Patents

Literature

138results about How to "Fully dehydrated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

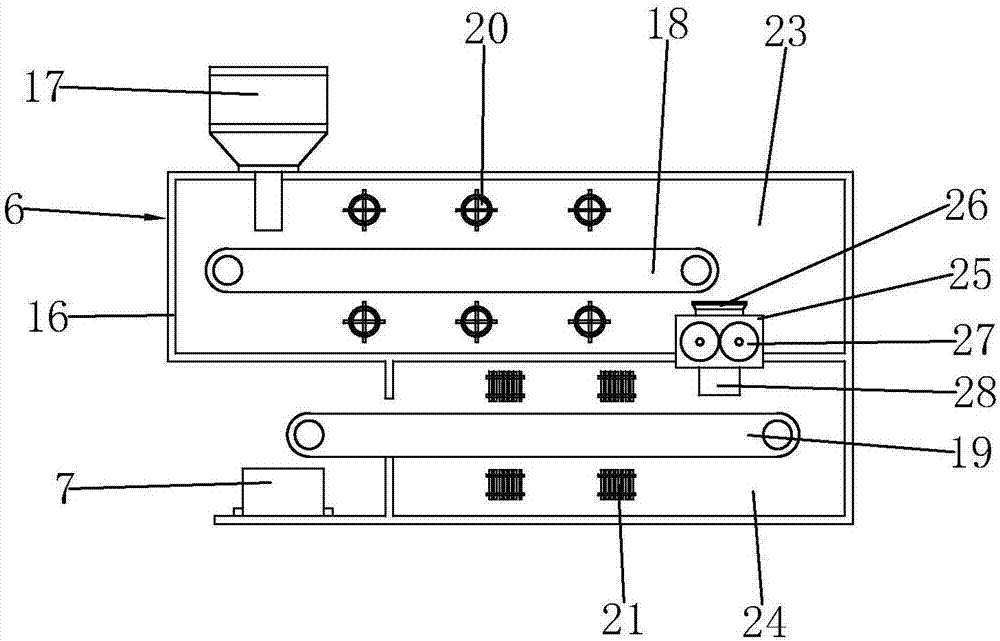

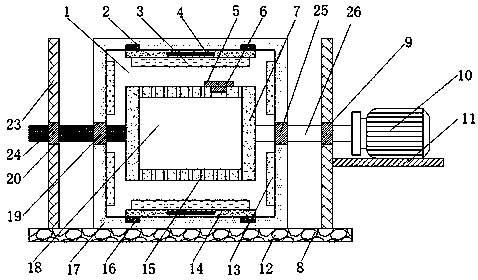

Drying device of long medical gauze

InactiveCN107620185AEasy to moveImprove the extrusion effectLiquid/gas/vapor removal by squeezing rollersIroning machinesGear driveFixed frame

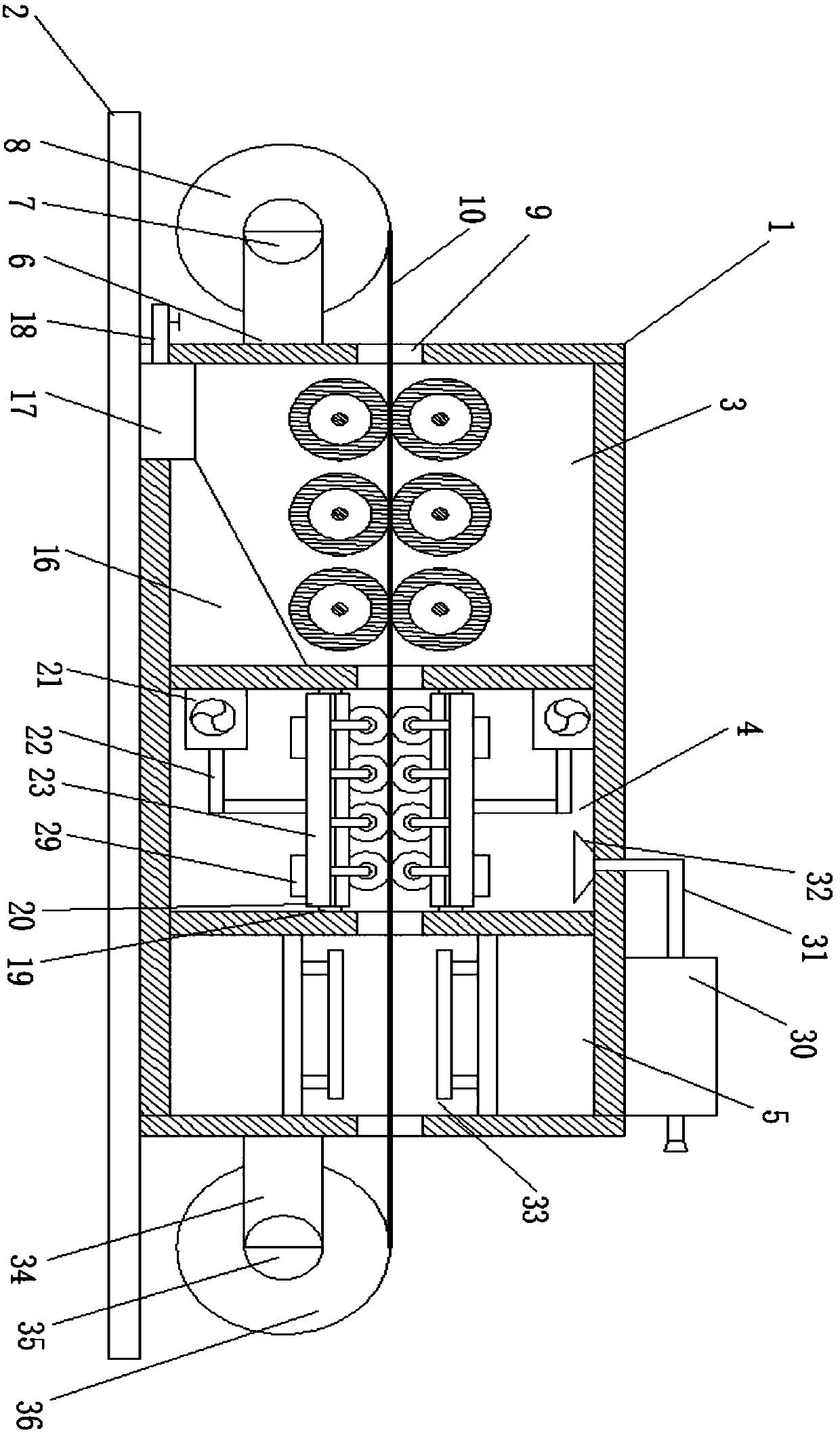

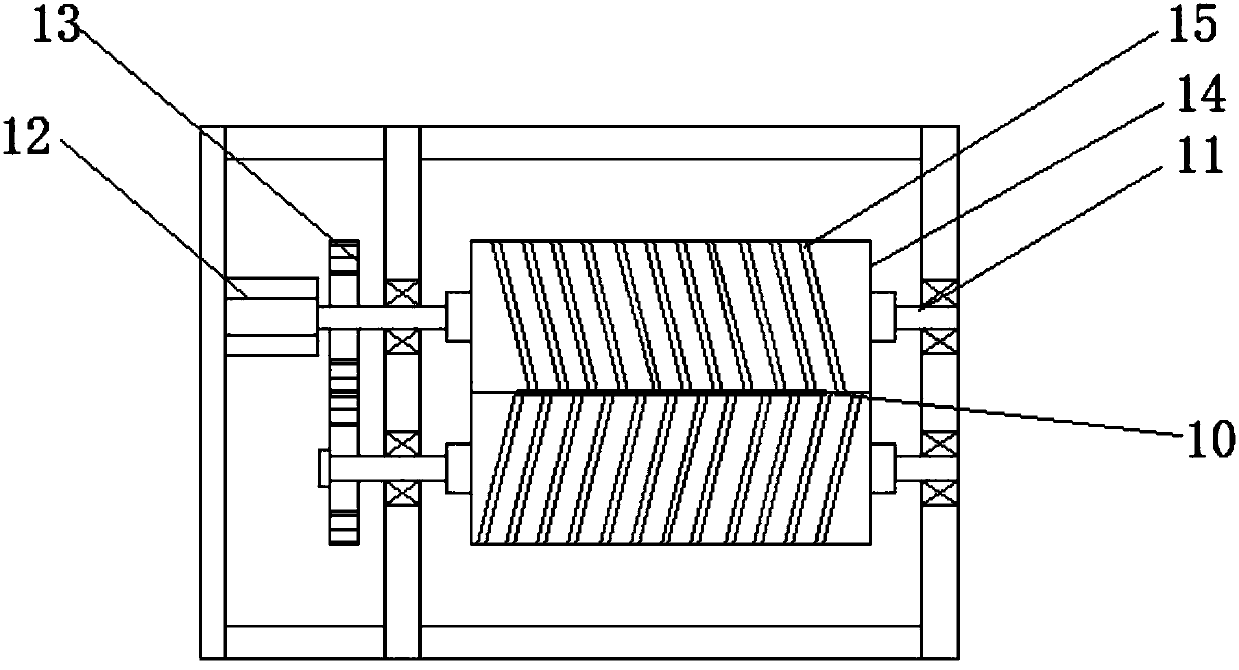

The invention discloses a drying device of long medical gauze. The drying device of the long medical gauze comprises a device case and a base. A first fixing frame and a second fixing frame are installed at the front and back sides of the device case respectively. A delivery rotation shaft and a collection rotation shaft are arranged on the first fixing frame and the second fixing frame respectively in a running-through mode. A delivery wheel disc and a collection wheel disc are mounted on the delivery rotation shaft and the collection rotation shaft respectively. The device case is divided into a dehydration room, a drying room and a disinfection room. Material through holes are formed in all the middles of the front and back walls of the dehydration room, the drying room and the disinfection room. The dehydration room, the drying room and the disinfection room are communicated by the material through holes. The gauze is wound around the delivery wheel disc. The gauze runs through thedehydration room, the drying room and the disinfection room through the material through holes, and the tail end of the gauze is wound around the collection wheel disc. According to the drying deviceof the long medical gauze, a gear drives a squeeze roller to rotate to squeeze the gauze to play the role of fully dehydration; an iron cylinder and the surface of the gauze are in contact, and therefore the role of high-temperature disinfection is further played.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

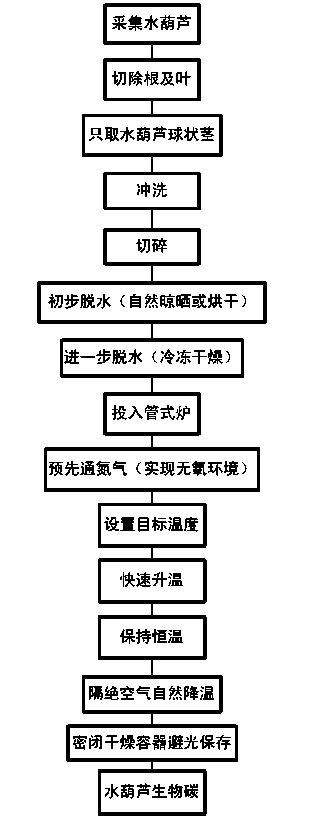

Preparation method of water hyacinth biochar

ActiveCN103936002ABroad prospects for resource utilizationFully preservedCarbon compoundsOther chemical processesActivated carbonFreeze-drying

The invention discloses a method for preparing biochar from water hyacinth. The method is mainly characterized by comprising the steps of cleaning expanded parts of leaf stalks of water hyacinth as raw materials, cutting, primarily dewatering, fully dewatering in a freeze-drying machine, quickly heating the freeze-dried raw materials in a tubular furnace in the absence of oxygen (pre-filling nitrogen to remove air from the furnace), and after the raw materials reach the set temperature and the temperature is kept for a certain time, obtaining the water hyacinth biochar. The biochar prepared by adopting the method has a good structure and stable performance, serves as high-quality active carbon and is wide in application range. A new way is opened up for water hyacinth recycling, and the headache for the problem of ecological invasion of the water hyacinth is conveniently solved.

Owner:广东华工碧水环境技术有限公司

High-efficiency energy-saving belt filter press

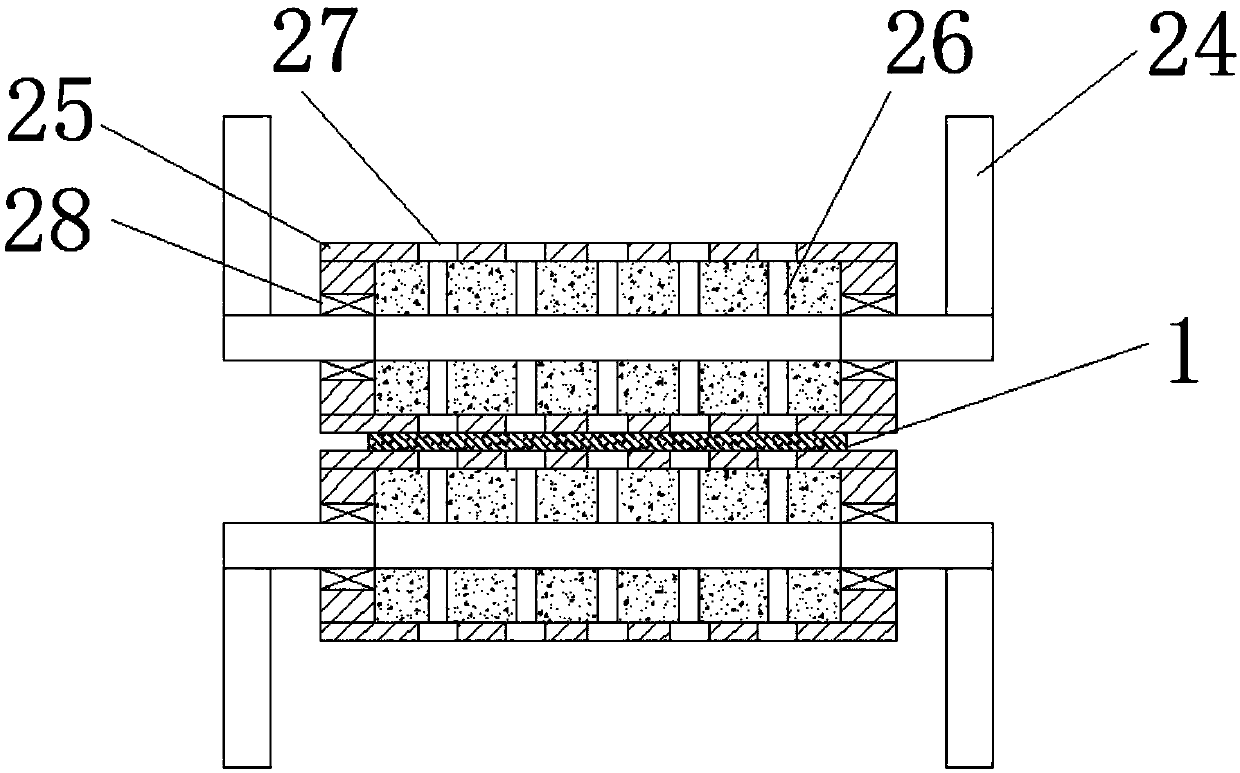

InactiveCN103007614ANot easy to runSolve slipperyChemical industryMoving filtering element filtersChemical industrySlag

The invention discloses a high-efficiency energy-saving belt filter press which comprises a frame, a filter press belt, a hopper and a motor, and is characterized in that a material equalizing regulation device is arranged at a discharging end of the frame; the filter press belt is a double-layer filter cloth belt; a four-stage press filtering mechanism is arranged on the discharged filter press belt at intervals; a vacuum suction filtration disc for vacuumizing by utilizing a vacuum pump is arranged below the filter press belt behind a mesh cage roller; a tail gas cleaning mesh-cleaning roller and a filter press belt gas ejector pipe are respectively arranged on the mesh cage roller and on a belt return part of the filter press belt. The machine is uniform in feeding, long in service life, stable in performance, good in dewatering effect and high in yield, and the filter belt is difficult to block; the slag adhered to the mesh cage roller and the filter press belt is subjected to air injection cleaning by utilizing the vacuum pump tail gas, and water and electric energy are saved; and the machine is suitable for squeezing and dewatering manioc waste, cassava residues, bean dregs and distillers grains and water-containing raw materials in the industries such as municipal sludge, chemical industry, oil refining, papermaking and sugar refining.

Owner:陆汉克

Combination type efficient sludge dewatering conditioning method

ActiveCN104891779AFully dehydratedHas strong oxidizing propertiesSludge treatment by de-watering/drying/thickeningSulfatePotassium ferrate

The invention relates to a combination type efficient sludge dewatering conditioning method and belongs to the field of sludge dewatering preprocessing. According to the technical scheme, the method includes performing acidification treatment on sludge to be dewatered through concentrated sulfuric, adjusting the pH of a sludge system to range from 3.5 to 5, and stirring for 15 to 30min through a stirring blade; adding strong oxidizing agent, namely potassium ferrate, with the content of 0.2% to 4% of the total solid sludge into acidified sludge after water dissolving, stirring for 2min in the speed of 200 to 300 r / min rapidly, and stirring for 20 to 40min in the speed of 80 to 150 r / min slowly; adjusting the pH to range from 3.5 to 5 through concentrated sulfuric, adding ferrous sulfate with the content of 4% to 8% of the total solid sludge after preparing the ferrous sulfate as solution with the concentration of 20% to 50%, after stirring and scattering, adding H2O2, with the concentration of 30%, with the content of 4% to 8% of the total solid sludge, and reacting for 30 to 50min completely during slow stirring; finally, adding quicklime with the content of 3% to 8% of the total solid sludge into the sludge conditioning system, adjusting the system pH to range from 6 to 8, scattering the quicklime evenly, and dewatering.

