Patents

Literature

133 results about "Gold alloys" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The most common gold alloys include yellow gold, which contains copper, silver -- and in some instances cobalt -- and white gold, which contains copper, zinc, nickel and, in some instances, palladium. All types of jewelry, such as rings, bracelets, necklaces and earrings consist of both these alloys.

Electrocatalysts having platinum monolayers on palladium, palladium alloy, and gold alloy nanoparticle cores, and uses thereof

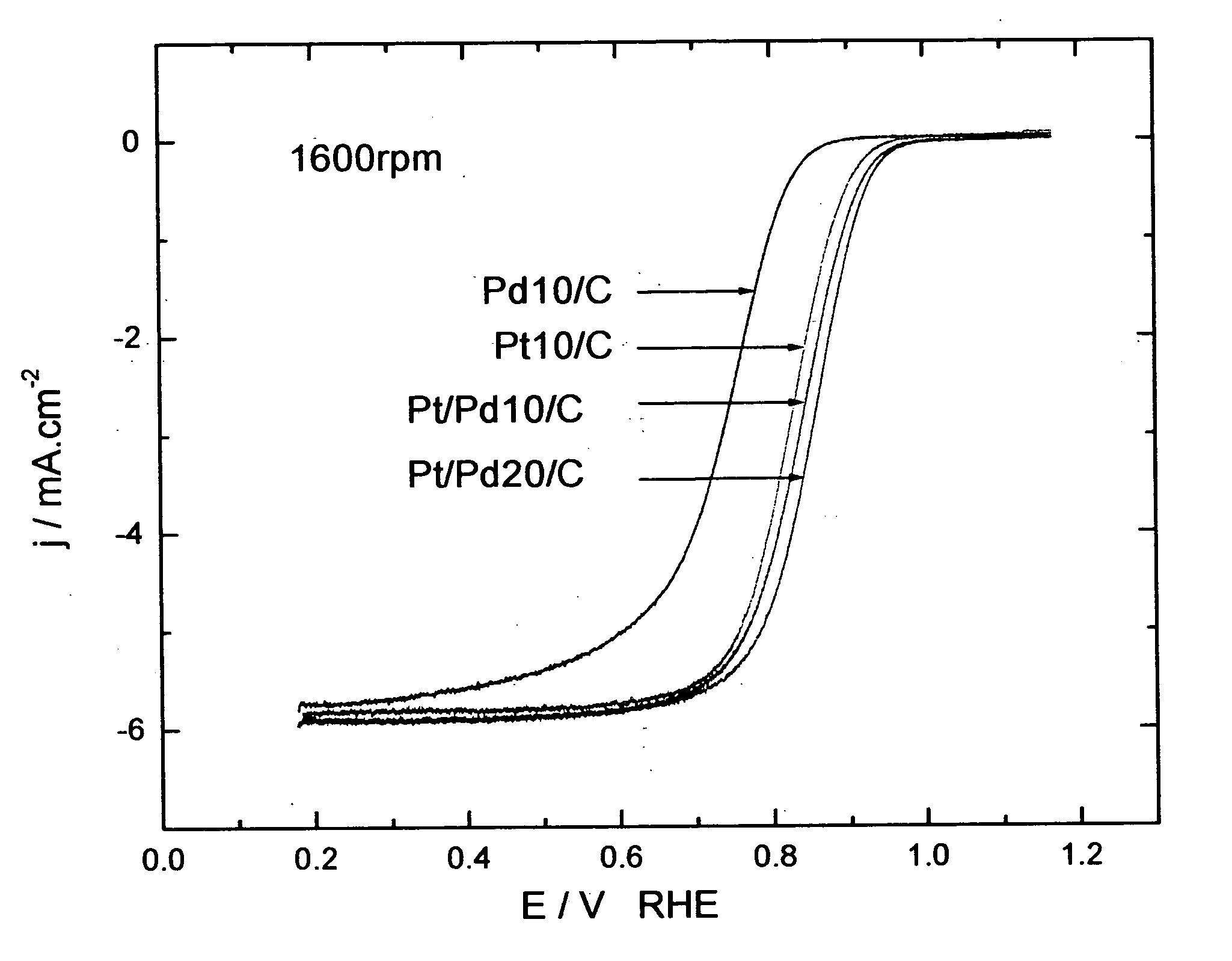

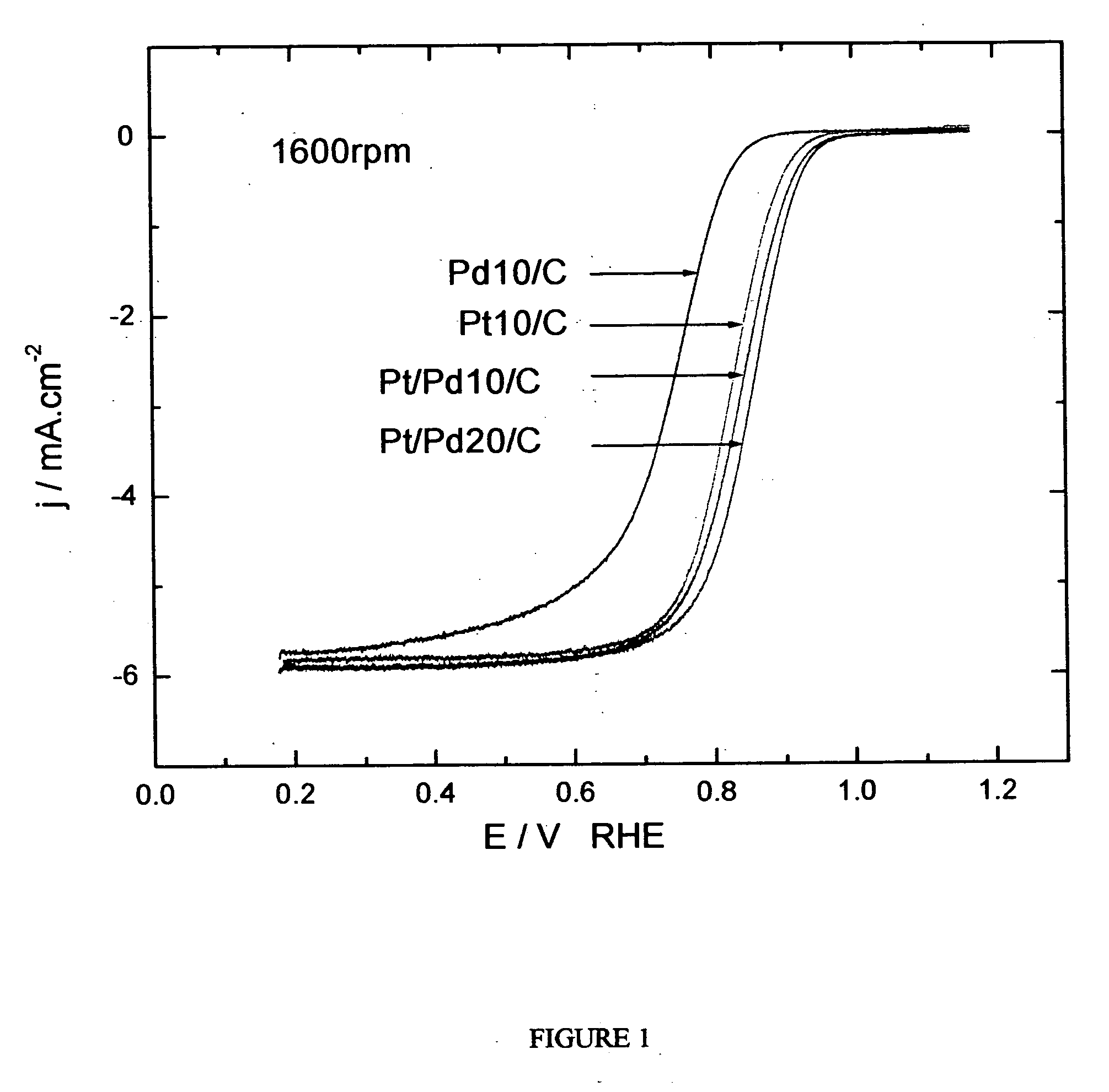

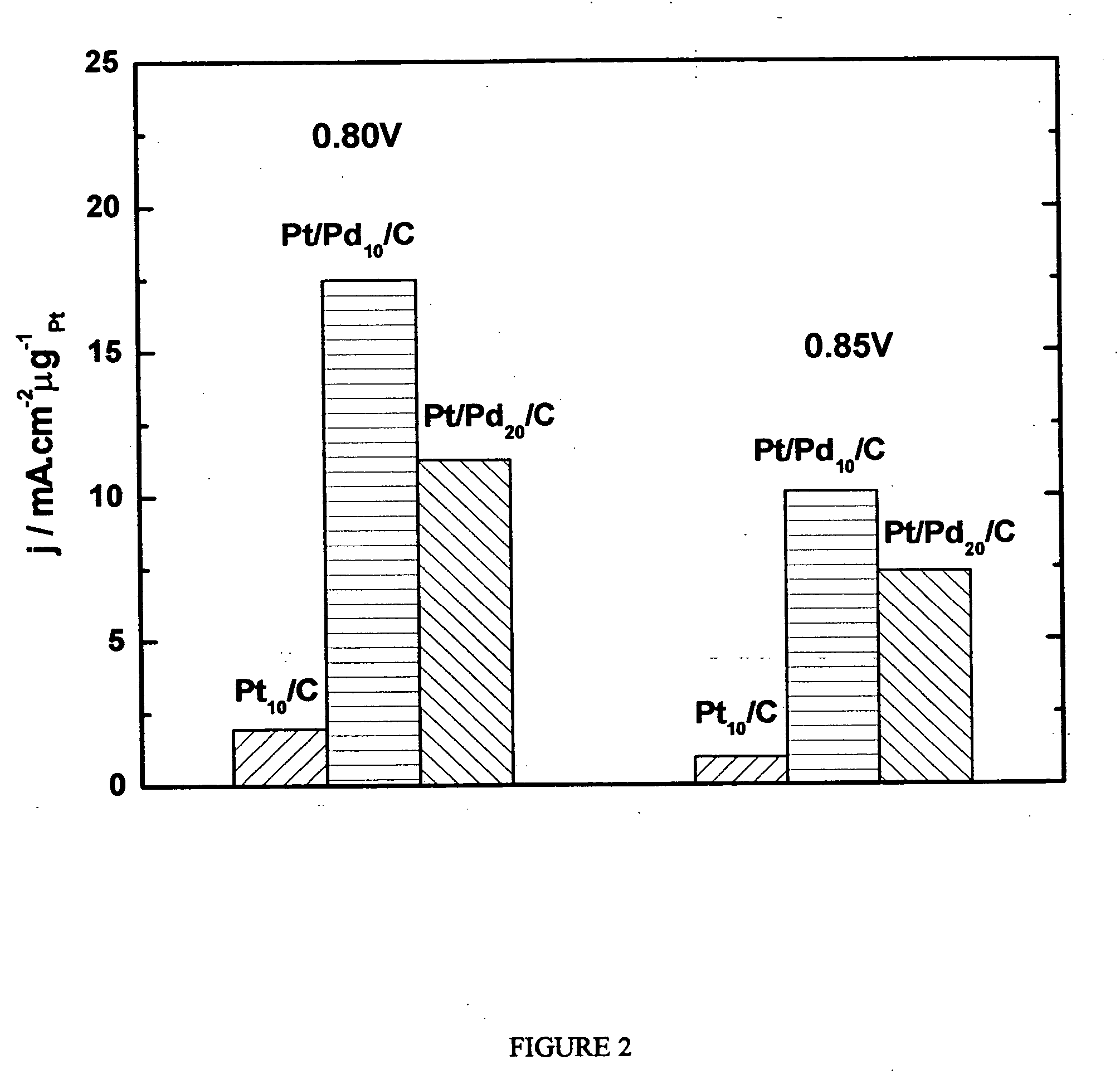

ActiveUS20070031722A1Improved oxygen-reducing catalytic activityLow platinum loadingMetal-working apparatusActive material electrodesRheniumGold alloys

The invention relates to platinum-coated particles useful as fuel cell electrocatalysts. The particles are composed of a noble metal or metal alloy core at least partially encapsulated by an atomically thin surface layer of platinum atoms. The invention particularly relates to such particles having a palladium, palladium alloy, gold alloy, or rhenium alloy core encapsulated by an atomic monolayer of platinum. In other embodiments, the invention relates to fuel cells containing these electrocatalysts and methods for generating electrical energy therefrom.

Owner:BROOKHAVEN SCI ASSOCS

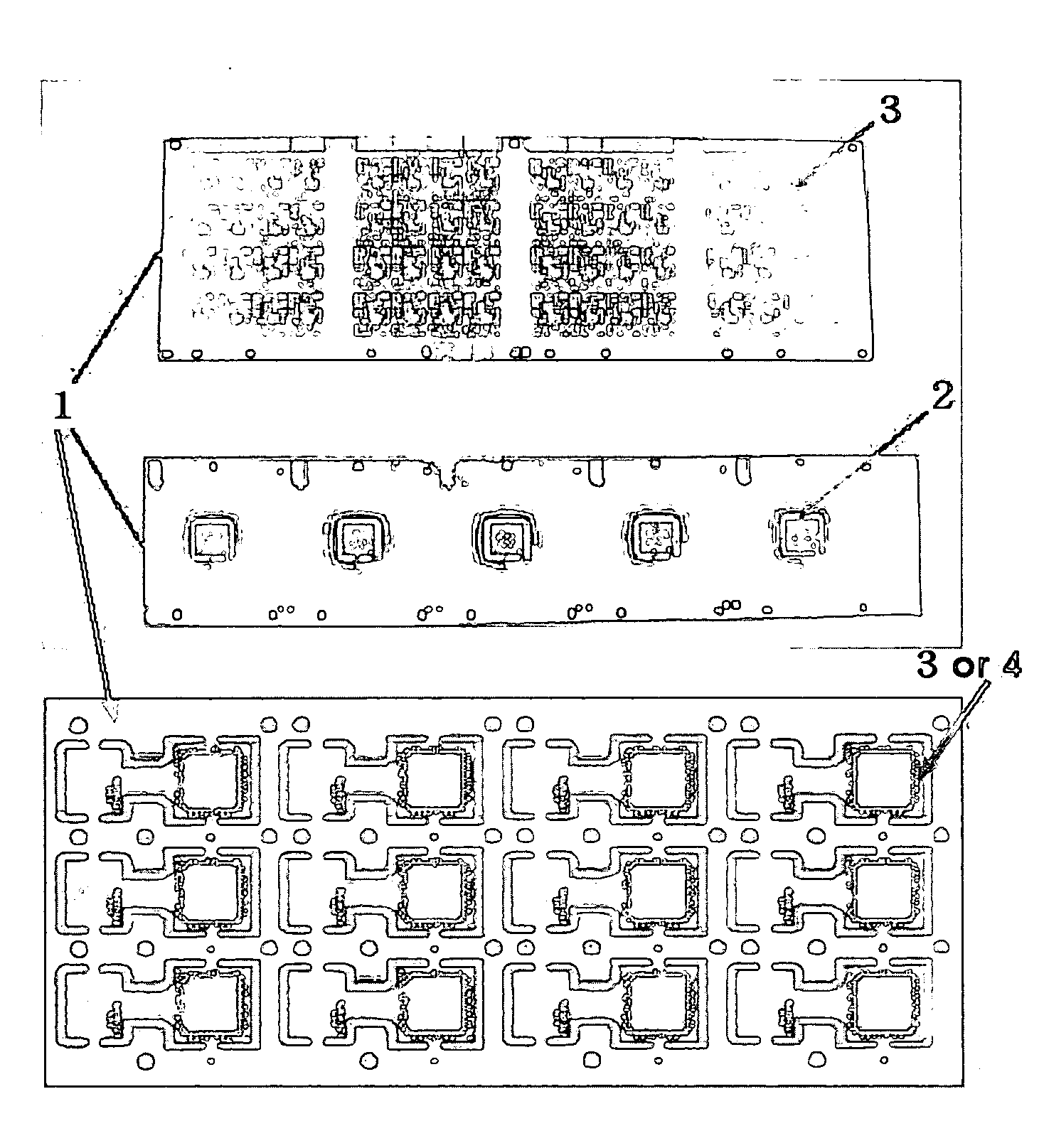

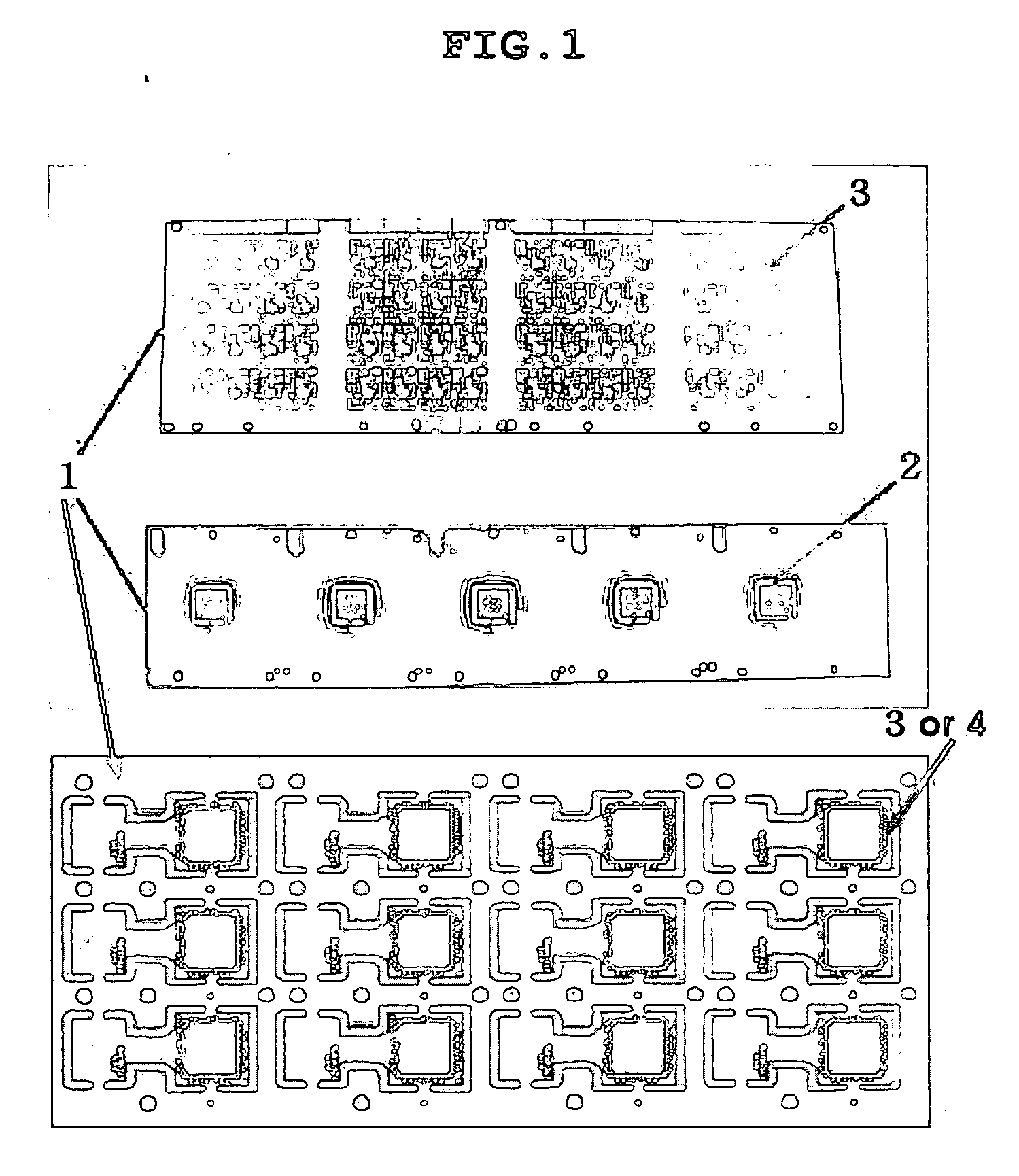

Method for plating printed circuit board and printed circuit board manufactured therefrom

InactiveUS20070104929A1Reduce thicknessDecreasing solderabilitySemiconductor/solid-state device detailsSolid-state devicesElectroless nickelCrazing

