Refractory high-entropy amorphous alloy material, and preparation method and application thereof

An amorphous alloy and refractory technology, which is applied in the field of refractory high-entropy amorphous alloy material and its preparation, can solve the problems of poor ductility at room temperature, difficult amorphous alloy, poor high-temperature oxidation resistance and the like, and the method is simple. , the effect of increasing the atomic radius difference and improving the ability to form amorphous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

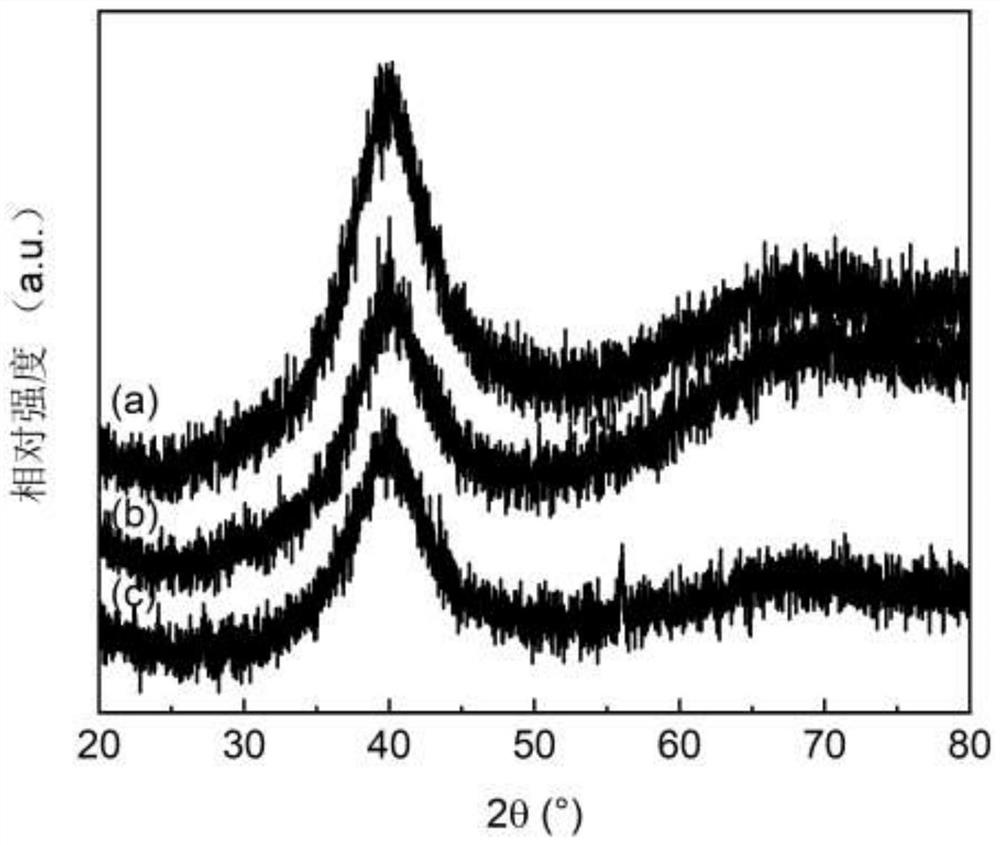

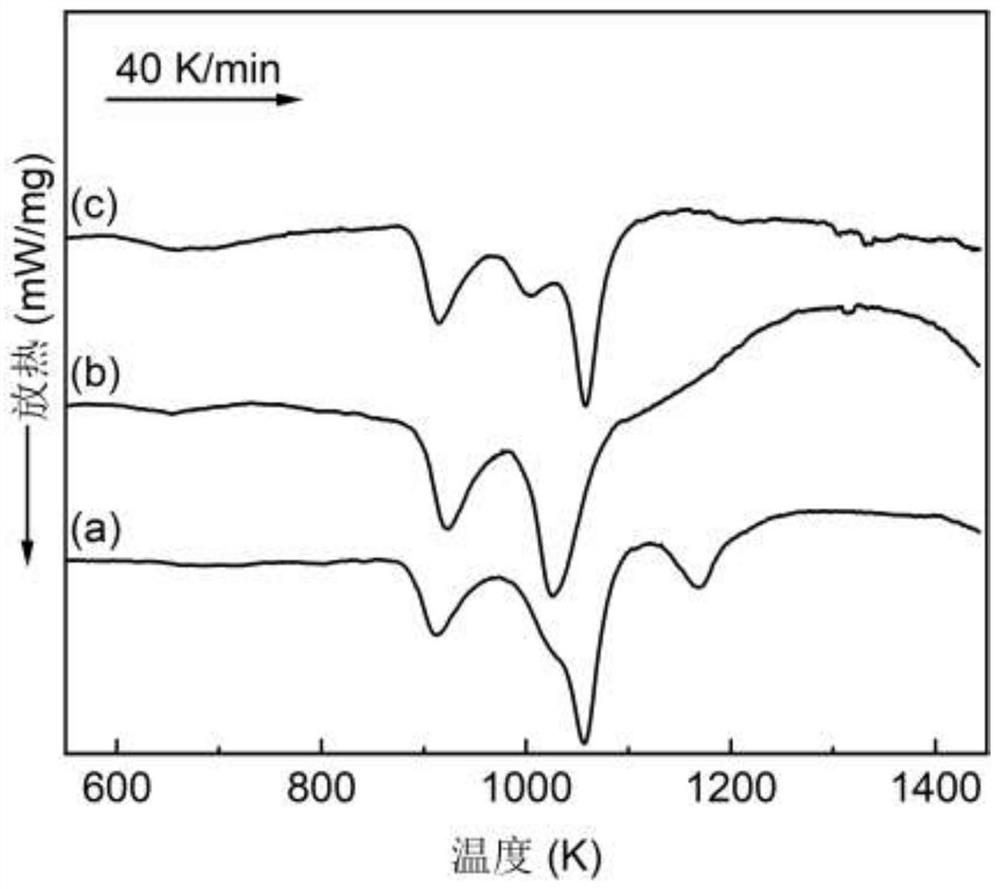

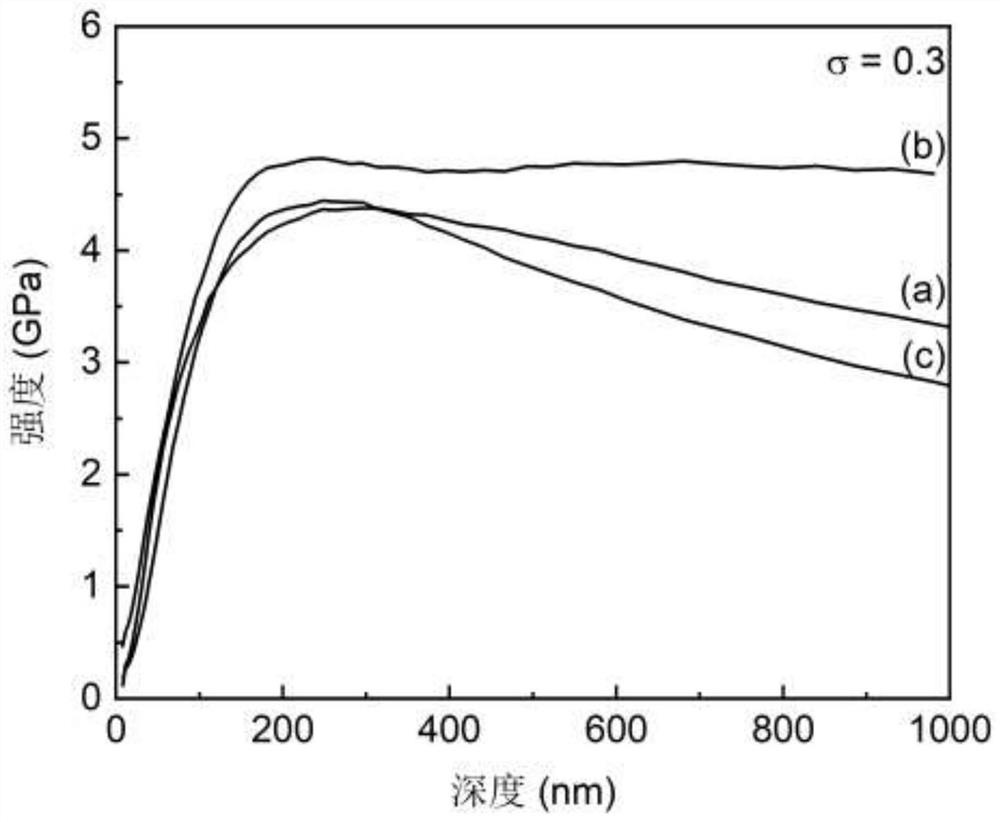

[0050] f 20 Ni 20 Ta 20 co 20 Nb 20 Preparation and property testing of refractory high-entropy amorphous alloy materials.

[0051] According to the atomic fraction of the refractory high-entropy amorphous alloy material converted into mass percentage and weighed, select high-purity Hf particles, Ni particles, Ta blocks, Co blocks, Nb particles (purity not less than 99.9%) as raw materials, and polish the scale Afterwards, ultrasonic cleaning was performed twice for 10 min with alcohol. The mass of the smelted alloy ingot is 19.930g, and the mass of each element is w(Hf)=6.241g, w(Ni)=2.052g, w(Ta)=6.327g, w(Co)=2.061g, w(Nb)= 3.249g.

