Patents

Literature

37results about How to "Feed amount controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

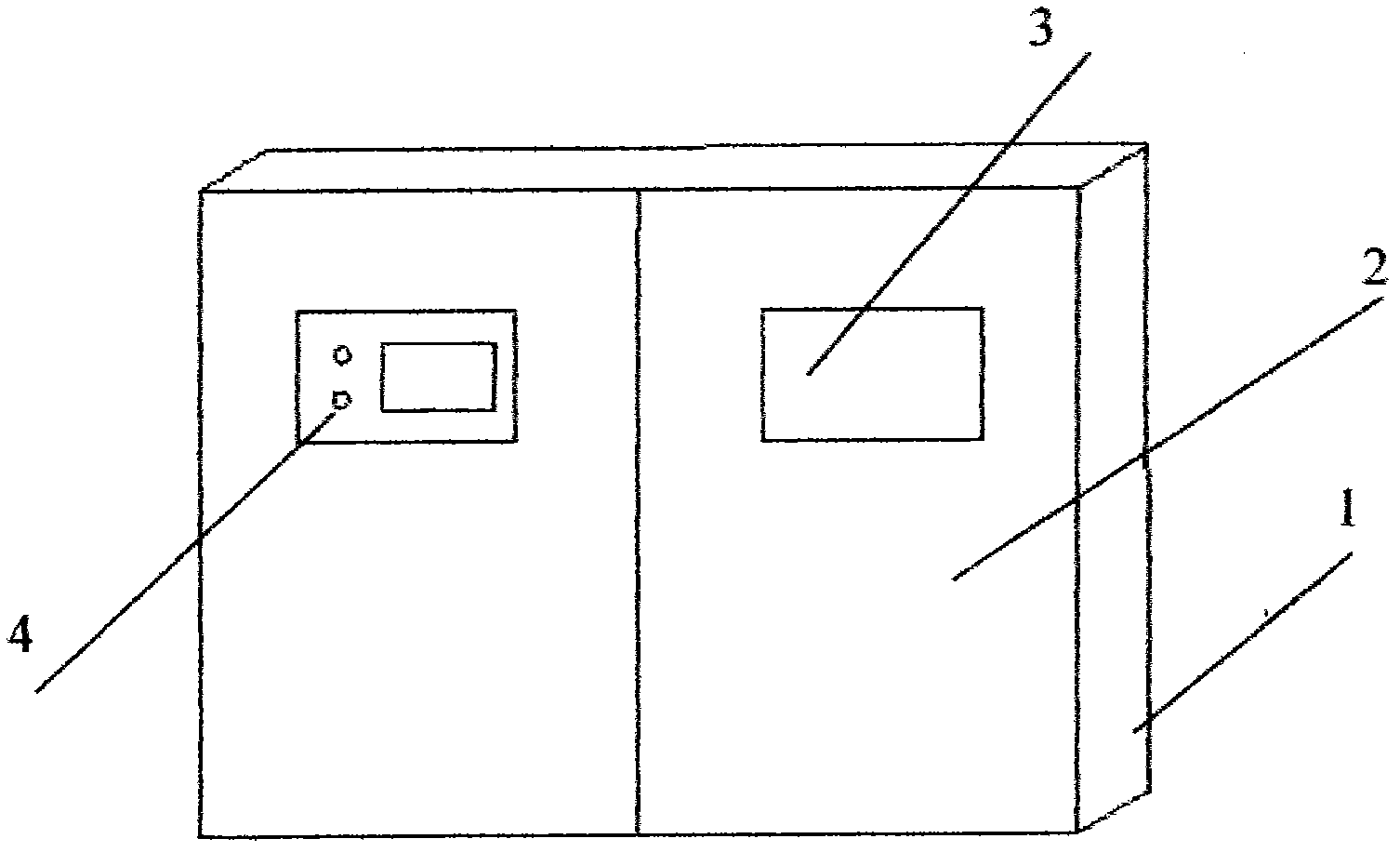

Animal incubator and production method thereof

InactiveCN102342251AConducive to epidemic preventionGood treatment effectAnimal feeding devicesAnimal housingTemperature controlSurveillance camera

The invention relates to an animal incubator and a production method thereof and belongs to equipment which has integrated functions of nursing young animals, protecting and raising. The animal incubator mainly comprises box body, wherein a nursing device, a temperature control device, an illumination lamp and a monitoring camera are arranged in the box body; and an ultraviolet sterilization lamp and an audio device which can be synchronously opened or closed in the process of nursing are also arranged at the top of the interior of a box body. The invention aims at providing the animal incubator which can be used for nursing multiple young animals with fixed amounts in fixed time points at the same time, is convenient for the immunizing and treating of the animals and also can create suitable temperature and humidity, so that the survival rate and reproductive rate of the young animals are improved and the problem of the batch breeding is solved.