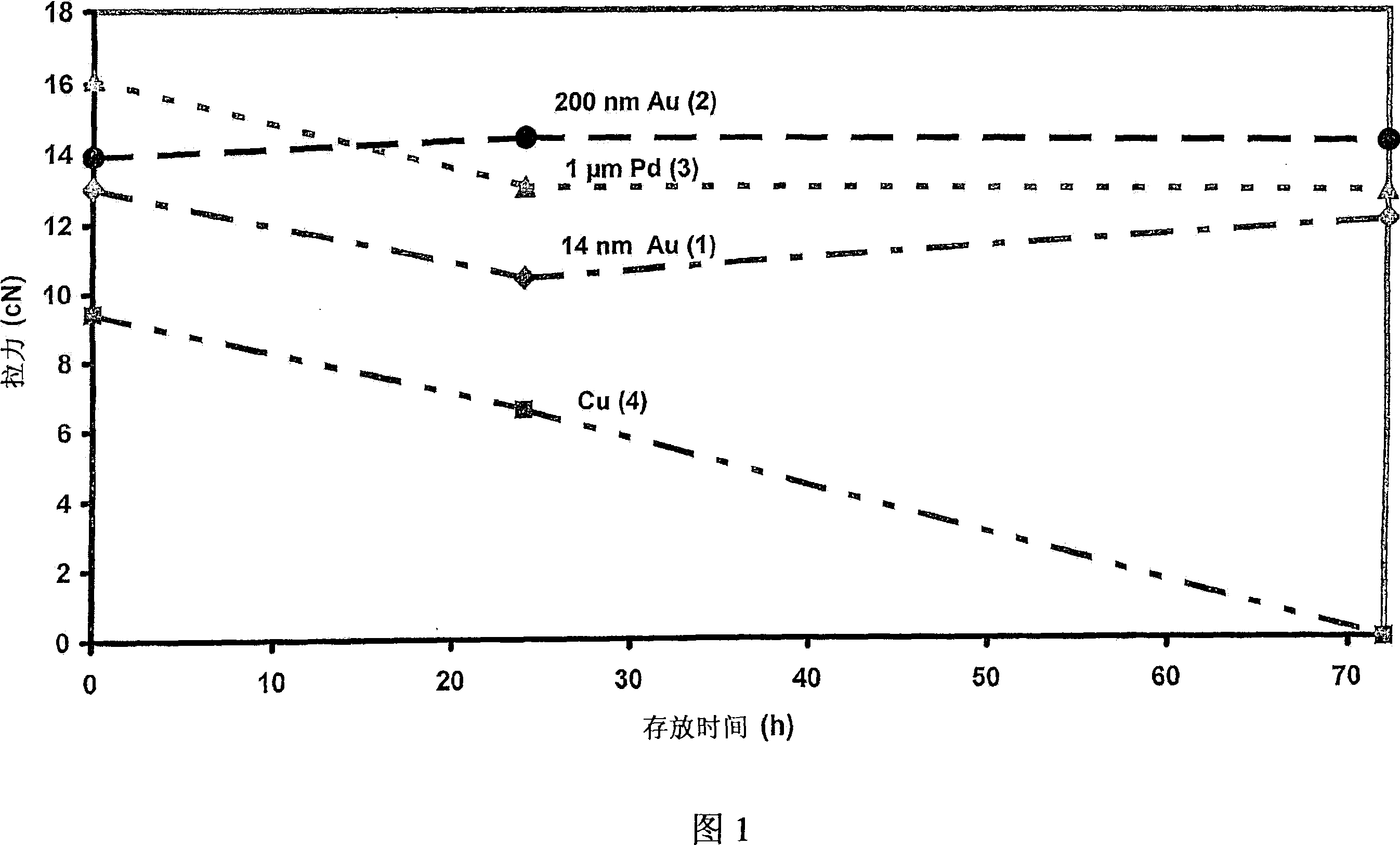

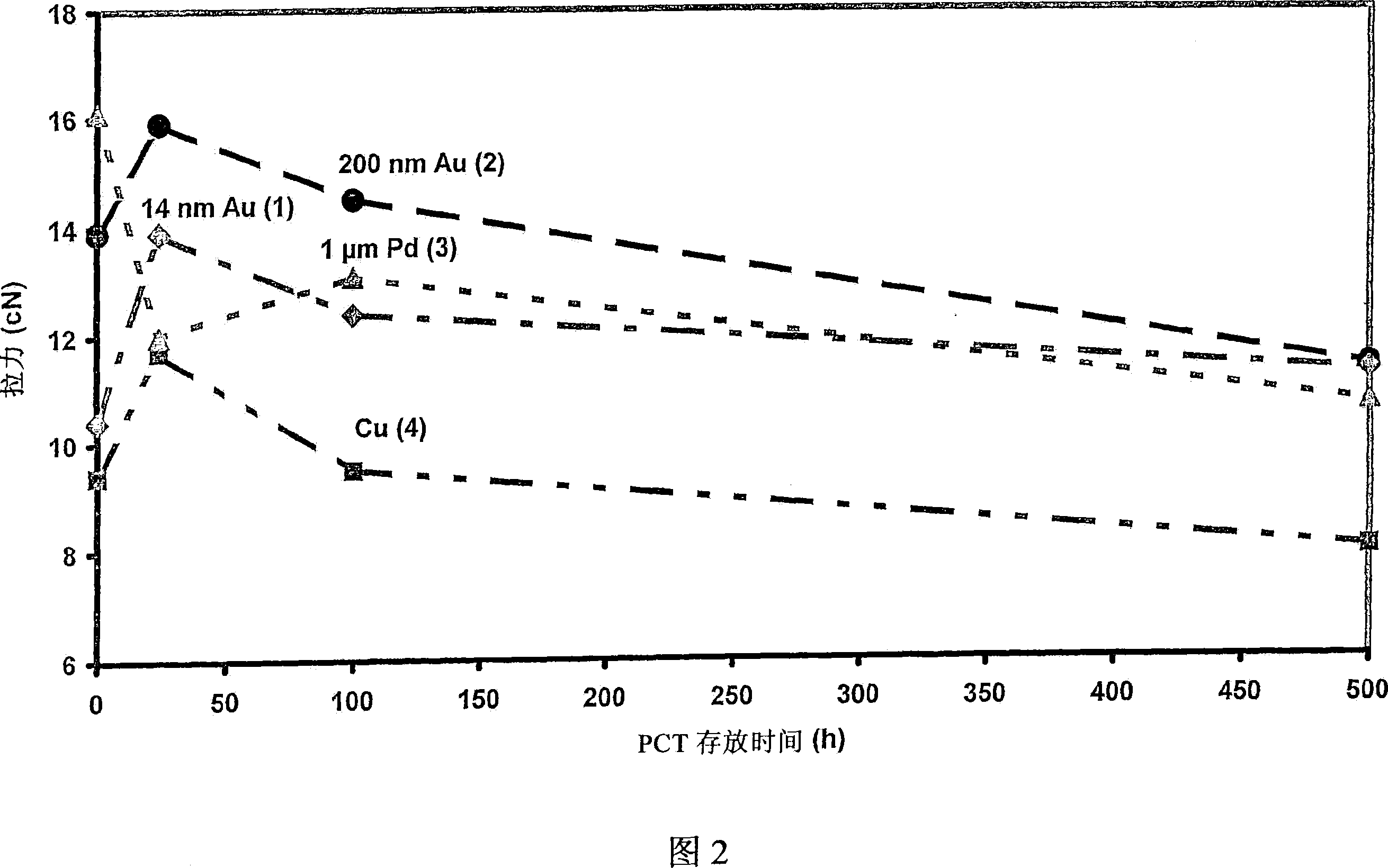

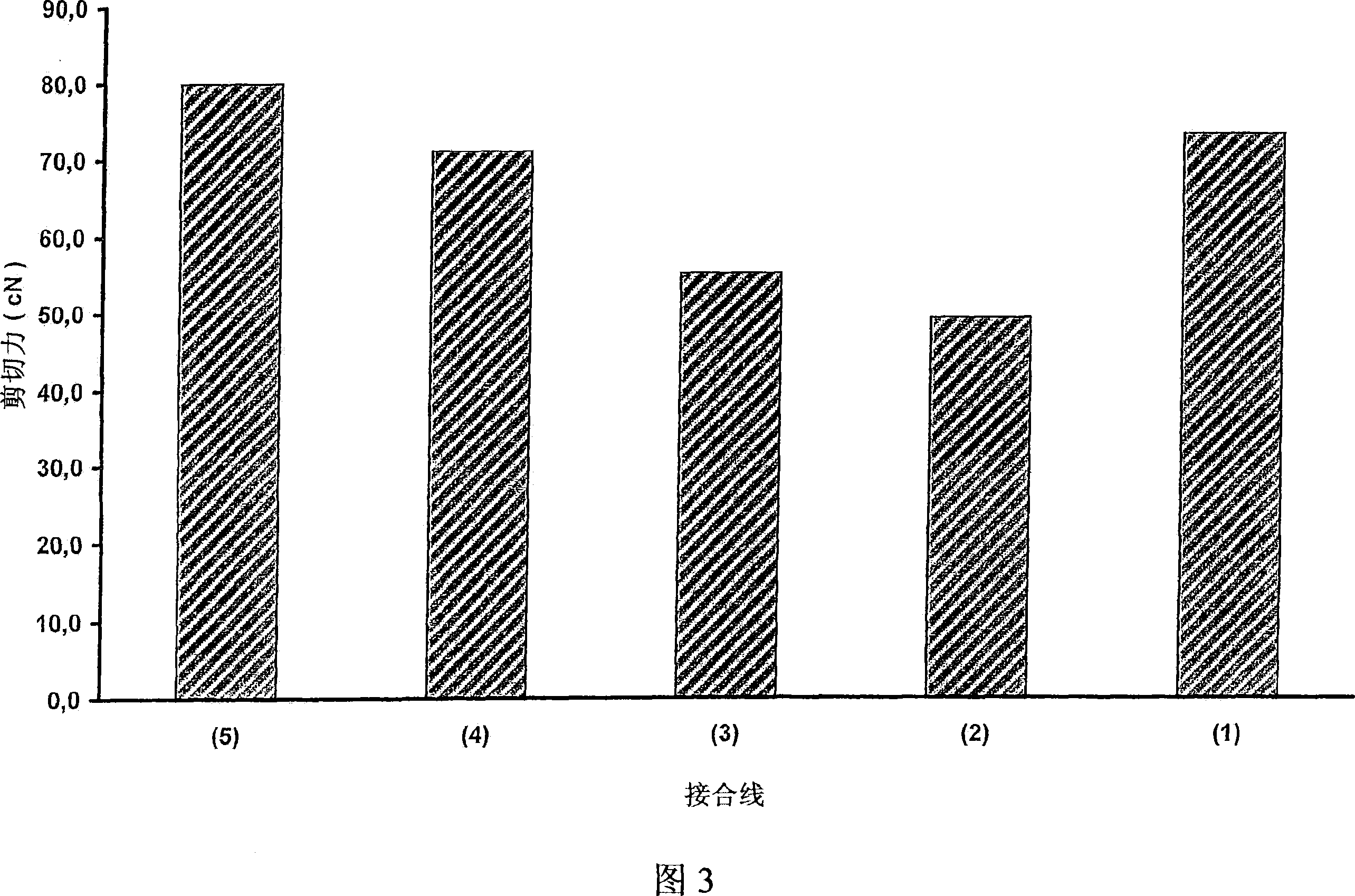

Disclosed herein are a method for plating a printed circuit board and the printed circuit board manufactured therefrom. In the method, a bare soldering or wire bonding portion of a copper (Cu)- or copper alloy layer, is plated with palladium (Pd) or a palladium alloy, and then gold (Au) or a gold alloy is deposited over the palladium or palladium alloy plated layer by an electroless substitution plating process based on ionization tendency. Having superior hardness, ductility and corrosion resistance, palladium is suitable for use between a connector and a substrate and meets requirements for the printed circuit board even when applied to a low thickness, greatly reducing the process time. Accordingly, the problem of black pad, which frequently occur on electroless nickel and electroless gold finish upon surface mount technology, can be perfectly solved. Particularly, fatal bending cracks can be prevented from occurring in the rigid-flexible or flexible printed circuit boards.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

Metal member and electric contact using same

InactiveUS20050196634A1Improve wear resistanceReduce the amount requiredThin material handlingMetal layered productsGold alloysImpurity

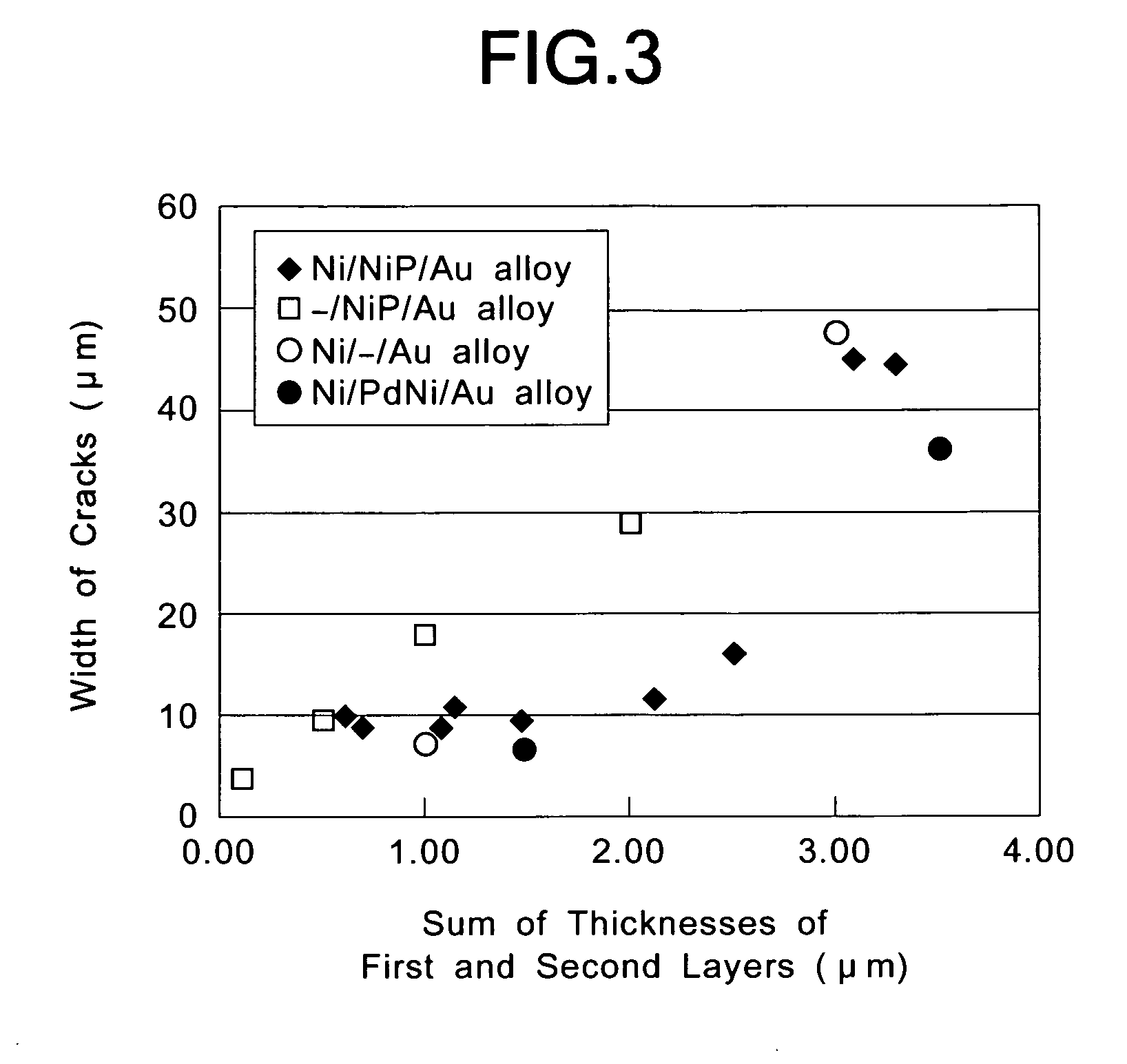

A metal member includes: a metal base; a first plating layer of nickel and unavoidable impurities, which is formed on the metal base; a second plating layer of nickel, phosphorus and unavoidable impurities, which is formed on the first plating layer; a third plating layer of a gold alloy and unavoidable impurities, which is formed on the second plating layer; and a fourth layer formed on the third plating layer by a sealing process, wherein the first plating layer has a thickness of 0.5 to 2.5 μm and the second plating layer has a thickness of 0.05 to 0.5 μm, the sum of the thickness of the first plating layer and the thickness of the second plating layer being in the range of from 0.60 μm to 2.5 μm, and the third plating layer having a thickness of not less than 0.05 μm.

