A kind of doped gold alloy bonding wire and cryogenic treatment preparation method thereof

A technology of alloy bonding and cryogenic treatment, which is applied in the field of doped gold alloy bonding wire and its cryogenic treatment preparation, which can solve the problems of wire oxidation, insufficient push-pull force, and solder joint slippage, and achieve smooth surface and drawing process Effect of smoothness and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

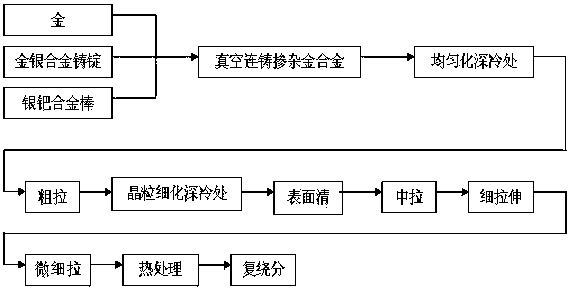

Method used

Image

Examples

Embodiment 1

[0053] Step 1: Select gold ingots with a purity of 99.99%, silver ingots with a purity of 99.99%, and palladium flakes with a purity of 99.99%, wash them with 15.0% sodium hydroxide, rinse them with deionized water, and dry them in an oven for later use;

[0054] Step 2: Prepare gold-silver alloy ingots: put 80% gold ingots and 20% silver ingots into a high-purity graphite crucible according to the weight percentage, and place them in a vacuum alloy furnace, vacuumize for intermediate frequency induction heating, and heat to 1200°C; after the material is completely melted, fill it with high-purity argon and keep it warm for 60 minutes, then pour the liquid gold-silver alloy into a high-purity graphite tank to obtain a gold-silver alloy ingot with a width of 3 cm, a length of 20 cm, and a thickness of 1.5 cm;

[0055] Step 3: Preparation of silver-palladium alloy rods: put 72% silver and 28% palladium into a high-purity graphite crucible according to the weight percentage, and p...

Embodiment 2

[0068] Step 1: Select gold ingots with a purity of 99.99%, silver ingots with a purity of 99.99%, and palladium flakes with a purity of 99.99%, wash them with 20.0% sodium hydroxide, rinse them with deionized water, and dry them in an oven for later use;

[0069] Step 2: Prepare gold-silver alloy ingots: put 70% gold ingots and 30% silver ingots into a high-purity graphite crucible according to the weight percentage, and place them in a vacuum alloy furnace, vacuumize for intermediate frequency induction heating, and heat to 1100°C; after the material is completely melted, fill it with high-purity argon and keep it warm for 90 minutes, then pour the liquid gold-silver alloy into a high-purity graphite tank to obtain a gold-silver alloy ingot with a width of 5 cm, a length of 20 cm, and a thickness of 1.5 cm;

[0070] Step 3: Preparation of silver-palladium alloy rods: put 70% silver and 30% palladium into a high-purity graphite crucible according to the weight percentage, and p...

Embodiment 3

[0083] Step 1: Select gold ingots with a purity of 99.99%, silver ingots with a purity of 99.99%, and palladium flakes with a purity of 99.99%, wash them with 25.0% sodium hydroxide, rinse them with deionized water, and dry them in an oven for later use;

[0084]Step 2: Prepare gold-silver alloy ingots: put 60% gold ingots and 40% silver ingots into a high-purity graphite crucible according to the weight percentage, and place them in a vacuum alloy furnace, vacuumize for intermediate frequency induction heating, and heat to 1300°C; after the material is completely melted, fill it with high-purity argon and keep it warm for 30 minutes, then pour the liquid gold-silver alloy into a high-purity graphite tank to obtain a gold-silver alloy ingot with a width of 8 cm, a length of 20 cm, and a thickness of 1.5 cm;

[0085] Step 3: Prepare silver-palladium alloy rods: put 68% silver and 32% palladium into a high-purity graphite crucible according to the weight percentage, and place the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com