Production method of zinc-aluminum alloy suitable for hot-dip galvanized steel pipe

A zinc-aluminum alloy and production method technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problem of uneven coating thickness on the surface of galvanized steel pipe, dark color of the coating on the surface of galvanized steel pipe, composition Segregation etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

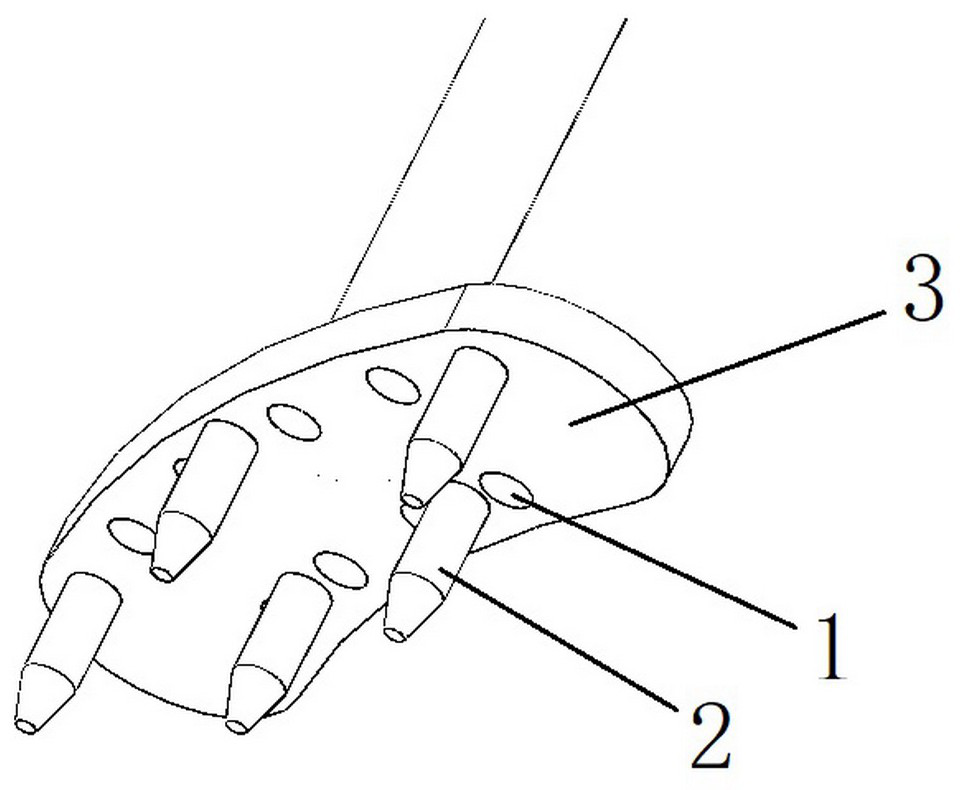

Image

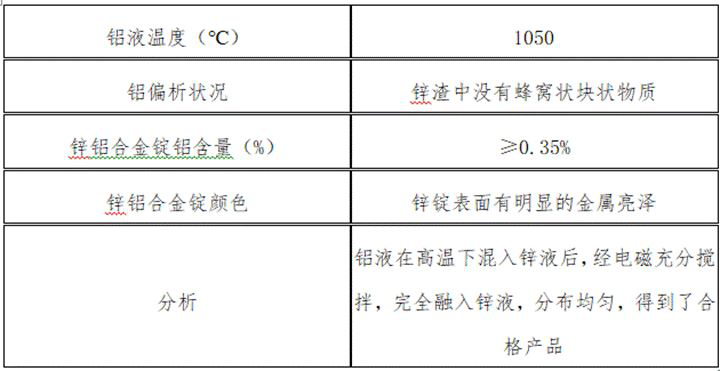

Examples

Embodiment Construction

[0009] A method for producing zinc-aluminum alloys suitable for hot-dip galvanized steel pipes, the operation steps are as follows:

[0010] 1. The chemical composition of zinc-aluminum alloy is: Al% 0.3-0.4, % of impurities is less than: Pb<0.005, Fe<0.005, Cd<0.002, Sn<0.002, Cu<0.002, balance% Zn; zinc melting process: raw material preparation, intermediate frequency furnace melting zinc and intermediate frequency furnace melting aluminum, refining and slag removal, casting out of the furnace, demoulding, grinding and packaging;

[0011] 2. Smelting equipment, use the intermediate frequency furnace melting equipment to realize the production of zinc melting. The intermediate frequency furnace is a power supply device that converts the power frequency 50Hz alternating current into intermediate frequency (300Hz to 1000Hz), and converts the three-phase power frequency alternating current into direct current after rectification. , and then change the direct current into an adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com