Rare-earth-doped iron-based amorphous thick strip and preparing method thereof

An iron-based amorphous and rare earth doped technology, applied in the field of magnetic functional materials, can solve the problems of limiting strip production efficiency, iron core preparation efficiency and performance improvement, and achieve the effect of ensuring standardization and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

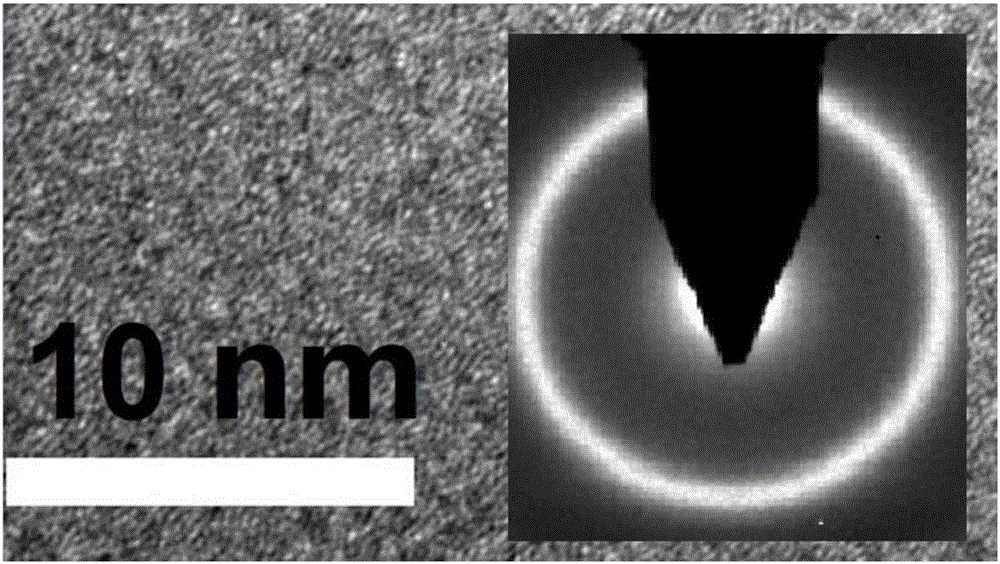

[0053] The present invention adopts the method of adding trace rare earth elements, so that the molten steel of the alloy of the present invention in the smelting process is reasonably purified, and the fluidity of the molten liquid is significantly improved; at the same time, because the rare earth Y element has a large atomic size, it is compatible with The atomic size of other elements in the system is very different, so a large mismatch ratio is formed, which improves the amorphous forming ability of the system; the strong amorphous forming ability and excellent melt fluidity make the preparation of thick amorphous ribbons The process is safer and more reliable, and the qualification rate of thick belt products is obviously improved. Within the chemical composition range of the iron-based amorphous alloy described in the present invention, 8 different iron-based amorphous alloy components are selected respectively, and the serial numbers are 1-8, and the iron-based amorphou...