Owner:BEIJING UNIV OF TECH

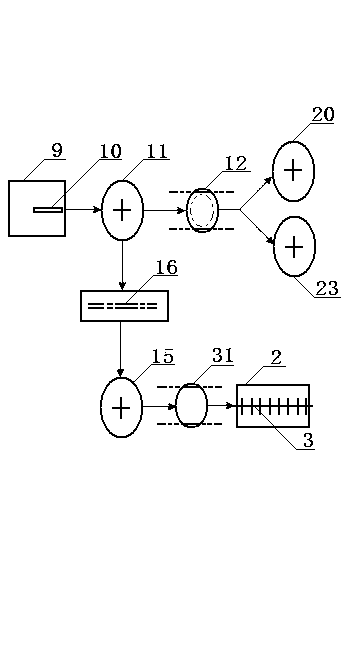

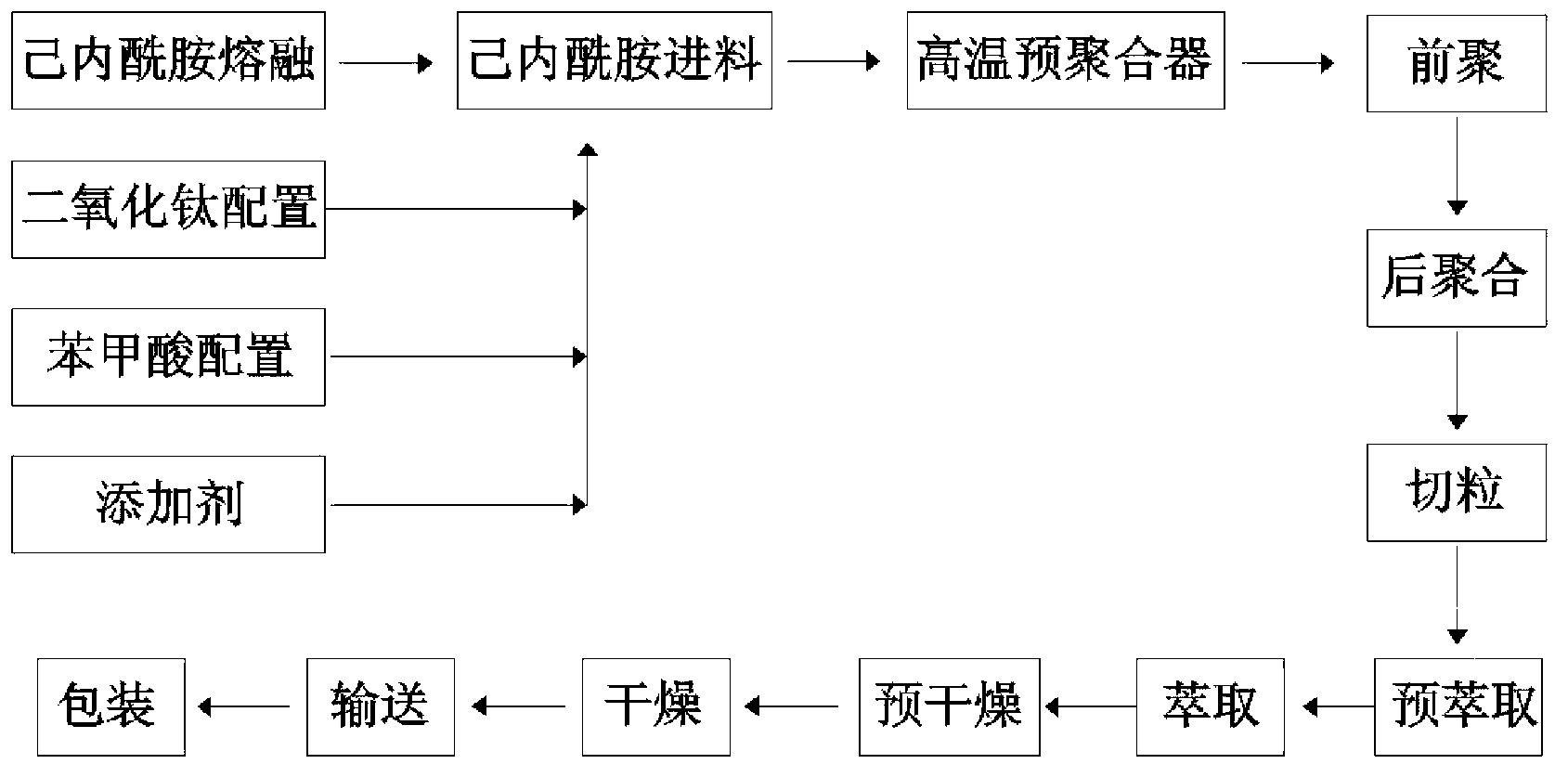

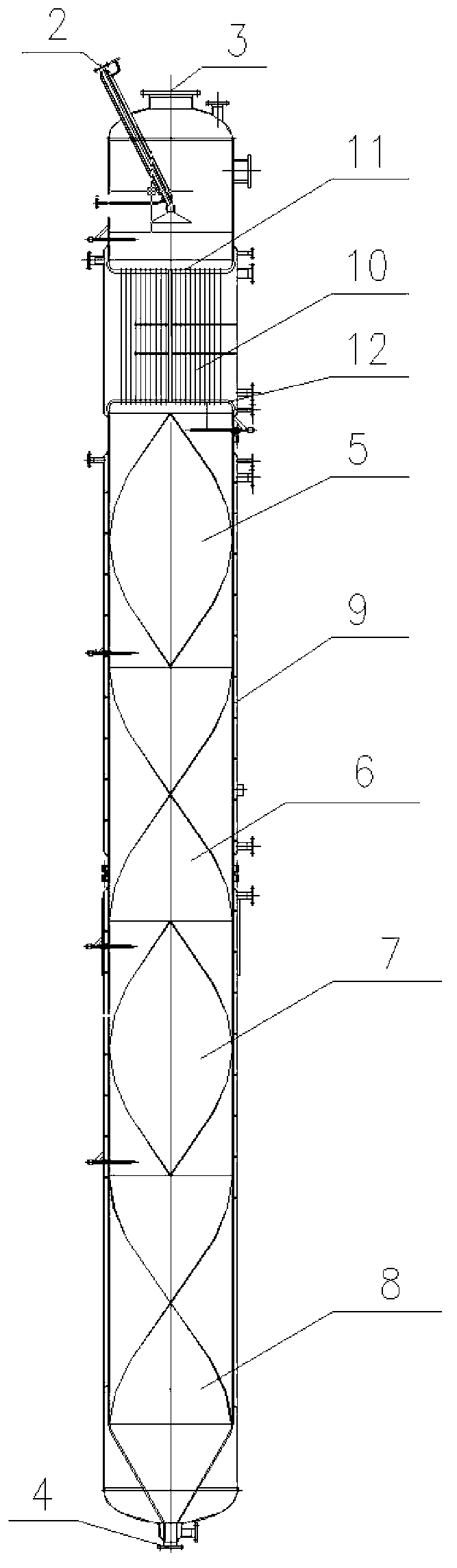

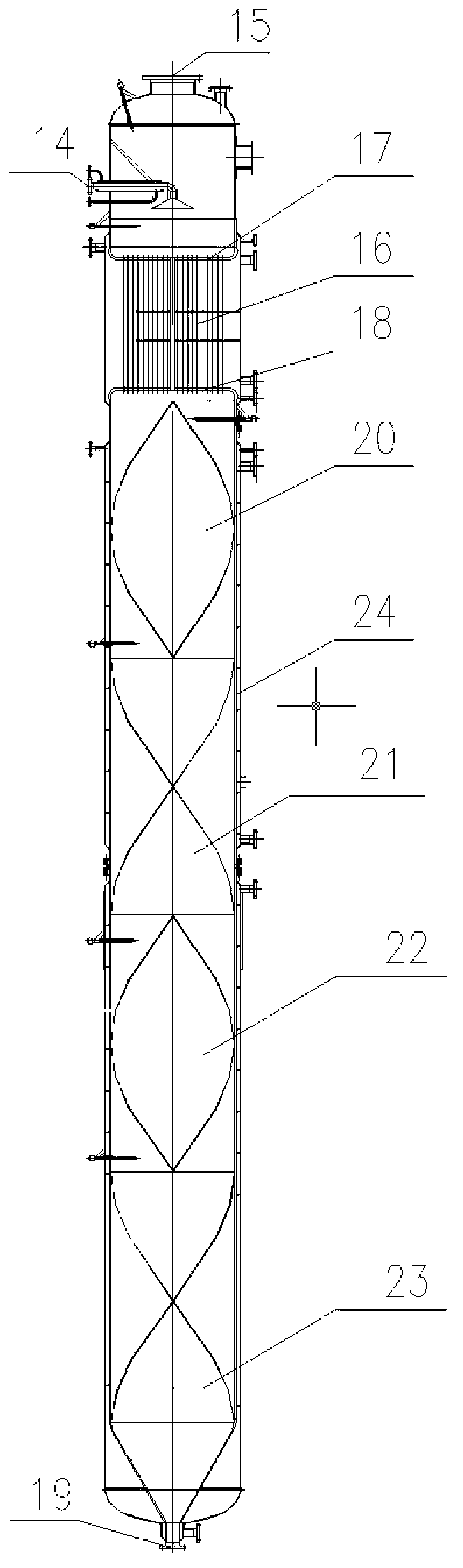

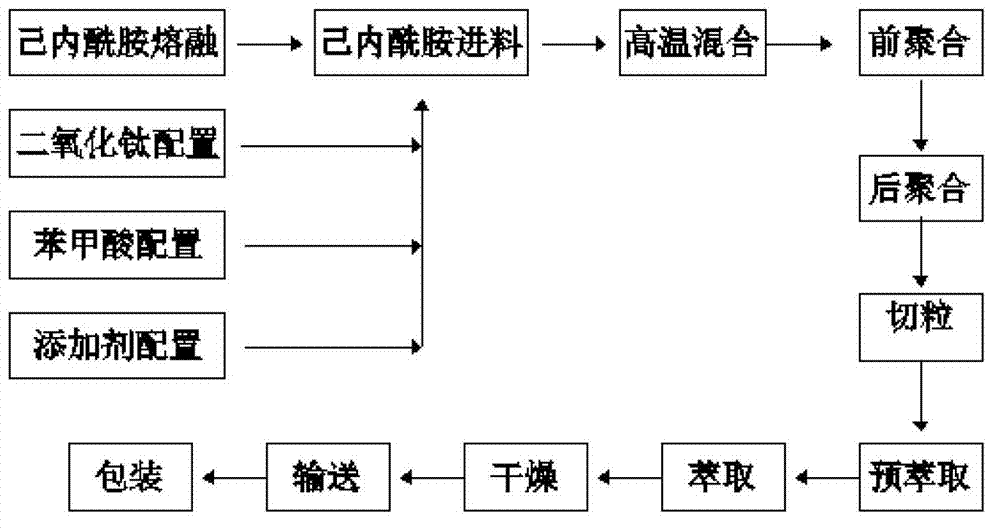

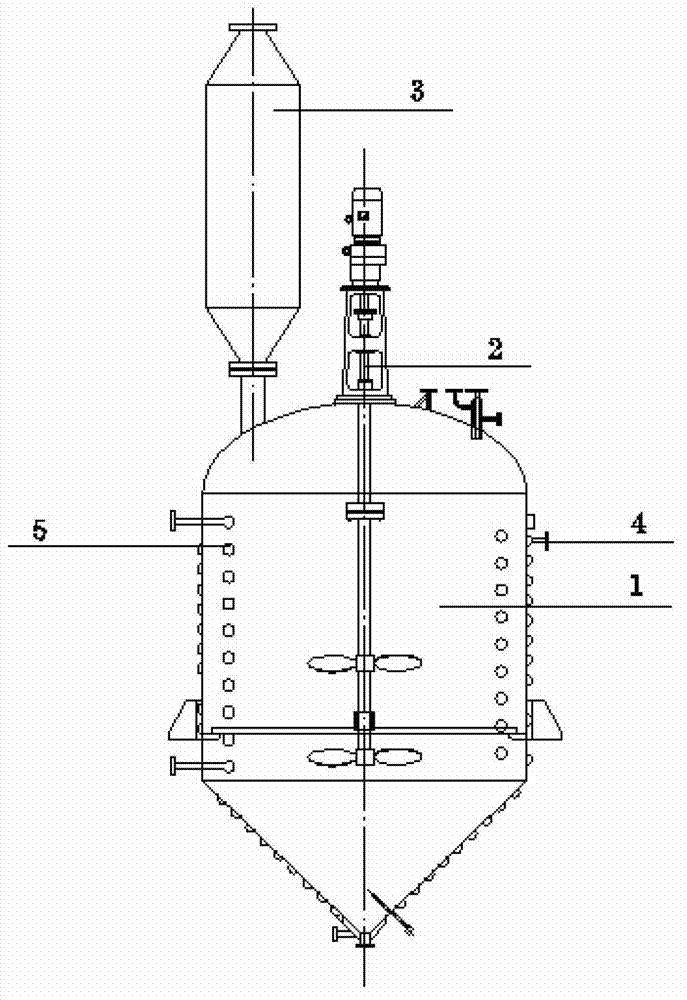

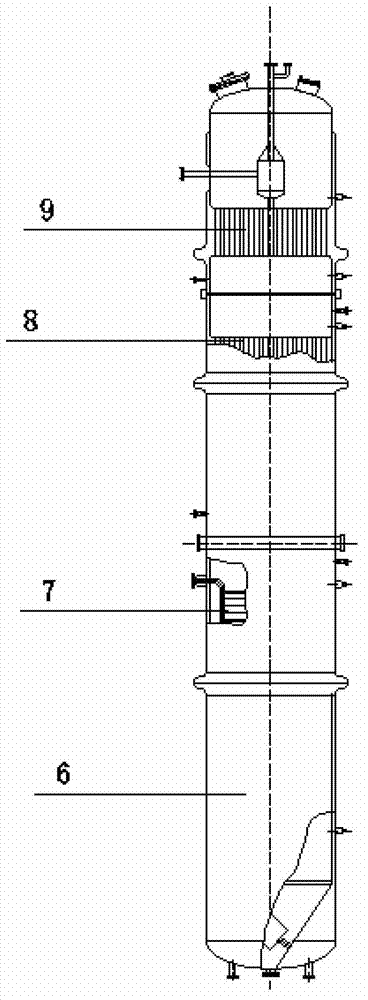

Polyamide polymerization production process and equipment for same

The invention relates to a polyamide polymerization production process and equipment for the same. The polyamide polymerization production process comprises the following steps of: carrying out prepolymerization on melted caprolactam, titanium dioxide, benzoic acid, and the like at a high temperature, and then carrying out front polymerization and post polymerization; pelleting; pre-extracting; extracting; pre-drying; and drying to obtain a product. The production equipment comprises a hexanolactam melting system, a preparation system, a feed system, a high-temperature prepolymerization device, a front polymerization tower, a rear polymerization tower, a pelleting system, a pre-extraction tower, an extraction tower, a pre-drying tower, a drying tower, and the like. According to the invention, static state flow guide spiral mixer assemblies are additionally arranged in the extraction tower and the lower sections of each row of tubes of the high-temperature prepolymerization device, the front polymerization tower and the post polymerization tower; the polyamide hydrolyzing ring opening and dewatering are more uniform and sufficient and faster; the front polyaddition reaction is sufficient and stable; the rear polycondensation stage is more uniform and stable in molecular distribution; the extraction tower more sufficiently and stably extracts a caprolactam monomer; the pre-drying tower can be used for removing the surface moisture of a slice; the drying tower dries combined water; a recovery system can be used for recovering an oligomer and extracts the caprolactam monomer contained in water.

