High-corrosion-resistance iron-based amorphous alloy material and preparation method thereof

A technology of iron-based amorphous alloys and alloy materials, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of no corrosion resistance, failure to achieve, soft magnetic properties cannot be achieved, etc., to achieve high corrosion resistance, High thermal stability and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

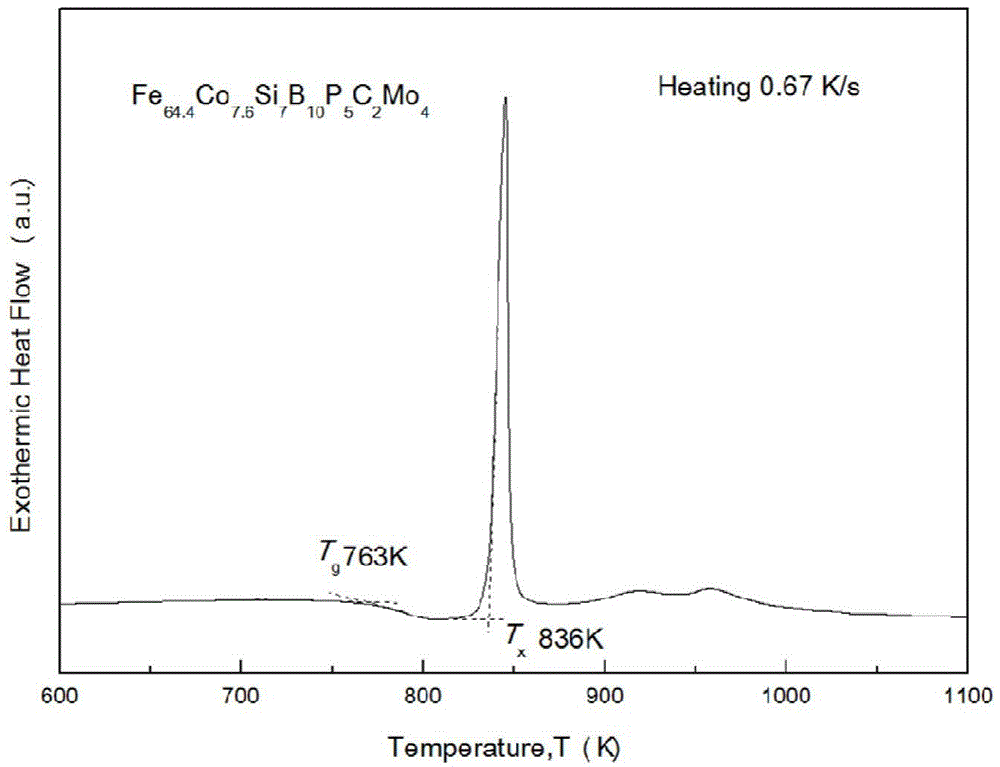

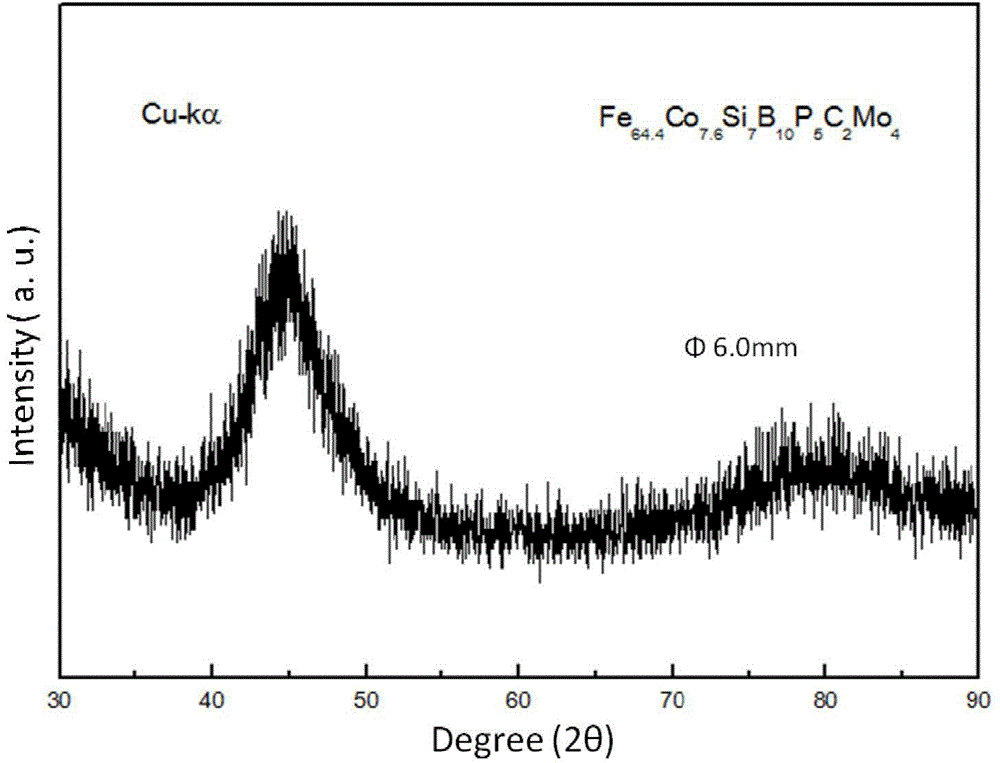

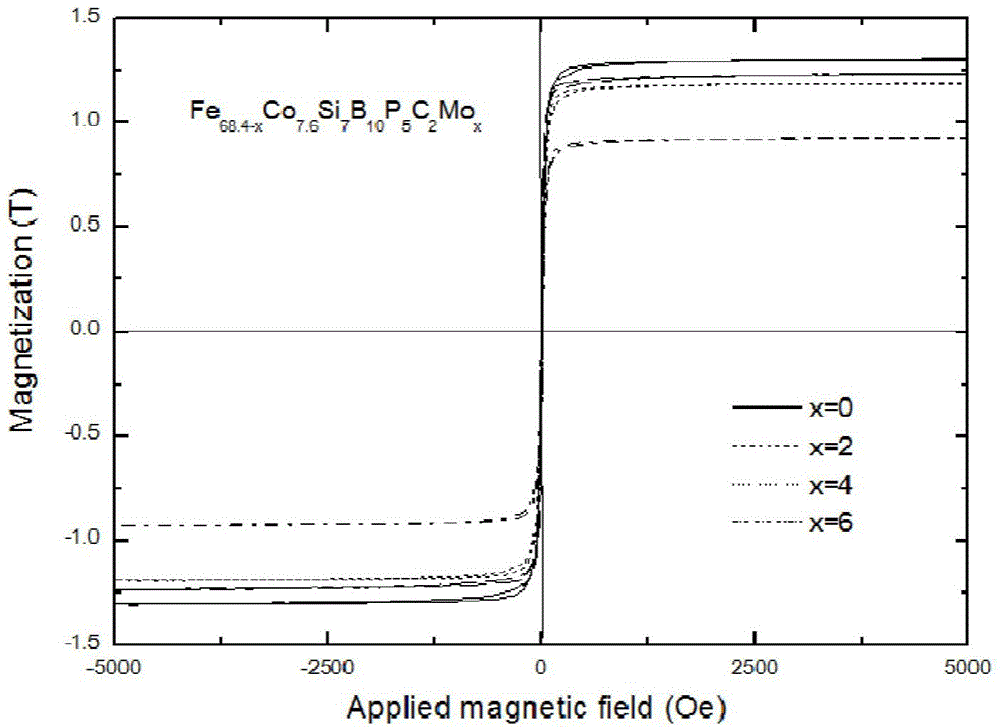

[0032] A high corrosion resistance iron-based amorphous alloy material, its chemical formula is Fe 68.4-x Co 7.6 Si 7 B 10 P 5 C 2 Mo x , Where, embodiment 1: x=0; embodiment 2: x=2; embodiment 3: x=4; embodiment 4: x=6.

[0033] The steps of a method for preparing a high corrosion resistance iron-based amorphous alloy material are as follows:

[0034] a. According to the chemical formula Fe 68.4-x Co 7.6 Si 7 B 10 P 5 C 2 Mo x (x=0,2,4,6), add raw materials Fe, Co, Si, B, P, C, Mo ingredients, where P and C are added in the form of FeP and FeC alloys, and the purity mass percentages of the remaining raw materials Both are above 99%;

[0035] b. Put the raw materials prepared in step a into the induction melting furnace and vacuumize to 2x10 -3 Below pa, fill with argon gas to the pressure of 200-1000mbar for smelting, gradually adjust the current to 8-10A, wait until the raw materials are completely melted and keep the molten state for 10-20min, then quickly pour the alloy liquid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com