Owner:泸西县沐塘果牧种养殖有限公司

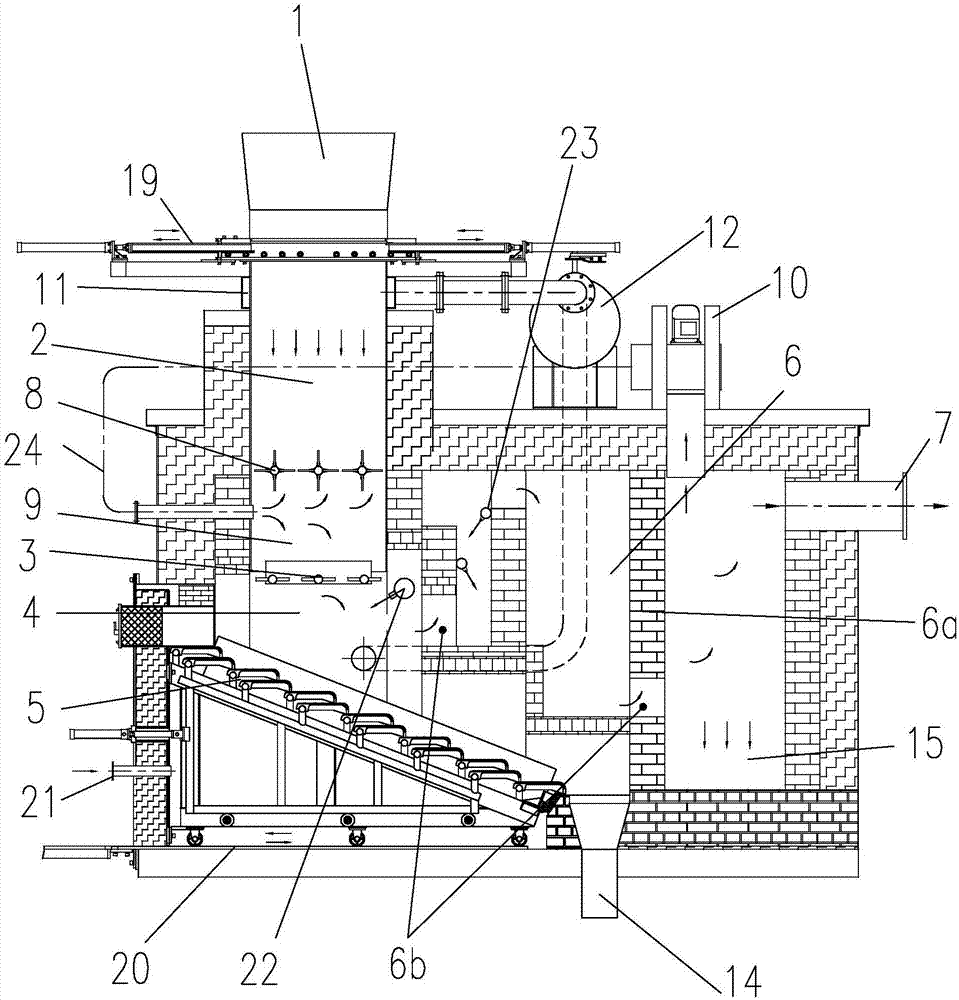

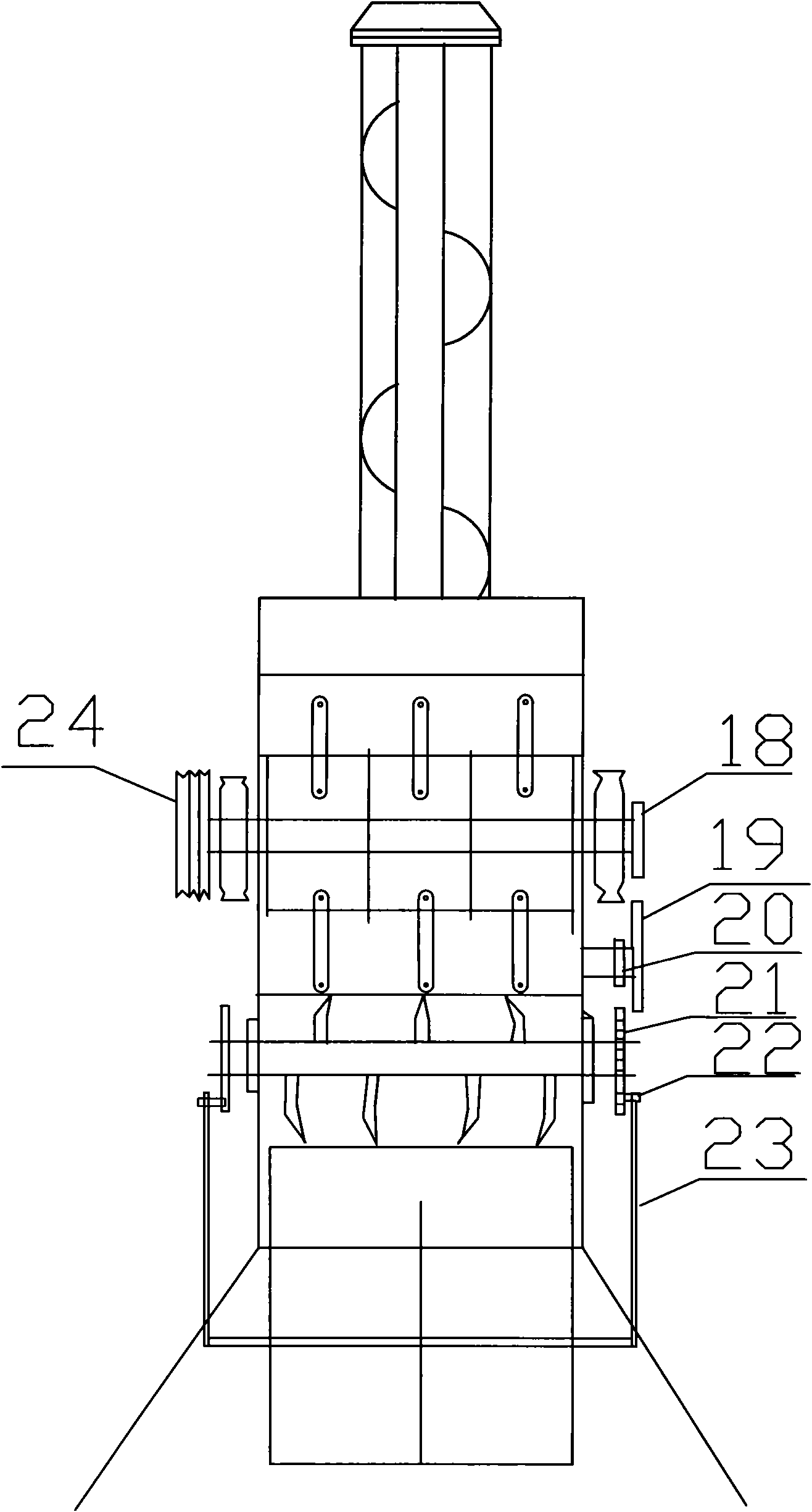

Partition cavity type small-sized rubbish pyrolysis and gasification incinerator

PendingCN107120658ASimple structureReduce construction costsIncinerator apparatusCombustion chamberThermodynamics