Owner:武汉森大科技研究发展中心

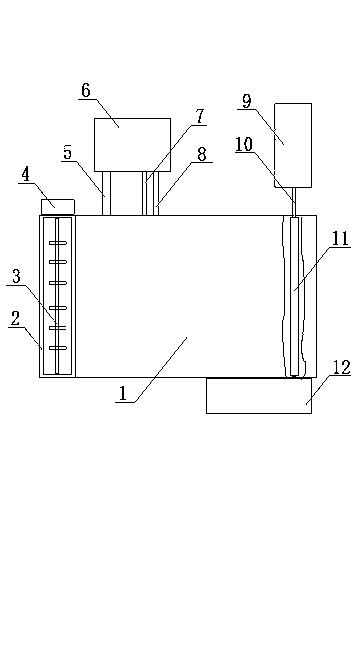

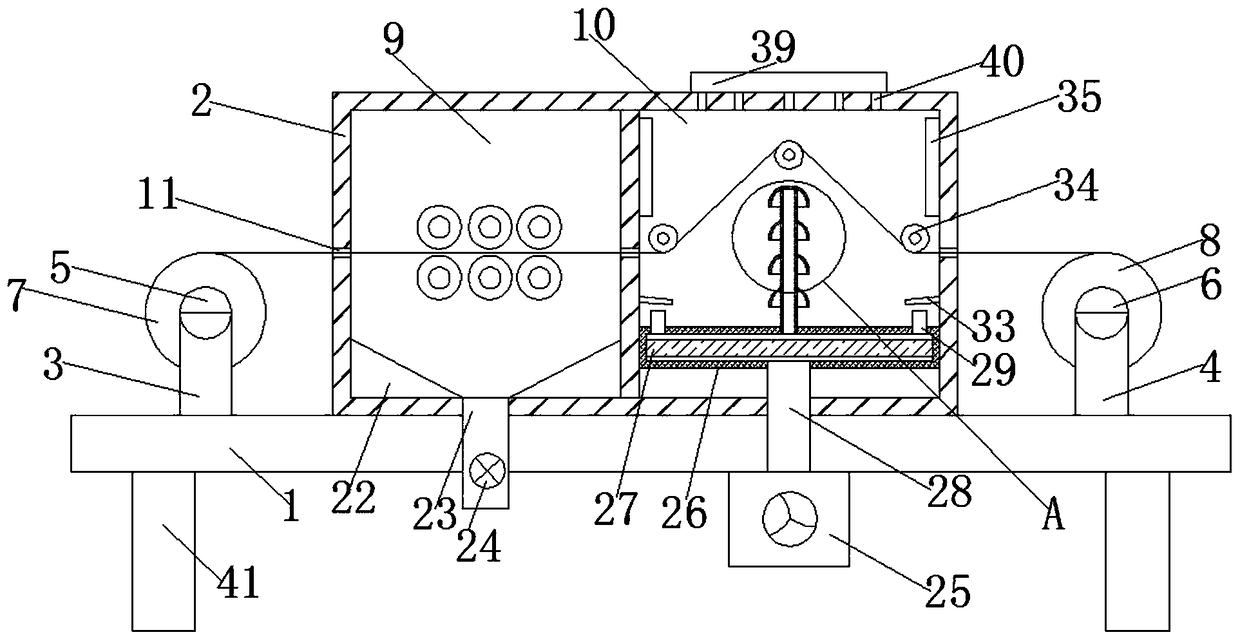

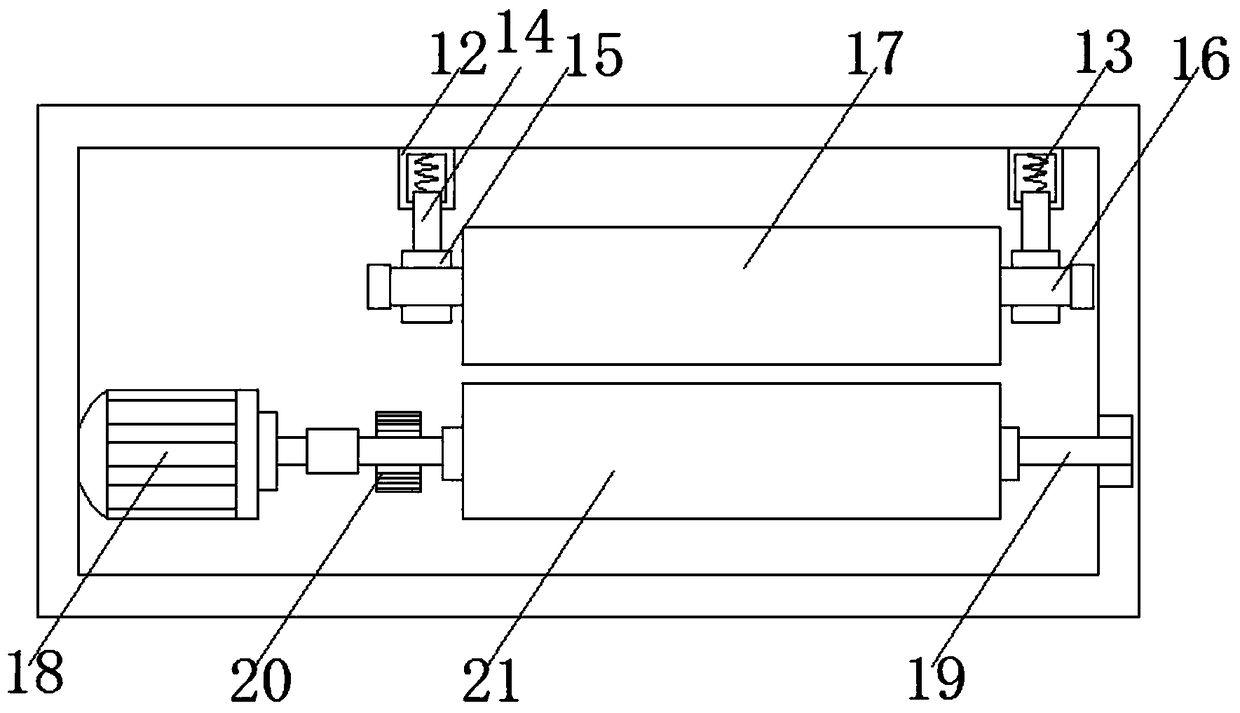

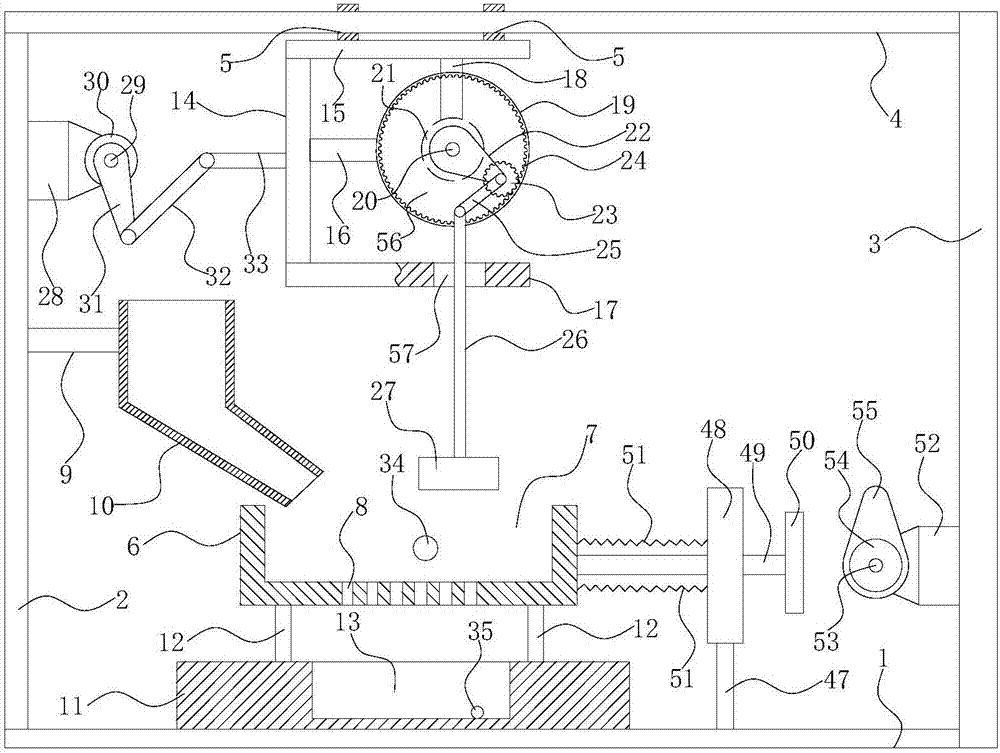

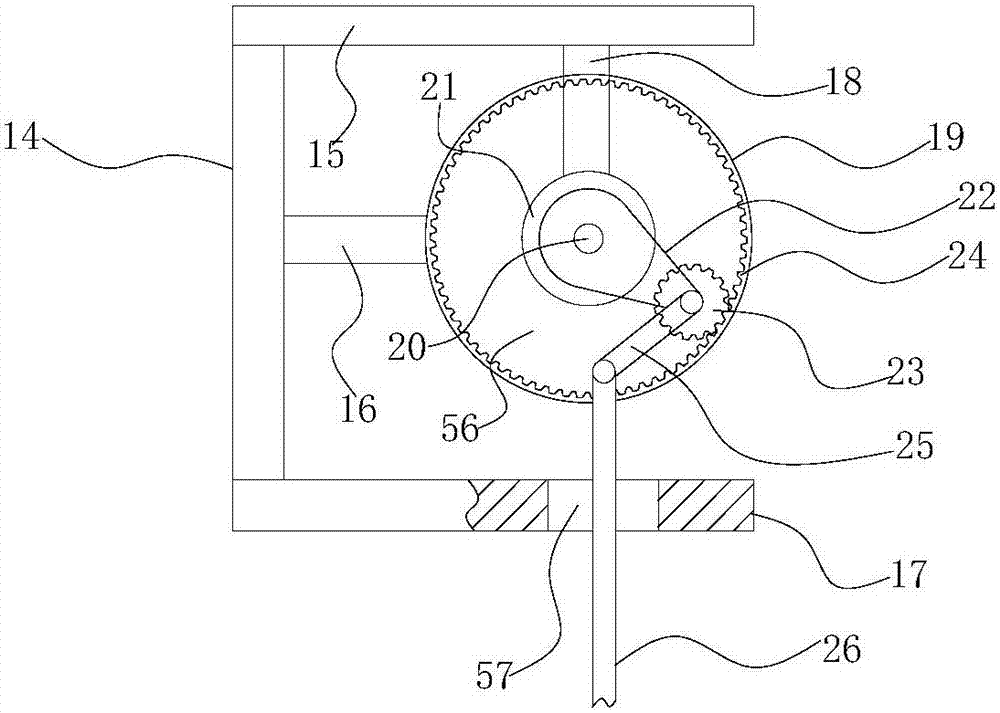

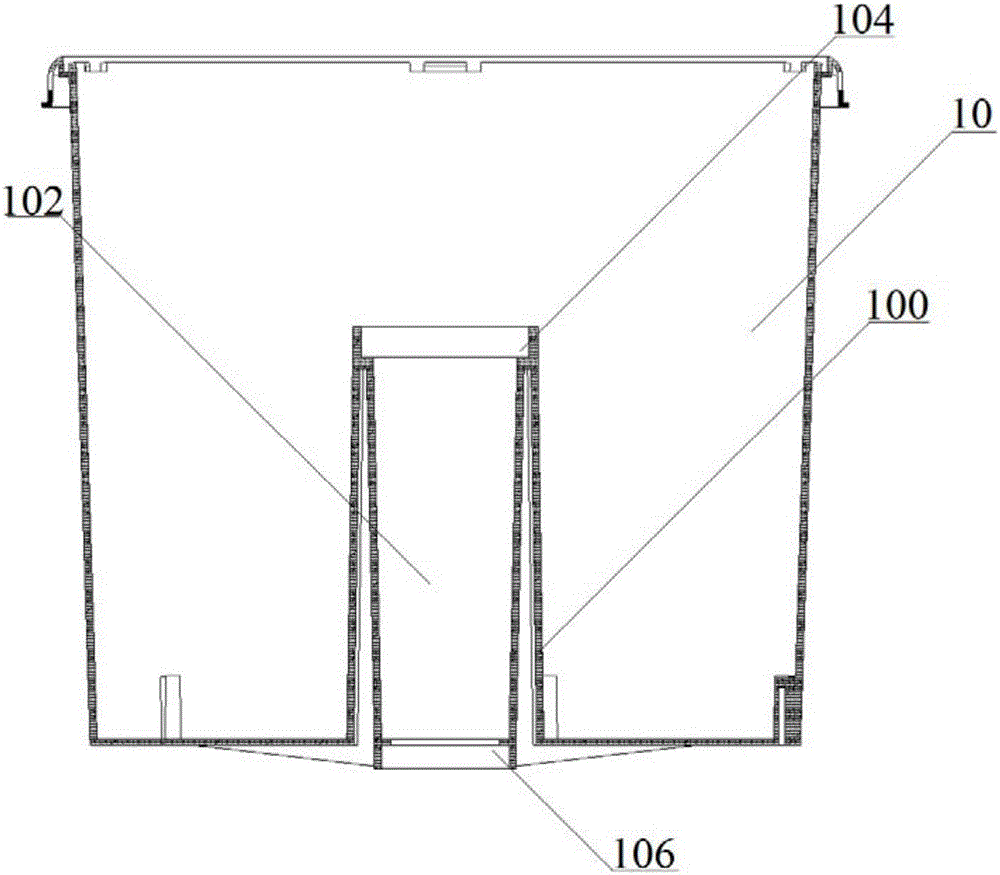

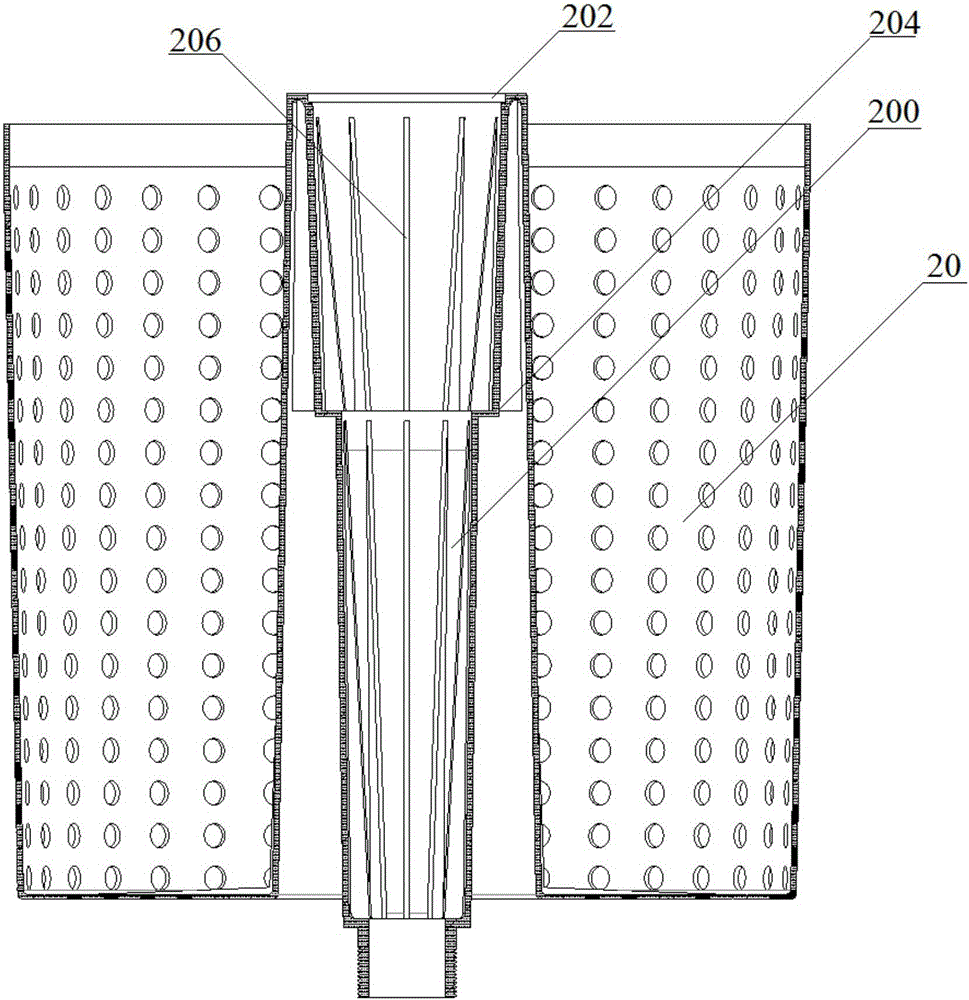

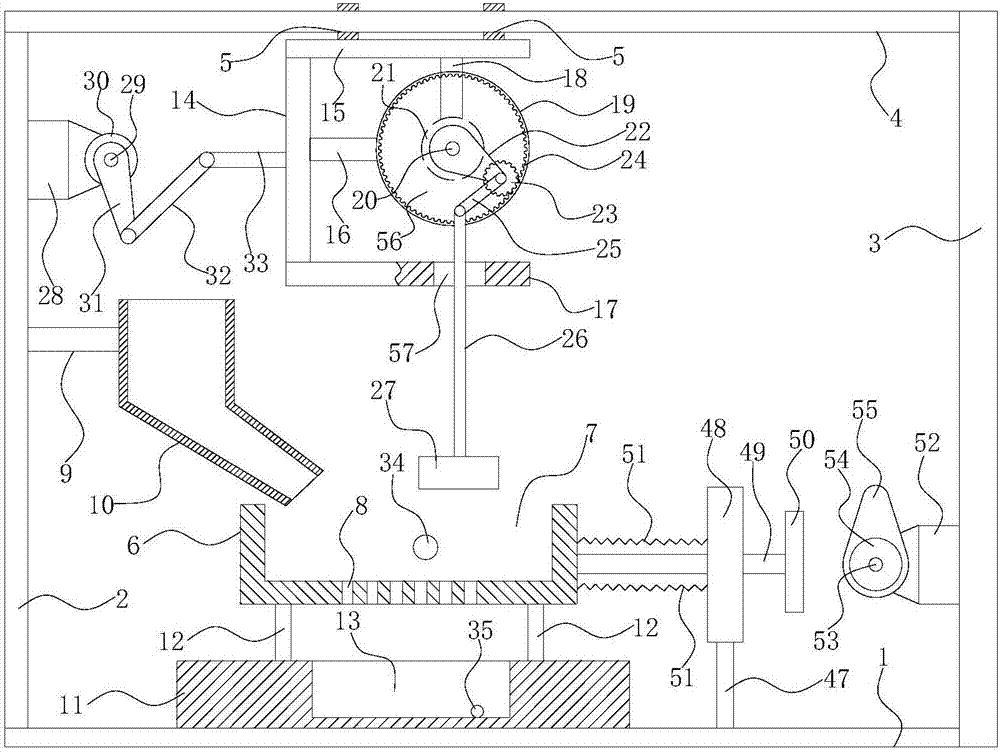

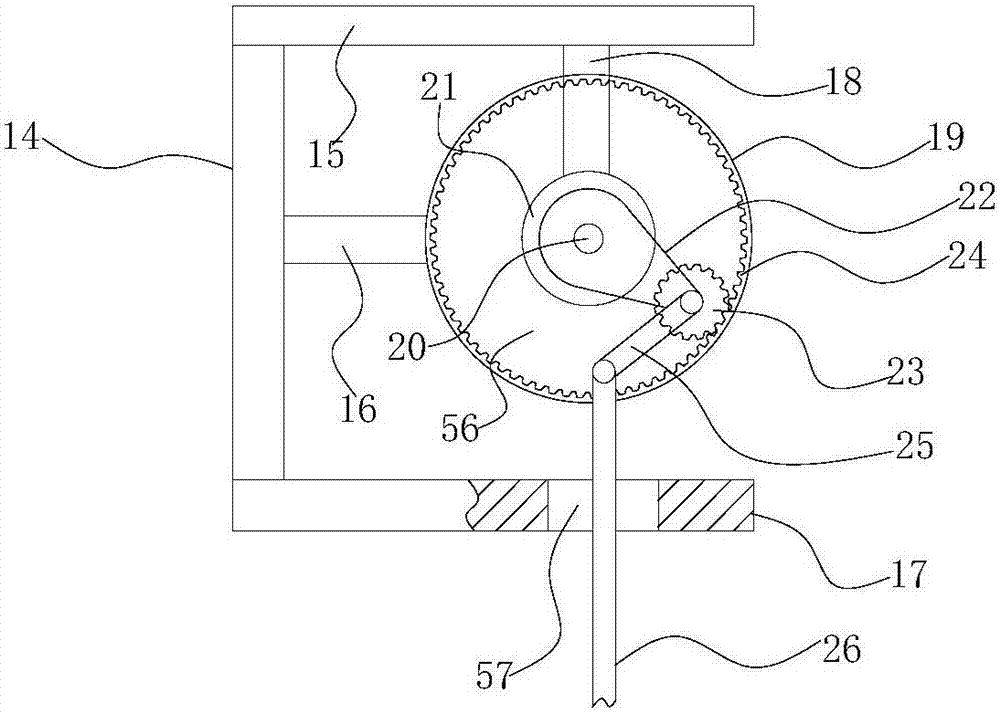

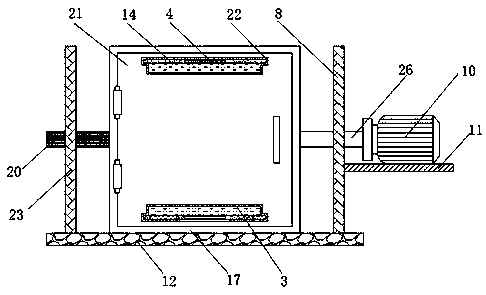

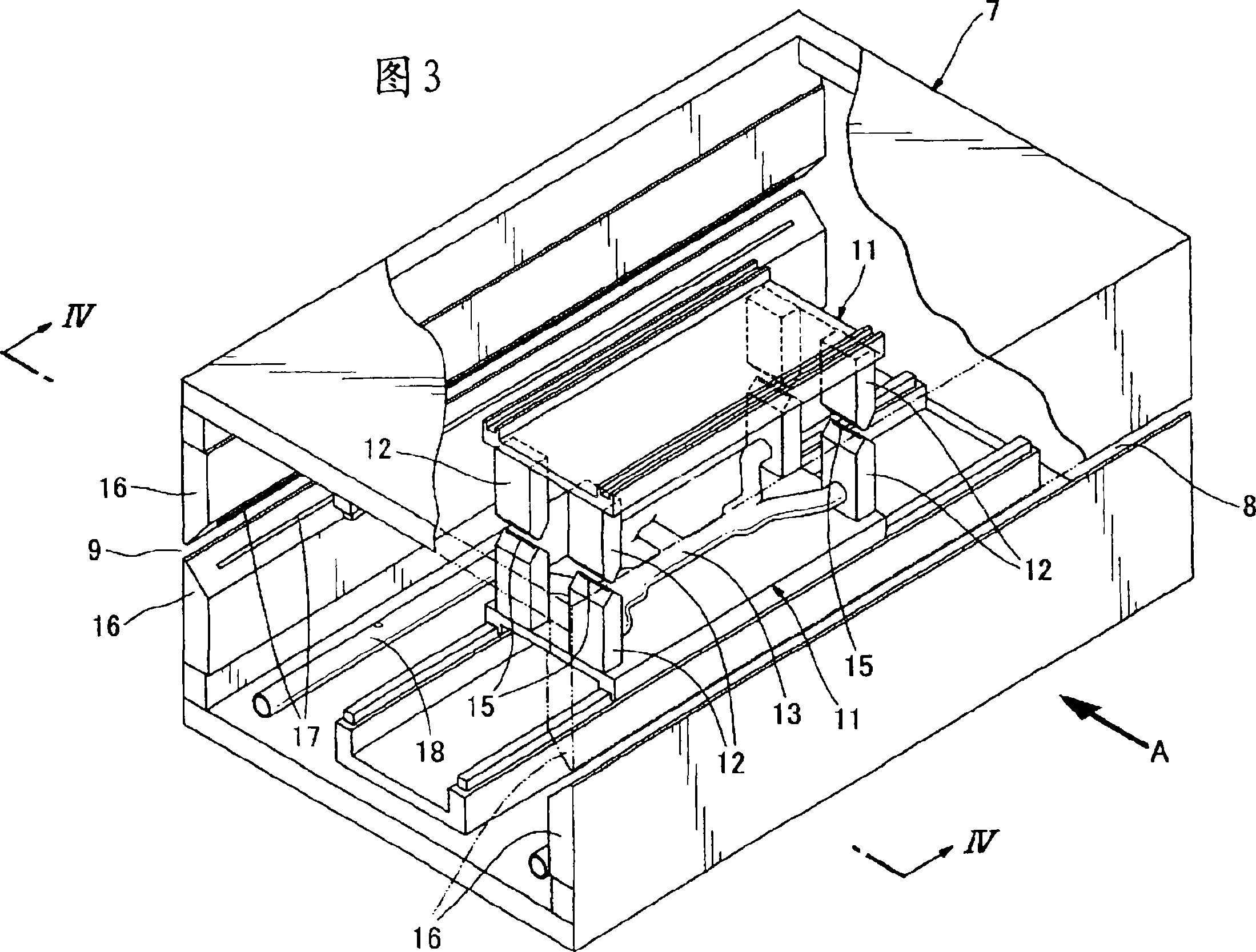

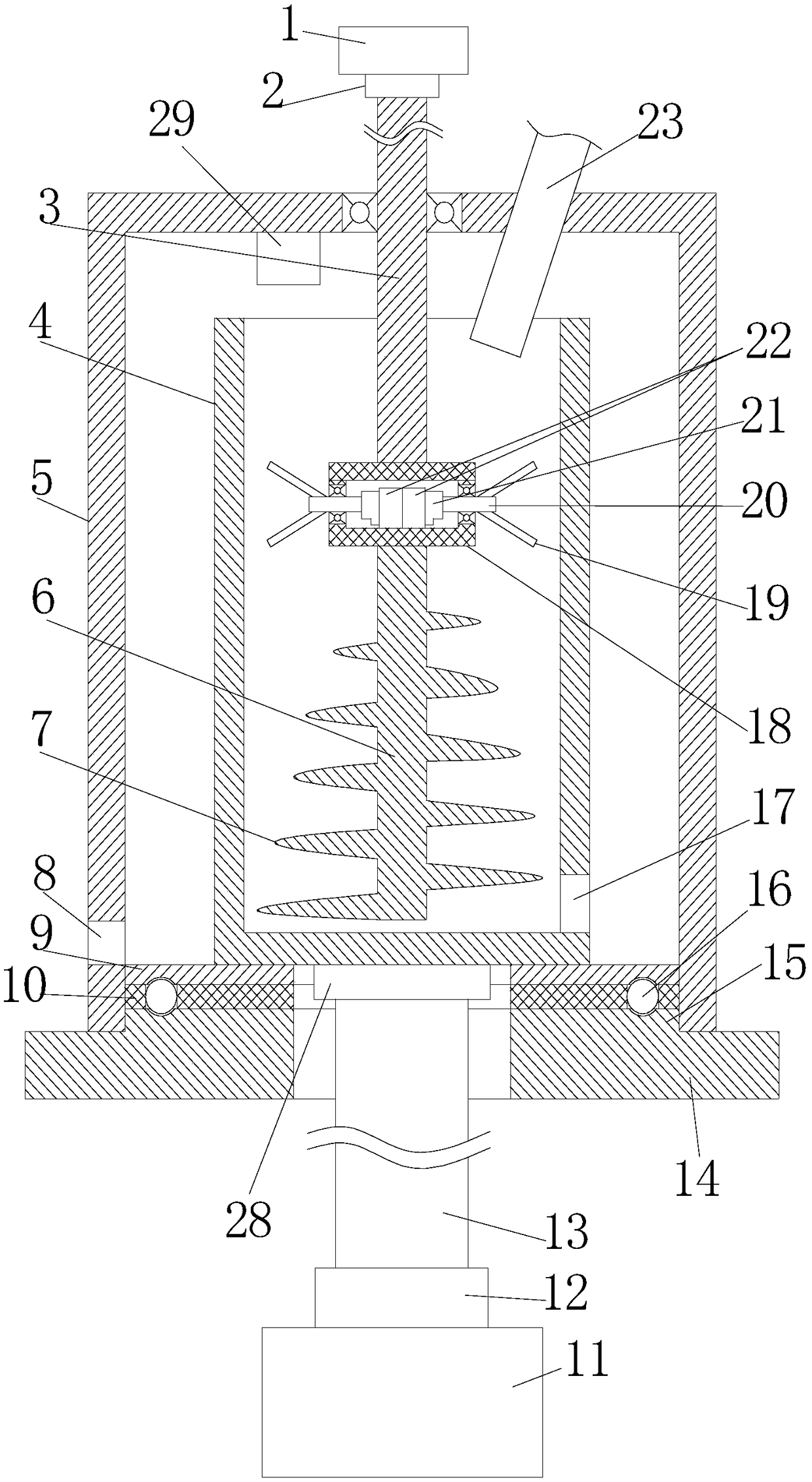

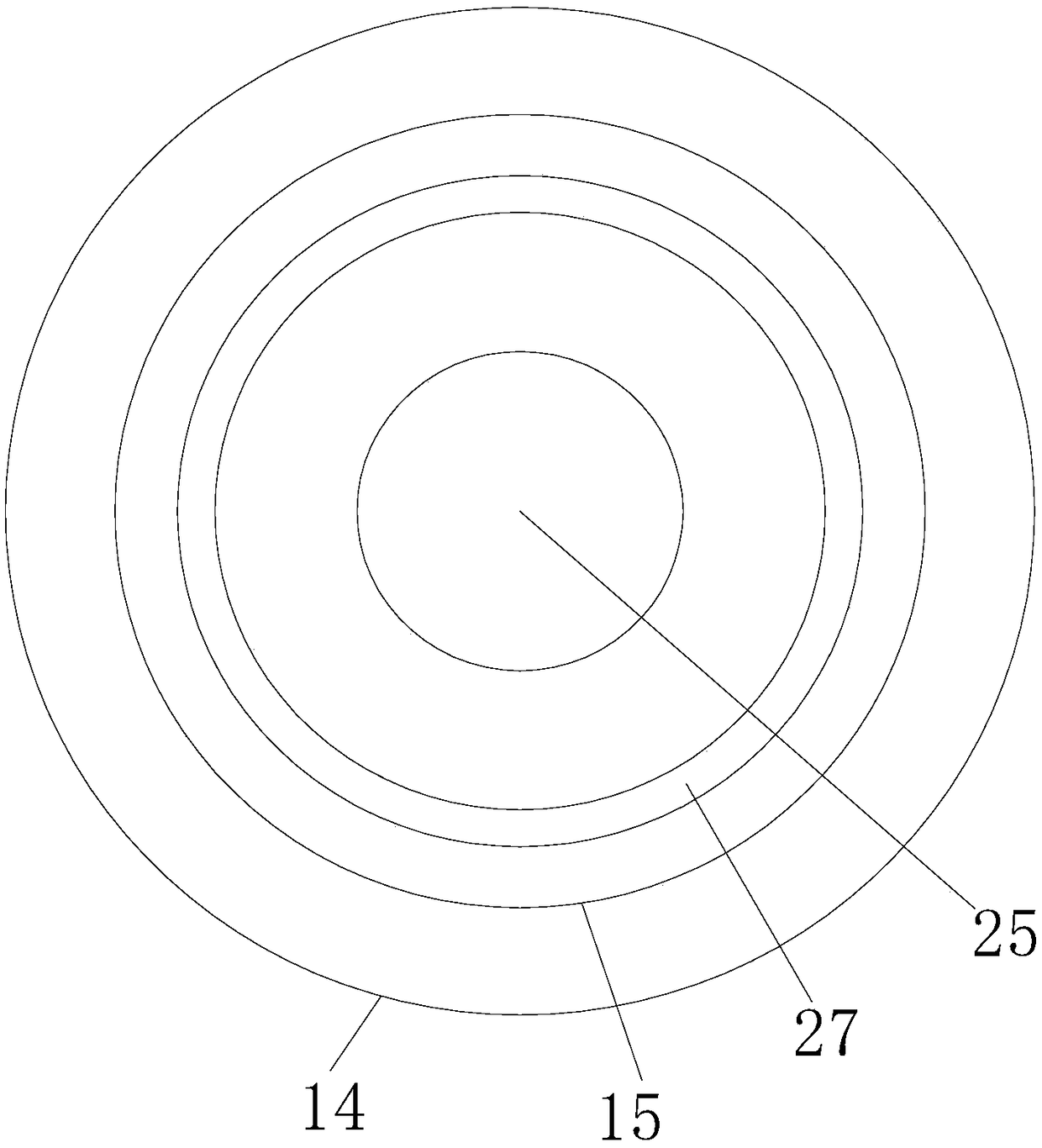

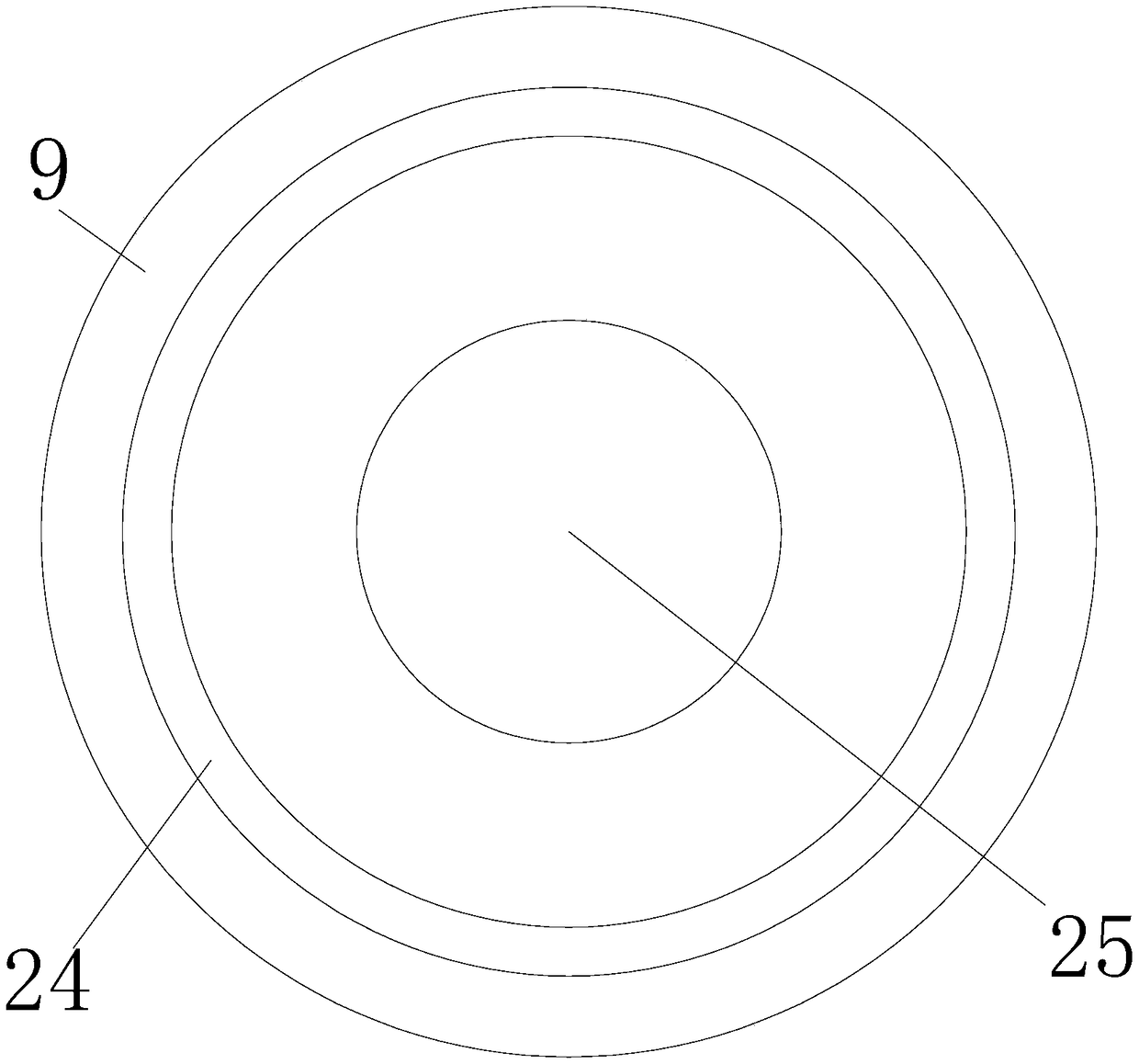

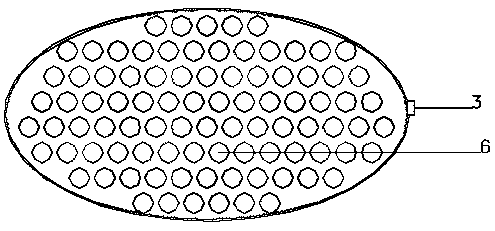

Gauze drying and disinfecting device

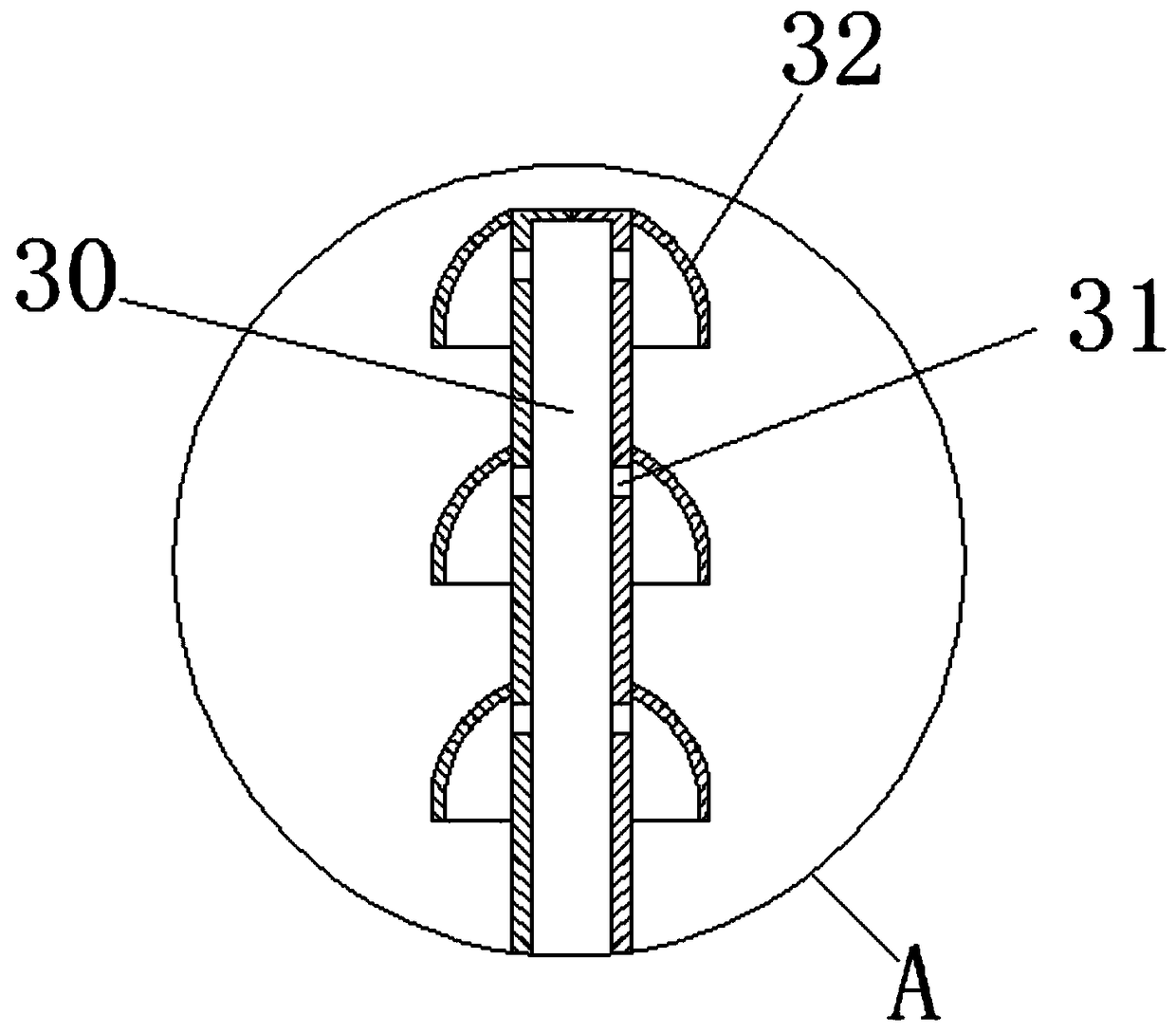

InactiveCN109114933AImprove the extrusion effectFully dehydratedDrying solid materials without heatDrying gas arrangementsDrive motorEngineering

The invention provides a gauze drying and disinfecting device, and relates to the technical field of textile machinery. The gauze drying and disinfecting device comprises a base, the top of the base is fixedly provided with a drying box, a first support and a second support, a material conveying rotating shaft and a material collecting rotating shaft are arranged on the first support and the second support respectively in a penetrating mode, the material conveying rotary shaft and the material collecting rotary shaft are respectively and fixedly provided with a material conveying rotary disc and a material collecting rotary disc, and the drying box is divided into a dehydrating chamber and a drying and disinfecting chamber. According to the gauze drying and disinfecting device, an upper pressing roller, a lower pressing roller, a second roller shaft, a first roller