Owner:DOWA METALTECH CO LTD

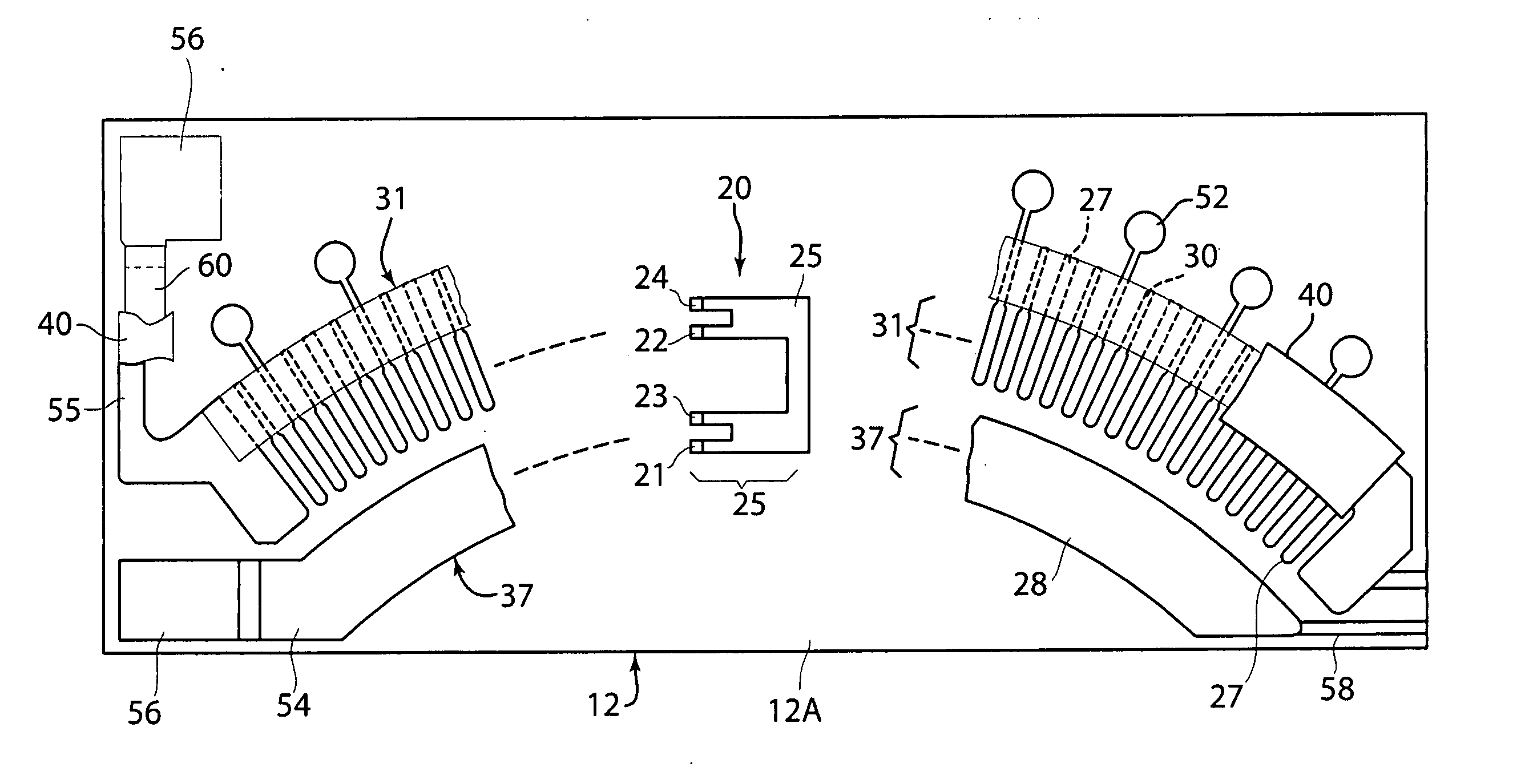

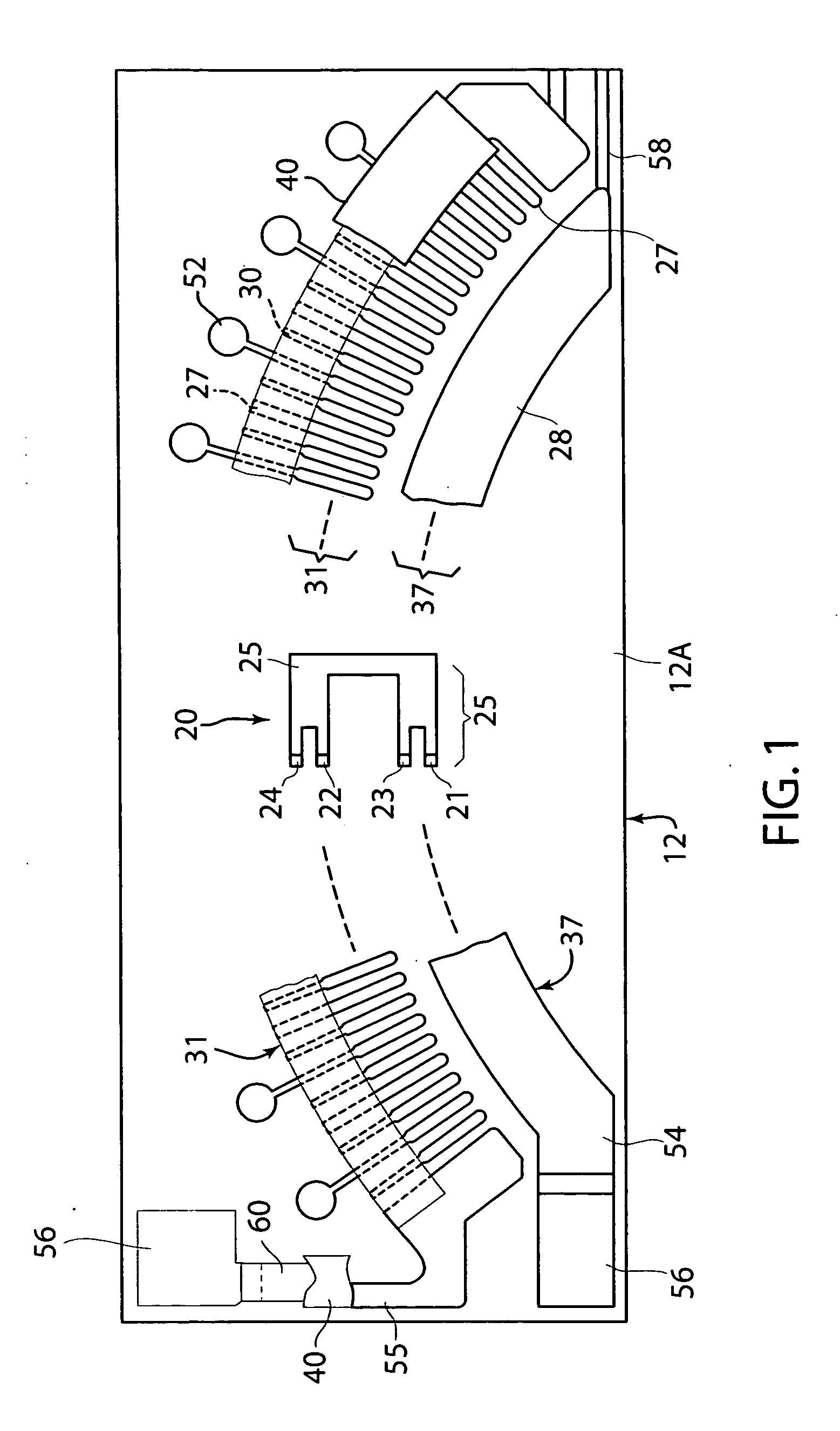

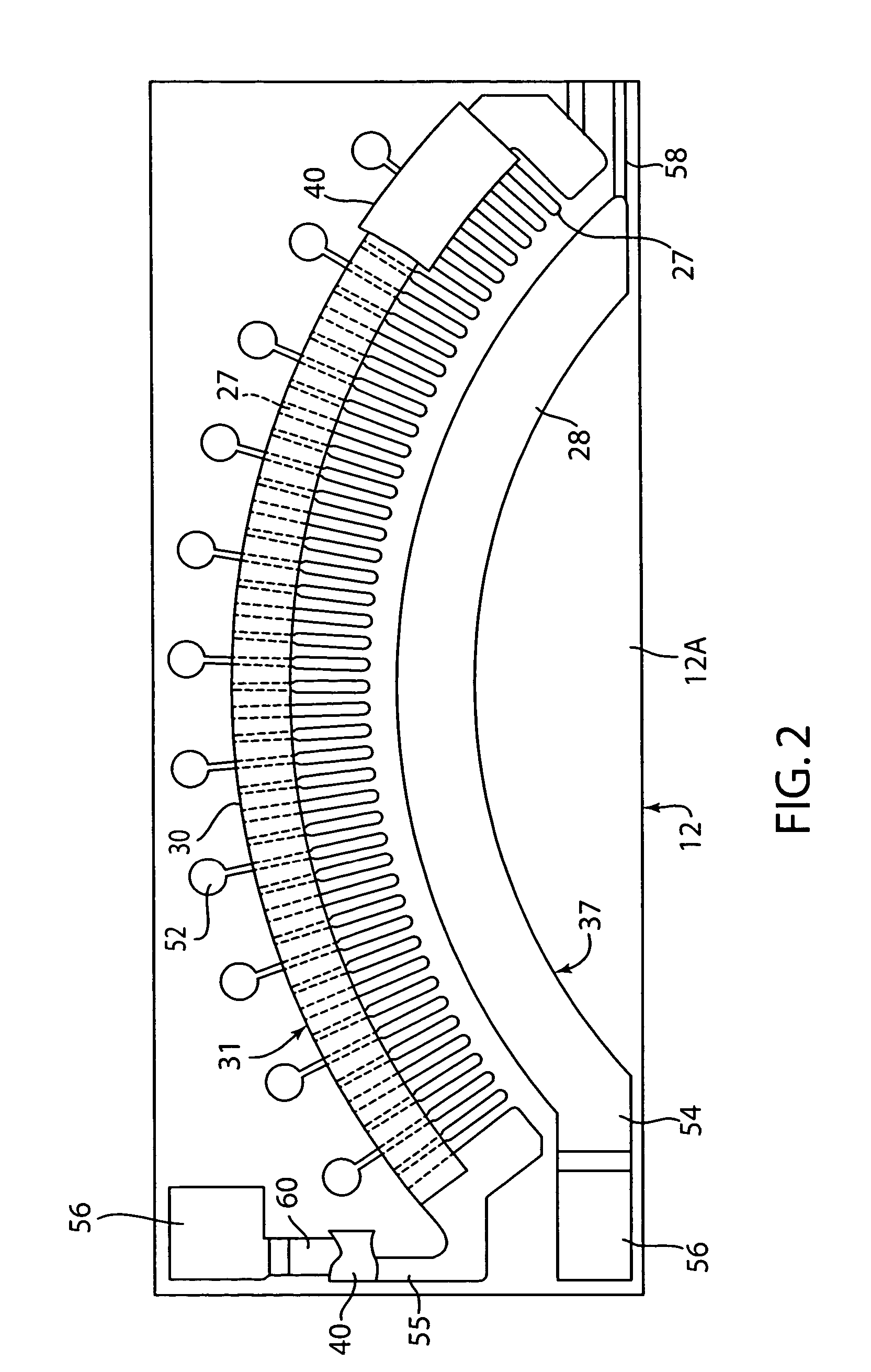

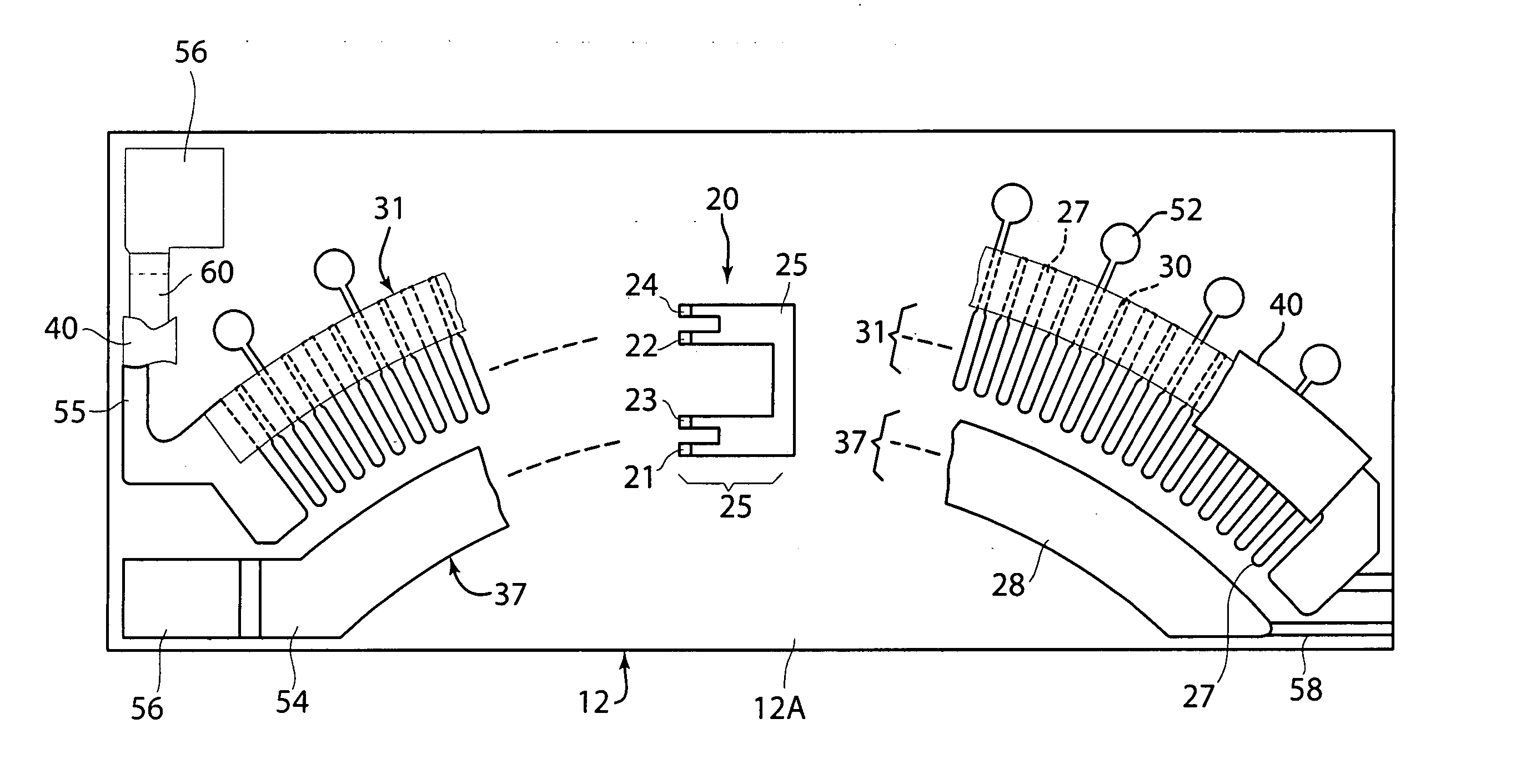

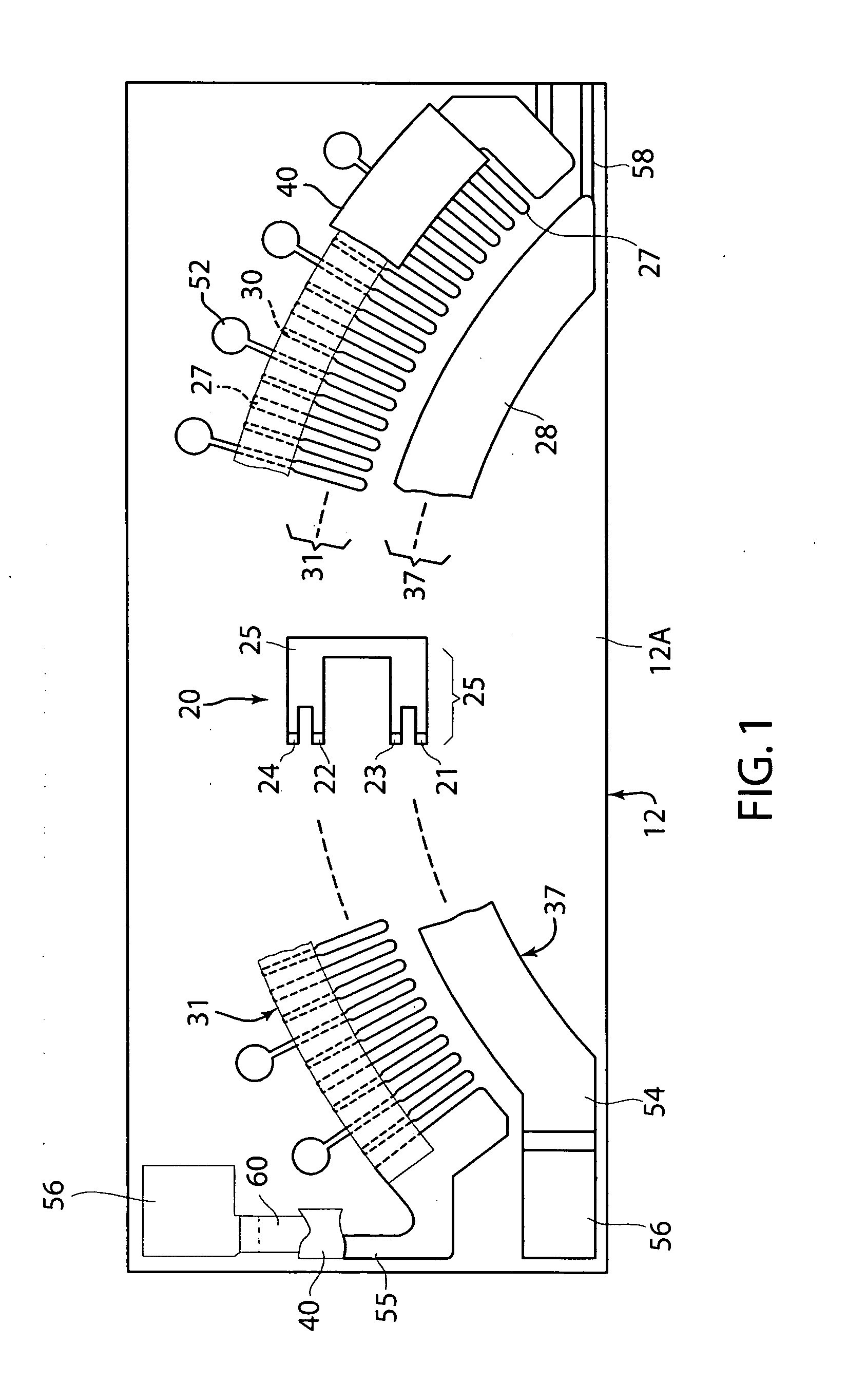

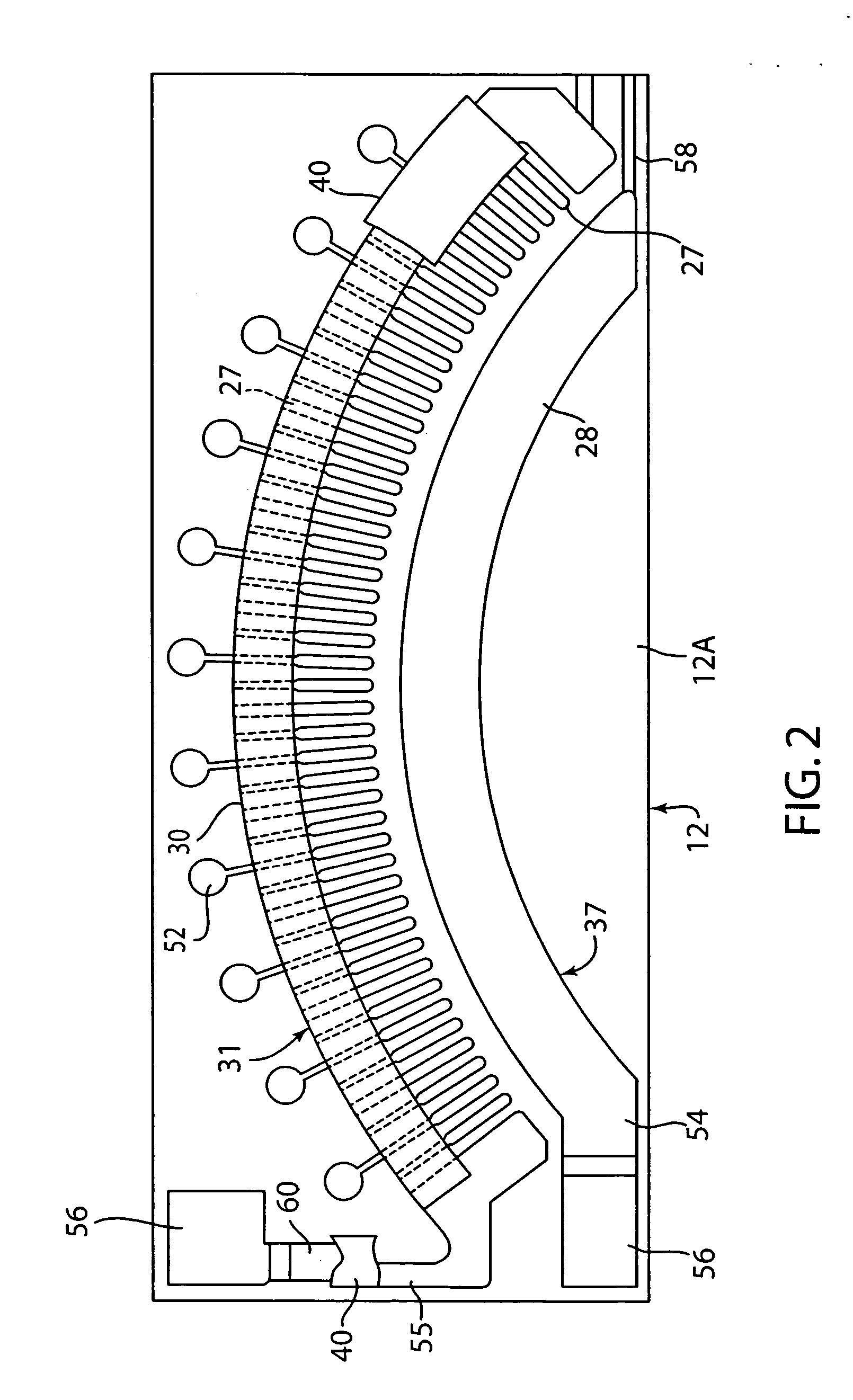

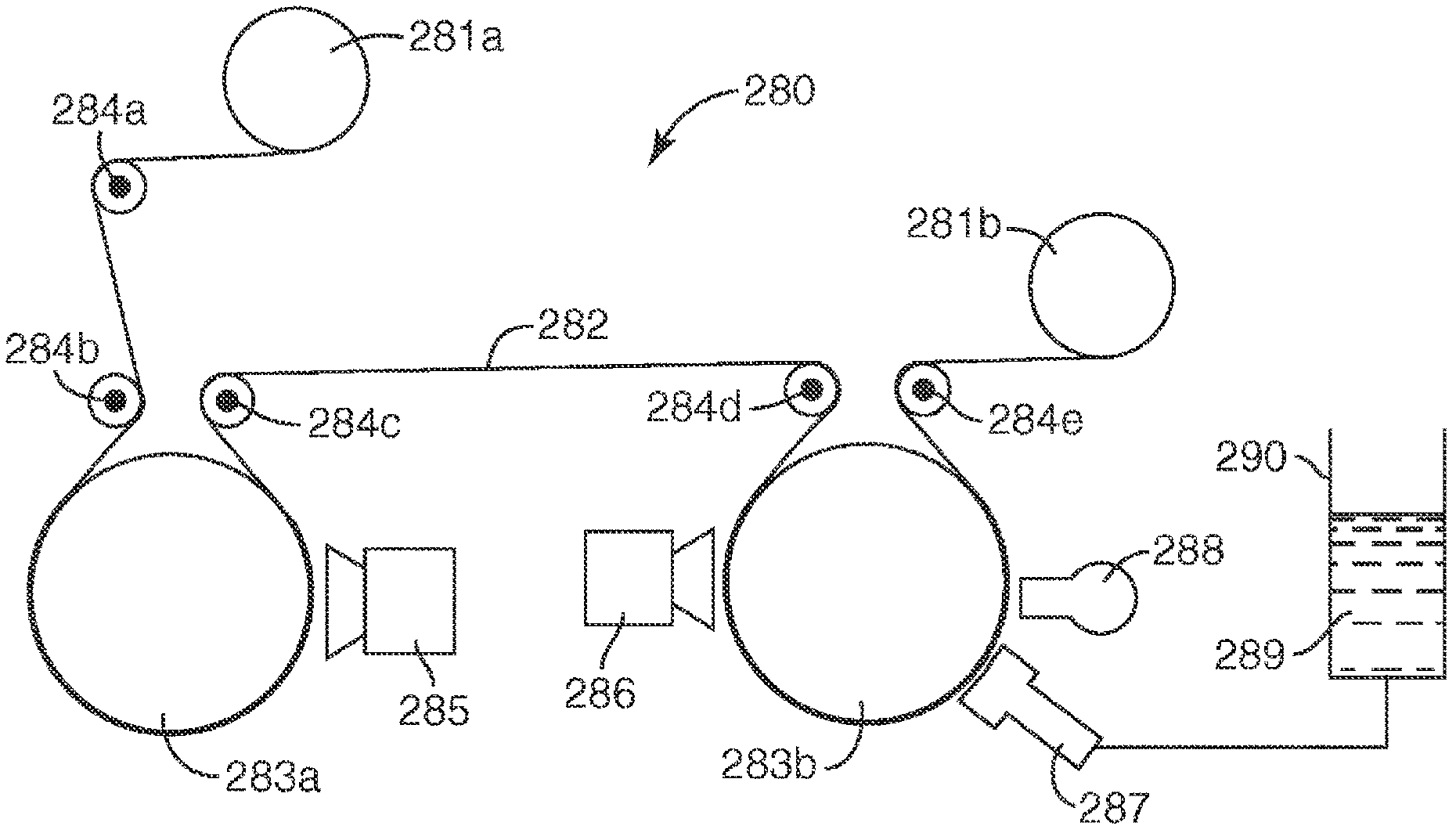

Heating lamp system

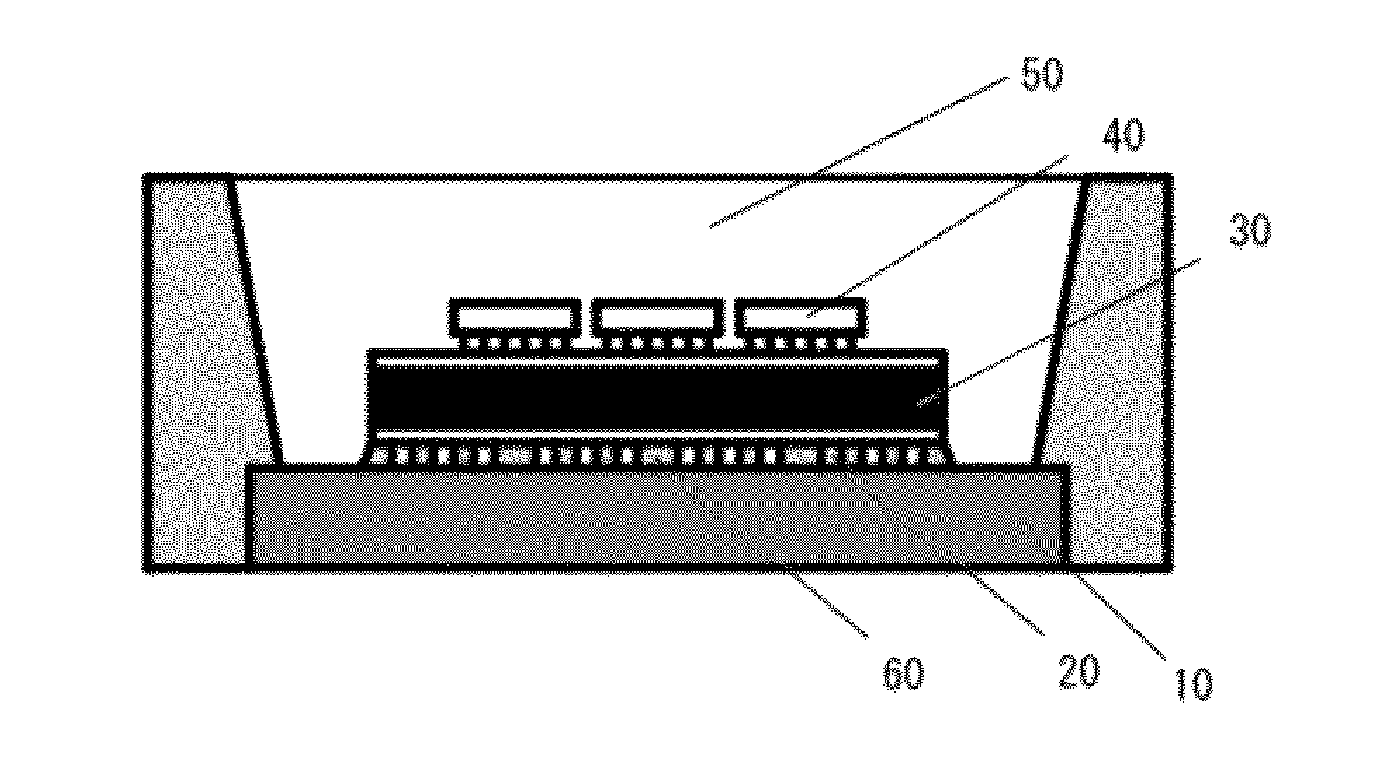

InactiveUS20100209082A1Polycrystalline material growthDrying solid materials with heatReactor systemGold alloys

