Rapid hydrothermal-synthesized H-LTA-type molecular sieve and preparation method and application thereof

A hydrothermal synthesis and molecular sieve technology, which is applied in the direction of molecular sieve catalysts, molecular sieves and base exchange compounds, chemical instruments and methods, etc., can solve the problems of complex operation procedures, low primary ion exchange rate, and easily etched zeolite channel structure, etc., to achieve The raw materials are cheap and easy to obtain, the ability to resist etching and skeleton collapse is improved, and the effect of avoiding strong water absorption and low water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Feeding molar ratio H 2 O-SiO 2 -Al 2 O 3 -(TMA) 2 O=272:12.4:1:4.9

[0050] 1.60g Al(OH) 3 The powder (purity: 99.9%, 3500 mesh) was dissolved in 5.00 g of high-purity water, 35.50 g of tetramethylammonium hydroxide solution (the mass content of TMAOH was 25 wt%) was added to the obtained solution, and the mixture was stirred uniformly to obtain a suspension. Under stirring and normal temperature conditions (25℃, RH=40%), 24.80g SiO was gradually added dropwise to the aluminum source 2 Sol (SiO 2 The mass content is 30wt%), the initial gel is obtained after 2 hours of stirring, which is aged for 2 hours at room temperature, and then transferred to a hydrothermal kettle for rotation and crystallization. The crystallization time was 3 days and the crystallization temperature was 101°C to obtain the initial product. The product was washed 3 to 4 times by centrifugation and ultrasound, the pH of the supernatant 2 O-XO 2 -Y 2 O 3 =1:7.5:1.