shaft, a driving motor, a transmission gear and an extrusion spring are arranged in a cooperated mode, the driving motor drives one of the second roller shafts to rotate, the lower pressing roller is driven to rotate together through the transmission gear, the corresponding upper pressing roller is driven to rotate in the rotating process of the lower pressing roller, the gauze is dehydrated, the follow-up drying work is facilitated, the squeezing effect of the gauze is increased through the squeezing spring, and dewatering is more sufficient.

Owner:江西美宝利实业有限公司

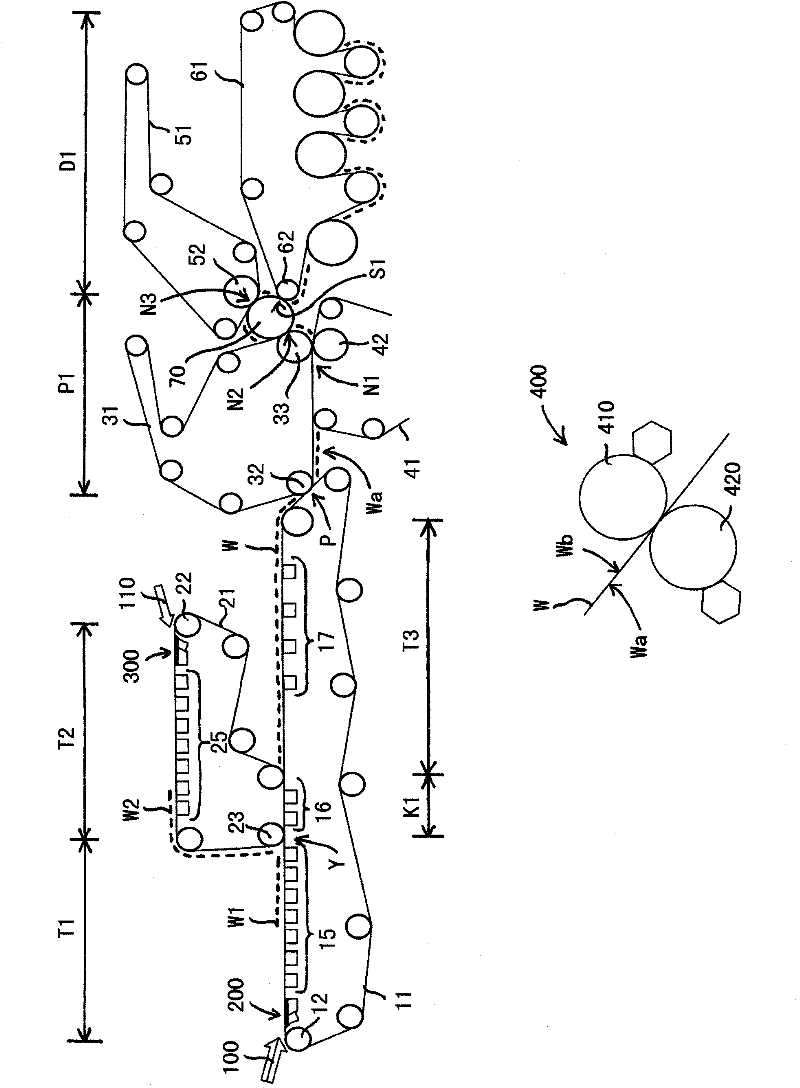

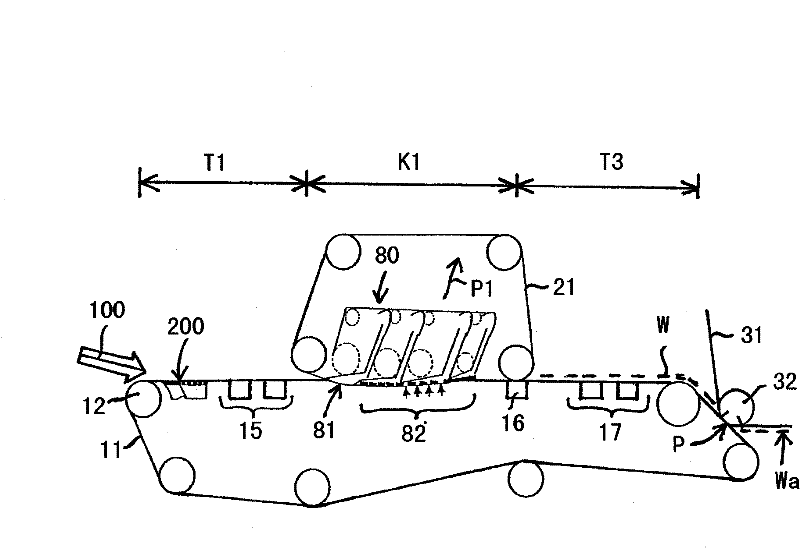

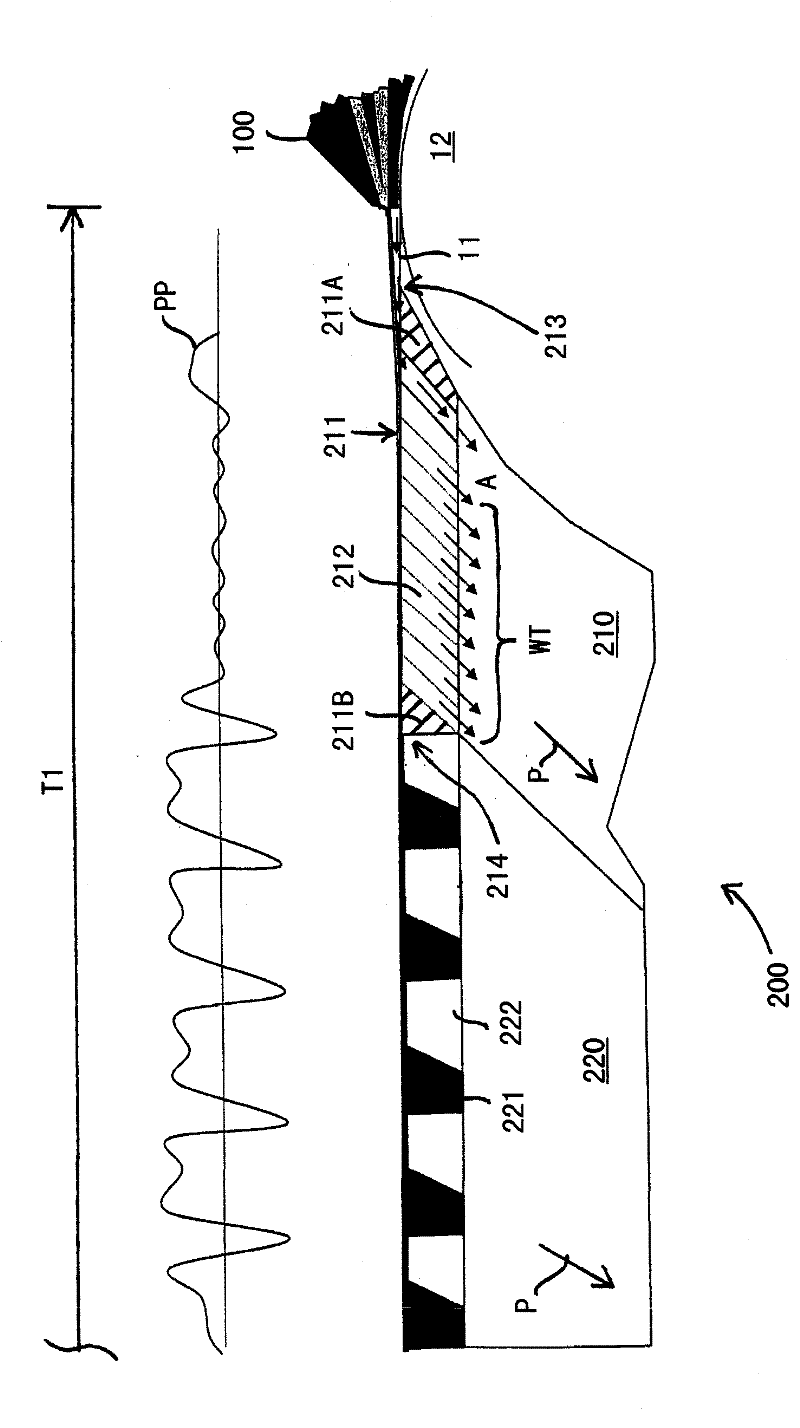

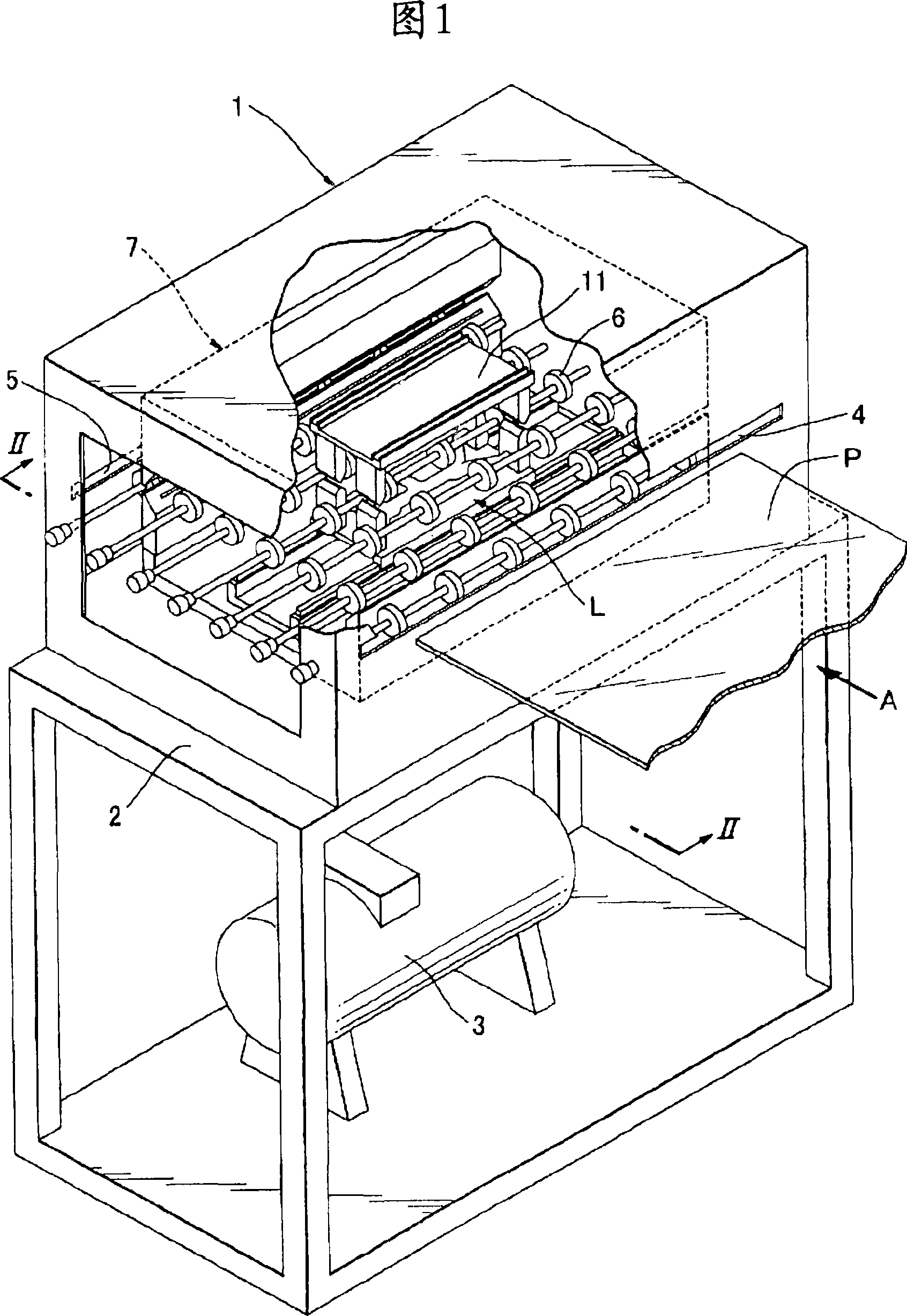

Board machine

InactiveCN102131981ADoes not affect layered purityAvoid deformationMachine wet endEngineeringCoating

A board machine comprises a forming section where a lower wire loop (11) forms a fourdrinier-wire section (Tl) at the beginning of which is located a forming board (200) which consists of at least one stationary, non-pulsating forming shoe (210). In the forming shoe (210), there is a cover (211) provided with thorough holes (212), setting against the inner surface of the lower wire loop (11). A first headbox (100), which is a multi-layer headbox, feeds a pulp suspension jet onto the forming shoe (210). The board machine further comprises a press section (Pl) where a surface (Wa) of the web (W) having been against the lower wire loop (11) is pressed against a smooth surface, a dryer section (Dl) where the web (W) is dried with at least one cylinder-dryer group and a coating section (400) where at least the surface (Wa) of the web (W) having been against the lower wire (11) is coated.

