloy, the volatilization of B would be avoided.

Owner:DALIAN UNIV OF TECH

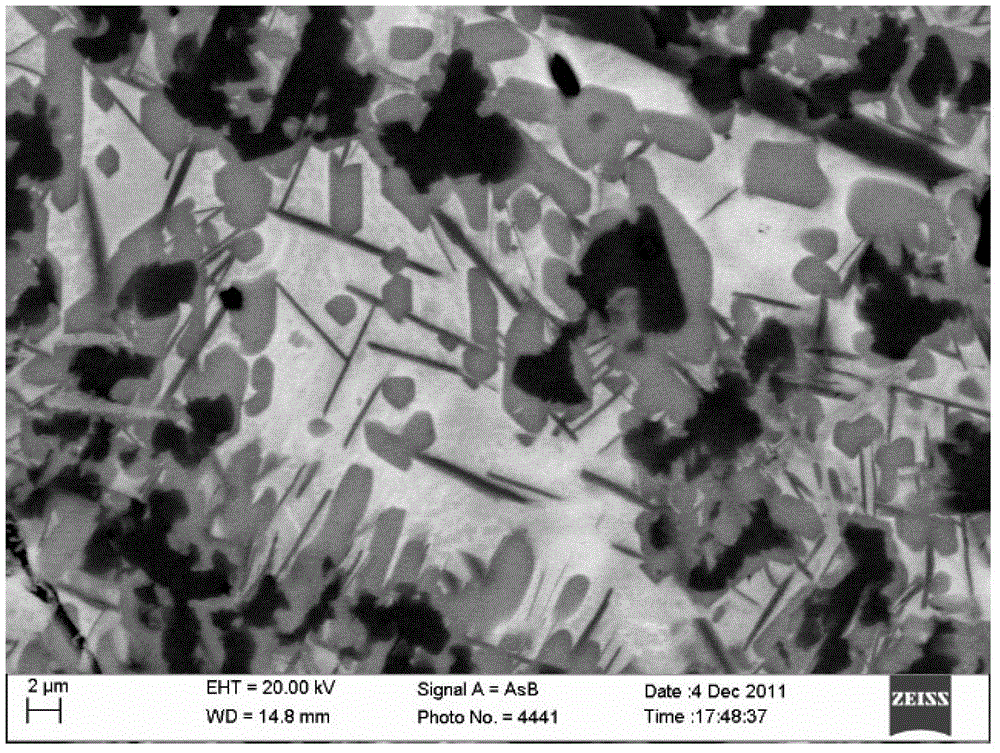

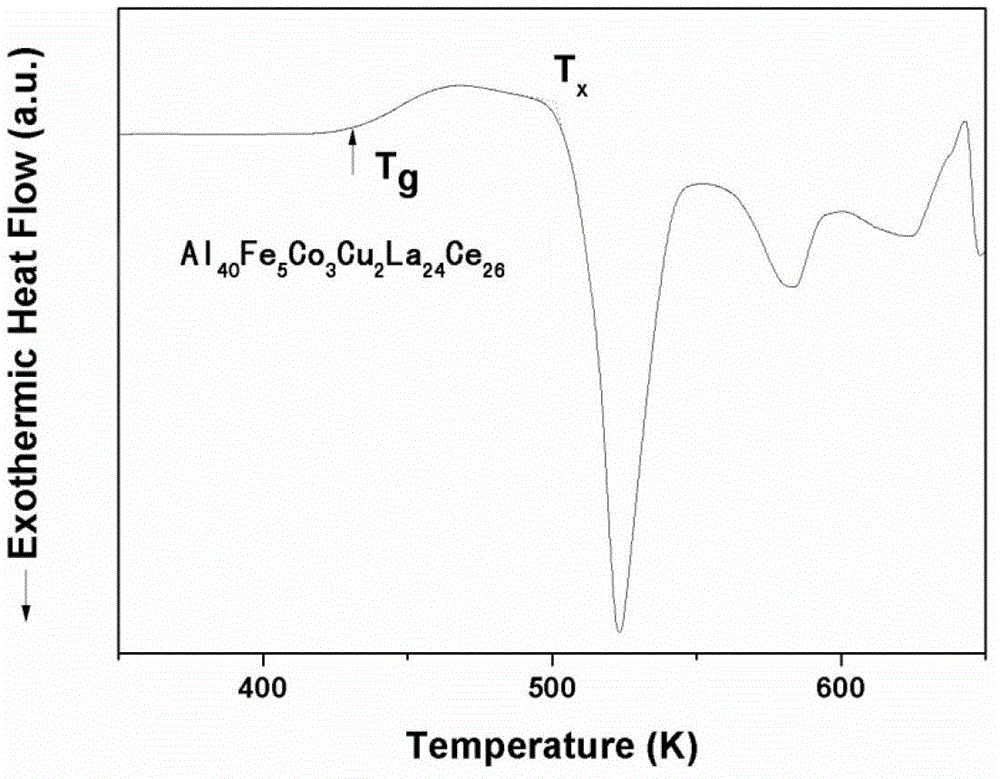

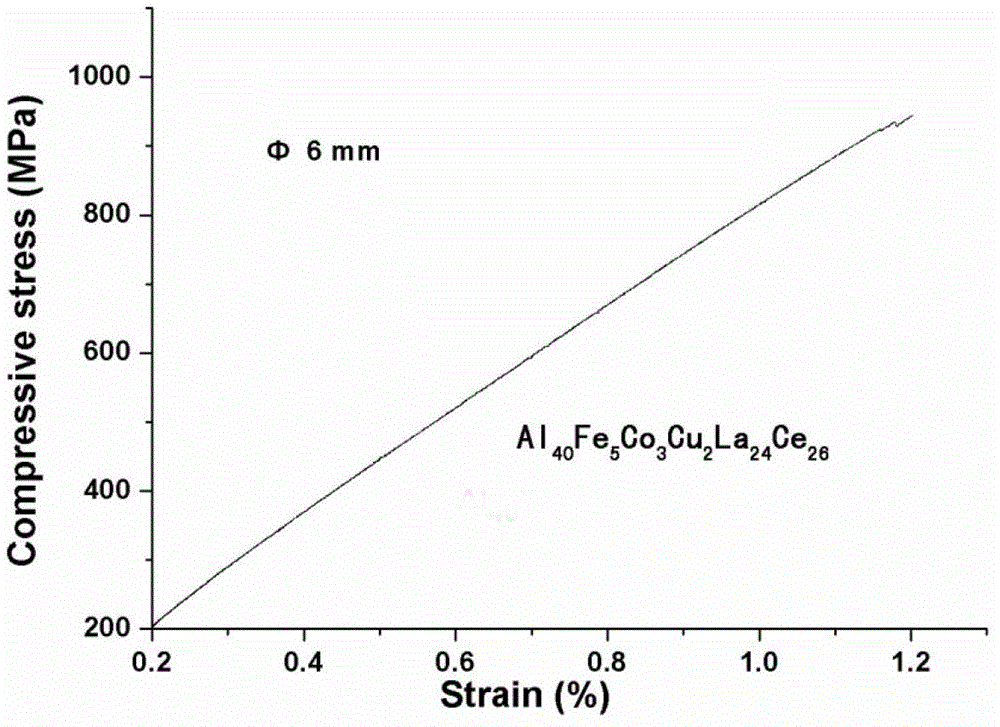

High-strength aluminum-based bulk amorphous composite material

ActiveCN102719769AStrong Amorphous Formation AbilityHigh content of lightweight aluminum elementsRare-earth elementMetalloid

