Patents

Literature

43results about How to "Maintain metallic luster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal polishing solution

The invention discloses metal polishing solution, which comprises the following components in percentage by weight: 15-20% of sodium oleate, 2-5% of citric acid, 5-7% of sodium tripolyphosphate, 3-4% of sodium dodecyl benzene sulfonate, 1-2% of 2-(heptadecene)-4,5-dihydro-1H-imidazole-1-ethanol, 8-10% of quartz sand and the balance of water. According to the metal polishing solution disclosed by the invention, greasy dirt and rust spots on the surface of a metal appliance, such as steel, iron, copper and aluminum can be effectively removed, and metallic luster of the appliance is kept and the appliance is bright as new, and the appliance is prevented from being rusted again for more than one year after cleaning one time.

Owner:深圳市永霖科技有限公司

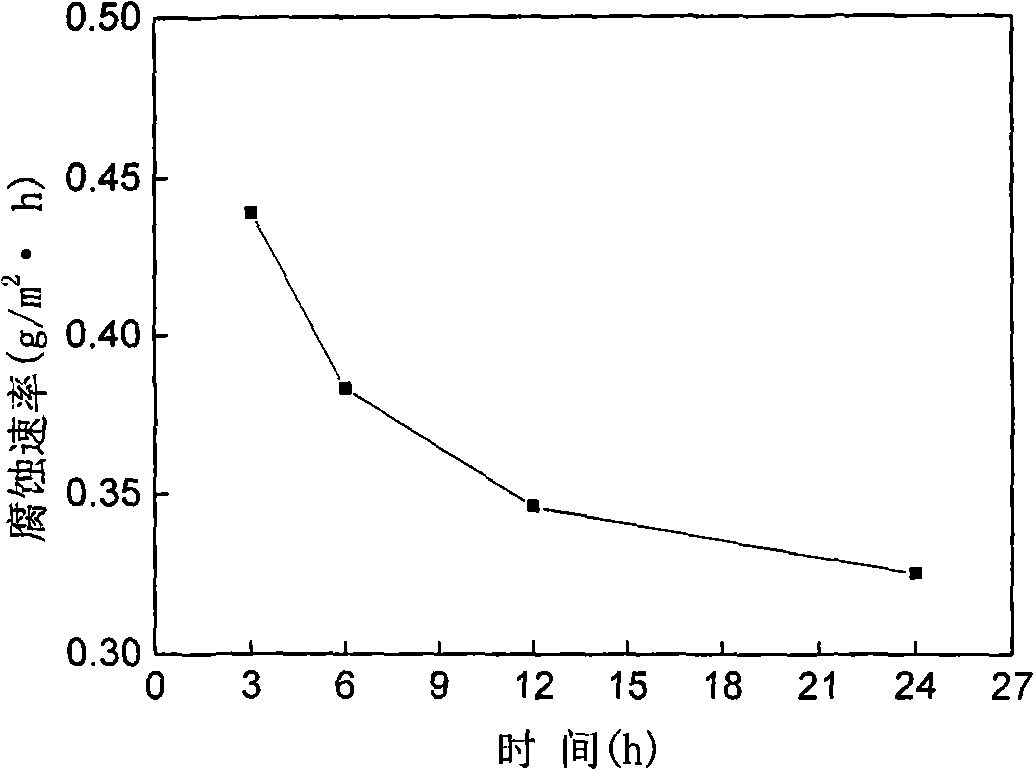

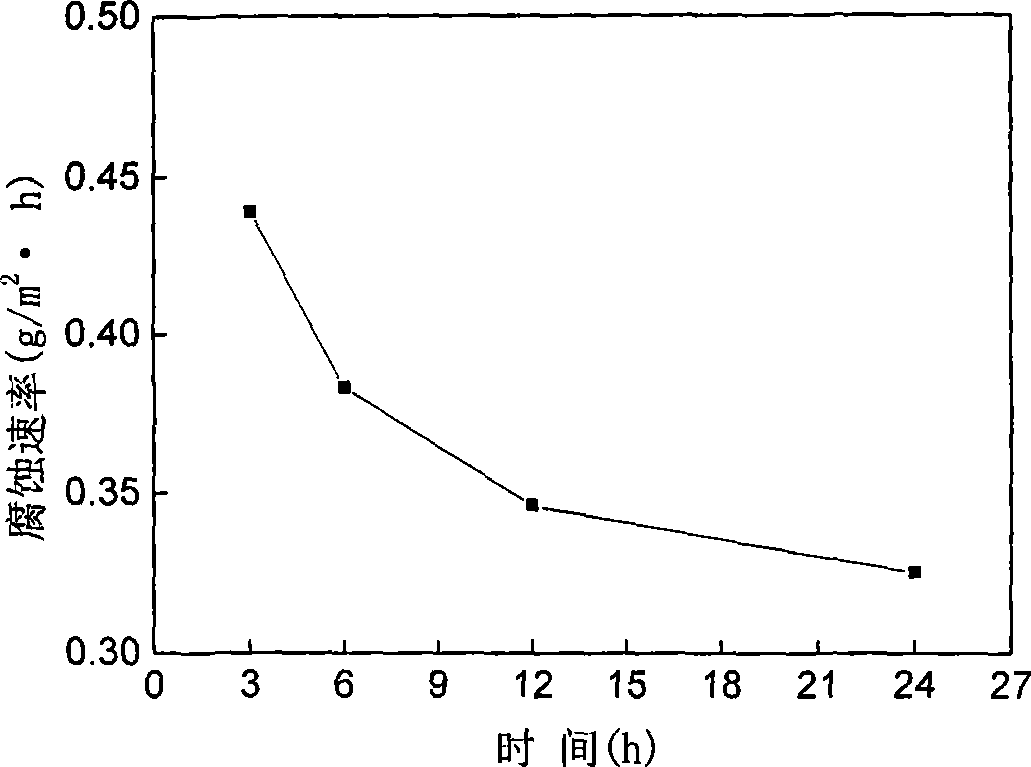

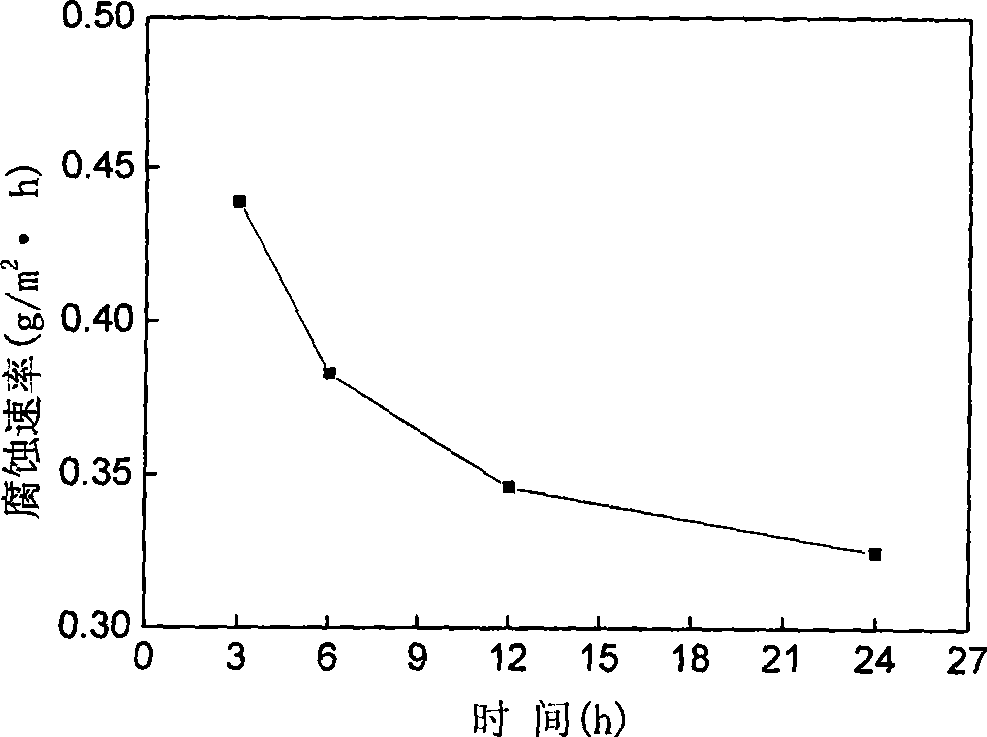

Inhibitor in aqueous heat exchange medium for La-Fe-Si series room temperature magnetic refrigeration materials

The invention relates to an inhibitor in an aqueous heat exchange medium for La-Fe-Si series room temperature magnetic refrigeration materials, which belongs to the field of functional materials and can significantly improve the corrosion resistance of the La-Fe-Si series room temperature magnetic refrigeration materials in an aqueous heat exchange fluid. The inhibitor consists of the following components in percentage by weight: 0.1 to 10 weight percent of molybdenate, 0 to 5 weight percent of dichromate, 0 to 8 weight percent of nitrite, 0.5 to 3 weight percent of orthophosphate, 0.05 to 2 weight percent of silicate, 0 to 1 weight percent of borate, 0 to 3 weight percent of sodium benzoate, 0 to 0.1 weight percent of zinc sulfate, 0 to 0.5 weight percent of sodium carbonate, and 0 to 10 weight percent of triethanolamine. The inhibitor has the characteristics of a small usage amount, simple using method and high corrosion inhibition efficiency, and can significantly improve the corrosion resistance of the magnetic refrigeration materials after being added into the aqueous heat exchange medium.

