Patents

Literature

355results about How to "Promote lysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

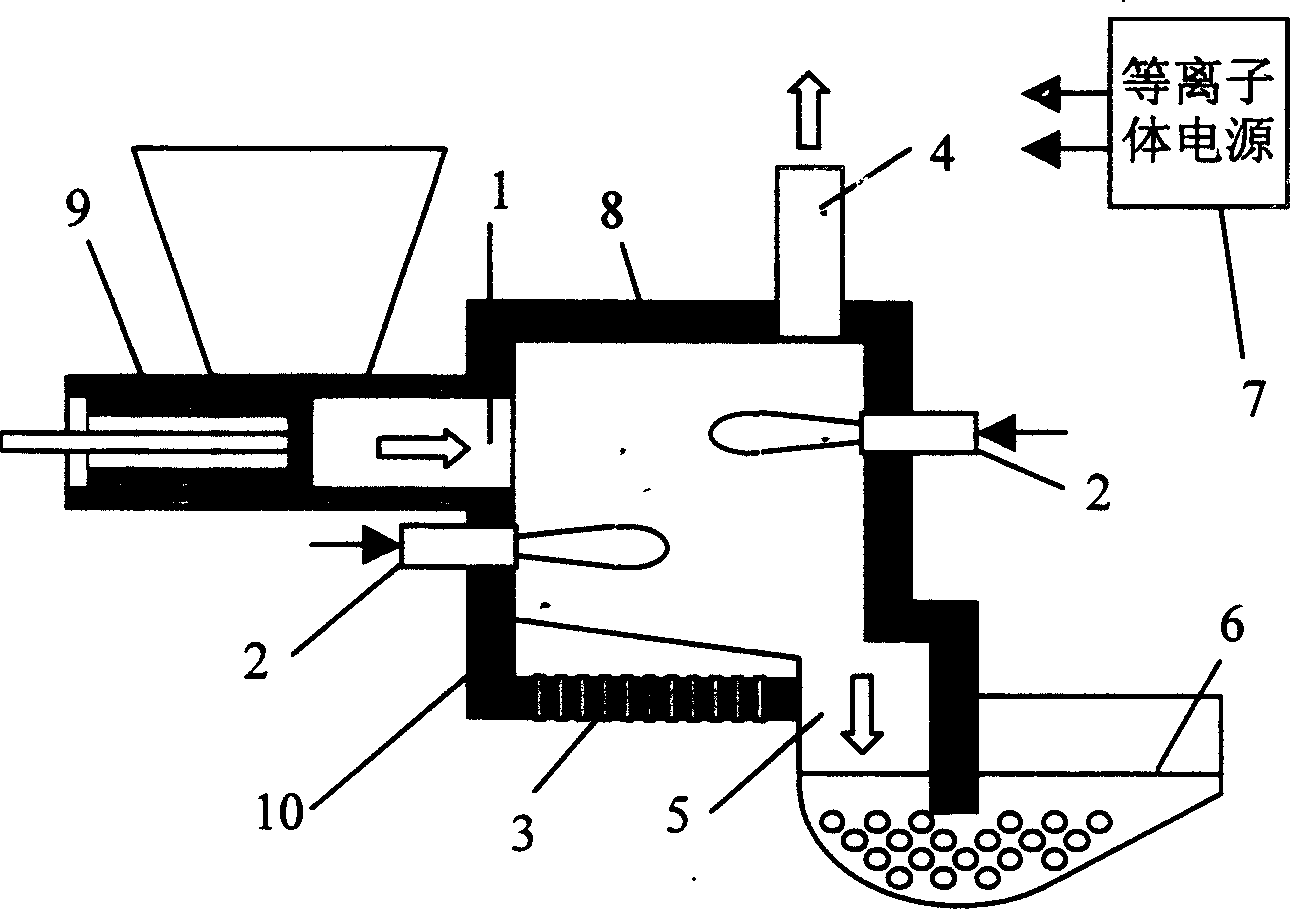

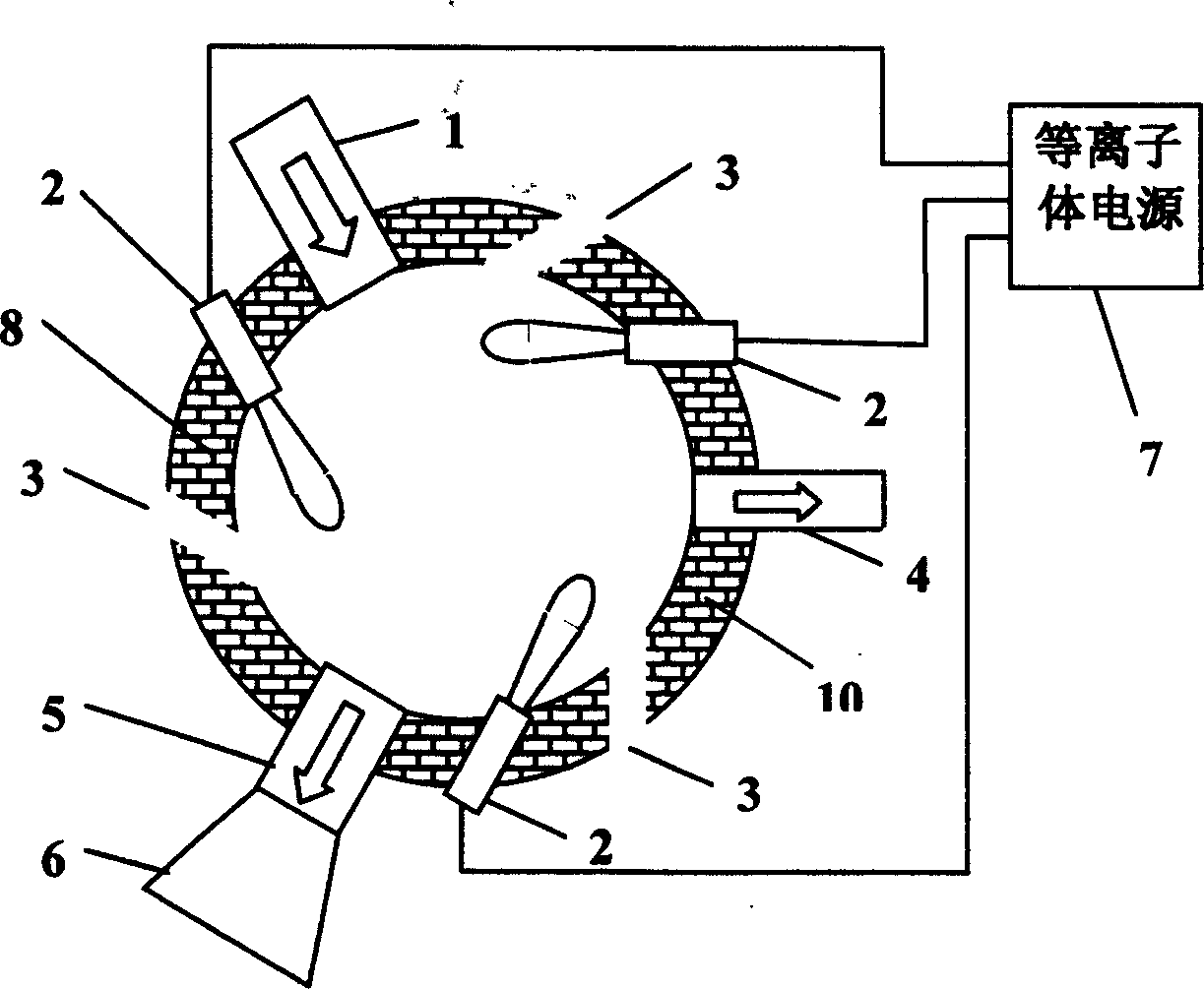

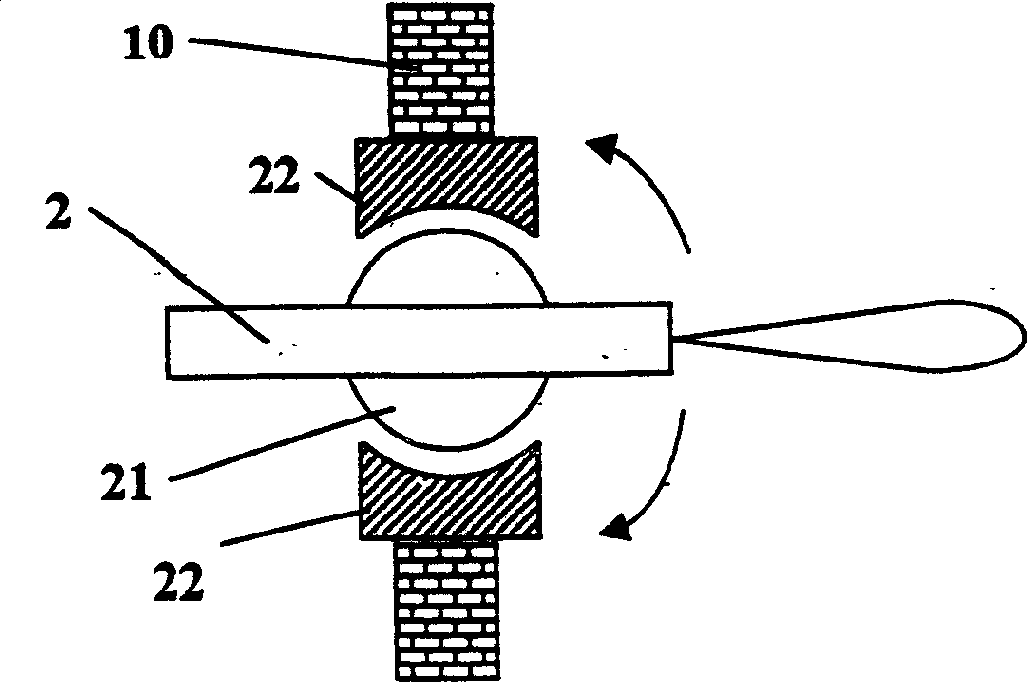

Method for cracking organic debris reinforced by plasma and plasma furnace

InactiveCN1616886AHelp flowUniform thermal crackingIncinerator apparatusCombined combustion mitigationLiquid stateSlag

The present invention relates to plasma reinforced organic waste cracking method and plasma furnace. The plasma furnace includes furnace body, furnace hearth with material feeding port, plasma torch, bottom slag hole, top exhaust port and at least one gas inlet port connected via gas cylinder via pipeline with valve. The plasma reinforced organic waste cracking method includes the pre-treatment of solid, semi-solid, liquid or gaseous organic waste, high temperature cracking the waste in the plasma furnace of the present invention, re-burning the cracked gas and purifying cracked gas before or after re-burning. The present invention has low power consumption, low cost in apparatus and running, stable and simple operation, and is suitable for treating various kinds of organic waste.

Owner:深圳市中科等离子体研究院有限公司

Method for increasing yield of ethylene and propylene from olefin with four carbon or above

ActiveCN101239878APromote lysisGood catalytic cracking effectMolecular sieve catalystsBulk chemical productionMolecular sieveAlkene

The invention relates to a method for increase production of ethylene and propylene from C4 or more alkene, which mainly solves the technology problems of the prior art, such as low selectivity and low yield of ethylene and propylene. The invention uses alkene mixtures of C4 or more alkene as materials, the alkene materials are contacted with a catalyst to generate an effluent containing ethylene and propylene, wherein the catalyst uses a carrier selected from at least one of SiO2 or compound molecular sieve, and contains a composition AaBbPcOx based on atom ratio. In this way, the invention solves the problems well and is useful in increase industrial production of ethylene and propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

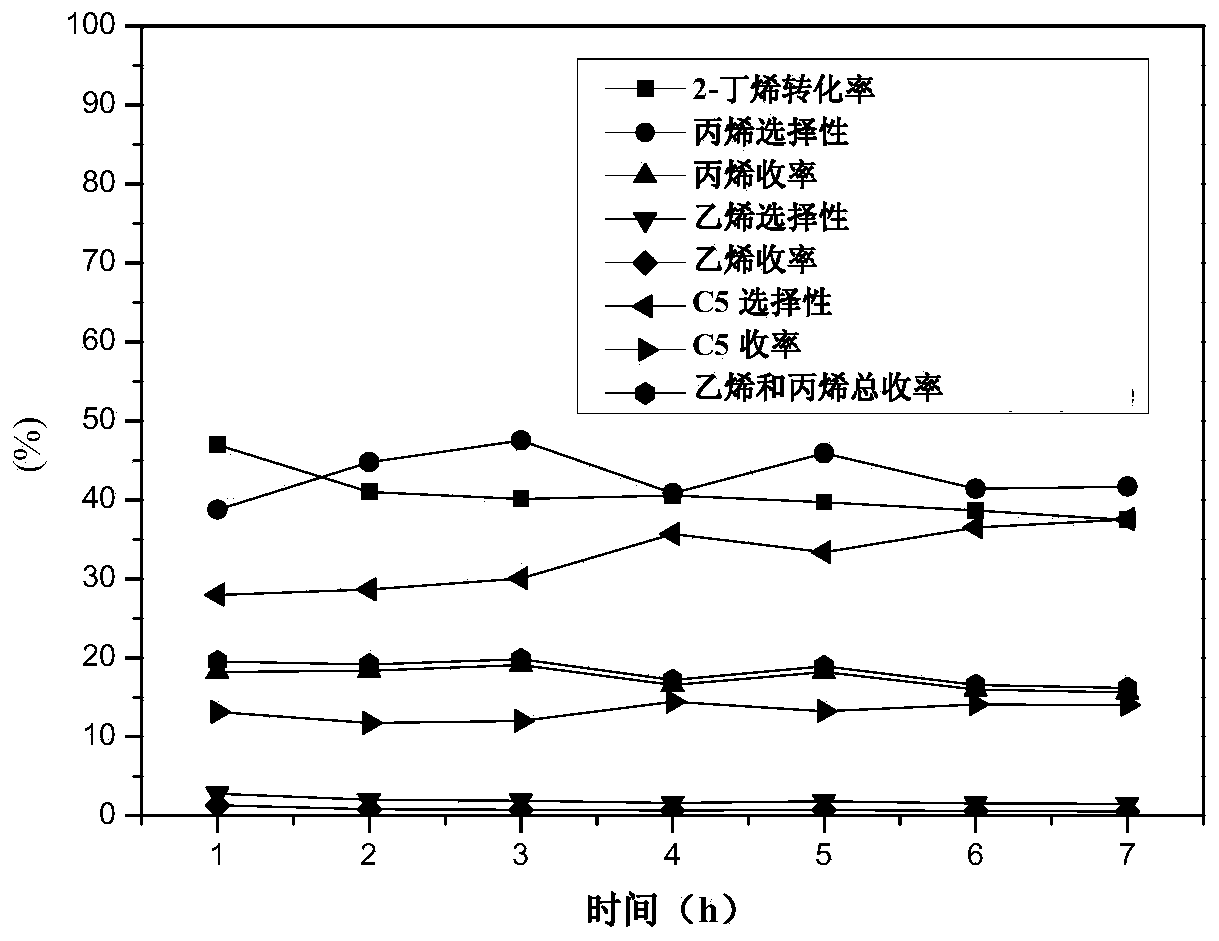

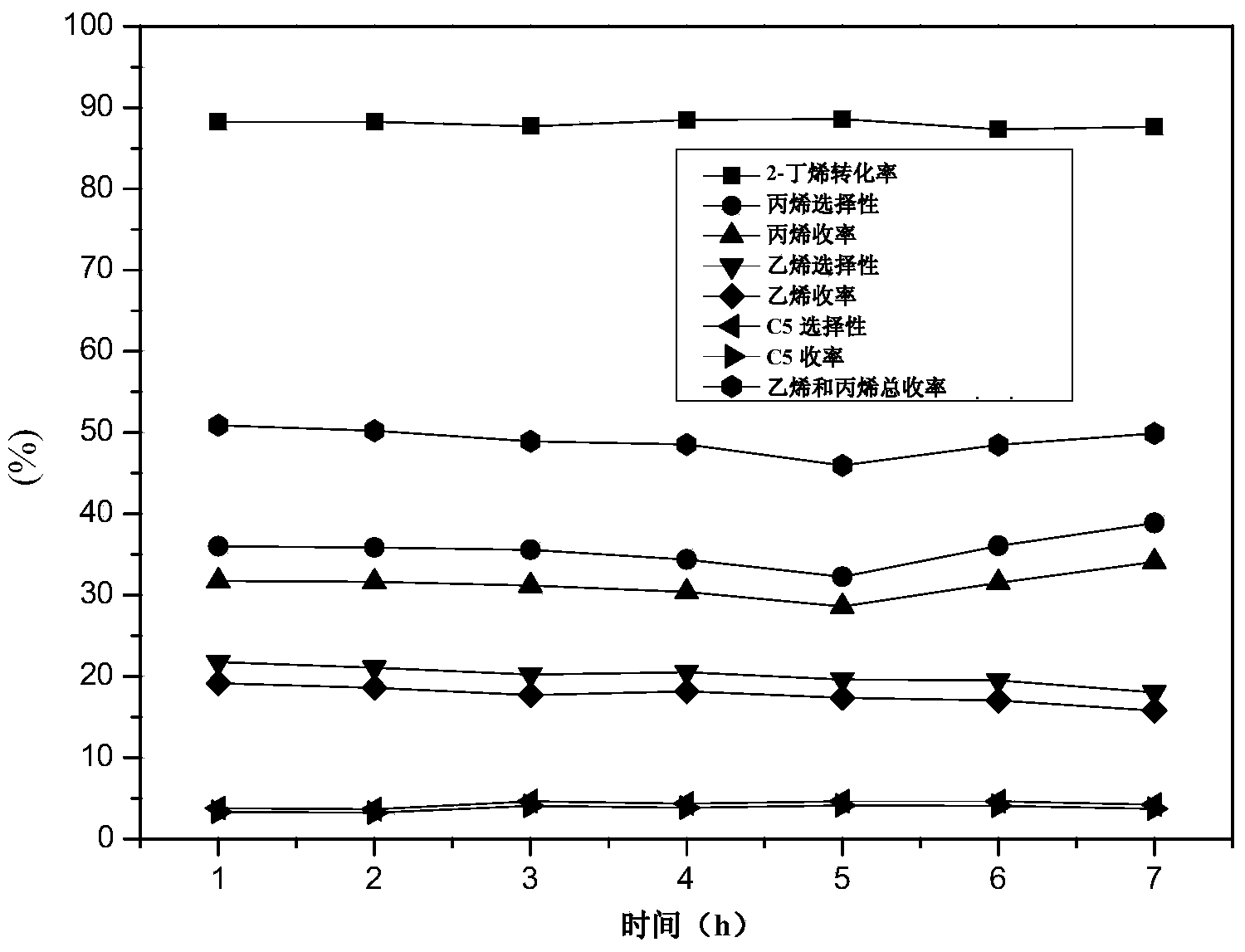

Method for producing propylene and coproducing ethylene from C4 olefins

ActiveCN104370676AHigh yieldPromote lysisHydrocarbon by metathesis reactionHydrocarbon by hydrocarbon crackingDisproportionationCracking reaction

The invention provides a method for producing propylene and coproducing ethylene from C4 olefins, which comprises the following steps: filling the mixture of an olefin disproportionation catalyst and a catalytic cracking catalyst in one reactor or sectionally filling the olefin disproportionation catalyst and catalytic cracking catalyst in differential reactors which are connected in series, and passing a C4 olefin raw material through the olefin disproportionation catalyst and catalytic cracking catalyst to carry out C4 olefin disproportionation reaction and low-carbon olefin cracking reaction, thereby generating the propylene and ethylene. The method couples a low-carbon olefin disproportionation technique with a low-carbon olefin deep catalytic cracking technique, and adopts an appropriate combination mode for the olefin disproportionation catalyst and olefin cracking catalyst, thereby achieving the goal of enhancing the yields of the propylene and ethylene.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

