Manufacture method of flexible substrate and solar cell and production method thereof

A technology of flexible substrates and manufacturing methods, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of insufficient bending, large thermal expansion differences, and reduction, so as to reduce the expansion coefficient difference and improve the crystal lattice Interface, the effect of reducing process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The implementation of the present invention will be described in more detail below in conjunction with the drawings and component symbols, so that those skilled in the art can implement it after studying this specification.

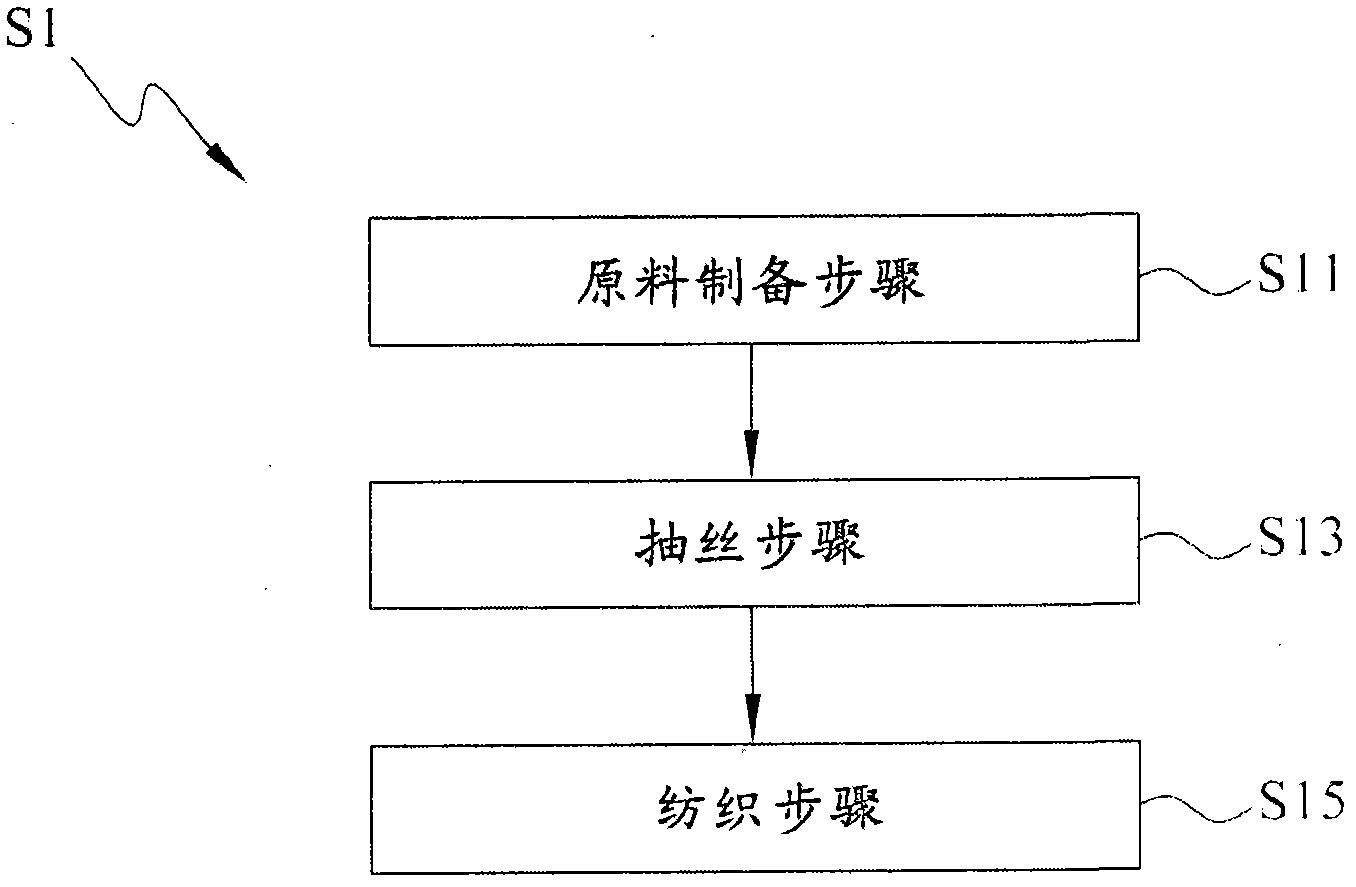

[0065] figure 1 It is a flow chart of the first embodiment of the method for fabricating a flexible substrate with nanocrystalline grains having a light-absorbing function. Such as figure 1 As shown, the manufacturing method S1 of the flexible substrate of nanocrystalline grains with light-absorbing function of the present invention includes a raw material preparation step S11, a spinning step S13 and a spinning step S15, and the raw material preparation step S11 is a crystalline nanocrystal with a light-absorbing function. Rice powder such as copper indium gallium selenide (CIGS) crystalline nanopowder or copper indium gallium selenide (CIGS) crystalline nanopowder and polymer material to form composite colloidal particles, and the spinning step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com