The invention discloses a partition cavity type small-sized rubbish pyrolysis and gasification incinerator comprising a hopper, a gate, a drying cavity, an upper fire grate, a combustion hearth cavity, a lower fire grate and a secondary combustion chamber. High-temperature smoke in the secondary combustion chamber is guided into a pyrolysis gasification cavity. A part of high-temperature smoke flows upward into the drying cavity to dry rubbish, generated steam is guided into a condensation liquefying tank to be liquefied through a steam suction cavity, odor flows back into the combustion hearth cavity for high-temperature calcinations treatment, and smoke and the odor are prevented from escaping. The other part of high-temperature smoke flows downwards and is combined with heat generated by the combustion hearth cavity to form convection and radiation, rubbish is made to conduct pyrolysis and gasification at the same time, gasified gas flows out downwards from the upper fire grate to enter the combustion hearth cavity to be combusted, rubbish carbon overturned downwards by the upper fire grate is combusted on the lower fire grate, an opposite firing flame is formed between the upper fire grate and the lower fire grate, the gasified gas and pyrolyzed rubbish carbon form complementary combustion in the combustion hearth cavity, a durable high temperature keeping area enables dioxin type harmful matter to be decomposed, and heat energy generated by combustion is fully recycled.

Owner:重庆航天工业有限公司

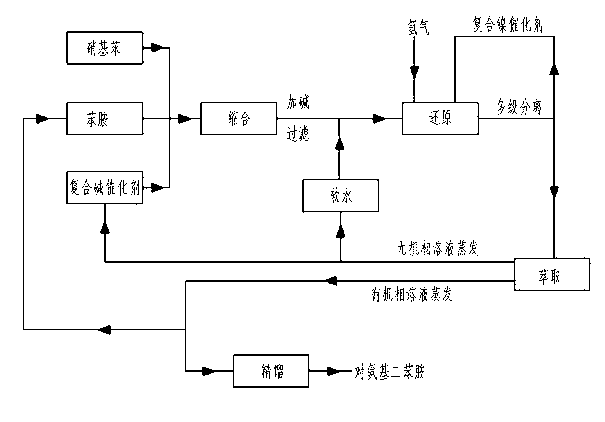

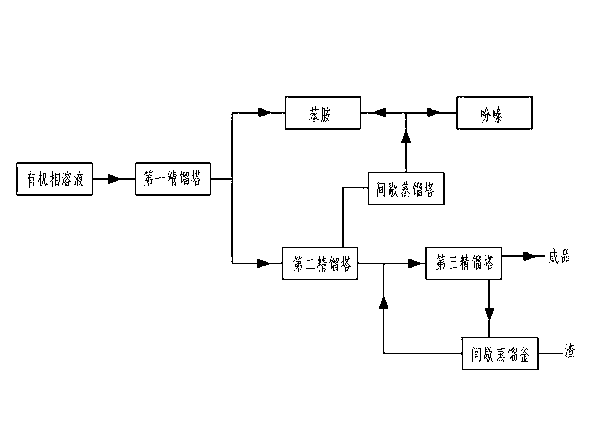

Preparation method for p-aminodiphenylamine

InactiveCN102796011AImprove continuityReduce operating unitAmino compound purification/separationOrganic compound preparationNickel catalystHydrogen

The invention relates to a preparation method for p-aminodiphenylamine, and belongs to the technical field of industrial preparation for p-aminodiphenylamine. The technical problem to-be-solved is to provide a preparation method for p-aminodiphenylamine with a condensation reaction catalyst capable of being activated and reused and a reduction reaction solvent having no danger and being easily separated. The technical solution adopted includes: a first step of feeding nitrobenzene, aniline and a complex alkali catalyst into a reactor for a condensation reaction to generate a condensation liquid; a second step of adding alkali to form salt to get a qualified condensation liquid; a third step of adding soft water and composite nickel catalyst slurry, and feeding hydrogen to perform a reduction reaction to get a reduction liquid; a fourth step of extracting and distilling the reduction liquid to get a rectification raw material; and a fifth step of performing a multi-stage rectification for the rectification raw material to get the finished p-aminodiphenylamine. The method can be widely applied to the field of p-aminodiphenylamine preparation.