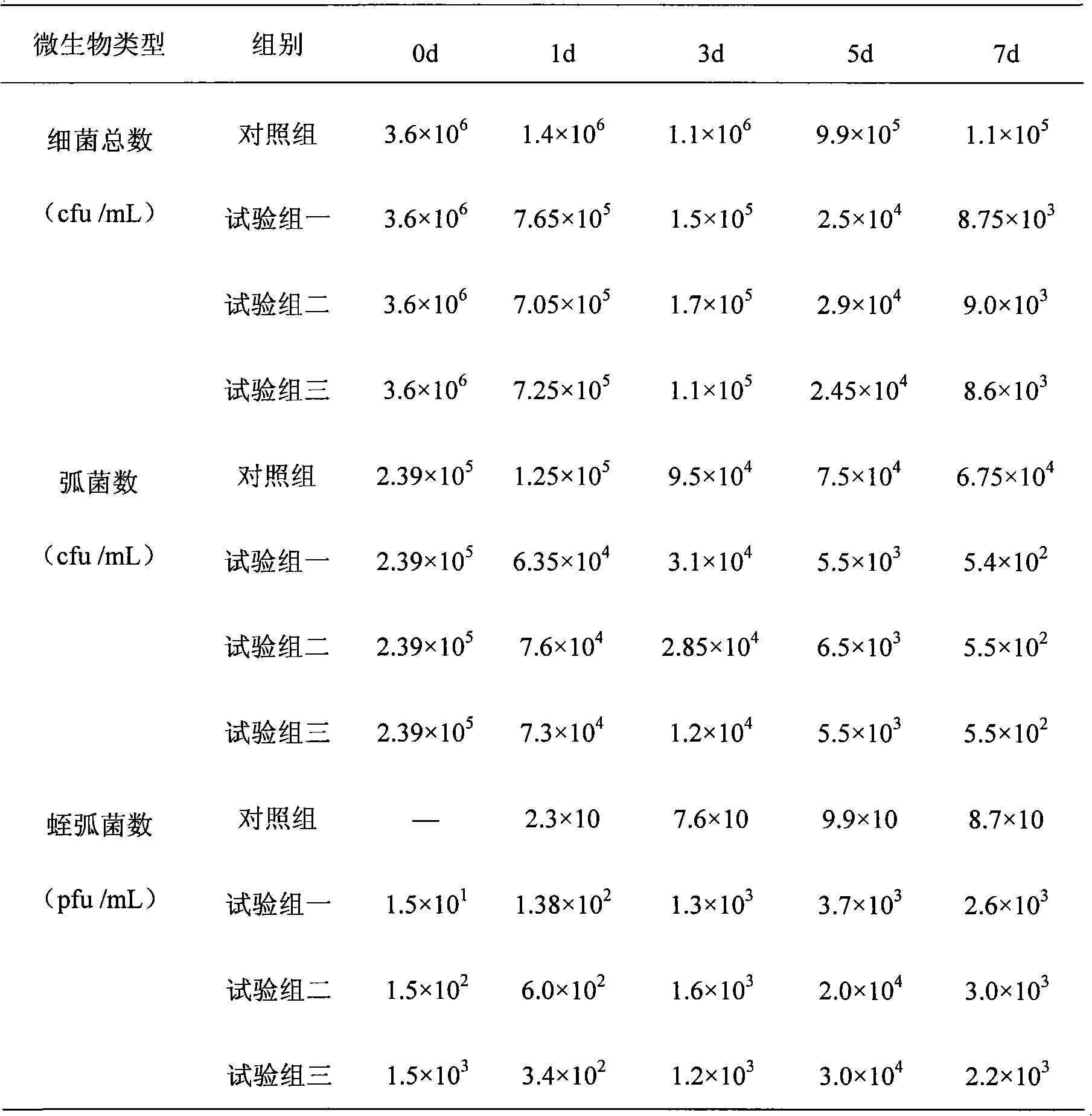

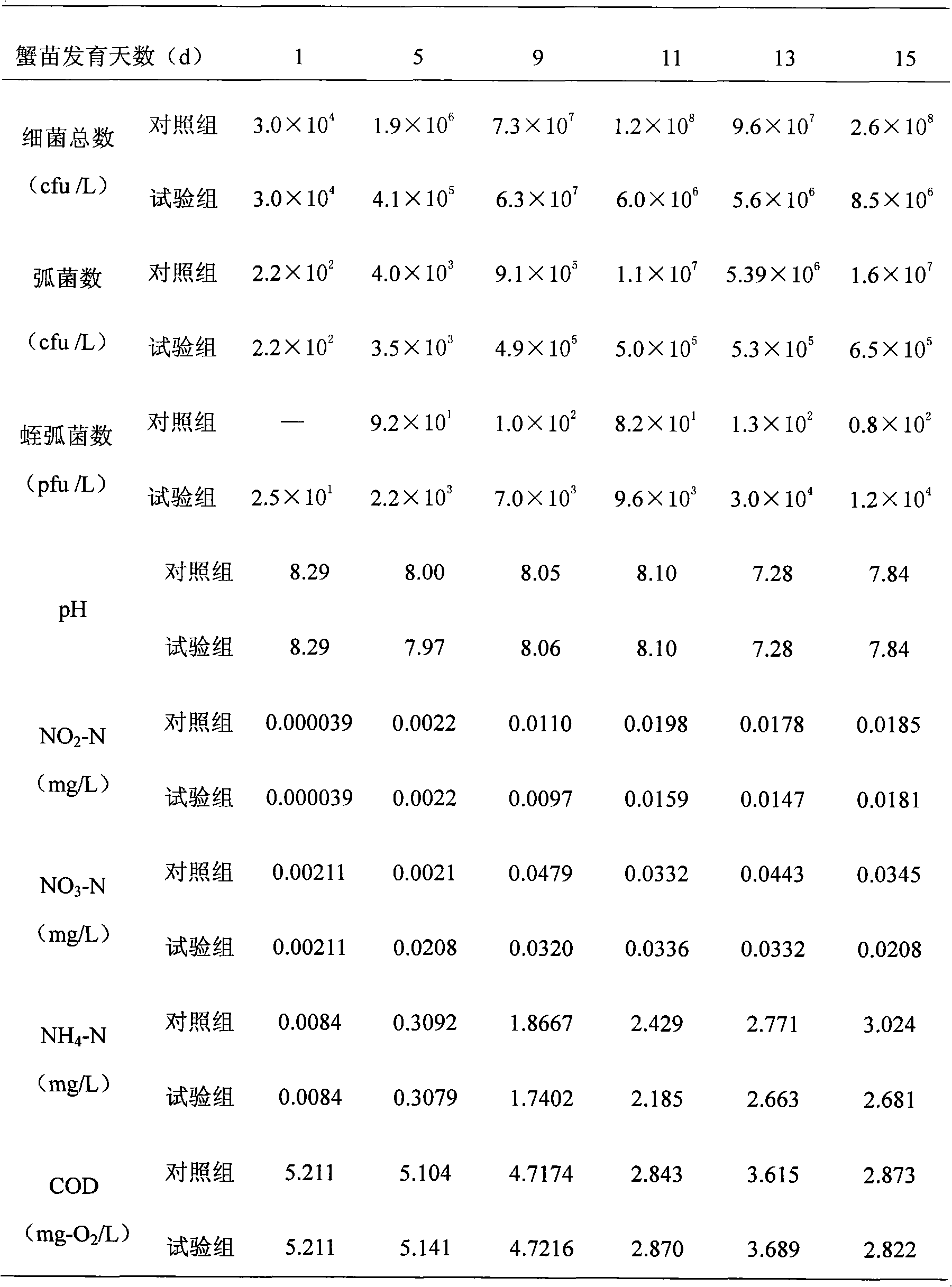

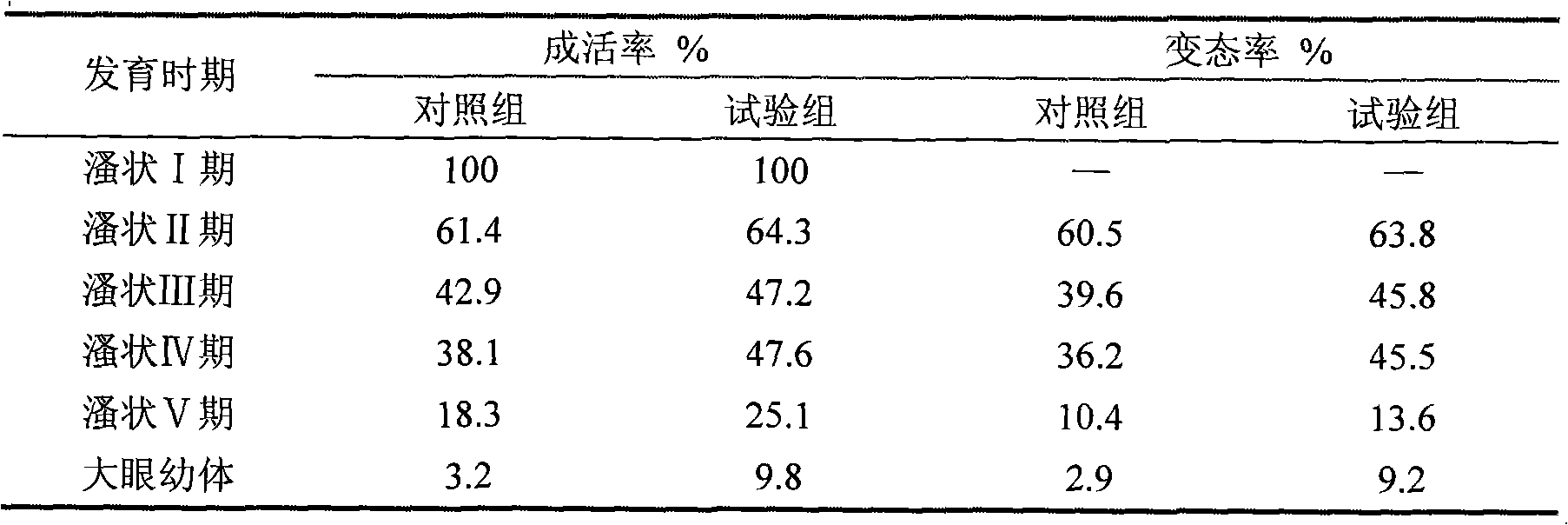

Preparation method and application of sea bdellovibrio bacteriovorus ecological preparation

InactiveCN101781627AGuaranteed lytic activityPromote lysisBiocideBacteriaNutrient brothCulture mediums

The invention provides a preparation method and application of a sea bdellovibrio bacteriovorus ecological preparation, and relates to a sea microbial ecological preparation and a preparation method of a bdellovibrio bacteriovorus preparation for mariculture. The preparation method comprises the following steps of: preparing a host bacteria suspension; separating and purifying bdellovibrio bacteriovorus; and propagating and culturing bdellovibrio bacteriovorus. The preparation method is characterized in that after pseudomonas stutzeri is connected with an incline and is activated, adding physiological saline in a test tube to prepare the bacterial suspension; then propagating and culturing with nutrient bouillon; adding a flocculating agent in the obtained bacterial suspension; standing and precipitating after uniformly shaking; adding the physiological saline to obtain 1012 cfu / mL of host bacteria suspension; separating and purifying the bdellovibrio bacteriovorus of collected sea and bottom sediment samples with a double agar plate method; pouring culture media containing the host bacteria suspension and the collected samples into sea agar in the lower layer for culture after uniformly mixing; and adding the host bacteria and the bdellovibrio bacteriovorus obtained by separation into sterilized natural sea, and culturing until the concentration of the bdellovibrio bacteriovorus is 108 to 109 pfu / mL for future use.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

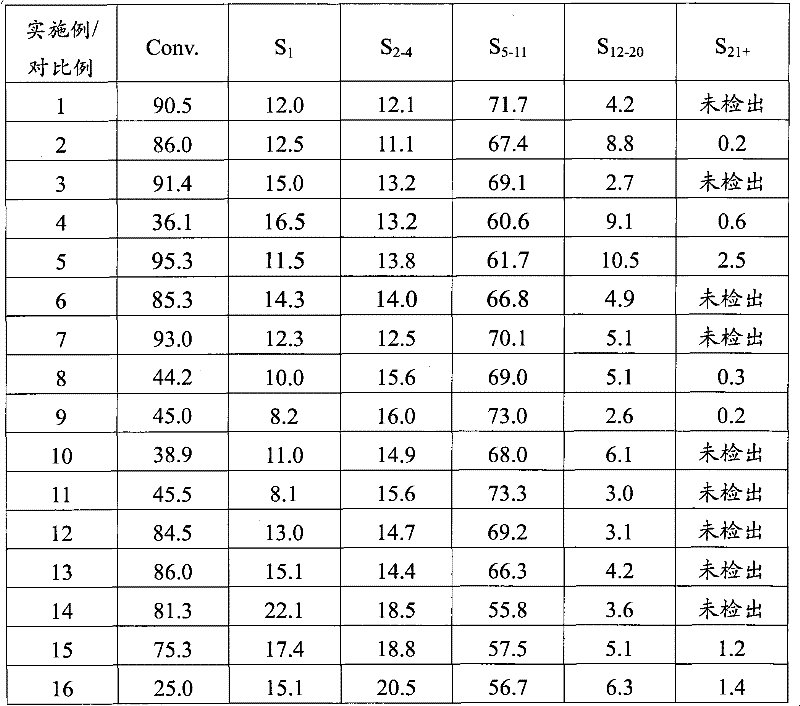

Catalyst for preparing high-quality gasoline fraction by virtue of syngas high selectivity and preparation method thereof

InactiveCN102211034AReduce stickingReduce pipe blockage and other problemsMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneMolecular sieve

The invention provides a catalyst for preparing a high-quality gasoline fraction by virtue of syngas high selectivity and a preparation method thereof. The catalyst comprises the following components in percentage by weight: 1-30% of metallic cobalt, 0.01-5% of assistant elements and the balance of molecular sieve. The catalyst has good selectivity to isoparaffin with 5-11 carbon atoms and quite low selectivity to the waxy hydrocarbons with more than 20 carbon atoms, so that the catalyst can be used for preparing high-quality gasoline fuels, and the catalyst carbon deposition can be avoided or obviously reduced. In addition, the invention further provides the preparation method of the catalyst.

Owner:WANHUA IND GRP

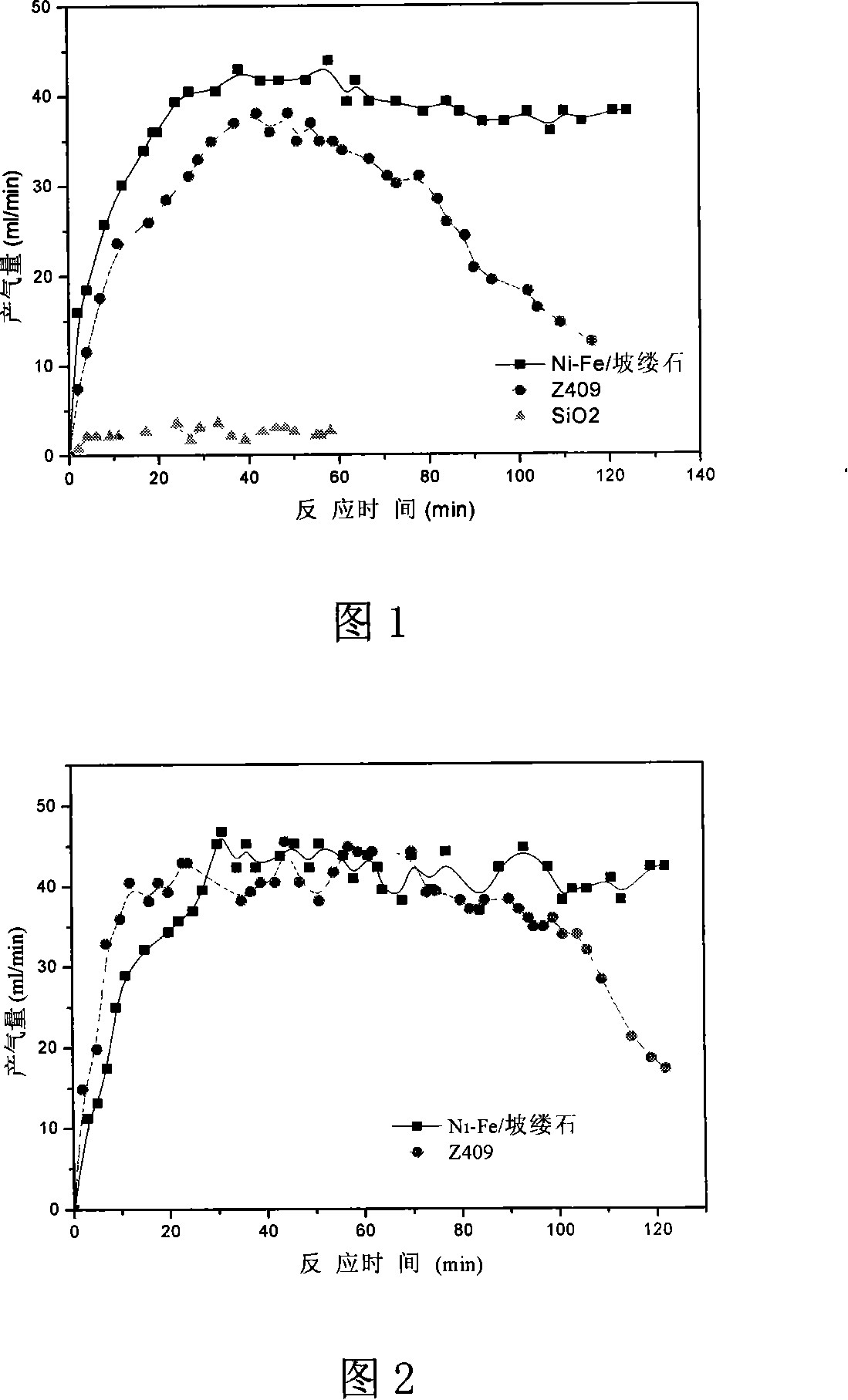

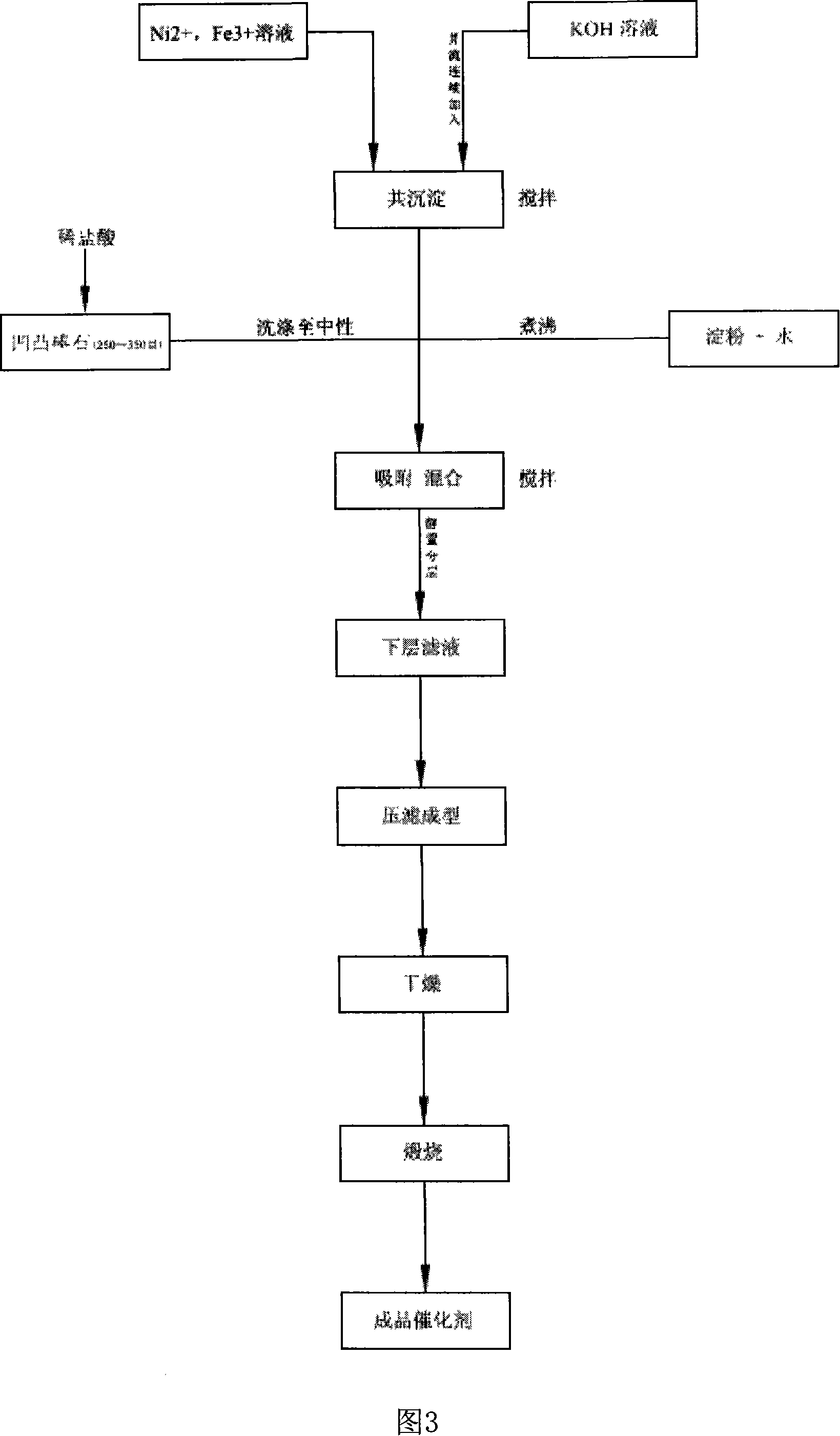

Palygorskite load nickel base biomass tar oil recapitalization hydrogen manufacturing catalyzer and preparation method thereof

InactiveCN101172232AHigh strengthWide variety of sourcesHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingAlkane

The invention discloses nickel-based catalyst taking a palygorskite as the carrier and a preparation method thereof, according to the weight percentage, the content of nickel oxide is 1 to 4 percent, ferric oxide is 5 to 20 percent, and potassium oxide is 1 to 10 percent. The nickel and the iron are supported onto the surface of the palygorskite in a way of coprecipitate adsorbing, and the catalyst is filtered, shaped, dried and calcined to obtain the finished catalyst. Under the operation condition of atmospheric pressure and 480 to 650 DEG C reaction temperature, in a fixed bed reactor, the gas production and the lytic rate of the pyrolytic tar are greatly improved, compared with the catalyst used for converting the commercial light oil vapour for hydrogen production, the prepared catalyst has the advantages of low cost, good low-temperature activity, easiness of restoration and strong anti-carbon deposition capability. The invention can be widely suitable for the hydrogen production from steam reforming of various types of paraffin in the chemical field and the chemical industry field.

Owner:DALIAN UNIV OF TECH

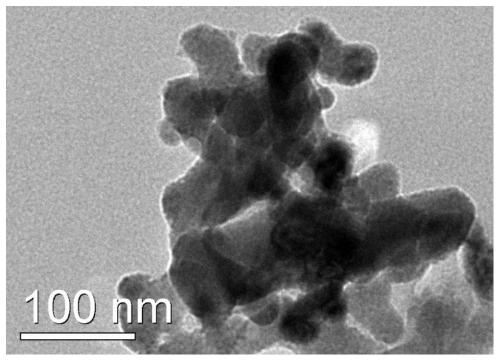

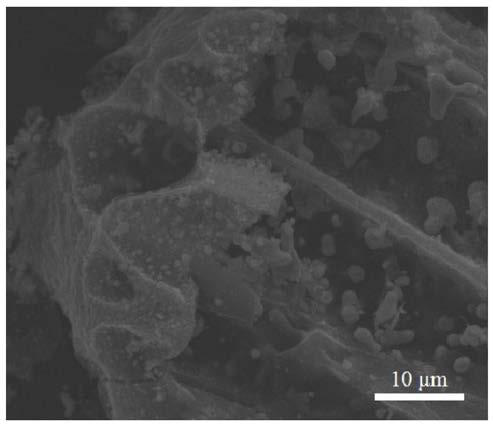

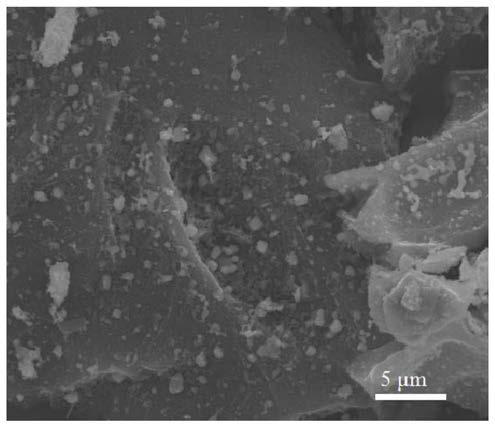

Biochar-based nanometer zero-valent iron material and preparation method thereof

ActiveCN109847697APromote lysisIncrease loadOther chemical processesWater contaminantsIron saltsNitrogen

The invention discloses a biochar-based nanometer zero-valent iron material and a preparation method thereof, and belongs to the technical field of environmental protection materials. The preparationmethod comprises the following steps: dissolving an iron salt in water, and adding nitric acid to adjust pH; adding grinded and sieved biochar into the iron salt solution, performing magnetic stirringto obtain a composite material; and performing drying on the composite material, carrying out the carbothermal reduction reaction of the dried composite material under nitrogen protection, and performing cooling to obtain the biochar-based nanometer zero-valent iron material. The interior of the biochar-based nanometer zero-valent iron material is coated with a large amount of nanometer zero-valent iron, so that the removal performance of the biochar-based nanometer zero-valent iron material is greatly enhanced.

