Iron-based nanocrystalline magnetically soft alloy and preparation method thereof

A technology of iron-based nanocrystals and soft magnetic alloys, applied in magnetic materials, manufacturing tools, magnetic objects, etc., can solve the problems of difficult to achieve comprehensive soft magnetic properties, short holding time for crystallization treatment, low saturation magnetic induction intensity, etc. Achieve the effect of promoting industrial production, simplifying heat treatment process, and high comprehensive soft magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

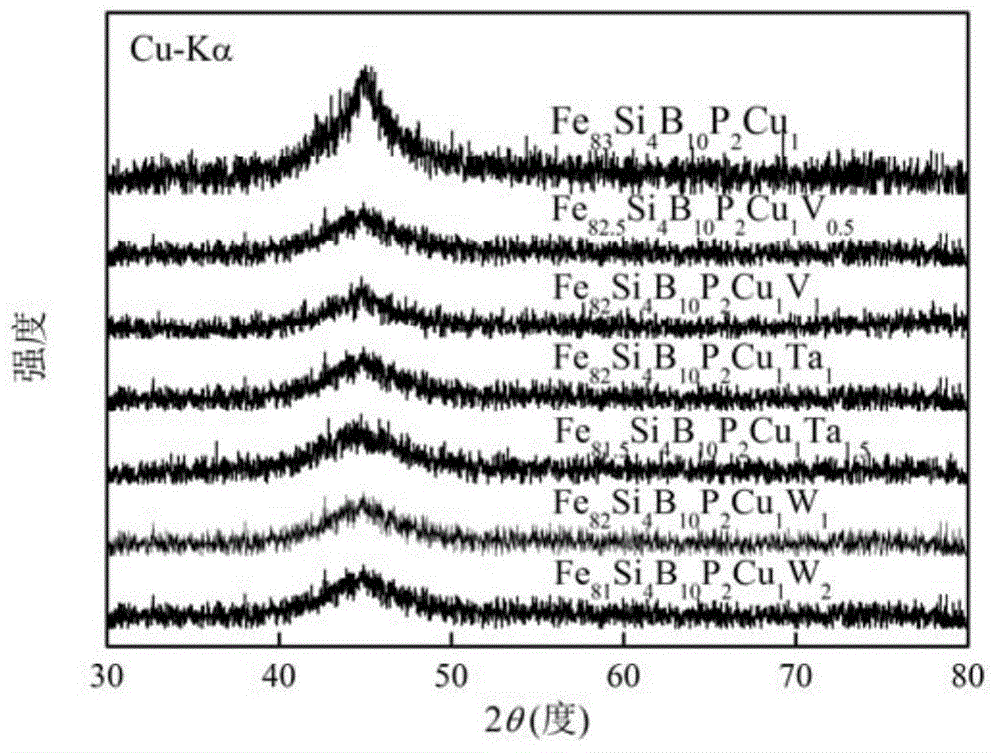

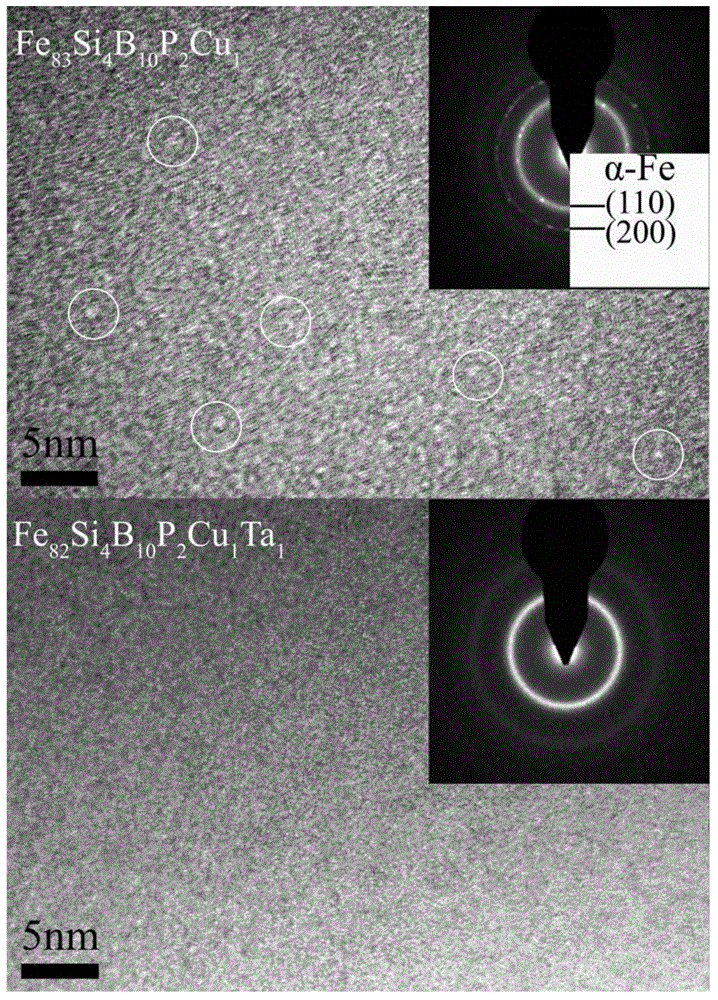

[0038] In this embodiment, the compositional chemical formula of the iron-based nanocrystalline soft magnetic alloy is Fe 82 Si 4 B 10 P 2 Cu 1 V 1 .