Owner:UNIV OF SCI & TECH BEIJING

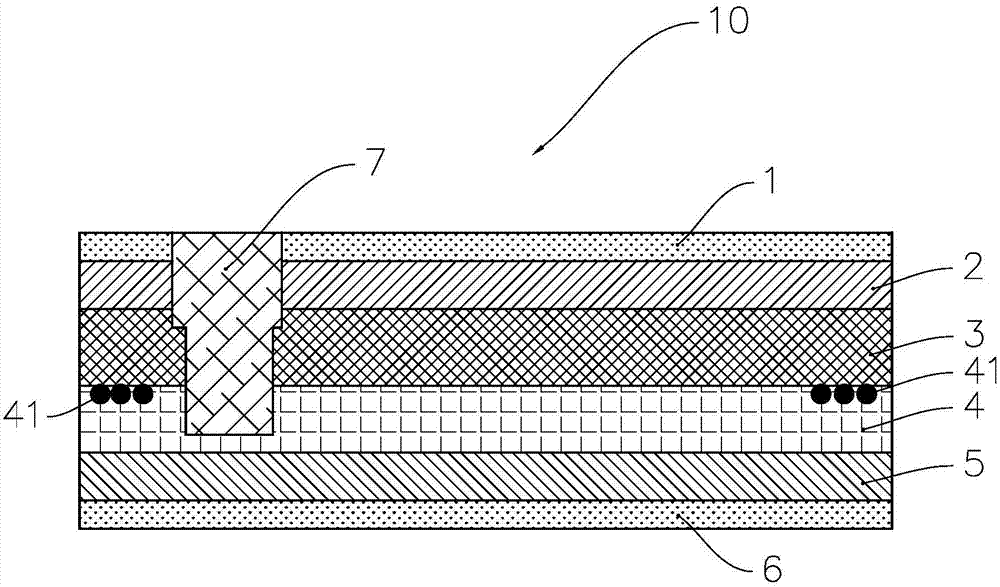

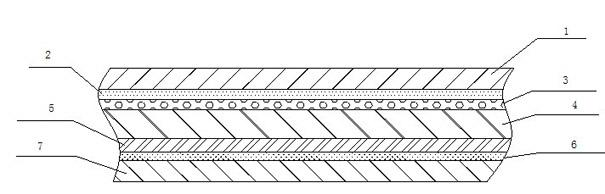

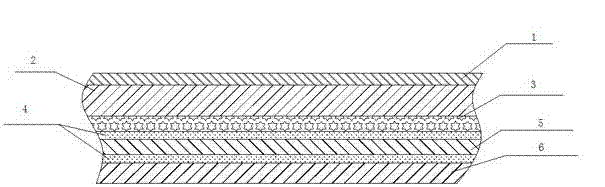

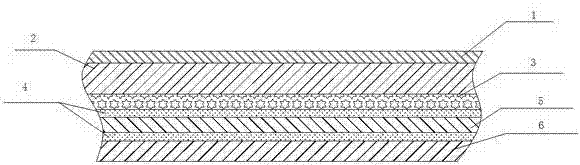

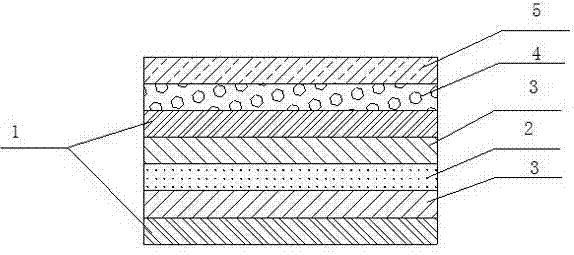

Intelligent card with metal luster and preparation method of intelligent card

The invention provides an intelligent card with metal luster and a preparation method of the intelligent card. The intelligent card comprises a card base. A front face protection film, a front face transparent printing layer, a metal layer, a pre-laminating sheet, a back face transparent printing layer and a back face protection film are successively laminated on the card base. Shading patterns are printed on the surface of the metal layer. An IC chip is arranged on the card base, successively penetrates through the front face protection film, the front face transparent printing layer and the metal layer and then is embedded into the pre-laminating sheet. The IC chip is electrically connected with a coil in the pre-laminating sheet. According to the invention, the card base is prepared by use of non-conventional cold pressing technique, the metal luster of the metal layer is ensured; and the intelligent card has metal luster, top-grade and simple appearance and an anti-fake function.

Owner:GOLDPAC GRP LTD

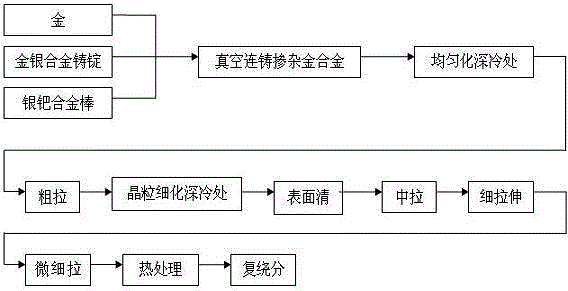

Alloy-doped gold bonding wire and cryogenic-treatment preparation method thereof

The invention relates to an alloy-doped gold bonding wire and a cryogenic-treatment preparation method thereof. The alloy-doped gold bonding wire formed by using high-purity gold as a main ingredient and being doped with high-purity silver and high-purity palladium, which is provided by the invention, is prepared from the following ingredients in percentages by weight: 60 to 80 percent of gold, 0.5 to 3.5 percent of palladium and the balance of silver. A bonding wire product has favorable oxidation resistance; an appearance is basically golden; the performance of the product is approximate to that of a pure-gold bonding wire; and the alloy-doped gold bonding wire is suitable for IC (Integrated Circuit) and COB (Chip On Board) encapsulation and high-end LED (Light-Emitting Diode) encapsulation. During the bonding of encapsulation, any gas shield is not needed; and in comparison with a gold bonding wire, the cost of the product is only approximately 3 / 5 to 4 / 5 of that of the gold bonding wire. In the preparation process of the product, the cryogenic treatment is carried out on a bonding wire twice; the arrangement of internal crystal textures of a material is improved; the physical properties of the material are enhanced; and the bonding properties of the alloy-doped gold bonding wire is improved. When the product is used for downstream encapsulation and wire bonding modes are BSOB (Bond Stitch On Ball) and BBOS (Bond Ball On Stitch), a wire stock and a ball are guaranteed to be eutectic.

Owner:河北乐通金属材料有限公司

Cosmetic

InactiveCN1476319AImprove surface smoothnessPrevent sticking or agglomerationCosmetic preparationsMake-upMetal allergyCosmetics

A cosmetic is provided that contains a powder that exhibits a shininess characteristic of a metal film and yet is not prone to leaching out of metal ions, whereby the cosmetic is not prone to causing discoloration or degeneration, and is not prone to bringing about a metal allergy. The powder contained in the cosmetic is comprised of a base material, and a metal film and a metal oxide film formed in this order on the base material.

Owner:NIPPON SHEET GLASS CO LTD

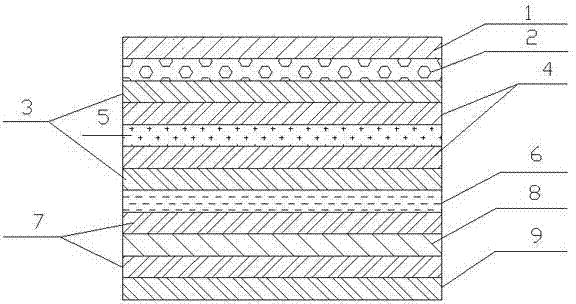

PET (Polyethylene Terephthalate)-PET imitation stainless steel compound colored plate

InactiveCN102398391ALow costOxygen isolationMetal layered productsTextile printerPolyethylene terephthalate glycol

The invention discloses a PET (Polyethylene Terephthalate)-PET imitation stainless steel compound colored plate, which comprises a steel plate basic layer and an imitation aluminum stainless steel compound film, wherein the imitation aluminum stainless steel compound film comprises a printing and coloring layer, two PET film layers, a first bonding agent layer and a wire drawing aluminum foil layer; the steel plate basic layer comprises a steel plate and a passivation layer; and the passivation layer of the steel plate basic layer is boned with the PET film layer on the non-wire drawing surface of a wire drawing aluminum foil layer in the imitation stainless steel compound film. The PET-PET imitation stainless steel compound colored plate has the typical metal luster and dense texture of a wire drawing stainless steel plate, and the effect of a high imitation wire drawing stainless steel plate is achieved; a wire drawing aluminum foil is coated inside the PET film layer, so that oxygen can be isolated, oxidation and corrosion are prevented, and the effect of keeping the original metal luster and wire drawing texture for a long time is achieved; and the PET-PET imitation stainless steel compound can be widely applied to the fields of automobiles, refrigerators, washing machines, kitchen equipment and the like.

