Zirconium base amorphous alloy

A technology of zirconium-based amorphous alloys and amorphous alloys, applied in the field of metal alloys, can solve the problem of parts and products that cannot be prepared with amorphous structures, Zr-based amorphous alloys have high preparation costs and cannot meet large-scale mass production and other problems, to achieve the effect of inhibiting the crystallization tendency, improving the ability of amorphous formation, and avoiding crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

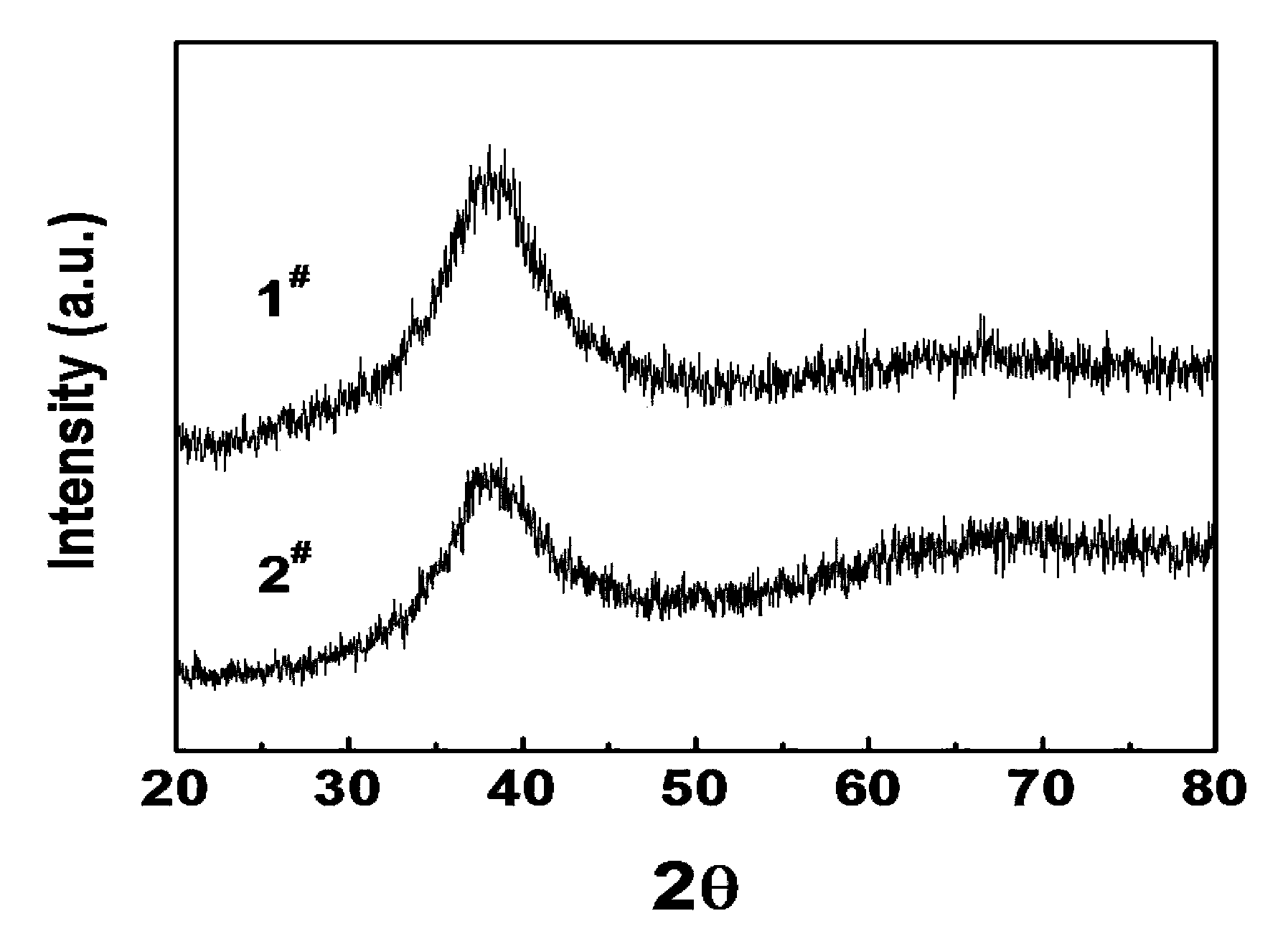

Image

Examples

Embodiment 1

[0048] The first embodiment of the present invention provides a zirconium-based amorphous alloy whose composition and atomic percentage conform to the following general formula:

[0049] Zr a Cu b Ti c Al d Re e ,

[0050] Among them, a, b, c, d, e are the atomic percentage content of each element in the amorphous alloy, respectively: 56≤a≤63, 22≤b≤35, 0.1≤c≤4, 7≤d≤13 , 0.05≤e≤2, a+b+c+d+e≤100, Re is one or more elements in rare earth, that is, Re is La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb, a combination of one or more of Lu elements or Re is La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, A combination of one or more of Tb, Pr, Sm, Yb, Lu and Y. The Re element group can be obtained by adding Misch Metal.

[0051] According to the general formula, the above-mentioned zirconium-based amorphous alloy manufacturing method is used for batching, smelting and casting cooling to form the zirconium-based amorphous alloy expressed by the general formula.

[0052] Wherein, Re ...

Embodiment 2

[0054] The second embodiment of the present invention provides a zirconium-based amorphous alloy whose composition and atomic percentage conform to the following general formula:

[0055] Zr a Cu b Ti c Al d Re e ,

[0056] Among them, a, b, c, d, e are the corresponding atomic percentage content of each element in the amorphous alloy, respectively: 46≤a≤52, 36≤b≤42, 0.1≤c≤4, 7≤d≤13 , 0.05≤e≤2, a+b+c+d+e≤100, Re is one or more elements in rare earth, that is, Re is La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb, a combination of one or more of Lu elements or Re is La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, A combination of one or more of Tb, Pr, Sm, Yb, Lu and Y. The Re element group can be obtained by adding Misch Metal.

[0057] According to the general formula, the above-mentioned zirconium-based amorphous alloy manufacturing method is used for batching, smelting and casting cooling to form the zirconium-based amorphous alloy expressed by the general formula.

[005...

Embodiment 3

[0060] The third embodiment of the present invention provides a zirconium-based amorphous alloy whose composition and atomic percentage conform to the following general formula:

[0061] (Zr,Hf) a Cu b Ti c Al d Re e ,

[0062] Among them, a, b, c, d, e are the atomic percentage content of each element in the amorphous alloy, respectively: 58≤a≤65, 22≤b≤35, 0.1≤c≤4, 7≤d≤13 , 0.05≤e≤2, a+b+c+d+e≤100, Re is one or more elements in rare earth, that is, Re is La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, Tb, Pr, Sm, Yb, a combination of one or more of Lu elements or Re is La, Ce, Po, Ho, Er, Nd, Gd, Dy, Sc, Eu, Tm, A combination of one or more of Tb, Pr, Sm, Yb, Lu and Y. The Re element group can be obtained by adding Misch Metal.

[0063] According to the general formula, the above-mentioned zirconium-based amorphous alloy manufacturing method is used for batching, smelting and casting cooling to form the zirconium-based amorphous alloy expressed by the general formula.

[0064] Wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com