Multi-layer dry paint decorative laminate having discoloration prevention barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

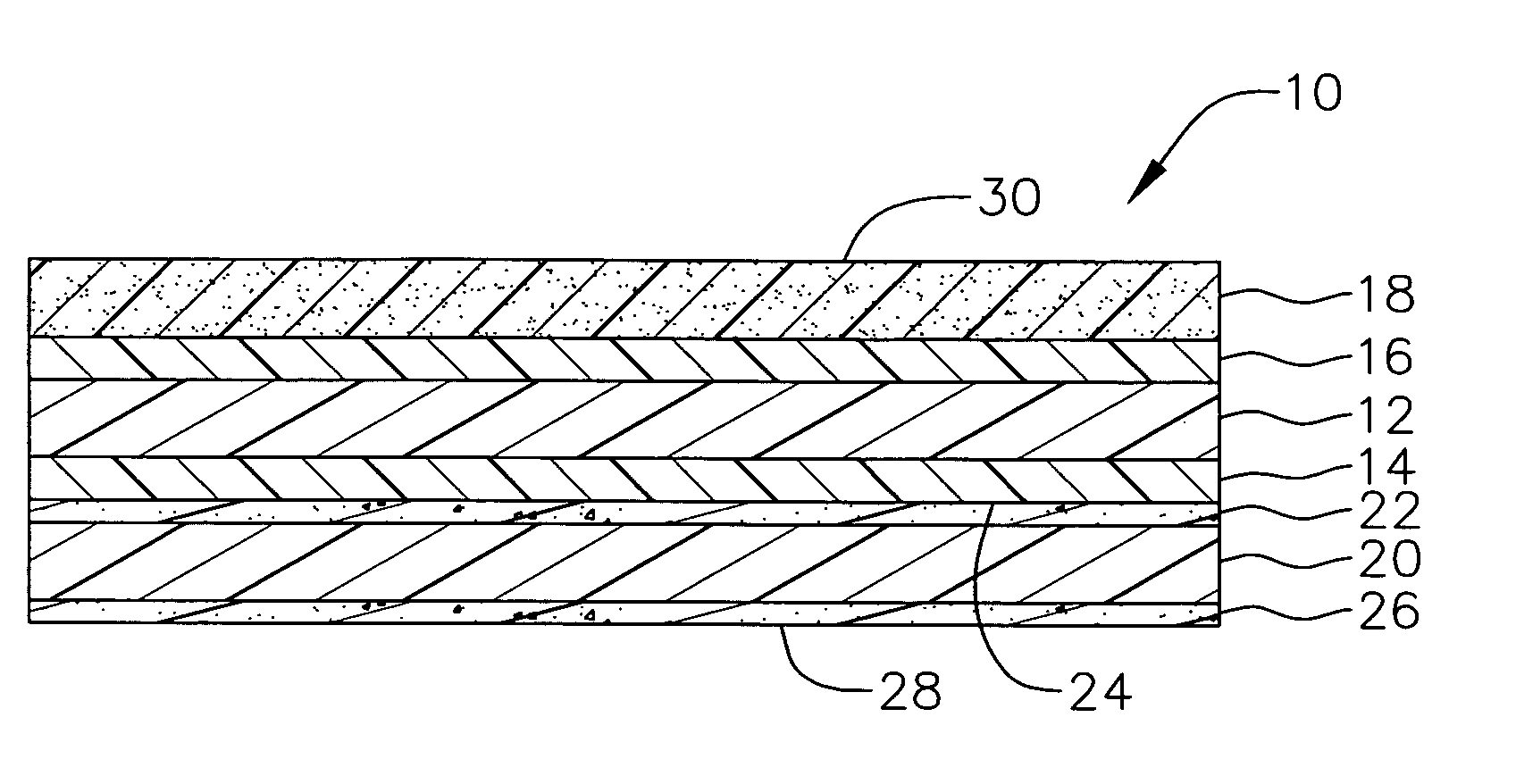

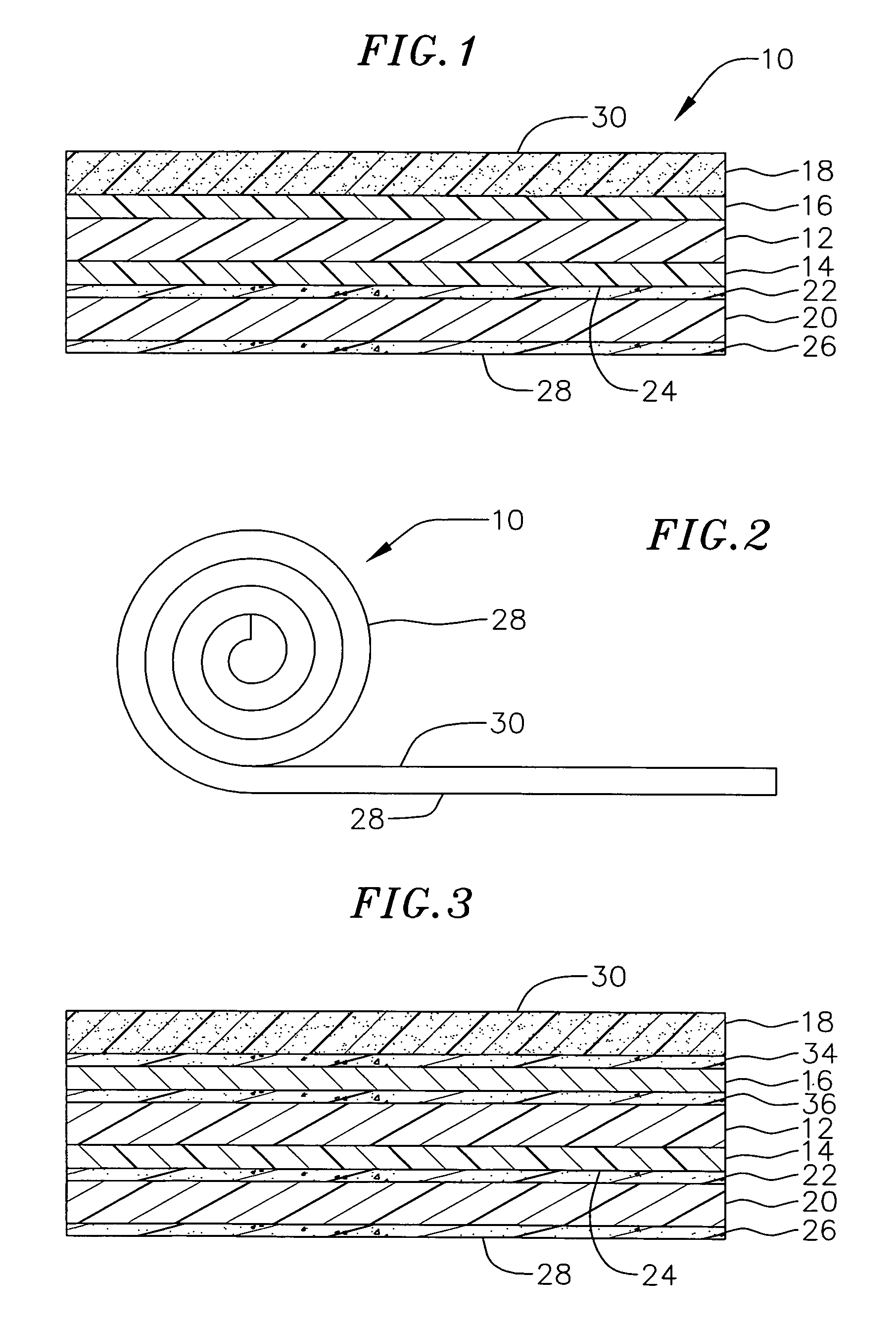

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0095] A PET liner is coated on one side with a silicone release coating corresponding to the adhesive release coat layer described above. The thickness of the silicone coated liner is 0.92 mil and comprises Mitsubishi 92 gauge SLK.

[0096] The matte release coat is applied to the other side of the release liner using gravure at a coat weight of 4.5 to 5.5 gsm. The formulation for the matte release coat is as follows (with all numerical values in parts by weight):

ComponentPartsMethyl isobutyl ketone (MibK)53.47Isopropanol6.49Lankyd 13-1245 (product of Akzo7.21Chemical, an acrylic modified alkyd)VAGH (product of Union Carbide, hydroxy8.72modified polyvinyl chloride / polyvinylacetate copolymerEFKA 5055 (a carboxylic acid ester1.10dispersing agent)Microtalc MP 15-38 (Barretts Minerals)23.02Cymel 303 (Cytec melamine resin)7.45Byk 451 (Byk Chemie blocked acid catalyst)3.50

[0097] In preparing the release coat material the base materials (VAGH, alkyd and talc) are compounded in a 100 part ...

example 2

[0105] An alternative embodiment of the matte release coat comprises the following formulation in which a dispersing agent is omitted and the catalyst is changed to an unblocked catalyst. (All numerical values are in parts by weight.)

ComponentPartsMibK50.54Isopropanol7.84Lankyd 13-12458.93VAGH10.68Microtale MP 15-3822.00Cymel 3036.80Cycat 4040 (paratoluene sulfonic acid)2.00

[0106] Adjustments may be made to release properties and gloss in this release coat formulation by optionally adding the following intermediate formulations in which the matte intermediate is used to adjust gloss down and the vehicle intermediate is used to adjust gloss upward.

Matte Intermediate ComponentPartsMibK28.05Lankyd 13-12454.05VAGH4.90Dispersing agent18.00Microtalc MP 15-3845.00

[0107] The dispersing agent comprises 10 parts by weight EFKA 5055 and 90 parts by weight MibK.