Owner:JIANGSU OBON PLASTIC

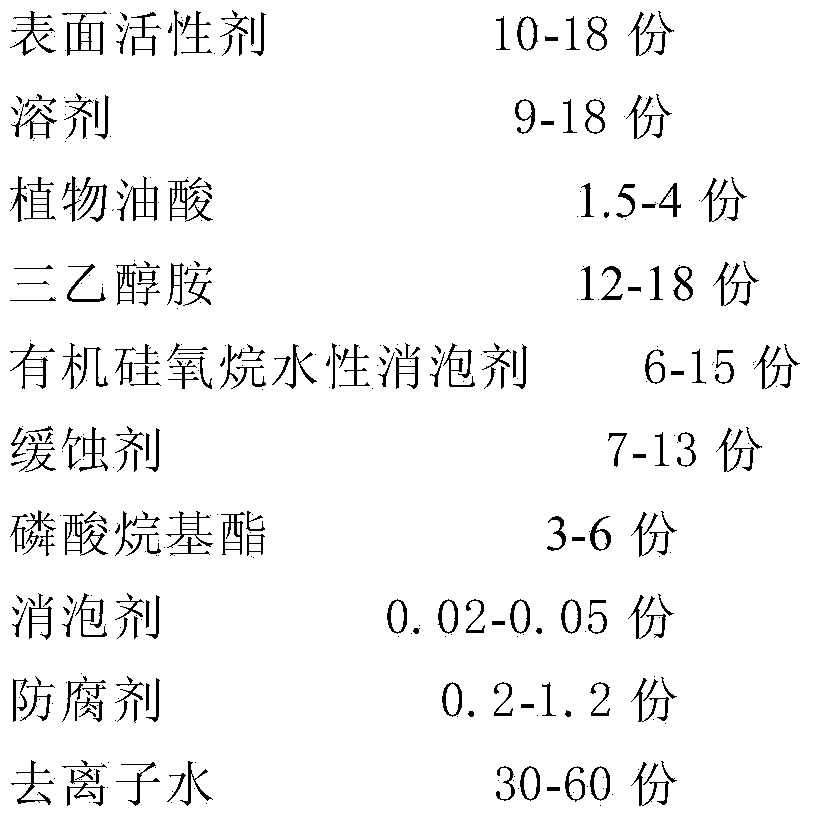

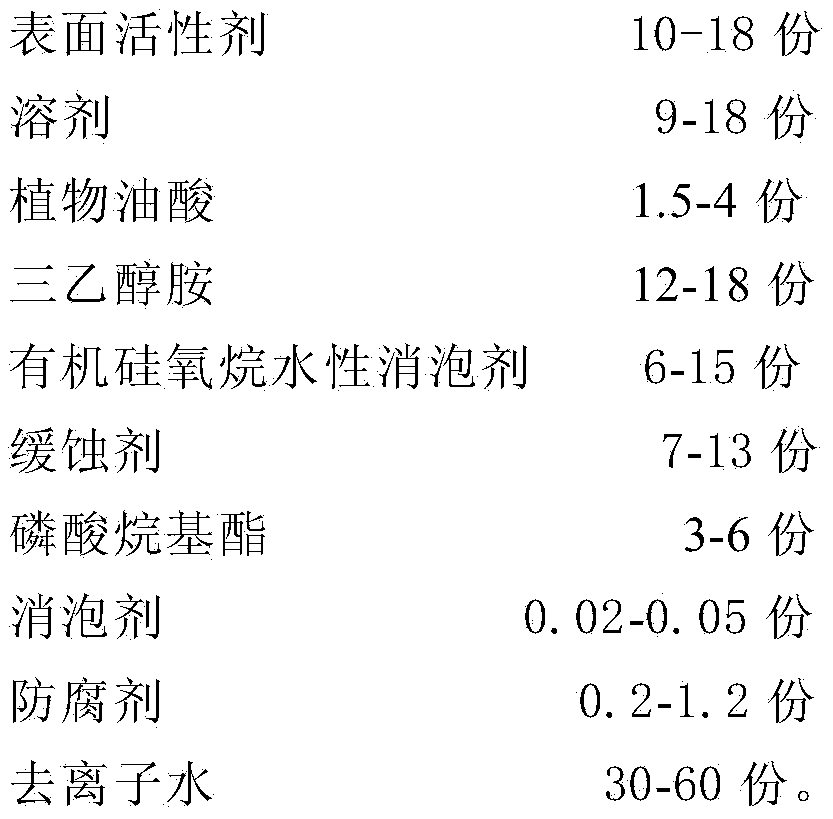

Special metal cleaning agent for water-based reactive aluminum product and preparation method thereof

The invention relates to a special metal cleaning agent for a water-based reactive aluminum product. The special metal cleaning agent is prepared from a surfactant, a solvent, plant oleic acid, triethanolamine, organosiloxane, a corrosion inhibitor, alkyl phosphate, a defoamer 575, a preservative 1227, deionized water and the like. The metal cleaning agent disclosed by the invention is non-toxic, harmless and pollution-free, is harmless to human, is corrosion-free to the surface of the aluminum product, is odorless during long-time use, does not deteriorate, has extremely excellent cleaning and antirusting functions, particularly cleans thick and hard deposited carbon and stubborn stains thoroughly, does not corrode aluminum products of various models and is applicable to ultrasonic machine cleaning, spraying machine cleaning, handed soak rinsing and the like, and the natural antirusting time of workpieces is over 60 days after cleaning.