Owner:METSO PAPER INC

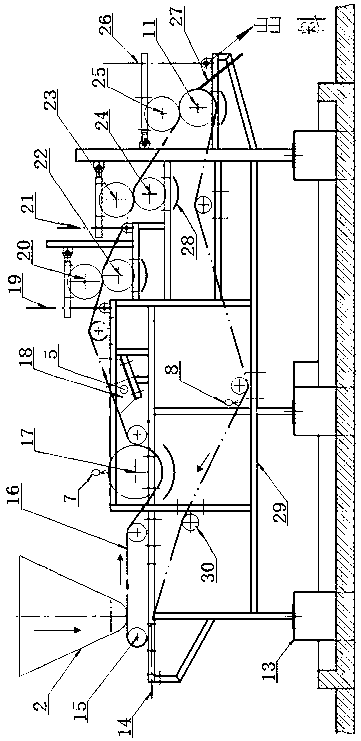

Polymerization manufacturing technique and device for polyamide

The invention relates to a polymerization manufacturing technique and device for polyamide. The manufacturing technique comprises the steps of feeding molten caprolactam, titanium dioxide, benzoic acid and an additive, dynamically mixing at a high temperature for prepolymerization and postpolymerization, granulating, pre-extracting, extracting and drying to obtain the final product. The device comprises a melting system, a feed system, a high-temperature dynamic mixing system, prepolymerization and postpolymerization towers, a pre-extraction column, an extraction column, a recycling system and a drying tower. According to the invention, a high-temperature dynamic mixing tank is set additionally. The mixing of the raw materials and hydrolysis for ring opening and dehydration of polyamide are performed at a state of dynamically mixing to achieve a more sufficient and stable pre-addition polymerization and a more uniform and stable molecular distribution of post-polycondensation. A slice and a water separator of the extraction column are used for mainly extracting oligomers through the pre-extraction column and extracting a caprolactam monomer through the extraction column with a stable concentration. A slice cooler of the drying tower is used for cooling the slices rapidly. An extraction water recycling system is used for recycling the oligomers in the pre-extraction water and the caprolactam monomer in the extraction water.

Owner:武汉森大科技研究发展中心

Combined conditioning method for sludge high-efficient dehydration

InactiveCN104973750AImprove sludge dewatering performanceGood flocculationSludge treatment by de-watering/drying/thickeningPre treatmentEnvironmental chemistry

The invention relates to a combined conditioning method for sludge high-efficient dehydration, and belongs to the field of sludge dehydration pretreatment. The method comprises the following steps: acidifying sludge to be dehydrated by concentrated sulfuric acid, adjusting the pH value of the sludge system to a range of 3.5-5, continuously stirring the sludge system by a stirring pad for 15 to 30 minutes; adding a strong oxidant (potassium ferrate) accounting for 0.2 to 4% of the total dried sludge weight into the acidified sludge, wherein the potassium ferrate is dissolved by water before addition; rapidly stirring the sludge for 2 minutes at a stirring speed of 200 to 300 r / min, then slowly stirring the sludge for 20 to 40 minutes at a stirring speed of 80 to 150 r / min; then adding polymeric ferric sulfate accounting for 6 to 12% of the total dried sludge weight into the sludge conditioning system, wherein the polymeric ferric sulfate is dissolved by water to prepare a solution with a mass concentration of 20-50% before addition; keeping on stirring at a slow stirring speed for 15 to 30 minutes; then adding quicklime accounting for 3 to 8% of the total dried sludge weight into the sludge conditioning system, adjusting the pH value to a range of 6-8, evenly dispersing the quicklime, and immediately dehydrating the sludge.

Owner:BEIJING UNIV OF TECH

Improved waste plastic dehydration equipment

InactiveCN107014158AFully dehydratedImprove dehydration effectDrying solid materials without heatCleaning using liquidsPulp and paper industryDewatering

The invention discloses improved waste plastic dehydration equipment. The improved waste plastic dehydration equipment comprises a bottom board, a left stand column, a right stand column, an ejector rod installed between the top of the left stand column and the top of the right stand column, a sleeve sleeving the ejector rod and capable of sliding left and right relative to the ejector rod, a slide frame connected with the sleeve, and a dehydration tank located below the slide frame, wherein the left stand column and the right stand column are installed on the bottom board; a first cavity is formed in the dehydration tank; a plurality of dehydration holes communicating with the first cavity are formed in the bottom wall of the dehydration tank; a supporting pipe is arranged on the left stand column and provided with a feeding hopper; a discharging outlet of the feeding hopper faces the first cavity; the bottom board is provided with a supporting tank; the bottom of the dehydration tank is fixedly connected with a slide block; the supporting tank is provided with a slide groove allowing the slide block to slide left and right; a second cavity is formed in the supporting tank and internally provided with a water collection tank; and the water collection tank is located below the dehydration holes. The improved waste plastic dehydration equipment can sufficiently dehydrate waste plastics and remarkably improve the dehydration effect.

Owner:江先庆

Spinach-carrot instant noodles

The invention relates to instant noodles, in particular to spinach-carrot instant noodles. The noodles cake comprises wheat flour, vegetable oil, starch, edible salt, gluten powder and food additive, and is characterized by further comprising carrot and spinach, wherein the weight ratio of the wheat flour to the carrot to the spinach is (9-11):1:1.5, the weight of the carrot refers to the weight of the peeled carrot, and the weight of the spinach refers to the weight of the spinach subjected to washing and root removal; and the starch, the edible salt, the gluten powder, the food additive, the carrot and the spinach are all accessories. The instant noodles prepared by the invention are high in vitamin content, are simple and practical to prepare, and can be prepared based on the original production line without changing equipment.

Owner:西安美立方产品设计开发有限公司

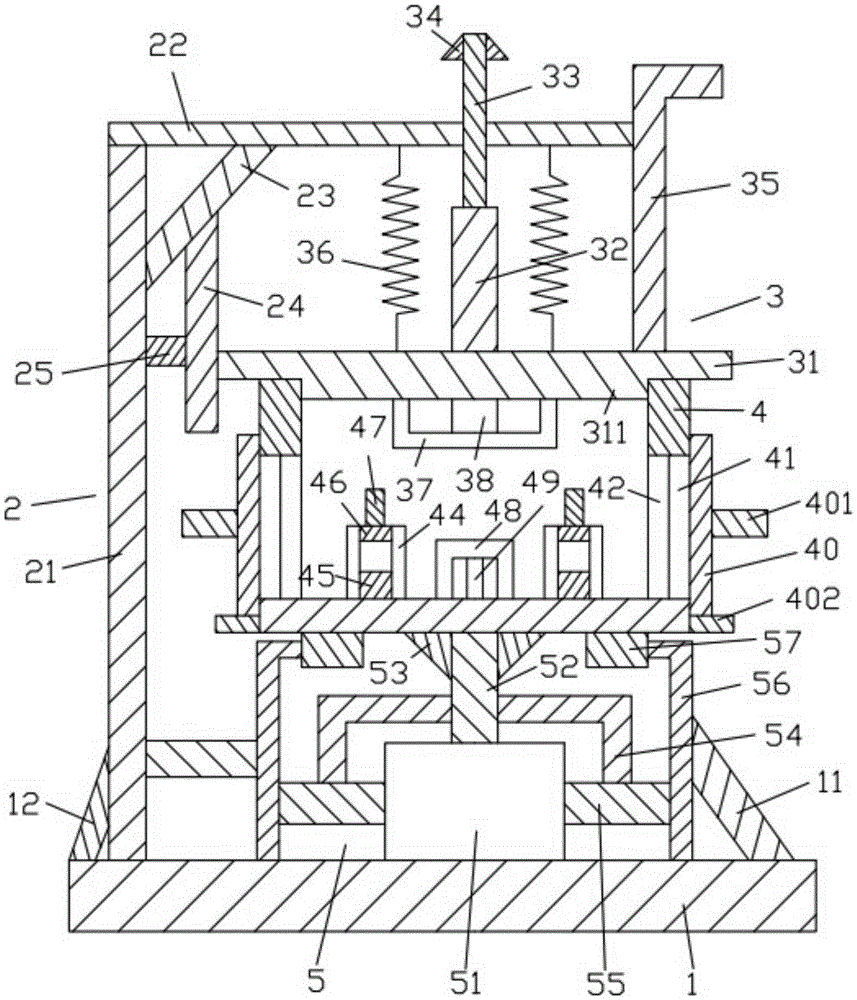

Dewatering device for medical treatment

A dewatering device for medical treatment comprises a bottom plate, a support device, a cover plate device, a frame body and a motor device. A first inclined rod and a second inclined rod are arranged on the bottom plate. A first supporting rod, a first transverse rod, a third inclined rod, a first vertical rod and a second transverse rod are arranged on the support device. A first cover plate, a second vertical rod, a third vertical rod, a positioning ring, a pull frame, a first spring, a first cooling frame and a first heating bar are arranged on the cover plate device. The frame body is provided with a first through hole, a first filter screen, a blocking column, a cushion block, a second cover plate, a first holding rod, a second cooling frame, a second heating bar and a check ring. The motor device is provided with a motor, a rotating shaft, a fixed ring, a positioning frame, a third transverse rod, a fixed frame and a wheel. Sufficient dewatering and drying can be conducted on medical instruments, dewatering is rapid, the effect is obvious, medical work efficiency can be greatly improved, labor intensity of medical staff is relieved, medical instruments are disinfected after heating, and disease infection is avoided.

Owner:HAIMEN THE YUECAI TEXTILE TECH CO LTD

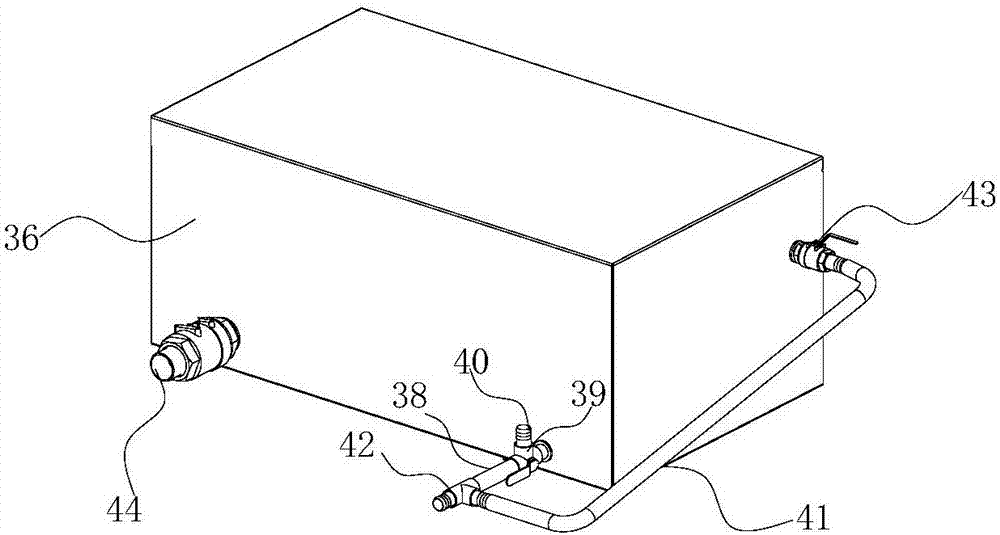

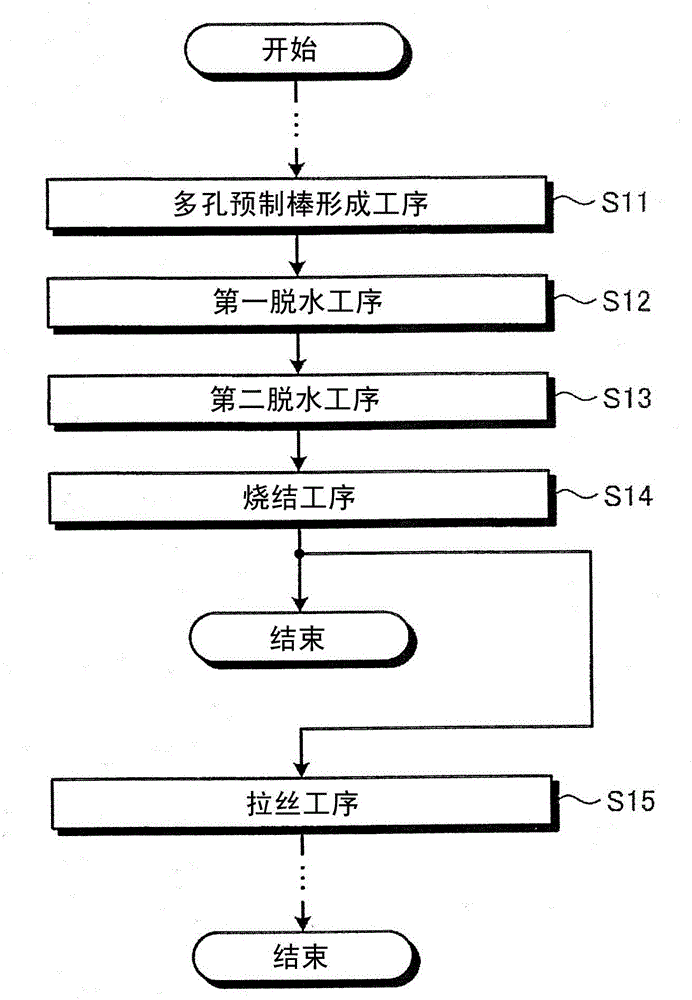

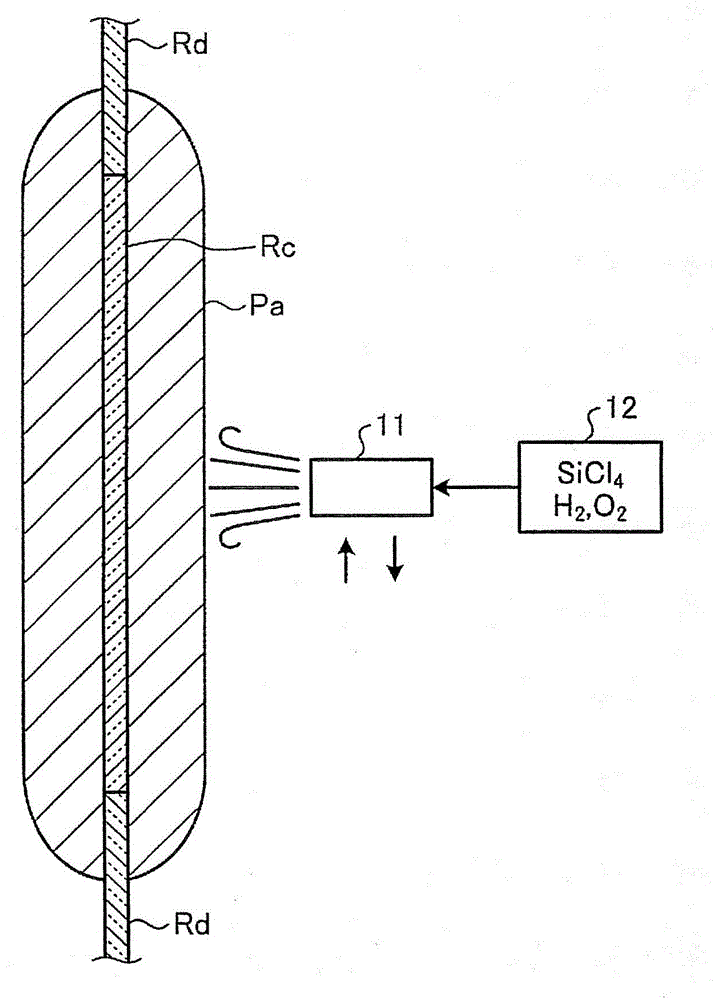

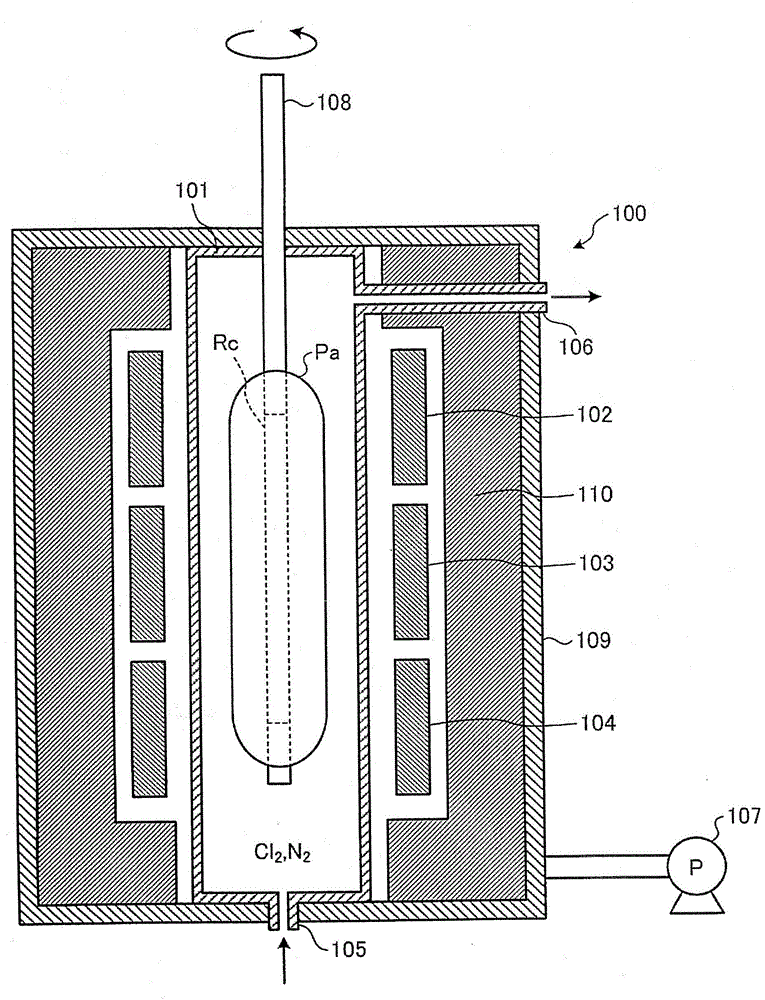

Method for producing optical fiber preform and method for producing optical fiber

InactiveCN105916823AFully dehydratedGlass making apparatusOptical articlesSilica particleVitrification

A method for producing an optical fiber preform comprises: a step for forming a porous preform by depositing fine silica particles on the outer circumference of a target rod; and a vitrification step in which the porous preform is dehydrated and sintered by at least three heat treatment steps. The porous preform is dehydrated in an atmosphere that contains a halogen gas or a halogen-based compound gas in the first heat treatment step, which is a heat treatment step carried out first among the three heat treatment steps, and in the second heat treatment step, which is a heat treatment step carried out secondly among the three heat treatment steps. The treatment temperature in the second heat treatment step is higher than the treatment temperature in the first heat treatment step.

Owner:FURUKAWA ELECTRIC CO LTD

Compressed and preserved fruits and vegetables produced by ultralow-temperature freeze-drying equipment

InactiveCN107410973ADoes not change nutritionWon't change colorFood dryingFruits/vegetable preservation by dehydrationEnvironmental resistanceFreeze-drying

The invention relates to the field of food preservation, in particular to compressed and preserved fruits and vegetables produced by ultralow-temperature freeze-drying equipment through low-temperature drying, retaining of food nutrient substances, prolonging of food shelf life and reducing of food size. A production process includes following steps: 1), washing; 2), shredding; 3), drying; 4), compressing; 5), packaging. Low temperature is utilized for drying, so that strong dewatering can be realized without damaging nutrition of the fruits and the vegetables, dewatering effect is good, own color of the fruits and the vegetables can be maintained even, and the shelf life is prolonged greatly; in the process of drying and packaging, no additive is used, so that the fruits and the vegetables are more natural and environment-friendly, can be ready for eating by soaking with hot water or can be eaten directly and can quickly supplement energy for human bodies; compression equipment is used, so that the size is greatly reduced, and more convenience is brought to transportation and storage.