[0039] The preparation method of the above-mentioned iron-based nanocrystalline soft magnetic alloy is as follows:

[0040] (1) Prepare commercially available Fe 3 P intermediate alloy ingot;

[0041] (2) The pure raw materials of Fe, Si, B, Cu, V with a purity of 99.99% and the intermediate alloy ingot Fe 3 P (99.9%), according to the atomic percentage of the alloy composition;

[0042] (3) Place the raw materials weighed in step (2) in a high-frequency induction melting furnace for melting, first vacuumize to 5×10 -2 Below Pa, then fill in an appropriate amount of protective gas argon. After the alloy is melted, keep it warm for 30 minutes to melt the alloy raw material evenly, then pour it into the casting copper mold, and cool to obtain the alloy ingot;

[0043] (4) Break the alloy ingot, put the broken alloy ingo...

Embodiment 2

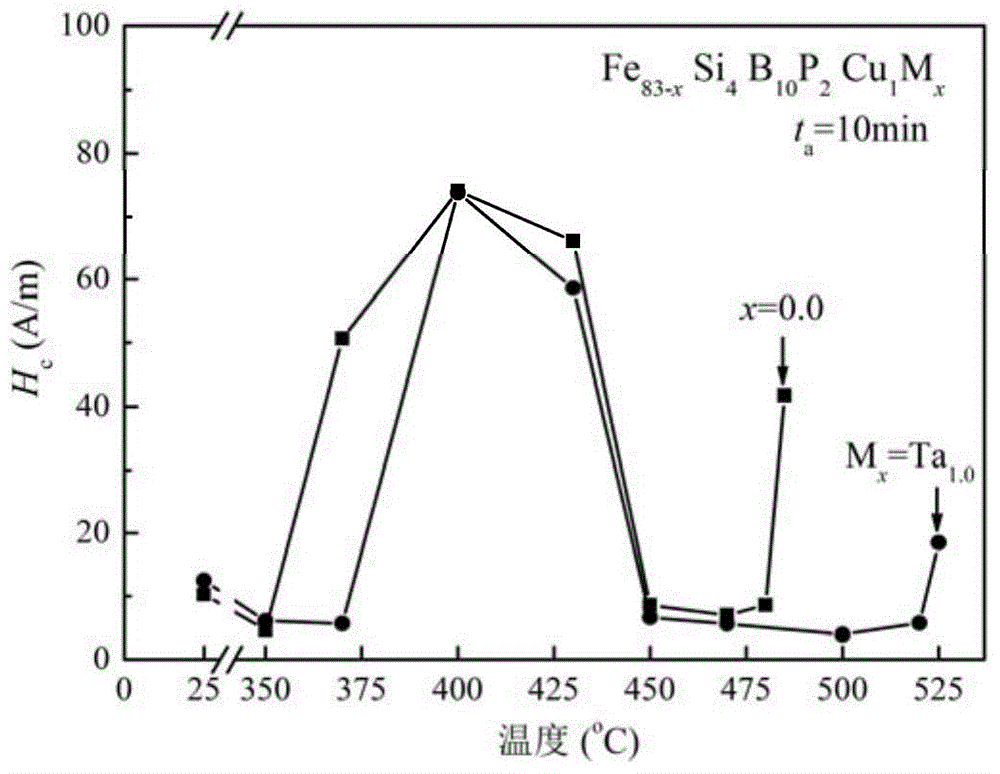

[0051] In this embodiment, the compositional chemical formula of the iron-based nanocrystalline soft magnetic alloy is Fe 82 Si 4 B 10 P 2 Cu 1 Ta 1 .

[0052] The preparation method of the above-mentioned iron-based nanocrystalline soft magnetic alloy is as follows:

[0053] (1) Prepare commercially available Fe 3 P intermediate alloy ingot; the high-purity Fe and Ta raw materials are made into Fe according to the alloy composition (atomic percentage) 23 Ta 2 The proportion of ingredients, the prepared Fe 23 Ta 2 The alloy raw materials are put into the water-cooled copper crucible of the electric arc melting furnace, and the vacuum is firstly evacuated to 5×10 -2 Below Pa, then fill in an appropriate amount of protective gas argon for smelting, smelt evenly and then cool down with the furnace, repeat arc smelting 4 times under the same conditions to obtain Fe with uniform composition 23 Ta 2 master alloy ingot;

[0054] (2) Fe, Si, B, Cu pure raw materials with ...

Embodiment 3

[0060] In this embodiment, the compositional chemical formula of the iron-based nanocrystalline soft magnetic alloy is Fe 82 Si 4 B 10 P 2 Cu 1 W 1 .

[0061] The preparation method of the above-mentioned iron-based nanocrystalline soft magnetic alloy is as follows:

[0062] (1) Prepare commercially available Fe 3 P intermediate alloy ingot; the high-purity Fe and W raw materials are converted to Fe according to the alloy composition (atomic percentage) 9 The ratio of W is used for batching, and the prepared Fe 9 Put the W alloy raw material into the water-cooled copper crucible of the electric arc melting furnace, and firstly evacuate to 5×10 -2 Below Pa, then fill in an appropriate amount of protective gas argon for smelting, smelt evenly and then cool down with the furnace, repeat arc smelting 4 times under the same conditions to obtain Fe with uniform composition 9 W master alloy ingot;

[0063] (2) Fe, Si, B, Cu pure raw materials with a purity of 99.99% and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com