Owner:TIANJIN AOLUPU LUBRICATION TECH CO LTD

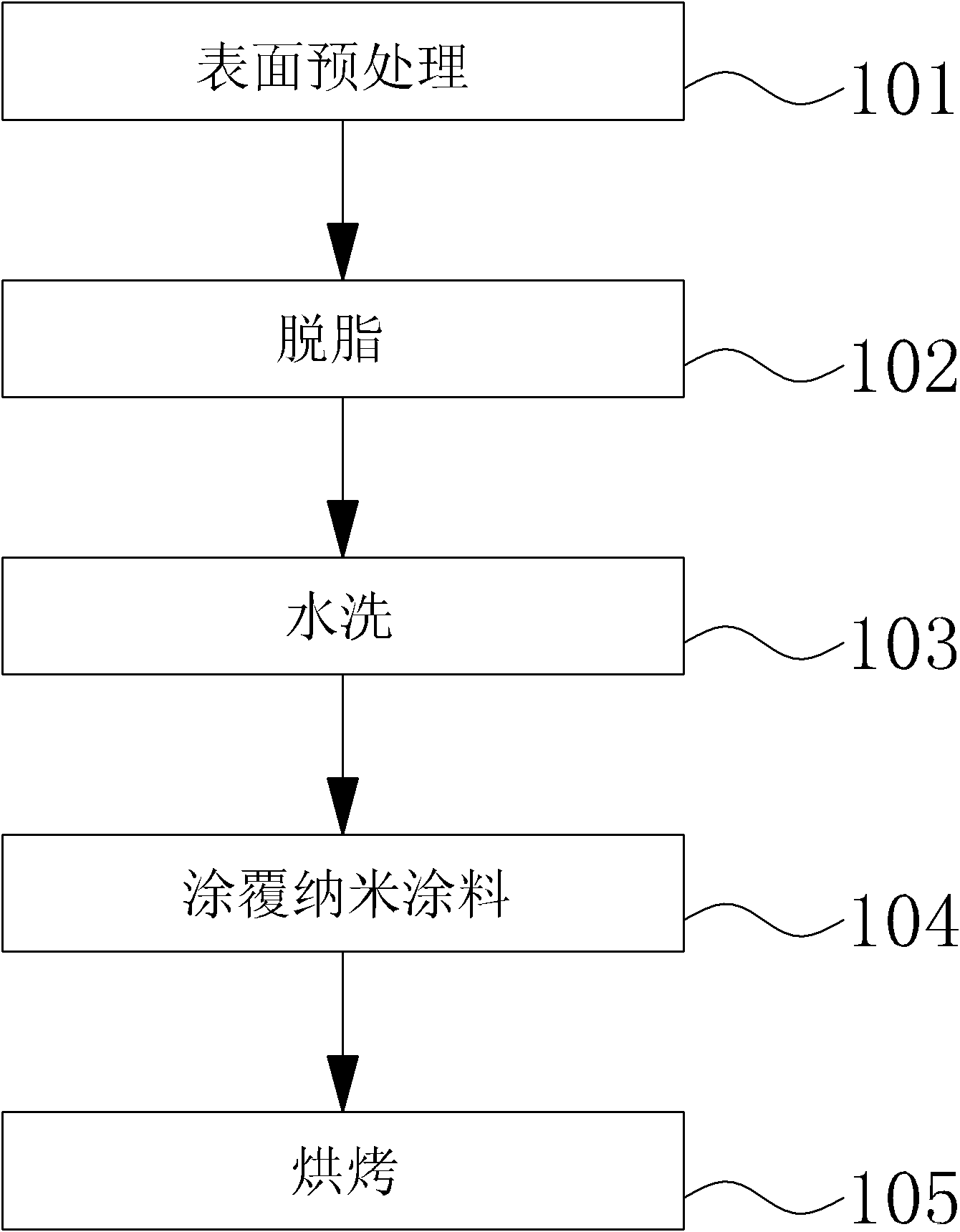

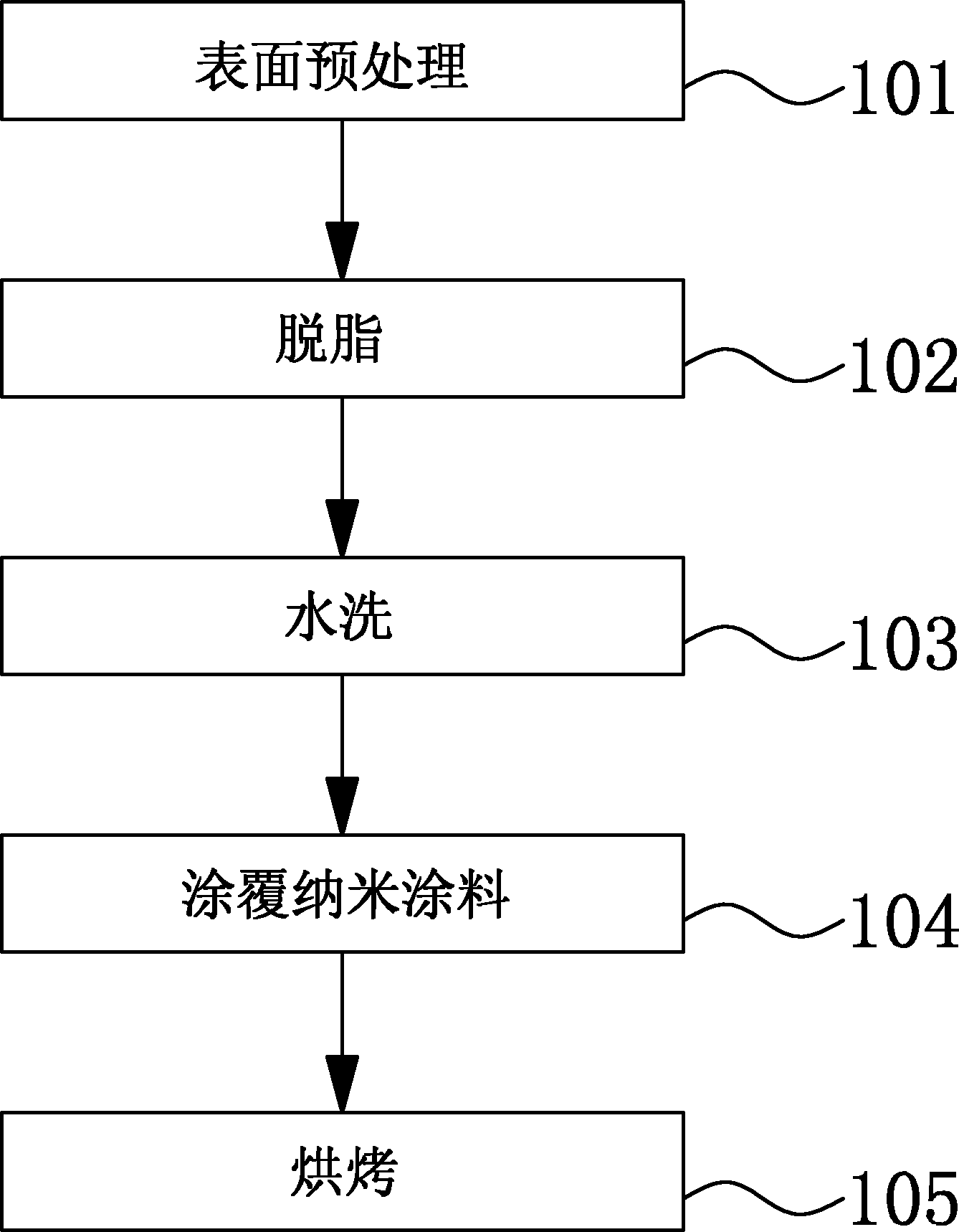

Preparation method of magnesium alloy surface colorless transparent film

InactiveCN102652937AImprove corrosion resistanceIncrease brightnessPretreated surfacesCoatingsIsobutanolEther

The invention provides a preparation method of a magnesium alloy surface colorless transparent film which is characterized by mainly comprising the following steps: (1) surface pretreatment; (2) degreasing; (3) water washing; (4) application of nano paint; and (5) baking. In the step (4), the nano paint mainly comprises the following components in percentage by weight: 20-50% of isobutanol, 40-70% of ethylene glycol monobutyl ether and 5-20% of nano sol-gel. Compared with the prior art, the preparation method provided by the invention has the advantages of simple technique, less required equipment and low cost; and the magnesium alloy surface colorless transparent film prepared by the method provided by the invention has the advantages of favorable corrosion resistance, high brightness and low ohmic value of the product surface, and can keep the metallic color and luster of the magnesium alloy.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Ceramic glaze with copper-like luster

InactiveCN107698153AReduce voidsImproved dielectric properties and mechanical strengthPotassium feldsparCeramic glaze

The invention relates to a ceramic glaze with copper-like luster. The ceramic glaze is prepared from potassium feldspar, albite, white glass, boric acid powder, ochre, potassium nitrate, glaze stone,green glass, tin crystals and copper oxide. The ceramic glaze with copper-like luster has the advantages that a green body can be compact, gaps in the green body can be reduced, and mechanical strength and dielectric property of the green body can be improved. A proper amount of ochre is added, so that the ceramic glaze with copper-like luster can keep metal cluster continuously, has a good use effect, can be applied to building sanitary ceramics as well as surfaces of products such as concrete slabs, plastic plates, gypsum boards, paint, plastics, textiles and the like, is wide in applicationrange and has good popularization value; the preparation process of the ceramic glaze with copper-like luster is simple, the performance is stable, and the preparation cost of the ceramic glaze withcopper-like luster is low.

Owner:NANNING SHENGRUN TECH

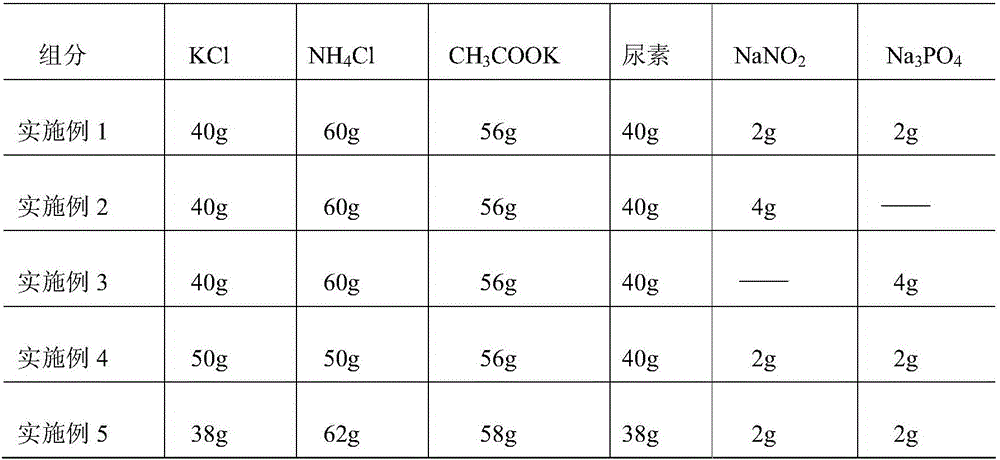

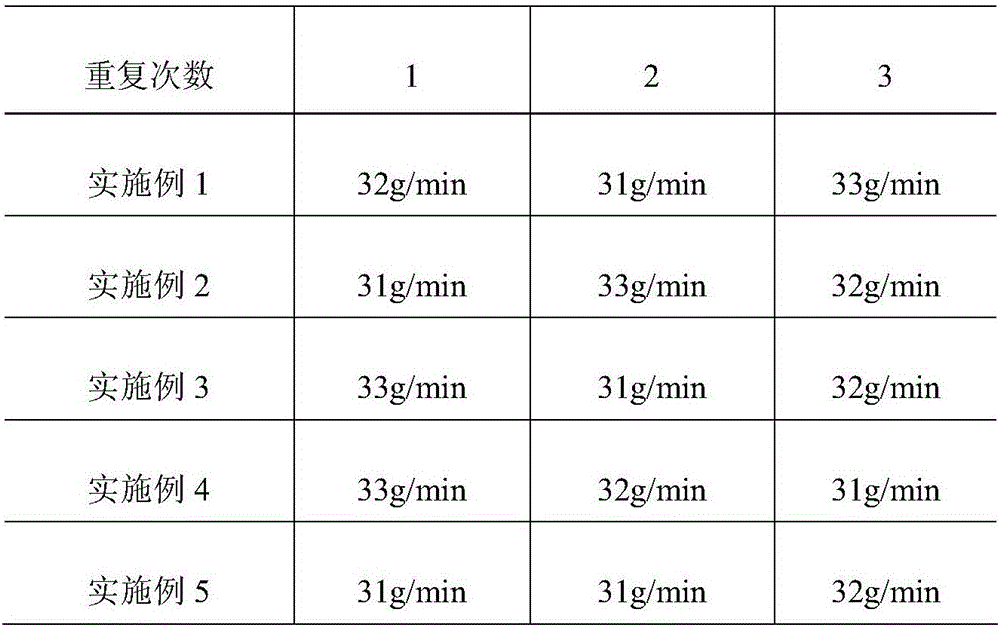

Environmentally-friendly composite type snow-melting agent and preparation method thereof

ActiveCN106634841ARaw materials are easy to getLow costOther chemical processesSodium phosphatesSnow melting

The invention relates to an environmentally-friendly composite type snow-melting agent and a preparation method thereof. The snow-melting agent is prepared from the following raw materials in parts by weight: 40 to 55 parts of chlorine salt, 45 to 55 parts of organic salt and 1 to 2 parts of a corrosion inhibitor, wherein the chlorine salt is prepared from the following raw materials in parts by weight: 15 to 20 parts of potassium chloride and 25 to 35 parts of ammonia chloride; the organic salt is prepared from the following raw materials in parts by weight: 25 to 30 parts of potassium acetate and 20 to 25 parts of urea; the corrosion inhibitor is one of or a mixture of sodium nitrite and sodium phosphate; and the snow-melting agent is prepared from the following raw materials in parts by weight: 50 parts of chlorine salt, 48 parts of organic salt and 2 parts of a corrosion inhibitor. The snow-melting agent is doped with the corrosion inhibitor; and related corrosiveness tests indicate that the snow-melting agent doped with the sodium phosphate has smallest corrosion effect on metal and can protect the surface of the metal, the metal still can maintain the original metal luster when being soaked into a salt solution, and a good metal corrosion-resistant effect is achieved.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

