Flexible self-supporting metal oxide / graphene nano-composite membrane and preparing method and application thereof

A nanocomposite and graphene technology, applied in the field of nanomaterials, can solve the problems of large particle size and uneven distribution of metal oxide particles, and achieve the effects of large equivalence ratio range, abundant raw materials, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0039] In Examples 1-8:

[0040] The graphene oxide is prepared by the improved Hummers method.

Embodiment 1

[0042] 1. Preparation:

[0043] S1. Measure 168ml of absolute ethanol in a 250ml beaker, and slowly add 9.4ml of GO solution with a concentration of 3.2mg / ml into the beaker under magnetic stirring; then measure 0.9ml of TiCl with a concentration of 0.55mol / L 4 / Anhydrous ethanol solution, slowly drop into the beaker; measure 2.6ml of deionized water dropwise into the beaker, stir magnetically for 10min to obtain a uniform dispersion;

[0044] S2. Transfer the dispersion to a hydrothermal reactor and react at 100°C for 2 hours;

[0045] S3. Suction filter the reacted product into a film, wash with absolute ethanol and deionized water, and evaporate and dry at 25°C for 24h to obtain TiO 2 / Graphene nanocomposite filter membrane;

[0046] S4. Dissolve the filter membrane with methanol to obtain TiO 2 / Graphene nanocomposite film.

[0047] 2. Performance analysis:

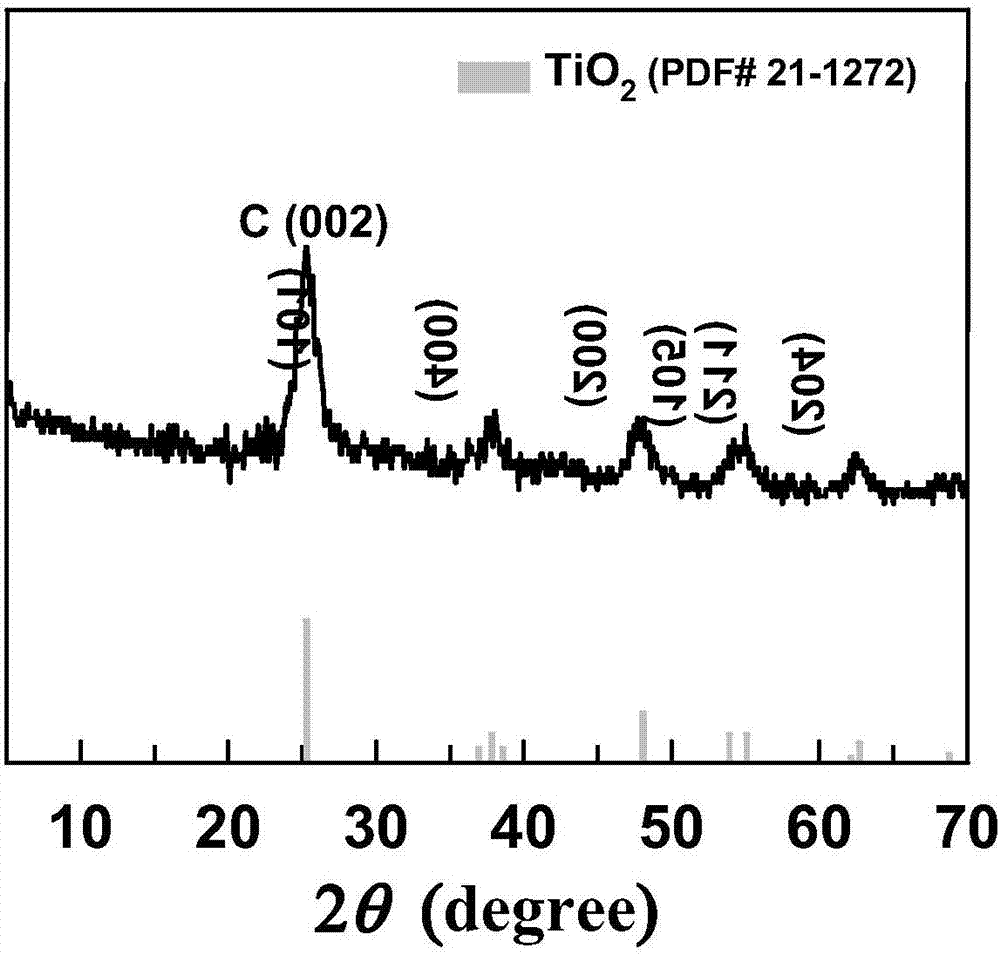

[0048] tested, figure 1 and figure 2 TiO 2 / Photographs of graphene nanocomposite membranes tiled and ben...

Embodiment 2

[0050] 1. Preparation:

[0051] S1. Measure 168ml of methanol solution in a 250ml beaker, and slowly add 9.4ml of GO solution with a concentration of 3.2mg / ml dropwise into the beaker under magnetic stirring; then measure 0.9ml of SnCl with a concentration of 0.5mol / L 4 / methanol solution, slowly drop into the beaker; measure 4ml of deionized water dropwise into the beaker, stir magnetically for 10min to obtain a uniform dispersion;

[0052] S2. Transfer the dispersion to a hydrothermal reactor for 2 hours at 100°C;

[0053] S3. Suction filter the reacted product into a film, wash with deionized water, and evaporate and dry at 30°C for 20 hours to obtain SnO 2 / Graphene nanocomposite filter membrane;

[0054] S4. Dissolve the filter membrane with acetone to obtain SnO 2 / Graphene nanocomposite film.

[0055] 2. Performance analysis: After testing, SnO 2 / SnO in graphene nanocomposite film 2 The nanoparticles are uniformly distributed, and the particle size is 3-4nm. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com