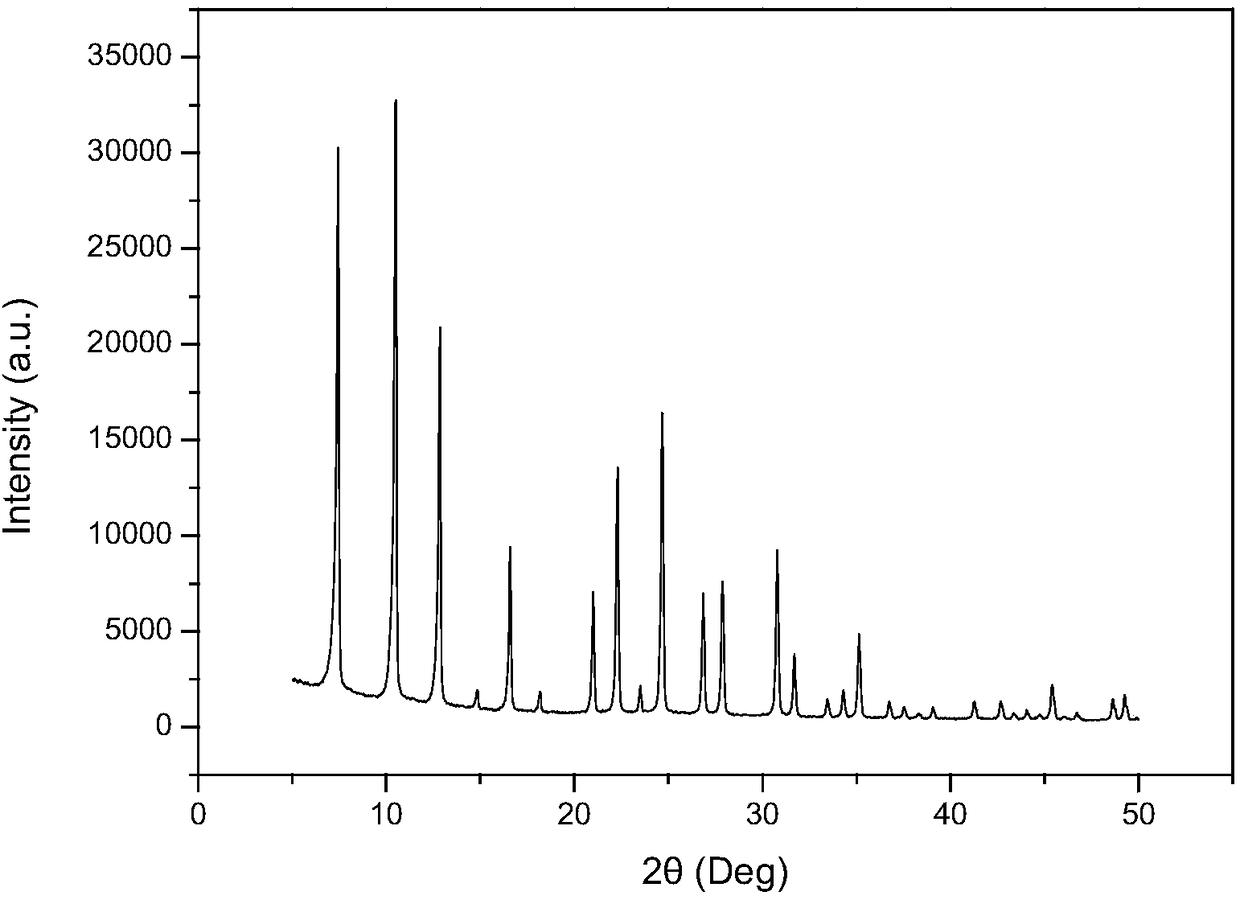

[0051] XRD test results such as figu...

Embodiment 2

[0053] Feeding molar ratio H 2 O-SiO 2 -Al 2 O 3 -(TMA) 2 O=214:10.2:1:3.5

[0054] 1.60g Al(OH) 3 The powder (purity: 99.9%, 3500 mesh) was dissolved in 5.00 g of high-purity water, and 25.50 g of tetramethylammonium hydroxide solution (the mass content of TMAOH was 25 wt%) was added to the obtained solution, and the mixture was stirred uniformly to obtain a suspension. Under stirring and normal temperature conditions (25°C, RH=40%), gradually add 20.50g of SiO to the configured aluminum source and template agent mixture. 2 Sol (SiO 2 The mass content is 30wt%), the initial gel is obtained after 2.5 hours of stirring, which is aged at room temperature for 4 hours, and then transferred to a hydrothermal kettle to rotate and crystallize. The crystallization time was 3 days and the crystallization temperature was 101°C to obtain the initial product. The product was washed 3 to 4 times by centrifugation and ultrasound, the pH of the supernatant 2 O-XO 2 -Y 2 O 3 =1:4.9:1.