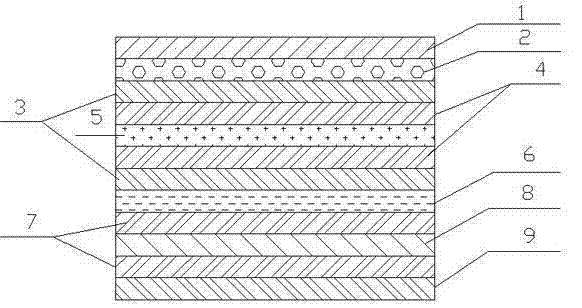

Copper wire drawing simulated composite glass

InactiveCN102501466AOxygen isolationPrevent oxidationNatural patternsSpecial ornamental structuresTextile printerCopper wire

The invention discloses copper wire drawing simulated composite glass. The copper wire drawing simulating composite glass comprises a toughened glass plate and a copper wire drawing simulated composite film layer, wherein the copper wire drawing simulated composite film layer comprises a printing and coloring layer, a PET (Polyethylene Glycol Terephthalate) film layer subjected to wire drawing treatment, a second adhesive layer and a PVC (polyvinyl chloride) film layer; the printing and coloring layer is arranged on the non-wire-drawing surface of the PET film layer; a vacuum aluminizing film layer is arranged on the wire-drawing surface of the PET film layer; the PVC film layer is adhered to the vacuum aluminizing film layer through the second adhesive layer; and one side of the toughened glass is adhered to the printing and coloring layer of the copper wire drawing simulated composite film layer through a first adhesive layer. Another technical scheme is that the PVC film layer is replaced by the common PET film. The copper wire drawing simulating composite glass has bronze metal luster and wire-drawing texture of a wire-drawing copper metal material; the aluminizing film layer is positioned between a PET film and a PVC / PET film, so oxygen can be isolated, oxidation is avoided and the effect of maintaining the original metal luster for a long time is achieved; and the process is simple, the operation is easy and the cost is low.

Owner:JIANGSU OBON PLASTIC

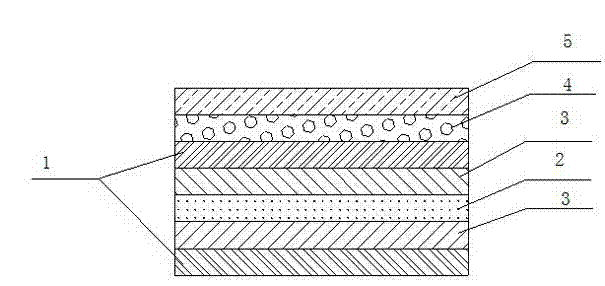

Imitation aluminum composite membrane

InactiveCN102371729AMaintain metallic lusterRetain glossMetal layered productsPolyvinyl chlorideMetallic materials

Owner:JIANGSU OBON PLASTIC

Inhibitor in aqueous heat exchange medium for La-Fe-Si series room temperature magnetic refrigeration materials

The invention relates to an inhibitor in an aqueous heat exchange medium for La-Fe-Si series room temperature magnetic refrigeration materials, which belongs to the field of functional materials and can significantly improve the corrosion resistance of the La-Fe-Si series room temperature magnetic refrigeration materials in an aqueous heat exchange fluid. The inhibitor consists of the following components in percentage by weight: 0.1 to 10 weight percent of molybdenate, 0 to 5 weight percent of dichromate, 0 to 8 weight percent of nitrite, 0.5 to 3 weight percent of orthophosphate, 0.05 to 2 weight percent of silicate, 0 to 1 weight percent of borate, 0 to 3 weight percent of sodium benzoate, 0 to 0.1 weight percent of zinc sulfate, 0 to 0.5 weight percent of sodium carbonate, and 0 to 10weight percent of triethanolamine. The inhibitor has the characteristics of a small usage amount, simple using method and high corrosion inhibition efficiency, and can significantly improve the corrosion resistance of the magnetic refrigeration materials after being added into the aqueous heat exchange medium.

Owner:UNIV OF SCI & TECH BEIJING

Static electricity resistant anticorrosive paint and preparation method thereof

InactiveCN102344723AMaintain metallic lusterWith anti-static effectAnti-corrosive paintsIodidePolyvinyl alcohol

The invention discloses a static electricity resistant anticorrosive paint and a preparation method thereof. The paint is prepared form the following steps: dissolving polyvinyl butyral in ethanol with stirring to obtain a 5-25wt% polyvinyl butyral solution; adding auxiliaries being 5-28wt% of the polyvinyl butyral into the solution and stirring for 50-80 min; adding corrosion inhibitor being 2-8wt% of the polyvinyl butyral into the prepared solution and stirring to complete dissolve; adding molybdate or iodide being 2-6wt% of the polyvinyl butyral into the prepared solution with stirring and stirring for 50-80 min. The environment-friendly paint of the invention can be applied to non-ferrous metal surface treatment, has good protective and anticorrosive effects and can keep original metal luster; a surface drying speed is fast with a time of 13-18 min; the coating has flattening and light appearance, good adhesion, high hardness, good salt spray resistance and antistatic effect.

Owner:江苏海云花新材料有限公司

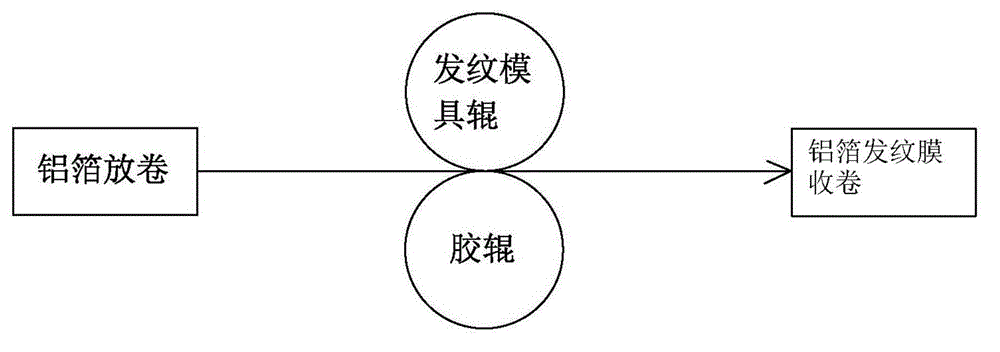

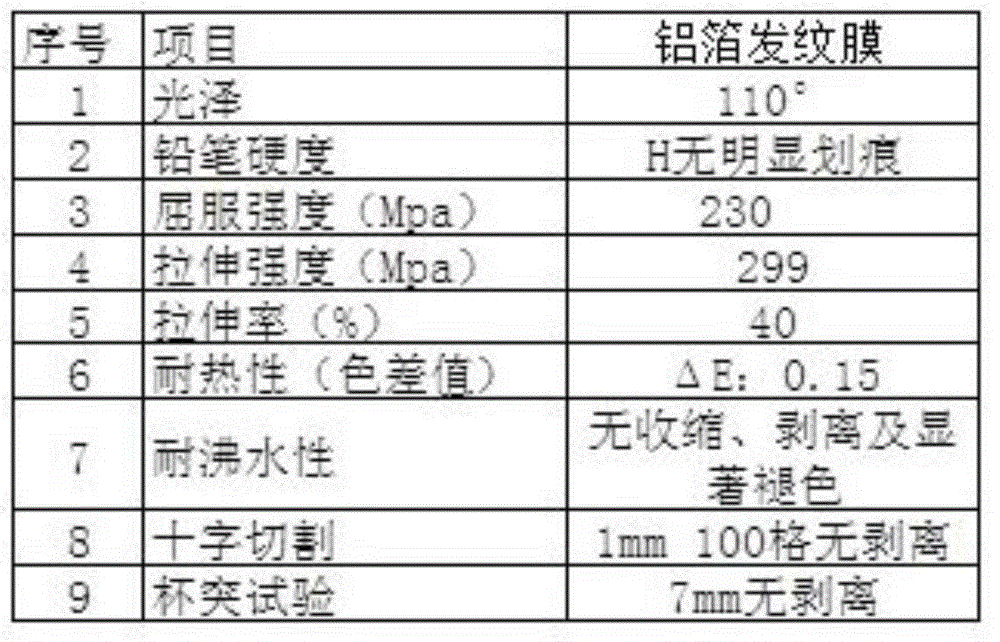

Preparation forming technology of aluminum foil hairline crack film

InactiveCN102717644ASpecial three-dimensional flash effectMaintain metallic lusterEmbossing decorationsMicrometerAluminum foil

The invention discloses a preparation forming technology of an aluminum foil hairline crack film, which comprises the steps as follows: an aluminum foil with thickness ranging from 7 to 20 micrometers and width ranging from 800 to 1400mm passes through acting force points of a hairline crack die roller and a rubber roller, and the hairline crack die roller can squeeze the front side of the aluminum foil; in addition, concave-convex textures are formed on the hairline crack die roller, so that the textures on the hairline crack die roller are pressed on the aluminum foil to form the aluminum foil hairline crack film. The preparation forming technology utilizes the characteristic of no rebound after the forming of the aluminum foil and the principle of specific metallic luster of the aluminum foil to produce the aluminum foil hairline crack film, and the produced aluminum foil hairline crack film achieves special three-dimensional iridescent effect and can be used as a high simulation stainless steel film in the field of household appliance manufacturing.

