Toughness-enhanced iron-based bulk amorphous soft magnetic alloy and preparation method thereof

A soft magnetic alloy, iron-based technology, applied in the field of iron-based bulk amorphous soft magnetic alloy and its preparation, can solve the problems of brittle fracture, increase the cost of raw materials, and deteriorate soft magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

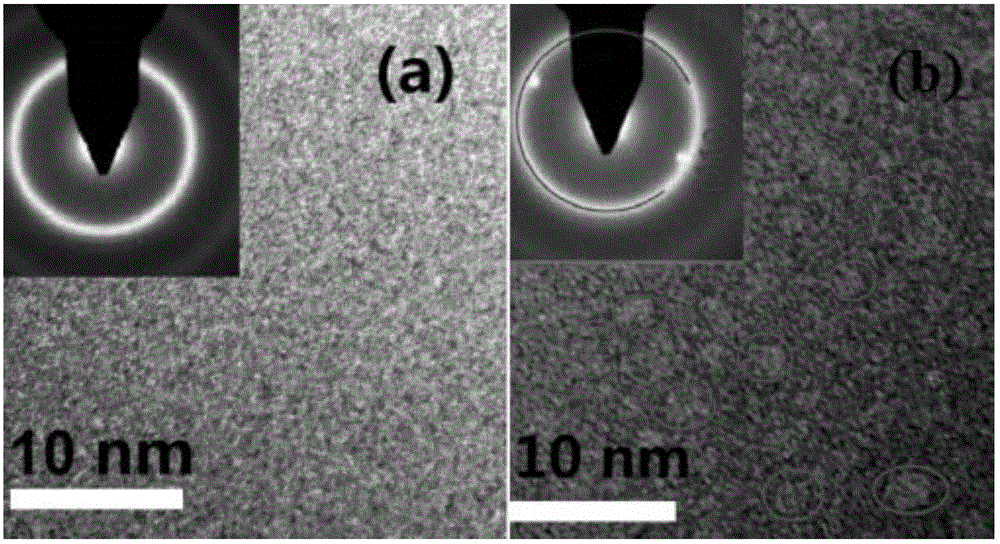

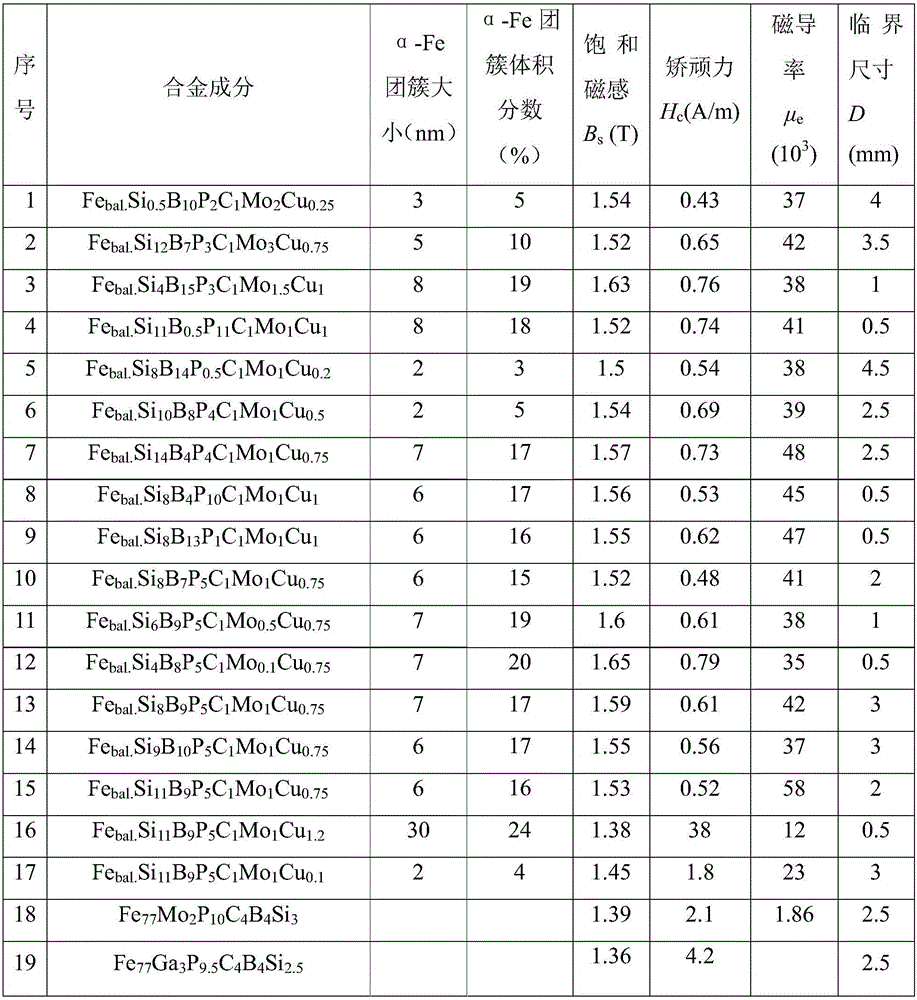

[0050] According to the composition range of the iron-based bulk amorphous soft magnetic alloy of the present invention, we have done a series of experiments. Dosing according to the composition of the present invention and the composition of the comparative example, see Table 1 (serial number 1-22) for the specific composition and atomic percentage content; put the raw materials with the ratio into an induction melting furnace or an electric arc melting furnace, and vacuumize to 5× 10 -3Below Pa, then filled with argon atmosphere protection, smelting at 1400°C for 35 minutes, and then holding the temperature for 30 minutes after complete melting to melt the alloy raw materials into a uniform molten steel, pour into the mold and cool to obtain a master alloy ingot with a uniform composition; then crush the master alloy ingot ; Then put the broken master alloy into a quartz tube and melt it into molten steel. The melting temperature is about 1300°C. The molten steel is rapidly ...

Embodiment 2

[0061] According to the composition range of the iron-based nanocrystalline alloy of the present invention, we have done a series of experiments. The Fe of the high saturation magnetic induction intensity that present embodiment prepares x Si a B b P c C d Mo e m f alloy, the M component of the