[0052] The master alloy ingot was prepared by arc melting method under vacuum and argon protective atmosphere, and the vacuum was repeatedly pumped and washed three times until the vacuum degree was 5×10 -3 Pa, pour high-purity argon gas with a purity of 99.999% until the pressure of the vacuum chamber is -0.05MPa, mix evenly and melt in...

Embodiment 2

[0062] f 19 Ni 19 Ta 19 co 19 Nb 19 Re 5 Preparation and property determination of refractory high-entropy amorphous alloy materials.

[0063] According to the atomic fraction of the refractory high-entropy amorphous alloy material converted into mass percentage and weighed, high-purity Hf particles, Ni particles, Ta blocks, Co blocks, Nb particles, Re particles (purity not less than 99.9%) are selected as raw materials, After polishing the scale, ultrasonically clean it twice with alcohol for 10 minutes. The mass of the smelted alloy ingot is 20g, and the mass of each element is w(Hf)=5.767g, w(Ni)=1.896g, w(Ta)=5.847g, w(Co)=1.904g, w(Nb)=3.002 g, w(Re) = 1.583g.

[0064] The master alloy ingot was prepared by arc melting method under vacuum and argon protective atmosphere, and the vacuum was repeatedly pumped and washed three times until the vacuum degree was 5×10 -3 Pa, pour high-purity argon gas with a purity of 99.999% until the pressure of the vacuum chamber is ...

Embodiment 3

[0073] f 19 Ni 19 Ta 19 co 19 Nb 19 B 5 Preparation and property determination of refractory high-entropy amorphous alloy materials.

[0074] According to the atomic fraction conversion of the refractory high-entropy amorphous alloy material into mass percentage and weighing, select high-purity Hf particles, Ni particles, Ta blocks, Co blocks, Nb particles, B particles (purity not less than 99.9%) as raw materials, After polishing the scale, ultrasonically clean it twice with alcohol for 10 minutes. The mass of the smelted alloy ingot is 20g, and the mass of each element is w(Hf)=6.232g, w(Ni)=2.049g, w(Ta)=6.318g, w(Co)=2.058, w(Nb)=3.244g , w(B)=0.099g.

[0075] The master alloy ingot was prepared by arc melting method under vacuum and argon protective atmosphere, and the vacuum was repeatedly pumped and washed three times until the vacuum degree was 5×10 -3 Pa, pour high-purity argon gas with a purity of 99.999% until the pressure of the vacuum chamber is -0.05MPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com