Owner:山西翔宇化工有限公司

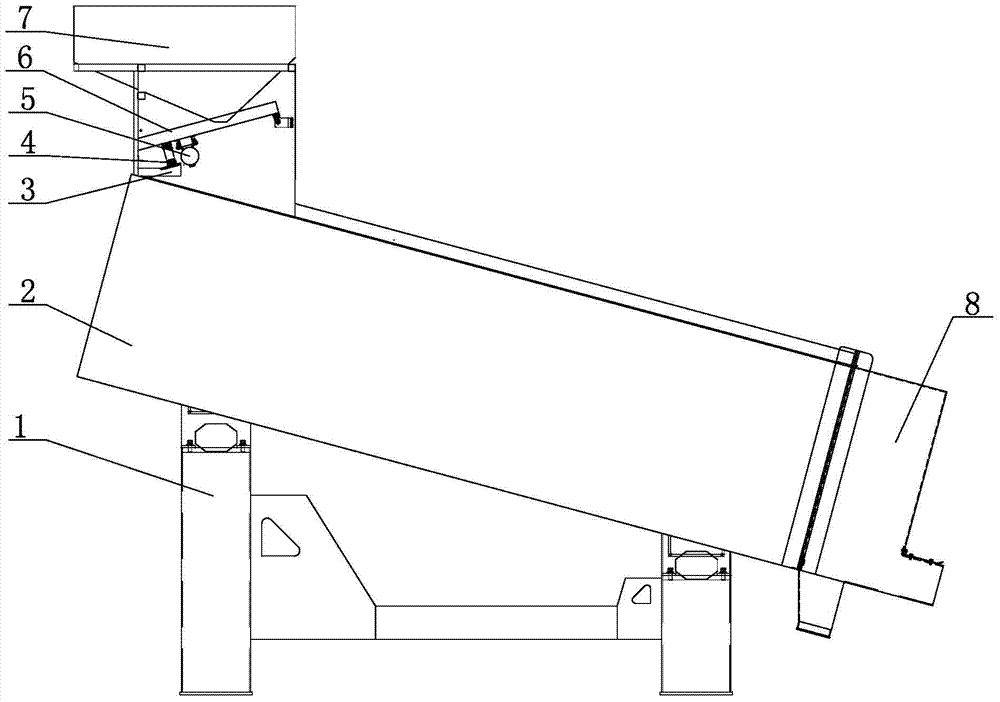

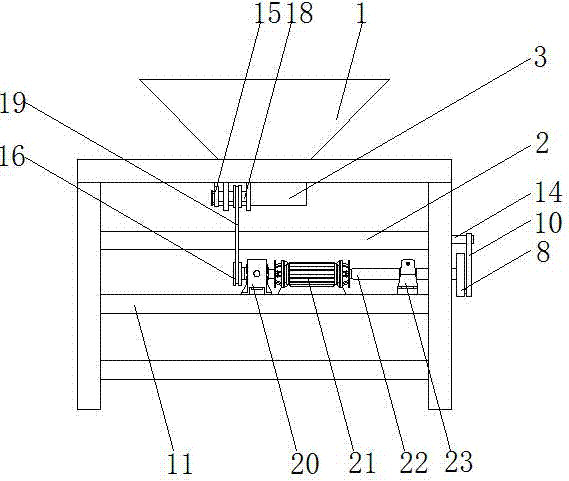

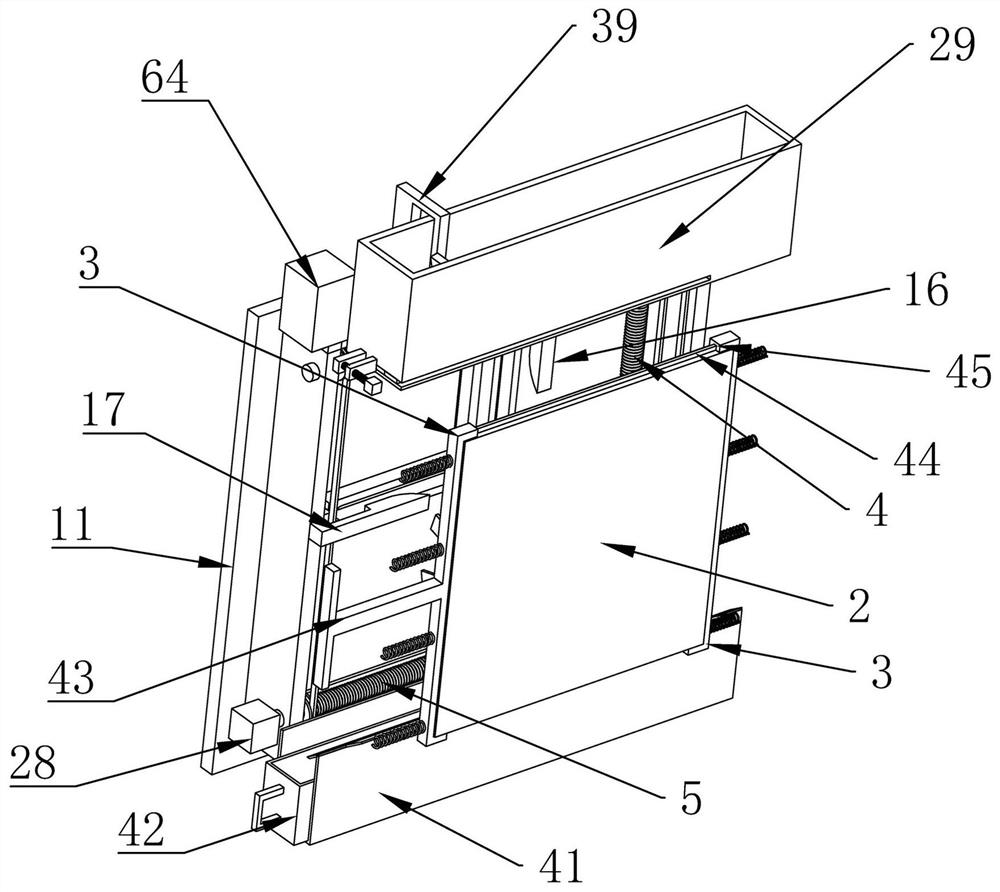

Automatic feeding device of grain cleaning sieve

The invention relates to an automatic feeding device of a grain cleaning device, and belongs to the field of grain cleaning equipment. The automatic feeding device of the grain cleaning device comprises a rack, a sieve body, a feeding box and a discharging box and is characterized in that a downward-inclining vibration plate is arranged below an outlet of the feeding box, and the vibration motor is arranged at the bottom of the vibration plate; the top end of the vibration plate is hinged to the inner wall of the rack, and the lower end of the vibration plate is a discharging end; and a vibration spring is connected to the bottom of the discharging end, and is mounted on the rack through a support. The automatic feeding device is simple and reasonable in structure, and grains fall in the vibration below the feeding box from the feeding box; through the vibration plate, the defined amount of materials can be evenly fed in the sieve body to be cleaned and sieved, and the vibration amplitude and the vibration frequency of the vibration plate can be controlled by adjusting the vibration motor, so that the needed grain feeding effect is achieved; and material falling is even, the material falling speed and the feeding amount are controllable, and the automation level is high.