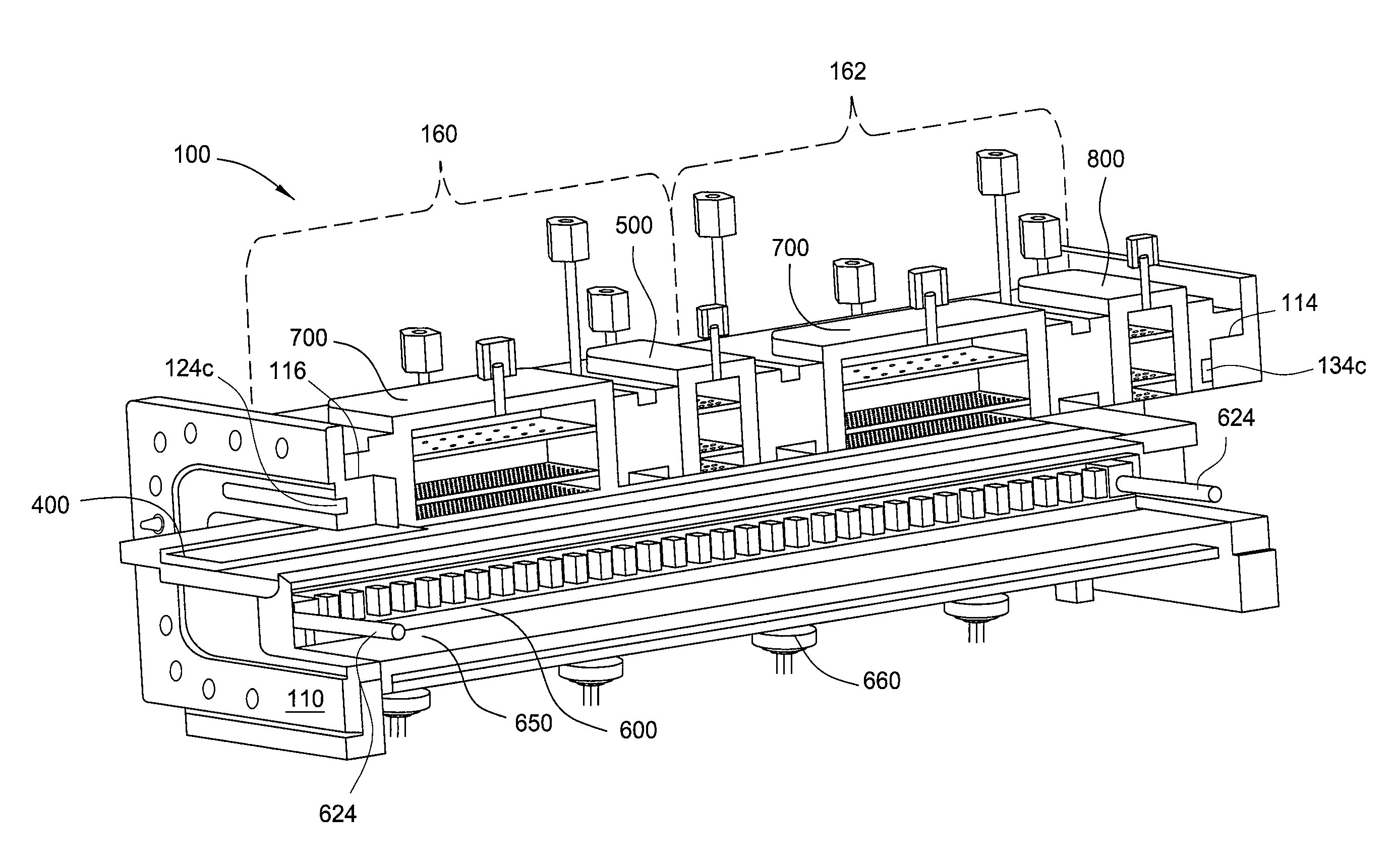

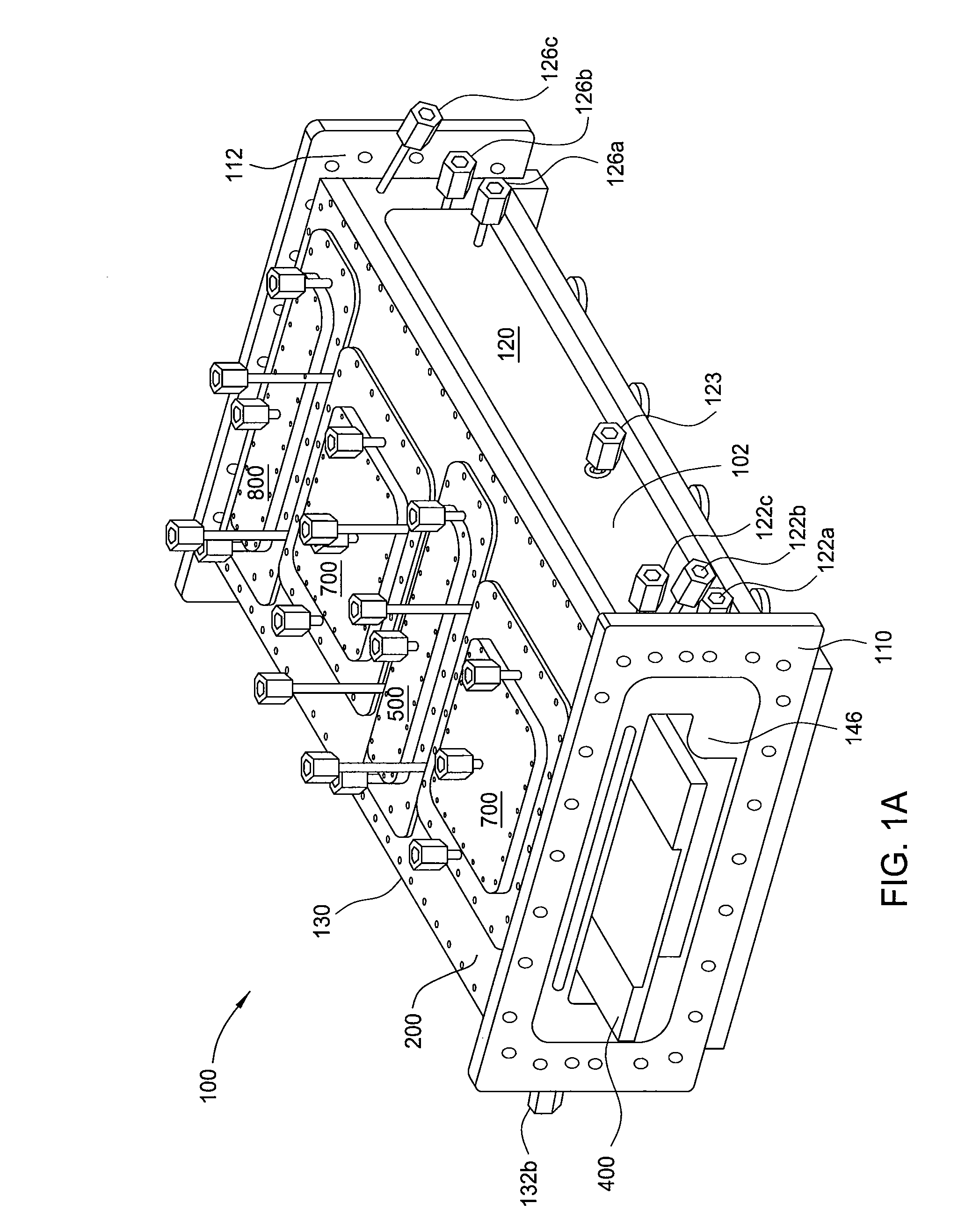

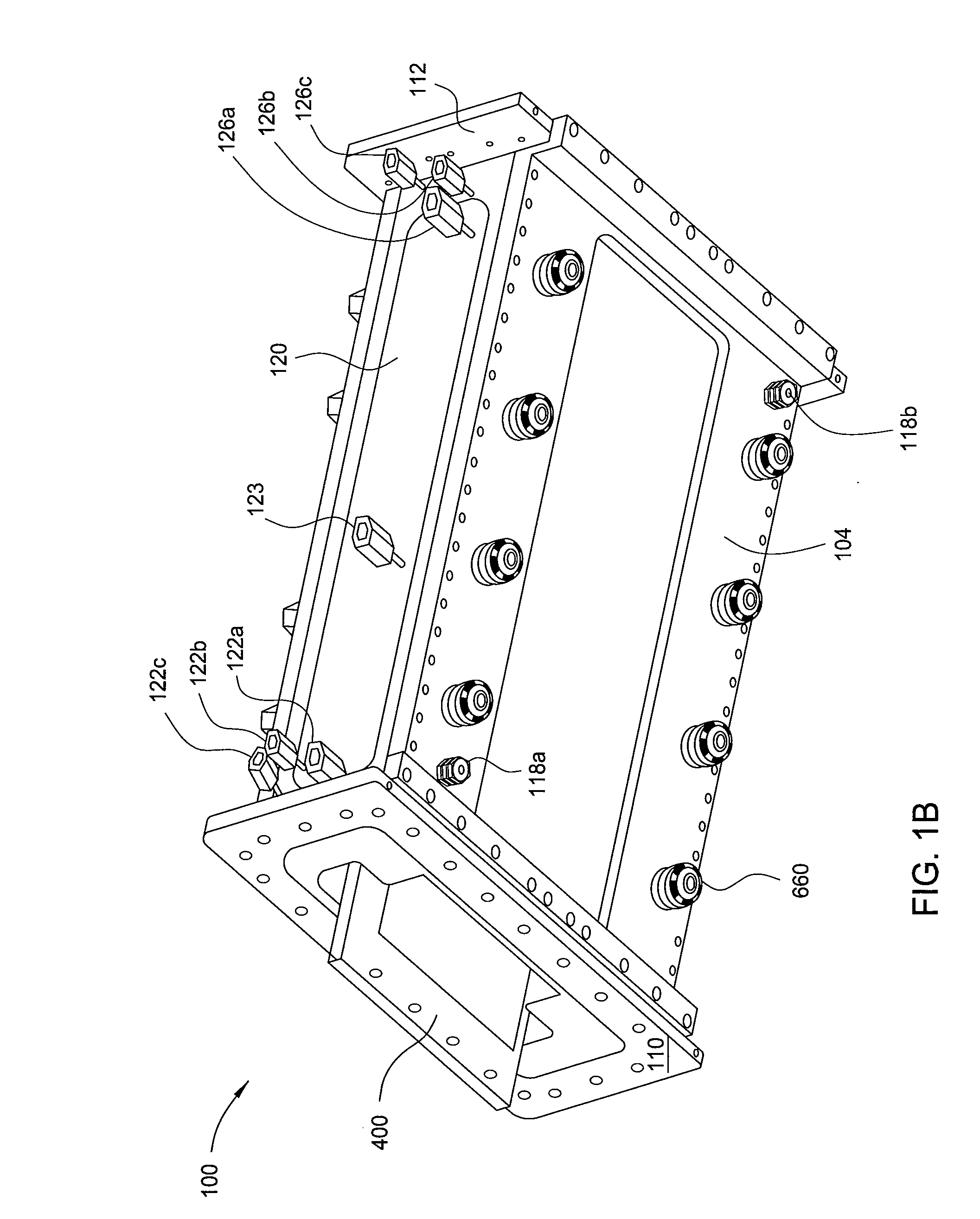

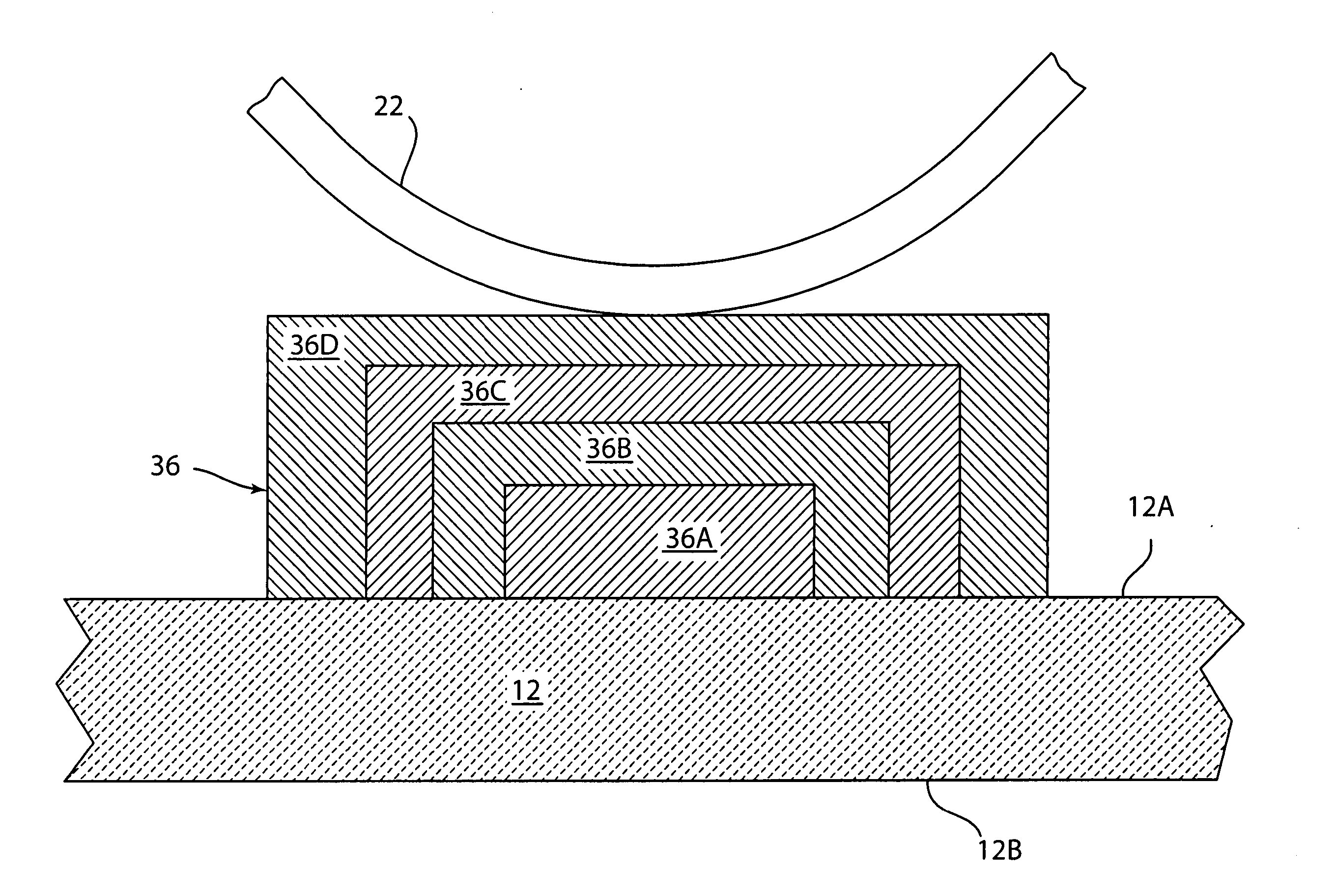

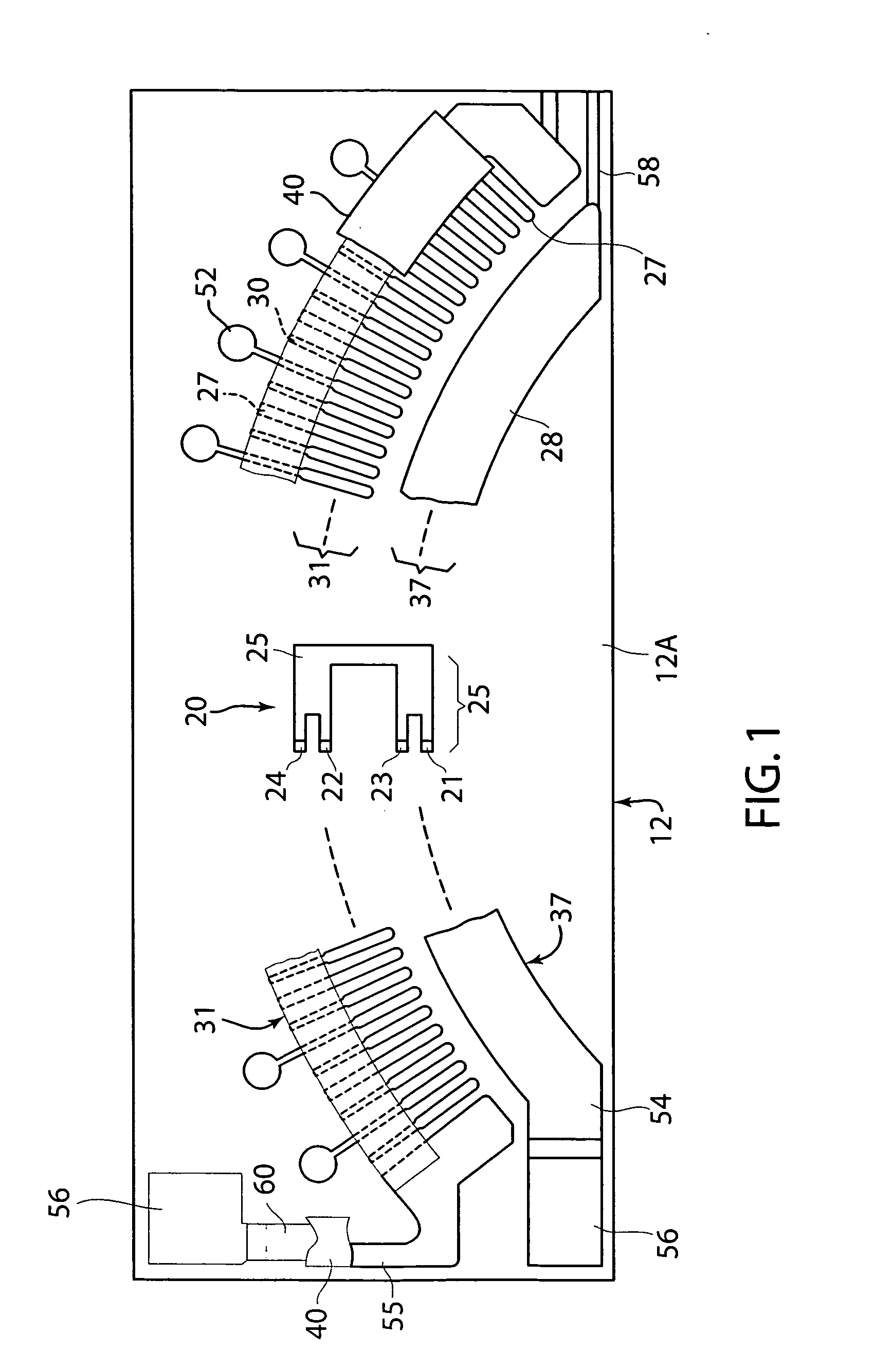

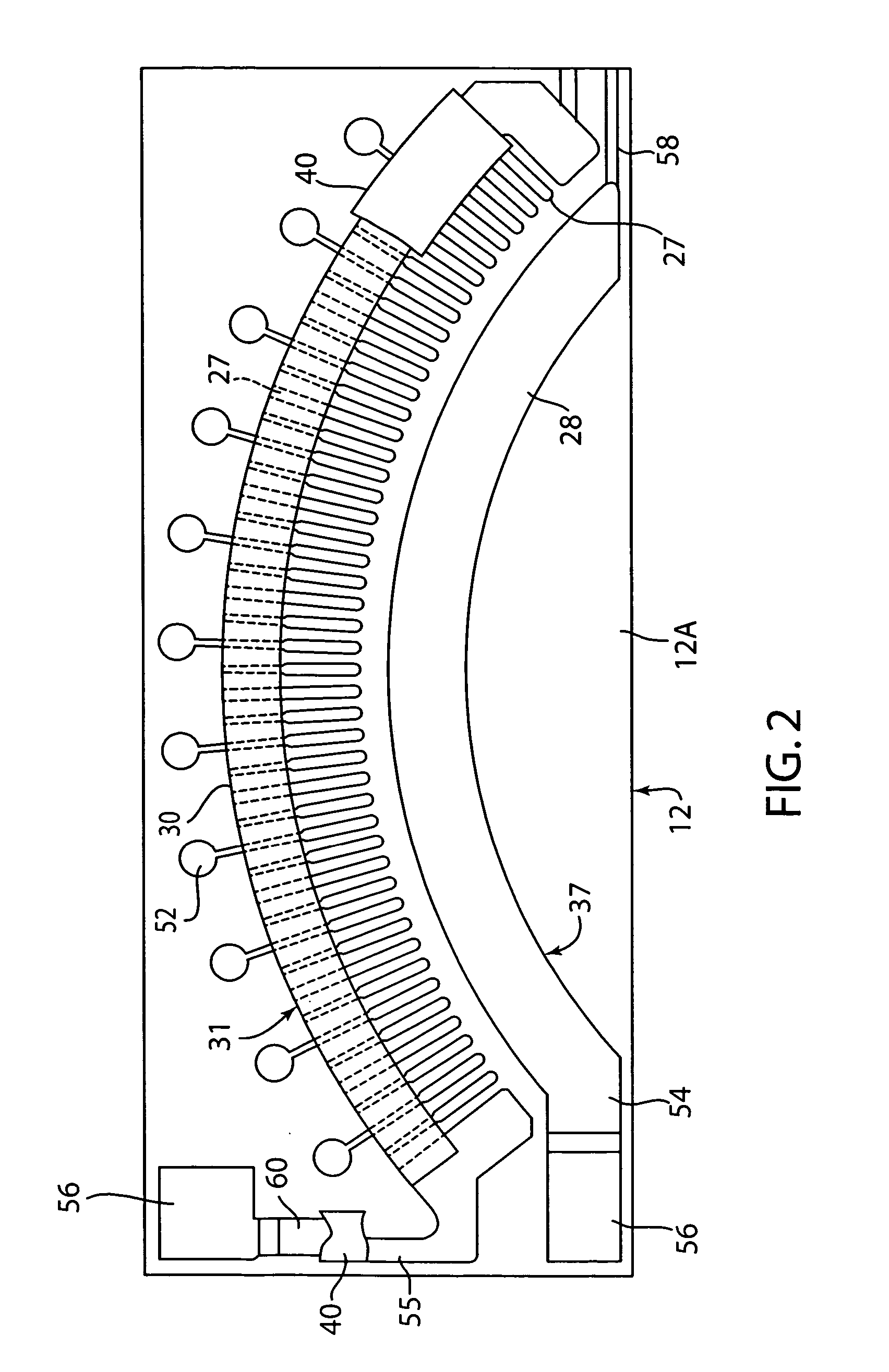

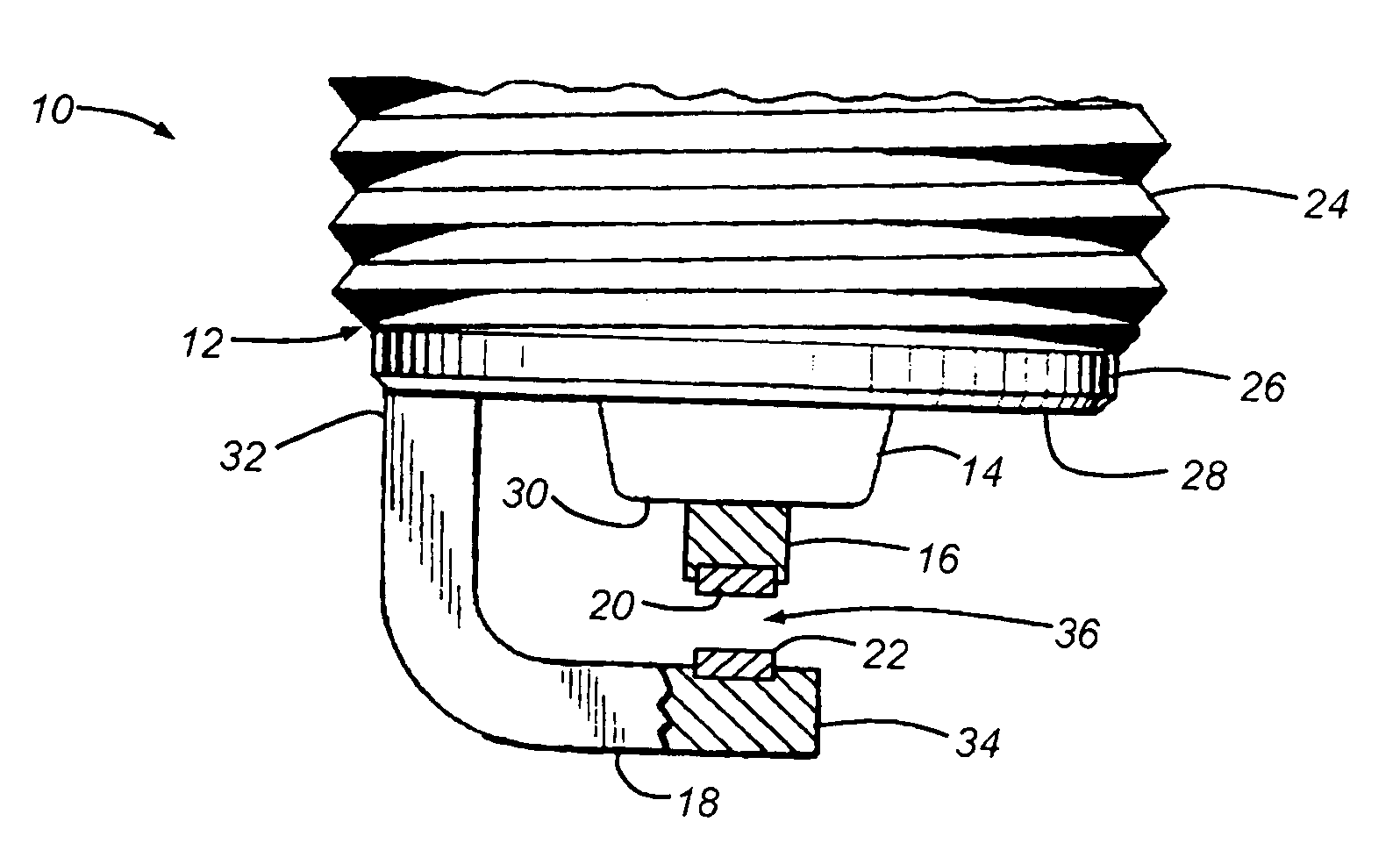

Embodiments of the invention generally relate to apparatuses for chemical vapor deposition (CVD) processes. In one embodiment, a heating lamp assembly for a vapor deposition reactor system is provided which includes a lamp housing disposed on an upper surface of a support base and containing a first lamp holder and a second lamp holder and a plurality of lamps extending from the first lamp holder to the second lamp holder. The plurality of lamps may have split filament lamps and / or non-split filament lamps, and in some examples, split and non-split filament may be alternately disposed between the first and second lamp holders. A reflector may be disposed on the upper surface of the support base between the first and second lamp holders. The reflector may contain gold or a gold alloy.

Owner:ALTA DEVICES INC

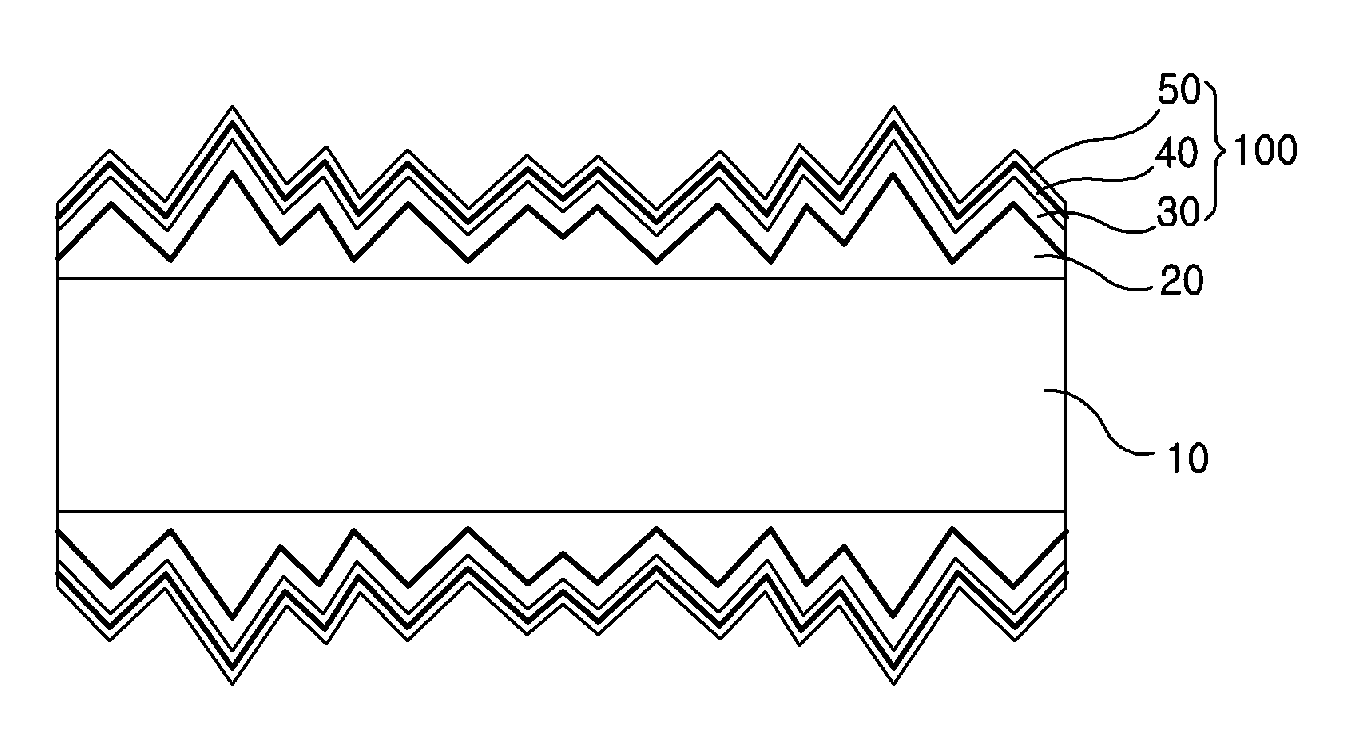

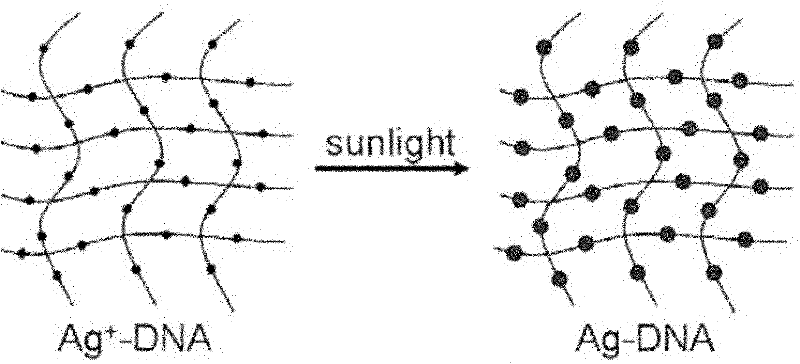

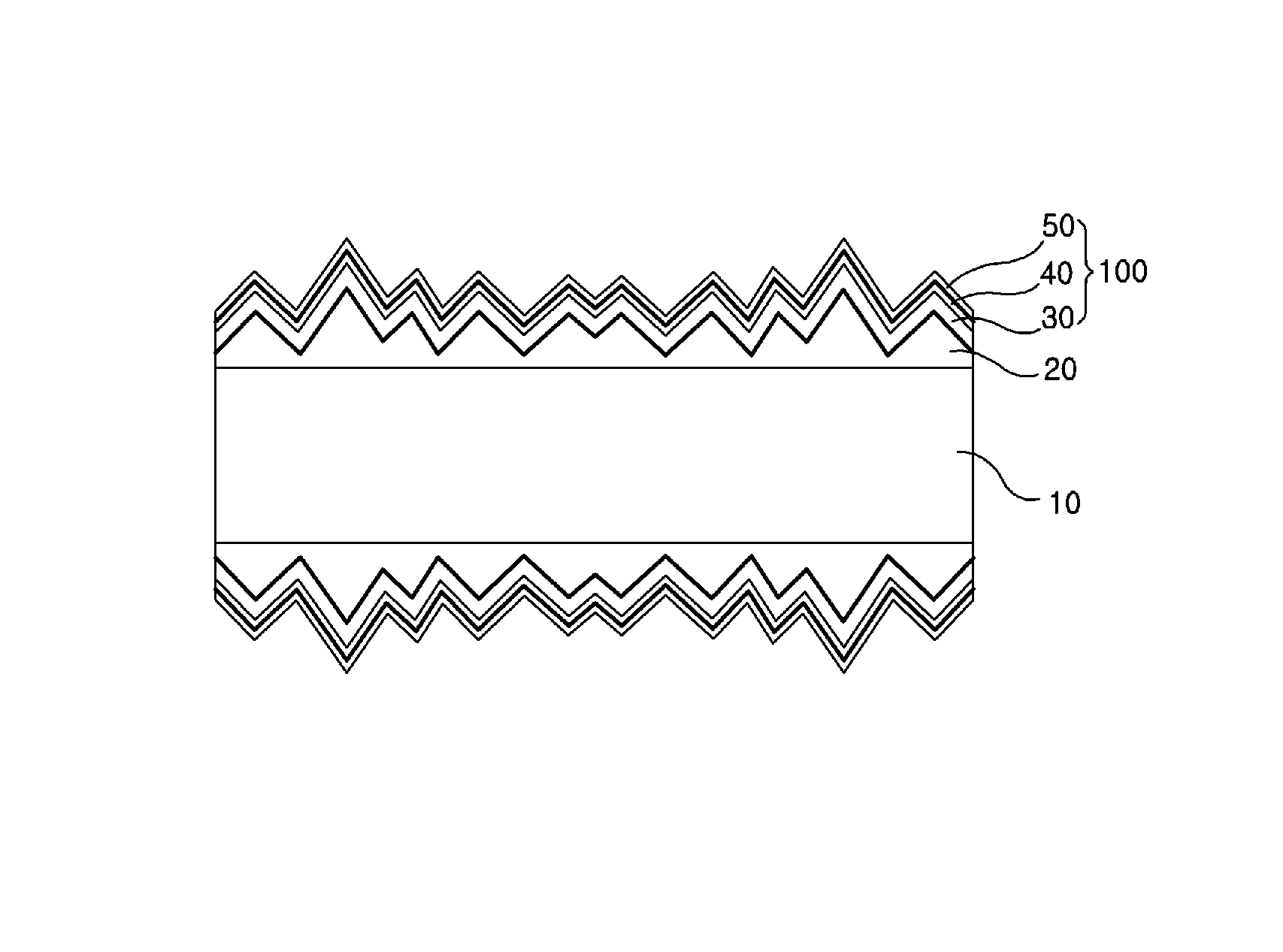

Lead Frame and Method For Manufacturing the Same

InactiveUS20120001307A1Reduce thicknessLow costSemiconductor/solid-state device detailsSolid-state devicesCopper platingGold alloys

A lead frame comprises: a base metal layer; a copper plating layer, including one of a copper layer and an alloy layer including a copper, configured to plate the based metal layer to make a surface roughness; and an upper plating layer, including at least one plating layer including at least one selected from the group of a nickel, a palladium, a gold, a silver, a nickel alloy, a palladium alloy, a gold alloy, and a silver alloy, configured to plate the copper plating layer.

Owner:ALS

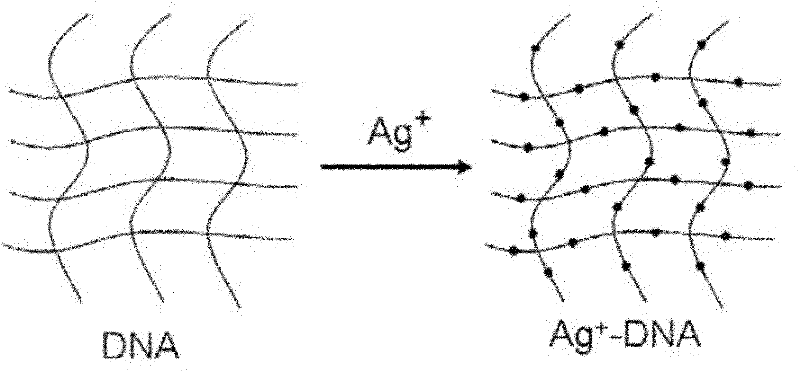

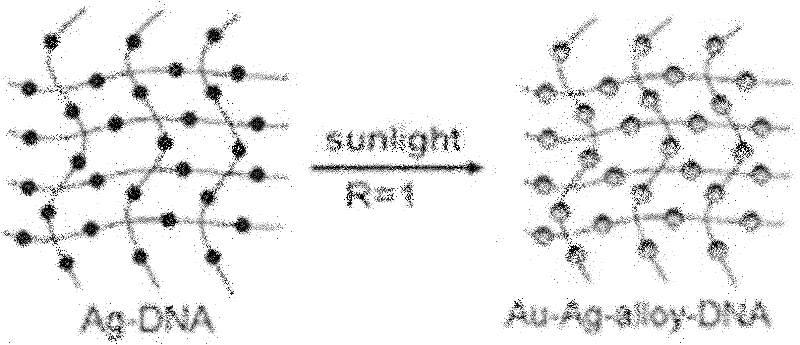

Light irradiation preparation method and use of ultra-sensitive surface enhanced Raman scattering active base

InactiveCN102183503ARaise the enhancement factorGood repeatabilityRaman scatteringNanotechnologyLight irradiationGold particles

The invention discloses a light irradiation preparation method and a use of an ultra-sensitive surface enhanced Raman scattering active base. The light irradiation preparation method comprises the following steps of: firstly, depositing silver nano particles on a surface of a DNA, then, taking the silver as a nucleation site to assemble the gold on the silver; and then, depositing small gold particles on a nano structure of silver-DNA by the sunlight again. The silver-nucleus gold-shell or silver-gold alloy nano DNA network structure is a good surface enhanced Raman scattering (SERS) active base obviously effective in TNT detection. The lowest detection limit can reach the prior lowest detection level, and enhancement factors can reach the order of magnitude of 1011-1012. The Light irradiation preparation method and the use of the ultra-sensitive surface enhanced Raman scattering active base provide a quick and accurate detection method for detecting explosives, such as TNT and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Fuel tank resistor card having improved corrosion resistance

InactiveUS20050040929A1Improve wear resistance and corrosion resistanceAvoid corrosionFixed resistors with intervening connectorsPrinted circuit aspectsSulfurFuel tank

A resistor card for a fuel level sensor has improved resistance to corrosion and wear. The resistor card has a substrate with a resistive layer and a conductive layer. A nickel layer covers the conductive layer. A nickel-gold alloy layer covers the nickel layer. The nickel-gold alloy layer protects the conductive layer from sulfur corrosion and improves wear resistance.

Owner:CTS CORP ELKHART

Fuel tank resistor card having improved corrosion resistance

InactiveUS20050040930A1Improve wear resistance and corrosion resistanceAvoid corrosionFixed resistors with intervening connectorsPrinted circuit aspectsSulfurFuel tank

A resistor card for a fuel level sensor has improved resistance to corrosion and wear. The resistor card has a substrate with a resistive layer and a conductive layer. A nickel layer covers the conductive layer. A nickel-gold alloy layer covers the nickel layer. The nickel-gold alloy layer protects the conductive layer from sulfur corrosion and improves wear resistance.

Owner:CTS CORP ELKHART

Ignition Device Electrode Composition

InactiveUS20080050264A1Improved performance characteristicsLow costSparking plugsIron based alloyGold alloys

An ignition device includes a ground electrode, center electrode, or both composed of a cobalt-based alloy including: Ni in an amount between about 20 and 24% by weight; Cr in an amount between about 20 and 24% by weight; W in an amount between about 10 and 16% by weight; and Co in an amount between about 32 and 47% by weight or alternately an iron-based alloy comprising: Cr in an amount between about 18 and 24% by weight; Al in an amount between about 4 and 7% by weight; and Fe in an amount between about 67 and 78% by weight. It is believed that the electrode alloys may also include Zr and B in an amount, by weight, of 0.005-0.5% Zr and 0.001-0.10% B. Center or ground electrodes of the invention may also include firing tips attached at a sparking end thereof. The firing tips may be formed of at least one of gold, a gold alloy, a platinum group metal or a tungsten alloy.