The invention relates to a high strength aluminum-based bulk amorphous composite material, belonging to the field of composite materials. The composite material is characterized in that the atom percentage of aluminum element is more than 40%; and the alloy composition is shown in the following formula of AlaFebLacCedCoeCufMgNhOi, wherein M is one or more of Ti, V, Cr, Mn, Mg, Ni, Zn, Ag, Mo, Nb and Zr, N is one or more of rare earth elements except for La and Ce, O is one or more of metalloid elements C, B, Si and P, a is not less than 40 and not more than 80, b is not less than 0 and not more than 20, c is not less than 5 and not more than 30, d is not less than 5 and not more than 30, e is not less than0 and not more than 10, f is not less than 0 and not more than 10, g is not less than 0 and not more than 10, h is not less than 0 and not more than 10, i is not less than 0 and not more than 10, and a+b+c+d+e+f+g+h+i = 100. The composite material has high specific strength, and is fully simple in preparation process, thereby being low in cost and wide in industrial application prospects.

Owner:UNIV OF SCI & TECH BEIJING

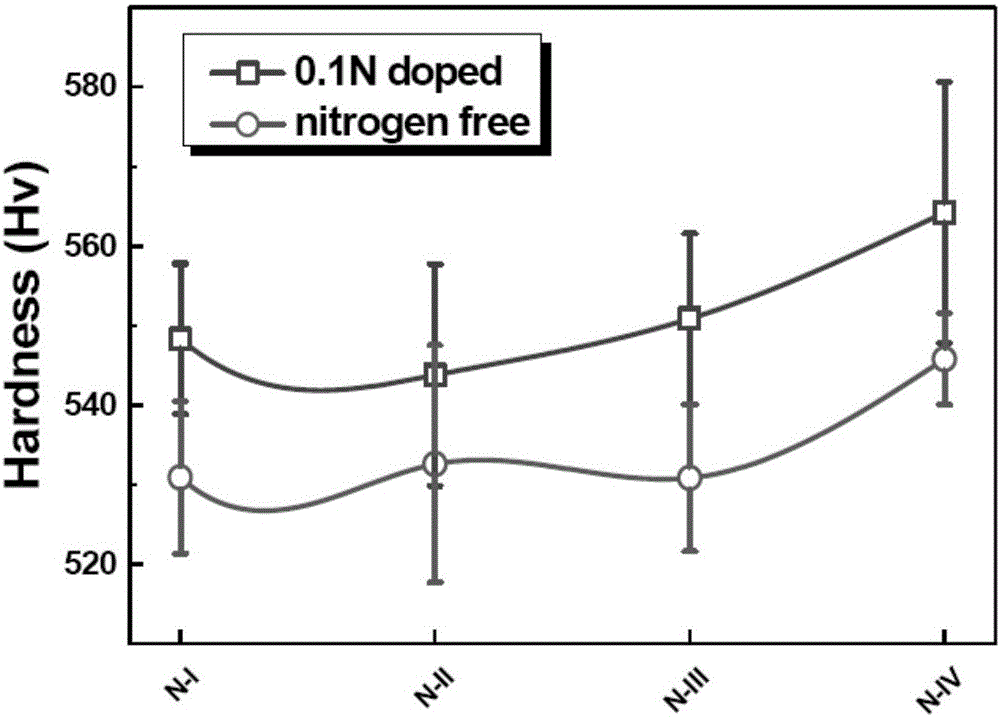

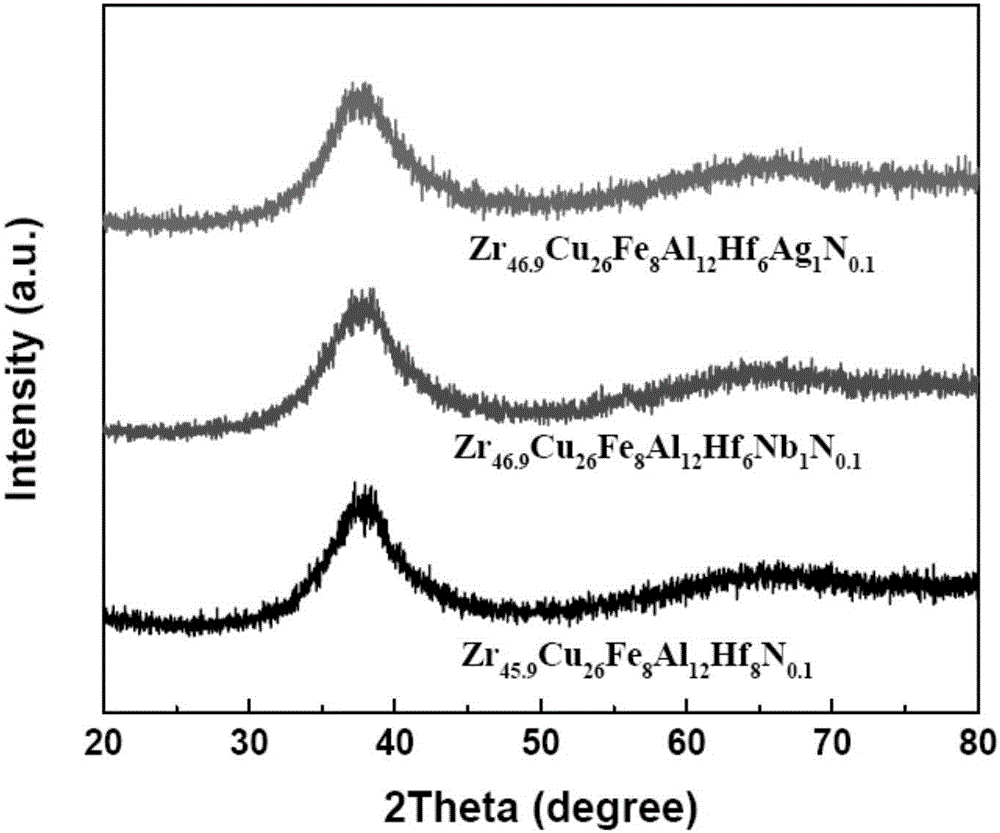

N-containing Be-free Ni-free high-hardness Zr matrix body amorphous alloy and preparation method thereof

ActiveCN106702292AGood biocompatibilityStrong Amorphous Formation AbilityRare-earth elementBiocompatibility Testing