Owner:SUZHOU XINYING NEW MATERIAL TECH

Surface treatment method for sewage inspection well cover

ActiveCN107502126AMaintain metallic lusterHeating fastAntifouling/underwater paintsPretreated surfacesAdhesion forceSewage

The invention mainly relates to the technical field of machining and discloses a surface treatment method for a sewage inspection well cover. The surface treatment method for the sewage inspection well cover comprises the steps of polishing, cleaning, quenching and covering with a film. The method is simple and convenient to operate. The inspection well cover is polished after being frozen, so that polishing difficulty and high temperature generated by polishing are lowered, the metal luster of the inspection well cover is maintained and the polishing efficiency is improved; the inspection well cover is heated rapidly after cleaning and then put into a urea solution to perform quenching cooling and a protective film is formed on the surface, so that the corrosion of the inspection well cover is avoided, and the combining capacity of the inspection well cover and the film is improved; the inspection well cover is heated to the original temperature after quenching, so the combining capability of the coating film is improved; the inspection well cover is spray-coated with coating, the coating raw material is rich, safe, non-toxic and strong in adhesion force, so the wear resistance of the film is improved, the antibacterial property, the stability and the wear resistance of the film are enhanced, and the service life of the inspection well cover is prolonged by 23 to 25 percent.

Owner:FUNAN COUNTY FENJIN MACHINERY MFG

Silver plating anti-color changing protecting agent composition

InactiveCN101503798BPrevent discolorationDoes not affect conductivityMetallic material coating processesBenzoxazoleSilver plate

The invention relates to a silver plating anti-tarnish protectant compound. The protectant compound comprises the following components in percentage by weight: 13 to 15 percent of aliphatic alcohol polyoxyethylene ether, 8 to 10 percent of 1-phenyl-pentasulfhydyl tetrazole, 4 to 5 percent of 2-sulfhydryl benzoxazole, 3 to 5 percent of t-dodecyl mercaptan, 3 to 5 percent of 2-sulfhydryl benzimidazole, 8 to 10 percent of anhydrous ethanol, 8 to 10 percent of ethylene glycol, and the balance of deionized water. The silver plating anti-tarnish protectant compound forms a protective complex film on a silver surface, has a higher corrosion inhibition rate, and obviously improves the sulfidation resistance and abrasion resistance of the silver surface. The silver plating anti-tarnish protectant compound is mainly used for the tarnish prevention of silvered electronic parts and components, and is also applied to the sulfidation and tarnish prevention of silver or silvered jewellery, jewelry, ornaments, artwork, tableware, and the like. The silver plating anti-tarnish protectant compound can effectively protect silvered articles against sulfidation and tarnish in a certain period, keep theoriginal metal luster and has no influence on the conductivity and weldability of the parts.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Bronze ware cleaning brightener

The invention discloses a bronze ware cleaning brightener and belongs to the technical field of daily cleaning product processing. The bronze ware cleaning brightener is prepared from the raw materials of oxalic acid, reduced glutathione, ethanol, parolin oil, silicone oil, diatomite, defoamer L62, and lauroylmonoethanolamide. The bronze ware cleaning brightener not only can eliminate the dirt, but also can brighten the bronze ware like before. The reduced glutathione added in the bronze ware cleaning brightener is able to remove the toxic harmful substances generated by oxidation of the old bronze ware, relieve the toxicity of the oxalic acid and greatly reduce the side effect after being detoxified and restored. The product is simple, convenient and practical and is able to remove the dirt, the rust and the spot and does not corrode the bronze; the powdered diatomite is used for scrubbing the bronze ware so that the surface of the bronze ware is smooth, delicate and bright.

Owner:FOSHAN SHUNDE BAOTONG METAL TECH

Handling method for improving corrosion resistance of stainless steel mold

InactiveCN107868928AImprove corrosion resistanceHigh strengthSolid state diffusion coatingFurnace typesDiammonium phosphateSS - Stainless steel

The invention mainly relates to the technical field of mold machining, and discloses a handling method for improving corrosion resistance of a stainless steel mold. The method includes cleaning, polishing, quenching, nitrogen leaching and packaging. The method is simple and operation is convenient. The cast stainless steel mold is subjected to ultrasonic cleaning, impurities are removed, the stainless steel mold can further be homogenized, and the corrosion resistance of the mold is improved. Low-temperature freezing is conducted at first and then low-temperature polishing is conducted after cleaning. The metallic luster of the stainless steel mold can be maintained, polishing difficulties are lowered, the roughness is lowered to 0.09 microns, and machining efficiency is improved. The temperature is raised quickly after polishing, and then the stainless steel mold is put into a diammonium phosphate solution for quenching. A protective film is formed on the mold surface, and the corrosion resistance of the mold is improved.

Owner:蚌埠中梁机械科技有限公司

PET-PET (Polyether) imitation stainless steel composite membrane

InactiveCN102371728AAchieve the effect of high imitation brushed stainless steelHigh hardnessSynthetic resin layered productsMetal layered productsTextile printerLaundry washing machine

Owner:JIANGSU OBON PLASTIC

Cleaning antirust agent for diesel engine casting body and preparation method thereof

The invention discloses a cleaning antirust agent for a diesel engine casting body and a preparation method thereof. The agent comprises the following raw materials, by mass, 30-40% of an agent A, 40-50% of an agent B, 3-7% of sodium tripolyphosphate, 3-6% of a special surfactant for bubbleless normal temperature spray degreasing, 8-12% of an organosilicon antifoaming agent and 0.5-1% of isothiazolinone, wherein the agent A comprises, by mass, 2-6% of phytic acid, 8-10% of a normal temperature steel surface conditioning agent, 1-3% of ammonium bicarbonate, 3-7% of triethanolamine, 3-5% of polyethylene glycol, 0.6-1.2% of the organosilicon antifoaming agent, and the balance water; and the agent B comprises, by mass, 2-4% of sodium carbonate, 10-20% of sodium nitrite, 10-16% of triethanolamine, and the balance water.

Owner:DALIAN SANDAAOKE CHEM

A surface treatment method for a washing machine motor casing

ActiveCN107528435BExtend your lifeEasy to useNatural resin coatingsRosin coatingsPulp and paper industryQuenching