Owner:SHANDONG YIKAI STORAGE ENG

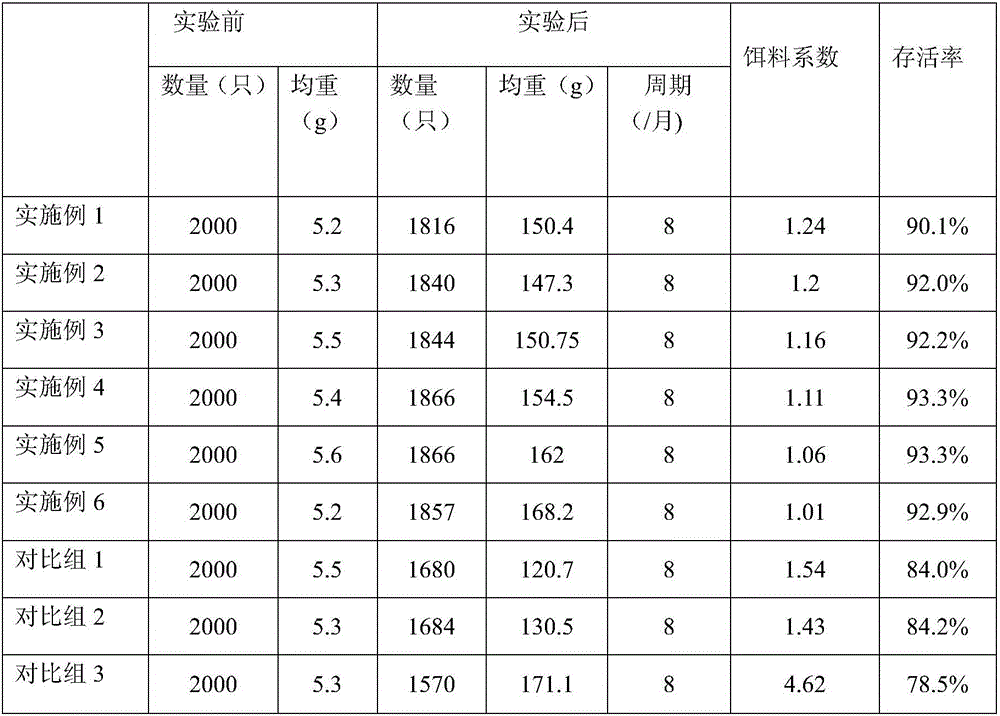

High-efficient environmentally-friendly feed for quasipaa spinosa and preparation method of high-efficient environmentally-friendly feed

InactiveCN106036200AReduce feed factorImprove the survival rate of breedingFood processingClimate change adaptationAnimal scienceBetaine

The invention discloses a high-efficient environmentally-friendly feed for quasipaa spinosa. The high-efficient environmentally-friendly feed is made from the following raw materials and components in percentage by mass: 20-25% of fish meal, 2-10% of chicken meat powder, 1-6% of porcine blood corpuscle protein powder, 1-5% of dried earthworm powder, 2-5% of dried fly larva powder, 10-30% of soybean meal, 18-28% of flour, 1-3% of soybean lecithin, 2-6% of fish oil, 0.6-0.8% of composite vitamins, 1-2% of composite mineral substances, 1-3% of calcium dihydrogen phosphate, 0.1-0.4% of choline chloride, 0.01-0.04% of betaine, 0.01-0.05% of L-carnitine, 0.01-0.04% of bile acid and 0.01-0.02% of phytase. The invention further discloses a preparation method of the feed. According to the feed for the quasipaa spinosa disclosed by the invention, the fermented soybean meal and the phytase are added, so that the coefficient of the feed is reduced; the dosage of the dried earthworm powder, the dosage the dried fly larva powder and the dosage of the betaine are adopted, so that the feed has excellent food-calling effects on the quasipaa spinosa, after being domesticated and raised for a long term, the quasipaa spinosa can be completely adapted to feeding of artificial compound feeds, the water resistance is good, breeding water bodies are not polluted, and the survival rate is increased.

Owner:珠海海为饲料有限公司

Self-blanking vibrating screen

The invention discloses a self-blanking vibrating screen which comprises a screen box, a first eccentric wheel, a lifting rod, a double-shaft motor and a baffle, wherein the left end and the right end of the screen box are respectively mounted on a mounting rack by a supporting rod and the lifting rod; the left end of a transmission shaft is connected with a motor shaft on the double-shaft motor; the double-shaft motor is fixed in the middle of the left end of the mounting rack by a motor seat; a shaft seat is fixed in the middle of the bottom of the left end of an upper supporting plate; a sliding groove is formed in the left side face of a discharge disc; a fixed shaft is arranged on the sliding groove; a discharge hopper is fixed on the upper supporting plate; supporting tables are fixed below upright columns; a collecting disc is placed on the supporting tables; a fastening bolt is mounted on the lifting rod. The vibrating screen is stable in operation, convenient to maintain, good in screening effect, convenient to use, and self-blanking, and requires no manual operation.

