Method and device for plasma-assisted preparation of high-conductivity graphene metal composite material

A composite material and graphene technology, applied in graphene, metal rolling, metal rolling, etc., can solve the problems of limited copper electrochemical performance improvement, limited copper application range, poor heat resistance, etc., to avoid Adverse effects, energy consumption reduction, and productivity improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

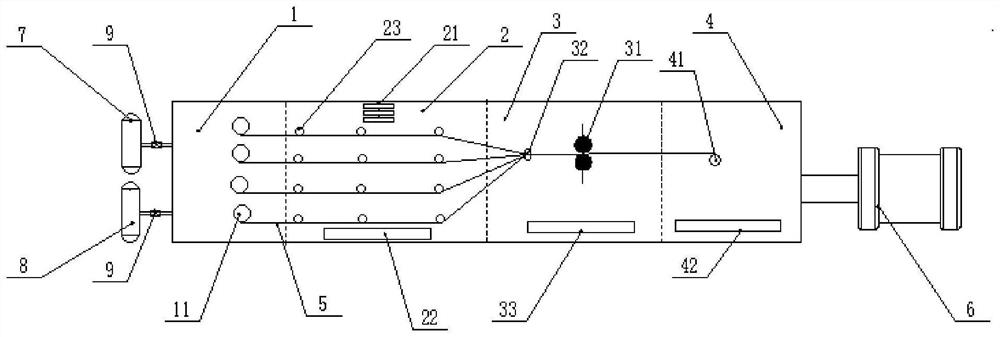

[0060] Such as figure 1 The device for preparing the graphene-metal layered composite material assisted by the plasma includes:

[0061] The sample inlet chamber 1, the plasma-assisted decomposition chamber 2, the thermocompression chamber 3 and the sample outlet chamber 4 connected in sequence are used for feeding the sample inlet chamber 1, the plasma-assisted decomposition chamber 2, the thermocompression chamber 3 and the outlet chamber. The growth carbon source gas path mechanism 8 of the gaseous growth carbon source connected to the sample chamber 4 is used to feed the auxiliary gas into the sample chamber 1, the plasma-assisted decomposition chamber 2, the hot-press chamber 3 and the sample outlet chamber 4. The gas circuit mechanism 7 and the vacuum mechanism 6 for pumping the pressure in the sample injection chamber 1, the plasma-assisted decomposition chamber 2, the hot-press chamber 3 and the sample discharge chamber 4 to a low vacuum state;

[0062] The sampling c...

Embodiment 2

[0074] Adopt the device of embodiment 1 to prepare graphene copper-based layered composite material, concrete steps are as follows:

[0075] 10 pieces of copper foil with a thickness of 25 μm are discharged through the feeding roller 11, and the copper foil is fed to the heat-pressing mechanism through the guide roller 23 and the pre-pressing roller 32 sequentially under the pulling action of the discharging mechanism 41, so that the multi-channel The copper foil is in a connected state from the feed roller 11 to the discharge mechanism 41;

[0076] The sample inlet chamber 1, the plasma-assisted decomposition chamber 2, the hot-press chamber 3 and the sample outlet chamber 4 are vacuumized by the vacuum mechanism 6, and the degree of vacuum is 0.1 Pa. During the vacuum process, the vacuum mechanism 14 will inject the sample The gas in the chamber 1, the plasma-assisted decomposition chamber 2, the hot-press chamber 3 and the sample outlet chamber 4 is extracted and discharged...

Embodiment 3

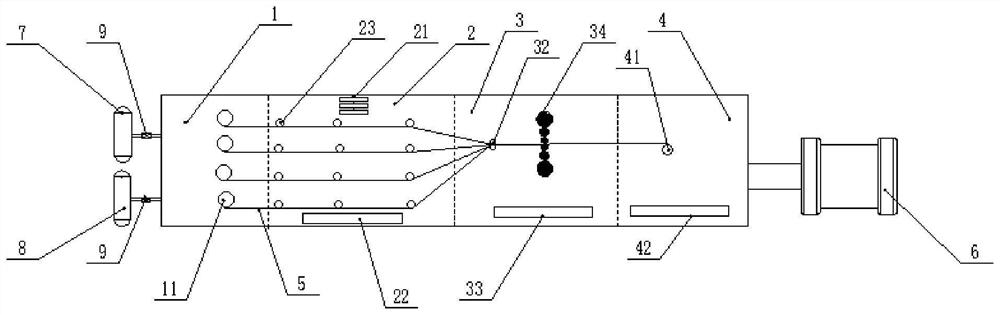

[0085] The difference between this embodiment and Embodiment 2 is that: the hot pressing mechanism adopts a rolling mill 34, the rolling temperature is 900° C., the pressure is 45 MPa, and the rolling time is 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com