Owner:FEDERAL MOGUL WORLD WIDE

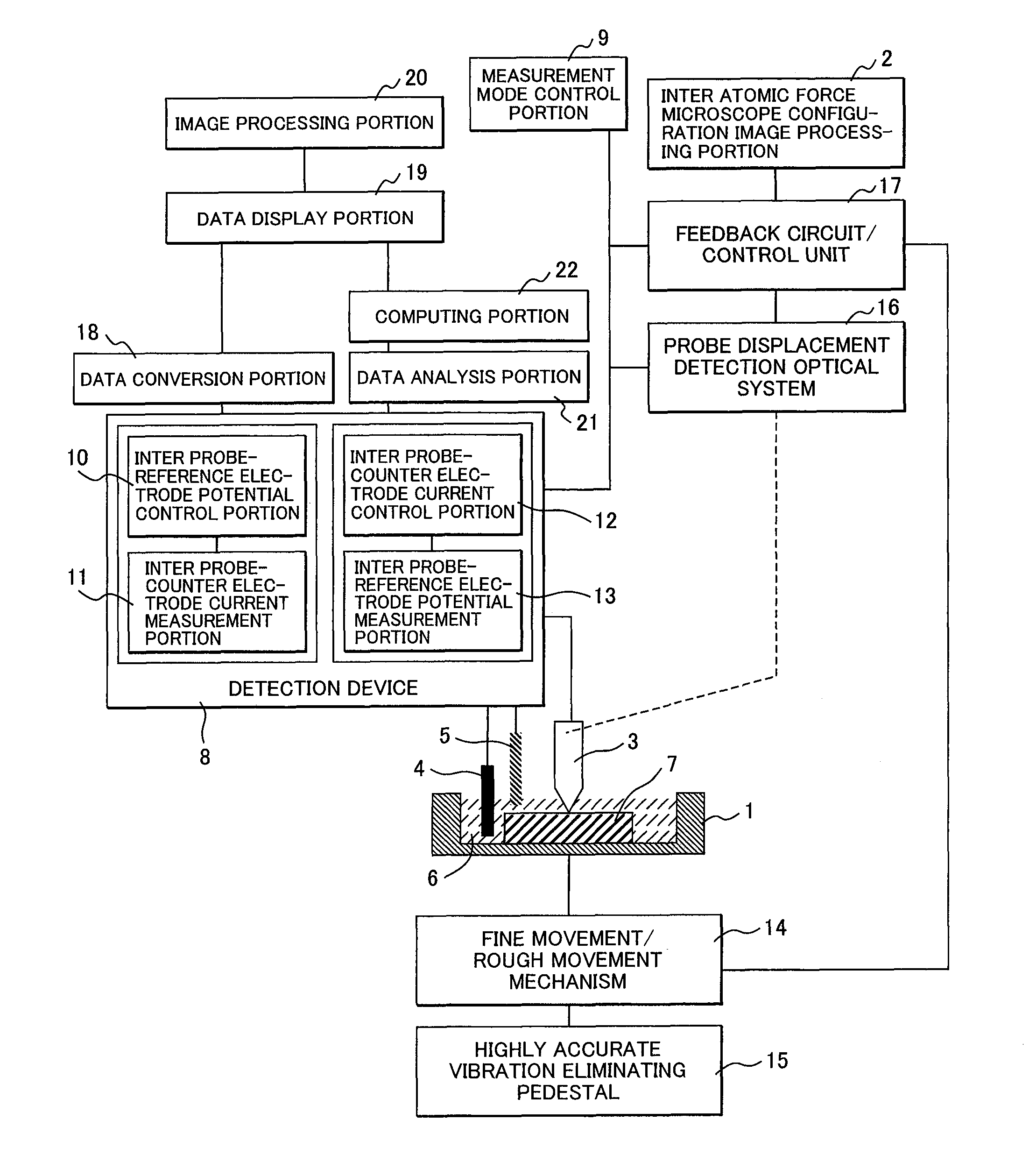

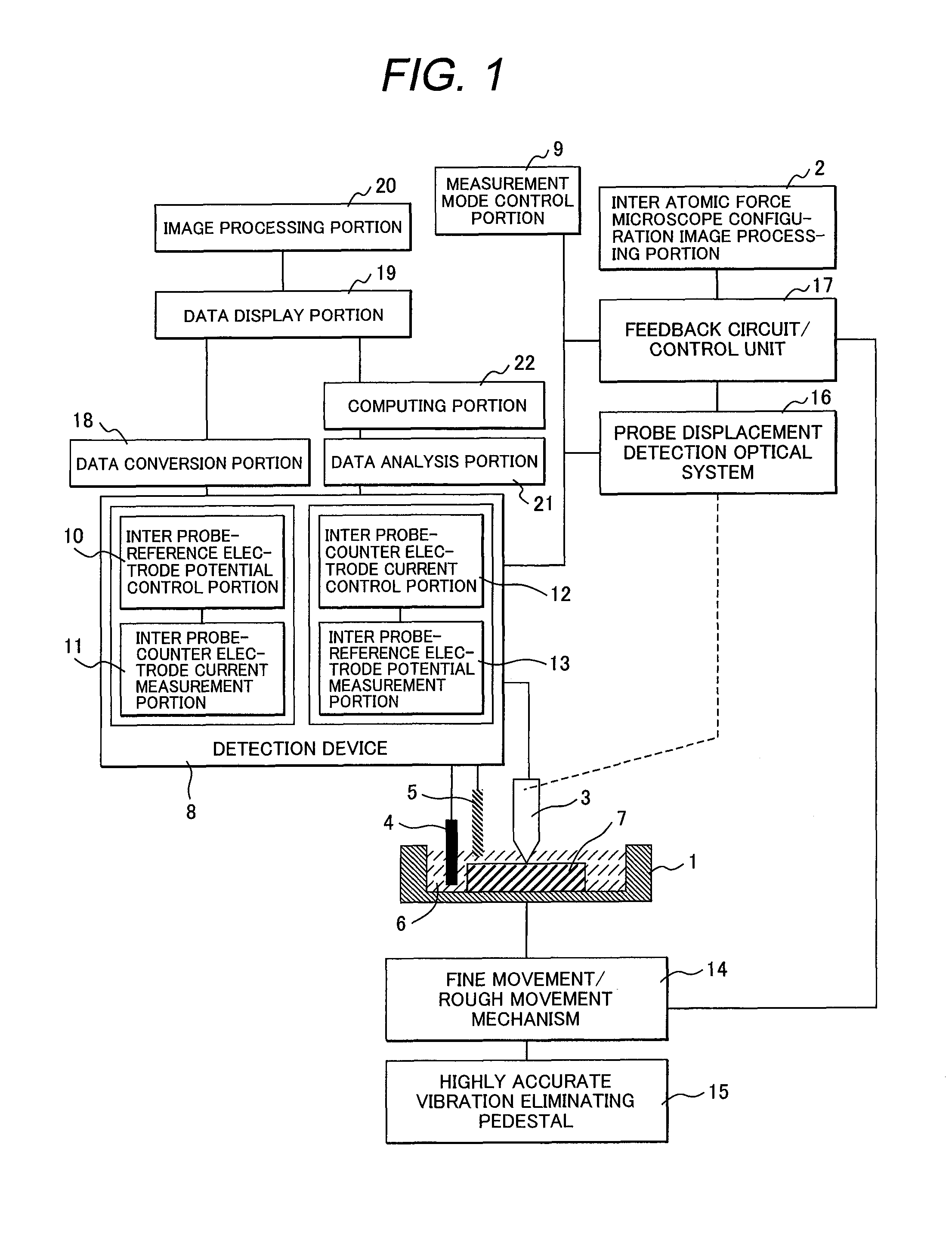

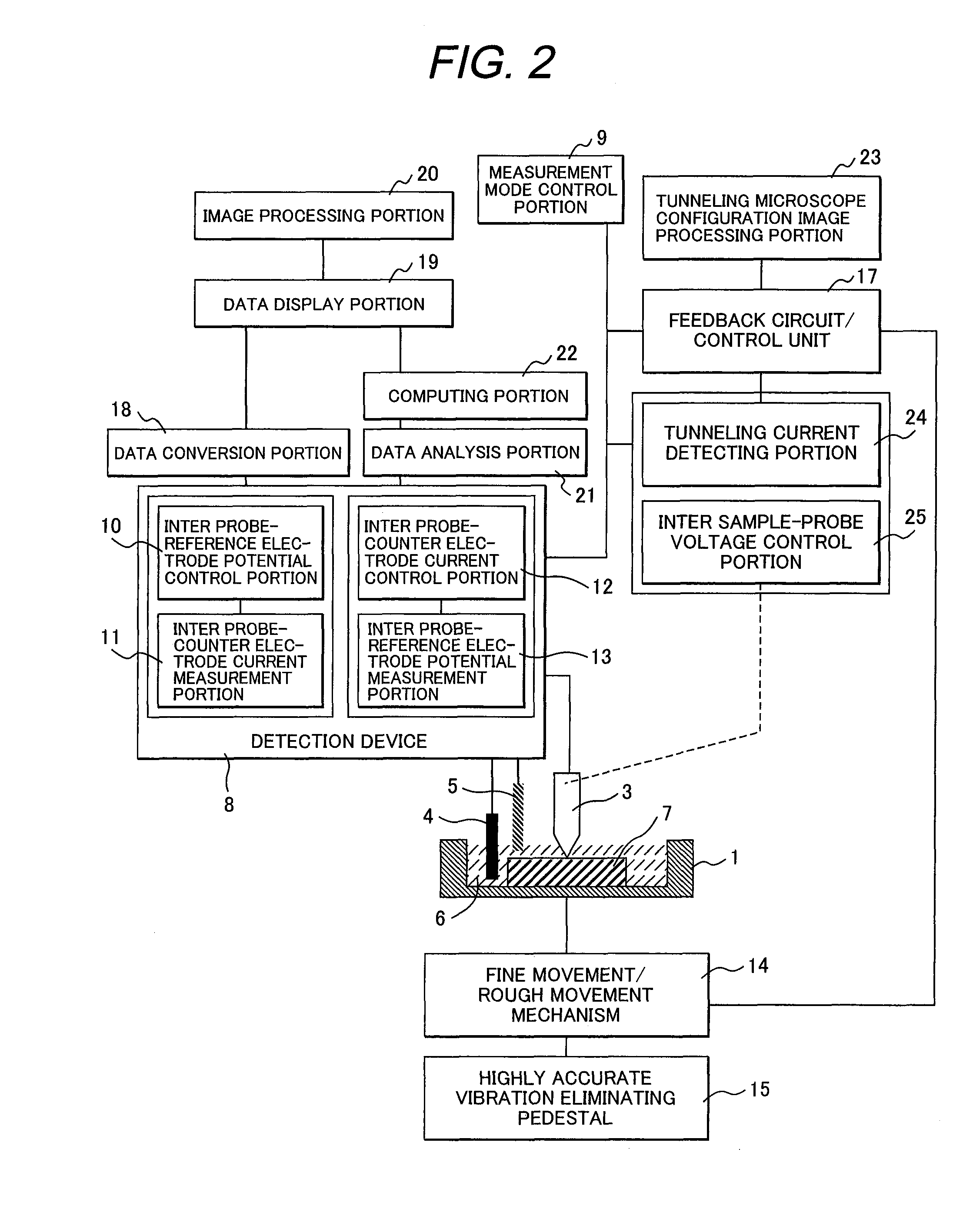

Probe Microscope

An object of the present invention is to provide a probe microscope that permits qualitative and quantitative evaluation on ions existing near the surface of a sample and permits to detect further simply and easily such as impurities, flaws and corrosion origins existing on the sample in high sensitivity. A probe microscope according to the present invention is provided with a test cell that holds a sample and permits to receive liquid, a probe, a counter electrode, a reference electrode, a drive mechanism that causes the probe to follow the surface of the sample as well as to scan the same, a potential control portion that controls a potential between the probe and the reference electrode and a current measuring portion that measures a current flowing between the probe and the counter electrode, and is characterized in that the material of the probe is constituted by a conductive body containing any of gold or gold alloy, carbon or carbon compound, boron, zinc, lead, tin and mercury.

Owner:HITACHI LTD

Manufacturing method of fine silver-gold alloy bonding line for polycrystalline serial LED

ActiveCN104388861AReduce local stress concentrationImprove organizational structureSolid-state devicesSemiconductor devicesUltimate tensile strengthHeat treated

The invention relates to a manufacturing method of a fine silver-gold alloy bonding line for polycrystalline serial LED. The fine silver-gold alloy bonding line comprises 35-55wt% of Au, 0.3-0.5wt% of Ce and the balance Ag. The manufacturing method comprises the following steps of 1, silver-gold alloy bonding line blank melting and continuous casting, 2, silver-gold alloy rod drawing and 3, silver-gold alloy line intermediate heat treatment. The manufacturing method solves the problems of ignited balls, ball offset and sharpening of the common silver-gold alloy bonding line, improves silver-gold alloy bonding line corrosion resistance, and solves the problem that the existing polycrystalline serial LED has a small bonding point size and produces an irregular first welding spot ball in bonding thereby causing welding spot short circuit and bonding strength reduction.

Owner:HENAN POLYTECHNIC UNIV +2

Fuel tank resistor card having improved corrosion resistance

InactiveUS20050035843A1Improve wear resistance and corrosion resistanceAvoid corrosionFixed resistors with intervening connectorsPrinted circuit aspectsSulfurFuel tank

A resistor card for a fuel level sensor has improved resistance to corrosion and wear. The resistor card has a substrate with a resistive layer and a conductive layer. A nickel layer covers the conductive layer. A nickel-gold alloy layer covers the nickel layer. The nickel-gold alloy layer protects the conductive layer from sulfur corrosion and improves wear resistance.

Owner:CTS CORP ELKHART

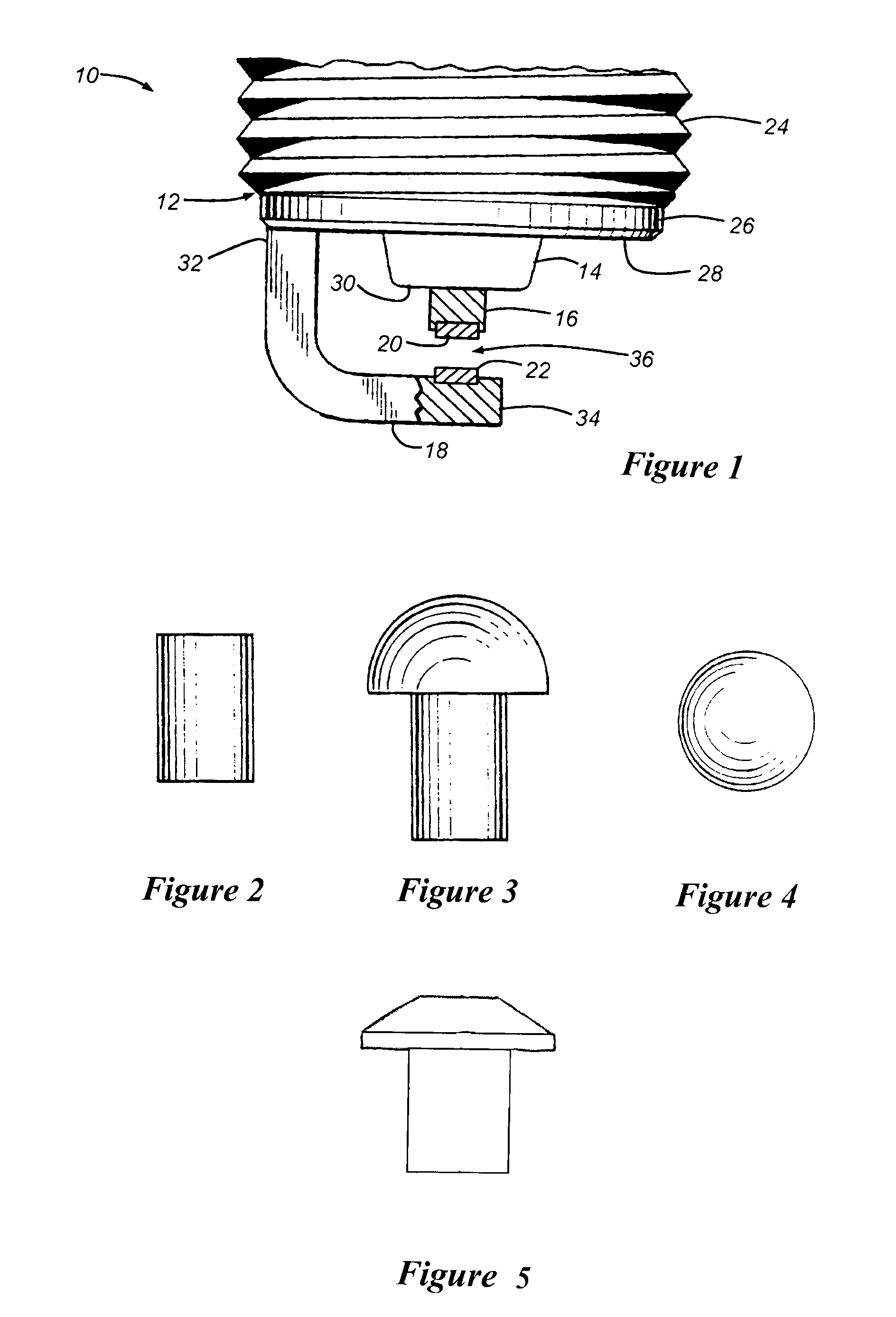

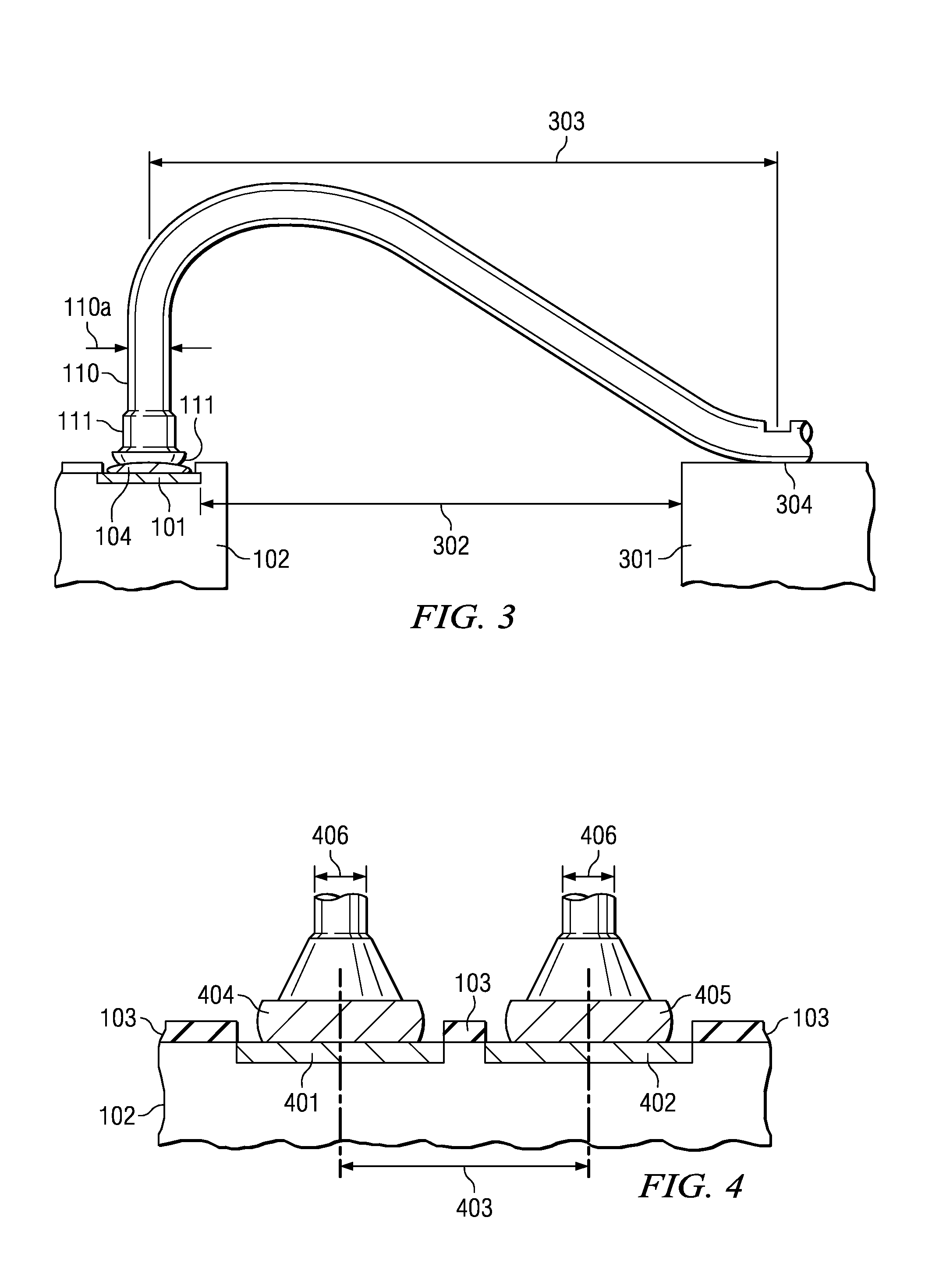

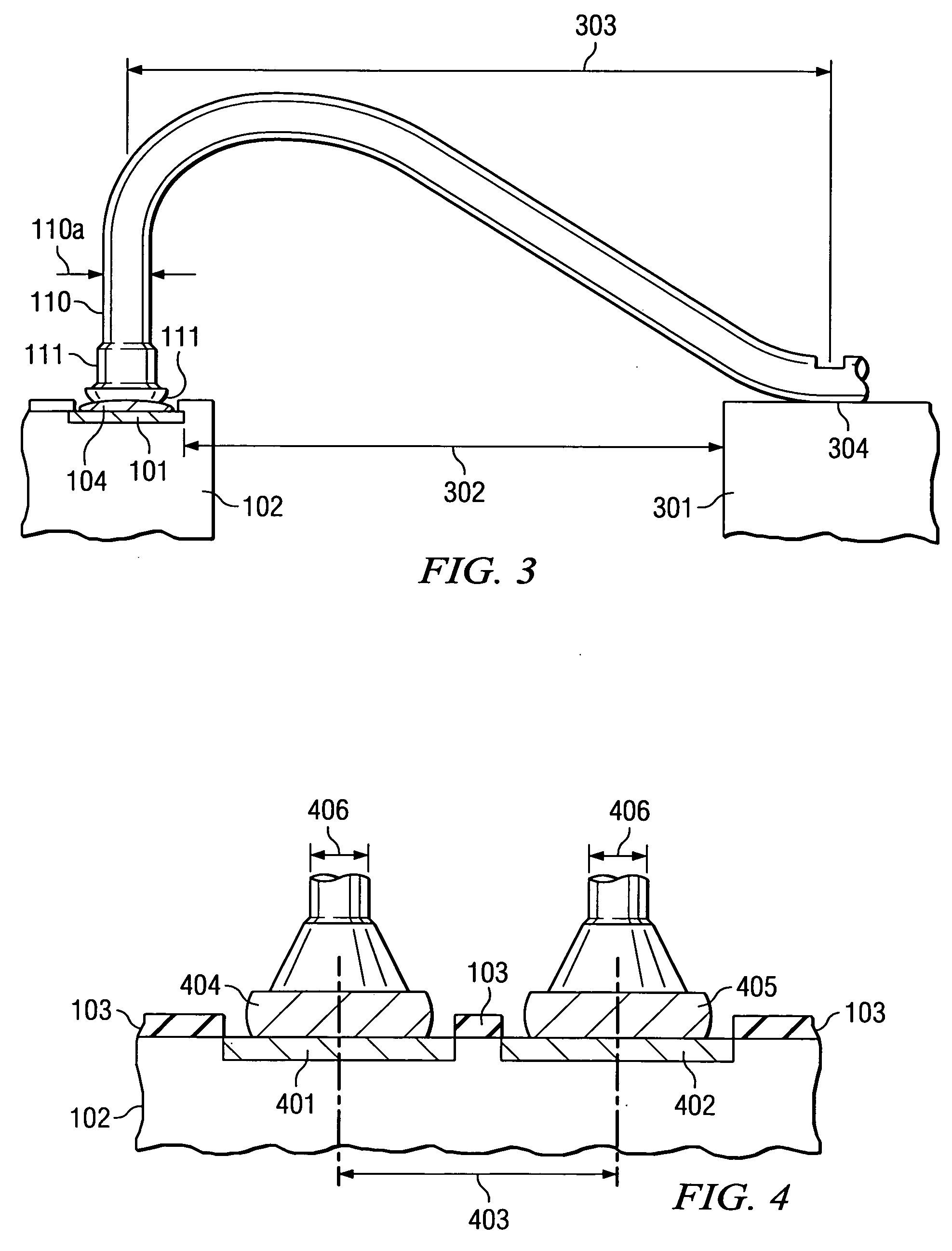

Method and apparatus for making hollow seamless links for use in jewelry

Method and apparatus for making hollow links or rings and for making chain made from hollow links by receiving seamless wire which has an inner core and an exterior surface, for example, a gold alloy surface, making a perforation in the wire so as to expose the inner core at the perforation, and forming the wire into an open or closed link such that the perforation is located on a hidden portion of the link. The inner core may then be removed from the open or closed link by dissolving it in acid, wherein the acid contacts the inner core at the perforation thus allowing the acid to dissolve the inner core. A chain may be made by coupling each link with at least one preceding link to produce the chain.