Owner:SUN YAT SEN UNIV

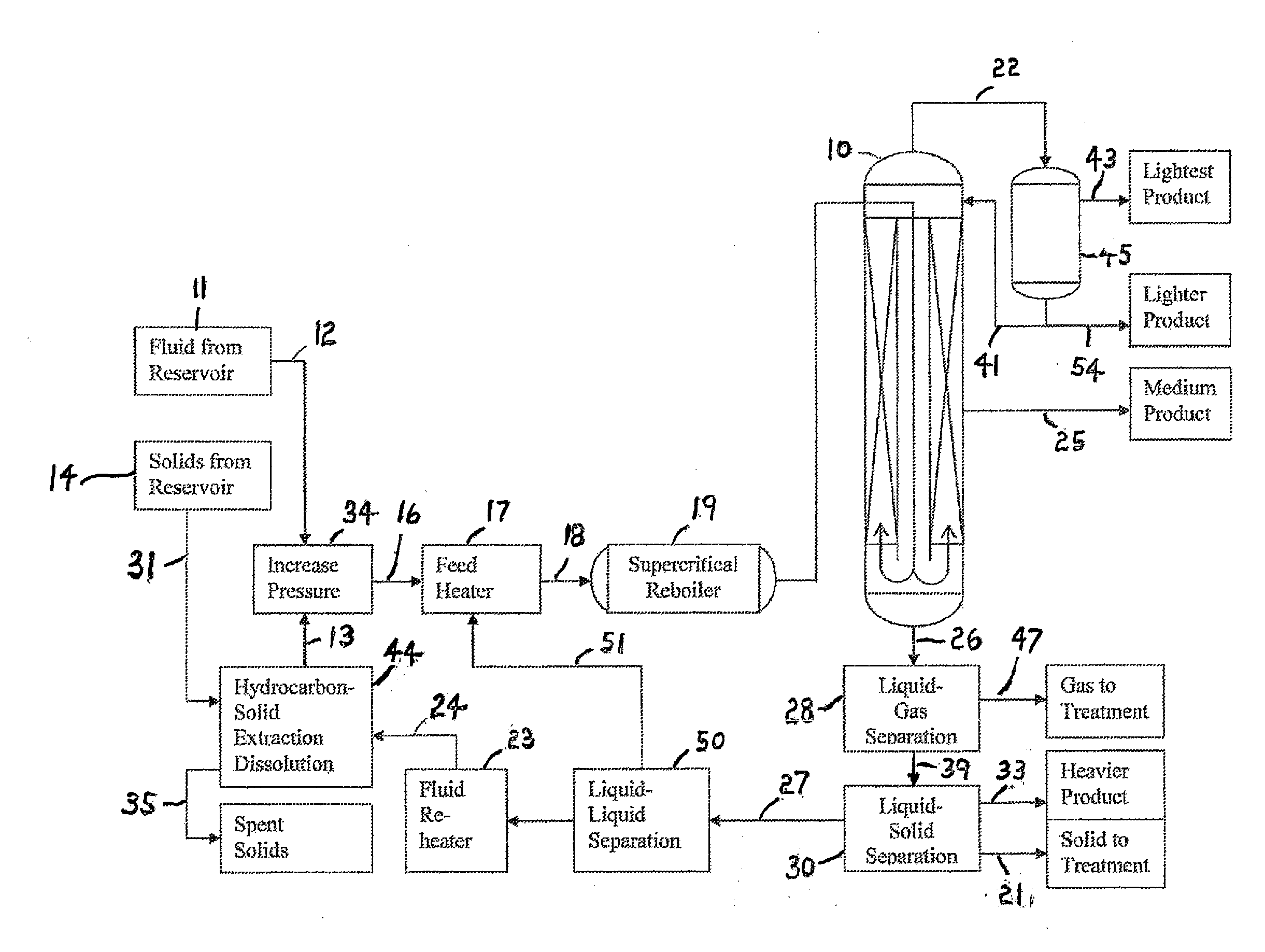

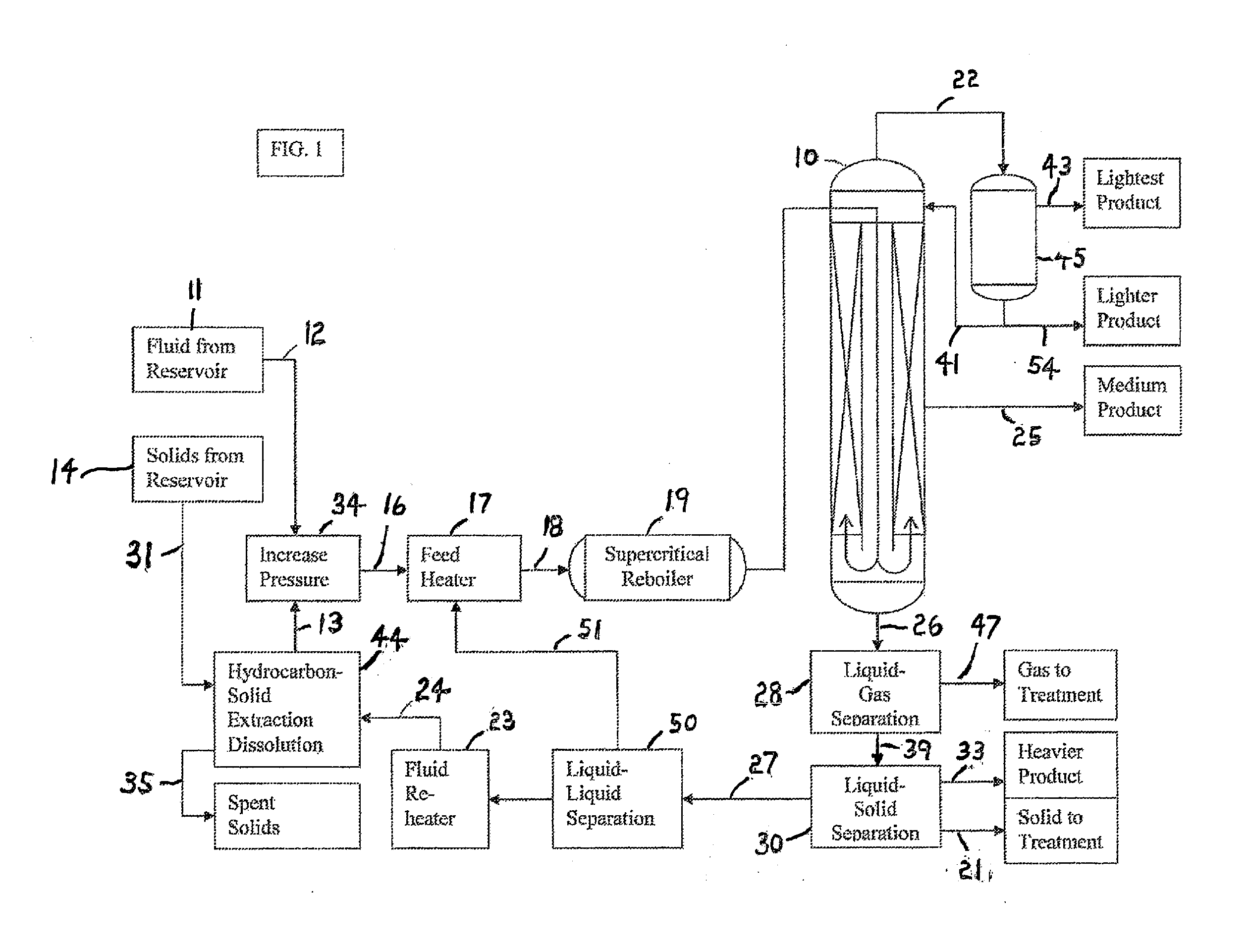

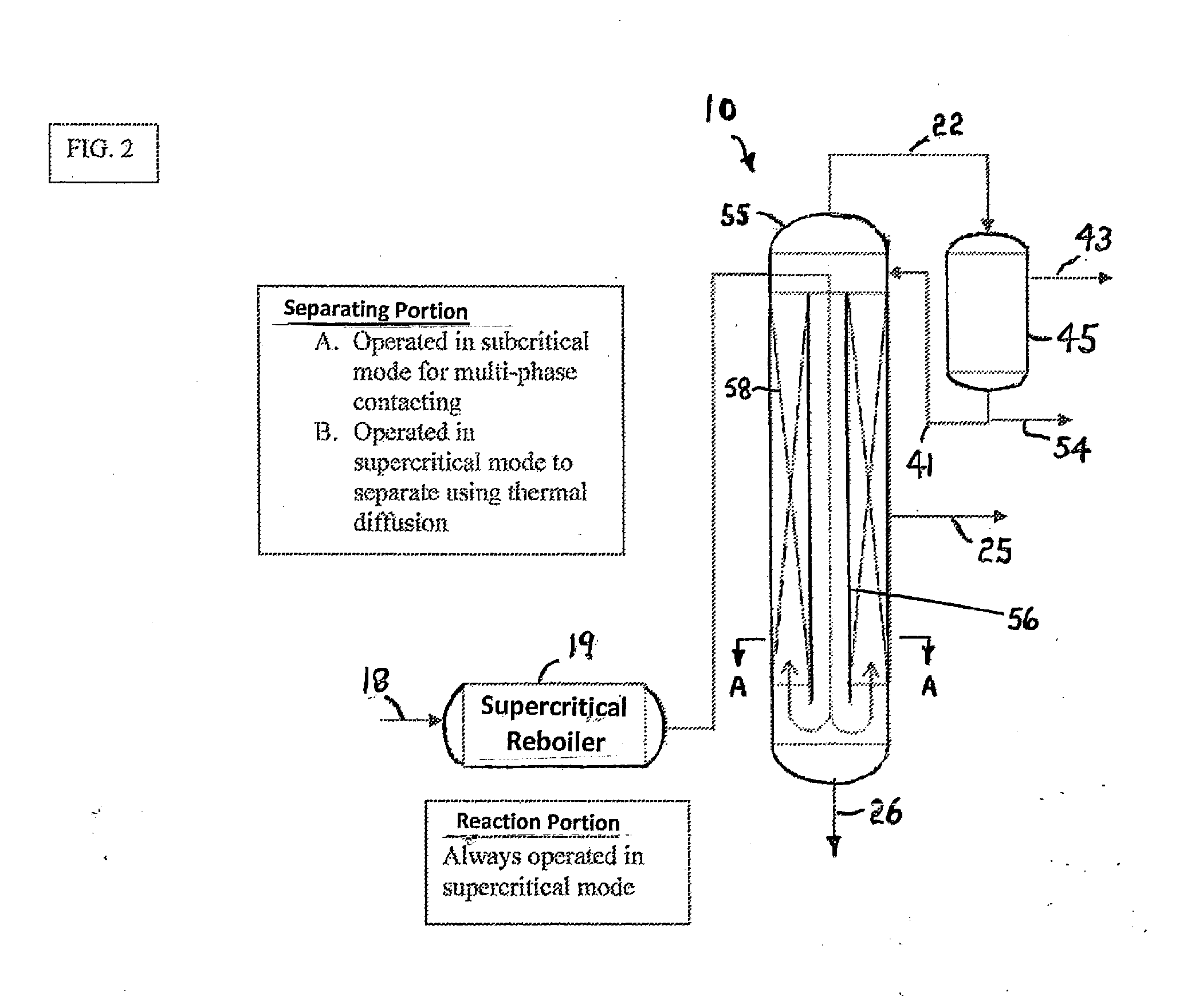

Using supercritical fluids to refine hydrocarbons

ActiveUS20130206645A1Easy to controlImprove securityThermal non-catalytic crackingRefining with oxygen compoundsMomentumAPI gravity

A system and method for reactively refining hydrocarbons, such as heavy oils with API gravities of less than 20 degrees and bitumen-like hydrocarbons with viscosities greater than 1000 cp at standard temperature and pressure, using a selected fluid at supercritical conditions. A reaction portion of the system and method delivers lightweight, volatile hydrocarbons to an associated contacting unit which operates in mixed subcritical / supercritical or supercritical modes. Using thermal diffusion, multiphase contact, or a momentum generating pressure gradient, the contacting unit separates the reaction products into portions that are viable for use or sale without further conventional refining and hydro-processing techniques.

Owner:HEAVY OIL SOLUTIONS INC

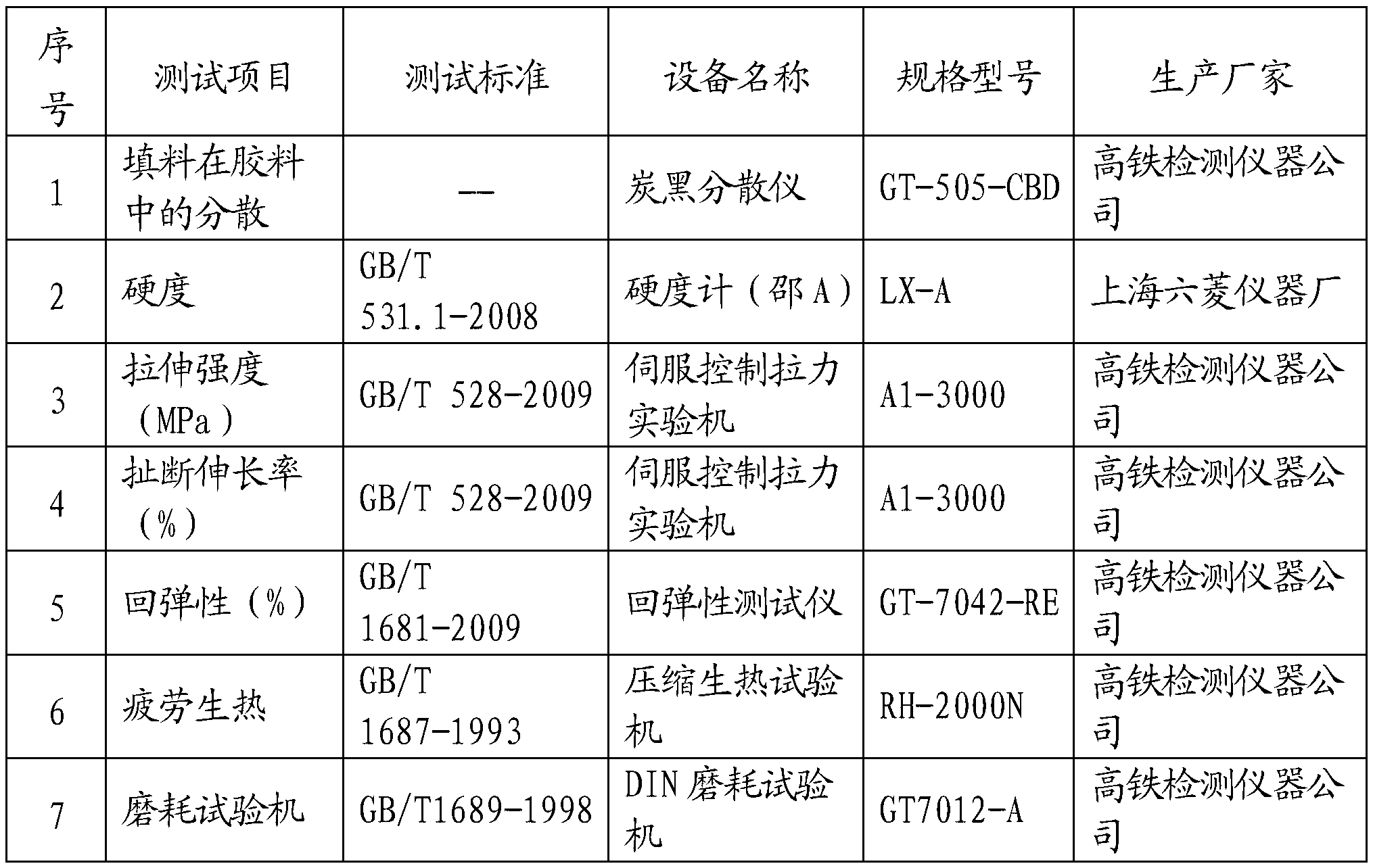

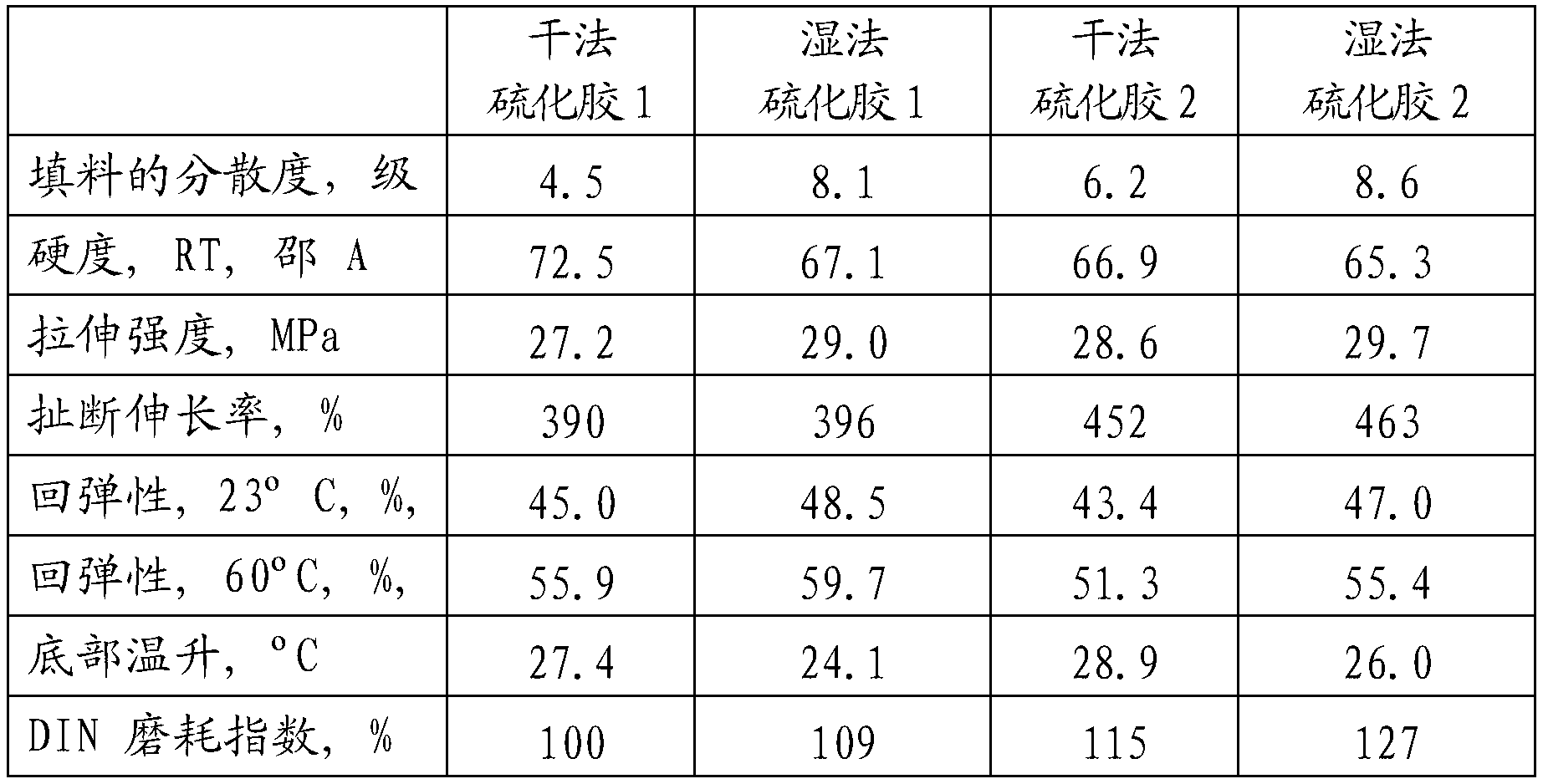

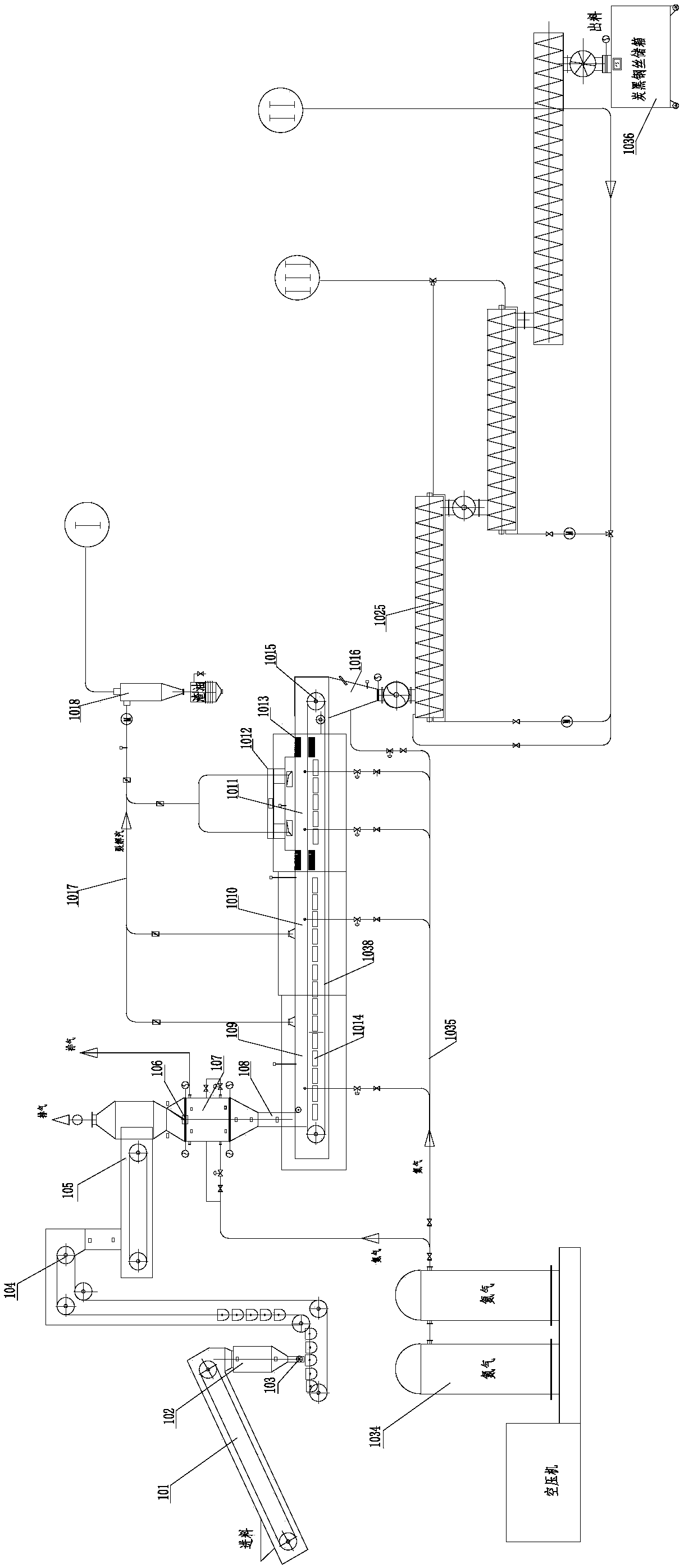

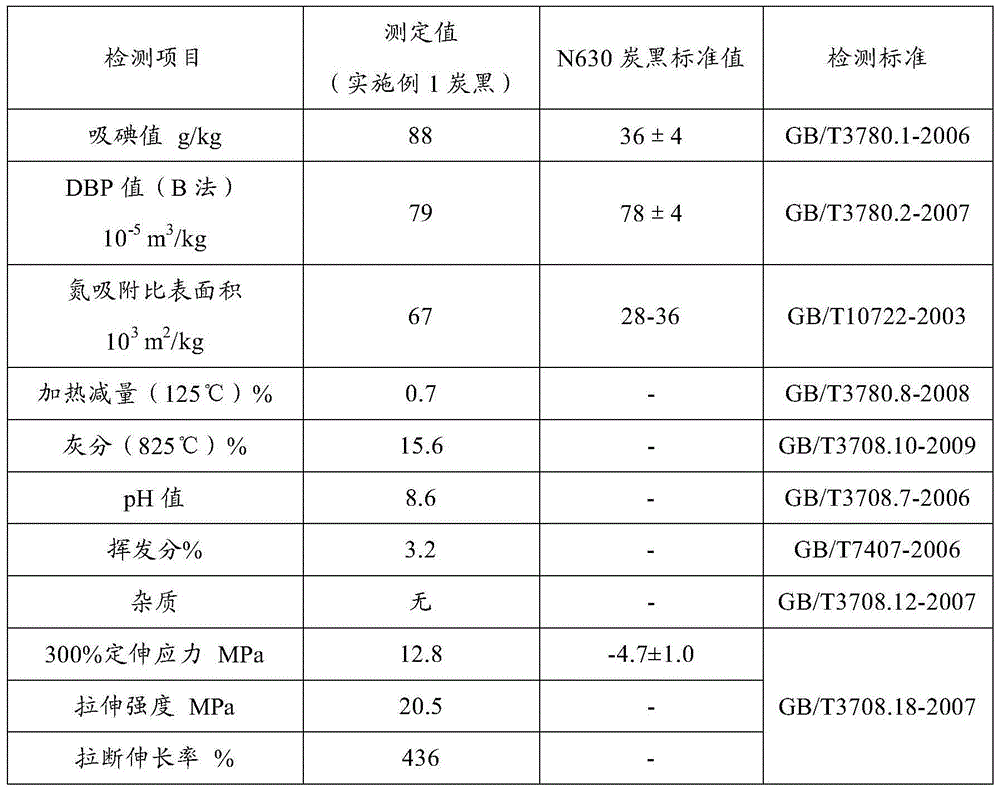

Filler, synthetic rubber and wet rubber compound integrated production method

ActiveCN103224659ABreakthrough applicabilityBreakthrough performancePigmenting treatmentSilicon oxidesSynthetic rubberIntegrated production

The invention discloses a filler, synthetic rubber and wet rubber compound integrated production method. A filler is selected from carbon black, white carbon black or a combination of the carbon black and the white carbon black. Compared with traditional and respective independent technologies, the method disclosed in the invention has the advantages of omitting of the post-treatment technologies of the filler and a synthetic rubber, realization of the cycle of sodium carbonate, and full utilization of carbon dioxide and heat generated in a traditional carbon black production technology. So the method can reduce production equipment and simultaneously realize the low carbon and low pollution discharge through the integrated optimization of the process flow in order to reach the recycle purpose.

Owner:EVE RUBBER RES INST

Combination type efficient sludge dewatering conditioning method

ActiveCN104891779AFully dehydratedHas strong oxidizing propertiesSludge treatment by de-watering/drying/thickeningSulfatePotassium ferrate

The invention relates to a combination type efficient sludge dewatering conditioning method and belongs to the field of sludge dewatering preprocessing. According to the technical scheme, the method includes performing acidification treatment on sludge to be dewatered through concentrated sulfuric, adjusting the pH of a sludge system to range from 3.5 to 5, and stirring for 15 to 30min through a stirring blade; adding strong oxidizing agent, namely potassium ferrate, with the content of 0.2% to 4% of the total solid sludge into acidified sludge after water dissolving, stirring for 2min in the speed of 200 to 300 r / min rapidly, and stirring for 20 to 40min in the speed of 80 to 150 r / min slowly; adjusting the pH to range from 3.5 to 5 through concentrated sulfuric, adding ferrous sulfate with the content of 4% to 8% of the total solid sludge after preparing the ferrous sulfate as solution with the concentration of 20% to 50%, after stirring and scattering, adding H2O2, with the concentration of 30%, with the content of 4% to 8% of the total solid sludge, and reacting for 30 to 50min completely during slow stirring; finally, adding quicklime with the content of 3% to 8% of the total solid sludge into the sludge conditioning system, adjusting the system pH to range from 6 to 8, scattering the quicklime evenly, and dewatering.

