High magnetic striction iron based metallic glass magnetic material and preparation thereof

A technology of iron-based metal and magnetic material, applied in the field of iron-based metal glass magnetic material and its preparation, to achieve the effects of good thermal stability, high magnetostriction coefficient and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

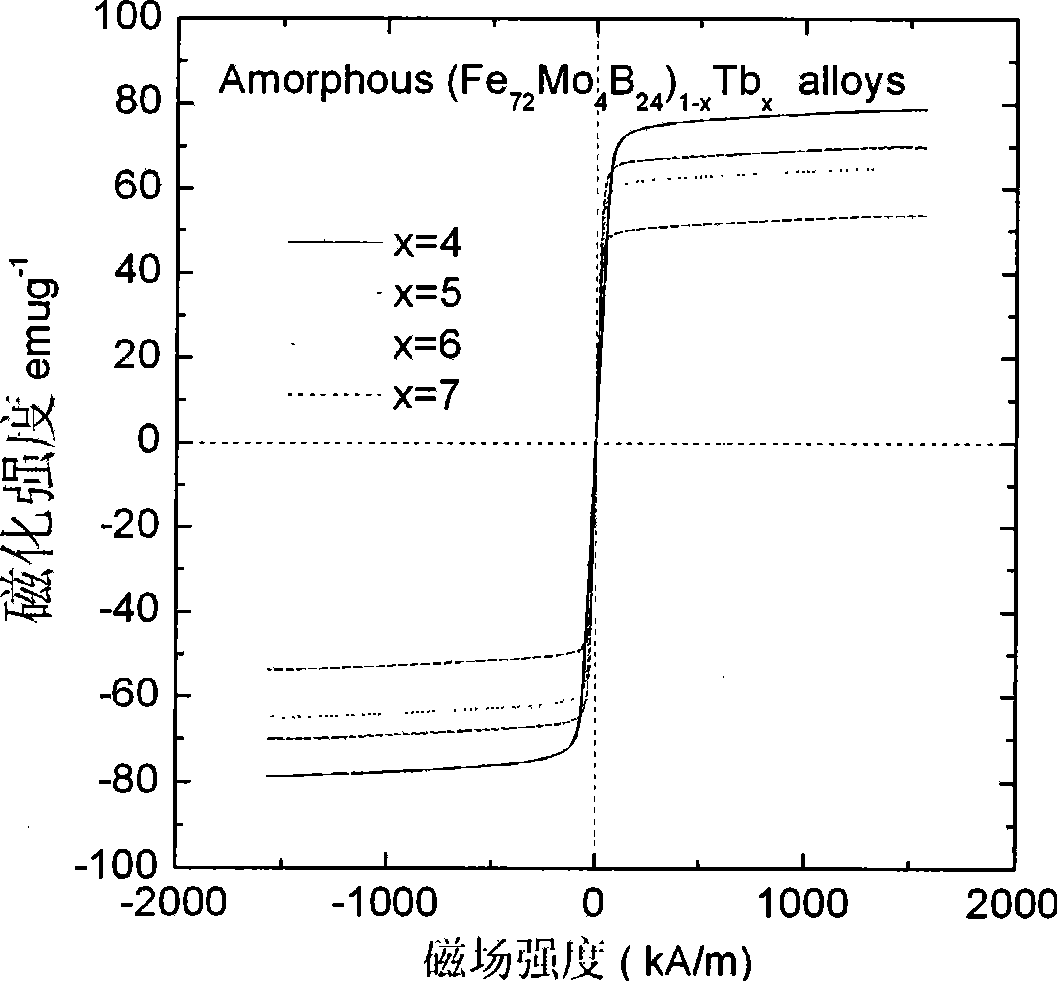

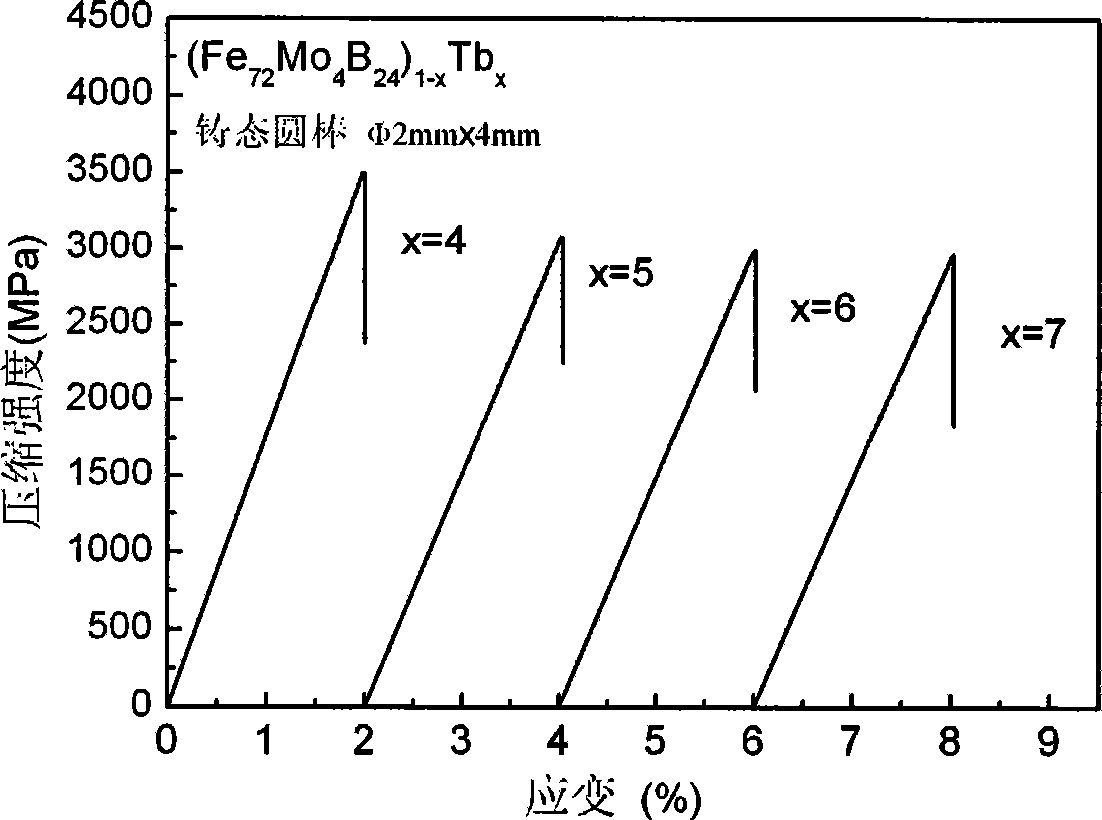

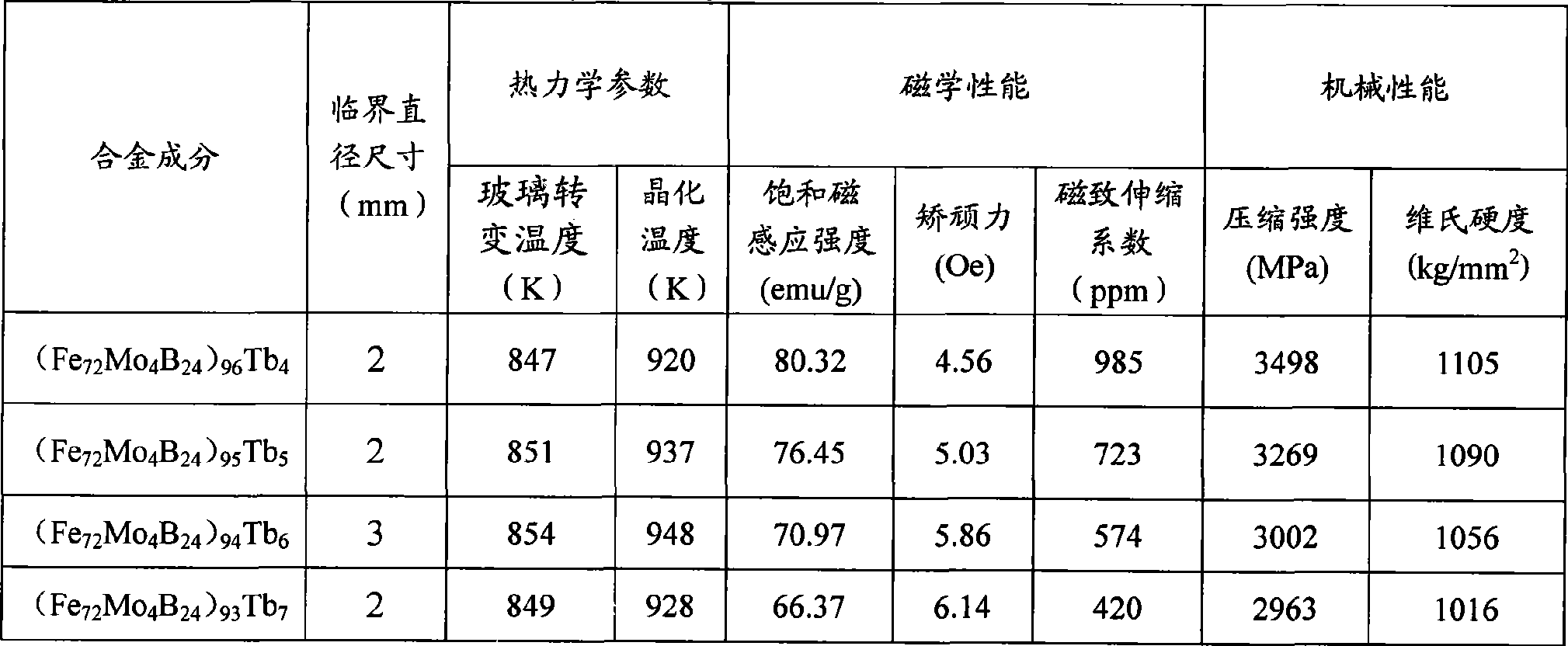

[0016] This embodiment adopts copper mold injection casting method to prepare diameter 2-3mm (Fe 72 Mo 4 B 24 ) 96 Tb 4 Metal glass alloy rod.

[0017] Fe, Mo, B and Tb elements according to (Fe 72 Mo 4 B 24 ) 96 Tb 4 After the alloy atomic percentage is converted into mass percentage, Fe with a purity of 99.6%, Mo with a purity of 99.8%, Tb with a purity of 99.9% and FeB alloy are accurately weighed and put into the quartz tube in the induction furnace. Draw vacuum to 4.0×10 -3 Pa, filled with high-purity argon protection, adjust the current from small to large, induction heating until the sample melts. Repeated smelting 8 times to obtain a homogeneously