Thermal spraying nickel-based self-fused alloy amorphous coating

A nickel-based self-fluxing alloy, amorphous coating technology, applied in the field of materials, can solve the problems of difficult corrosion resistance and wear resistance, high cost of amorphous coating, achieve dense coating, good thermal stability, huge The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

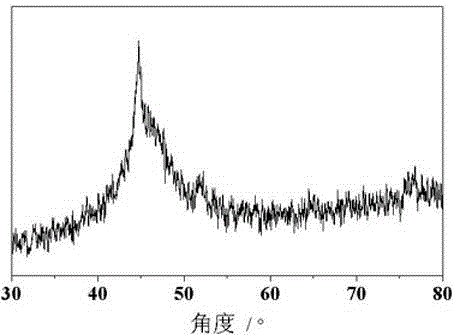

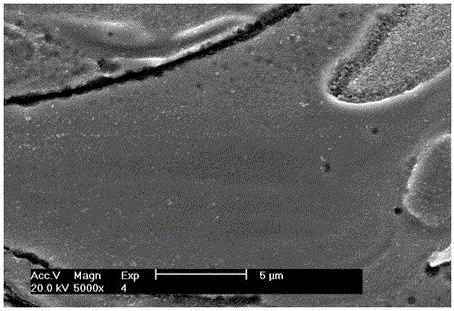

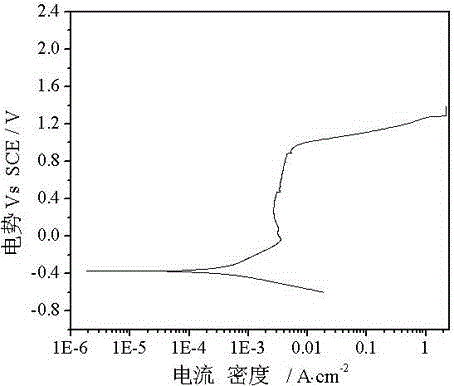

[0022] A thermal spraying nickel-based self-fluxing alloy amorphous coating is prepared by using a water atomization method to prepare nickel-based self-fluxing alloy as spray powder; after the surface of the workpiece to be sprayed is roughened and pretreated, it is sprayed by plasma spraying. It is sprayed on the surface of the workpiece to form the nickel-based self-fluxing alloy amorphous coating. During the spraying process, cold air can be used to forcibly cool the surface of the substrate to increase the cooling rate of the coating. After spraying, the workpiece can be used after a proper amount of fine grinding and other machining.

[0023] The element composition and the weight percentage of each element of the nickel-based self-fluxing alloy are: Cr 18%, B 4%, Si 4%, C 0.5%, Fe 3%, Ni 70.5%, and the particle size range of the spray powder formed by it is 50-70μm.

[0024] The process conditions of the plasma spraying are: arc voltage 55V; spraying current 450A; main...

Embodiment 2

[0030] A thermal spraying nickel-based self-fluxing alloy amorphous coating is prepared by using a water atomization method to prepare nickel-based self-fluxing alloy as spray powder; after the surface of the workpiece to be sprayed is roughened and pretreated, it is sprayed by plasma spraying. It is sprayed on the surface of the workpiece to form the nickel-based self-fluxing alloy amorphous coating. During the spraying process, cold air can be used to forcibly cool the surface of the substrate to increase the cooling rate of the coating. After spraying, the workpiece can be used after a proper amount of fine grinding and other machining.

[0031] The element composition and the weight percentage of each element of the nickel-based self-fluxing alloy are: Cr 20%, B 5%, Si 3%, C 1.1%, Fe 5%, Ni 68.9%, and the particle size range of the spray powder formed by it is 44-80μm.

[0032] The process conditions of the plasma spraying are: arc voltage 55V; spraying current 450A; main...

Embodiment 3

[0034] A thermal spraying nickel-based self-fluxing alloy amorphous coating is prepared by using a water atomization method to prepare nickel-based self-fluxing alloy as spray powder; after the surface of the workpiece to be sprayed is roughened and pretreated, it is sprayed by plasma spraying. It is sprayed on the surface of the workpiece to form the nickel-based self-fluxing alloy amorphous coating. During the spraying process, cold air can be used to forcibly cool the surface of the substrate to increase the cooling rate of the coating. After spraying, the workpiece can be used after a proper amount of fine grinding and other machining.

[0035] The elemental composition and weight percent of each element of the nickel-based self-fluxing alloy are: Cr 15%, B 3%, Si 5.5%, C 0.6%, Fe 3%, Ni 72.9%, and the particle size range of the spray powder formed by it is 70-100μm.

[0036] The process conditions of the plasma spraying are: arc voltage 60V; spraying current 500A; main g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com