The invention relates to an N-containing Be-free Ni-free high-hardness Zr matrix body amorphous alloy. The expression of the alloy in atomic percentage is Zr Cu A <c> B <d> X <e>Z <f> N<g>, wherein A is one of Hf and Ti; B is a IIIA group element; X is one or more elements of VIII group elements or rare-earth elements except Ni; Z is one or more elements of IB group elements and VB group elements; a+b+c+d+e+f+g=100%, a is greater than or equal to 25 %, and is lower than or equal to 65 %; b is greater than or equal to 15 %, and is lower than or equal to 65 %; c is greater than or equal to 5 %, and is lower than or equal to 15 %; d is greater than or equal to 0, and is lower than or equal to 15 %; e is greater than or equal to 0, and is lower than or equal to 15 %; f is greater than or equal to 0, and is lower than or equal to 10 %; and g is greater than or equal to 0.05 %, and is lower than or equal to 0.5 %. The N-containing Be-free Ni-free high-hardness Zr matrix body amorphous alloy disclosed by the invention does not contain a metallic element Be and a metallic element Ni, so that the biocompatibility of a Zr -base alloy is improved; the N-containing Be-free Ni-free high-hardness Zr matrix body amorphous alloy has high glass forming ability, and the Zr matrix body amorphous alloy of which the critical dimension is not less than 2mm can be prepared through adopting a copper mold suction casting method; and compared with a N-free amorphous alloy, the N-containing Be-free Ni-free high-hardness Zr matrix body amorphous alloy has the advantage that the vickers hardness of an alloy system is not less than 540Hv.