Owner:界首永恩机电科技有限公司

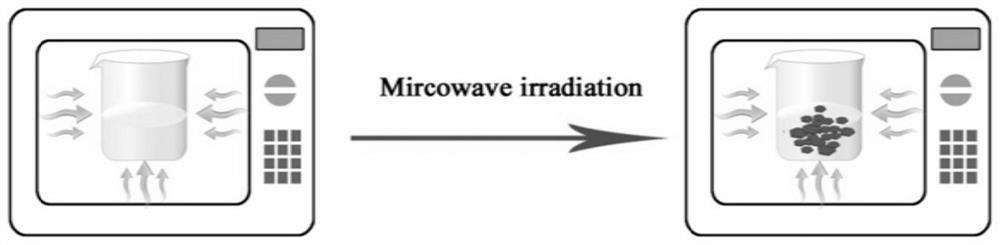

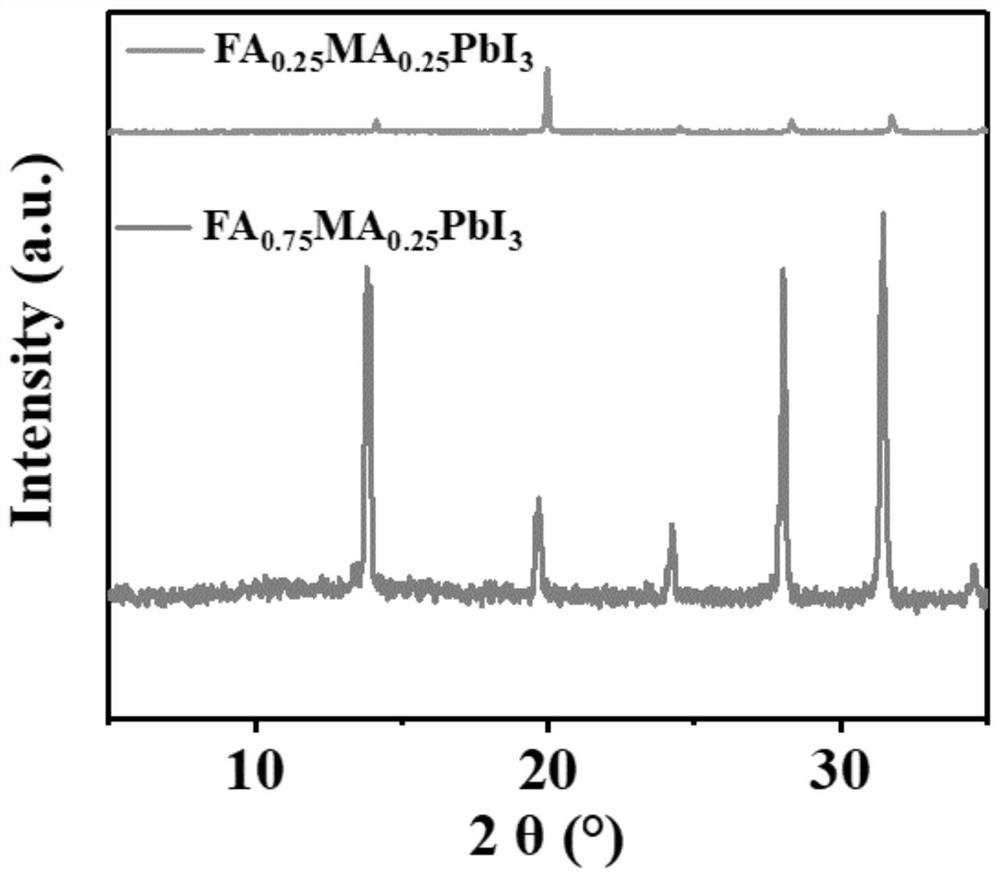

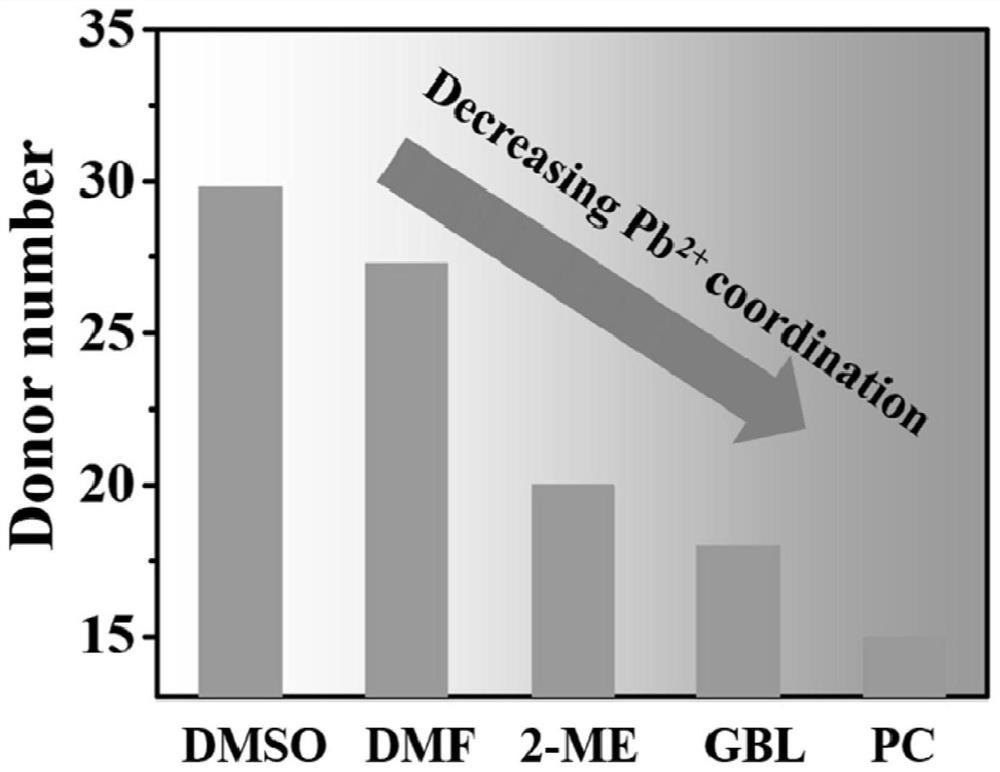

A method for efficiently preparing perovskite microcrystals by microwave method

ActiveCN113604867BThe synthesis method is simpleReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsMicrowave methodPropylene carbonate

The invention relates to the field of perovskite materials, and discloses a method for efficiently preparing perovskite microcrystals by a microwave method, and the general chemical formula of the perovskite microcrystals is MA X FA 1-X PB 3 , its preparation method comprises: (1) according to the molar mass ratio between each element of target product, weigh organic component and inorganic component, and organic component and inorganic component are dissolved in propylene carbonate, promptly obtain perovskite (2) Heating the perovskite precursor solution by microwave method, the heating temperature is controlled at 70-130°C, and the heating time is 10-30min; (3) After the reaction is complete, black microcrystals are precipitated, and after filtration and washing Perovskite crystallites were obtained. The present invention adopts the microwave method and a suitable perovskite precursor solvent to heat the inside and outside of the perovskite precursor solution at the same time quickly, uniformly and with low energy consumption, and raise the temperature at the same time, and crystallize evenly, so as to ensure the quality of the crystal and increase the yield .

Owner:SUN YAT SEN UNIV

A surface treatment method for sewage manhole cover

ActiveCN107502126BMaintain metallic lusterHeating fastAntifouling/underwater paintsPretreated surfacesAdhesion forceSewage

The invention mainly relates to the technical field of machining and discloses a surface treatment method for a sewage inspection well cover. The surface treatment method for the sewage inspection well cover comprises the steps of polishing, cleaning, quenching and covering with a film. The method is simple and convenient to operate. The inspection well cover is polished after being frozen, so that polishing difficulty and high temperature generated by polishing are lowered, the metal luster of the inspection well cover is maintained and the polishing efficiency is improved; the inspection well cover is heated rapidly after cleaning and then put into a urea solution to perform quenching cooling and a protective film is formed on the surface, so that the corrosion of the inspection well cover is avoided, and the combining capacity of the inspection well cover and the film is improved; the inspection well cover is heated to the original temperature after quenching, so the combining capability of the coating film is improved; the inspection well cover is spray-coated with coating, the coating raw material is rich, safe, non-toxic and strong in adhesion force, so the wear resistance of the film is improved, the antibacterial property, the stability and the wear resistance of the film are enhanced, and the service life of the inspection well cover is prolonged by 23 to 25 percent.

Owner:FUNAN COUNTY FENJIN MACHINERY MFG

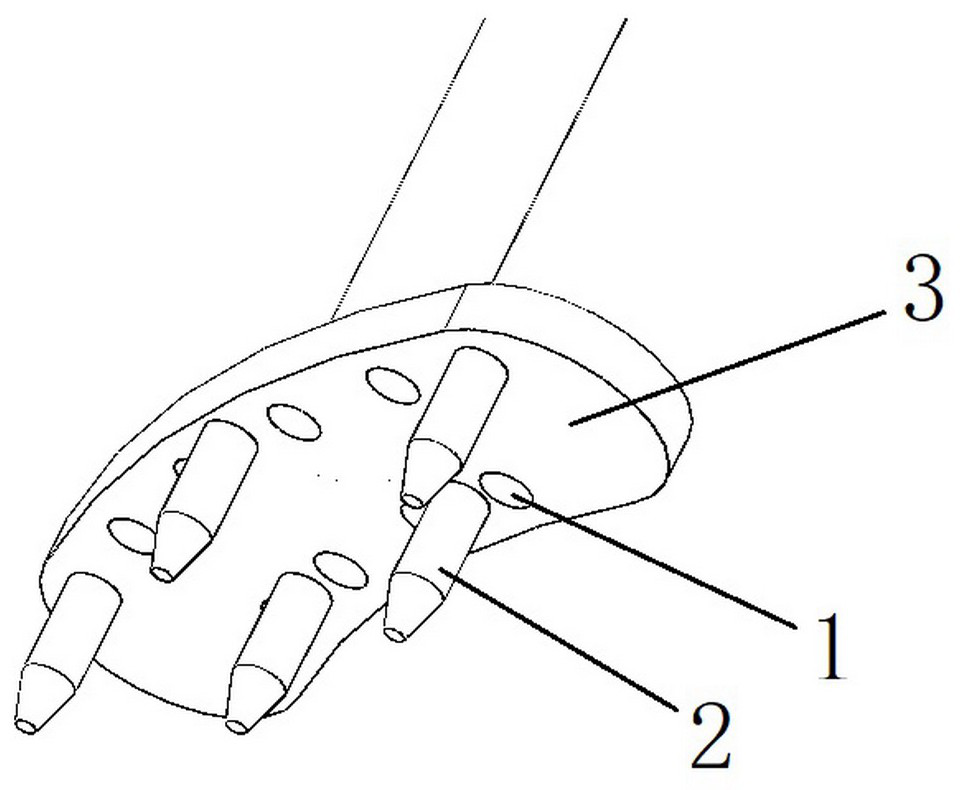

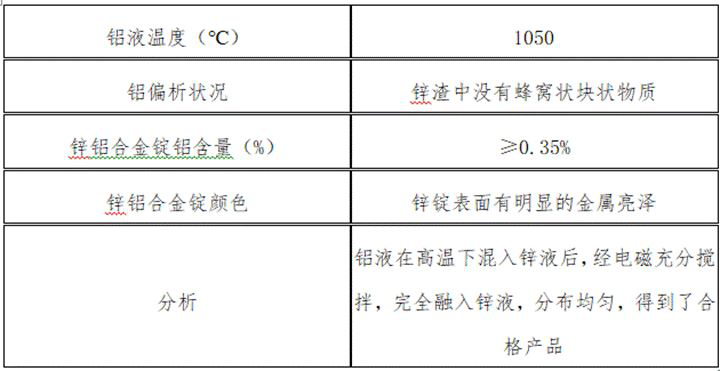

Production method of zinc-aluminum alloy suitable for hot-dip galvanized steel pipe

PendingCN114262856AImprove liquidityMaintain metallic lusterHot-dipping/immersion processesZincSteel tube

The invention discloses a production method of a zinc-aluminum alloy suitable for a hot-dip galvanized steel pipe. The production method comprises the following operation steps: the zinc-aluminum alloy comprises the following chemical components in percentage by mass: 0.3-0.4% of Al and less than Pblt of impurities; 0.005, Filt, 0.005, Filt; 0.005, Cd < lt >; 0.002, Sn < lt >; 0.002, Cut, 0.002, Cut; 0.002, the balance being Zn; intermediate frequency furnace smelting equipment is used for realizing zinc melting production; a modified vibrating and beating flat hammer is adopted, 4-5 round holes with the diameter phi being 10 mm are drilled in a plate head of the flat hammer, four knotting claws are welded to the working face of the vibrating and beating flat hammer, the temperature curve of an oven is determined to be 0-220 DEG C, and the heating time is 0.5 h; then keeping the temperature at 220 DEG C for 2 hours; the temperature is raised for 0.5 hour at 220-440 DEG C, and then the temperature is kept at 440 DEG C for 2 hours; the temperature is increased for 0.5 hour at 440-660 DEG C, and the temperature is kept at 660 DEG C for 2 hours; the temperature is increased for 0.5 hour at the temperature of 660-880 DEG C, and then the temperature is kept at 880 DEG C for 2 hours; and the temperature of the molten aluminum is further increased to 1050 DEG C, so that the problem of aluminum segregation can be solved.