Owner:BEIJING UNIV OF TECH

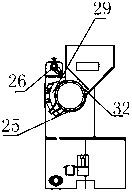

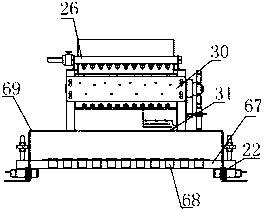

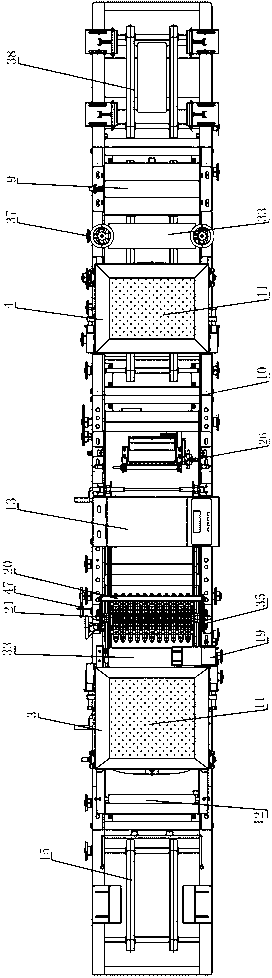

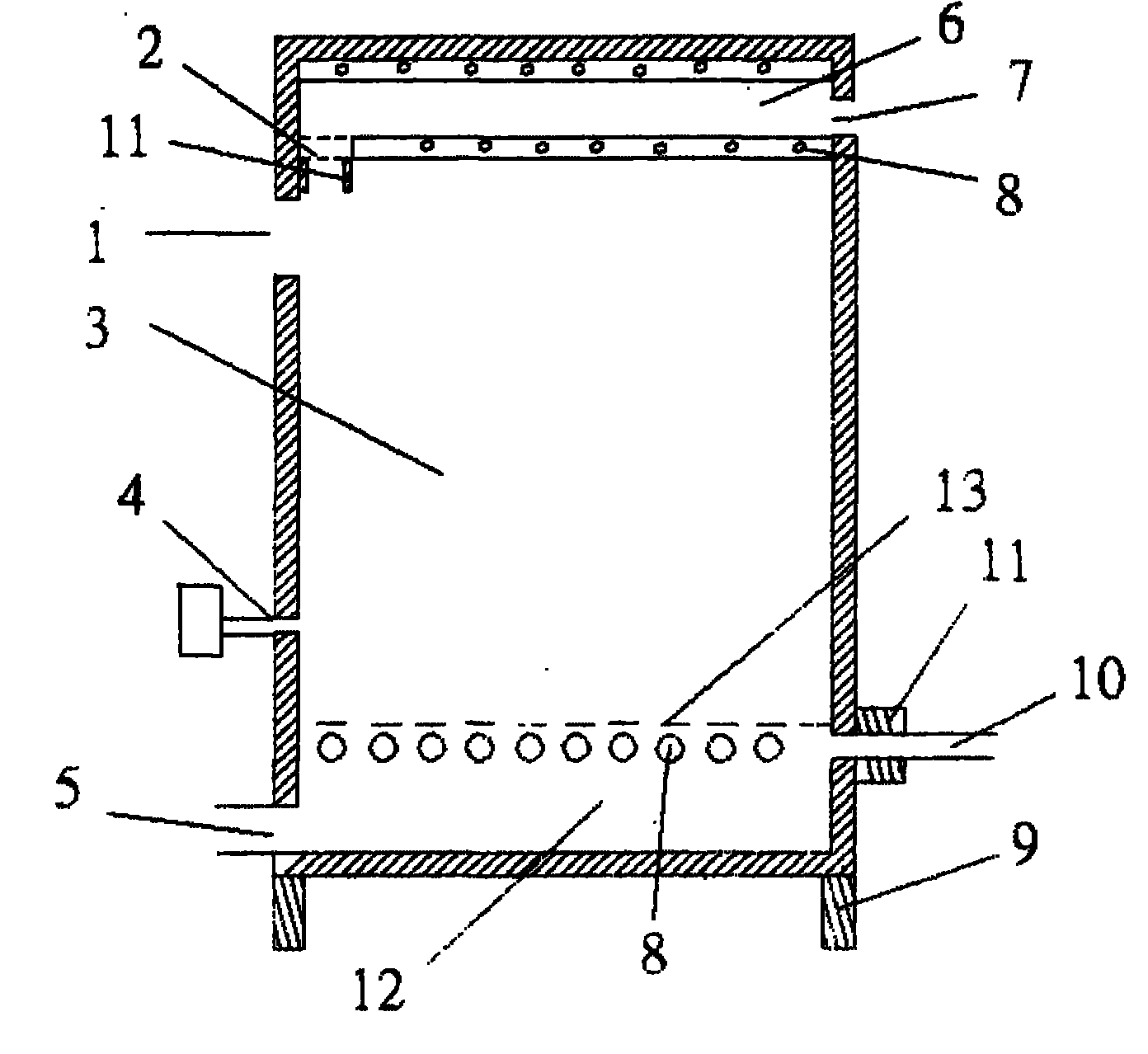

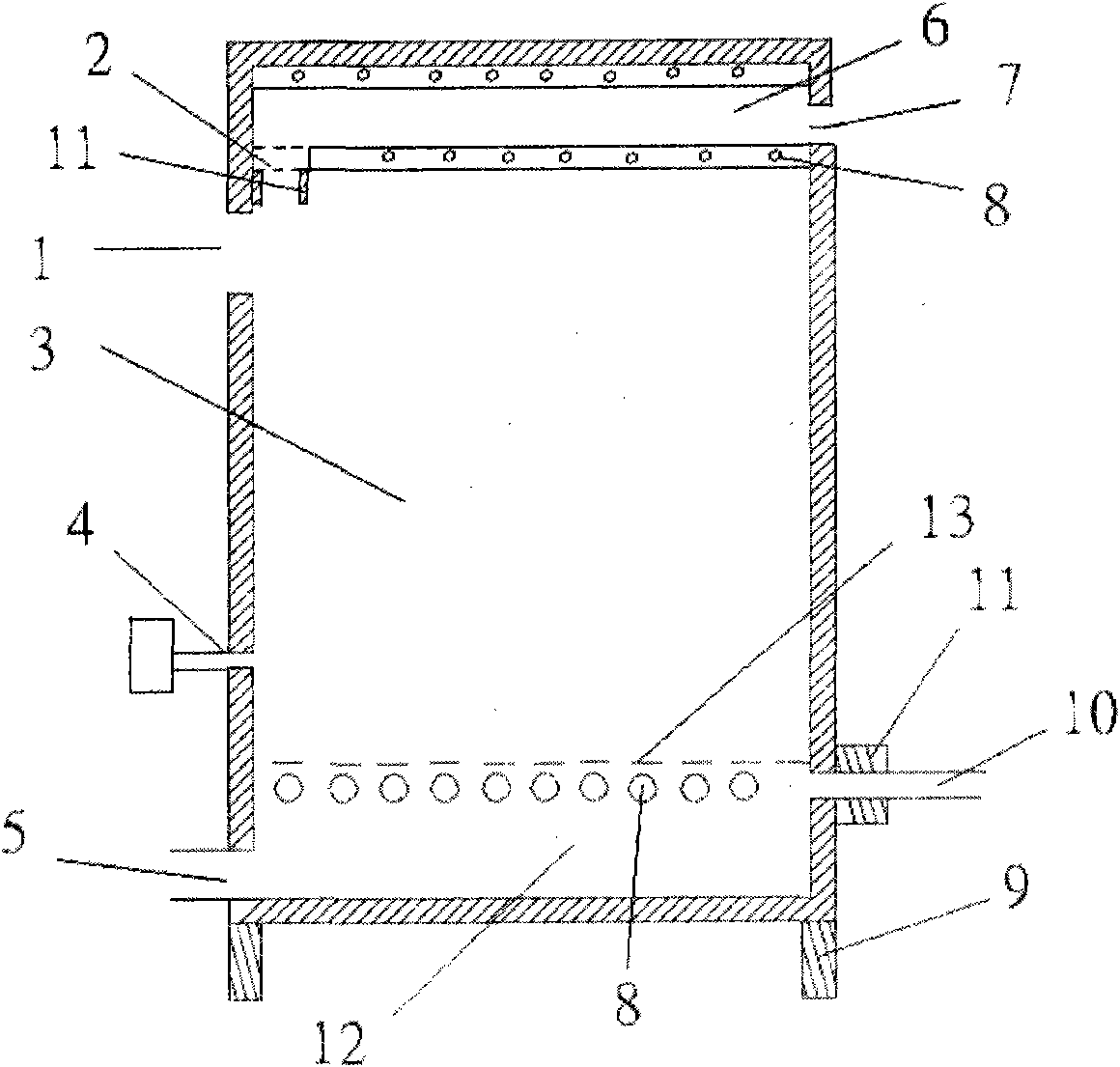

Sowing machine capable of realizing intelligent precision dibbling

InactiveCN102696317AImprove seeding accuracyPrecise sowingCultivating equipmentsSeed depositing seeder partsControl systemEngineering

The invention relates to a sowing machine capable of realizing intelligent precision dibbling. The method comprises a master controller (13), a rack (1), a transmission assembly (8) arranged on the rack, a substrate filling assembly (3), an indenting assembly (7), a seed dibbling assembly (6) and an earthing assembly (4), wherein the seed dibbling assembly is realized by adopting the following manner: a seedling raising plate moves to a position sensor and triggers a master control system to control a stepping motor to drive a sowing roller to rotate, seeds enter a corresponding sowing hole when the sowing roller rotates, unnecessary seeds on the sowing hole are cleaned by virtue of a gas seed cleaning device, seeds reserved in the sowing hole are dropped at a fixed position by virtue of a seed protective device, the seeds enter the corresponding holes along a guide pipe, and thus the accurate sowing is realized. The sowing machine disclosed by the invention solves the technical problems that the conventional sowing is inaccurate, the time and the effort are wasted and the working efficiency is low; and the sowing machine disclosed by the invention has the advantages of high sowing accuracy, accurate and passive indenting, simplicity, energy conservation and high efficiency.

Owner:XIAN SENWAS AGRI SCI & TECH

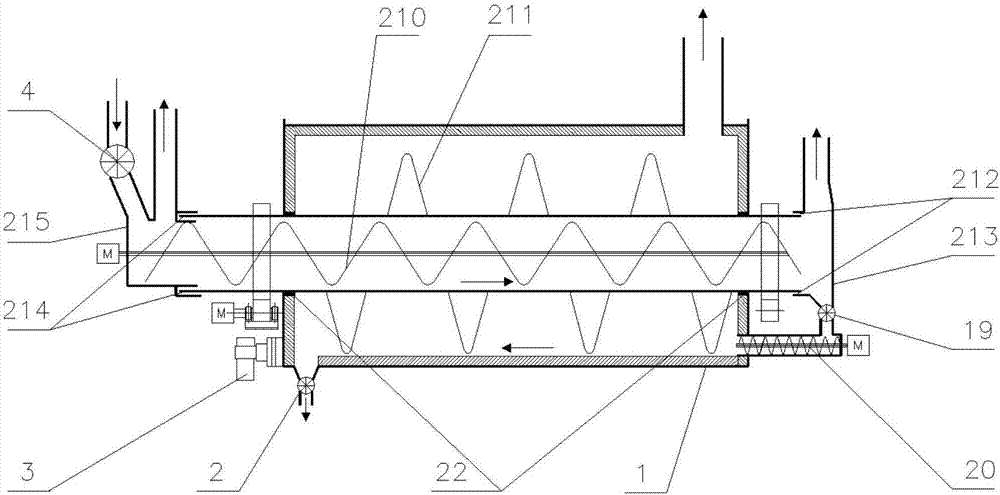

Indirect thermal cracking and ash combustion smelting furnace and treatment method thereof

ActiveCN107120656ASimple structureReduce calorie consumptionIncinerator apparatusCombustion chamberNitrogen gas

The invention belongs to the technical field of organic solid waste treatment, and particularly relates to an efficient and energy-saving indirect thermal cracking and ash combustion smelting furnace with a wide utilization range. The efficient and energy-saving indirect thermal cracking and ash combustion smelting furnace comprises a rotary thermal cracking and ash combustion smelting furnace body and a rotary barrel / rotary kiln sealing device, wherein the rotary thermal cracking and ash combustion smelting furnace body comprises an indirect thermal cracking barrel body with a spiral pushing device in the middle and a spiral inverse pushing ash combustion smelting heating furnace at the outer part of the barrel body; the rotary kiln sealing device comprises a rotary barrel body, a feeding end material collection hood, a discharge end material collection hood, a water seal filling sealing ring, a nitrogen emergency sealing air chamber and scale sealing pieces; the rotary indirect thermal cracking barrel body is lined with a heat-resistant steel barrel made from a silicon carbide material; a rotary screw conveyer is arranged in the heat-resistant steel barrel; and a high temperature resistant ceramic screw conveyer blade is fixed to the outer part of the barrel body. According to the efficient and energy-saving indirect thermal cracking and ash combustion smelting furnace, a cracking furnace, a secondary combustion chamber and a smelting furnace are integrated in one furnace body, noncondensable gas, condensed oil and carbon residues generated after cracking can be utilized as fuel makeup, heat consumption is greatly reduced, and remaining ash is smelted till ash reaches the safe landfill standard.

Owner:无锡爱普特设备科技有限公司

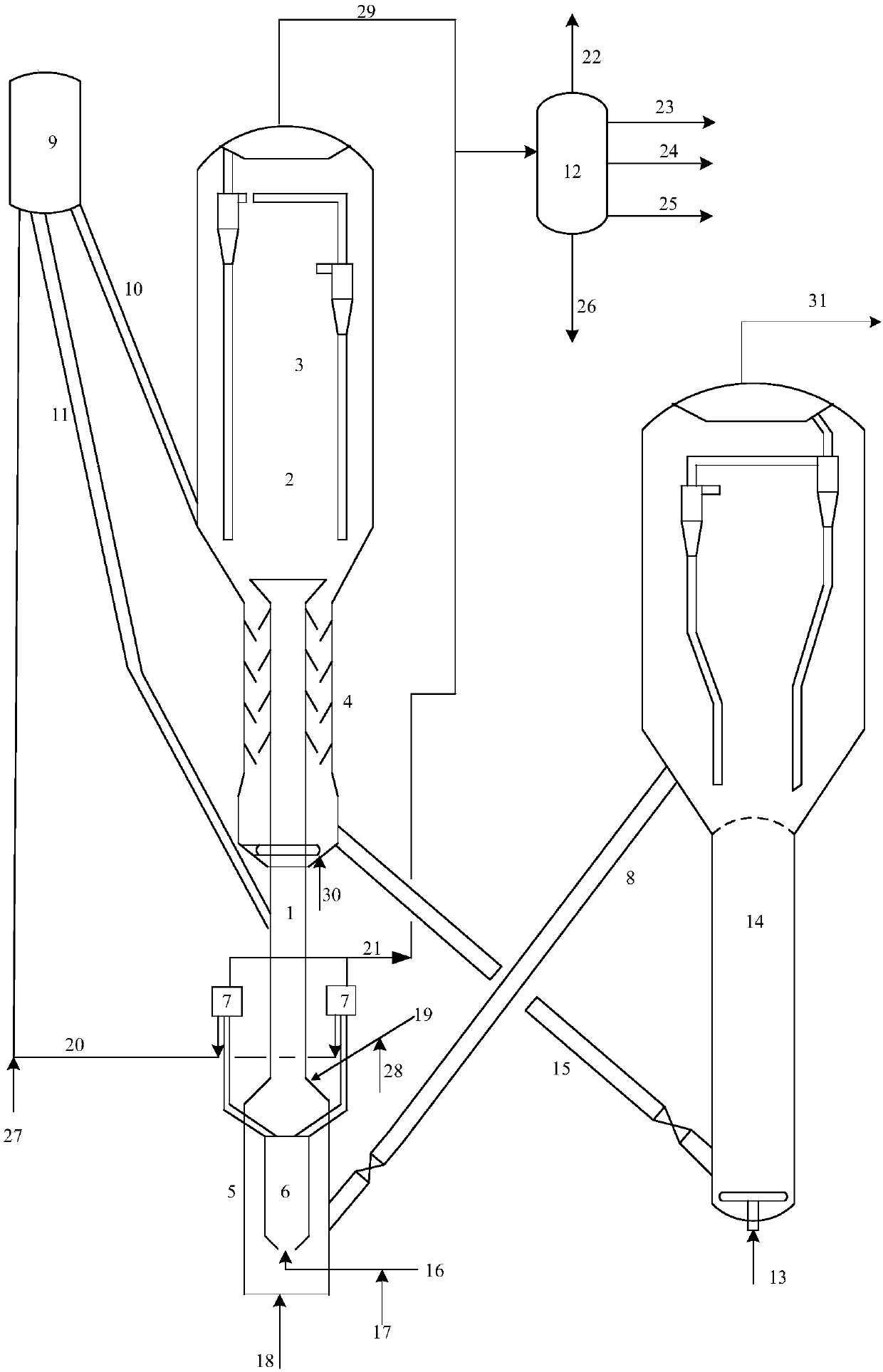

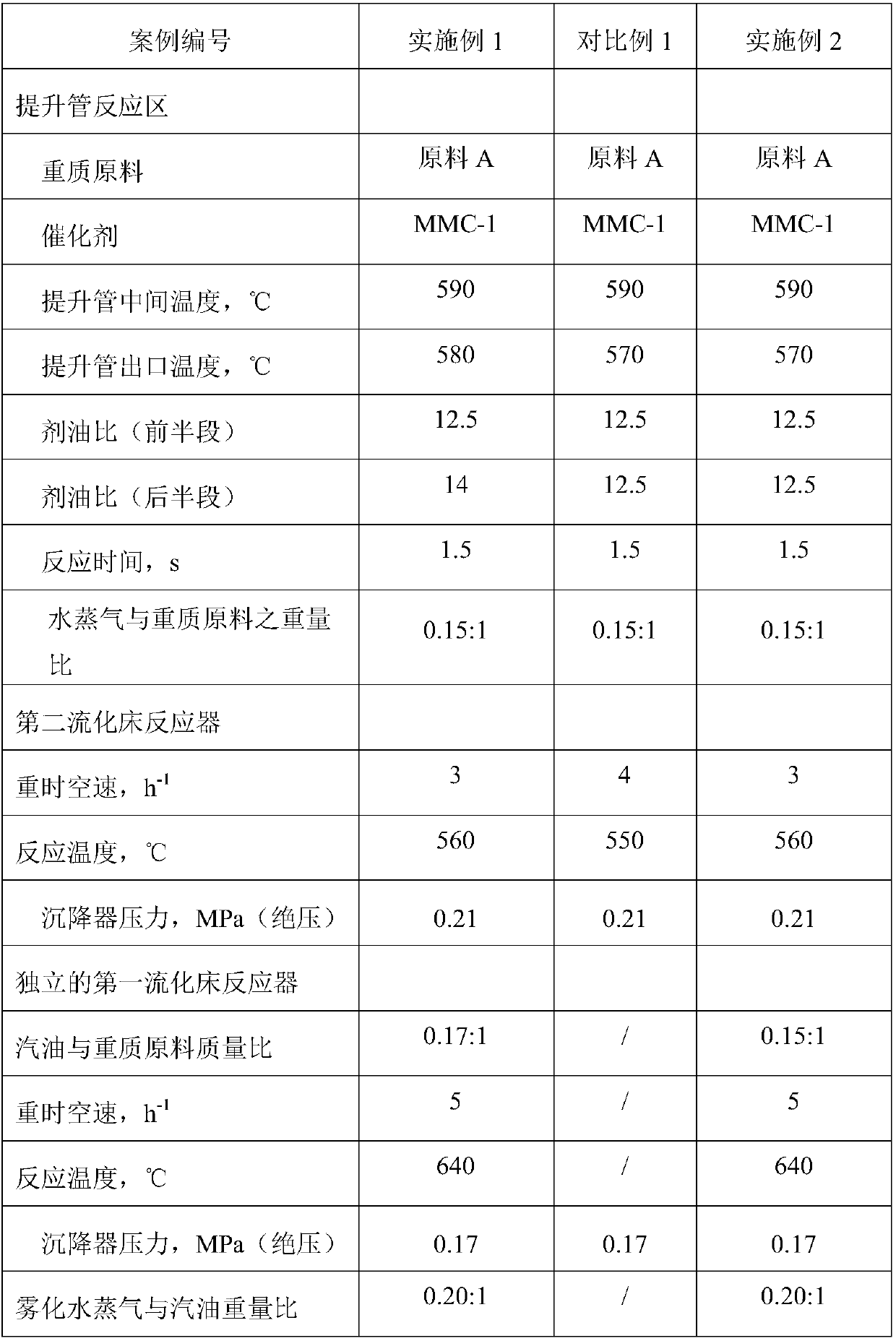

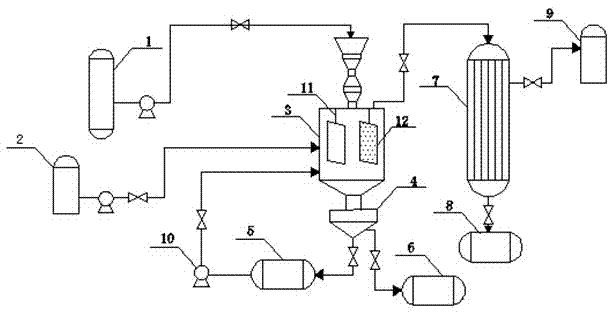

Technology and system for catalytic cracking

ActiveCN107597026AHigh conversion rate of heavy oilPromotes re-lysisCatalytic crackingChemical/physical processesChemistryDry gas

The invention discloses a technology and system for catalytic cracking. The technology for the catalytic cracking comprises the steps of feeding light raw oil into a first fluidized bed reactor (6) which is arranged in a pre-lift zone (5) for a first catalytic cracking reaction, and feeding heavy raw materials into a lift-pipe reaction zone and a second fluidized bed reactor (2) for a second catalytic cracking reaction and a third catalytic cracking reaction sequentially. According to the technology based on the system, the yield of propylene can be increased, and meanwhile the increase of theyields of dry gases and coke can be slowed down.