Owner:云南牧工商茶叶进出口股份有限公司

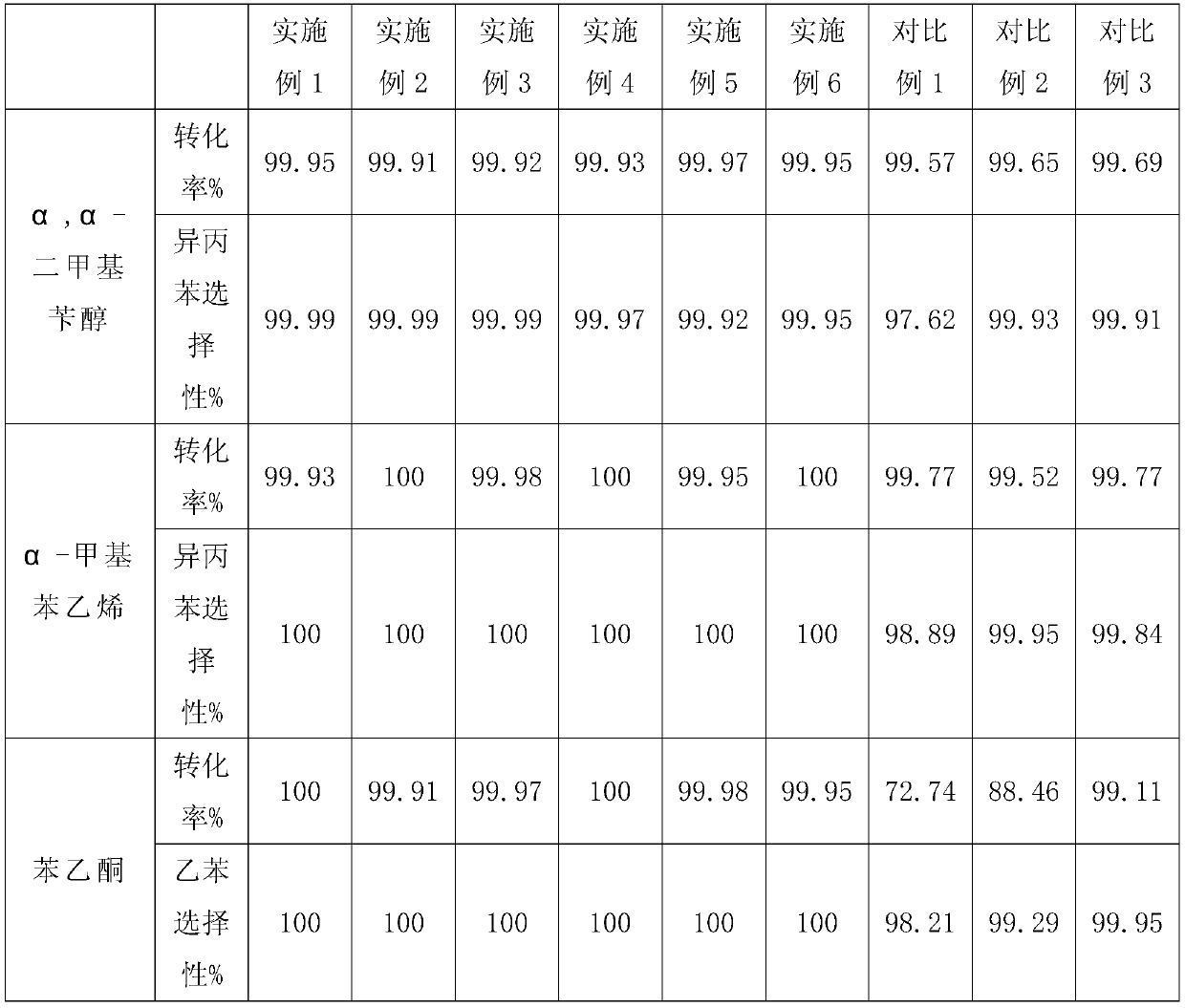

Catalyst for hydrogenolysis and preparation method thereof

ActiveCN110813319AHigh conversion rate and target product selectivityHigh reactivityMolecular sieve catalystsHydrocarbon by hydrogenationSodium acid carbonateEngineering

The invention discloses a catalyst for hydrogenolysis, which comprises the following components in percentage by mass: (a) 40-80% of component A; (b) 0.5 to 10% of a component B; (c) 0.01 to 1% of a component C; (d) 0.1 to 5% of a component D; and (e) 10-50% of a component E; the preparation method of the catalyst comprises the following steps: (1) dropwise adding a sodium carbonate solution and afirst metal salt solution into deionized water; (2) adding a second metal salt solution and the component E; and (3) filtering, forming and calcining the solution to form a catalyst finished product.According to the catalyst, a small amount of second metal components containing elements such as zinc, magnesium, calcium and barium are added into copper, nickel and palladium as main components, sothat the dispersion effect of the main components such as copper, nickel and palladium in the catalyst can be effectively improved, and meanwhile, the reaction activity and the reaction stability ofthe catalyst are improved.