Vehicle Intermediate ComponentPartsMibK64.83Isopropanol13.00Lankyd 13-124510.03VAGH12.14

example 3

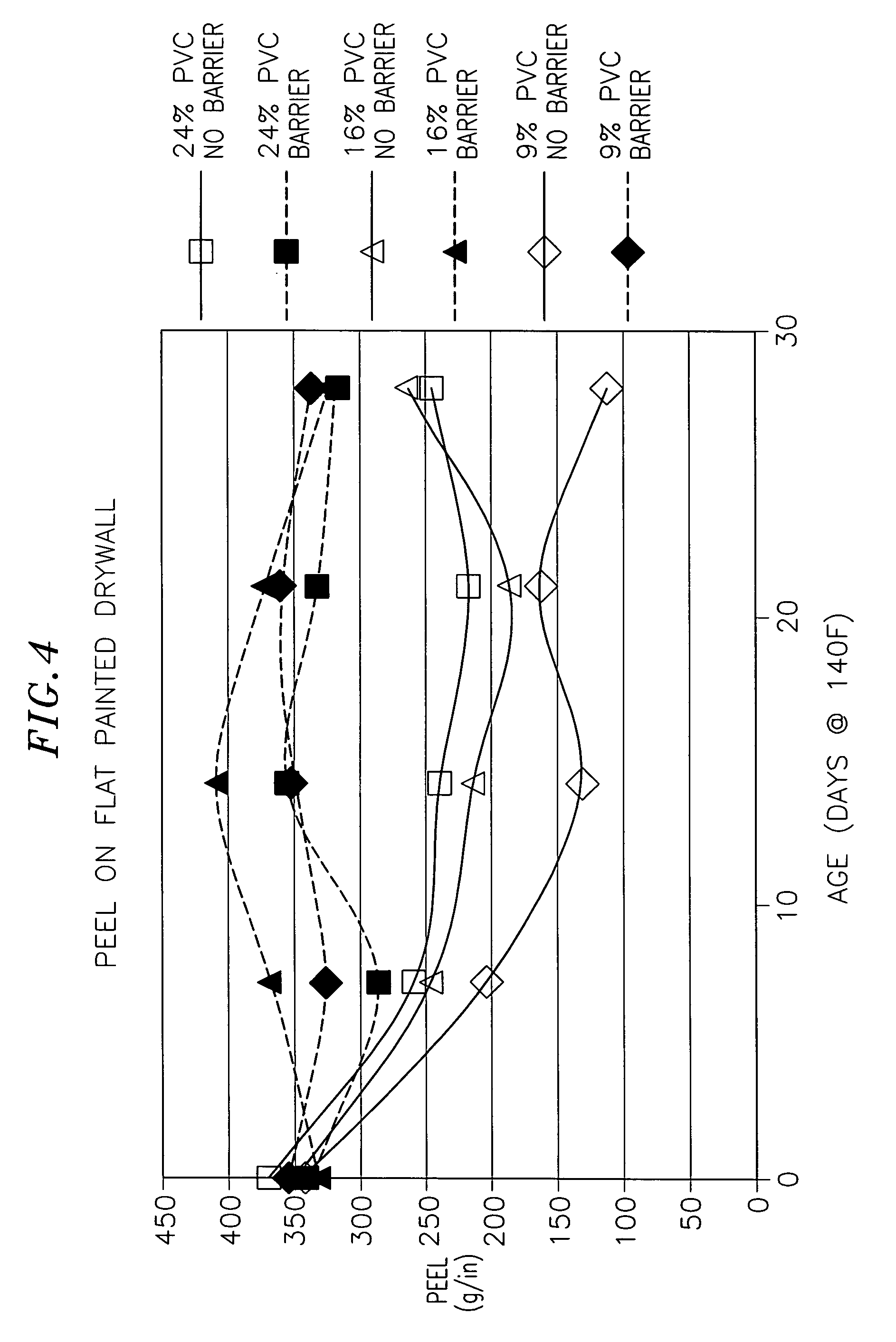

[0108] Test panels were prepared and tested for color shift, comparing color shift for: (1) wall films similar to Example 1 containing a barrier coat and (2) similar wall films in the absence of a barrier coat. The test films were applied to a medium yellow (Hansa Yellow 10G and Dalamar Yellow PY74) painted surface and subjected to accelerated aging. The test films were measured for discoloration (color shift) caused by migration of azo-type color constituents that passed from the painted surface through the PSA layer to the color layer of the test sample. The test panels were prepared using a dry paint color layer containing a plasticized vinyl-based paint layer containing a dispersed white pigment. The S-3506 PSA was applied to the color layer. The test panels included a white wall film with 2.5 gsm EVOH / urethane barrier, a white wall film with 6.5 gsm EVOH / urethane barrier, and a white wall film with no barrier layer. The modified EVOH barrier layers were thermoplastic. No tie la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com