Owner:WEINBERG EITAN

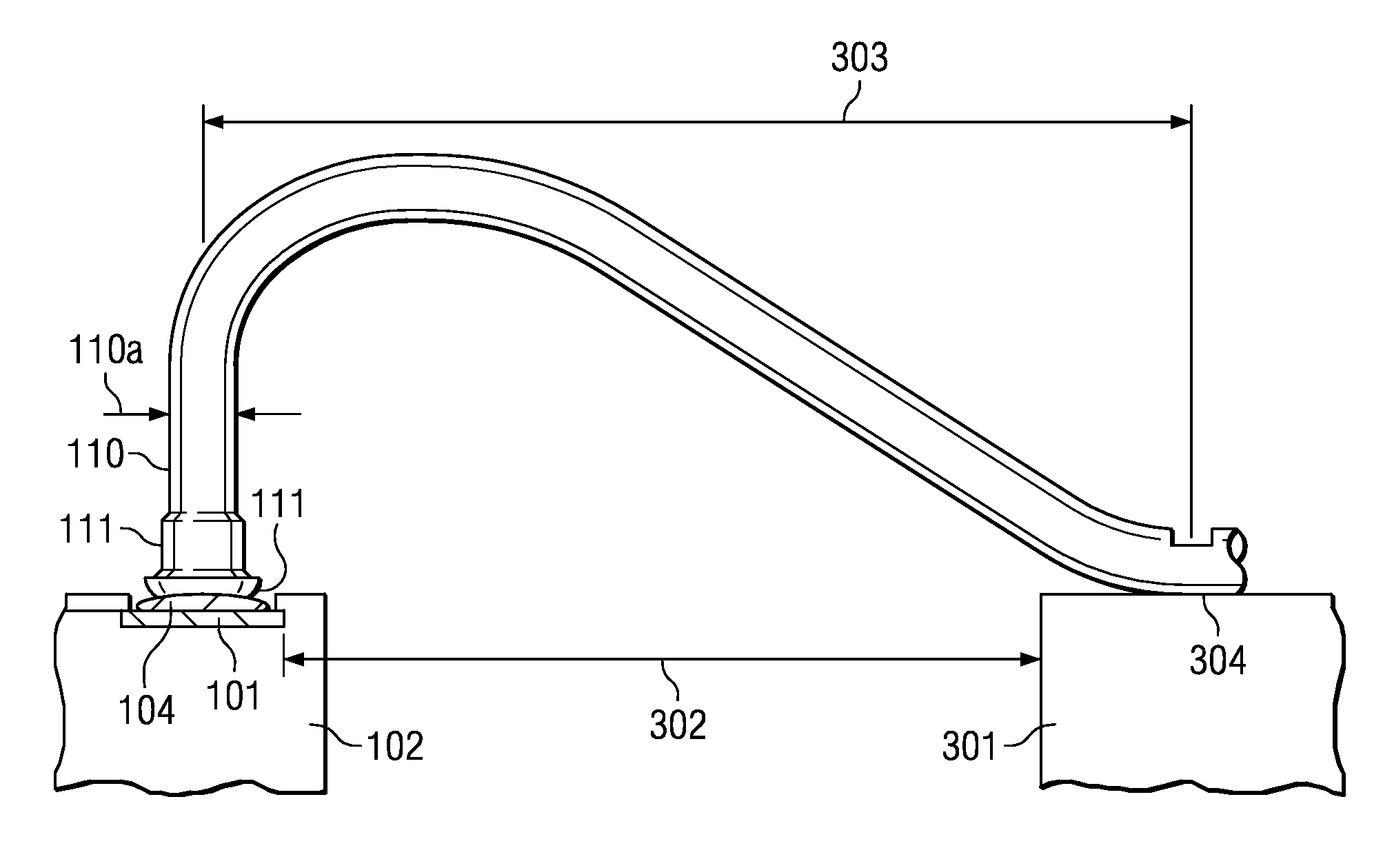

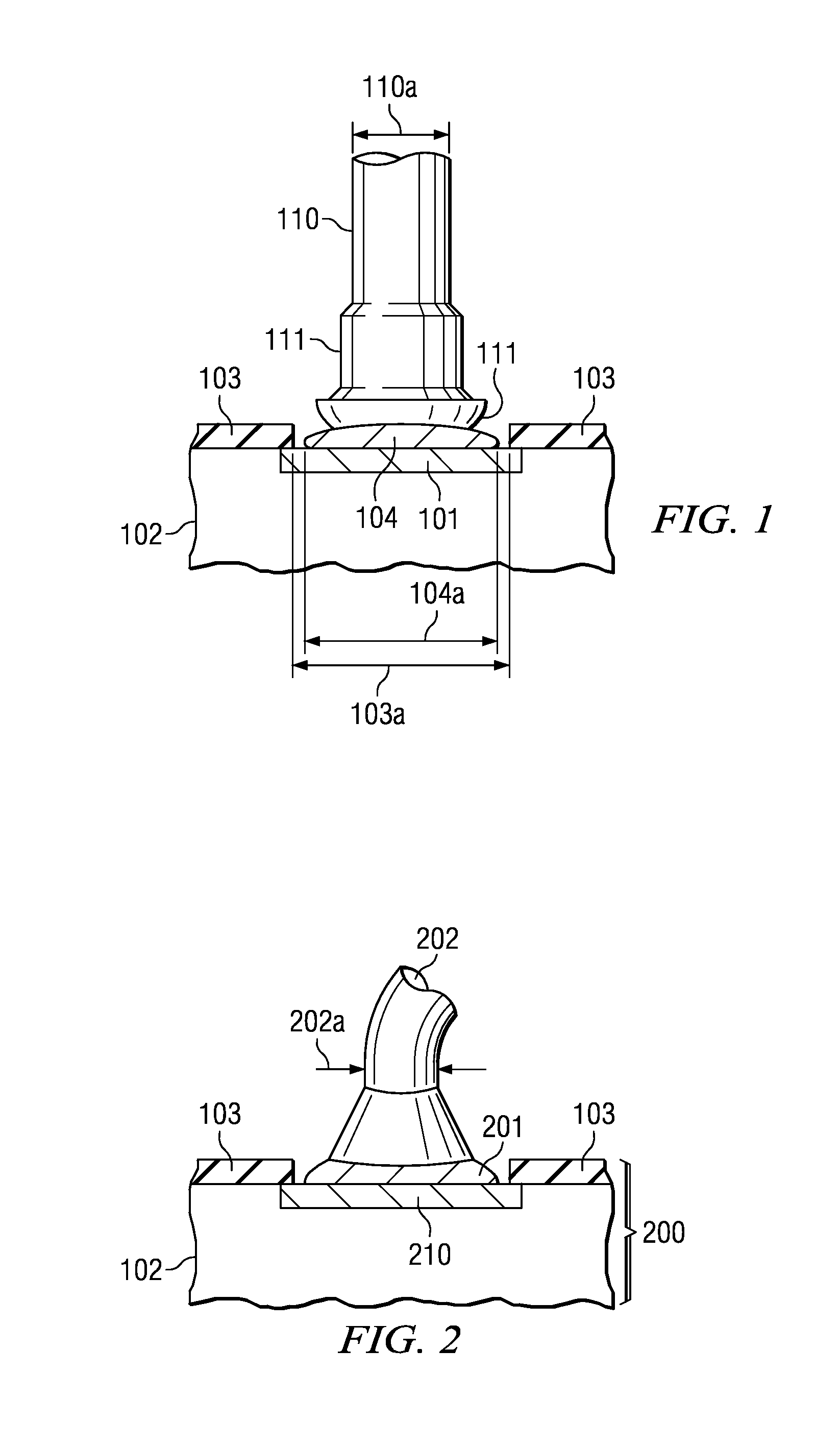

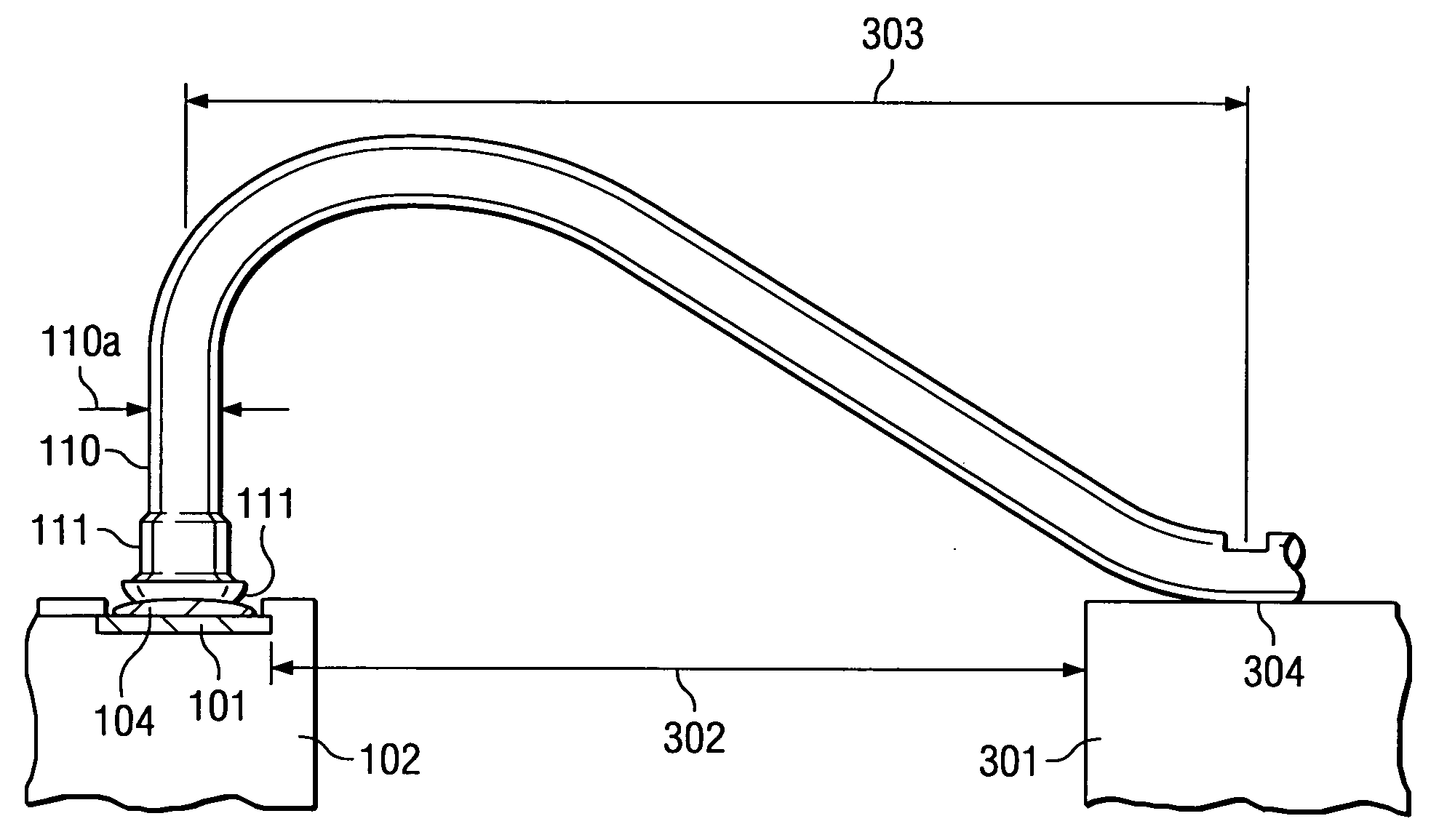

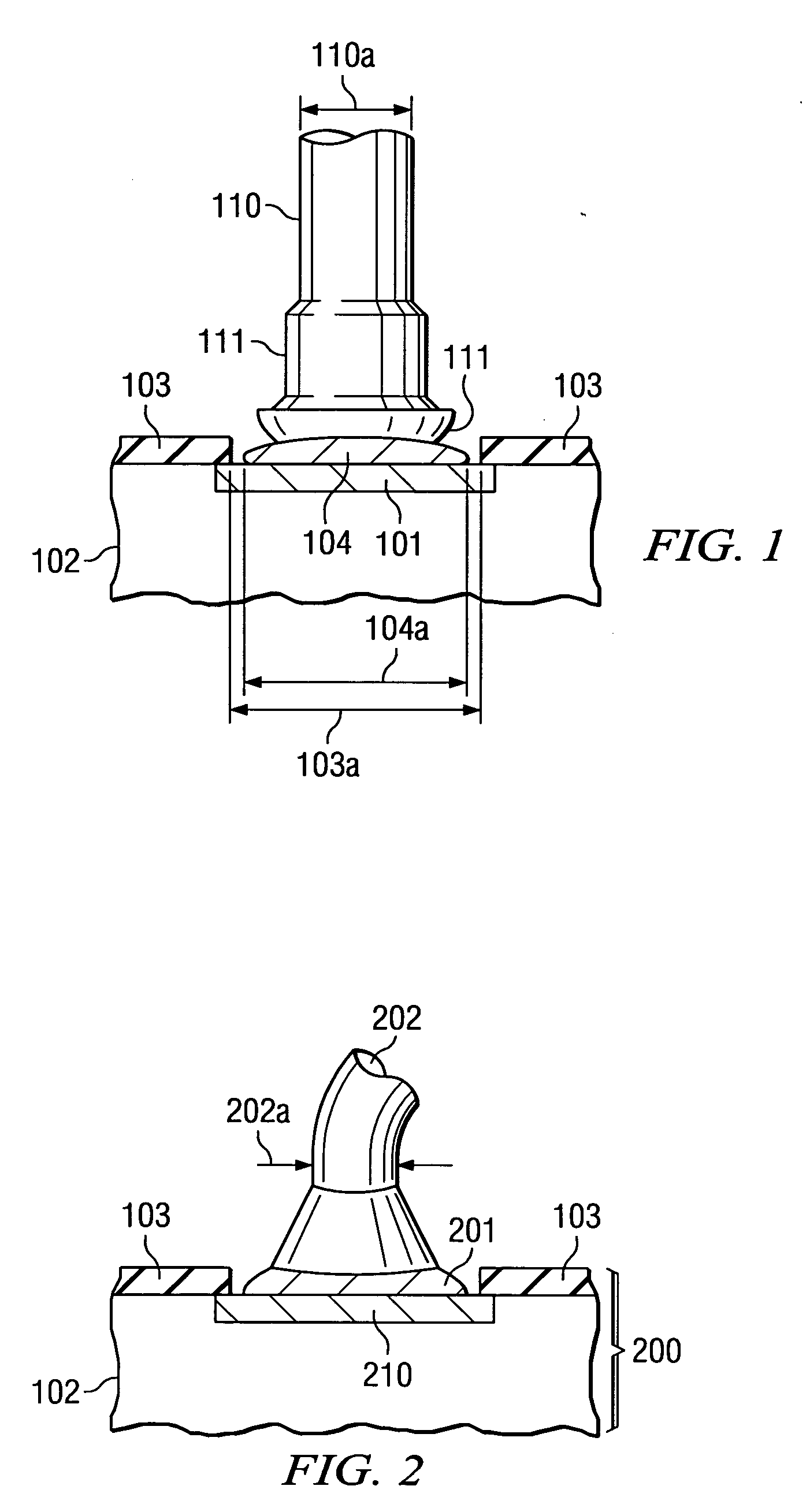

Wire bonds having pressure-absorbing balls

ActiveUS7404513B2Lift restrictionsRisk minimizationSoldering apparatusSolid-state devicesWire rodGold alloys

A semiconductor device with a chip having at least one metallic bond pad (101) over weak insulating material (102). In contact with this bond pad is a flattened metal ball (104) made of at least 99.999% pure metal such as gold, copper, or silver. The diameter (104a) of the flattened ball is less than or equal to the diameter (103a) of the bond pad. A wire (110) is connected to the bond pad so that the wire has a thickened portion (111) conductively attached to the flattened metal ball. The wire is preferably made of composed metal such as gold alloy. The composition of the flattened ball is softer than the wire. This softness of the flattened ball protects the underlying insulator against damage caused by pressure or stress, when the composed ball is attached.

Owner:TEXAS INSTR INC

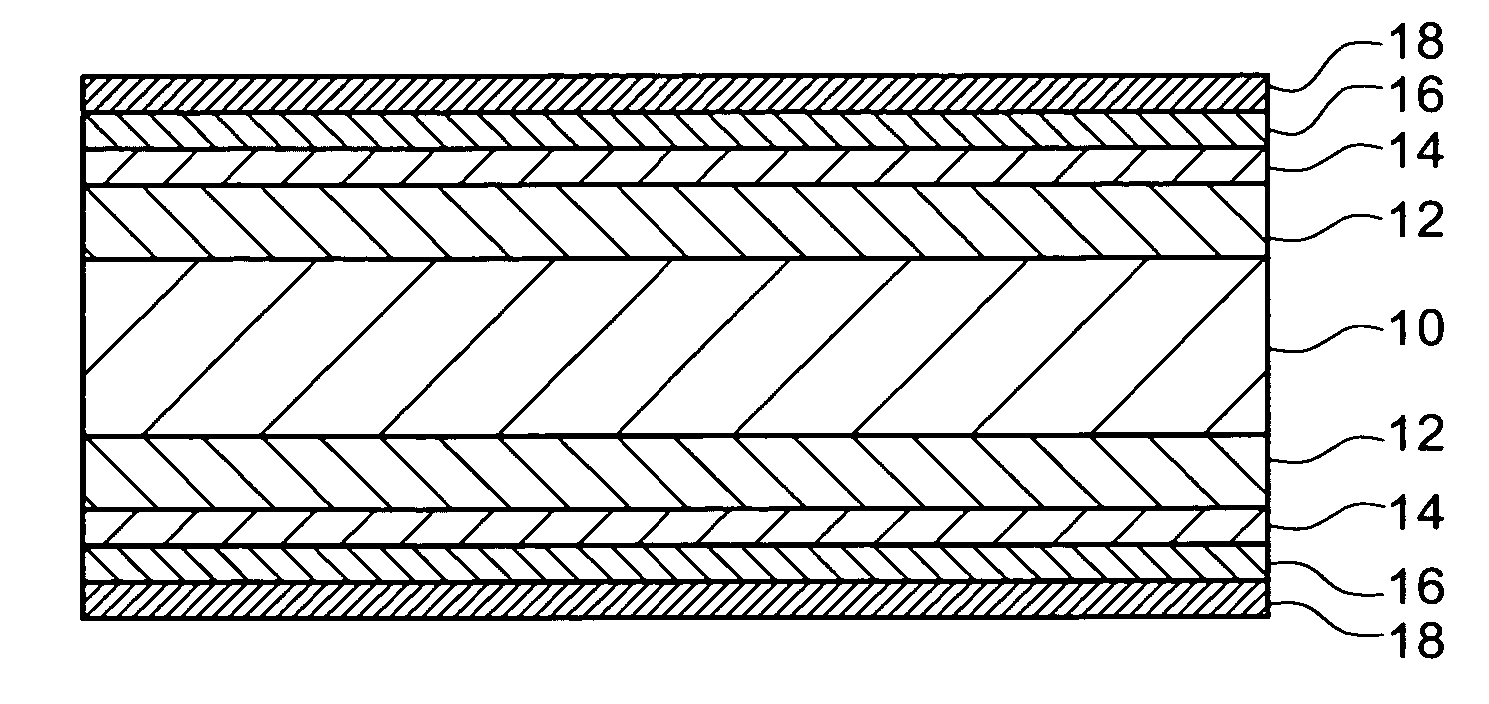

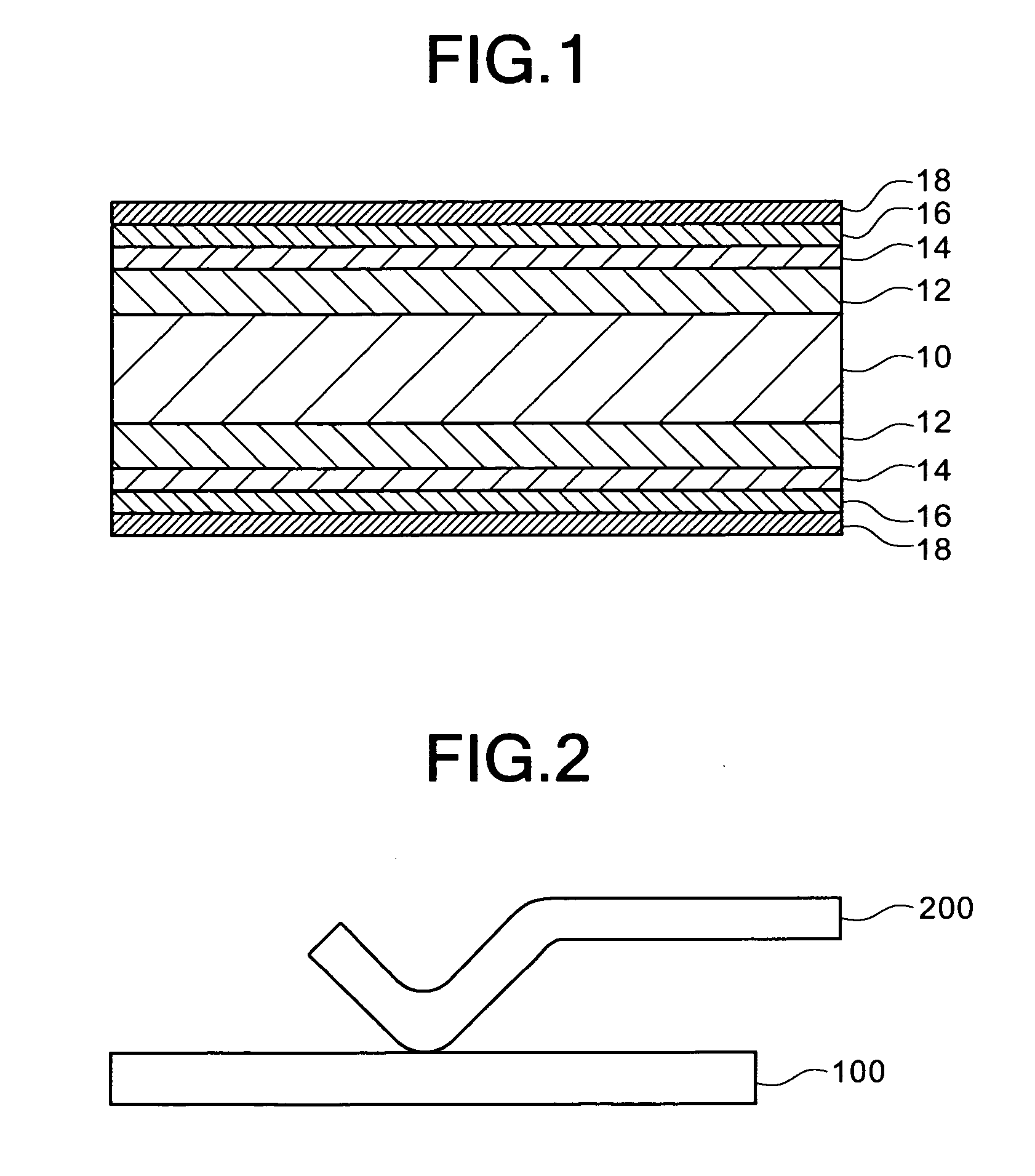

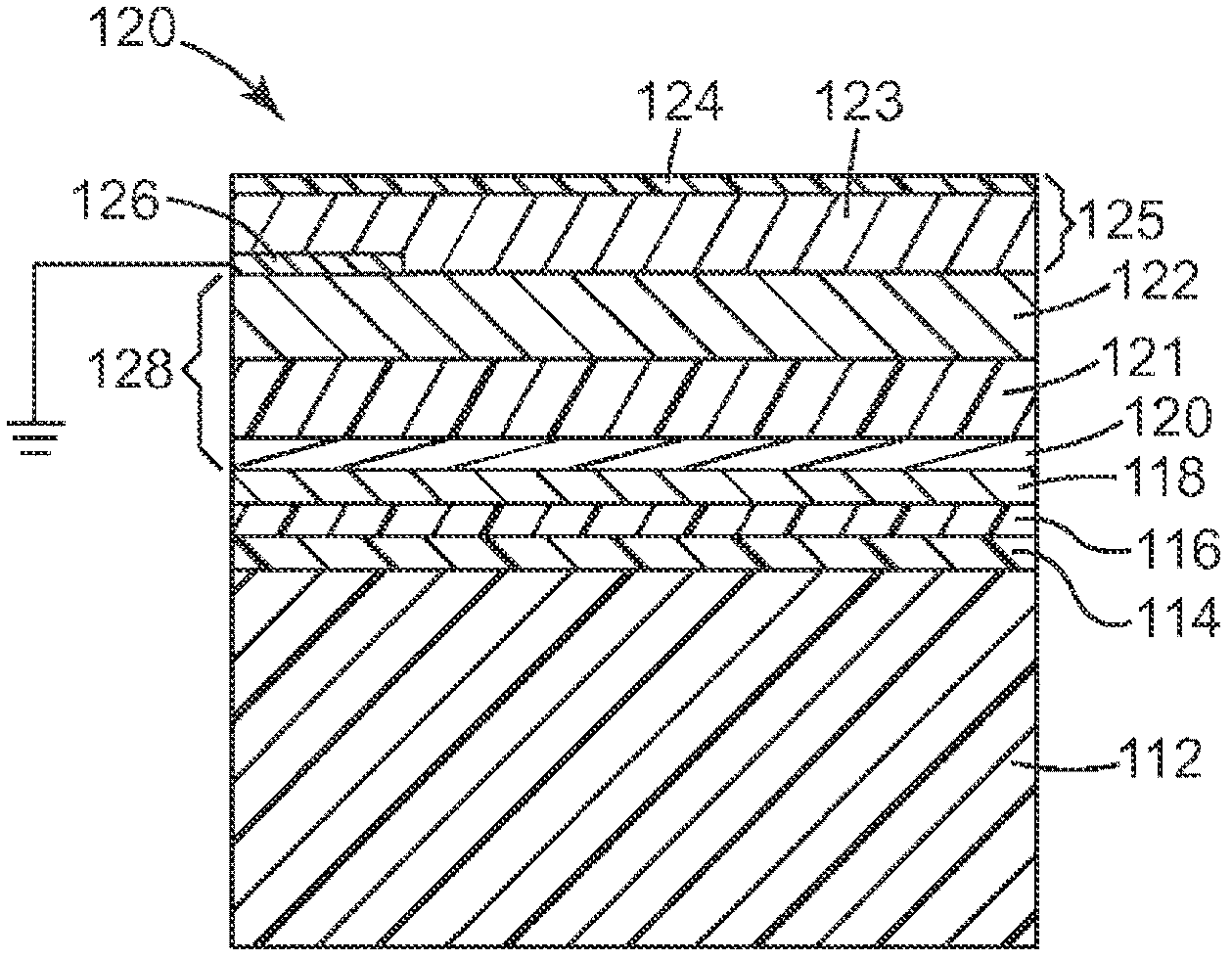

Process for forming optically clear conductive metal or metal alloy thin films and films made therefrom

ActiveCN102474999ASufficient conductivityGood EMI shielding performanceMagnetic/electric field screeningVacuum evaporation coatingMetal alloyGold alloys

A process of forming optically clear conductive metal or metal alloy thin films is provided that includes depositing the metal or metal alloy film on a polycrystalline seed layer that has been deposited directly on a nucleation layer of metal oxide comprising zinc oxide. Also conductive films made by this process are provided. In some embodiments, the metal alloy thin films include silver / gold alloys.

Owner:3M INNOVATIVE PROPERTIES CO

Method for preparing corrosion and abrasion resisting coating through supersonic electric arc spraying

The invention discloses a method for preparing a corrosion and abrasion resisting coating through supersonic electric arc spraying. The method comprises the following steps that a matrix is subjected to surface roughening, and impurities on the surface of the matrix are removed; a surface roughness tester is used for carrying out quality inspection on a sprayed part of the matrix; an abrasion-proof material such as monel alloy or cobalt-gold alloy or nickel-tungsten alloy or a composite hard material is selected; supersonic electric arc spraying is carried out on the sprayed part of the matrix to prepare the metal coating, wherein the spraying speed ranges from 300 m / s to 400 m / s; and low surface energy matter is sprayed on the coating, drying is carried out at the temperature ranging from 800 DEG C to 1,200 DEG C, and the corrosion and abrasion resisting coating is prepared, wherein the hardness of the coating is HV397, the coating is of a layer texture structure, the void ratio of the coating ranges from 0.9% to 2.3%, and the average particle size of spraying particles is 4.32 micrometers. The obtained coating is better in bonding strength, lower in void ratio, more uniform in compactness, free of deformation of the sprayed matrix and very high in corrosion and abrasion resistance.

Owner:焦作安泰新型耐磨材料有限公司

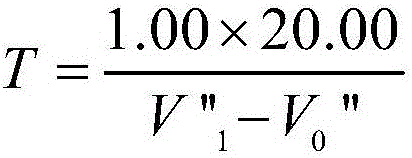

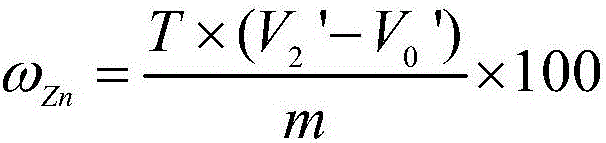

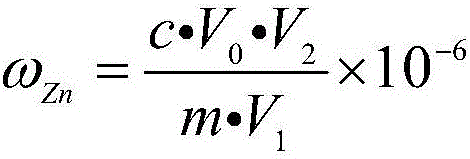

Determination method of zinc in gold alloy

ActiveCN106198854AAccurate determination of contentSuitable for large batch analysisChemical analysis using titrationColor/spectral properties measurementsSodium acetateHydrazine compound

The invention relates to a determination method of zinc in gold alloy, and belongs to a determination method of amount of zinc in gold alloy. The method comprises the following steps: aqua regia is used for dissolving a sample material, hydrazine hydrate is used for deposition and separation gold, filtering is carried out, and filter residues are used for recycling gold; sodium hydroxide and a hydrogen peroxide solution are added into a filtrate for deposition and separation of nickel and copper, filtering is carried out, and an acetic acid-sodium acetate buffer solution is added into the filtrate; xylenol orange is used as an indicator, EDTA is used for titration till the color of the solution changes into luminous yellow from wine red, and the titration volume is used for calculating the content of zinc; hydrochloric acid is added into the filter residue for dissolving, volumetric flask is prepared, the amount of zinc is determined by an atomic absorption spectrometer at the wavelength of 213.8nm, and sum of the zinc contents which are determined by the two determination methods is the content of the zinc in the alloy. The method can be used for accurately determining the content of zinc in the gold alloy, and is suitable for analysis on a large scale, at the same time the method fills the blank of determination methods of zinc in gold alloy.

Owner:SHENZHEN JINZHI GOLD&SILVER JEWELLERY INSPECTION RES CENT CO LTD

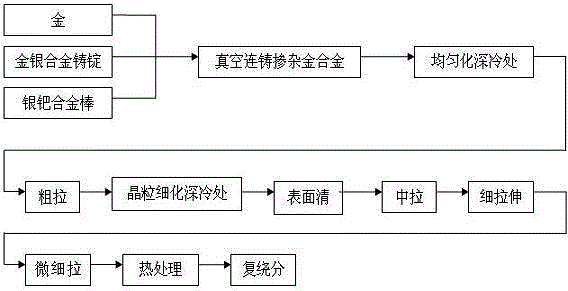

Alloy-doped gold bonding wire and cryogenic-treatment preparation method thereof

The invention relates to an alloy-doped gold bonding wire and a cryogenic-treatment preparation method thereof. The alloy-doped gold bonding wire formed by using high-purity gold as a main ingredient and being doped with high-purity silver and high-purity palladium, which is provided by the invention, is prepared from the following ingredients in percentages by weight: 60 to 80 percent of gold, 0.5 to 3.5 percent of palladium and the balance of silver. A bonding wire product has favorable oxidation resistance; an appearance is basically golden; the performance of the product is approximate to that of a pure-gold bonding wire; and the alloy-doped gold bonding wire is suitable for IC (Integrated Circuit) and COB (Chip On Board) encapsulation and high-end LED (Light-Emitting Diode) encapsulation. During the bonding of encapsulation, any gas shield is not needed; and in comparison with a gold bonding wire, the cost of the product is only approximately 3 / 5 to 4 / 5 of that of the gold bonding wire. In the preparation process of the product, the cryogenic treatment is carried out on a bonding wire twice; the arrangement of internal crystal textures of a material is improved; the physical properties of the material are enhanced; and the bonding properties of the alloy-doped gold bonding wire is improved. When the product is used for downstream encapsulation and wire bonding modes are BSOB (Bond Stitch On Ball) and BBOS (Bond Ball On Stitch), a wire stock and a ball are guaranteed to be eutectic.