alloy is in the alloy expression Fe in Example 1 x Si a B b P c C d Mo e Cu f The base is changed, that is, its Cu is partially or completely replaced by at least one element of Ag and Au with less than 1 atomic %. Dosing according to the composition of the present invention, see Table 2 (serial number 1-10) for the specific composition and atomic percentage content; put the raw materials with good ratio into induction melting furnace or electric arc melting furnace, and vacuumize to 5×10 -3 Below Pa, then filled with nitrogen atmosphere protection, smelting at 1400 ° C for 35 minutes, and after melting for 30 minutes to melt the alloy raw materials into a uniform molten st...

Embodiment 3

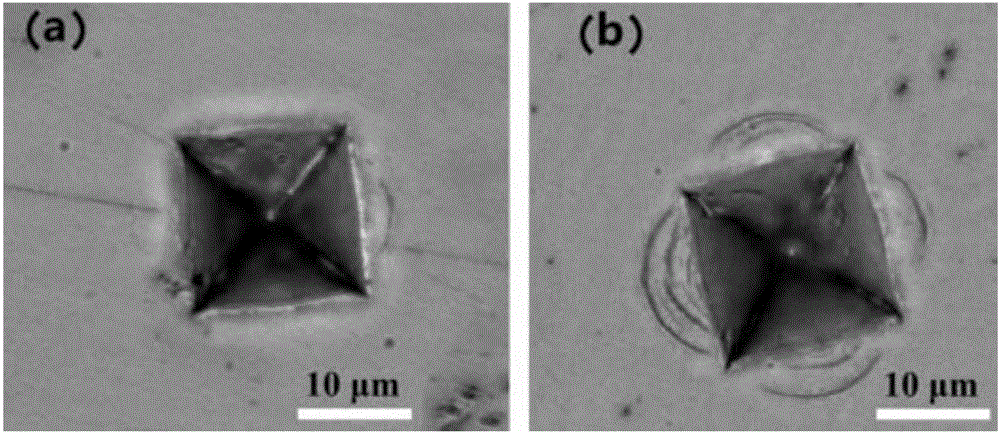

[0067] In this example, the copper mold casting method is used to prepare Febal.Si with high saturation magnetic induction. 12 B 7 P 3 C 1 Mo 3 Cu 0.75 Alloy. Amorphous alloy rods with a diameter of 3.5-5 mm were prepared under different viscosities, surface tensions, and casting temperatures. See Table 3 for specific parameters. Dosing according to the alloy composition; put the proportioned raw materials into the induction melting furnace or arc melting furnace, and vacuumize to 5×10 -3 Below Pa, then filled with argon atmosphere protection, smelting at 1400°C for 35 minutes, and after melting for 30 minutes to melt the alloy raw materials into a uniform molten steel, pour it into the mold and cool to obtain an alloy ingot with a uniform composition; crush the master alloy ingot; A small piece of master alloy is put into a quartz tube and melted into molten steel. The melting temperature is about 1550°C. The molten steel is rapidly cooled by copper mold casting in the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com