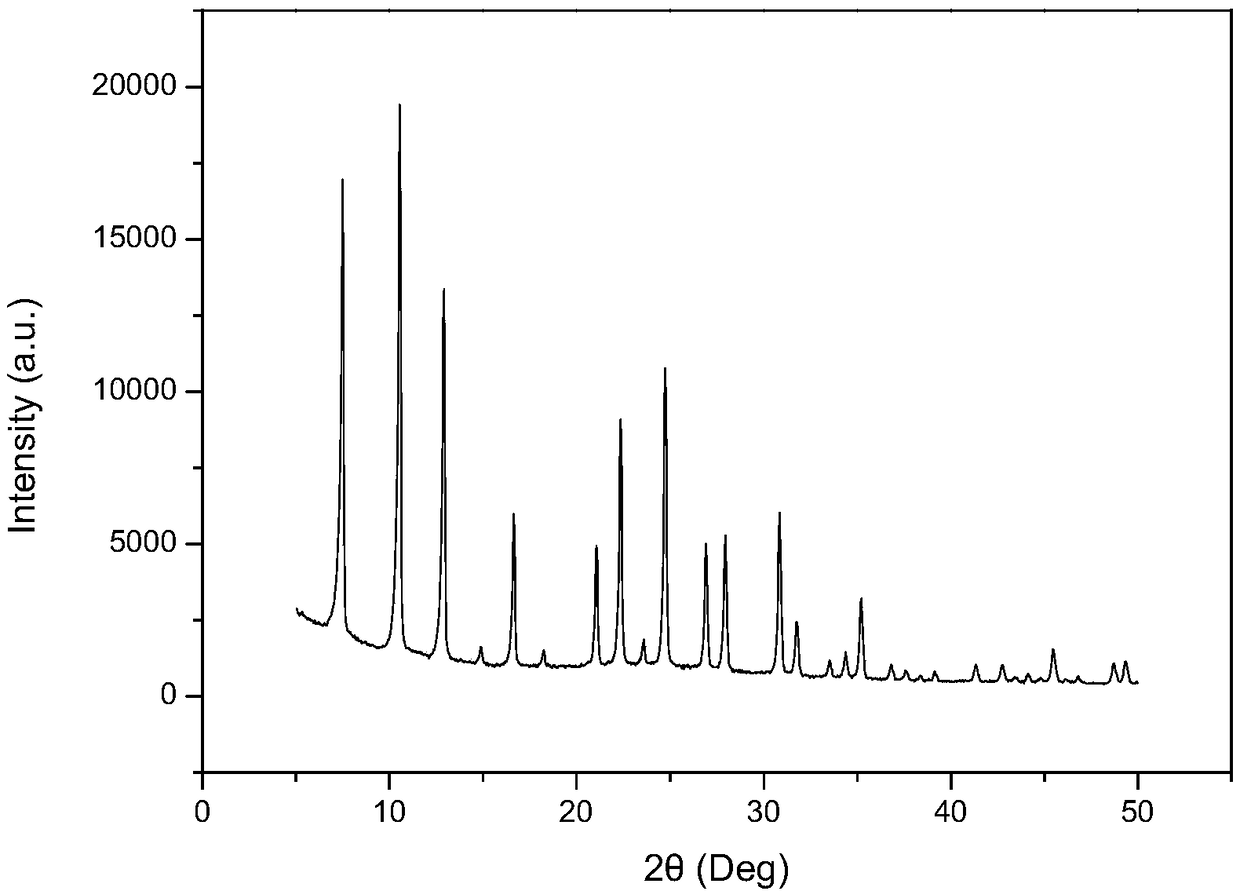

[0055] XR...

Embodiment 3

[0057] Feeding molar ratio H 2 O-SiO 2 -Al 2 O 3 -(TMA) 2 O=226:9.2:1:4.1

[0058] 1.60g Al(OH) 3 The powder (purity: 99.9%, 3500 mesh) is dissolved in 5.00 g of high-purity water, 30.50 g of tetramethylammonium hydroxide solution (the TMAOH mass content is 25 wt%) is added to the obtained solution, and the mixture is stirred uniformly to obtain a suspension. Under stirring and normal temperature conditions (25℃, RH=40%), gradually add 18.45g SiO 2 Sol (SiO 2 The mass content is 30% by weight), the initial gel is obtained after stirring for 1 h, which is aged for 2 h at room temperature, and then transferred to a hydrothermal kettle for rotation and crystallization. The crystallization time was 2 days and the crystallization temperature was 100°C to obtain the initial product. The product was washed 3 to 4 times by centrifugation and ultrasound, the pH of the supernatant 2 O-XO 2 -Y 2 O 3 =1:3.0:1.

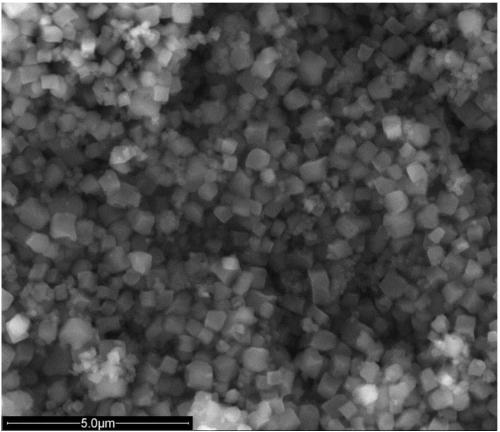

[0059] After testing, the SAR of the obtained H-LTA molecular sieve is 3.0, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com