Owner:CHINA PETROLEUM & CHEM CORP +1

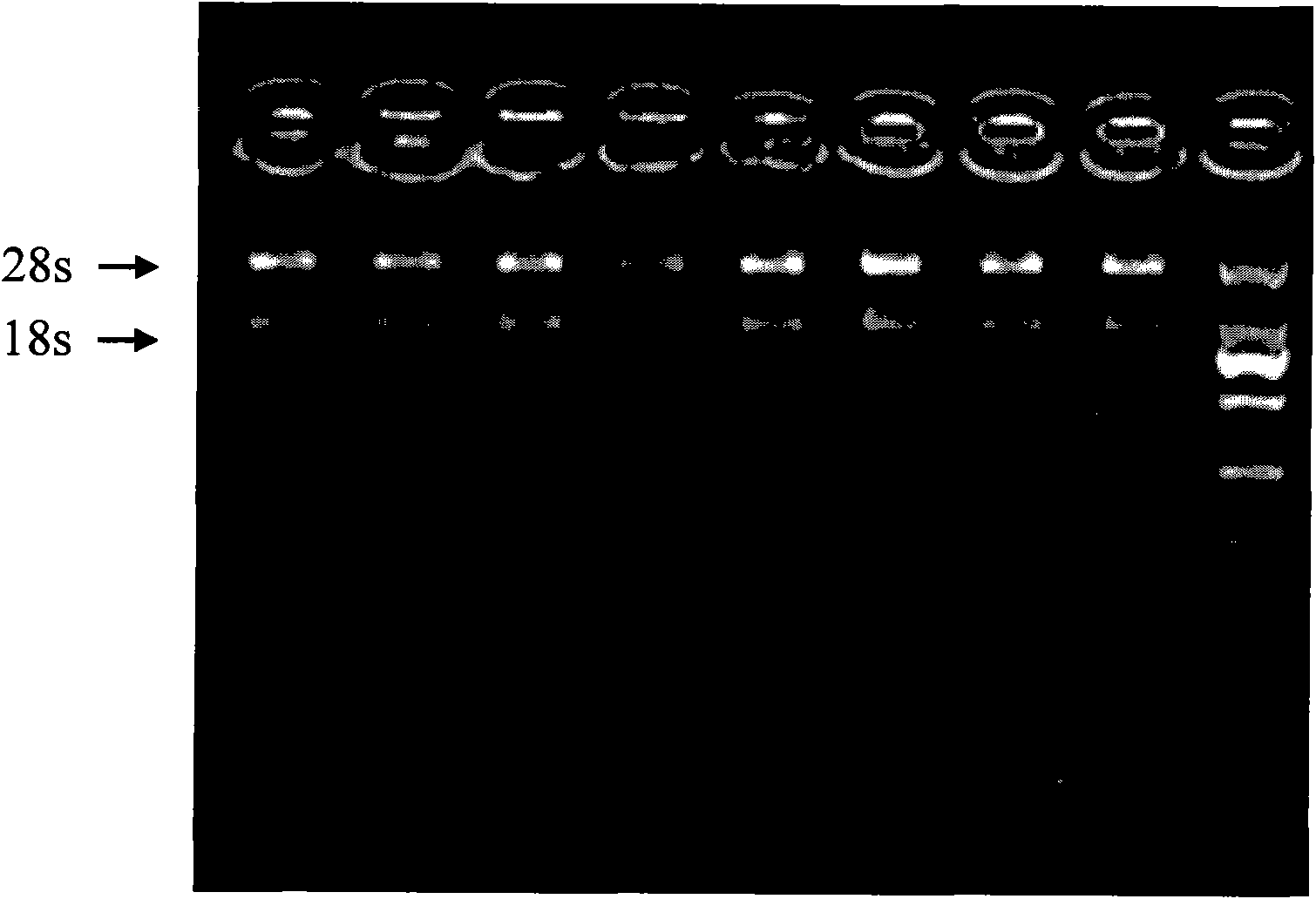

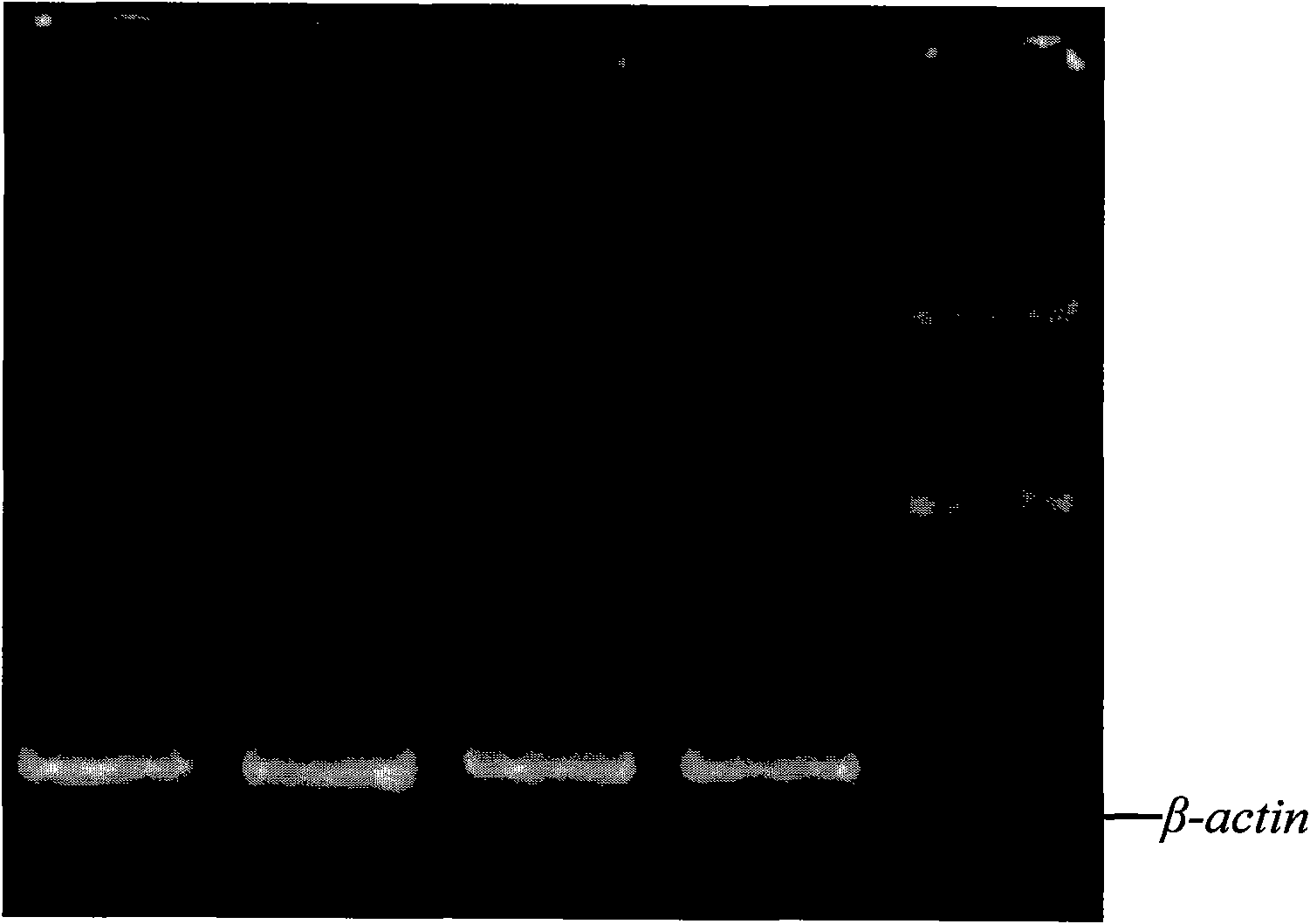

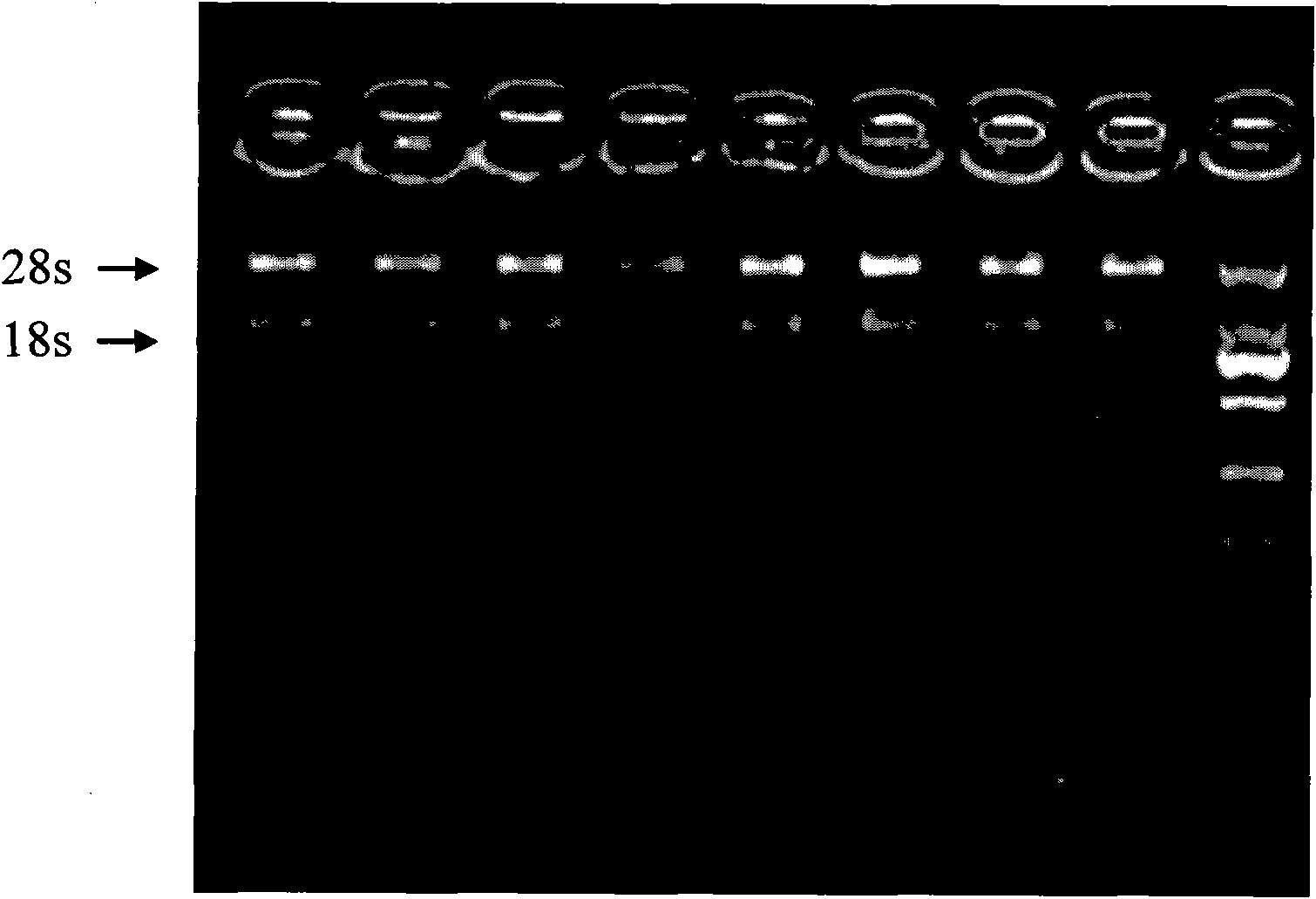

Extraction method of apostichopus japonicus body-wall total RNA

InactiveCN101864414AMeet Gene Expression AnalysisFulfil requirementsDNA preparationWater bathsTotal rna

The invention discloses a high-extraction-purity, good-integrity and high-yield extraction method of apostichopus japonicus body-wall total RNA (Ribonucleic Acid). The method comprises the following steps of: quickly freezing apostichopus japonicus body-wall tissue in liquid nitrogen; grinding and putting the frozen tissue in lysate to homogenate, centrifugate and take supernatant fluid; adding chloroform to the supernatant fluid and centrifugating to take the supernatant fluid to another centrifuge tube; then, adding a high-salt solution and isopropyl alcohol and filtering precipitation with ethanol; dissolving the precipitation with DEPC (diethypyrocarbonate) treated water to have constant volume; sequentially adding a DNA enzyme buffer solution without RNA enzymes, DNA enzymes without RNA enzymes and an RNA enzyme inhibitor to the dissolved solution to mix; carrying out a water bath at 37 DEG C to obtain DNA lysate; adding phenol and chloroform in a ratio of 5:1 to the DNA lysate to mix, centrifugate and take supernatant fluid; adding a glycogen solution, a potassium acetate solution and pre-cooling ethanol to the supernatant fluid; mixing and staying over night; centrifugating to discard the supernatant fluid; washing and dying the precipitation with ethanol; dissolving the solution with the DEPC treated water to have constant volume of 20 mu l; and storing at 80 DEG C below zero.

Owner:DALIAN OCEAN UNIV

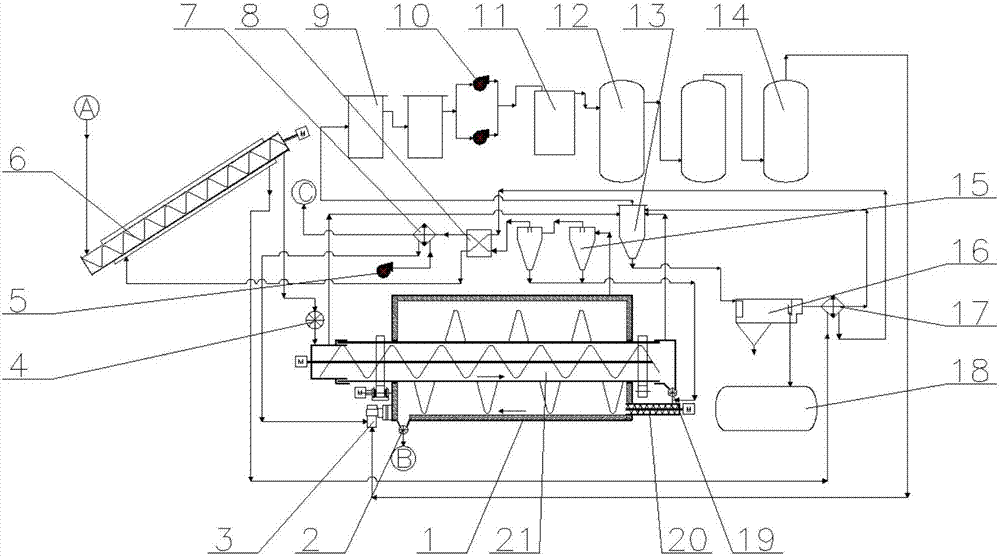

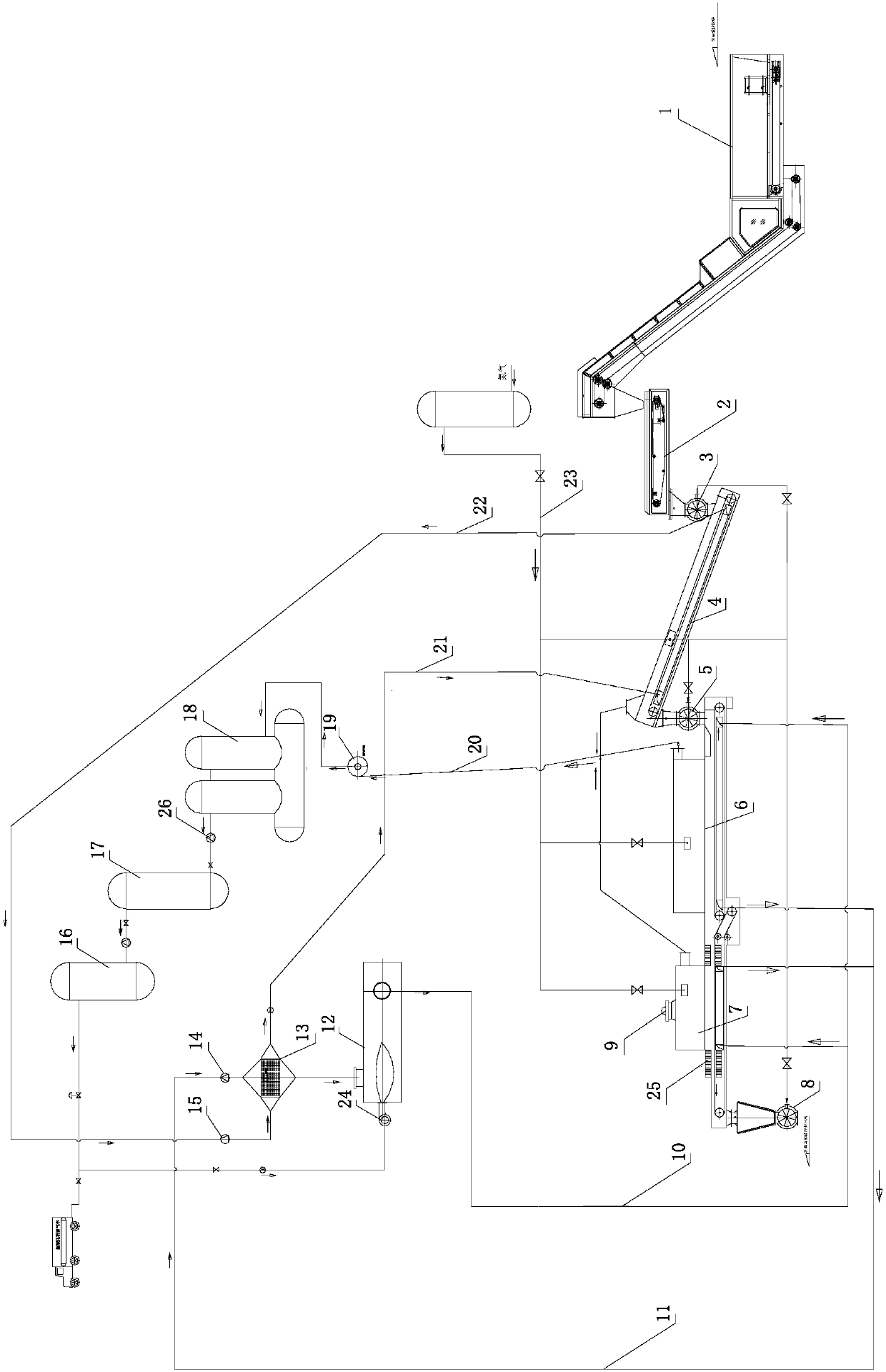

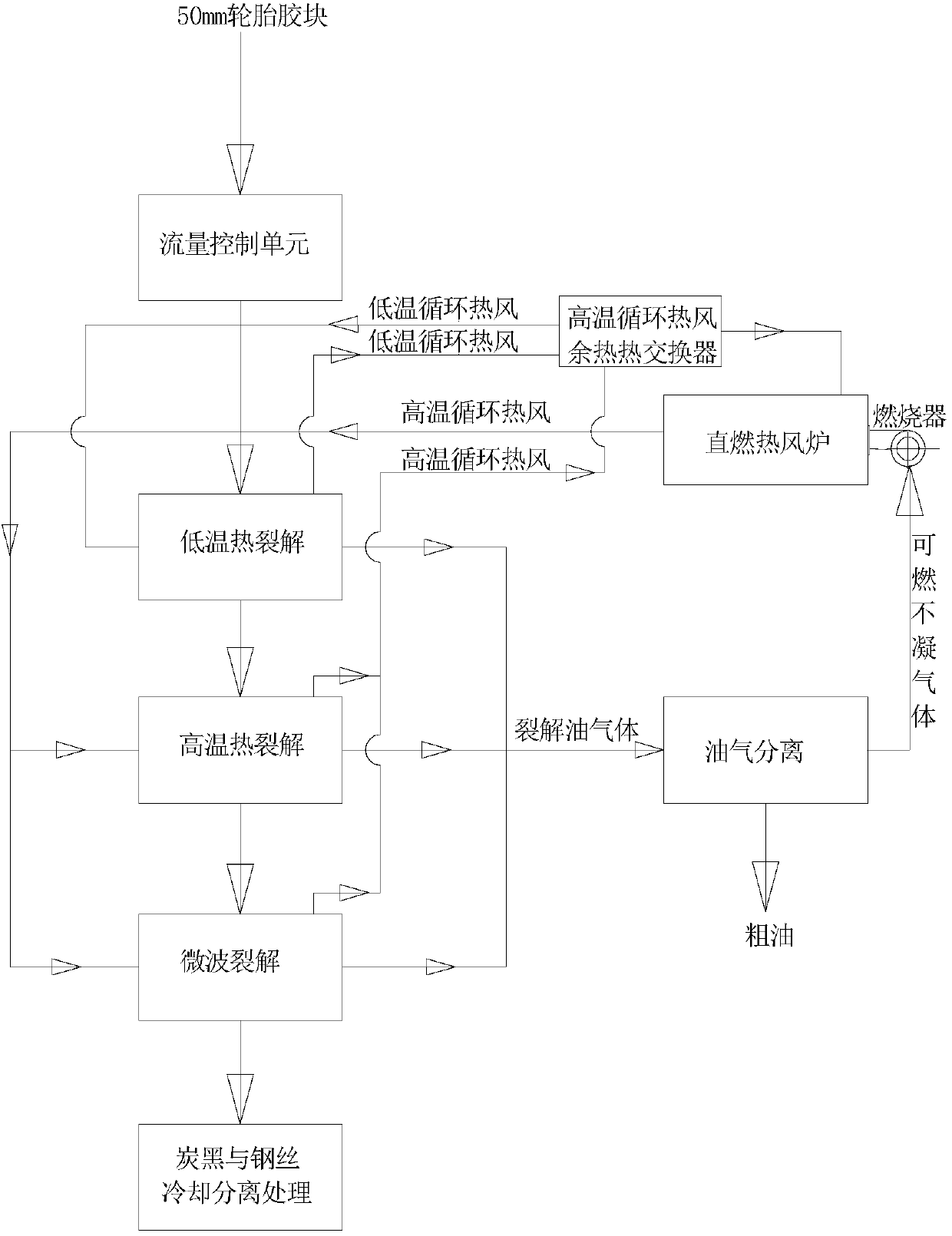

Method and system for cracking waste rubber

PendingCN108018062ARapid lysisReduce energy consumptionPigmenting treatmentTransportation and packagingMicrowaveWaste rubber

The invention provides a method and a system for cracking waste rubber. The waste rubber is sequentially sent to a low-temperature thermal cracking chamber, a high-temperature thermal cracking chamberand a microwave cracking chamber which respectively have an oxygen-free or oxygen-deficient environment, wherein thermal cracking of the waste rubber in the low-temperature thermal cracking chamber is carried out in a 200-400 DEG C environment, thermal cracking in the high-temperature thermal cracking chamber is carried out in a 500-800 DEG C environment, and microwave cracking in the microwave cracking chamber is carried out in a 500-800 DEG C environment; a cracking oil gas generated in the cracking process is continuously discharged from the low-temperature thermal cracking chamber, the high-temperature thermal cracking chamber and the microwave cracking chamber; and solids generated in the cracking process are recovered. The method and the system can effectively reduce the energy consumption in the cracking process and improve the cracking efficiency of the waste tire and the quality of cracked carbon black.

Owner:江苏林达智思环保科技有限公司

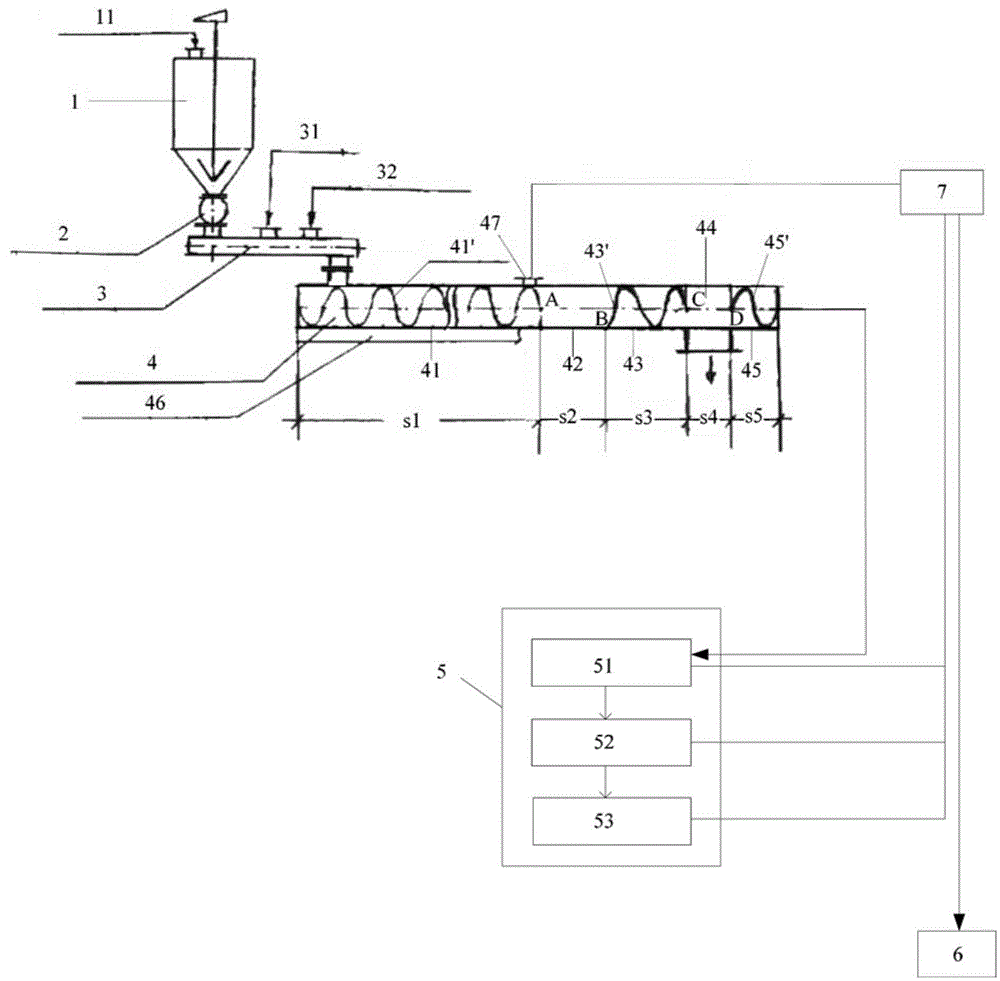

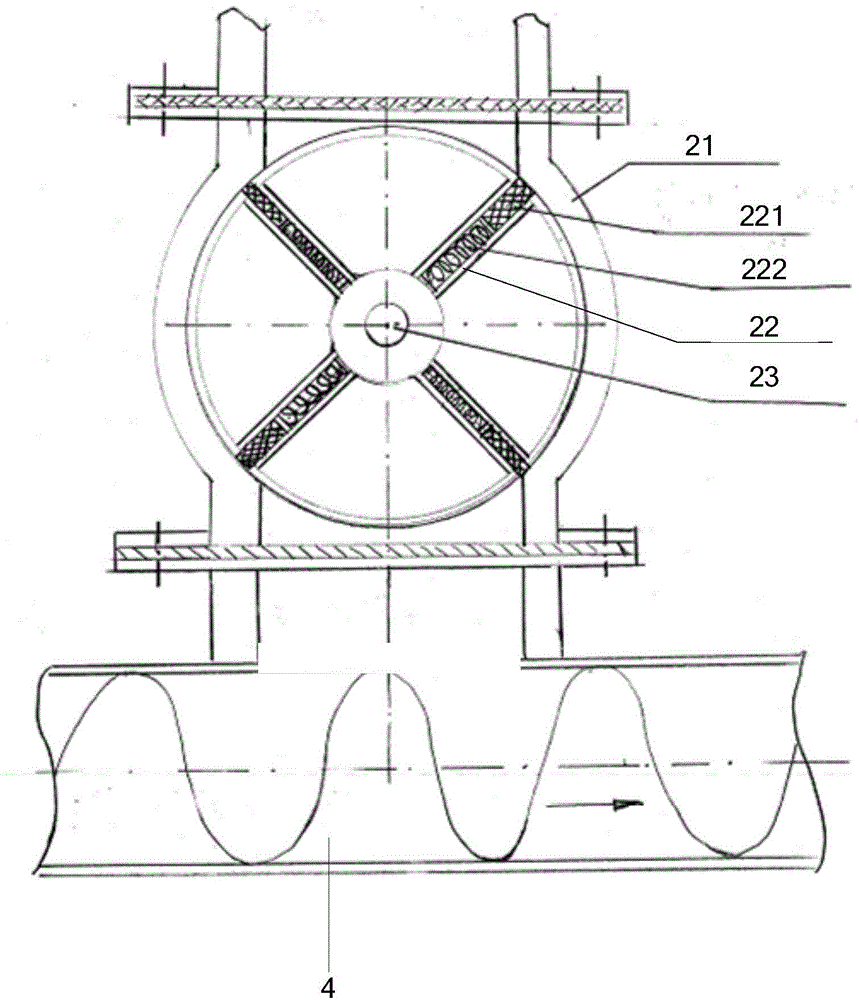

Continuous segmented cracking equipment and technology used for waste and old tyres and capable of preventing generation of dioxin

InactiveCN104479722AHigh activityQuality improvementPigmenting treatmentPlastic recyclingScrew conveyorCarbon black

The invention provides a continuous segmented cracking equipment and a technology used for waste and old tyres and capable of preventing generation of dioxin. The equipment comprises a raw material bin, a mixing feeding screw conveyor, a preheating furnace, a continuous thermal cracking device and an oil gas recovery device; the raw material bin is successively connected with the mixing feeding screw conveyor, the preheating furnace and the continuous cracking device; the preheating furnace successively comprises a heating segment, a sealing segment, a forward pushing segment and a discharging segment along the flowing direction of a raw material, the heating segment and the forward pushing segment are both provided with a screw pusher, and the screwing direction of the screw pushers in the heating segment and in the forward pushing segment are same, and the sealing segment is not provided with a screw pusher; and the continuous cracking device successively comprises a first cracking unit with the heating temperature of 340-360 DEG C, a second cracking unit with the heating temperature of 440-460 DEG C and a third cracking unit with the heating temperature of 540-560 DEG C. The equipment and the technology are capable of effectively preventing generation of dioxin in the process of processing waste and old tyres, improving the activity and the quality of carbon black, and realizing continuous cracking production of waste and old tyres.

Owner:中机国宏高分子技术研究(北京)中心

Garbage cracking catalytic gasification furnace

InactiveCN102031149AReduce manufacturing costsSmall external areaChemical industryCombustible gas productionCatalytic reformingWater vapor

The invention discloses a garbage cracking catalytic gasification furnace. The cracking catalytic gasification furnace mainly comprises a preheating chamber, a cracking gasification chamber and a catalytic reforming chamber, wherein the preheating chamber is provided with an air inlet, an ash outlet, a fire grate and an electric heating tube; the air inlet is connected with an air inlet pipe; the air inlet pipe is provided with a magnetizer; strong-magnetic-field magnets are arranged around an air passage in the magnetizer and the magnets with the same polarity are arranged opposite to each other; the cracking gasification chamber is provided with a feed port and a vapor inlet; the catalytic reforming chamber is provided with a gas inlet, a product gas outlet and an electric heating tube; a magnetizer is arranged at the gas inlet; and a proper amount of catalyst is placed in the catalytic reforming chamber. Combustion heat of low-temperature part of garbage can maintain continuous cracking of the garbage under the action of a magnetic field, and catalytic reforming temperature of tar gas can be obviously reduced, and energy is saved. The equipment has a simple structure, low cost and higher product gas calorific value and can realize low-cost recycling of the garbage.

