A method for efficiently preparing perovskite microcrystals by microwave method

A technology of perovskite and microwave method, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of large crystal quality difference, crystal inhomogeneity, temperature gradient difference, etc., and achieve good crystallinity and phase High purity, short time-consuming results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

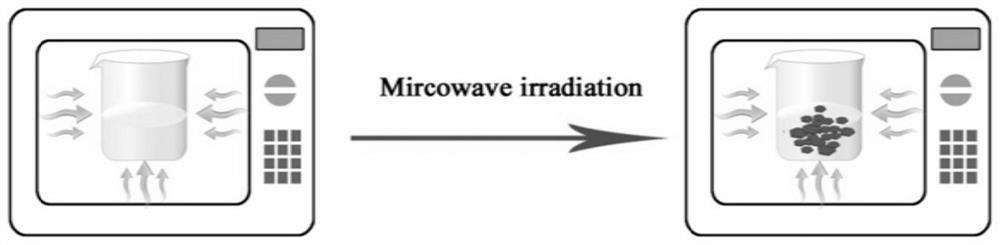

[0048] Efficient preparation of perovskite crystallites (MA) by a microwave method X FA 1-X PB 3 ) method, such as figure 1 shown, including the following steps:

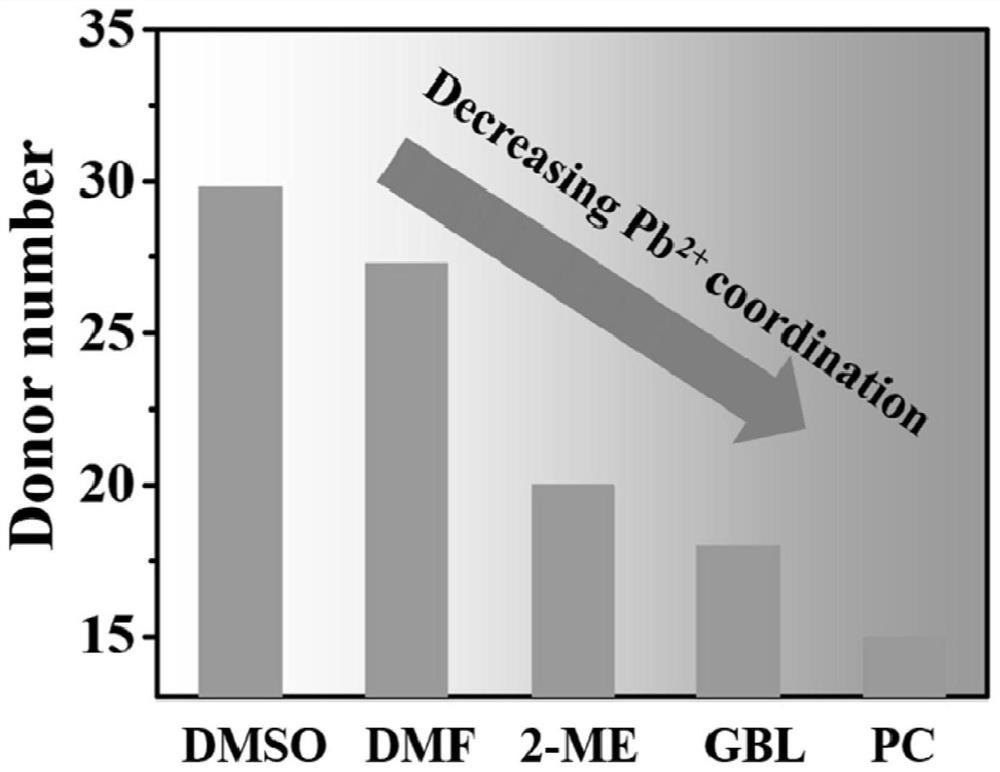

[0049] (1) Weigh MAI (methylamine iodide, CH 3 NH 3 I), FAI (formamidine iodide, HC (NH 2 ) 2 I) and PbI 2 (FAI+MAI and PbI 2 The molar ratio is 1:1), wherein the molar ratio between MAI and FAI is shown in Table 1, MAI, FAI and PbI 2 Dissolve in propylene carbonate, sonicate for the time shown in Table 1, and constantly stir for the time shown in Table 1 to obtain a clear solution, which is MA X FA 1-X PB 3 Perovskite Precursor Solution, MA X FA 1- X PB 3 The concentration of the perovskite precursor solution is shown in Table 1;

[0050] (2) put MA X FA 1-X PB 3 Put the perovskite precursor solution into a small beaker and transfer it to a microwave reactor for heating. Set the power of the microwave reactor to 250W, control the heating temperature as shown in Table 2, and the heating time as sh...

Embodiment 4

[0056] Efficient preparation of perovskite microcrystals (MAPbI) by a microwave method 3 ) method, such as figure 1 shown, including the following steps:

[0057] (1) Weigh MAI (methylamine iodide, CH 3 NH 3 I), and PbI 2 (FAI+MAI and PbI 2 The molar ratio is 1:1), MAI and PbI 2 Dissolve in propylene carbonate, sonicate for 10min, and keep stirring for 30min to obtain a clear solution, which is MAPbI 3 Perovskite precursor solution, MAPbI 3 The concentration of the perovskite precursor solution is 0.45mol / L;

[0058] (2) MAPbI 3 Put the perovskite precursor solution into a small beaker and transfer it to a microwave reactor for heating. Set the power of the microwave reactor to 250W, control the heating temperature to 100°C, and the heating time to 10min;

[0059] (3) After the reaction is complete, from MAPbI 3 Black microcrystals are precipitated in the perovskite precursor solution, and the black microcrystals are filtered and washed to obtain crystals with metall...

Embodiment 5

[0061] Efficient preparation of perovskite microcrystals (MAPbI) by a microwave method 3 ) method, each step and the reagents involved in each step, parameters, etc. are the same as in Example 4, the difference is: the temperature of microwave heating in step (2) is changed to 100 ° C, and the time of microwave heating is changed to 20min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com