Iron-based amorphous alloy and preparation method thereof

A technology for iron-based amorphous alloys and raw materials, applied in the field of iron-based amorphous alloys and their preparation, can solve the problems of low amorphous forming ability of iron-based amorphous alloys, and achieve high amorphous forming ability, Vickers hardness and Excellent compressive rupture strength and production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the iron-based amorphous alloy provided by the present invention includes melting and forming the raw material of the iron-based amorphous alloy, wherein the raw material of the iron-based amorphous alloy includes Fe, Co, ETM, C, B and RE, And their addition satisfies the ratio of each component represented by the following general formula: (Fe x co 1-x ) a (ETM) b C c B d RE e , where a, b, c, d and e are atomic percentages, 40≤a≤60, 0<b≤30, 0<c≤20, 0<d≤10, 0<e≤10, and a+ b+c+d+e=100; x is the atomic fraction, 0.5≤x<1; ETM is one or several elements in the IVB group elements, VB group elements and VIB group elements; RE is one of the rare earth elements one or more elements.

[0027] According to the preparation method provided by the invention, the smelting of the raw material of the iron-based amorphous alloy can be carried out either under a vacuum condition protected by a protective gas or under an air condition. The rare earth ele...

Embodiment 1

[0034] (Fe 0.87 co 0.13 ) 55 Ti 14 Zr 8 C 15 B 6 Y 2 Preparation of Bulk Amorphous Alloy

[0035] The strip-shaped Fe, Co, Ti, Zr, C, B, Y metal raw materials with a purity of 99.9% by weight are added to the vacuum arc melting furnace (Shenyang Scientific Instrument Factory) according to the atomic percentage shown in the above formula, and vacuumized to a vacuum of 1×10 -2 Pa, filled with argon with a purity of 99.99% as a protective gas so that the vacuum in the melting furnace is 0.05 MPa, and then smelted at 1800° C. for 5 minutes to completely melt and stir the alloy raw materials. The melt was then cast into copper molds with 10 2 The cooling rate of K / s is water-cooled to obtain sample A. The critical dimension of this sample was measured to be 15mm.