Owner:河北乐通金属材料有限公司

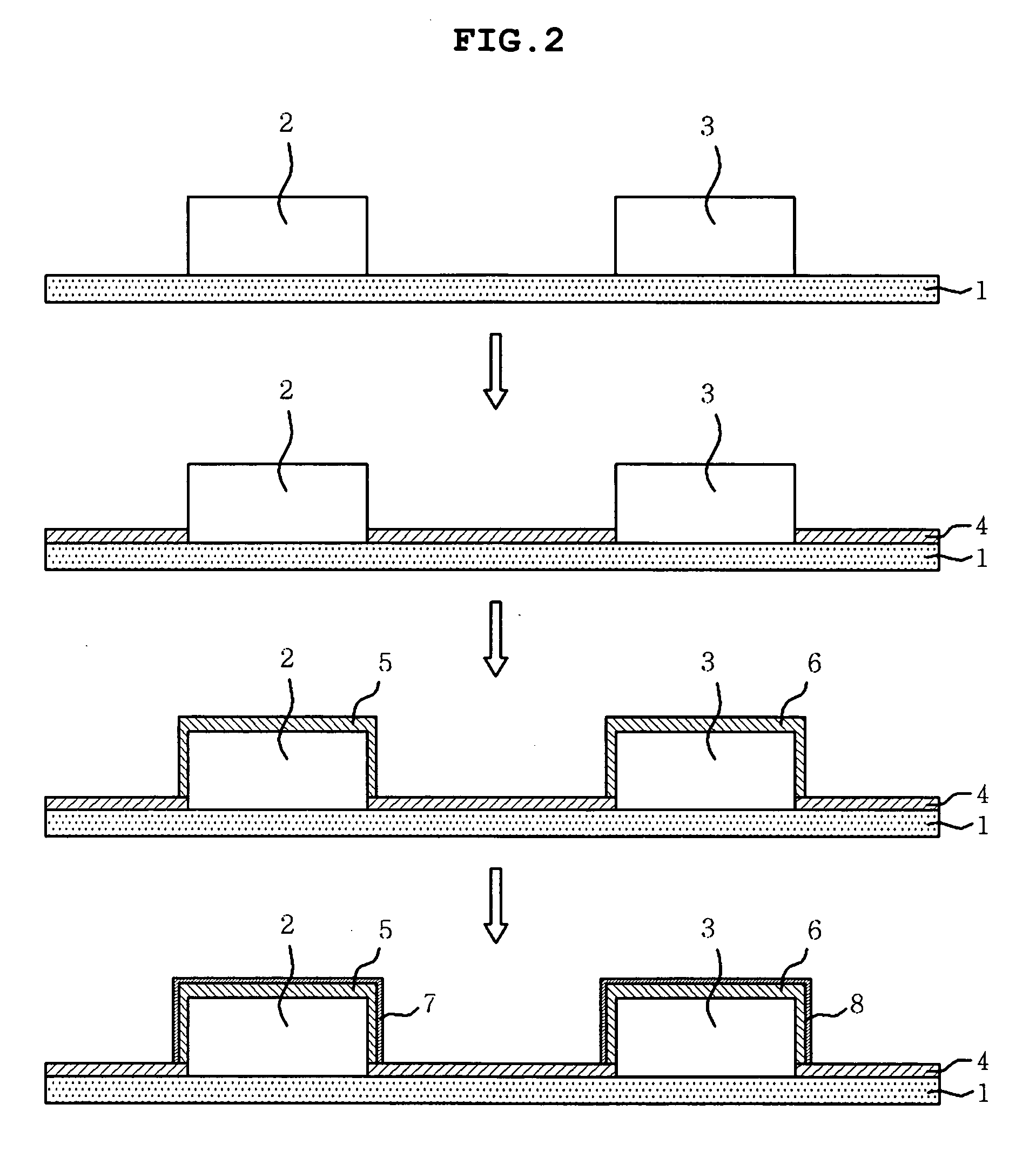

Lead frame and method for manufacturing the same

InactiveUS8564107B2Reduce thicknessLow costSemiconductor/solid-state device detailsSolid-state devicesCopper platingGold alloys

A lead frame comprises: a base metal layer; a copper plating layer, including one of a copper layer and an alloy layer including a copper, configured to plate the based metal layer to make a surface roughness; and an upper plating layer, including at least one plating layer including at least one selected from the group of a nickel, a palladium, a gold, a silver, a nickel alloy, a palladium alloy, a gold alloy, and a silver alloy, configured to plate the copper plating layer.

Owner:ALS

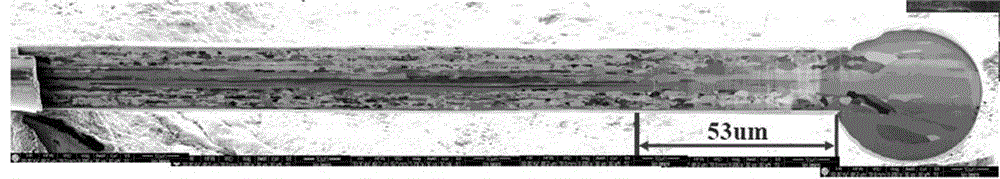

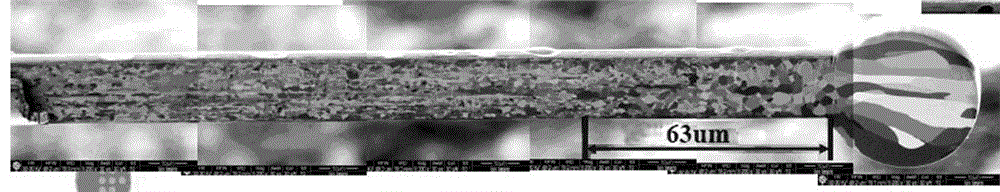

Gold alloy bonding wire and manufacturing method thereof

ActiveCN105908002ALow costShorten the lengthSemiconductor/solid-state device detailsSolid-state devicesGold alloysCerium

A gold alloy bonding wire comprises, by weight, 1-1.5% of palladium, 20-24% of silver, 2-200ppm of one or a combination comprising two or more of calcium, beryllium and cerium, and the balance of gold. The invention also provides a manufacturing method of the gold alloy bonding wire. The gold alloy bonding wire can be used in IC and LED packaging, and has excellent integral wiring performances, and the excellent integral wiring performances are characterized in that the length of heated affected zone is small (can reach 53-60[mu]m), and the wiring camber is greatly reduced; the performances of ignition balls are good, a moderate quantity of symmetric cylindrical crystals are obtained after FAB ball ignition, and the roundness of deformed balls is high; and packaged products have good heat shock resistance and high reliability.

Owner:NICHE TECH KAISER SHANTOU

An acidic gold alloy plating solution

The invention relates to a acid gold alloy plating liquid and a plating method thereof, and provides a gild liquid with high sediment selectivity. The gild liquid contains auroc cyanide, Co ions, formamine and special brightener.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Method for optimizing strength of thousand pure gold jewellery and gold alloy material

The invention relates to a method for optimizing strength of thousand-pure gold jewellery and a gold alloy material in the technical field of gold manufacturing. The method comprises the following steps of: firstly mixing micro alloyed calcium element and rare earth element, matching high-purity gold, and carrying out intermediate alloy smelting by adopting a vacuum induction smelting method, thus an intermediate alloy is obtained; then carrying out secondary smelting on the intermediate alloy mixed with the high-purity gold, and finally adding a grain refining element, cooling, and solidifying, thus strength optimization is realized, and the obtained finished product comprises the following components: 99.90-99.91% of gold element, 0.07-0.08% of calcium element, 0.005-0.01% of rare earthelement and 0.008-0.010% of grain refining element. By applying the method provided by the invention, the strength of the thousand-pure gold is improved, and the thousand-pure gold can be guaranteed to reach 24K, namely the gold content is not less than 99.9%, thus gold alloy material containing new component can be prepared, and the gold alloy material and is applicable to high-strength thousand-pure gold material used for gold jewellery processing.

Owner:SHANGHAI LAOFENGXIANG

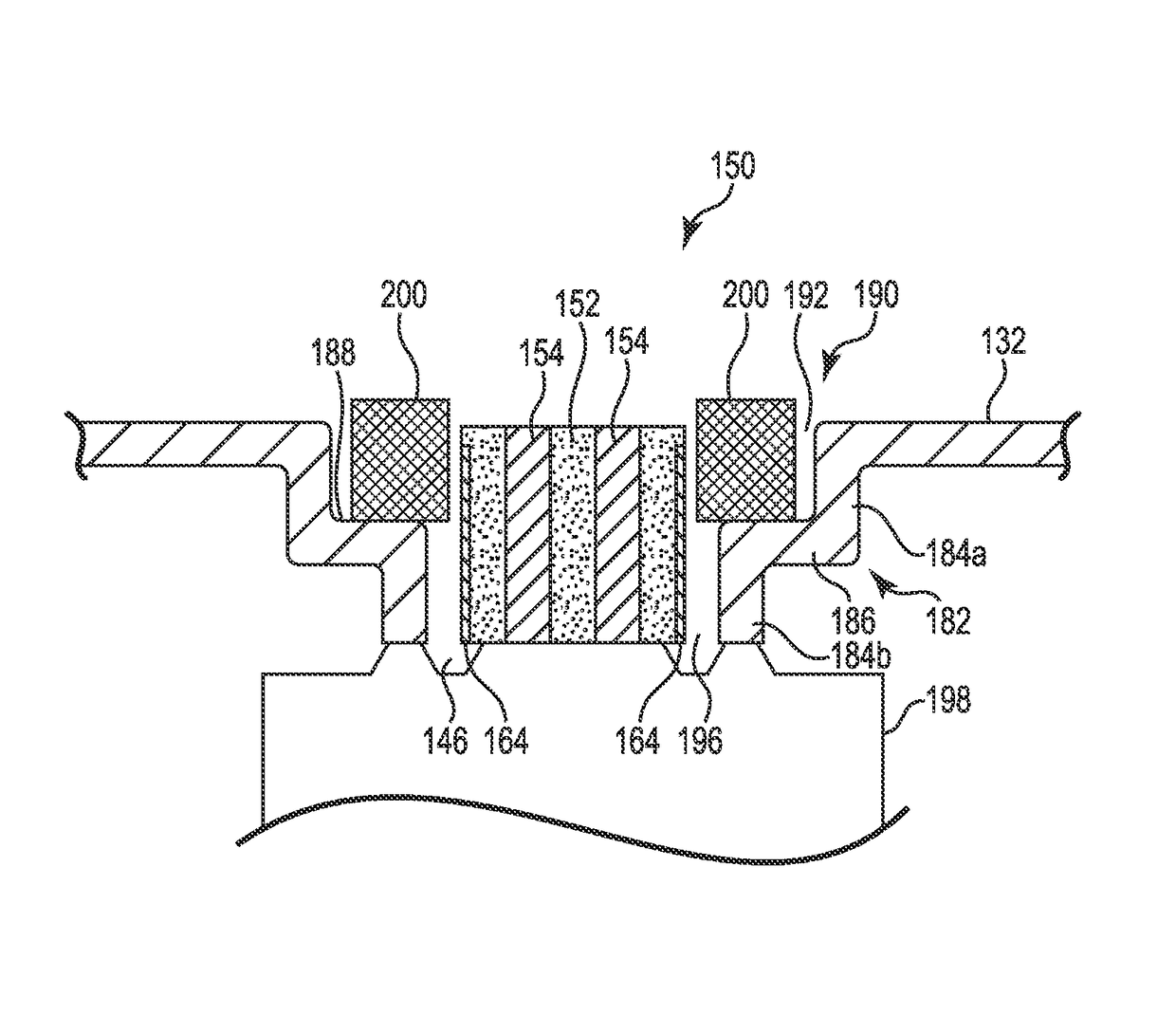

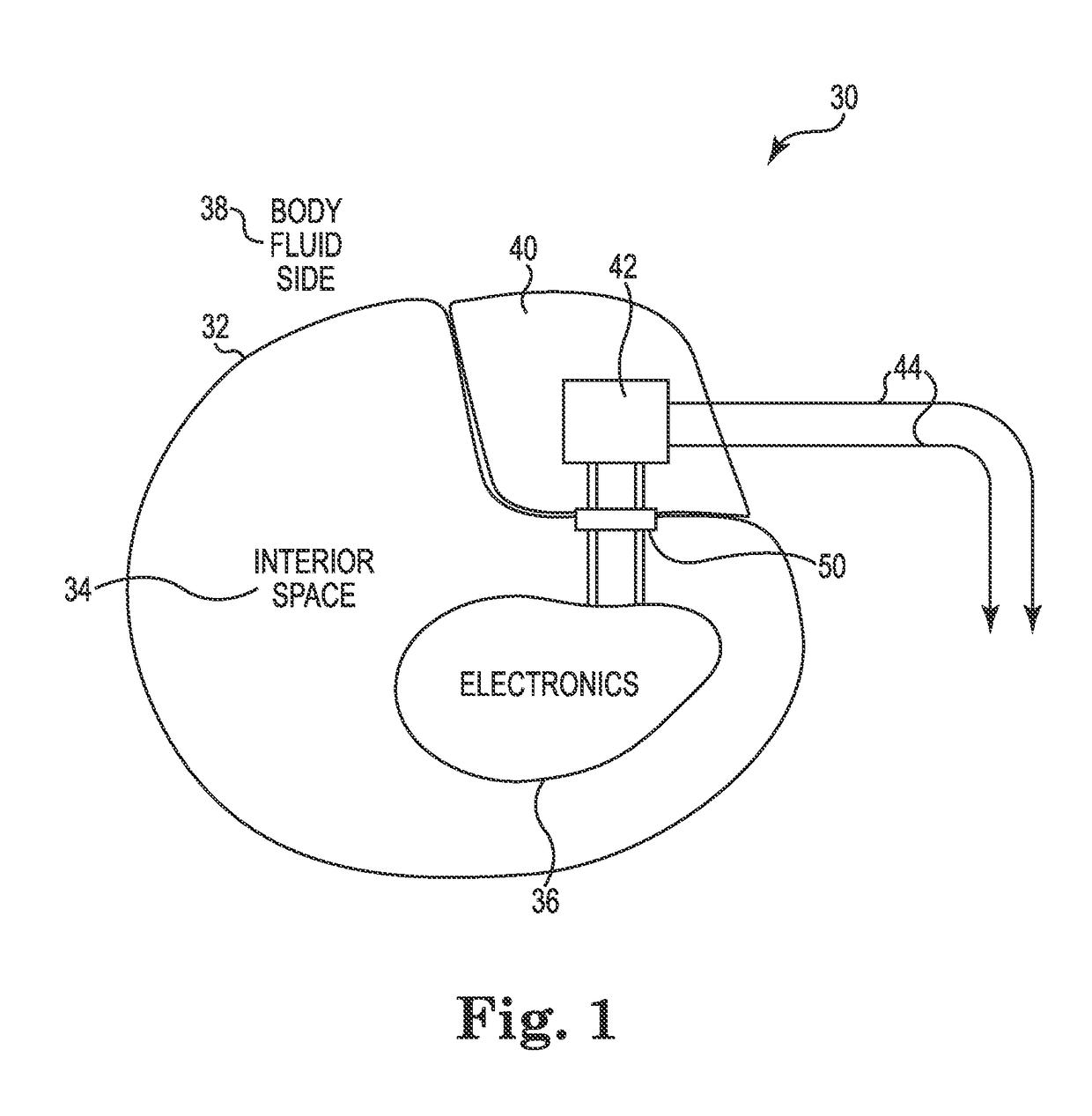

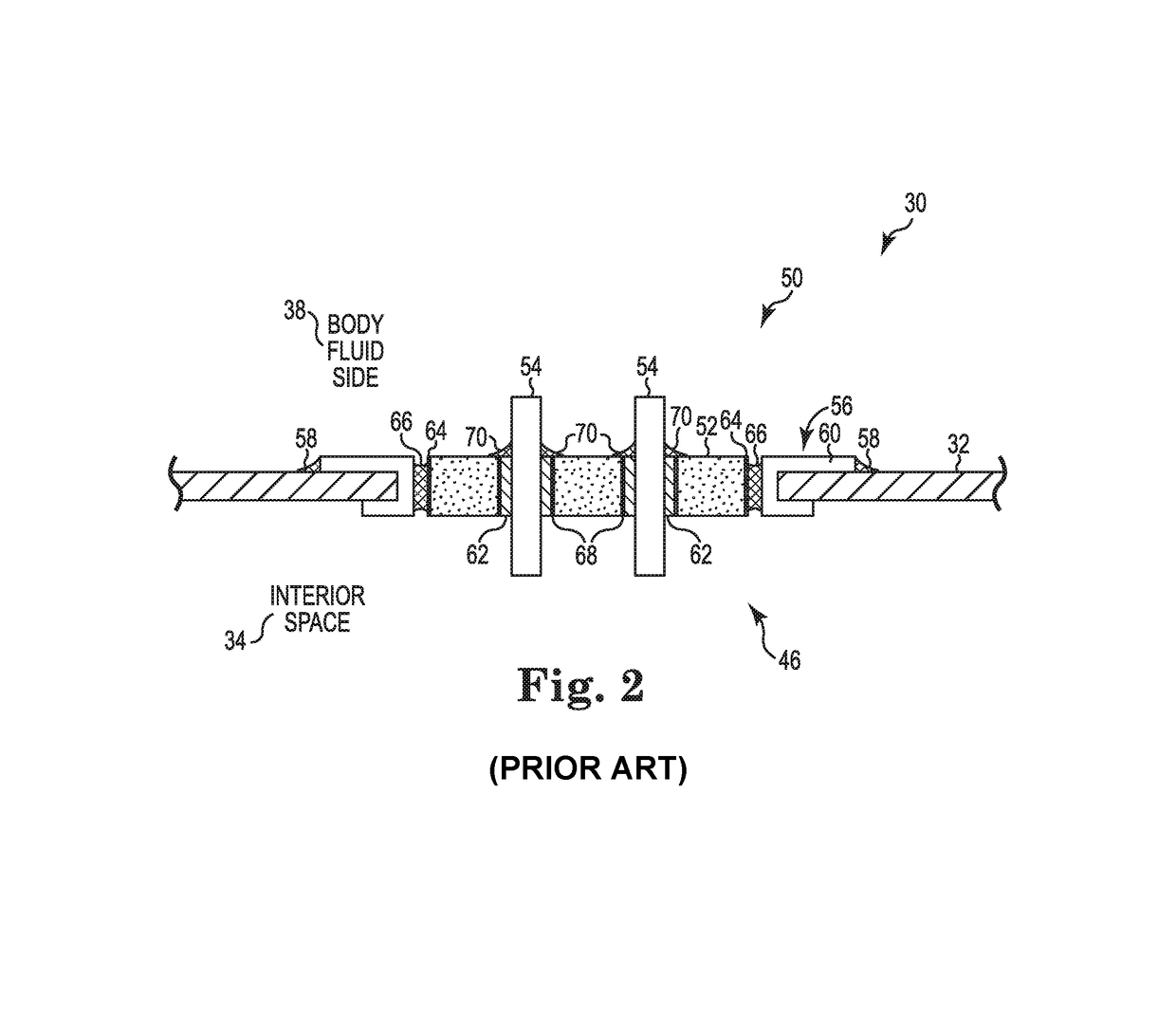

Direct integration of feedthrough to implantable medical device housing using a gold alloy

One aspect provides a method of attaching a feedthrough to a titanium housing of an implantable medical device. The method includes providing the housing with a flange forming a recess about an opening through the housing, the opening disposed within the recess. A feedthrough is positioned within the recess so as to form a gap between the flange and an insulator of the feedthrough. A braze preform is then positioned within the recess about the insulator, the braze preform comprising a biocompatible braze material having a melting point less than a β-transus temperature of the titanium of the housing. The preform is melted at a temperature less than the β-transus temperature of the titanium of the housing such that the melted braze material fills at least the gap, and then cooled to form a braze joint which bonds the insulator to the housing and hermetically seals the opening.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

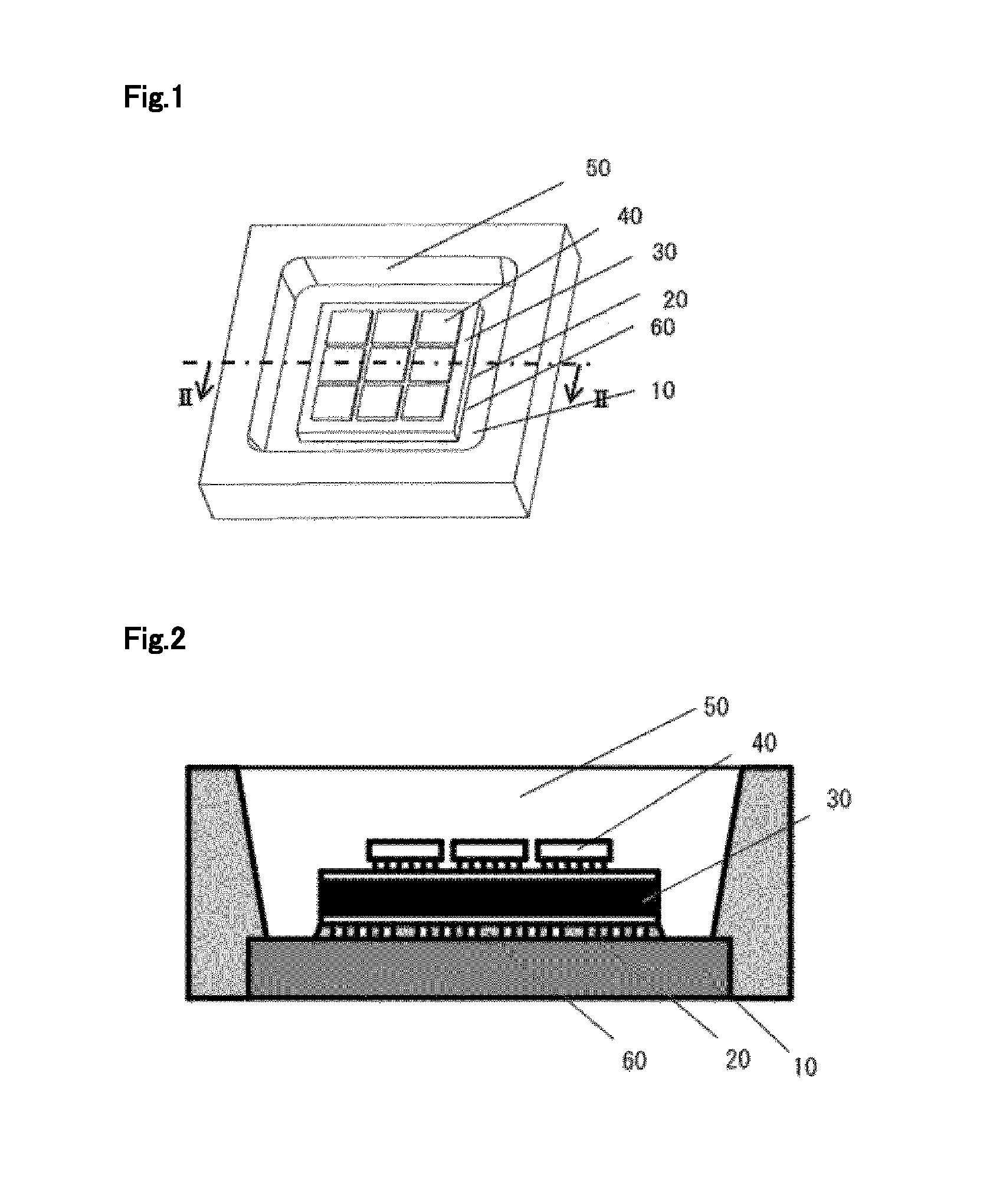

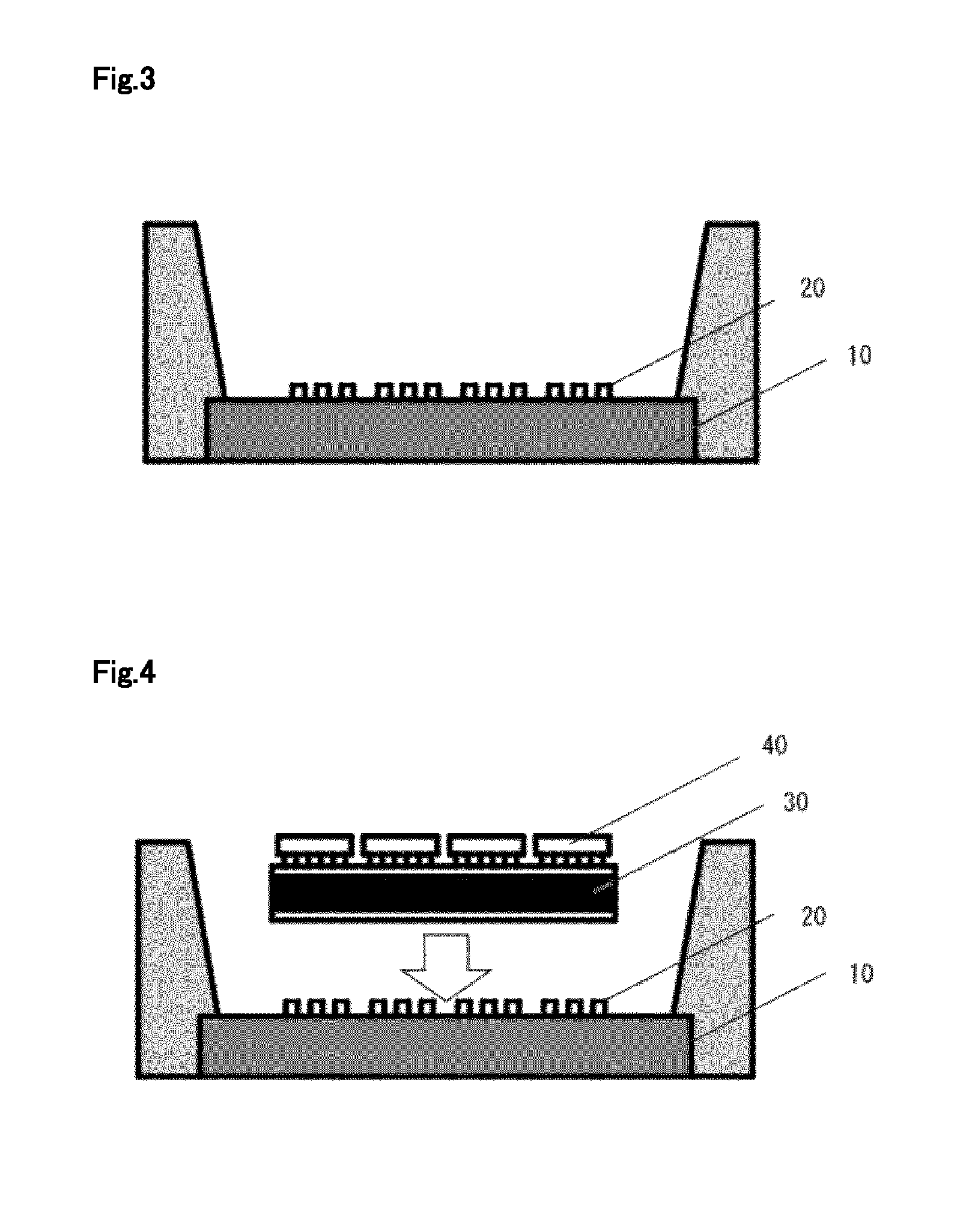

Light source, method for manufacturing the light source, and method for mounting the light source

ActiveUS20160093786A1High bonding strengthSolid-state devicesSemiconductor/solid-state device manufacturingGold alloysOptoelectronics

A light source includes a light emitting element configured to emit a light; a mounting substrate; and a ceramic substrate having a light emitting element mounted thereon and being bonded to the mounting substrate via a plurality of metal bumps made of gold, copper, a gold alloy, or a copper alloy. A method of manufacturing a light source includes forming a plurality of metal bumps on a mounting substrate; providing a ceramic substrate having at least one light emitting element mounted thereon; and bonding the mounting substrate and a ceramic substrate to each other via the metal bumps.