Owner:UNIV OF SCI & TECH BEIJING

Fe-based amorphous soft magnetic alloy and preparation method thereof

InactiveCN101552071AHigh saturation magnetic inductionStrong Amorphous Formation AbilityMagnetic materialsChemical compositionPrecious metal

The invention discloses a Fe-based amorphous soft magnetic alloy, which comprises the following specific chemical compositions by atomic ratio: Fe(a)P(b)B(c)C(d)Si(e), and a+b+c+d+e=100, wherein the atom percentage content of b is 8-11, the atom percentage content of c is 0-3, the atom percentage content of d is 6-10, the atom percentage content of e is 0-3, and the balance is a. The alloy material does not contain precious metal elements, has excellent soft magnetic property, good amorphous forming ability and very high engineering application value, and can be widely used in the fields of structural materials, magnetic materials and the like; in addition, the alloy has the advantages of simple preparation method and very low production cost.

Owner:BEIHANG UNIV

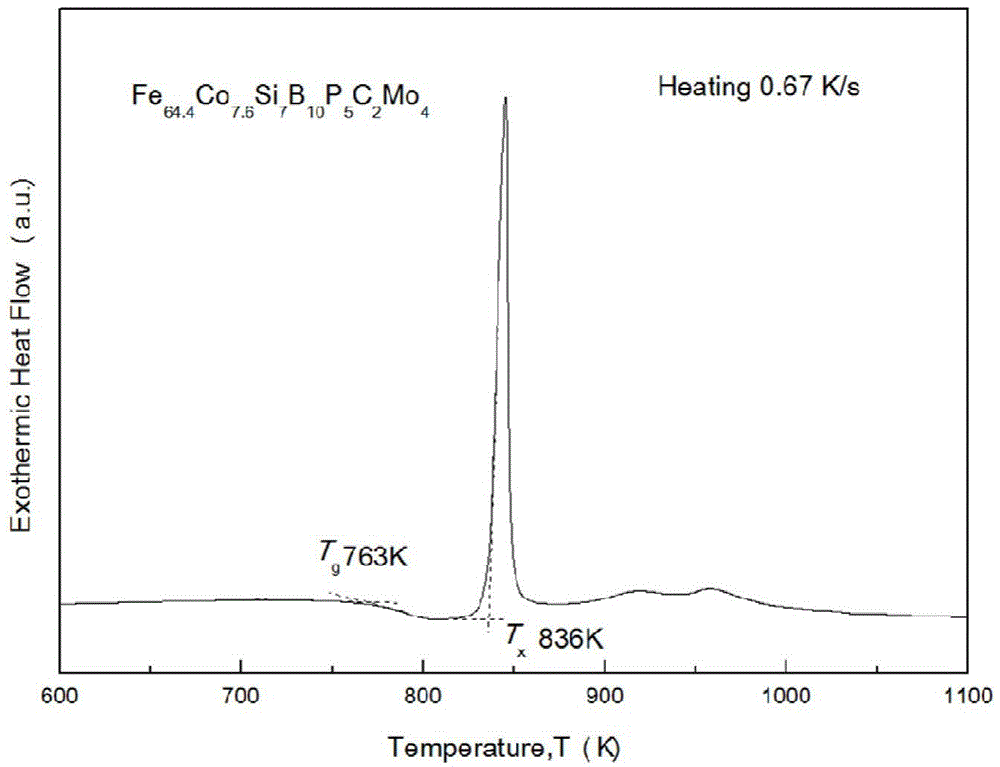

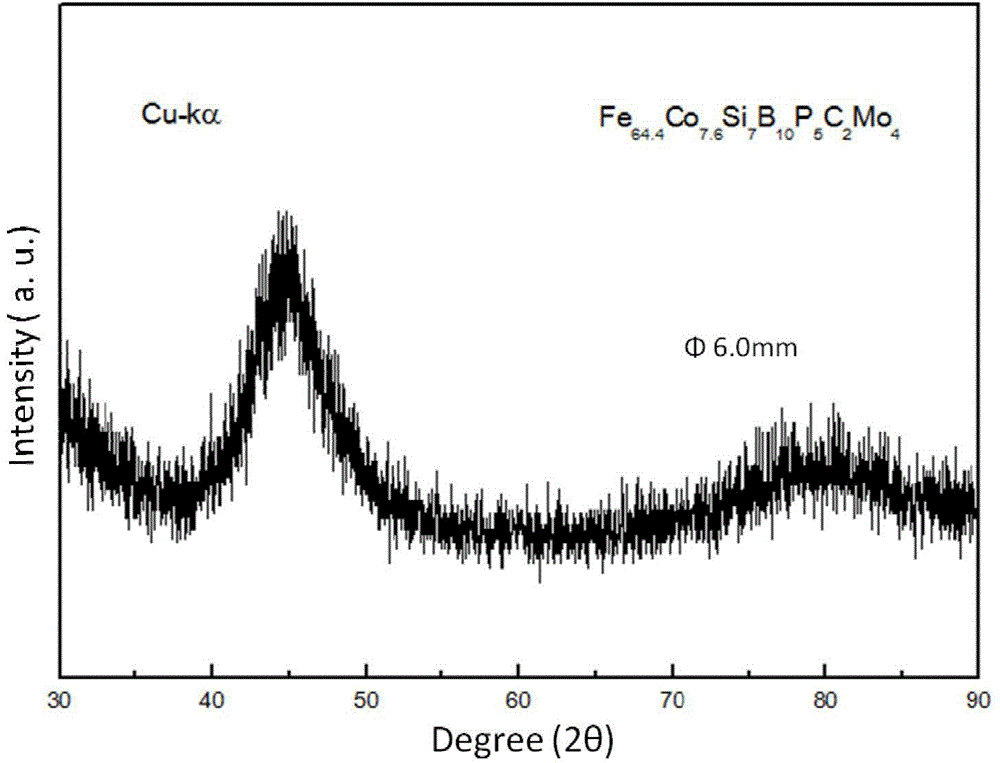

High-corrosion-resistance iron-based amorphous alloy material and preparation method thereof

The invention discloses a high-corrosion-resistance iron-based amorphous alloy material and a preparation method thereof. The iron-based amorphous alloy material has high corrosion resistance, high amorphous forming capability and excellent magnetic properties. The chemical formula of the alloy material is FeaCobSicBdPeCfMog, wherein a, b, c, d, e, f and g are the percent contents of various corresponding component atoms by mass respectively, a is greater than or equal to 60 and less than or equal to 80, b is greater than or equal to 5 and less than or equal to 12, c is greater than or equal to 5 and less than or equal to 10, d is greater than or equal to 7 and less than or equal to 13, e is greater than or equal to 3 and less than or equal to 8, f is greater than or equal to 1 and less than or equal to 4 and g is greater than or equal to 0 and less than or equal to 7 with the sum of a, b, c, d, e, f and g being 100. The preparation method of the alloy material comprises the steps of preparing raw materials, melting, cooling to form alloy ingots, removing impurities on the surfaces of alloy ingots, preparing iron-based amorphous alloy thin sheets or iron-based amorphous alloy bars and carrying out stress relief annealing. According to the alloy material and the preparation method thereof disclosed by the invention, the contents of the components in the FeCoSiBPCMo alloy system are controlled to be close to an eutectic point, a closely packed structure is easily formed, the amorphous forming capability is achieved, and the high corrosion resistance and excellent magnetic properties are simultaneously obtained; therefore, the iron-based amorphous alloy material can be used as an electromagnetic device in harsh environments.

Owner:辽宁秉航非晶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com