Owner:XINXIANG ZHEN YING MACHINERY EQUIP CO LTD

Large-water surface water tank type intensive culturing method

InactiveCN105393966AIncrease productionGood yieldClimate change adaptationPisciculture and aquariaDiseaseEcological environment

The invention discloses a large-water surface water tank type intensive culturing method. Culture is conducted in independent culturing environment formed water tanks or water channels. Fishes are cultured in a large lake with net cages sleeved in the water tank; characteristics of excellent water quality of a large water surface and inadequate utilization of resource are fully utilized to output of the large water surface can be increased by 15 to 50 kg / mu and 30% of efficiency can be improved; by the use of the culturing method, diseases can be prevented, fishes can be easily caught, bait casting amount can be controlled, fodder use can be reduced, stable water temperature and quality can be achieved and influence to the ecological environment can be reduced; bait utilization rate can be effectively improved; effects on water quality of the whole large lake surface can be reduced; pollution of water quality of each independent water tank or water channel can be avoided; and besides, survival competition between the cultured fishes and local fish species can be avoided and damage to fish genetic resource can be prevented.

Owner:HUNAN UNIV OF ARTS & SCI

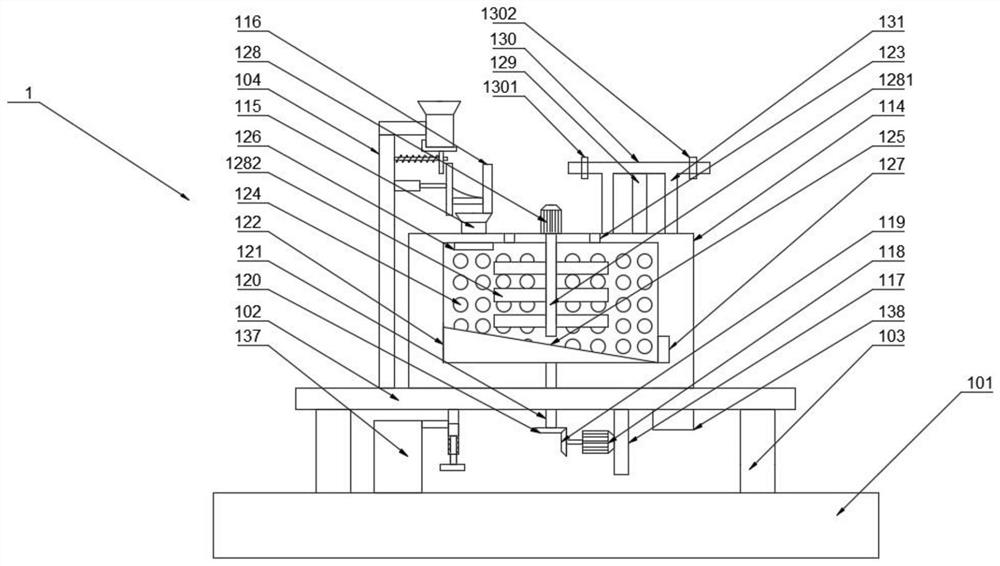

Polygonatum sibiricum processing manufacturing process

InactiveCN111789250ARealize automatic unloadingFeed amount controllableDrying gas arrangementsUnknown materialsElectric machineryPolygonatum sibiricum

The invention discloses a polygonatum sibiricum processing manufacturing process. The process comprises the following steps: weighing, baking, peeling, dehydrating, slicing, cooking, anti-mold treatment and vacuum packaging. Through the cooperation of a second horizontal rod, a slide block, a material blocking plate, a telescopic spring, an air cylinder, an extrusion plate, a first material guideplate and a second material guide plate, the purpose of automatic feeding and controllable feeding amount is realized; through the setting of a second motor, a second rotating shaft and rotating blades, the stirring of ginger-shaped polygonatum sibiricum in a rotating chamber can be realized while the rotating chamber is rotated, and the dehydrating and cleaning are more fully; and through the setting of a horizontal pipe, vertical pipes, a first valve, a second valve and water permeable holes, dehydrating apparatus not only can clean the ginger-shaped polygonatum sibiricum, but also can dehydrate the ginger-shaped polygonatum sibiricum, the diversity of the dehydrating apparatus is realized, and thereby the application range of the apparatus is improved.

Owner:金寨县丰乐园农业科技开发有限公司

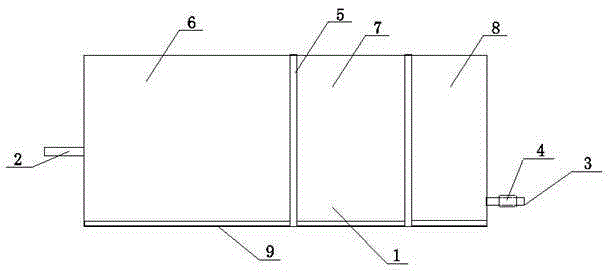

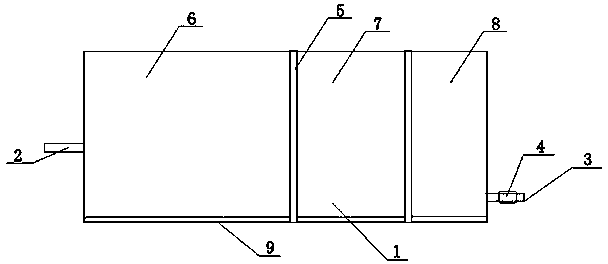

Dryer for composite fertilizer production

InactiveCN108645189AFeed amount controllableDry evenlyManure dryingDrying solid materialsBiochemical engineeringChassis

The invention discloses a dryer for composite fertilizer production. The dryer for composite fertilizer production comprises a treatment bin; a feed port is formed in one side of the treatment bin; astirring rod, movably connected, is arranged in the feed port; multiple arc scrapers are arranged on the outer surface of the stirring rod; a chassis is arranged on the other side of the treatment bin; multiple drying fans are arranged on the inner side wall of the chassis; one side of the inner wall of the treatment bin is hinged with a heating plate; an extension rod is horizontally arranged onthe inner side wall of the treatment bin under the heating plate; a first bracket is arranged at the bottom of the heating plate; a rotating rod, movably connected, is arranged in the first bracket; one end of the extension rod is fixedly connected with the rotating rod; an unloading hole vertically penetrates through the bottom of the treatment bin; a water tank is arranged at the top of the treatment bin; and the water tank is provided with a water transmission pipe at the top of the inner wall of the treatment bin. The dryer for composite fertilizer production is uniform in drying, improvesthe working efficiency, is easy to control the unloading quantity, prevents blockage, and is convenient to clean.

