Ignition Device Electrode Composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

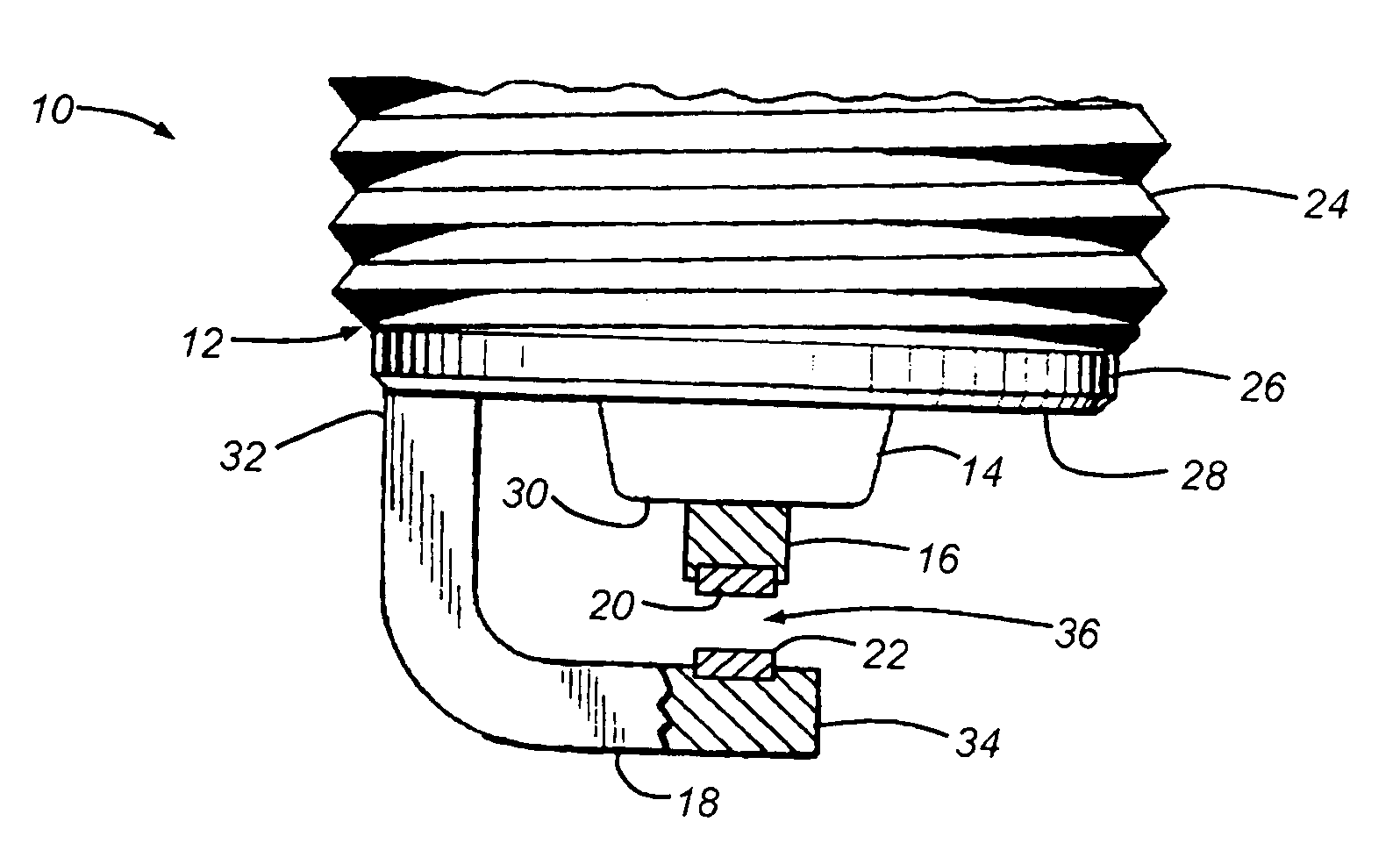

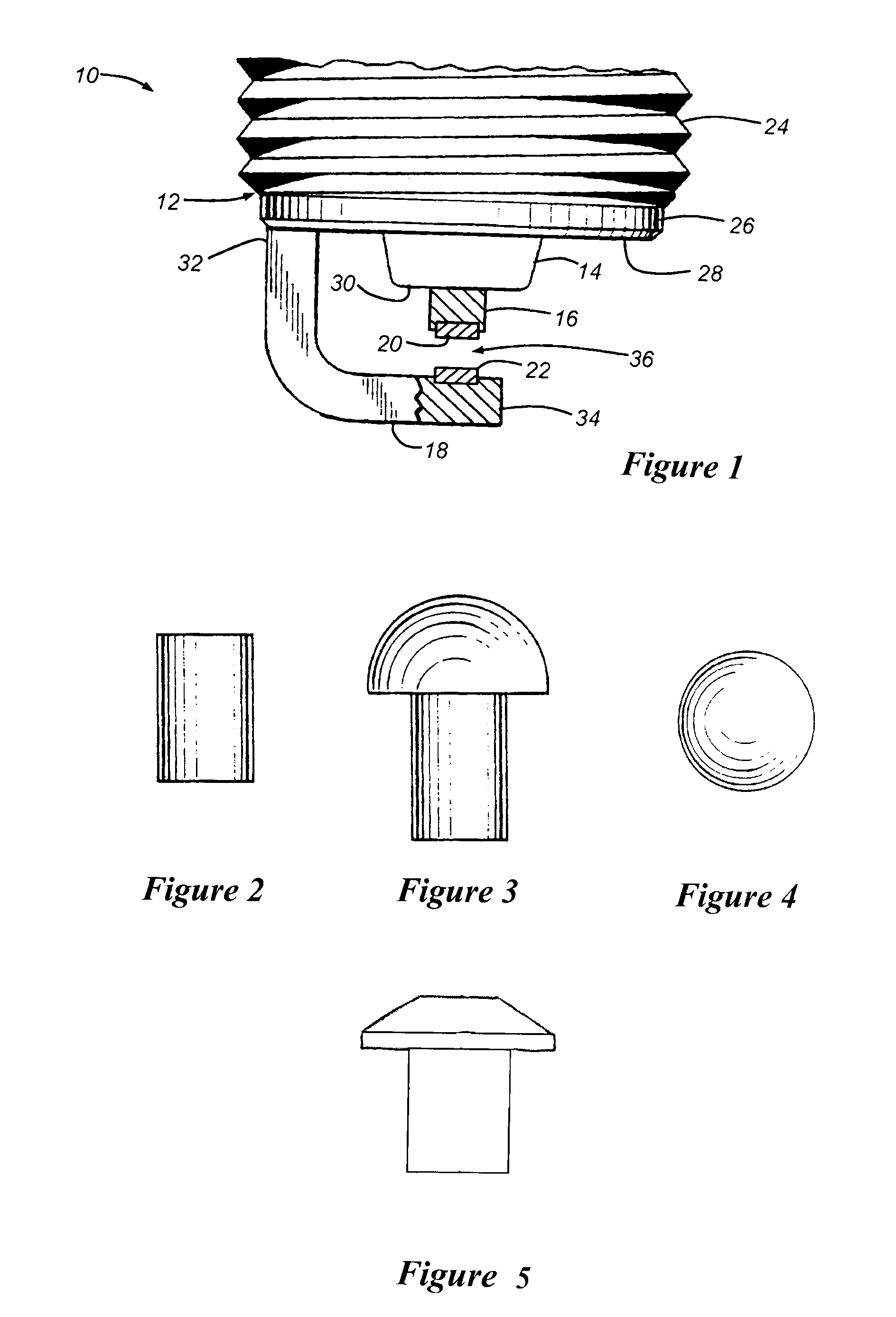

[0016]Referring to FIG. 1, there is shown the working end of an ignition device in the form of a spark plug 10 that includes an outer metal shell or housing 12, an insulator 14 secured within the housing 12, a center electrode 16, a ground electrode 18, and a pair of firing tips 20, 22 located opposite each other on the center and ground electrodes 16, 18, respectively. Housing 12 can be constructed in a conventional manner and can include standard threads 24 along with an annular lower end 26 to which the ground electrode 18 is welded or otherwise attached. Similarly, all other components of the spark plug 10 (including those not shown) can be constructed using known techniques and materials, excepting of course center electrode 16, or ground electrode 18, (or both of them) that is composed of a particularly advantageous alloy composition, as will be described below. While spark plug 10 is illustrated to include firing tips 20, 22, the alloys described herein may also be used as ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com