Owner:YANTAI UNIV

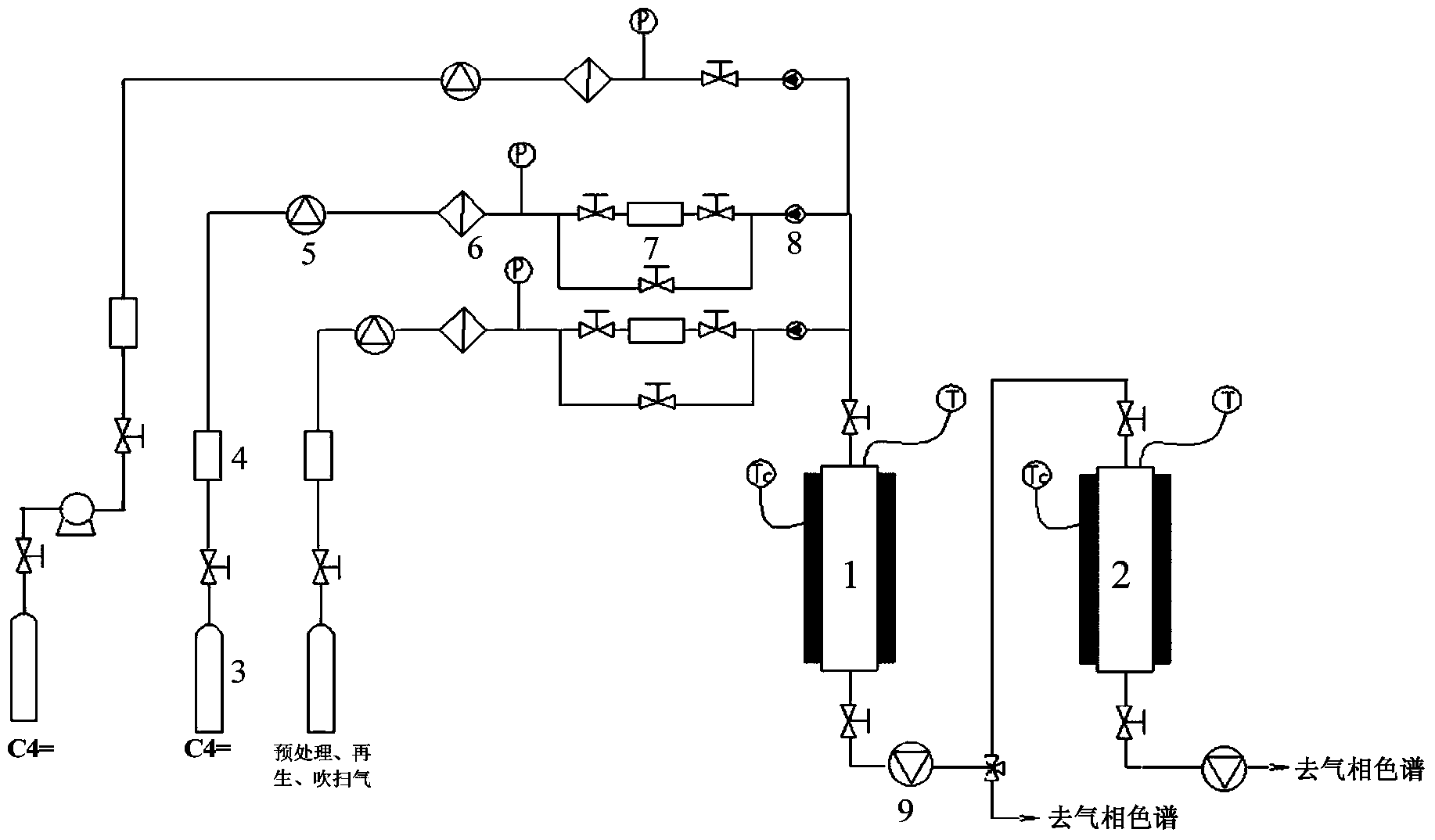

Method of preparing propylene and ethylene by catalytic cracking olefin

ActiveCN1927785AHigh activityConducive to gatheringBulk chemical productionHydrocarbon by hydrocarbon crackingRare earthReaction temperature

The present invention relates to process of catalytically cracking olefin to produce propylene and ethylene, and the process is superior to available technology, which has the problems of poor high temperature hydrothermal stability of catalyst with scaling, deactivation, etc. The technological scheme of the present invention is that C4 and C4+ olefin material is catalytically cracked to produce propylene at the reaction temperature of 450-650 deg.c, reaction pressure of -0.08 to 0.5 MPa and liquid space velocity of 0.5-15 / hr under the action of ZSM-5 molecular sieve catalyst containing RE metal and phosphorus oxide. The process may be used in industrial production of propylene through cracking olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

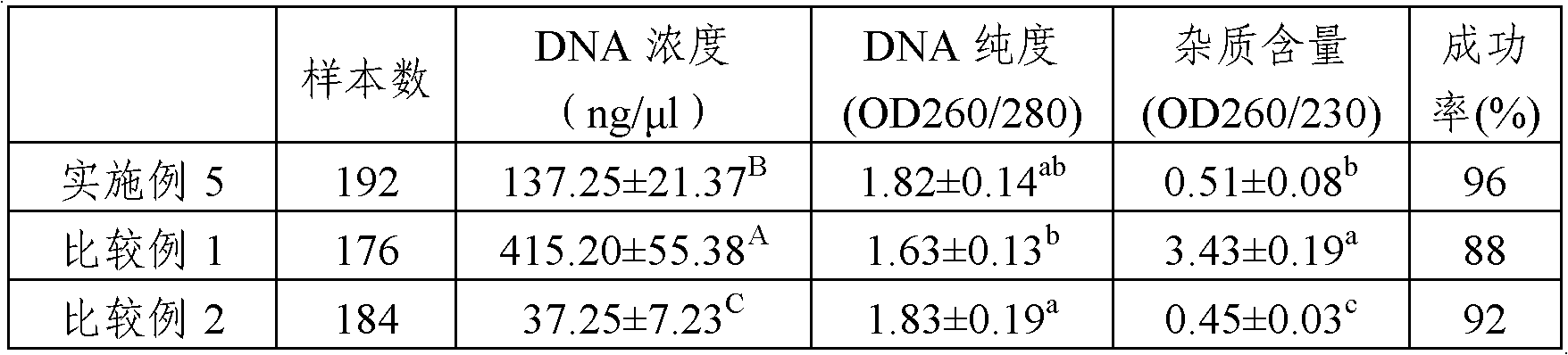

Cell lysis solution for extracting animal DNA, kit and method

The invention provides cell lysis solution for extracting animal DNA, a kit containing the lysis solution and a method for extracting animal DNA by using the kit. The cell lysis solution provided by the invention comprises Tris-base at a concentration of 20 to 30g / L, ethylene diamine tetraacetic acid (EDTA) at a concentration of 0.5 to 1.0g / L, sodium dodecyl sulfonate (SDS) at a concentration of 20 to 30g / L, NaCl at a concentration of 5 to 10g / L, urea at a concentration of 100 to 150g / L and the balance of sterile water, and the pH value of the cell lysis solution is regulated by NaOH to 8.0 to 9.0. When the animal DNA extraction kit provided by the invention is used, the extraction time is reduced by at least half hour compared with that in the prior art, the use of chloroform with strong toxic odor is avoided, the damage to the health of operators in an operation process is relieved, and the extracted DNA is high in yield and purity. The method provided by the invention is quick, simple, convenient, efficient and very repeatable. In the invention, the result is very stable, the success rate is high, extraction cost is reduced and large-scale extraction of DNA is easy.

Owner:SICHUAN AGRI UNIV

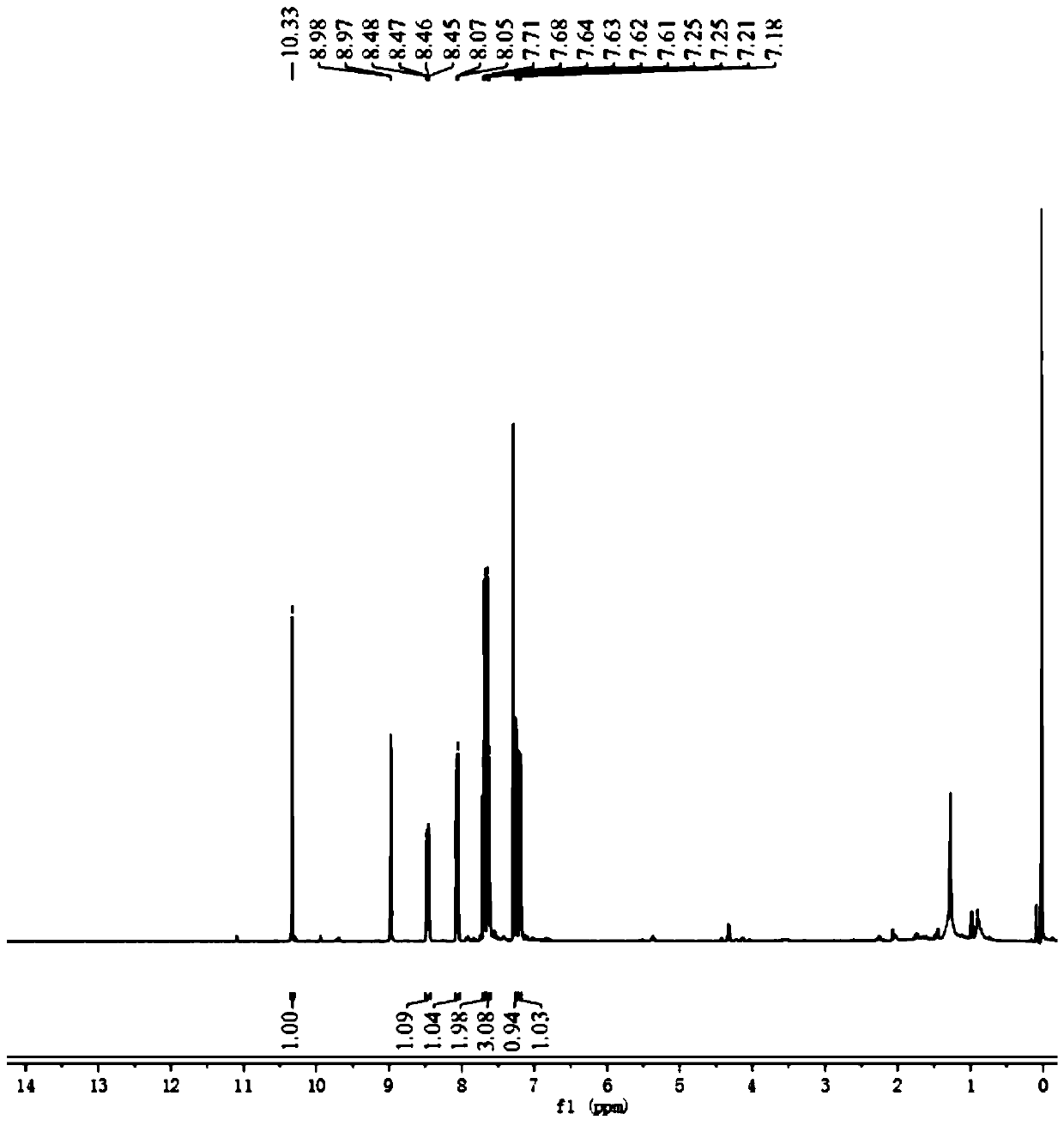

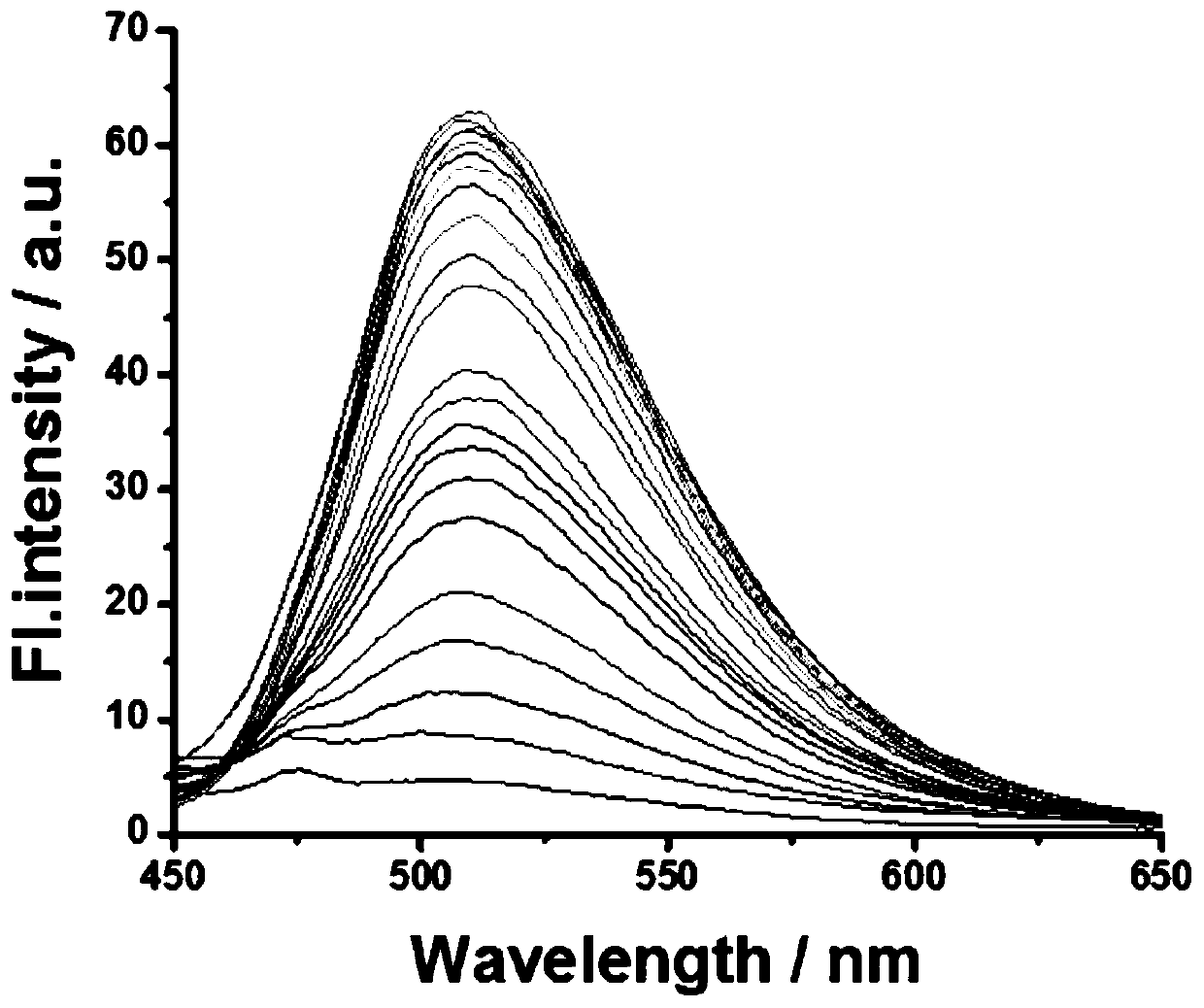

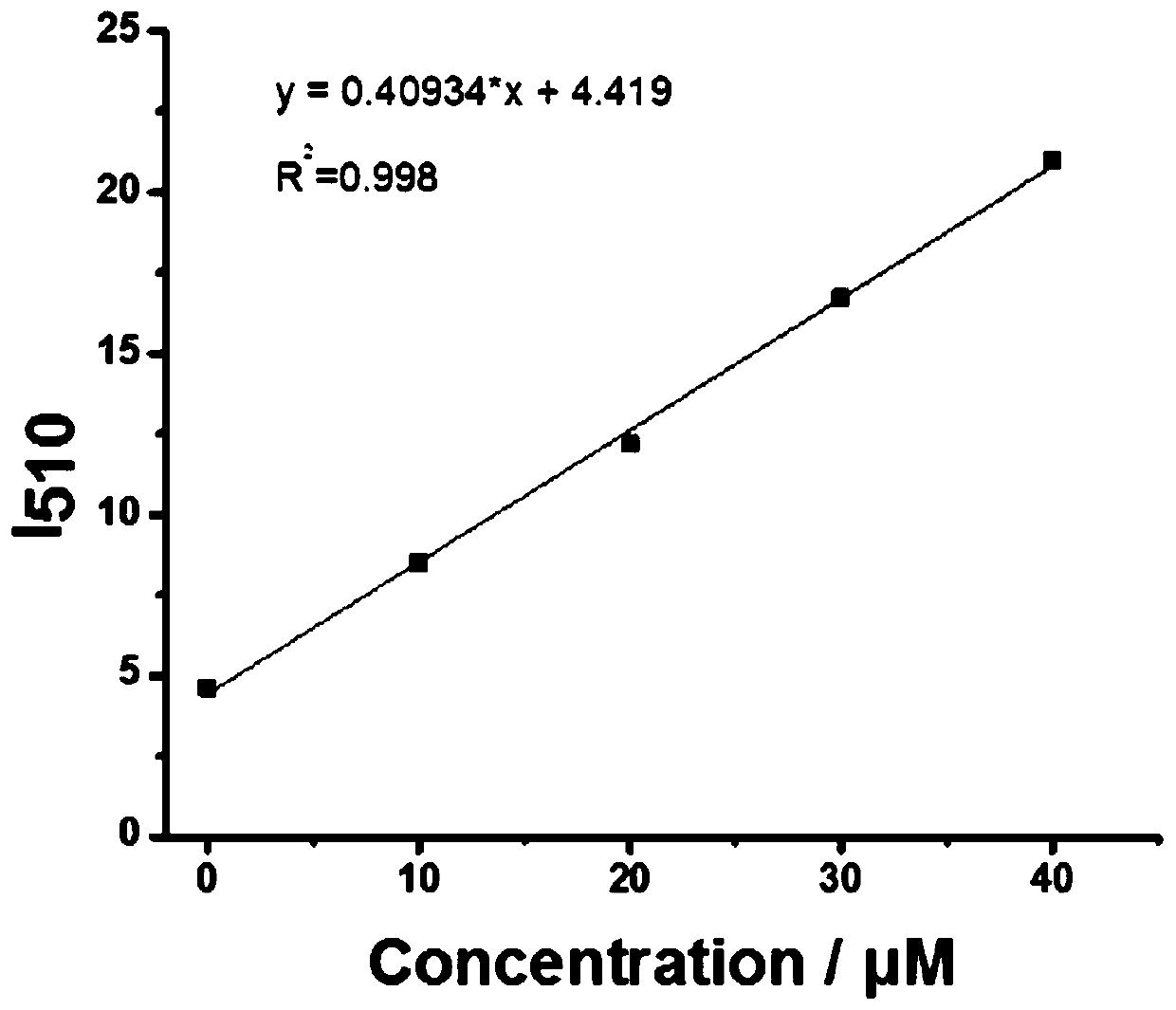

Fluorescent probe for detecting hydrogen sulfide in cells, method for preparing fluorescent probe and application thereof

InactiveCN109735328APromote lysisHigh fluorescence intensityCarboxylic acid nitrile preparationOrganic compound preparationChemical synthesisFluorescence

The invention provides a fluorescent probe for detecting hydrogen sulfide in cells, a method for preparing the fluorescent probe and application thereof. A chemical structural formula of the fluorescent probe is shown. Reaction can be carried out on 2,4-dinitrofluorobenzene and reaction products of 4-ethynylbenzonitrile and 4-bromine-2-hydroxybenzaldehyde to obtain the fluorescent probe. The hydrogen sulfide in solution or the cells or organisms can be detected by the fluorescent probe by the aid of fluorescence. The fluorescent probe, the method and the application have the advantages that the fluorescent probe can be obtained by means of chemical synthesis, synthesis processes are simple and feasible, raw materials are inexpensive and are easily available, and accordingly the fluorescentprobe is low in preparation cost; the fluorescent probe is high in specificity, and interference due to other components can be prevented in detection procedures; the fluorescent probe is short in response time, high in sensitivity and excellent in fluorescence emission spectral characteristic, and the hydrogen sulfide in the cells can be quickly and accurately detected by the fluorescent probe;the fluorescent probe has a broad application prospect in research on the influence of the hydrogen sulfide in the biological cells on physiological and pathological procedures.

Owner:UNIV OF JINAN

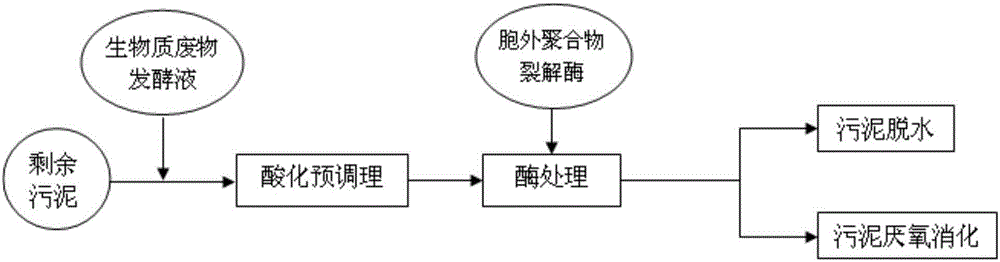

Method for pretreating surplus sludge by using extracellular polymer lyase

ActiveCN104909529APromote lysisPromote digestionSludge treatment by de-watering/drying/thickeningBiological sludge treatmentChemistryAnaerobic digestion

The invention relates to a method for pretreating surplus sludge by using extracellular polymer lyase, which comprises the following steps: (1) regulating the pH value of the surplus sludge to 4.0-5.0; (2) directly adding extracellular polymer lyase powder into the surplus sludge subjected to pH regulation, uniformly mixing and reacting; and (3) directly sending the sludge subjected to enzyme pretreatment into a dehydration procedure, or directly carrying out anaerobic digestion treatment. Compared with the prior art, the method can greatly enhance the release rate of sludge polysaccharides only by adding a small amount of extracellular polymer lyase, can form saccharide micromolecules, and is convenient for microbe utilization. Molecules coated by the saccharides and saccharide-like proteins are released, thereby enhancing the sludge utilization ratio and enhancing the integral digestion efficiency and dehydration property. The acidification conditioning solution before enzyme treatment can adopt a waste fermentation liquid, thereby further lowering the treatment cost.