Owner:新疆八钢佳域工业材料有限公司

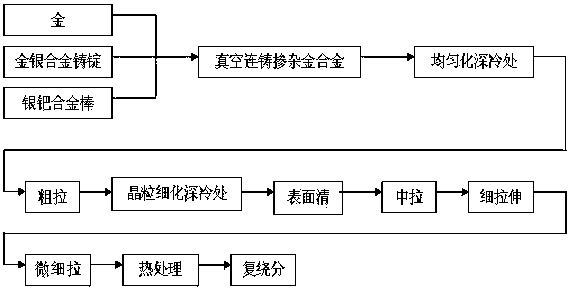

A kind of doped gold alloy bonding wire and cryogenic treatment preparation method thereof

The invention relates to an alloy-doped gold bonding wire and a cryogenic-treatment preparation method thereof. The alloy-doped gold bonding wire formed by using high-purity gold as a main ingredient and being doped with high-purity silver and high-purity palladium, which is provided by the invention, is prepared from the following ingredients in percentages by weight: 60 to 80 percent of gold, 0.5 to 3.5 percent of palladium and the balance of silver. A bonding wire product has favorable oxidation resistance; an appearance is basically golden; the performance of the product is approximate to that of a pure-gold bonding wire; and the alloy-doped gold bonding wire is suitable for IC (Integrated Circuit) and COB (Chip On Board) encapsulation and high-end LED (Light-Emitting Diode) encapsulation. During the bonding of encapsulation, any gas shield is not needed; and in comparison with a gold bonding wire, the cost of the product is only approximately 3 / 5 to 4 / 5 of that of the gold bonding wire. In the preparation process of the product, the cryogenic treatment is carried out on a bonding wire twice; the arrangement of internal crystal textures of a material is improved; the physical properties of the material are enhanced; and the bonding properties of the alloy-doped gold bonding wire is improved. When the product is used for downstream encapsulation and wire bonding modes are BSOB (Bond Stitch On Ball) and BBOS (Bond Ball On Stitch), a wire stock and a ball are guaranteed to be eutectic.

Owner:河北乐通金属材料有限公司

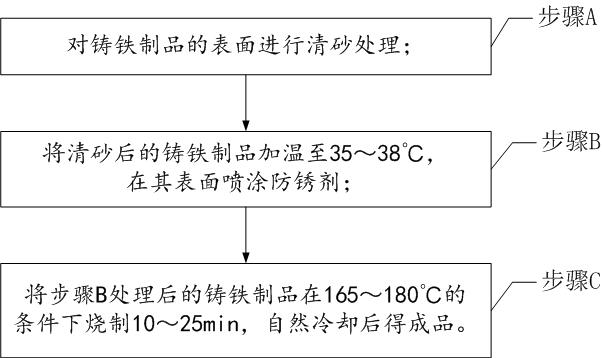

Surface treatment process of a cast iron product

ActiveCN107597530BMaintain metallic lusterMeet the requirements of food hygiene standardsPretreated surfacesSpecial surfacesFood hygieneMaterials science

The invention discloses a surface treatment process of a cast iron product, which comprises spraying a layer of transparent antirust agent on the surface of the cast iron product after performing sand cleaning treatment on the surface, and firing at 165-180°C for 10-25 minutes , maintain the original metallic luster of cast iron, and play a role in preventing cast iron from rusting, the sprayed antirust agent is non-toxic and harmless, meets the requirements of food hygiene standards, and the process is simple to operate, and the obtained products can be used at high temperatures No cracking, no smell.

Owner:佛山市高明福煌五金制品实业有限公司

Polishing solution for petroleum instrument

The invention discloses a polishing solution for a petroleum instrument. The polishing solution is prepared from, by weight, 15-20% of sodium oleate, 2-5% of citric acid, 5-7% of sodium triphosphate, 3-4% of sodium dodecylbenzene sulfonate, 1-2% of OP-10 activating agent, 8-10% of quartz sand and the balance water. The polishing solution has the advantages that oil stain and rust spots on the surface of hardware made from steel, iron, copper, aluminum and the like can be effectively removed, metallic luster of the hardware can be kept, the hardware is bright as new, and the hardware can be prevented from being re-rusted for one year or longer after being cleaned.

Owner:NANTONG HUAXING OIL EQUIP

High-fluidity anti-tarnish casting silver-base alloy and preparation method thereof

The invention relates to a high-fluidity anti-tarnish casting silver-base alloy and a preparation method thereof. The high-fluidity anti-tarnish casting silver-base alloy comprises, by weight, 79-97%of silver, 1-7% of zirconium, 1-7% of silicon and 1-7% of stannum. The melting temperature of the silver-base alloy is 790-795 DEG C. The viscosity of the molten silver-base alloy is 0.5-0.7 Pa.s. Thefluidity length of a spiral linear test specimen is 93.7-95.9 cm. According to the high-fluidity anti-tarnish casting silver-base alloy and the preparation method thereof, the metallic elements zirconium, silicon and stannum are added to the silver, and a mixture is subjected to smelting to obtain a base material; the base material is subjected to quenching and tempering treatment, the complex physical and chemical reactions occur between the alloy elements and between the alloy elements and oxygen in an atmosphere to generate an alloy phase with the structural integrity and stable chemical property. Thus, the anti-tarnish performance of the silver-base alloy is substantially improved after the silver-base alloy is subjected to quenching and tempering treatment.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

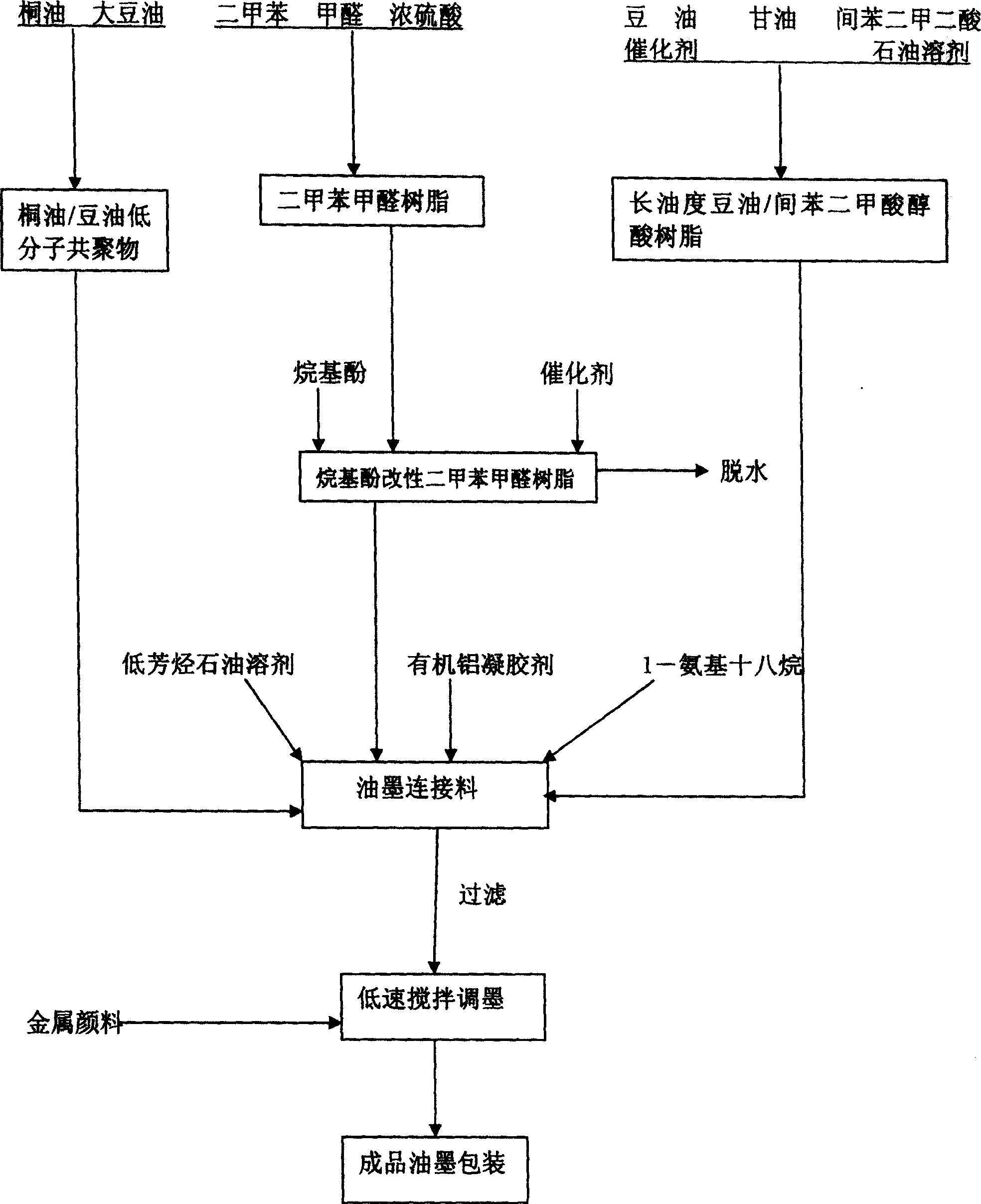

Environmental-protection soybean oil offset metal ink

The invention relates to environmental protection type soybean oil offset printing metal printing ink. It uses china wood oil / soybean oil low molecular copolymer, alkyl phenol modification xylene formaldehyde resin, and long oil length bean oil / isophthalic acid alkyd resin as main film forming matter which forms printing ink connecting material with soybean oil, low arene high boiling point petroleum solvent, organic alumina gel, and metallic pigment preservative agent 1-amino group octadecane. The printing ink connecting material cooperates with the metallic pigment to make blue-gold, red-gold, blue-red-gold, and aluminium ink according to material constituent weight percentage.

Owner:鹤壁百运佳大豆油墨科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com