Embodiment 2

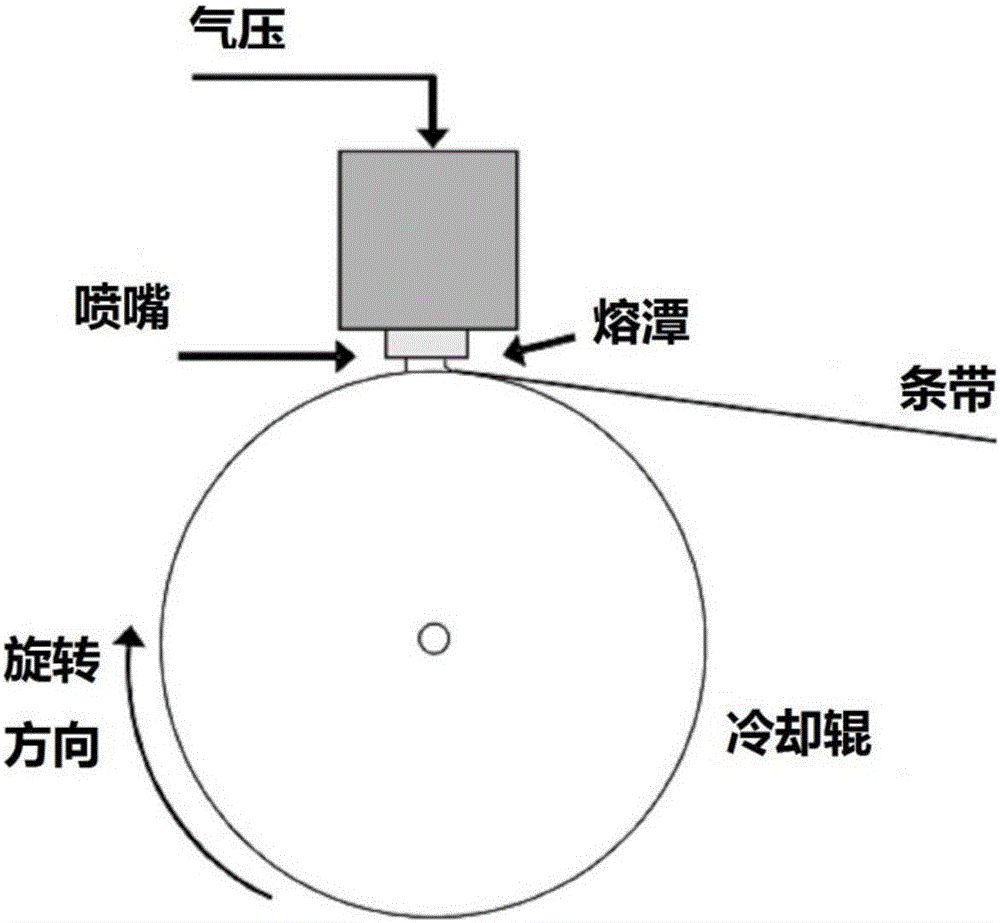

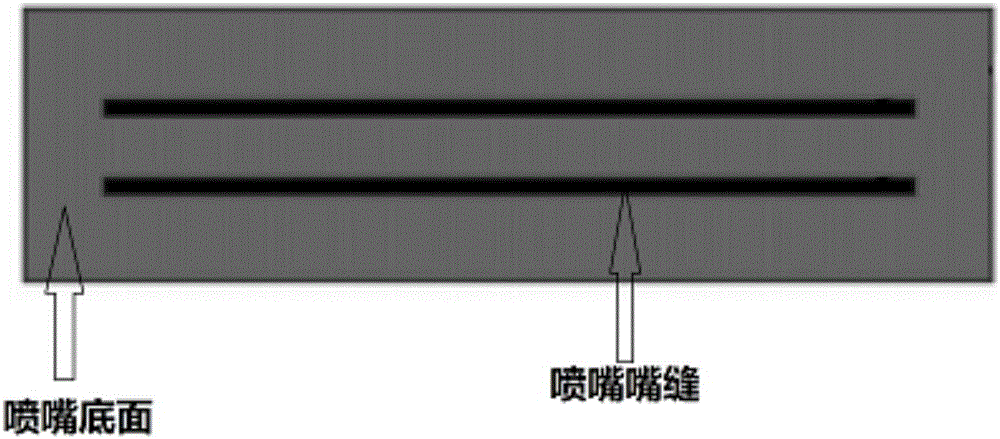

[0059] Since the nozzle slit width is the main factor determining the thickness of the strip, the present invention sets up a group of comparative experiments to investigate the influence of the traditional single-slit nozzle and the double-slit nozzle used in the present invention on the thickness of the prepared amorphous alloy strip. The present invention adopts described double slit nozzle and prior art adopts traditional nozzle, carries out comparative experiment under the same process condition, and the process flow chart of tape making is as follows figure 1 As shown, the structure of the double-slit nozzle is as figure 2 The specific process parameters for the preparation of amorphous alloy strips are listed in Table 2. Table 2 is the ingredients according to the components of the present invention. Put the raw materials with good ratio into induction melting furnace or arc melting furnace, and vacuumize to 5×10 -3 Pa below, then filled with nitrogen atmosphere prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com