Owner:NICHIA CORP

Wire bonds having pressure-absorbing balls

ActiveUS20060144907A1Lift restrictionsRisk minimizationSoldering apparatusSolid-state devicesWire rodDevice material

A semiconductor device with a chip having at least one metallic bond pad (101) over weak insulating material (102). In contact with this bond pad is a flattened metal ball (104) made of at least 99.999 % pure metal such as gold, copper, or silver. The diameter (104a) of the flattened ball is less than or equal to the diameter (103a) of the bond pad. A wire (110) is connected to the bond pad so that the wire has a thickened portion (111) conductively attached to the flattened metal ball. The wire is preferably made of composed metal such as gold alloy. The composition of the flattened ball is softer than the wire. This softness of the flattened ball protects the underlying insulator against damage caused by pressure or stress, when the composed ball is attached.

Owner:TEXAS INSTR INC

CIGS/CdTe dual-junction laminated thin-film solar cell and preparation method thereof

ActiveCN106340554AImprove conversion efficiencyAvoid Shortwave Loss ProblemsFinal product manufacturePhotovoltaic energy generationInsulation layerGold alloys

The invention provides a CIGS / CdTe dual-junction laminated thin-film solar cell comprising a substrate, a CIGS bottom cell, a composite conductive layer and a CdTe top cell. The CIGS bottom cell consists of a cnductive electrode, a p type CIGS absorption layer and a bottom cell n type CdS buffer layer successively from bottom to top. The composite conductive layer includes a bottom cell intrinsic zinc-oxide insulating layer, a conductive connection layer and a top cell intrinsic zinc-oxide insulation layer of bottom cell successively from bottom to top. The CdTe top cell includes an N type CdS buffer layer, a p type CdTe absorbing layer and a copper gold alloy electrode successively from bottom to top. According to the invention, the narrow-band-gap bottom cell and the broad-band-gap top cell are connected by using the composite conductive layer to form a laminated cell, thereby improving the conversion efficiency of the thin-film cell. The experiment result demonstrates that the cell conversion efficiency of the CIGS / CdTe dual-junction laminated thin-film solar cell can reach 17.3%.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Palladium-silver alloy material for dental department

InactiveCN103205594AImprove corrosion resistanceGuaranteed ductilityImpression capsDentistry preparationsGold alloysMechanical property

The invention discloses palladium-silver alloy for repairing an oral cavity. Alloy ingredients are optimized by an alloy material. Compared with the prior art, the obtained material has the advantages of good mechanical property, good corrosion resistance, low sensitization, and beautiful color and luster under the premise of not reducing the alloy property and clinical use effect; and the cost is just 1 / 4 to 1 / 3 of gold alloy.

Owner:SICHUAN QIHE PRECIOUS METALS CO LTD

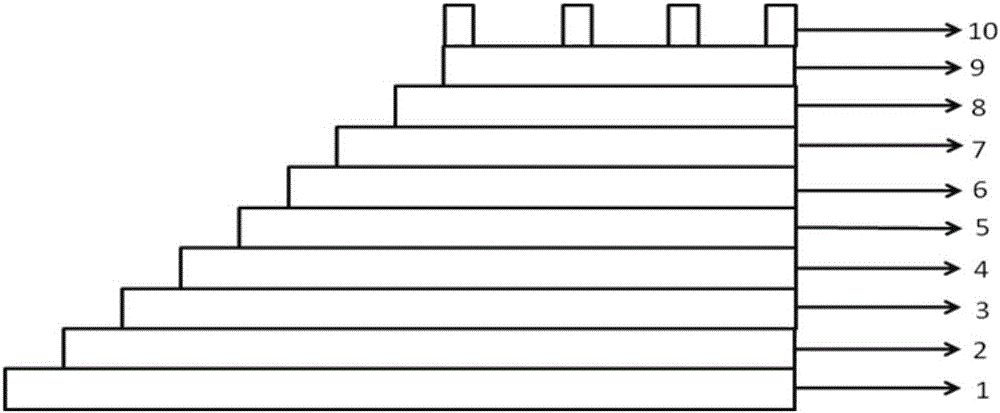

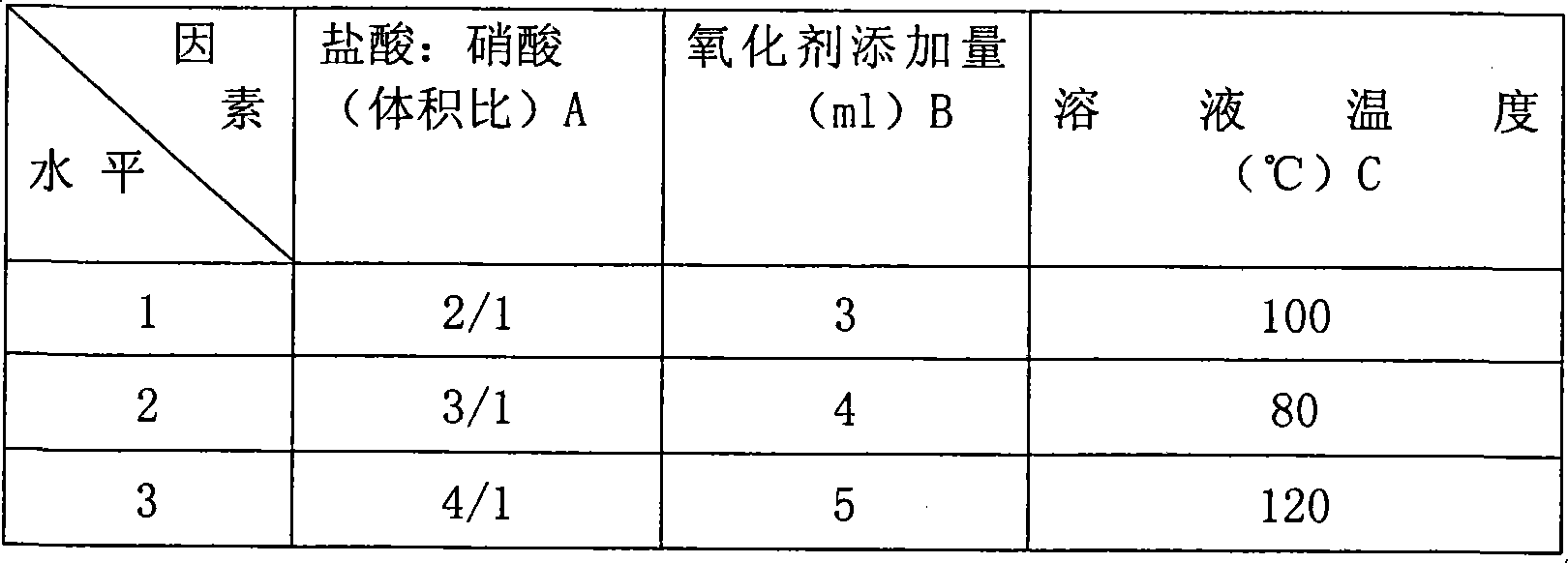

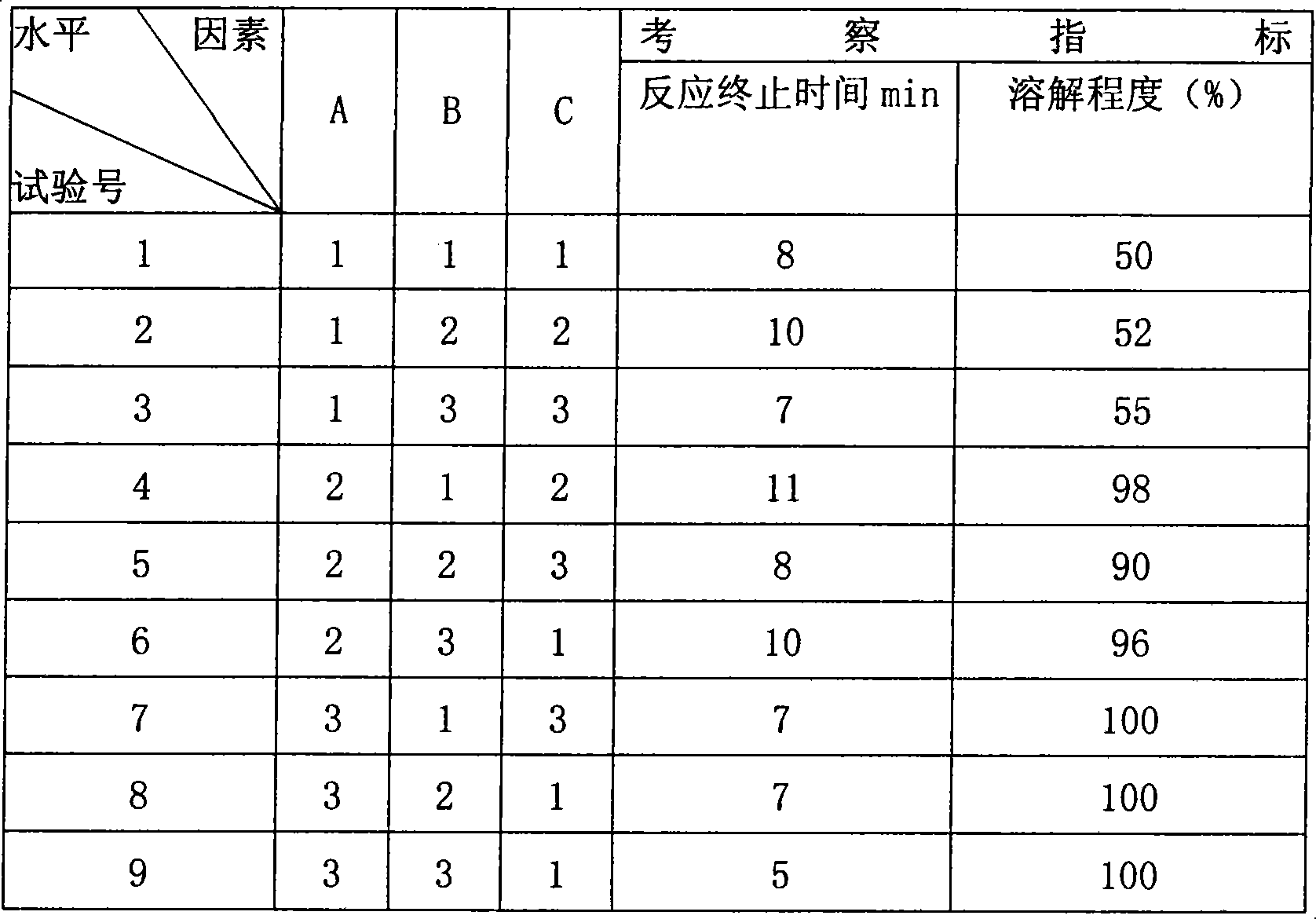

Gold base alloy chemical composition analytical method

ActiveCN101149316ASolve the problem of dissolutionImprove product qualityPreparing sample for investigationChemical methods analysisSal ammoniacChemical composition

The invention discloses a method to dissolve the gold alloy using the mixing acid of HCl and HNO3 as solvent and by adjusting temperature and adding the oxidant to analyze the chemical component precisely. It uses the AuAgNiCu22-3-1 alloy as example to descript the theory and test structure. It decomposes the AgCl by the ammonia directly and determines the component of Ag, Ni and Cu elements in AuAgNiCu22-3-1 alloy solution by the air-acetylene lean fuel flame atomic absorption spectrum, also after the multilevel and multifactor orthogonal test, it gets the proportion of HCl and HNO3 is 4:1. The error of the analysis method is smaller than 2%, the recovery rate is more than 95.0%; so it is an economic and quick detection method.

Owner:NANJING CHENGUANG GRP

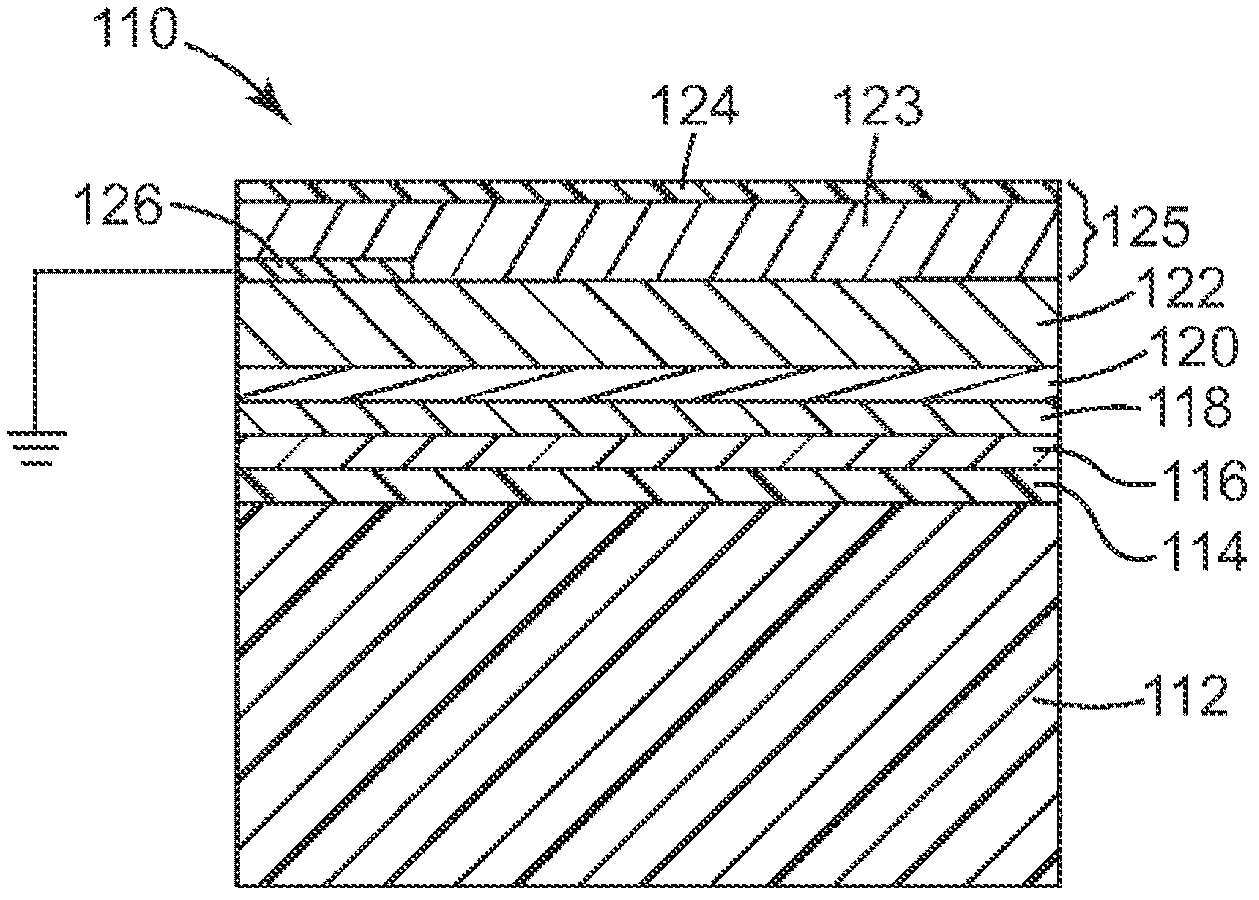

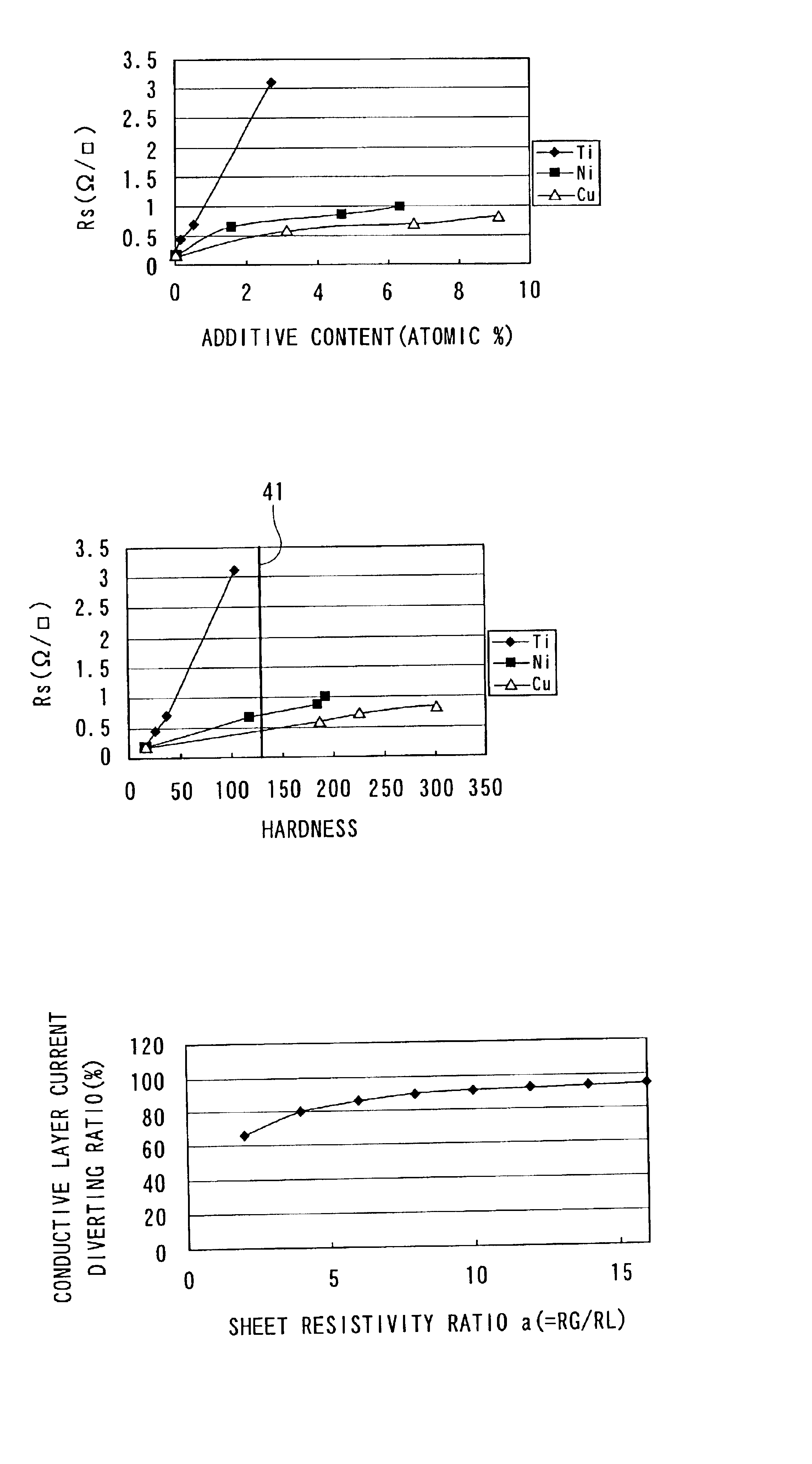

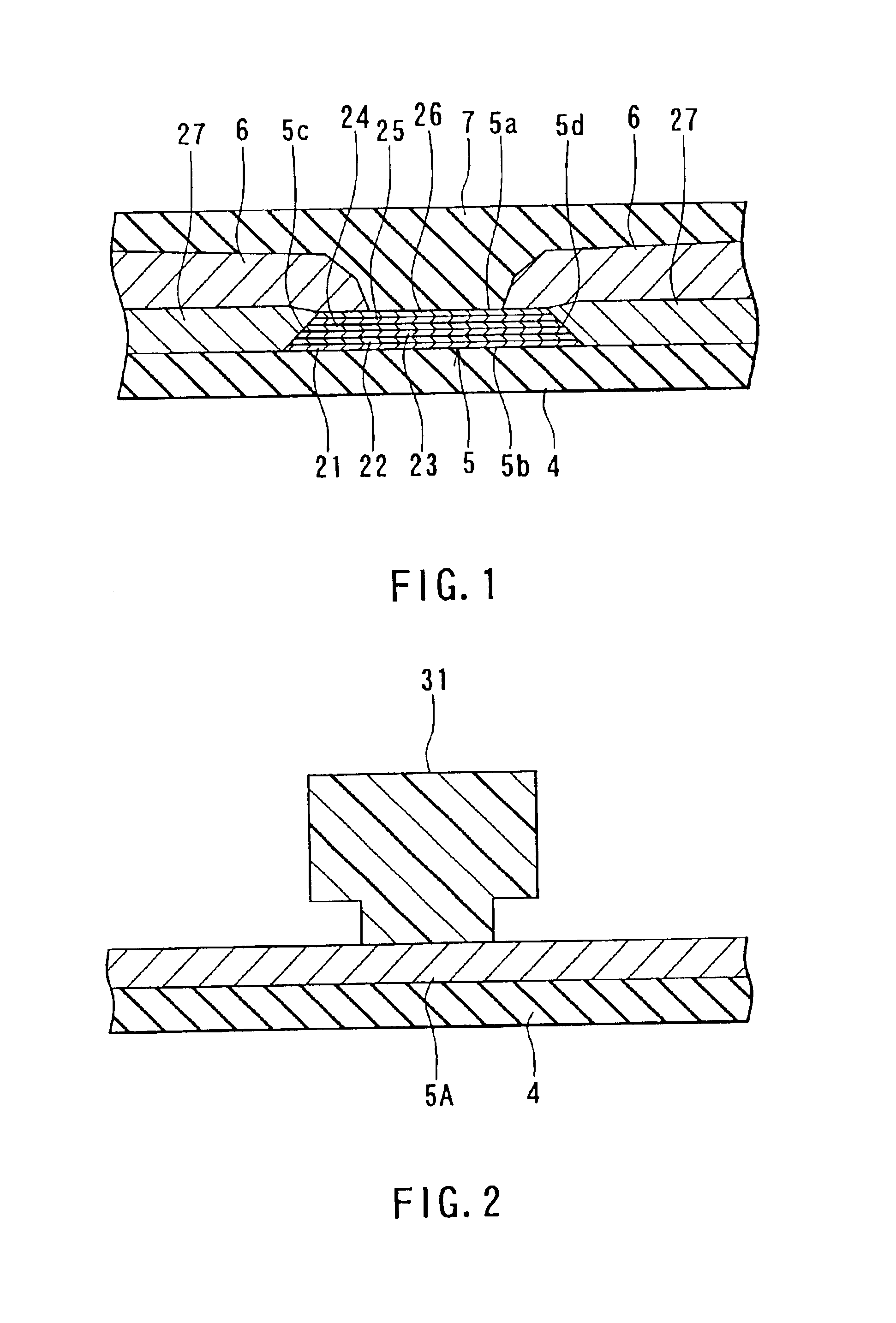

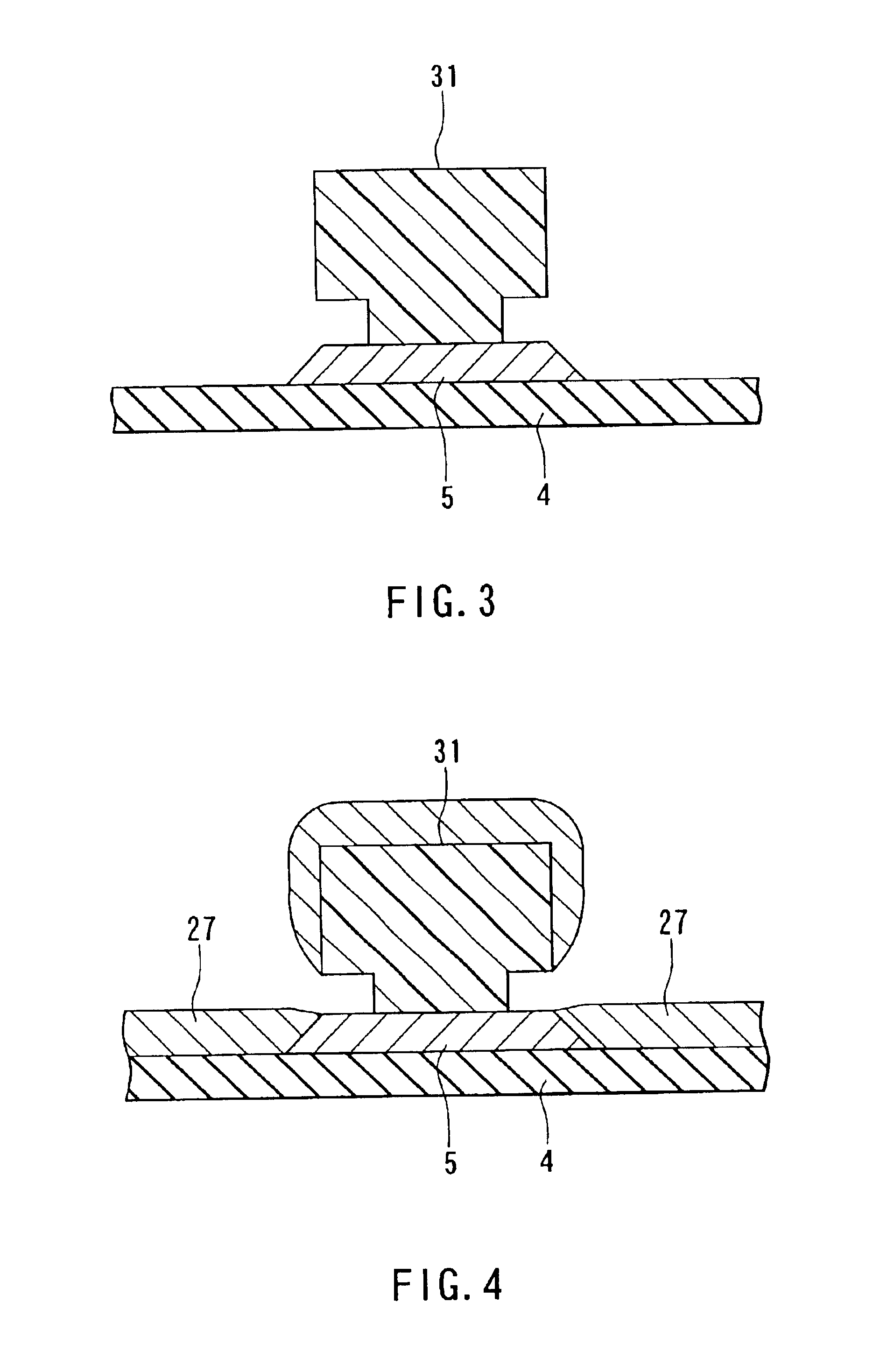

Thin-film magnetic head and method of manufacturing same, head gimbal assembly, and hard disk drive

InactiveUS6927950B2Satisfactory magnetic signal reading characteristicLower on-resistanceNanomagnetismNanoinformaticsHard disc driveBias field

A read head comprises an MR element, two bias field applying layers, and two conductive layers. The two bias field applying layers are adjacent to both side portions of the MR element, and apply a bias magnetic field to the MR element along the longitudinal direction. The two conductive layers feed a sense current to the MR element, each of the conductive layers being disposed to be adjacent to one of surfaces of each of the bias field applying layers and to overlap one of surfaces of the MR element. The conductive layers are each made of a gold alloy having a resistivity of less than 22 μΩ·cm and a hardness as high as or higher than the hardness of a material used for making the bias field applying layers.

Owner:TDK CORPARATION

Copper bonding or superfine wire with improved bonding and corrosion properties

InactiveCN101138086ASemiconductor/solid-state device detailsSolid-state devicesCopper wireGold alloys

A bonding or superfine wire is provided made of copper, with a gold enrichment on the surface thereof, in particular in an amount corresponding to a coating of at most 50 nm. The wire may be bonded by the ball / wedge method, has a copper-colored appearance, and the ball thereof after flame-off has a hardness of less than 95 according to HV0.002. In order to produce the bonding or superfine wire, a copper wire is coated with gold or a copper-gold alloy or gold is introduced into the surface of the copper wire. The wires are bonded to a semiconductor silicon chip.

Owner:HERAEUS MATERIALS TECHNOLOGY GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com