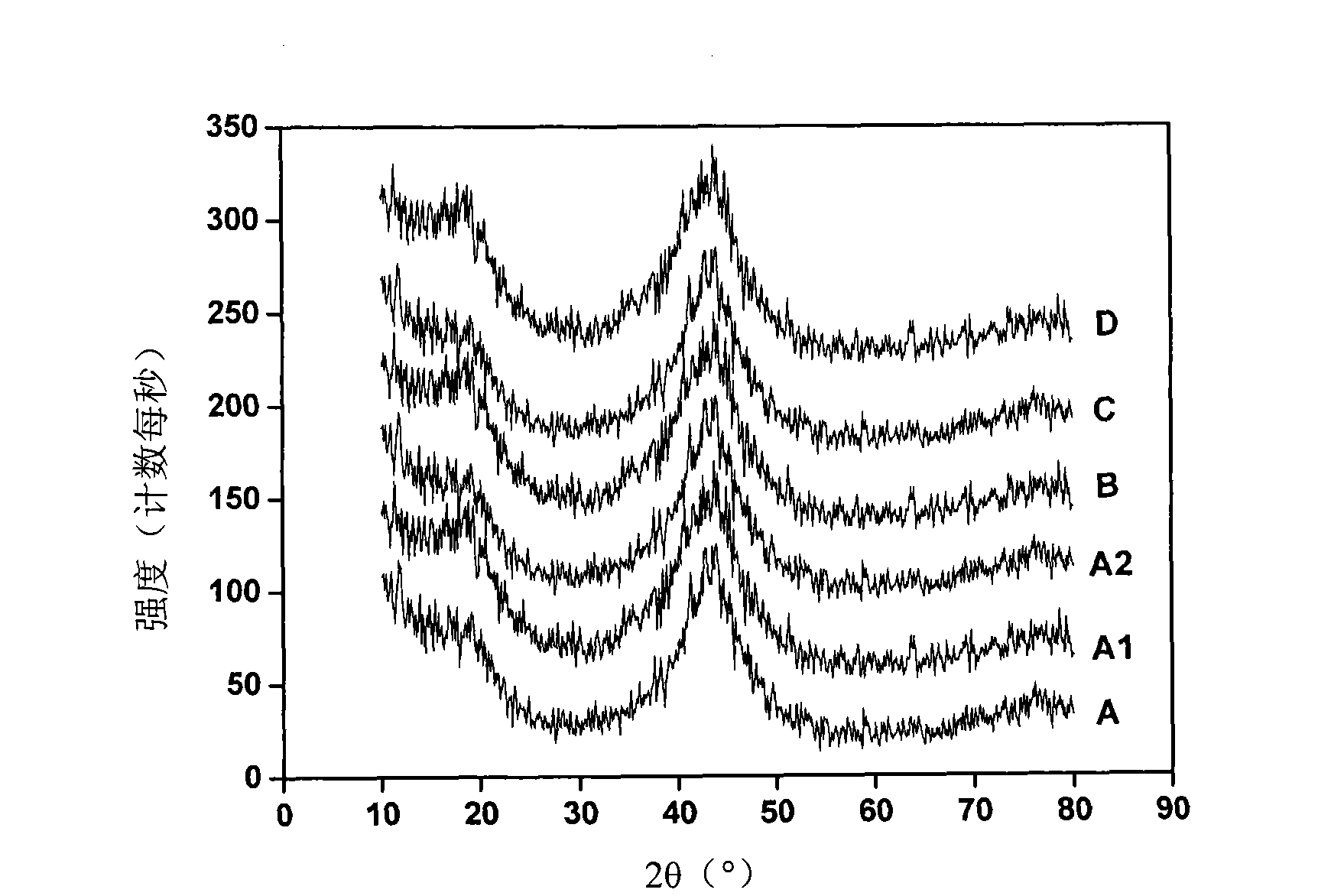

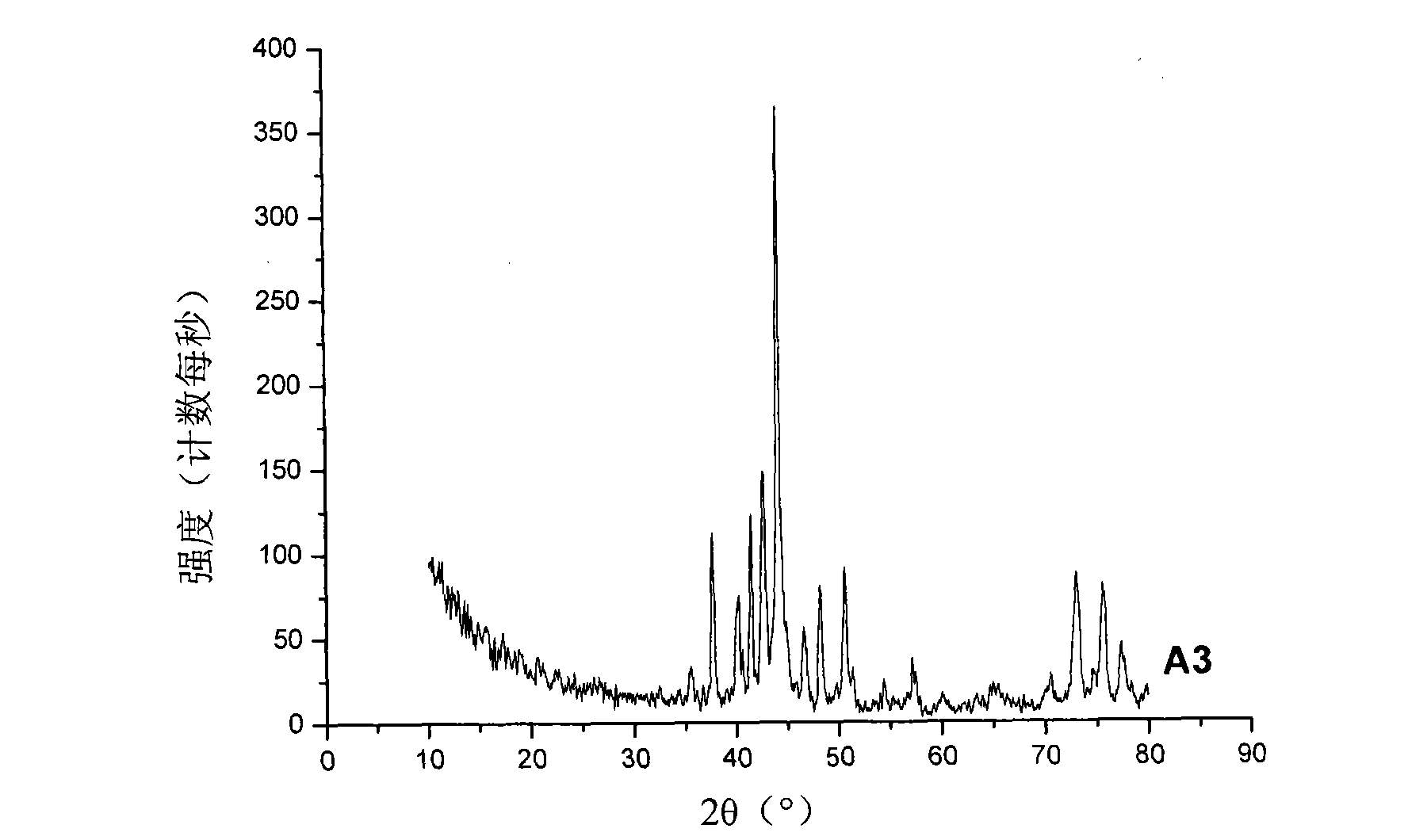

[0036] The obtained sample A is carried out XRD diffraction analysis on the X-ray powder diffractometer, and the obtained X-ray diffraction pattern is as follows figure 1 As shown in A, it can be seen from th...

Embodiment 2

[0047] (Fe 0.93 co 0.07 ) 55 Ti 15 Nb 10 C 12 B 6.5 Ce 1.5 Preparation of amorphous alloy

[0048] The bulk Fe, Co, Ti, Nb, C, B, Ce metal raw materials with a purity of 99.9% by weight are added to the vacuum induction melting furnace (Shenyang Scientific Instrument Factory) according to the atomic percentage shown in the above formula, and vacuumized to The vacuum degree is 10 Pa, and the argon gas with a purity of 99.99% is filled as a protective gas to make the vacuum degree in the melting furnace 0.05 MPa, and then smelted at 2000 ° C for 3 minutes to completely melt and stir the alloy raw materials. The melt was then cast into copper molds with 10 3 The cooling rate of K / s was water-cooled to obtain sample B. The critical dimension of this sample was found to be 12mm.

[0049] The obtained sample B is carried out XRD diffraction analysis on the X-ray powder diffractometer, and the obtained X-ray diffraction pattern is as follows figure 1 As shown in B in the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com