Natural gas hydrate continuous reaction device with synergistic effect of adsorption and hydration

A synergy and reaction device technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of slow growth, long induction period of natural gas hydrate formation process, low water conversion rate, etc., to accelerate nucleation and power generation , simple structure, and the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

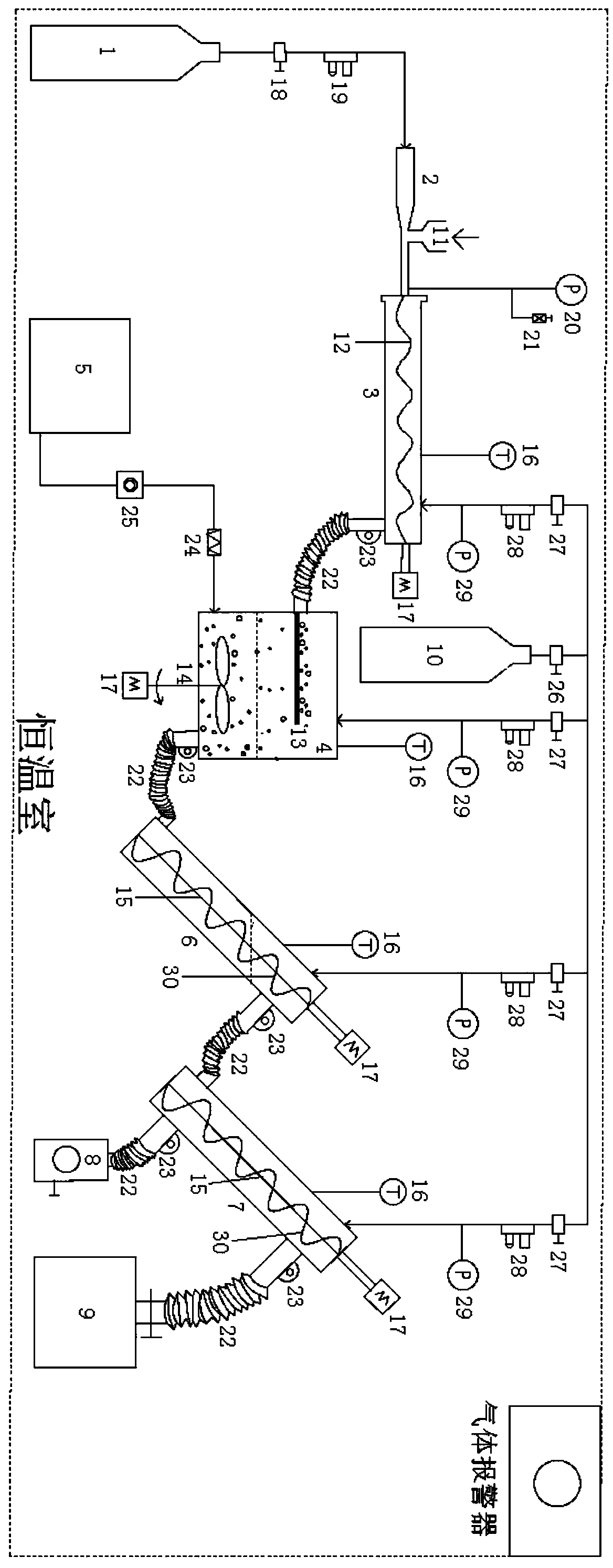

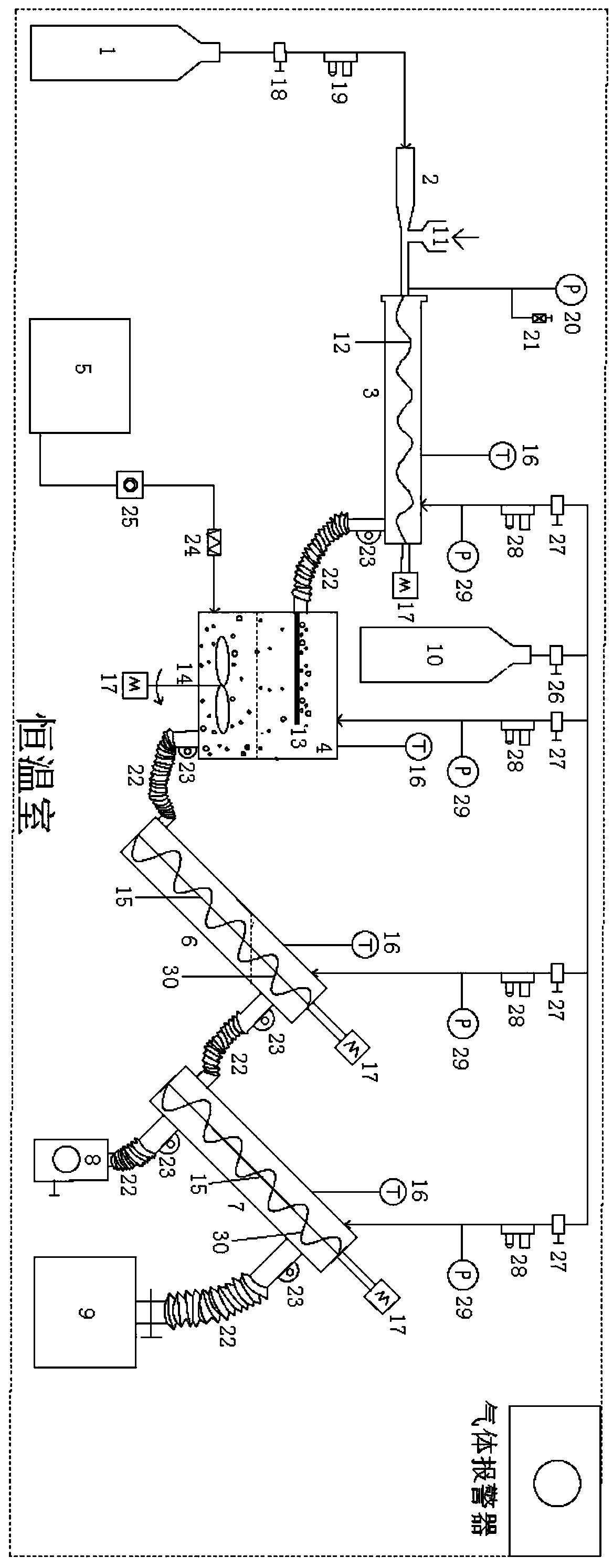

[0010] The main structure of the natural gas hydrate continuous reaction device with the synergistic effect of adsorption and hydration involved in this embodiment includes a No. 1 gas tank 1, a feed pipe 2, a screw pump adsorption tank 3, a solid-liquid mixing tank 4, a water tank 5, and a Reaction kettle 6, secondary reaction kettle 7, liquid collection tank 8, hydrate collection tank 9 and No. 2 gas tank 10; No. 1 gas tank 1 is connected to screw pump adsorption kettle 3 through feed pipe 2, and screw pump adsorption kettle 3 Connect with the solid-liquid mixing tank 4, the solid-liquid mixing tank 4 is connected with the water tank 5 and the primary reactor 6 respectively, the primary reactor 6 is connected with the secondary reactor 7, and the secondary reactor 7 is respectively connected with the liquid collection tank 8 It is connected with the hydrate collection tank 9, and the No. 2 gas tank 10 provided separately is connected with the screw pump adsorption tank 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com