Owner:HONGBAOLI GRP CO LTD

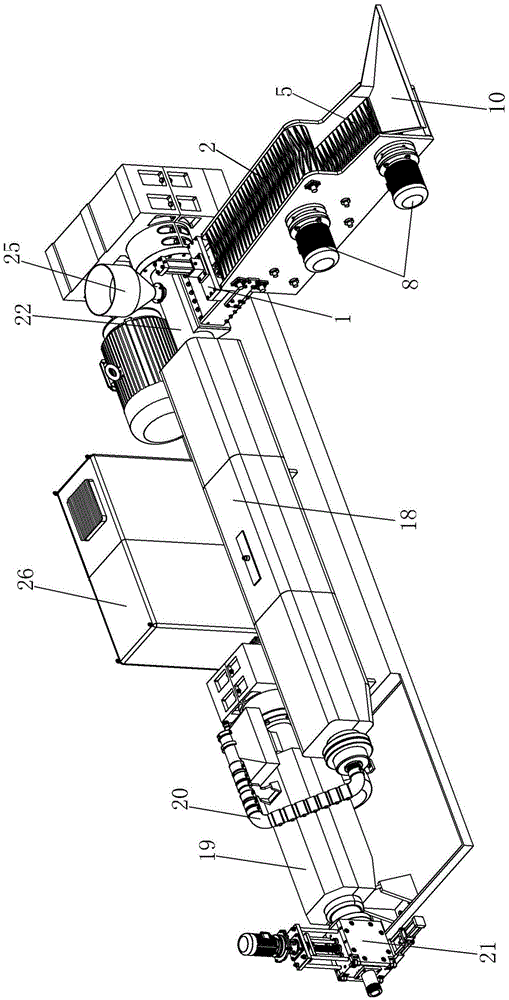

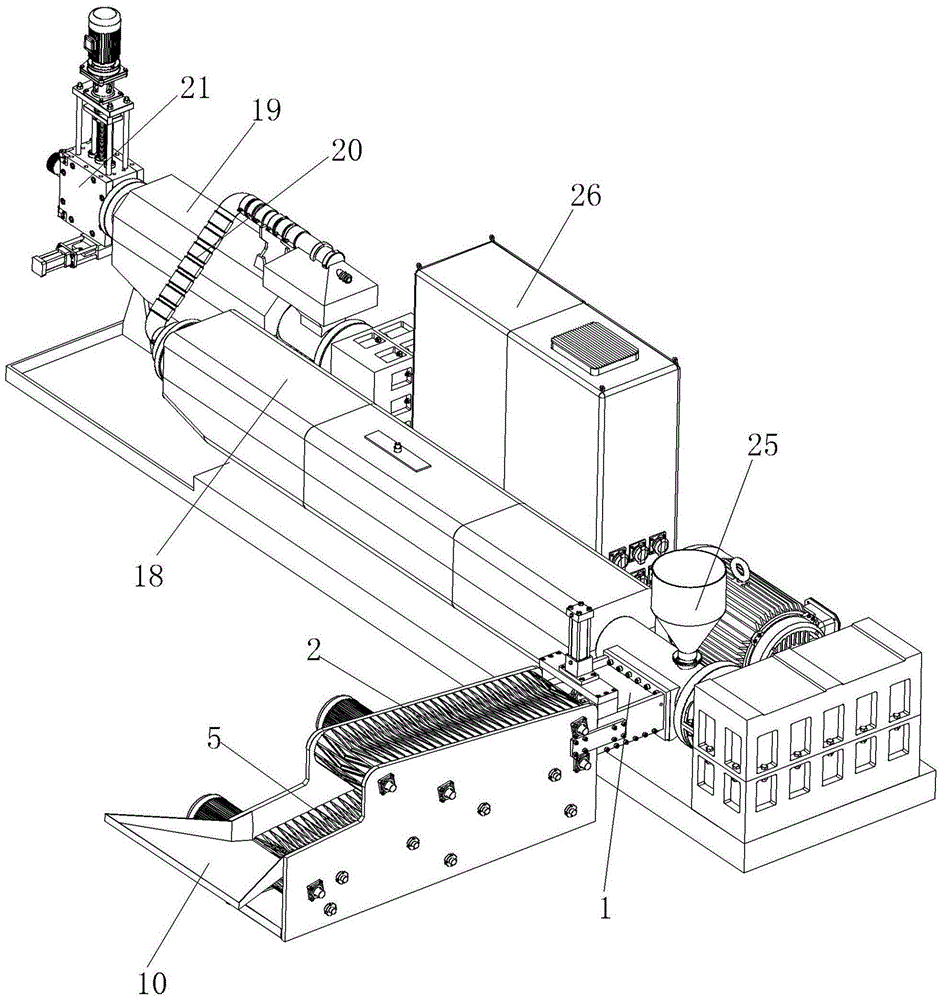

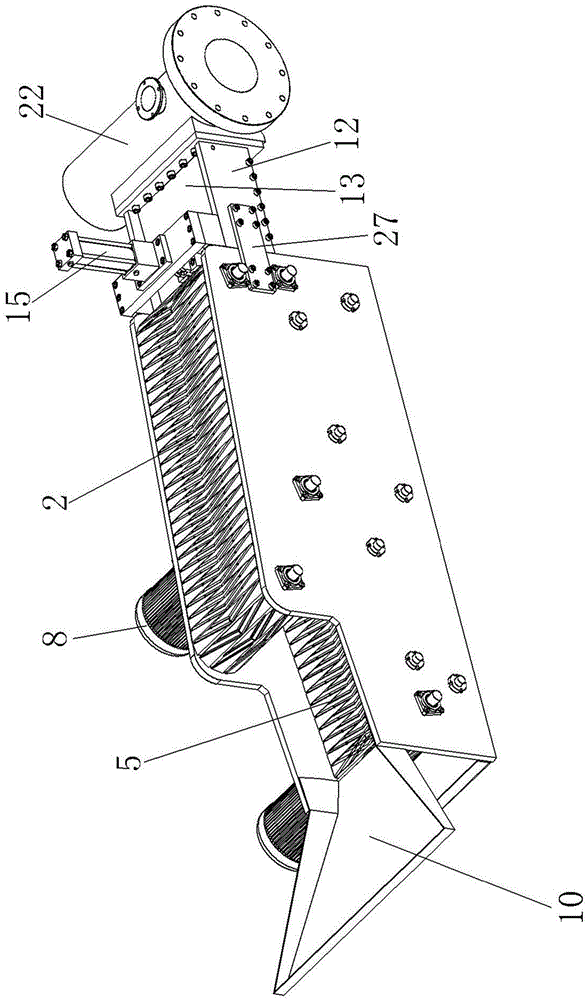

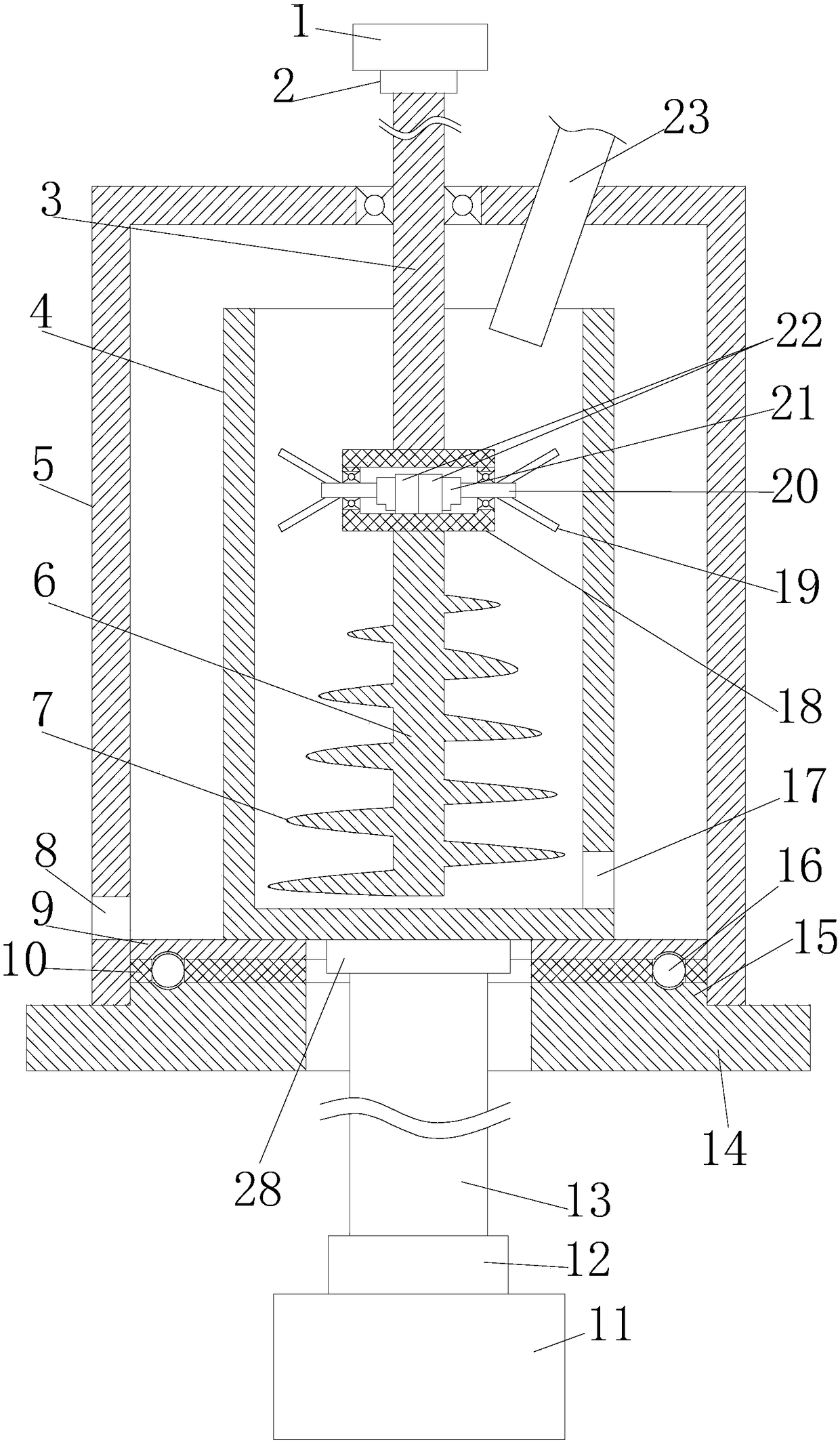

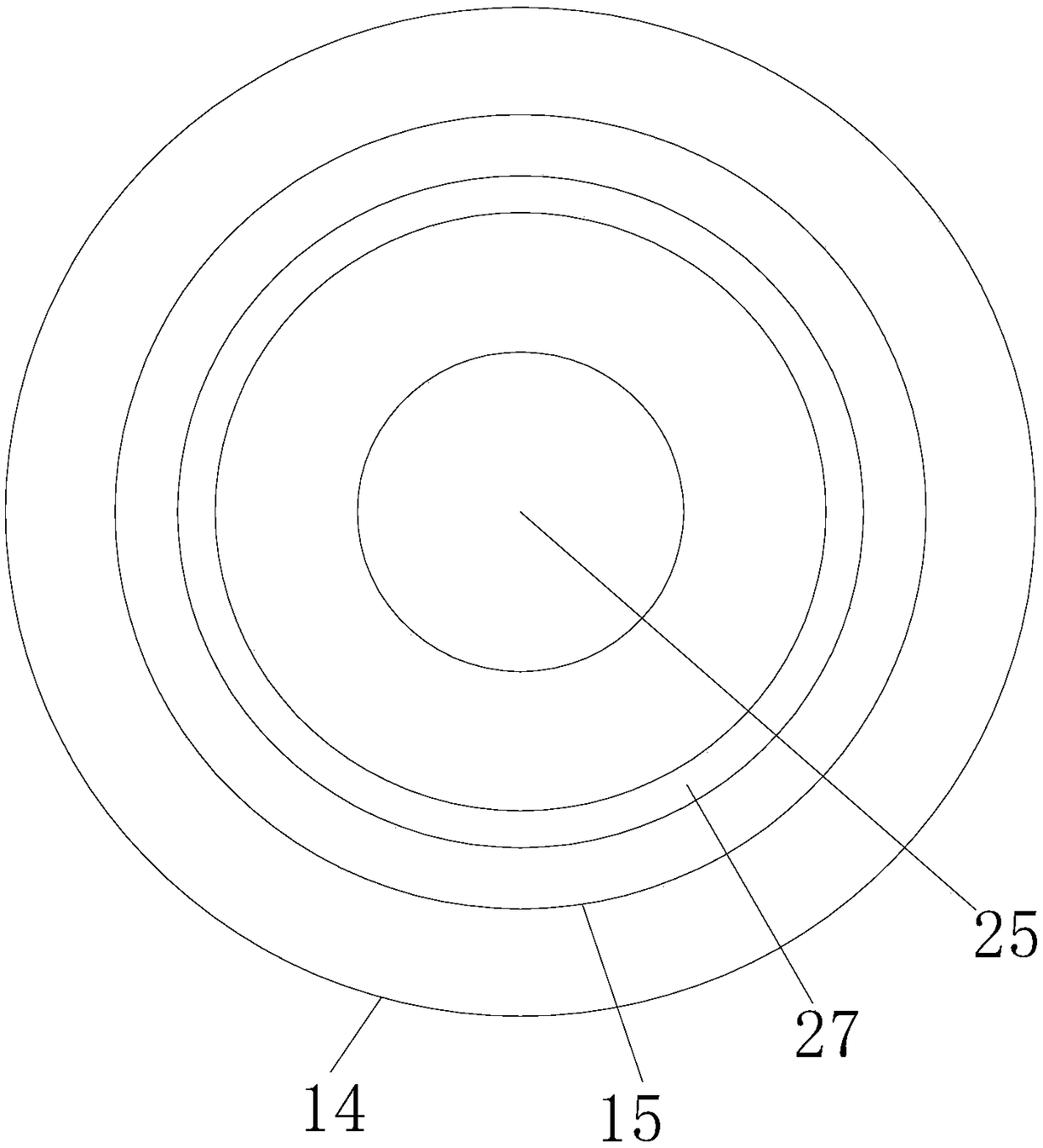

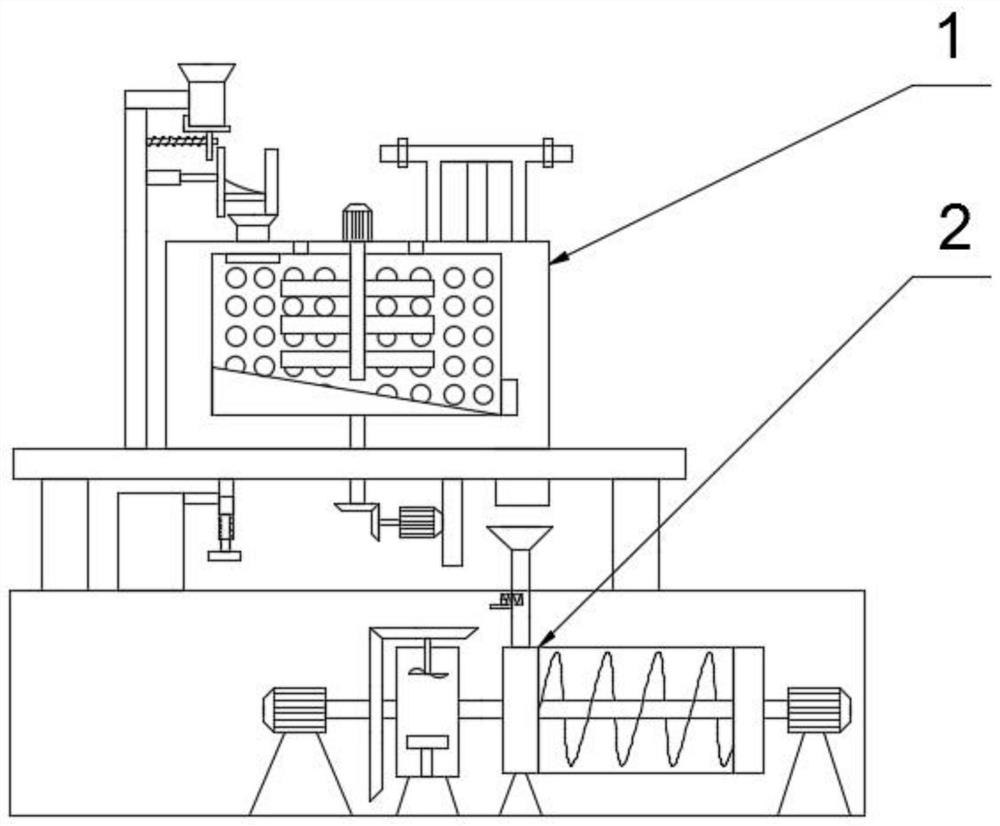

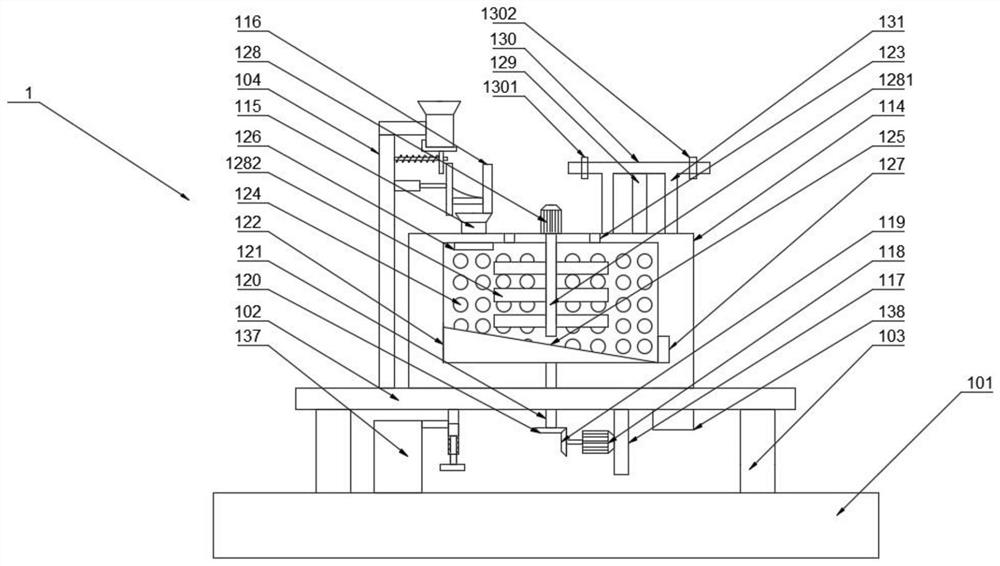

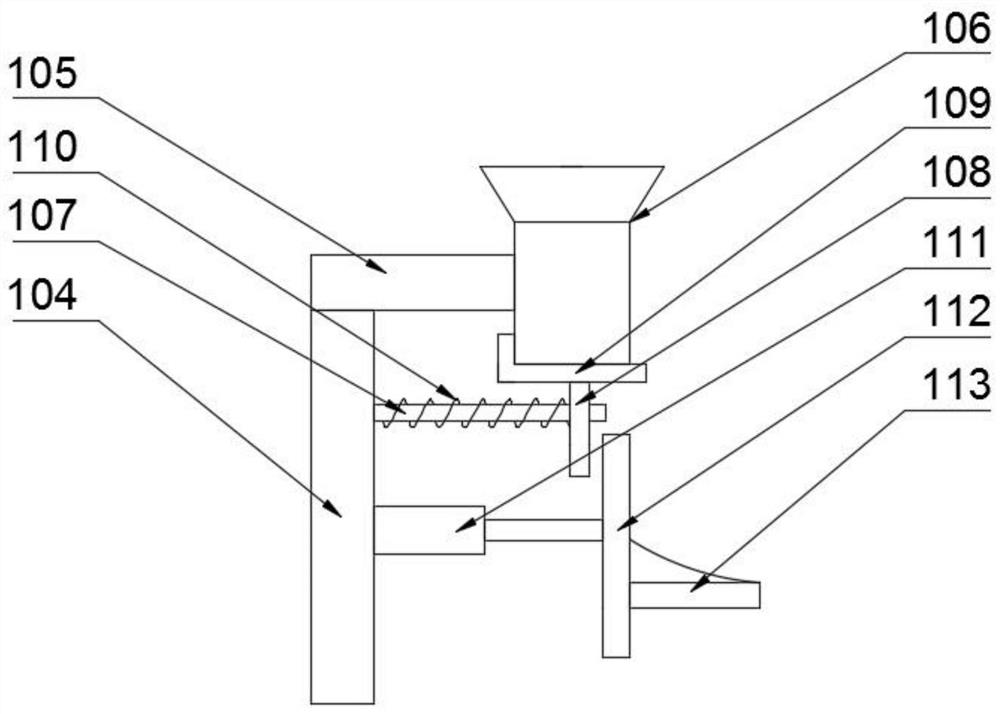

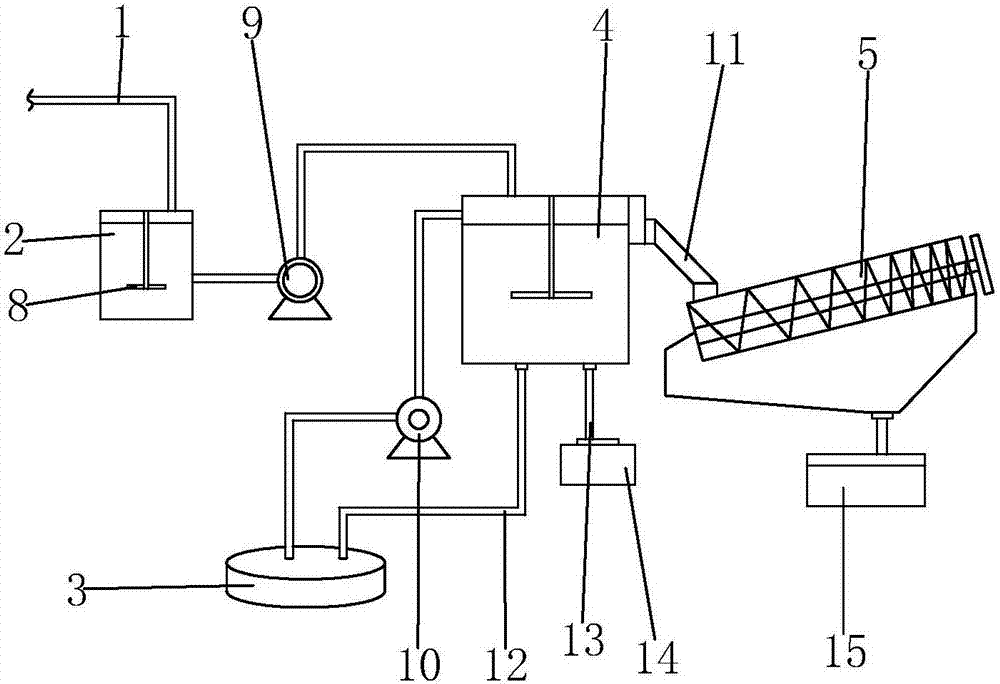

Automatic dehydration and forced feed high-efficiency pattern material pelletizing integrated machine

ActiveCN105619641AOutstanding and Beneficial Technical EffectsRealize automatic dehydrationCoatingsEngineeringDehydration

The invention belongs to the field of pelletizer equipment, in particular to an automatic dehydration and forced feed high-efficiency pattern material pelletizing integrated machine. The automatic dehydration and forced feed high-efficiency pattern material pelletizing integrated machine comprises a pelletizer set, and also comprises a crawler-type dehydration and feed device and a secondary extrusion and feed device; the crawler-type dehydration and feed device comprises two sets of extrusion conveyer belts and driving mechanisms a separately used for driving the two sets of extrusion conveyer belts to drive; the two sets of extrusion conveyer belts are arranged top and bottom oppositely; a top extrusion conveyer belt a comprises an extrusion face and a feed face; the extrusion face and a bottom extrusion conveyer belt b are oppositely arranged and form an extrusion passage; an angle formed between the feed face and the extrusion face is an obtuse angle; the discharge end of the extrusion conveyer belt b is connected with the feed end of the secondary extrusion and feed device; and the discharge end of the secondary extrusion and feed device is connected with the feed port of the pelletizer set. The automatic dehydration and forced feed high-efficiency pattern material pelletizing integrated machine disclosed by the invention has the advantages of being simple in structure, convenient to use, high in production efficiency and automation degree, reduced in amount of labor and fast in feed rate, and being capable of saving electric quantity and reducing occupied area.

Owner:ZHEJIANG LEENY TECH

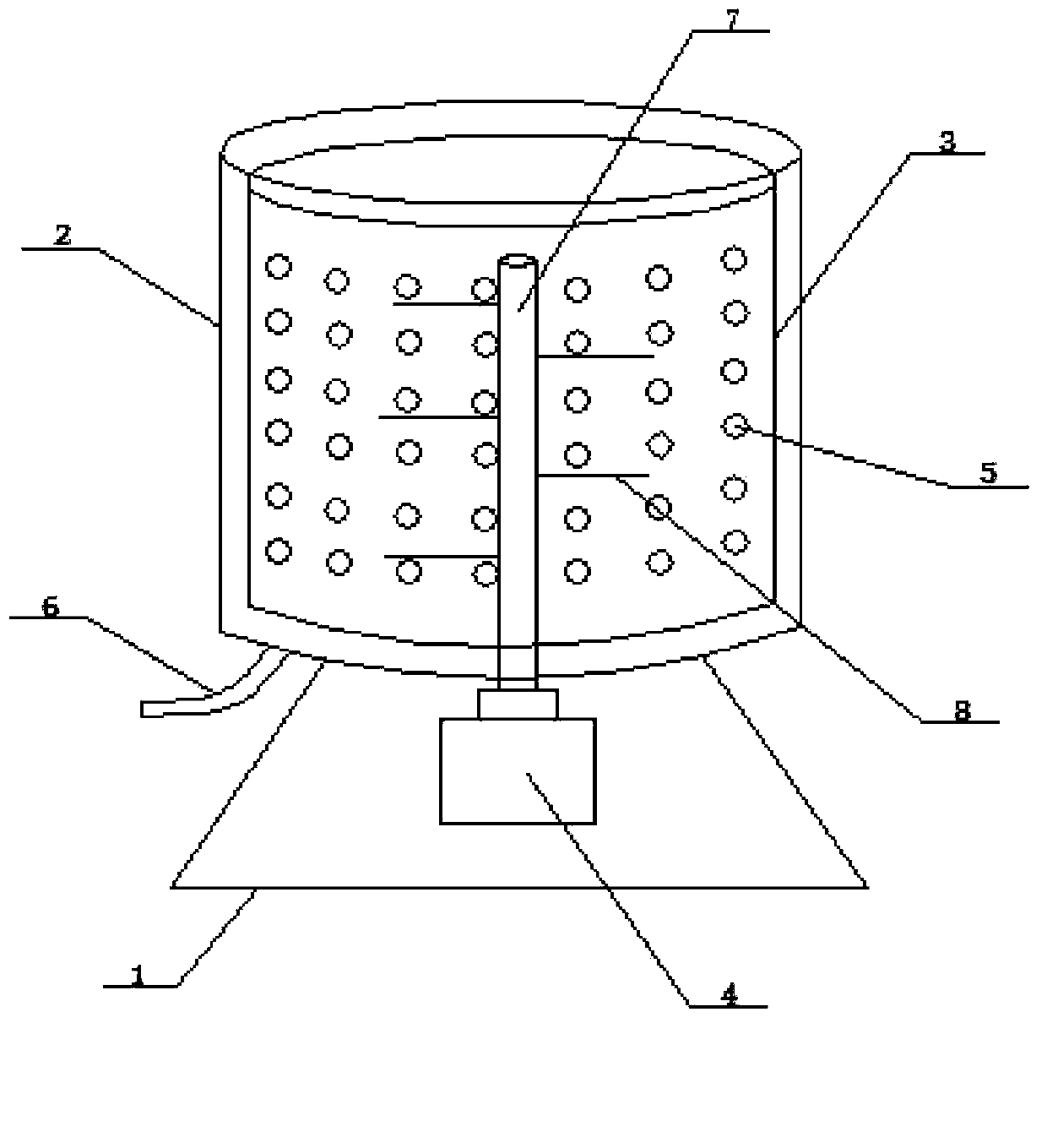

Agricultural quick dehydrator

InactiveCN103968655AFully dehydratedThoroughly dehydratedDrying machines with non-progressive movementsAgricultural engineeringAgricultural machinery

The invention discloses an agricultural quick dehydrator, and relates to the field of agricultural machinery. An outer barrel (2) is arranged on a pedestal (1); a dehydrating barrel (3) is arranged in the outer barrel (2); a motor (4) is arranged in the pedestal (1); a plurality of dehydrating holes (5) are uniformly formed in the dehydrating barrel (3); a water pipe (6) for discharging water is arranged at the bottom of the outer barrel (2); the agricultural quick dehydrator further comprises a stirring shaft (7) and stirring blades (8); one end of the stirring shaft (7) is connected with the motor (4) inside the pedestal (1), and the other end of the stirring shaft (7) is arranged in the dehydrating barrel (3); the stirring blades (8) are arranged on the stirring shaft (7). The agricultural quick dehydrator can overcome defects in the prior art, adopts the stirring blades to push twisted mulberry leaves aside, allows the mulberry leaves to be completely dehydrated, is quick in dehydrating speed, complete in dehydration, simple in structure, and easy to popularize and use, and can greatly improve working efficiency and quality.

Owner:KUNSHAN SHANGDAZHI MACHINERY

Baking-free ecological brick made of waste subway engineering mud and making method of baking-free ecological brick

ActiveCN110183202ASolve problems that cannot meet usage standardsCompliant with application standardsSolid waste managementBrickMixed materials

The embodiment of the invention provides a baking-free ecological brick made of waste subway engineering mud and a making method of the baking-free ecological brick and aims to solve the problem thatin the prior art a baking-free brick made of waste subway engineering mud cannot meet use standards because of a too high water content. The baking-free ecological brick comprises the following components in parts by weight: 60-80 parts of waste subway engineering mud, 7.5-20 parts of a dewatering agent, 12-25 parts of a monopotassium phosphate solution and 0.5-2.0 parts of borox. The making method comprises the following steps: putting a dewatering agent with overburnt magnesium oxide into the waste subway engineering mud, and carrying out uniform stirring so as to obtain a mixed material A;putting a monopotassium phosphate solution and borox into the mixed material A, and carrying out uniform mixing so as to obtain a mixed material B, wherein the water content of the mixed material B is22-30%; carrying out coextrusion on the mixed material B so as to obtain a primary brick block; and maintaining the primary brick block for days in an environment of which the temperature is 18-22 DEG C and the RH (relative humidity) is greater than or equal to 65%, so as to obtain the baking-free ecological brick.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Manual dewatering dryer

InactiveCN106637851ASimple structureFully dehydratedTextiles and paperSpin-dryersButt jointEngineering

The invention discloses a manual dewatering dryer. The dryer comprises an outer barrel of a hollow mounting part, a roller shaft is arranged on the hollow mounting part; the dryer further comprises a rotating barrel located in the outer barrel, a hollow butt joint part is arranged on the rotating barrel, the hollow butt joint part is inserted into the roller shaft and freely rotates in the roller shaft; the dryer also comprises a one-way ratchet device arranged in the hollow butt joint, the one-way ratchet device comprises a ratchet seat fixedly mounted on the rotating barrel, a spiral rod mounted in the ratchet seat, and a ratchet core sleeving on the spiral rod and fitted with the ratchet seat; the up-and-down reciprocal movements of the spiral rod drive the ratchet seat and the rotating barrel to rotate unilaterally; the dryer also comprises a guide device extending to the spiral rod, the spiral rod moves up and down reciprocally relative to the rotating barrel along the guide device driven by the guide device. The ratchet core is exerted a one-way rotating torque by the up-pulling and the down-pressing of the spiral rod by utilizing the frictional torque of a coarse pitch spiral rod and the one-way ratchet of the manual dewatering dryer, the ratchet seat and the rotating barrel are driven to rotate at a high speed, and the clothes and fabrics are thus fully dewatered.

Owner:卢报新

Centrifugal type sludge dehydrating device

InactiveCN108409101AWon't settlePrevent subsidenceSludge treatment by de-watering/drying/thickeningWater/sewage treatment apparatusDrive shaftMiniaturization

The invention aims to provide a centrifugal type sludge dehydrating device. The centrifugal type sludge dehydrating device comprises a housing, a base, a centrifugal barrel, a stirring mechanism, a first drive motor and a second drive motor, wherein the housing is of a tubular structure; the housing is reversely buckled on the base in a mode of enabling the bottom to face upwards; the centrifugalbarrel is coaxially arranged in the housing, and the centrifugal barrel can be fixedly arranged on the base in a rotatable mode; the stirring mechanism comprises an upper drive shaft, a mounting box,two third drive motors, two transverse stirring shafts and a longitudinal stirring shaft. The centrifugal type sludge dehydrating device can be used for sufficiently dehydrating sludge, so that the dehydrated sludge can reach specified water content standards, and therefore, follow-up treatment application is facilitated, environmental pollution is facilitated, miniaturization is facilitated and use is convenient.

Owner:CHONGQING JIAOTONG UNIVERSITY

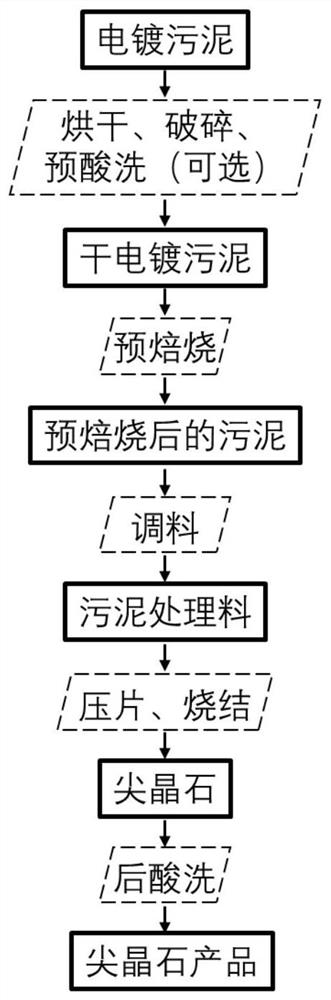

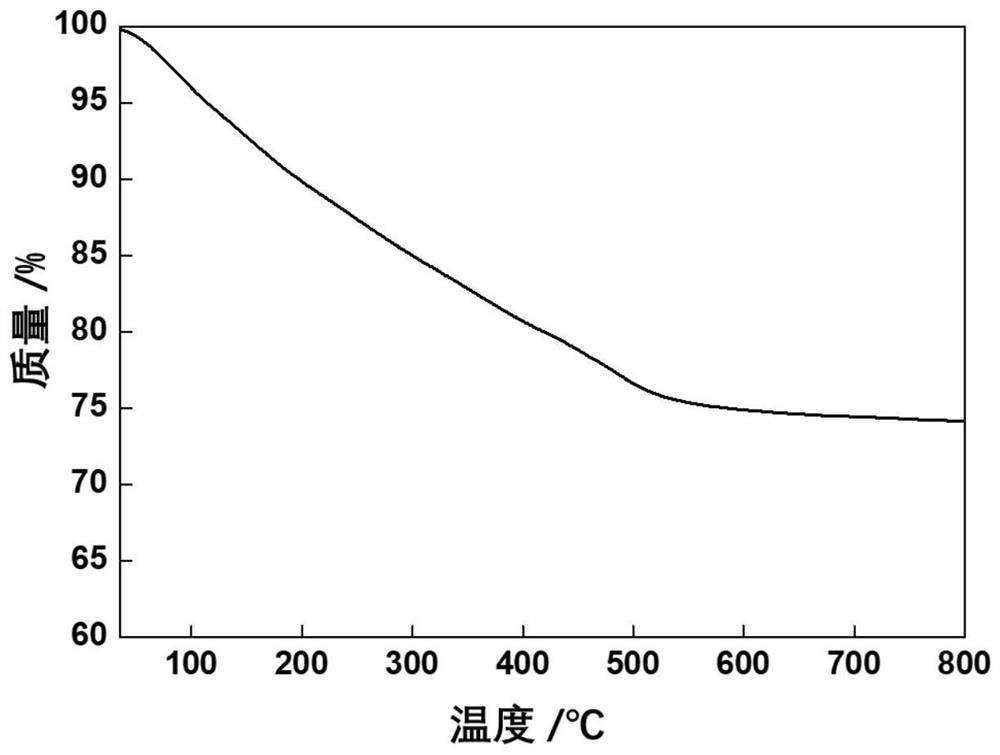

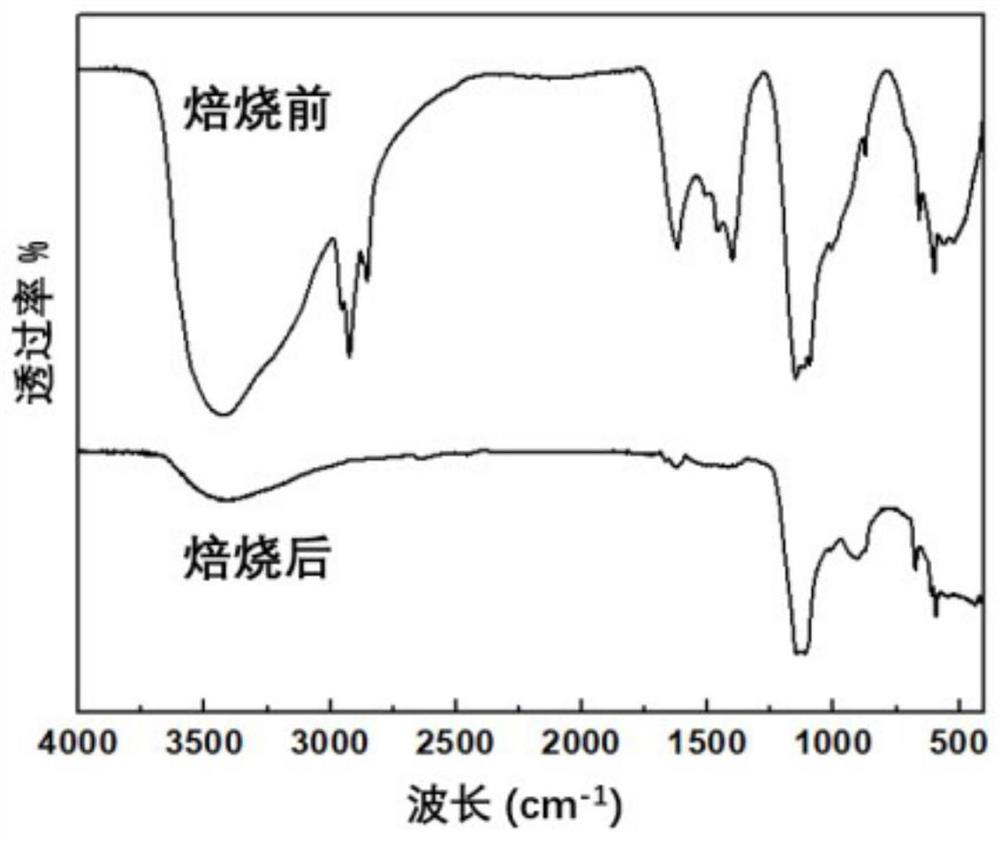

Method for preparing high-value spinel material by resourcefully treating electroplating sludge

ActiveCN112340757AHigh yieldAvoid secondary pollutionMangesium aluminatesInductances/transformers/magnets manufactureHeavy metalsOxide

The invention belongs to the field of resourceful treatment of solid waste containing heavy metals, and particularly relates to a method for preparing a high-value spinel material by resourcefully treating electroplating sludge. The method comprises the following steps: drying and crushing electroplating sludge, and then pre-roasting; supplementing positive bivalent or positive trivalent metal cation oxide to obtain a sludge treatment material; carrying out refined particle treatment and tabletting on the sludge treatment material, then carrying out high-temperature sintering, crushing and grinding, and washing with acid and water; and finally filtering and drying to obtain the spinel material. According to the method, the electroplating sludge containing rich heavy metals is converted into the spinel material, the application range of resource utilization of the electroplating sludge is expanded, and a new method for treating and disposing the electroplating sludge is provided.