mixed (Fe 72 Mo 4 B 24 ) 96 Tb 4 Master alloy ingots. The obtained spindles were broken into small pieces and placed in alcohol for ultrasonic cleaning. Then put it into a quartz tube with an open lower end and a hole diameter of 0.5mm, and draw a vacuum to 3.8×10 - After 3Pa, fill the induction furnace cavi...

Embodiment 2

[0019] This embodiment adopts copper mold injection casting method to prepare diameter 2-3mm (Fe 72 Mo 4 B 24 ) 95 Tb 5 Metal glass alloy rod.

[0020] Fe, Mo, B and Tb elements according to (Fe 72 Mo 4 B 24 ) 95 Tb 5 After the alloy atomic percentage is converted into mass percentage, Fe with a purity of 99.6%, Mo with a purity of 99.8%, Tb with a purity of 99.9% and FeB alloy are accurately weighed and put into the quartz tube in the induction furnace. Draw vacuum to 4.0×10 -3 Pa, filled with high-purity argon protection, adjust the current from small to large, induction heating until the sample melts. Repeated smelting 5 times to obtain a homogeneously mixed (Fe 72 Mo 4 B 24 ) 95 Tb 5 Master alloy ingots. Will get (Fe 72 Mo 4 B 24 ) 95 Tb 5 The master alloy ingot was broken into small pieces and ultrasonically cleaned in alcohol. Then put it into a quartz tube with an open lower end and a hole diameter of 0.6mm, and draw a vacuum to 3.7×10 -3 After Pa, ...

Embodiment 3

[0022] This embodiment adopts copper mold injection casting method to prepare diameter 2-4mm (Fe 72 Mo 4 B 24 ) 94 Tb 6 Metal glass alloy rod.

[0023] Fe, Mo, B and Tb elements according to (Fe 72 Mo 4 B 24 ) 94 Tb 6 After the alloy atomic percentage is converted into mass percentage, Fe with a purity of 99.6%, Mo with a purity of 99.8%, Tb with a purity of 99.9% and FeB alloy are accurately weighed and put into the quartz tube in the induction furnace. Draw vacuum to 4.0×10 -3 Pa, filled with high-purity argon protection, adjust the current from small to large, induction heating until the sample melts. Repeated smelting 7 times to obtain a homogeneously mixed (Fe 72 Mo 4 B 24 ) 94 Tb 6 Master alloy ingots. Will get (Fe 72 Mo 4 B 24 ) 94 Tb 6 The master alloy ingot was broken into small pieces and ultrasonically cleaned in alcohol. Then put it into a quartz tube with an open lower end and a hole diameter of 0.5mm, and draw a vacuum to 3.2×10 -3 After Pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com