Owner:TONGJI UNIV

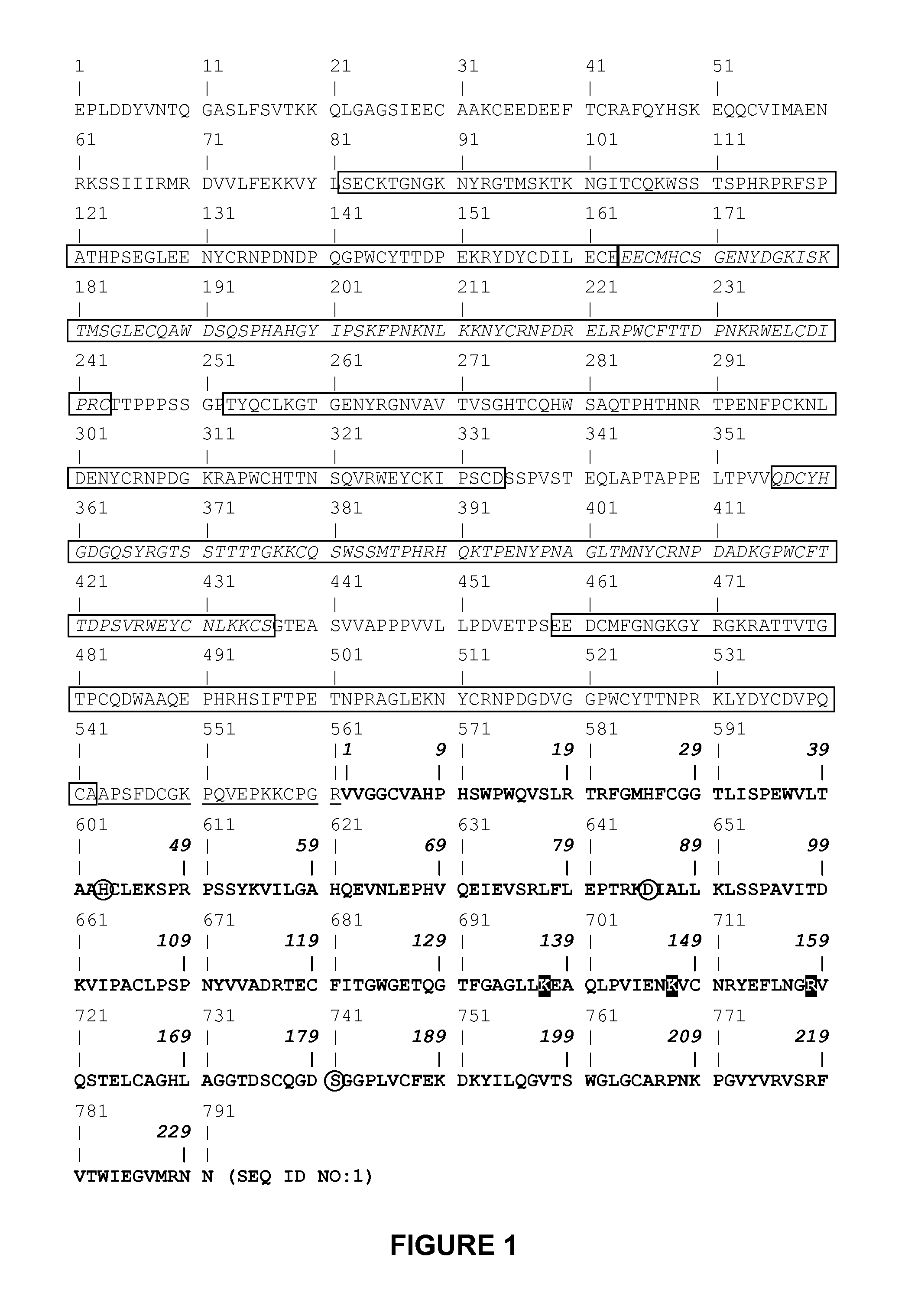

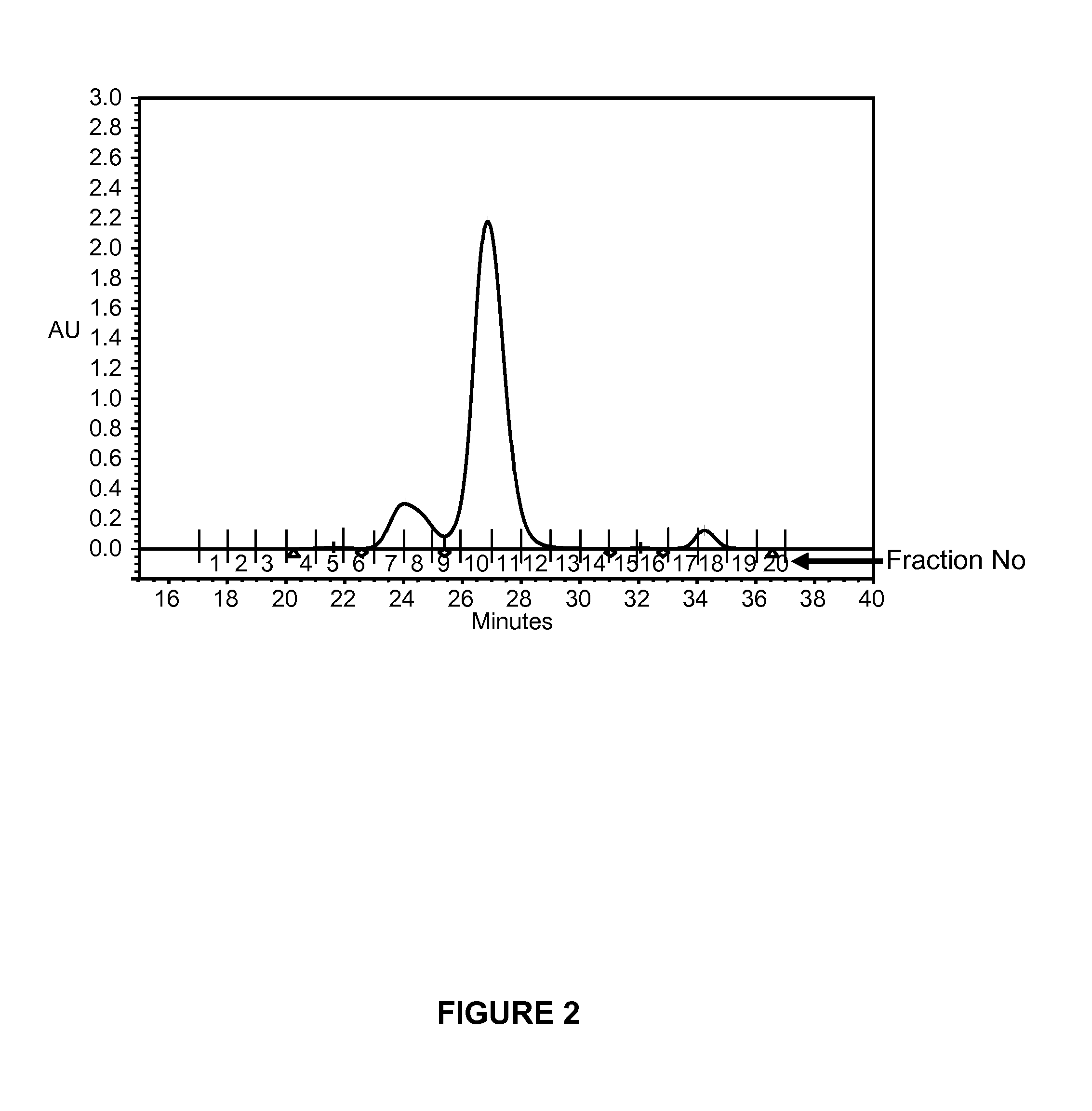

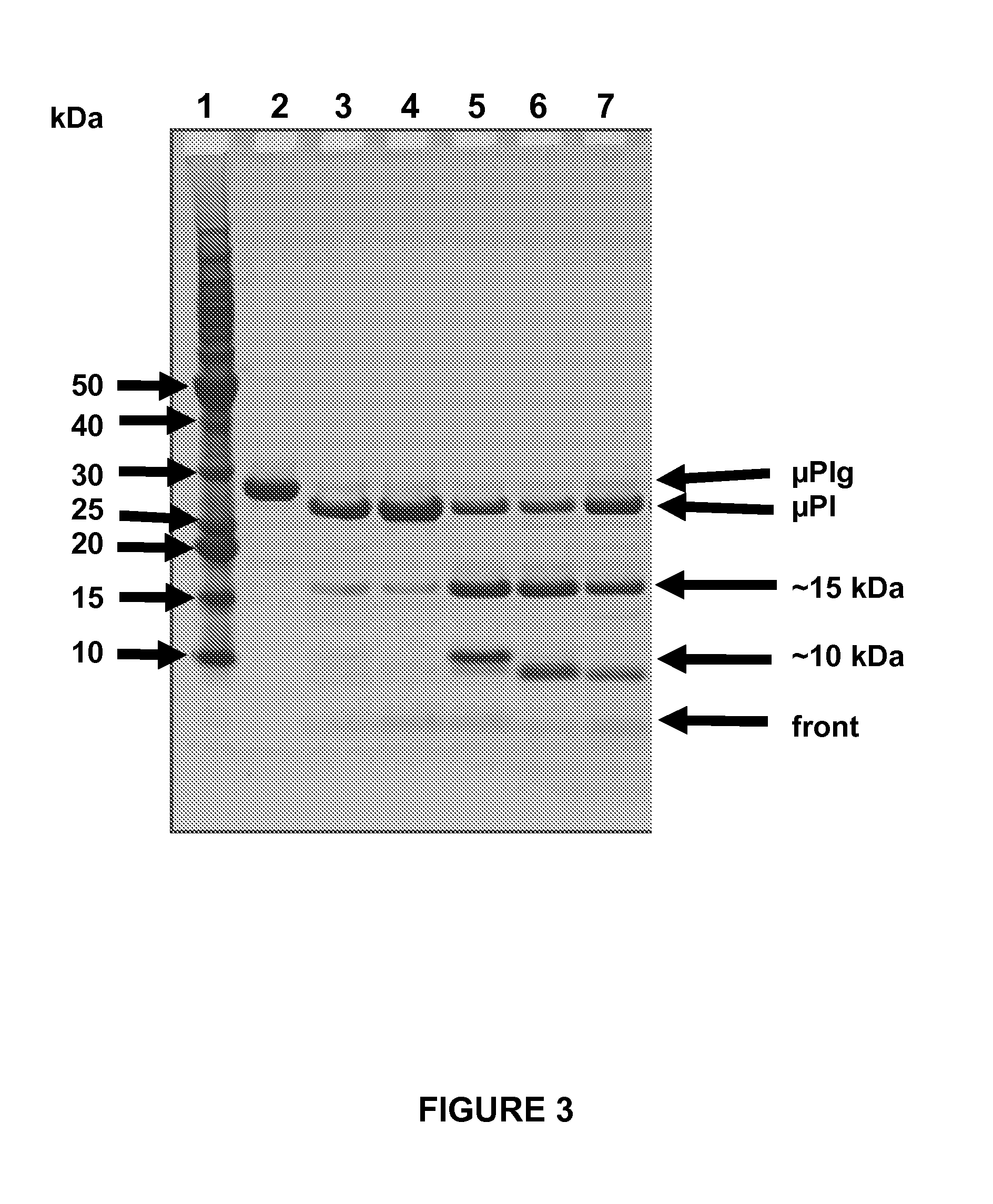

Variants of plasminogen and plasmin

InactiveUS20120114630A1Excellent long-term storage stabilityReducing circulating fibrinogenSenses disorderFungiProteinase activityPlasmin

The invention relates to variants of plasminogen and plasmin comprising one or more point mutations in the catalytic domain which reduce or prevent autocatylic destruction of the protease activity of plasmin. Compositions, uses and methods of using said variants of plasminogen and plasmin are also disclosed.

Owner:THROMBOGENICS NV

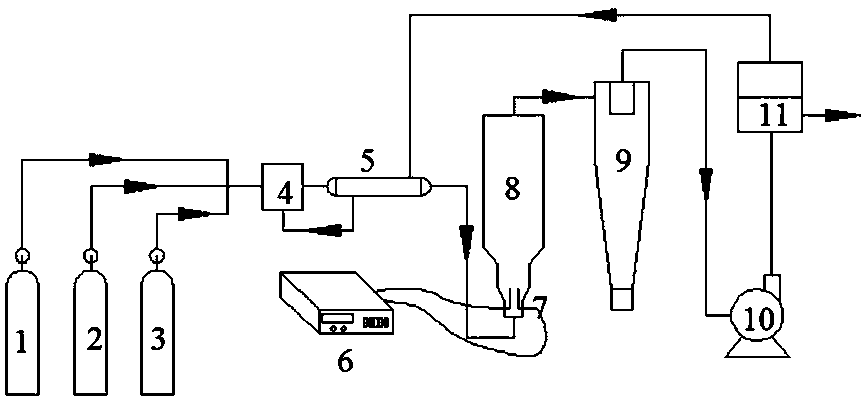

Graphene preparation method

The invention discloses a graphene preparation method comprising the following steps: performing lytic reaction via a plasma region by selecting a gaseous or gasifiable carbonaceous material as a carbon source, taking a gas which can be ionized to be plasma as carrier gas, taking a gas with reducibility as an additive, using a rotary gas intake manner and driving the carbon source by the carrier gas; after pyrolysis of the carbon source, entering a fluidized bed device, so as to promote further pyrolysis of the carbon source and nucleation and growth of graphene; and separating graphene from tail gas by a cyclone separator, so as to obtain graphene powder; the tail gas can be recycled to be used for preheating mixed gas of the carbon source, the carrier gas and the additive, and enters a plasma generator together with the mixed gas, and therefore, the use amount of the carrier gas can be reduced. According to the method, harsh terms are avoided, and wastes cannot be generated; the graphene is rapidly produced in a gas phase, and the carrier gas and partial non-lytic carbon source can be recycled.

Owner:FUZHOU UNIV

Electrochemical liquefaction method and device for biomass taking ionic liquid and supercritical CO2 as media

ActiveCN105441107APromote lysisEvenly heatedLiquid hydrocarbon mixture productionHydrocarbon oils treatmentLiquid fuelElectrochemistry

The invention relates to an electrochemical liquefaction method and device for biomass taking ionic liquid and supercritical CO2 as media. According to the method disclosed by the invention, the supercritical CO2 is taken as a medium, the biomass is treated in the presence of a catalyst, ionic liquid and water, and hydrogen is supplied by electrolysis of water to promote the biomass to be cracked into a bio-oil product; in the method, the biomass is uniformly heated, chemical bonds of lignocellulose are broken to generate an ionic pair intermediate and is subjected to electric field stimulation to quicken the cracking speed with high efficiency, the process is easy to control, and the utilization ratio of the biomass is increased; free hydrogen is supplied by continuous electrolysis of water to timely cut off a free radical chain reaction, such that the yield of a liquid fuel is effectively increased and the quality of the liquid fuel is improved; the supercritical CO2 is well dissolved in the ionic liquid, such that the viscosity of the ionic liquid is remarkably reduced, the conductivity of the ionic liquid is improved, and biomass cracking is effectively promoted.

Owner:KUNMING UNIV OF SCI & TECH

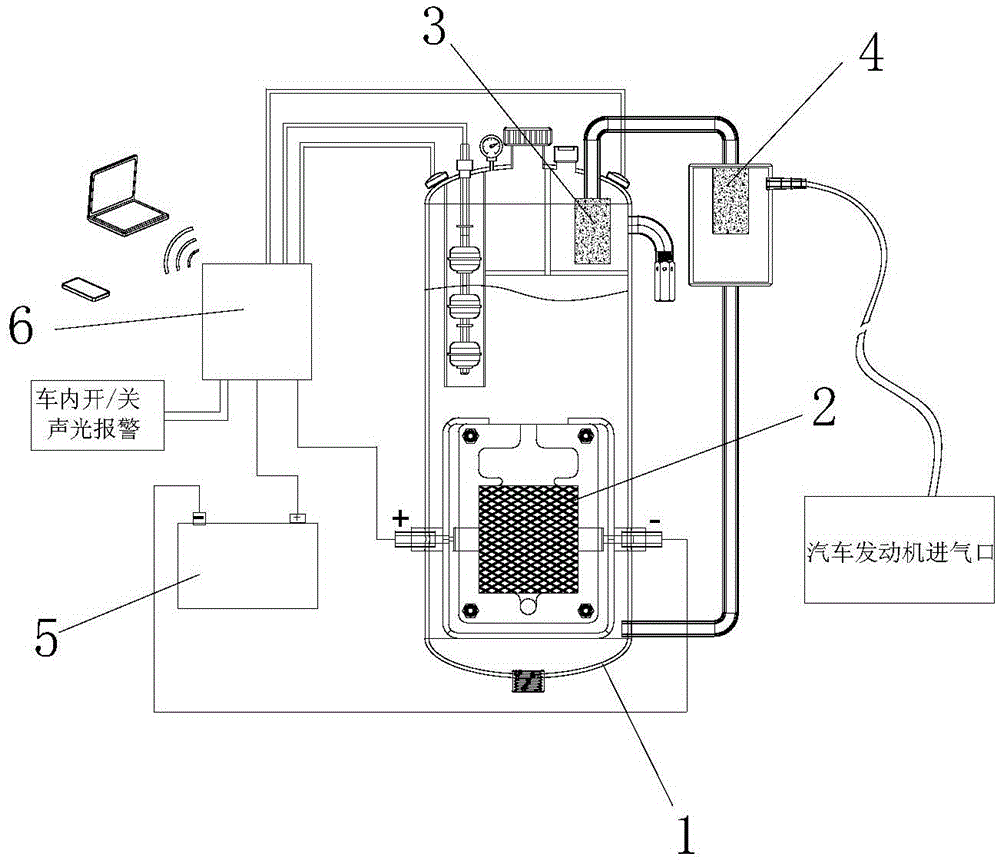

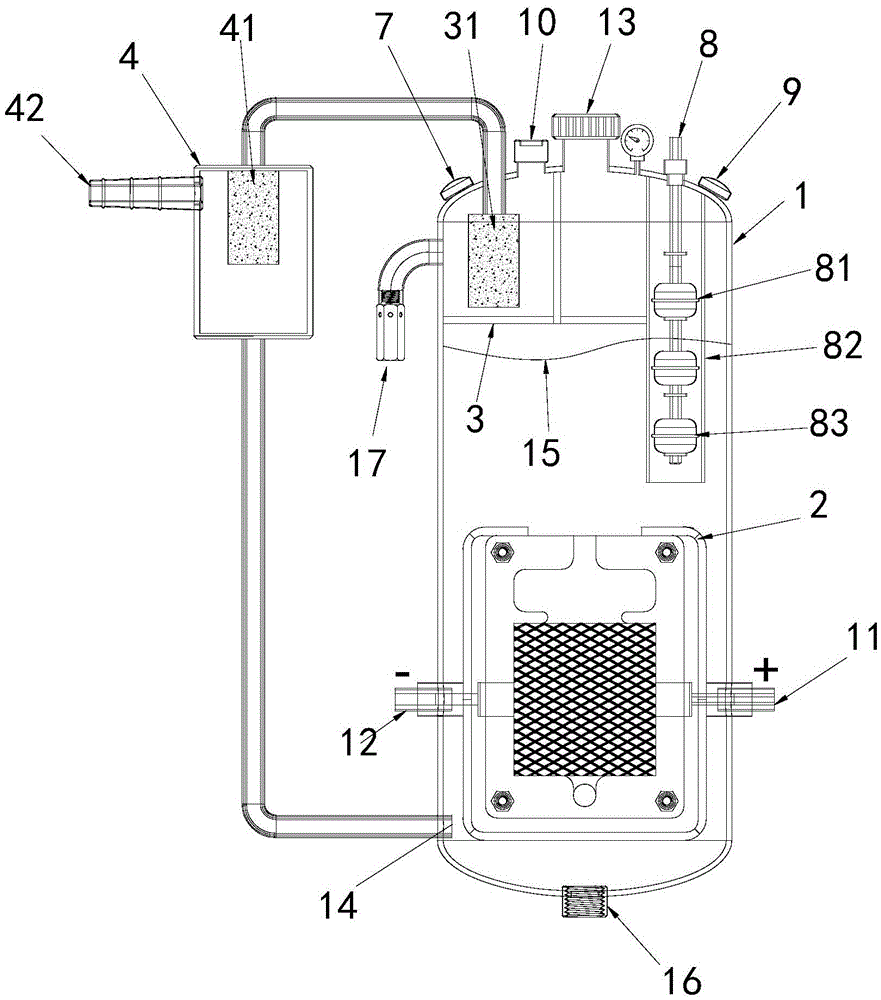

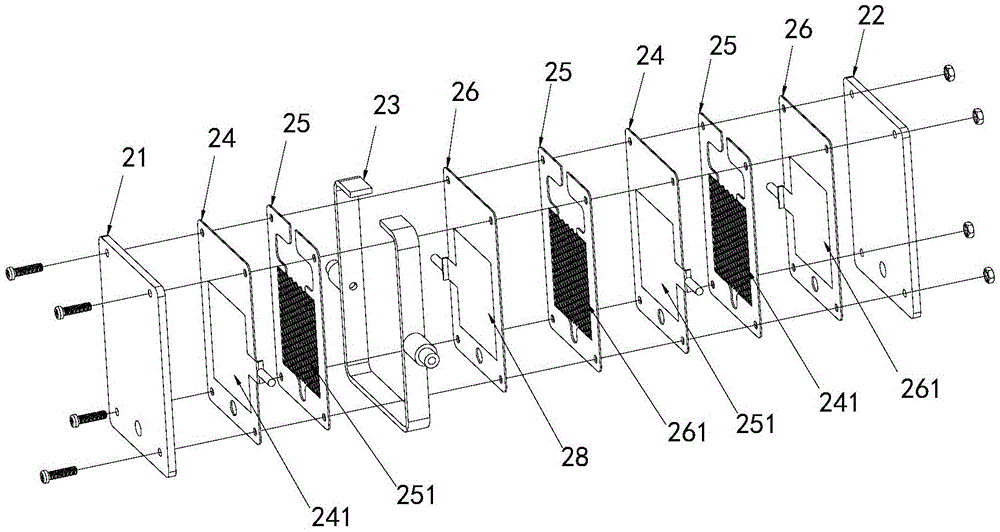

Vehicle-mounted oxy-hydrogen generation device

PendingCN106757121ABurn fasterBurn fullyElectrolysis componentsNon-fuel substance addition to fuelHydrogenEngineering

The invention discloses a vehicle-mounted oxy-hydrogen generation device mounted on a vehicle for providing hydrogen-oxygen mixed gas to an internal combustion engine. The vehicle-mounted oxy-hydrogen generation device comprises a stainless steel pressure container, an electrolysis tank, a first-grade steam-water separator, a second-grade steam-water separator, an accumulator and a controller. The electrolysis tank uses pure water as electrolyte for electrolysis to generate the hydrogen-oxygen mixed gas. In the device, the gas entering an engine is the hydrogen-oxygen mixed gas, and the hydrogen-oxygen gas separation is not needed; an electric conducting net is in middle of a water guide frame of the electrolysis tank to realize no diaphragm and no intermediate pole, that is, the pole distance of the electrolysis tank is nearly zero, so that the energy consumption is reduced, and the electrolysis efficiency is improved; the pure water can be efficiently electrolyzed; no alkaline substance is evaporated in the electrolysis process, so that the internal combustion engine has no alkaline corrosion; and meanwhile, the electrolysis tank has no diaphragm, so that the service life of the electrolysis tank is largely prolonged.

Owner:SHANGHAI XU NEW ENERGY TECH DEV CO LTD

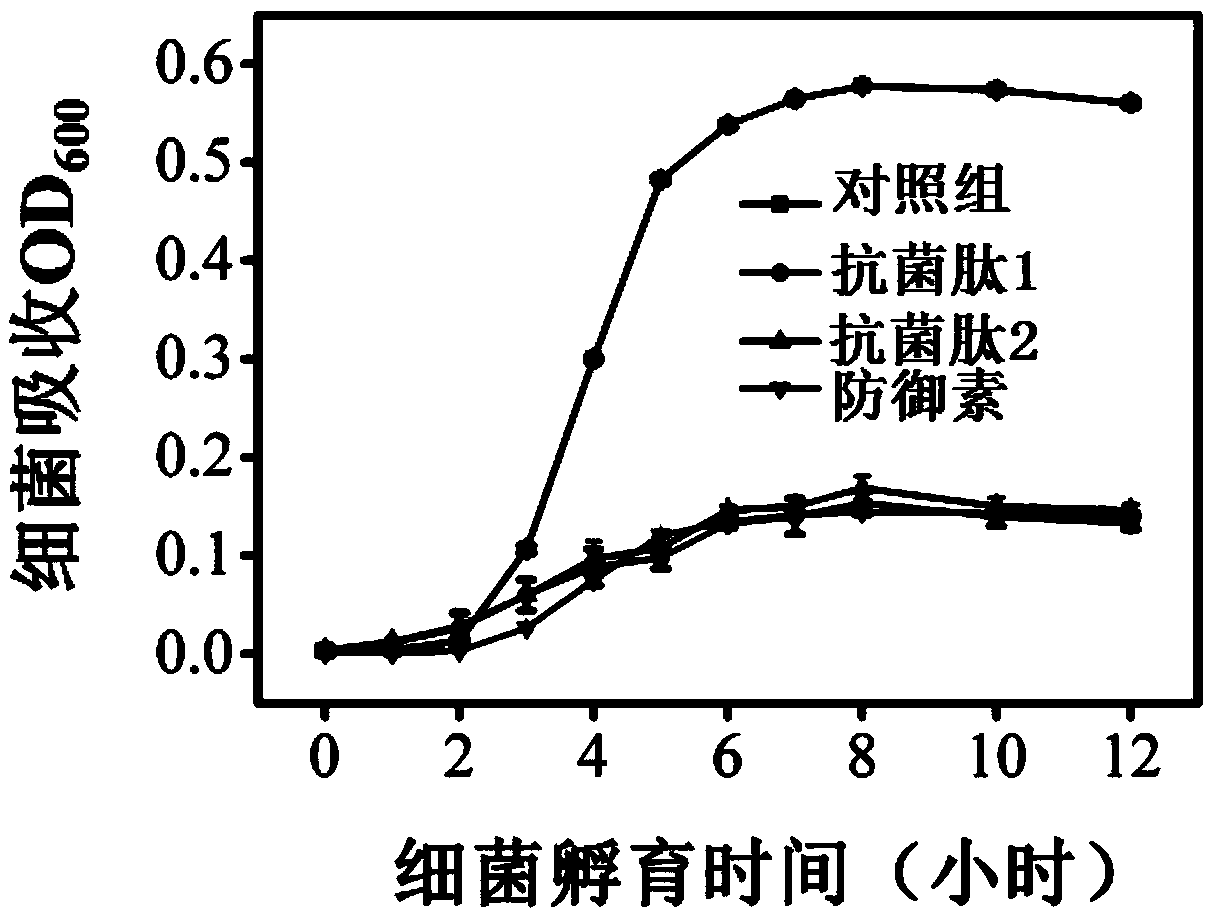

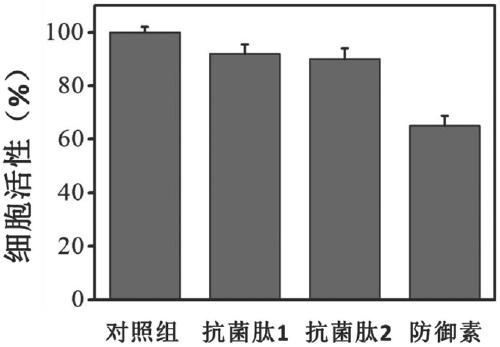

Anti-bacterial peptide, anti-bacterial peptide hydrogel and preparation method of anti-bacterial peptide hydrogel

ActiveCN109456389AHigh antibacterial activityGood biocompatibilityAntibacterial agentsPeptide/protein ingredientsBacteroidesCuticle

The invention relates to the technical field of biological pharmacy, in particular to an anti-bacterial peptide, an anti-bacterial peptide hydrogel and a preparation method of the anti-bacterial peptide hydrogel. The amino acid sequence of the anti-bacterial peptide is shown as SEQ ID NO:1. Experiments show that the polypeptide of the anti-bacterial peptide has high antibacterial activity and excellent biocompatibility. The anti-bacterial peptide hydrogel is made of the anti-bacterial peptide, a photo-thermal reagent and a wound growth promoting factor. Tests show that the anti-bacterial peptide hydrogel has a good killing effect on bacteria, especially drug-resistant bacteria, on the surface of a biological film, a bacterial biofilm can be effectively spitted and removed, growth and proliferation of wound epidermal cells, collagen formation and angiogenesis are facilitated, and rapid healing of wounds infected by the bacterial biofilm is achieved.