Owner:SOUTH CHINA UNIV OF TECH

Polygonatum sibiricum processing manufacturing process

InactiveCN111789250ARealize automatic unloadingFeed amount controllableDrying gas arrangementsUnknown materialsElectric machineryPolygonatum sibiricum

The invention discloses a polygonatum sibiricum processing manufacturing process. The process comprises the following steps: weighing, baking, peeling, dehydrating, slicing, cooking, anti-mold treatment and vacuum packaging. Through the cooperation of a second horizontal rod, a slide block, a material blocking plate, a telescopic spring, an air cylinder, an extrusion plate, a first material guideplate and a second material guide plate, the purpose of automatic feeding and controllable feeding amount is realized; through the setting of a second motor, a second rotating shaft and rotating blades, the stirring of ginger-shaped polygonatum sibiricum in a rotating chamber can be realized while the rotating chamber is rotated, and the dehydrating and cleaning are more fully; and through the setting of a horizontal pipe, vertical pipes, a first valve, a second valve and water permeable holes, dehydrating apparatus not only can clean the ginger-shaped polygonatum sibiricum, but also can dehydrate the ginger-shaped polygonatum sibiricum, the diversity of the dehydrating apparatus is realized, and thereby the application range of the apparatus is improved.

Owner:金寨县丰乐园农业科技开发有限公司

Dehydration device of waste plastic

ActiveCN106945329AFully dehydratedImprove dehydration effectPlastic recyclingPressesEngineeringWater collection

The invention discloses a dehydration device of waste plastic. The dehydration device comprises a bottom plate, a left upright post and a right upright post which are mounted on the bottom plate, a top rod mounted between the tops of the left upright post and the right upright post, sleeves which are mounted on the top rod in a sleeving manner and can slide left and right relative to the top rod, a sliding support connected with the sleeves, and a dehydration box below the sliding support, wherein a first chamber is arranged on the dehydration box; a plurality of dehydration holes which communicate with the first chamber are formed in the bottom wall of the dehydration box; a supporting tube is arranged on the left upright post; a feed hopper is mounted on the supporting tube; a discharge opening of the feed hopper faces the first chamber; a supporting box is arranged on the bottom plate; sliding blocks are fixedly connected at the bottom of the dehydration box; sliding grooves for allowing the sliding blocks to slide left and right are formed in the supporting box; a second chamber is further arranged on the supporting box; a water collection box is mounted in the second chamber; and the water collection box is below the dehydration box. According to the dehydration device, waste plastic can be fully dehydrated, and the dehydration effect is remarkably improved.

Owner:安徽青藤再生资源有限公司

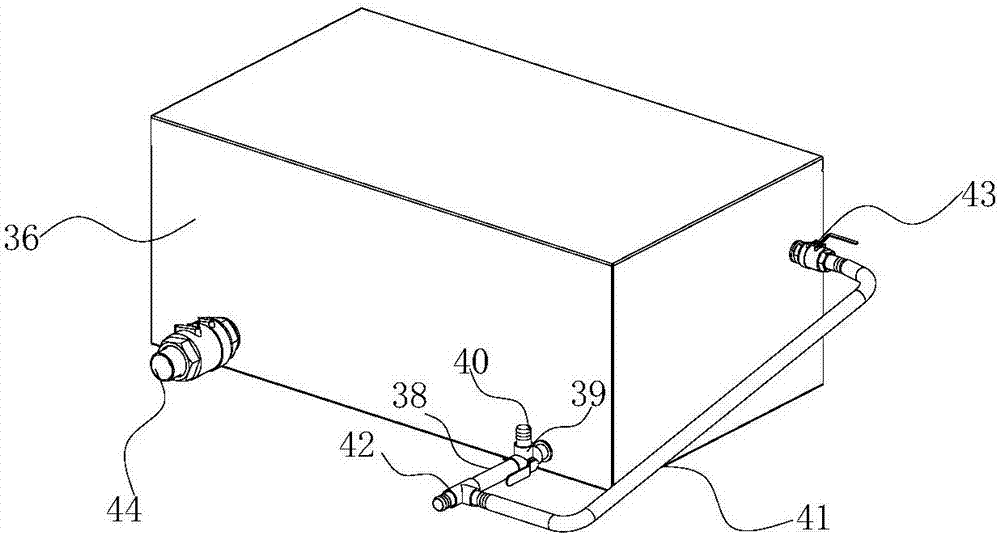

Concentrating and drying system and method for sludge treatment

InactiveCN107285603AAvoid pollutionEasy to handleSludge treatment by de-watering/drying/thickeningPulp and paper industryOrganic fertilizer

Owner:ZHEJIANG ZHENGHAN ENVIRONMENTAL PROTECTION TECH CO LTD

Vegetable noodles

InactiveCN108208571AImprove food tasteDoes not change nutritionFood freezingFruit and vegetables preservationAdditive ingredientNutrients substances

The invention discloses vegetable noodles and relates to the field of food. Especially, food nutrient substances in the vegetable noodles are reserved and the shelf life is prolonged by low-temperature drying. The vegetable noodles disclosed by the invention are characterized in that the noodles are prepared by the following steps: cleaning, pulping, drying, powdering, dough making, aging, noodlecutting and the like. According to the vegetable noodles disclosed by the invention, vegetables are subjected to low-temperature drying, a big amount of water is removed under the condition of not damaging the vegetable nutrients, the water removal effect is good, even the color of the vegetables can be maintained, and the shelf life is greatly prolonged; and meanwhile, a Pu'er tea component is added, so the noodles contain the tea fragrance, the nutrient substances of the Pu'er tea are mixed with the noodles, and the edible mouthfeel of the noodles is improved by adding the fragrances of thevegetables and the Pu'er tea to the noodles.

Owner:XUNDIAN MUGONGSHANG TEA IMPORT & EXPORT CO LTD

Drying machine for pesticide production

InactiveCN108716820AEasy maintenanceStable jobDrying solid materials without heatDrying machines with non-progressive movementsAgricultural engineeringRaw material

The invention discloses a drying machine for pesticide production. The drying machine for pesticide production comprises a base body, wherein a first support rod is fixedly connected to the left sideof the upper surface of the base body; a first bearing is fixedly embedded to the middle of the first support rod; a second support rod is fixedly connected to the right side of the upper surface of the base body; a second bearing is fixedly embedded to the middle of the second support rod; a support plate is fixedly connected to the right side surface of the second support rod; a motor is fixedlyconnected to the upper surface of the support plate; a drying machine body is fixedly connected to the middle of the upper surface of the base body; a door is fixedly hinged to the front surface of the drying machine body through a hinge; plate pulling ports are formed in the upper part and the lower part of the front surface of the door; and a first cavity is arranged in the drying machine body.According to the drying machine for pesticide production, the drying machine can be conveniently repaired and maintained, the working stability of the drying machine is realized, the drying machine is prevented from shaking during working, and pesticide raw materials can be dewatered.

Owner:WUXI JIABAO PESTICIDE & PHARMA

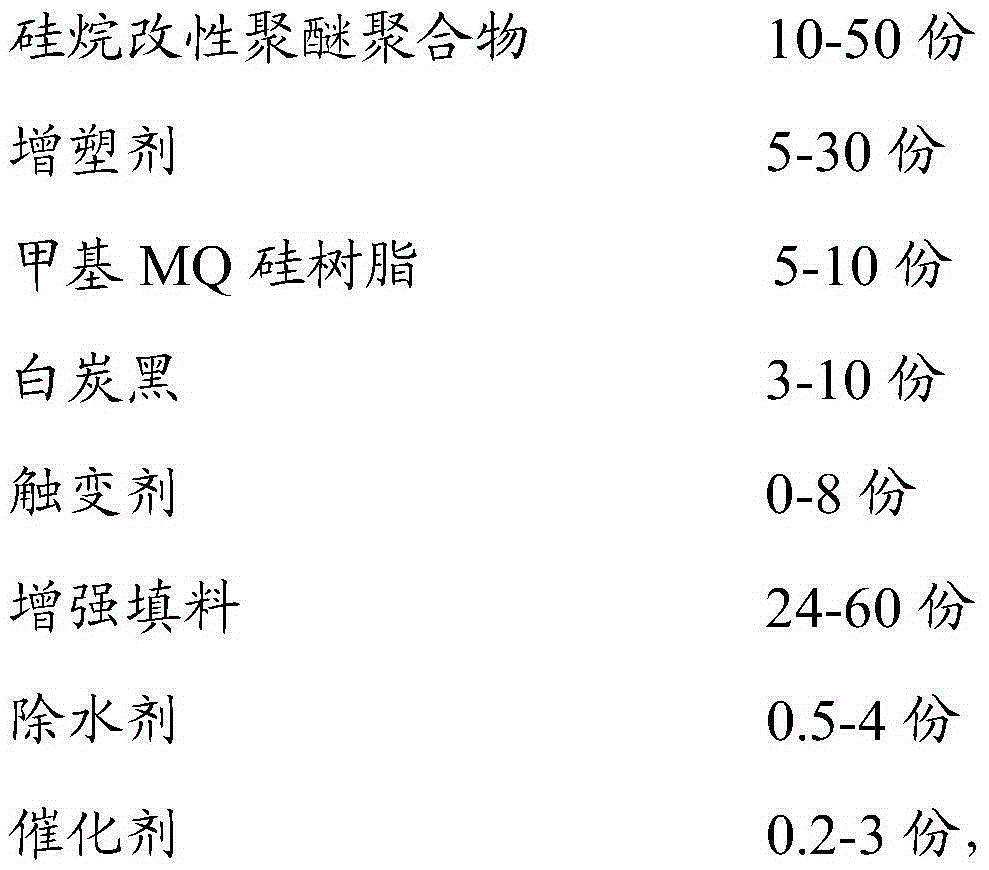

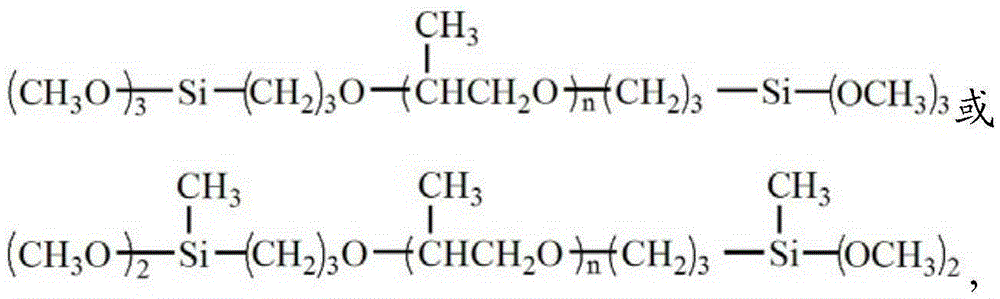

Environment-friendly nail-free glue and preparation method thereof

ActiveCN104449523BLow viscosityGuaranteed performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPlasticizerSolvent

The invention discloses environment-friendly nail-free glue and a preparation method of the environment-friendly nail-free glue. The environment-friendly nail-free glue comprises, by weight, 10-50 parts of silane-modified polyether polymers, 5-30 parts of plasticizer, 5-10 parts of methyl MQ silicon resin, 3-10 parts of white carbon black, 0-8 parts of thixotropic agents, 24-60 parts of reinforcing filler, 0.5-4 parts of dewatering agents and 0.2-3 parts of catalysts. The environment-friendly nail-free glue is good in comprehensive performance, high in construction efficiency, free of solvent, environmentally friendly and capable of replacing traditional iron nails to achieve a good bonding and fixing effect, and has very broad application prospect along with enhancement of the safety and environmental protection sense of people.

Owner:GUANGZHOU BAIYUN CHEM IND

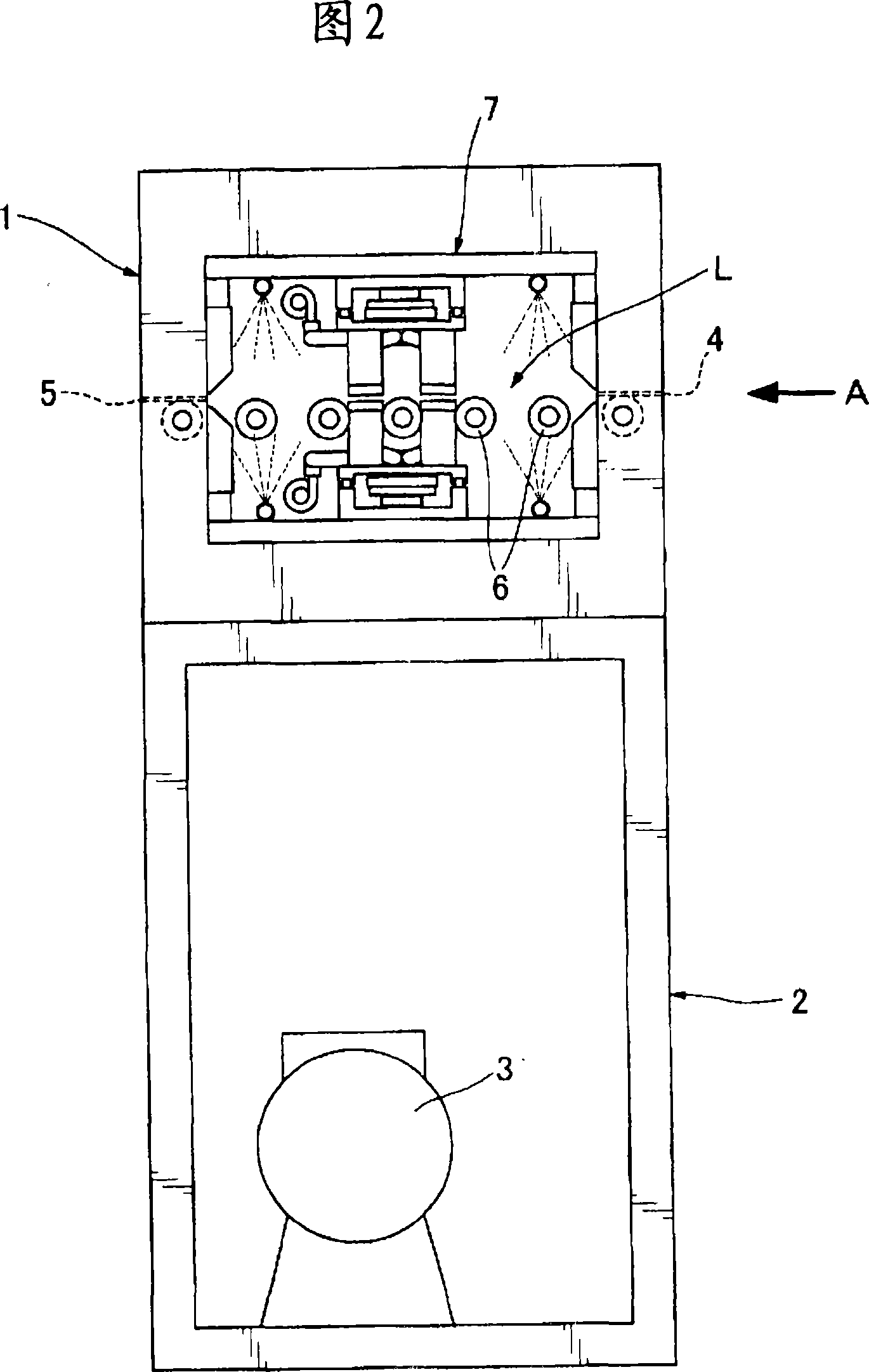

Drying apparatus

InactiveCN101163936AKeep dryFull drying effectDrying gas arrangementsSemiconductor/solid-state device manufacturingSpray nozzleLinear drive

A drying device has a linear drive device for linearly moving, in a drying box, a spray nozzle in a direction orthogonal to a conveyance direction of an object to be washed, and an ejection opening of the spray nozzle is formed as a slit stretching in the conveyance direction. A pair of nozzles is arranged at an inlet and outlet of the drying device, and each nozzle has a slit extended in the direction orthogonal to the conveyance direction, by the width of the object to be washed. Those surfaces of the nozzles that face each other are each inclined from an inner edge to an outer edge so that the distance between the inner edges of the nozzles is greater than the distance between the outer edges.

Owner:KYOWA KAKO KABUSHIKI KAISHA

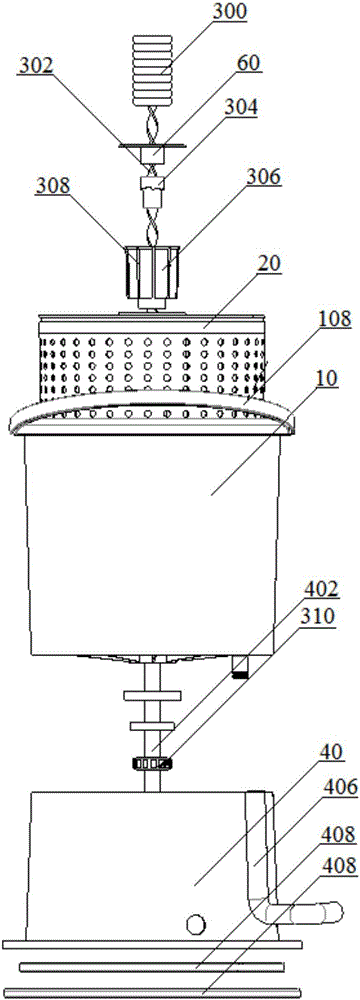

Centrifugal sludge dewatering device based on ultrasonic

InactiveCN108751655AWon't settleEfficient killingSludge treatment by de-watering/drying/thickeningSludge detoxificationDrive shaftSludge

The invention provides a centrifugal sludge dewatering device based on ultrasonic. The centrifugal sludge dewatering device comprises a shell, a base, a centrifugal cylinder, a stirring mechanism, anultrasonic generator, a first drive motor and a second drive motor, wherein the shell is of a cylindrical structure and the shell is buckled onto the base in an inverted manner that the bottom faces upwards; the centrifugal cylinder is coaxially arranged inside the shell and the centrifugal cylinder is rotatably fixedly arranged on the base; the second drive motor drives the centrifugal cylinder to rotate; the ultrasonic generator is arranged on the inner side of the bottom of the shell and the transmitting direction of the ultrasonic generator directly faces the cylinder opening of the centrifugal cylinder; and the stirring mechanism comprises an upper drive shaft, an installation box, two third drive motors, two transverse stirring shafts and a longitudinal stirring shaft. Sufficient dewatering can be carried out on sludge, a specified moisture content standard can be reached after sludge dewatering treatment, and further sterilization treatment is carried out by using ultrasonic inthe dewatering process, so that the device is beneficial to environmental protection.

Owner:CHONGQING JIAOTONG UNIVERSITY

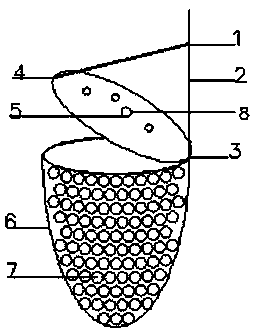

Easy-to-float explant disinfecting device for plant tissue culture and disinfecting method thereof

ActiveCN108935102APrevent outflowIntegrity guaranteedPlant tissue cultureHorticulture methodsDisinfectantEngineering

The invention relates to an easy-to-float explant disinfecting device for plant tissue culture and a disinfecting method thereof. The device comprises a screen cylinder and a sealing cover, wherein aplurality of screen holes is formed in the screen cylinder; one end of the screen cylinder is open; the sealing cover covers the opening of the screen cylinder; a connecting buckle is arranged on theopening side of the screen cylinder; the sealing cover is hinged on the connecting buckle; an adjustable handle is fixed on the connecting buckle and is perpendicular to the opening of the screen cylinder; a sliding groove is formed in the adjustable handle; an adjustable button is arranged in the sliding groove and slides up and down along the sliding groove; a connecting handle is also provided;one end of the connecting handle is fixedly connected with the adjustable button; the other end of the connecting handle is arranged at the upper part of the sealing cover; and the end, which is fixedly connected with the adjustable button, of the connecting handle is higher than the other end of the connecting handle. Through the device disclosed by the invention, explants are completely in contact with disinfectant and can be fully dehydrated after the disinfection is finished to avoid the problem of difficulty in dehydration of the micro-explants, so that the integrity of the explants is guaranteed and the disinfection efficiency of the explants is improved.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com