Owner:SUZHOU UNIV

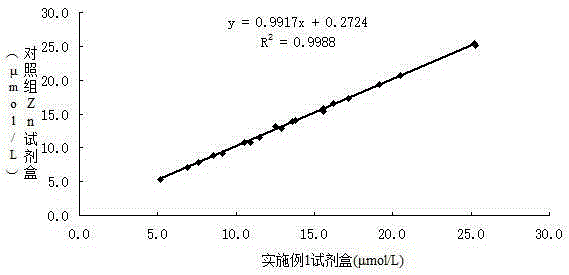

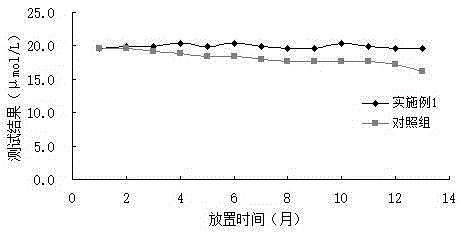

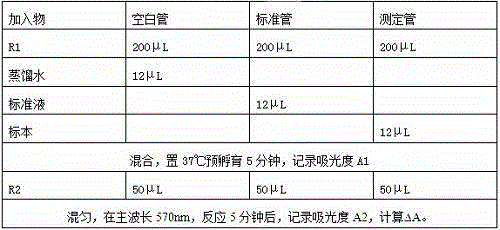

Stable good-interference resistance serum zinc detection reagent and detection method

InactiveCN105241831AImprove stabilityPromote lysisMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsPotassium ferrocyanideActive agent

The invention relates to the technical field of serum zinc detection and especially relates to a serum zinc detection reagent. A reagent R1 contains a buffer, salicylaldoxime, dimethylglyoximate, a fluorocarbon surfactant FSO-300, 2, 9-dimethyl-1, 10-phenanthroline, ascorbic acid, potassium ferrocyanide, polyethylene glycol 6000, glycol, trisodium citrate, NaCl and an antiseptic. A reagent R2 contains a buffer, dimethyl sulfoxide, nitro-PAPS, a fluorocarbon surfactant FSO-300, ascorbic acid, potassium ferrocyanide, polyethylene glycol 6000, glycol, trisodium citrate, NaCl and an antiseptic. The Tris buffer, the stabilizing agent and a plurality of anti-interference agents are used, can effectively eliminate interference caused by copper, iron, calcium and magnesium ions and can substantially improve reagent stability. The used novel non-ionic fluorocarbon surfactant FSO-300 can promote serum zinc cracking, prevent reaction system turbidity, improve chromogenic substance stability, prevent a pretreatment process such as protein removal and substantially improve reagent sensitivity and stability.

Owner:BIOBASE BIODUSTRY (SHANDONG) CO LTD

Kit capable of being applied to high-throughput extraction of genome DNA from animal tissue and extraction method thereof

ActiveCN108642048AFast cracking speedHigh extraction purityDNA preparationComposite effectMagnetic bead

The invention relates to the technical field of biology, in particular to a kit capable of being applied to high-throughput extraction of genome DNA from an animal tissue and an extraction method thereof. The kit capable of being applied to the high-throughput extraction of the genome DNA from the animal tissue comprises lysate buffer, binding buffer, a washing solution I, a washing solution II, eluant, protease K and magnetic beads, the composite effect of reagents is utilized to fully digest, split, damage cells for removing proteins to obtain high-purity DNA. Compared with a kit sold in themarket, the kit capable of being applied to the high-throughput extraction of the genome DNA from the animal tissue has the advantages that the pyrolyzing rate is quick, the extraction purity is high, the extraction volume is large, the used reagents are safe, stable and efficient, the kit is especially suitable for high-throughput automated production, so that the extraction efficiency of the genome DNA is greatly improved, the error is reduced, and the extraction is more accurate.

Owner:SHANDONG HONGJITANG PHARMA GRP JINAN E JIAO PROD CO LTD

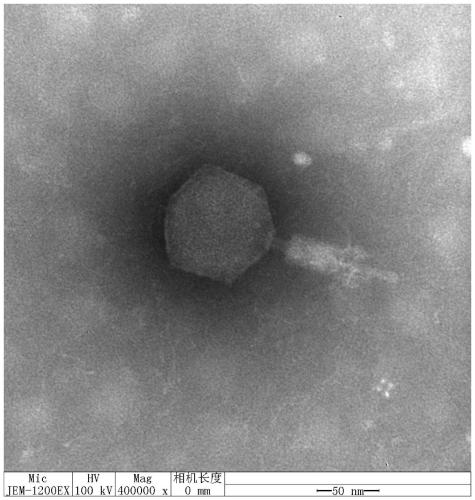

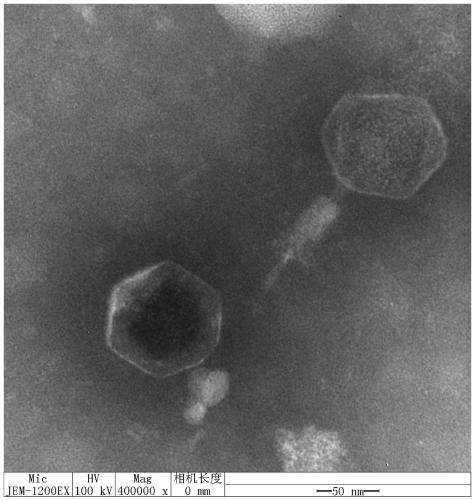

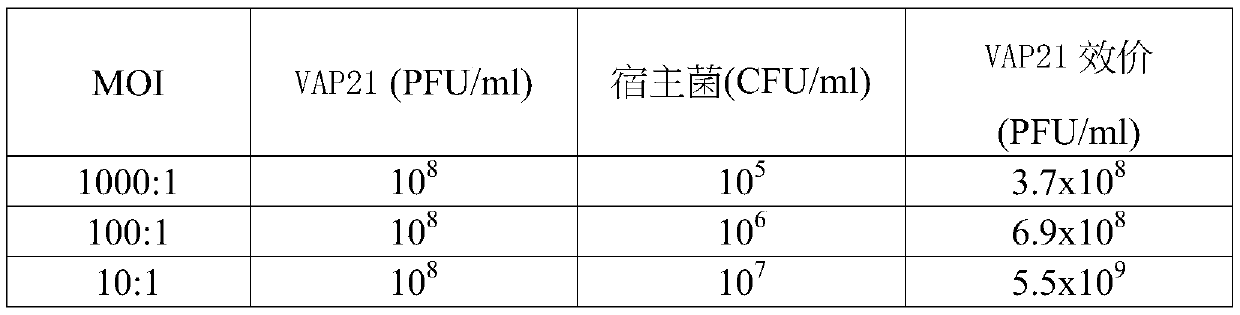

Alkali-resistant vibrio alginolyticus phage and composition thereof and kit, and application thereof

ActiveCN110205305APromote lysisImprove thermal stabilityAntibacterial agentsViral/bacteriophage medical ingredientsMicroorganismMicrobiology

The invention belongs to the technical field of research and development of vibrio alginolyticus phage, and in particular, relates to an alkali-resistant vibrio alginolyticus phage and a composition thereof, and a kit. The vibrio alginolyticus phage is vibrio alginolyticus phage VAP21, and has the preservation number of CCTCC NO:M 2018768. The invention also discloses an application of the vibrioalginolyticus phage, or a vibrio alginolyticus phage composition, or a reagent or kit containing the vibrio alginolyticus phage or the vibrio alginolyticus phage composition in killing and / or preventing vibrio microorganisms. The vibrio alginolyticus phage has wide host range, still has high toxicity to host bacteria at low concentration, good proliferation on non-pathogenic bacteria host and large-scale industrial production, and can provide excellent strain resources for an application of phagotherapy.

Owner:PHAGELUX (NANJING) BIO-TECH CO LTD

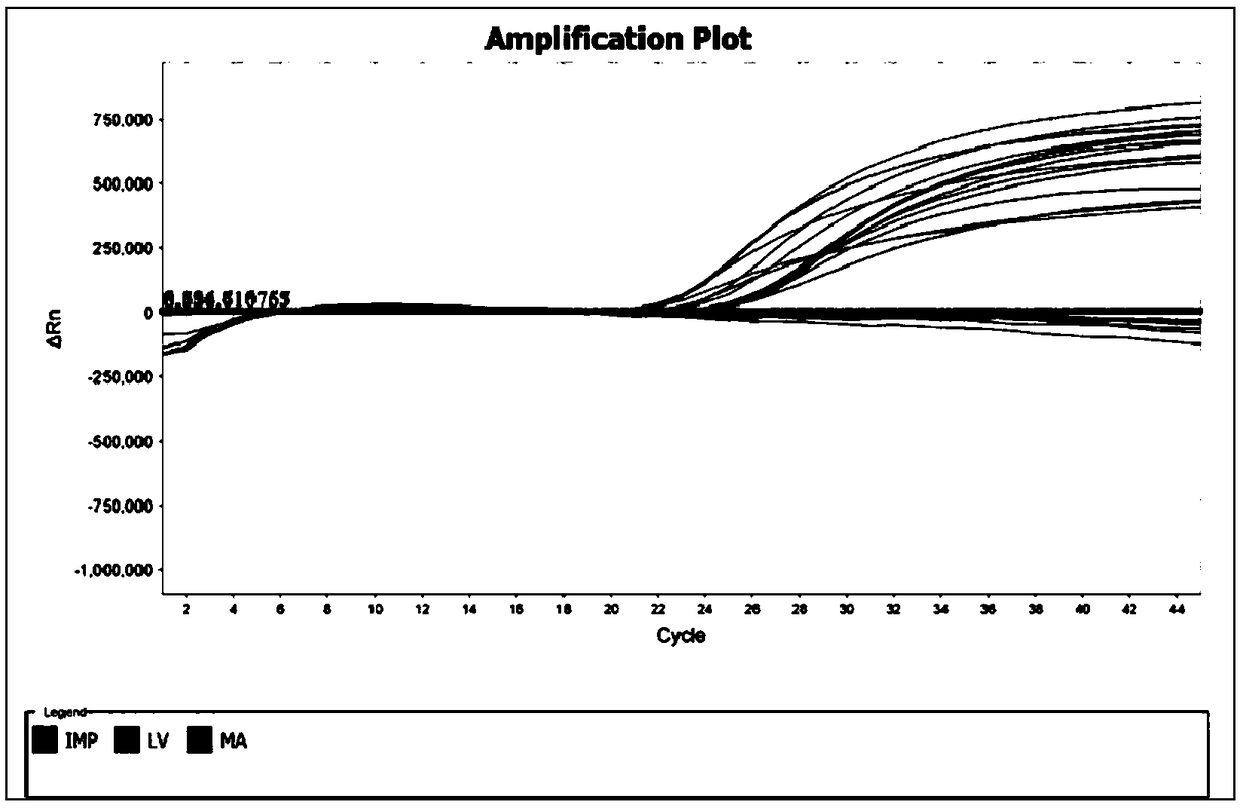

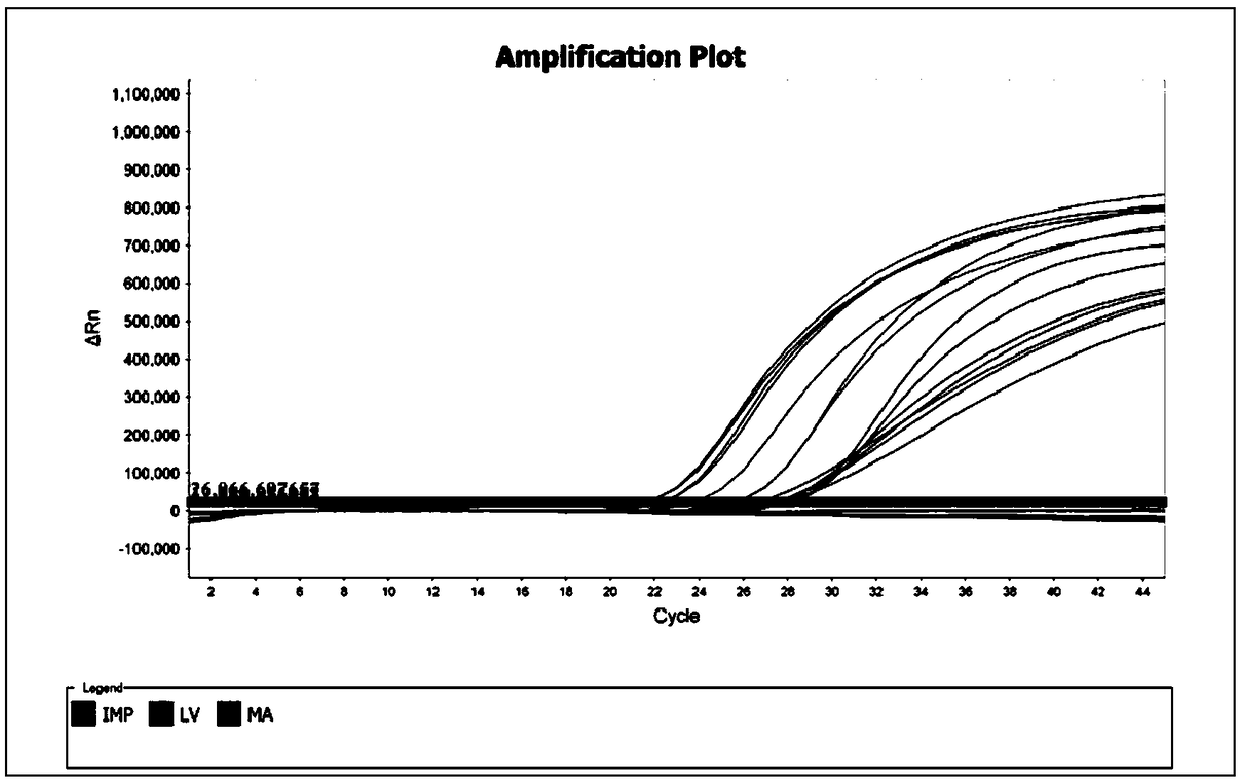

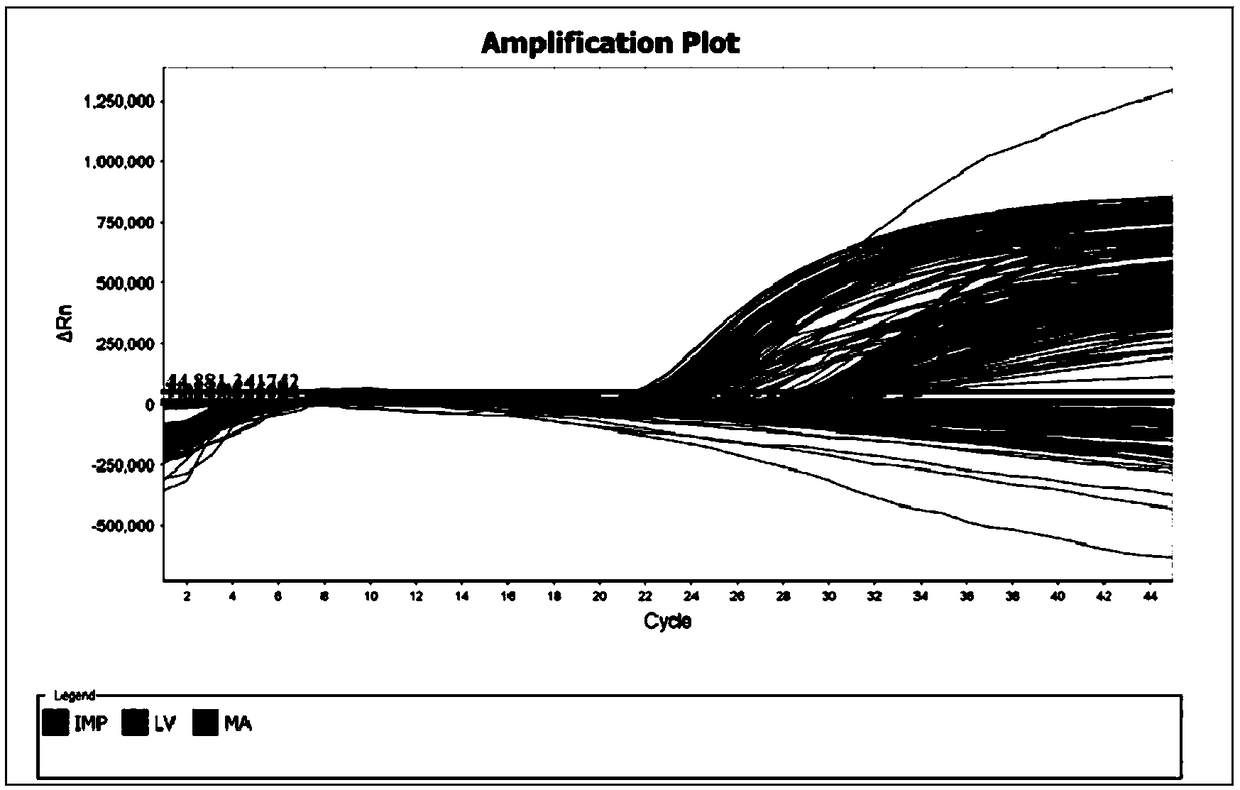

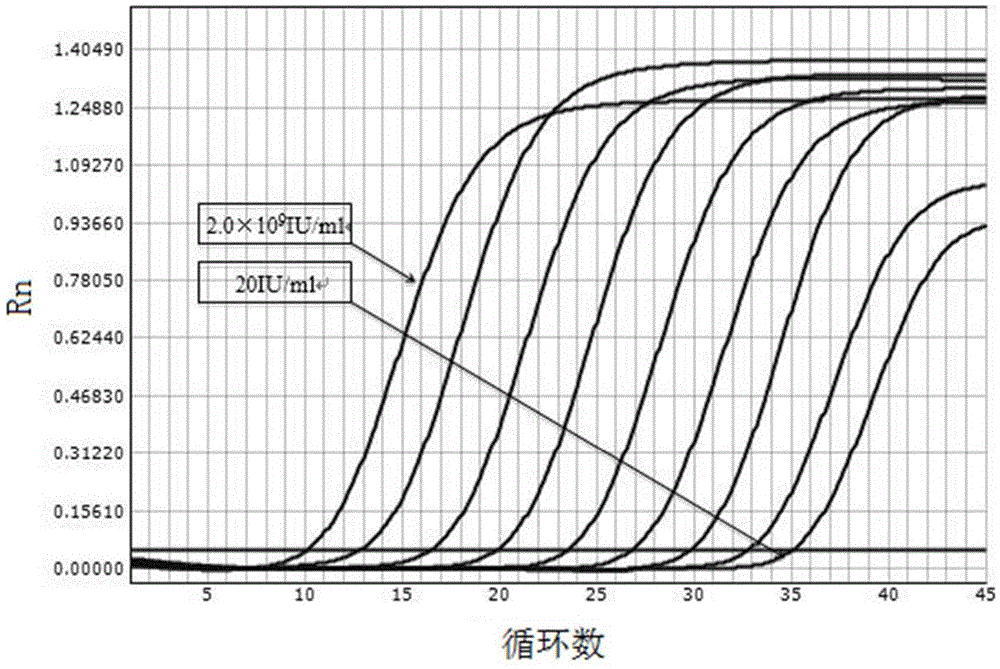

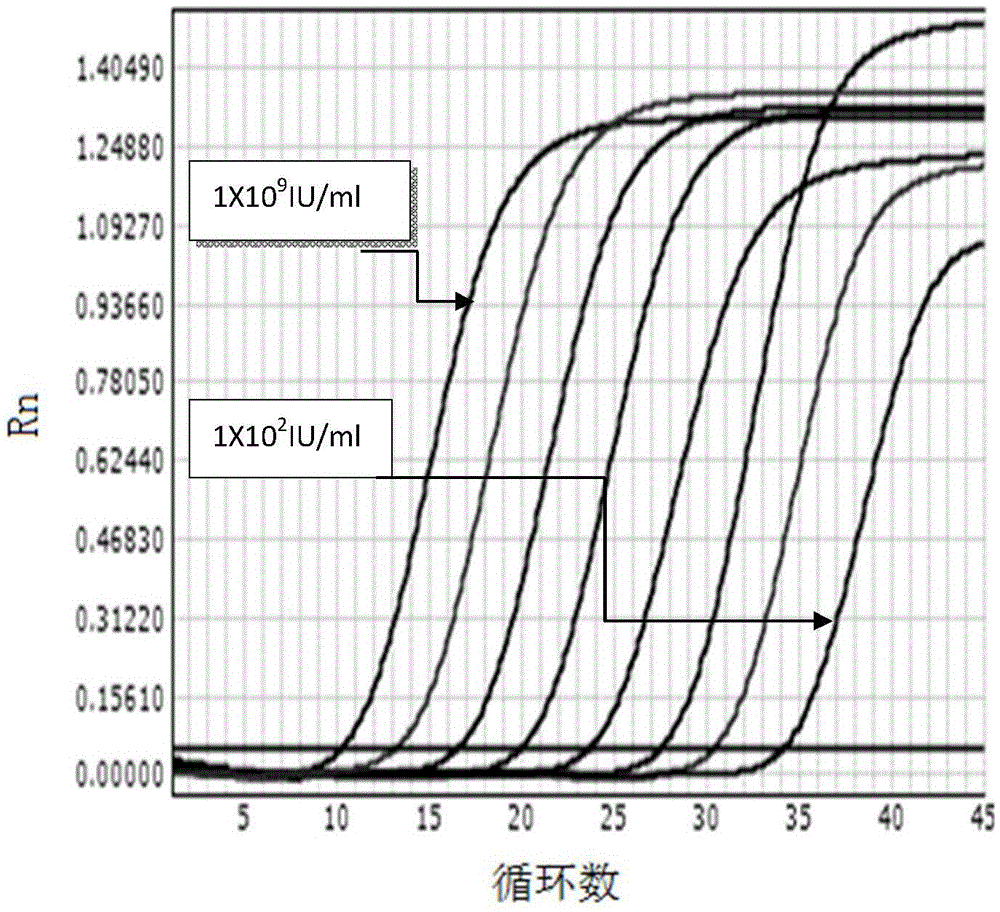

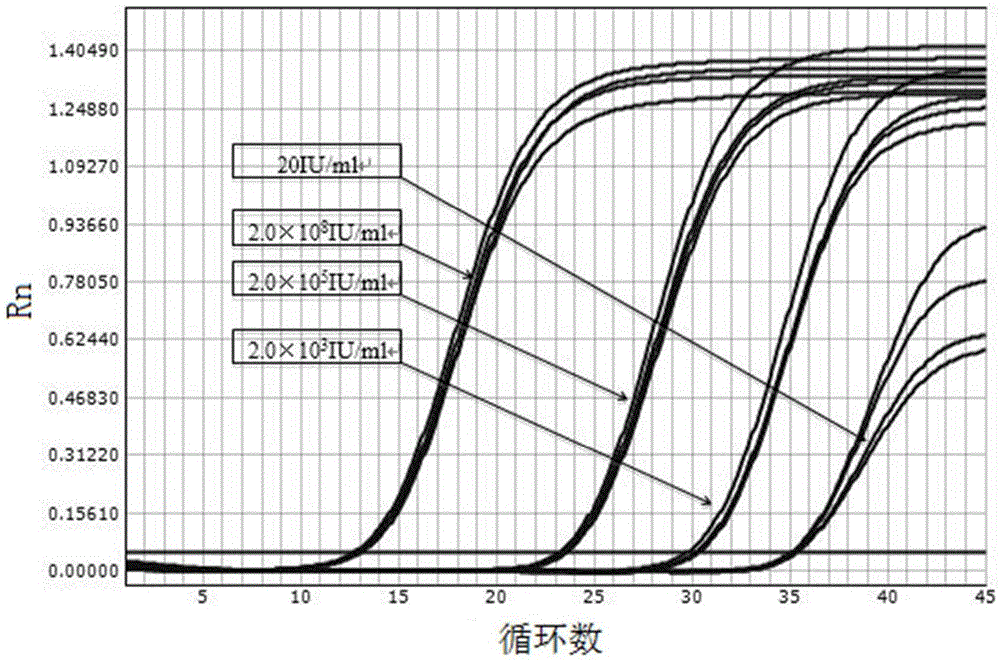

Direct real-time quantitative fluorescent PCR method of layered packaging tape indicator

ActiveCN105420416AKeep aliveRelease fullyMicrobiological testing/measurementMicroorganism based processesLysisFluorescence

The invention provides a direct real-time quantitative fluorescent PCR method of a layered packaging tape indicator. Hot-start DNA polymerase and PCR amplification reaction liquid are both packaged in a PCR amplification tube in layers. Nucleic acid lysis liquid and a sample to be detected are added when the method is used so that real-time quantitative fluorescent PCR can be carried out. By means of the method, the virus quantity lower to 20IU / ml can be detected, and the preferential detection range is 30-2*10<9>IU / ml. Detection results are not limited by the professional level of operators and experiment conditions in a laboratory, and the method has the advantages of being easy, convenient and quick to operate.

Owner:BEIJING NAGENE DIAGNOSTIC REAGENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com