Owner:胡小丽

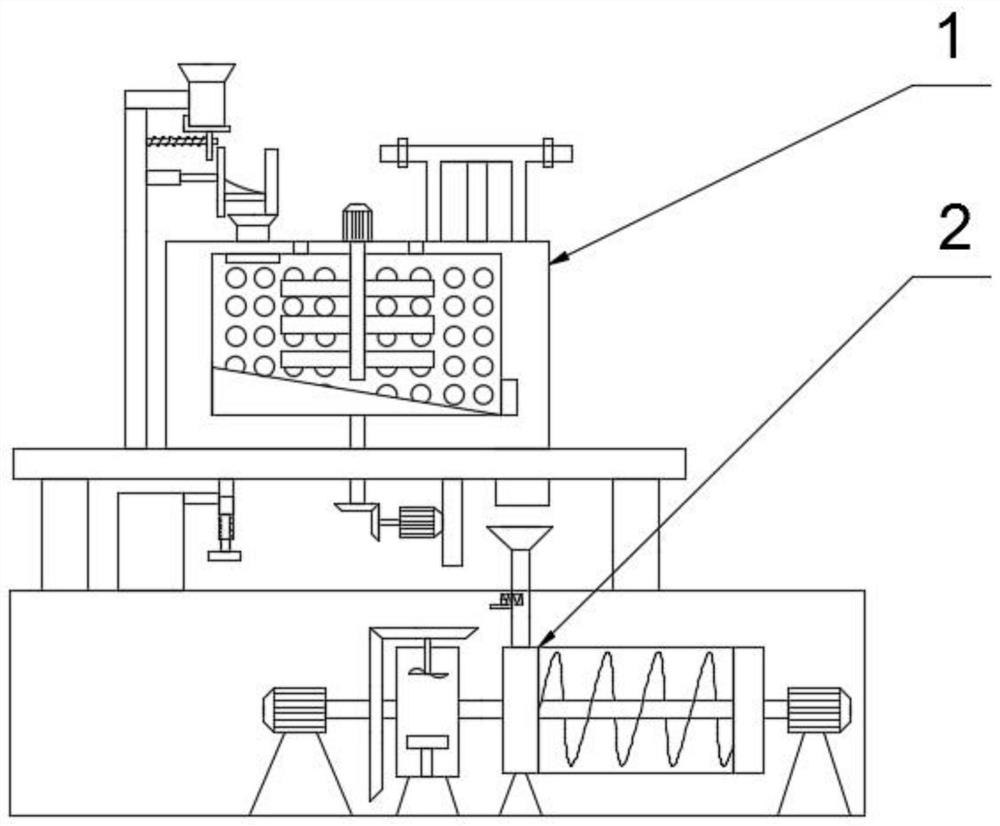

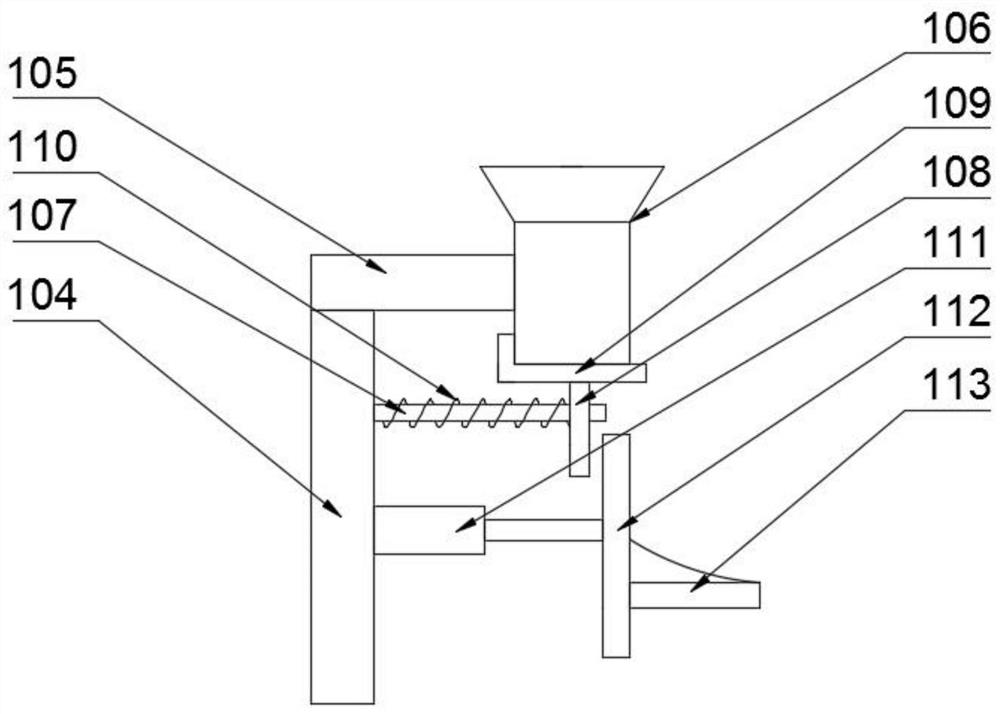

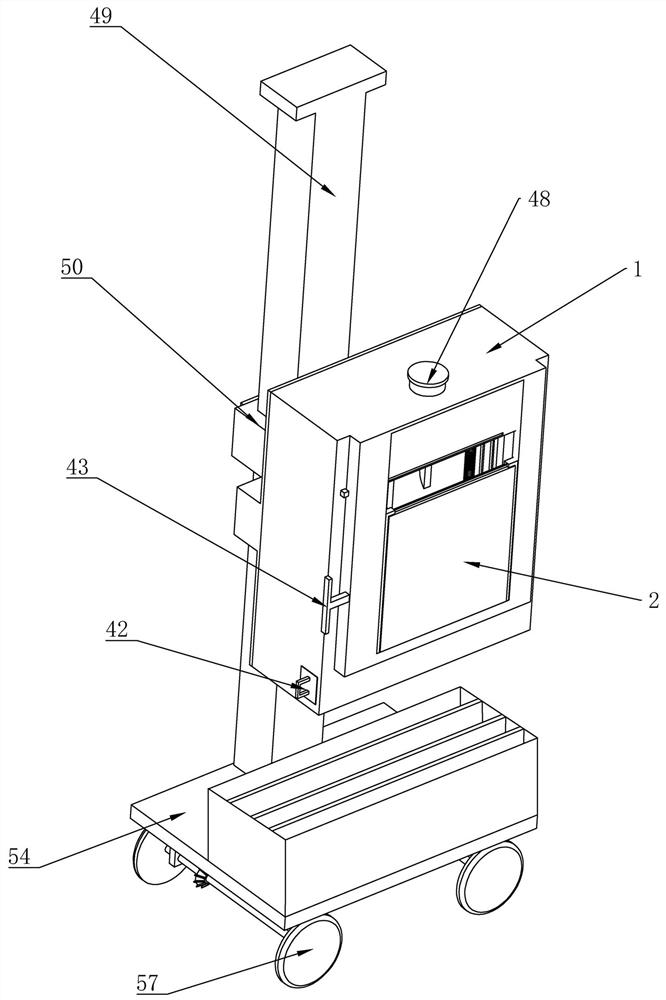

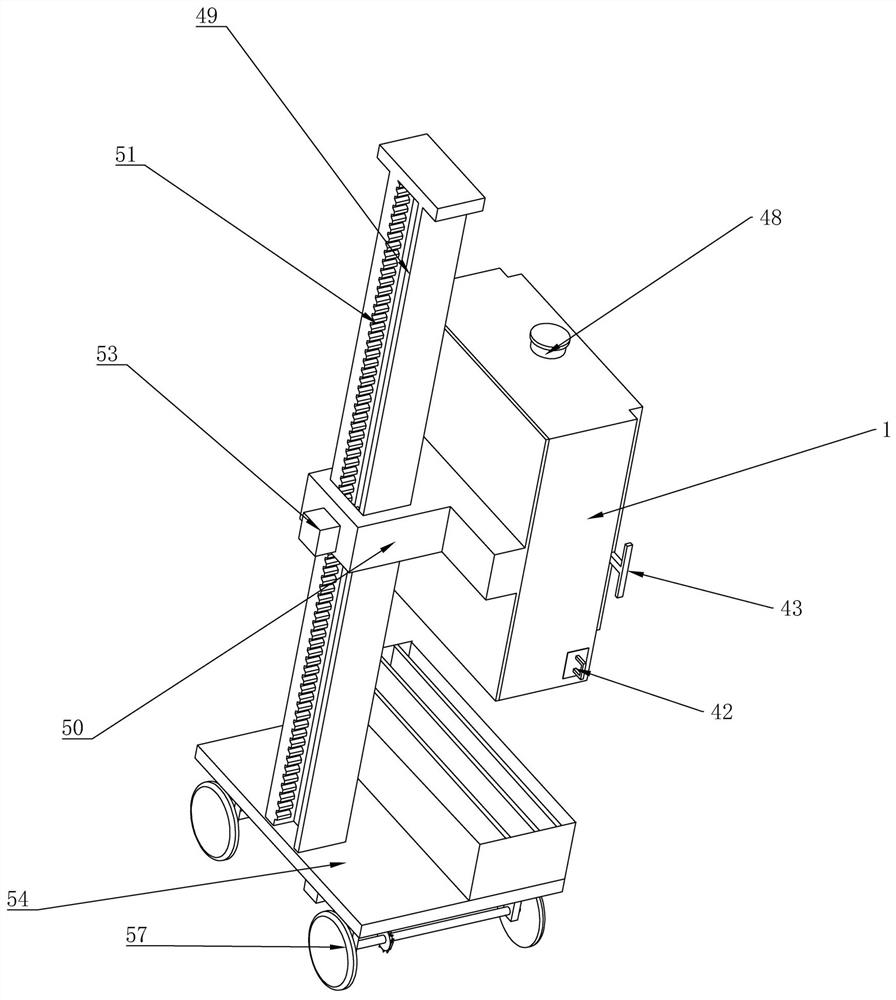

Automatic feed feeding device capable of controlling feeding amount and facilitating feed mixing

InactiveCN112058157AFeed amount controllableWell mixedSievingScreeningAnimal scienceAgricultural science

The invention relates to the technical field of livestock feed, and discloses an automatic feed feeding device capable of controlling feeding amount and facilitating feed mixing. The device comprisesa mixing box, a first motor is arranged on the upper surface of the mixing box, the output end of the first motor is fixedly connected with a stirring rod, and the rod body of the stirring rod is fixedly connected with a crusher; and a partition plate is arranged below the stirring rod, material leaking holes are formed in a plate body of the partition plate, and the lower end of the mixing box isfixedly connected with a feeding box. According to the automatic feed feeding device capable of controlling the feeding amount and facilitating feed mixing, the motor drives the crusher and a spiralfeeding rod to rotate to mix, crush and convey feed, and when the feed is added to a proper amount, a switch assembly arranged below a feeding trough cuts off a power source through a power source control device electrically connected with the switch assembly to stop feed adding, and therefore, the effects that different kinds of feed or medicine can be mixed conveniently, the feeding efficiency is improved, and the reasonable feeding amount can be controlled are achieved.

Owner:冯苗荣

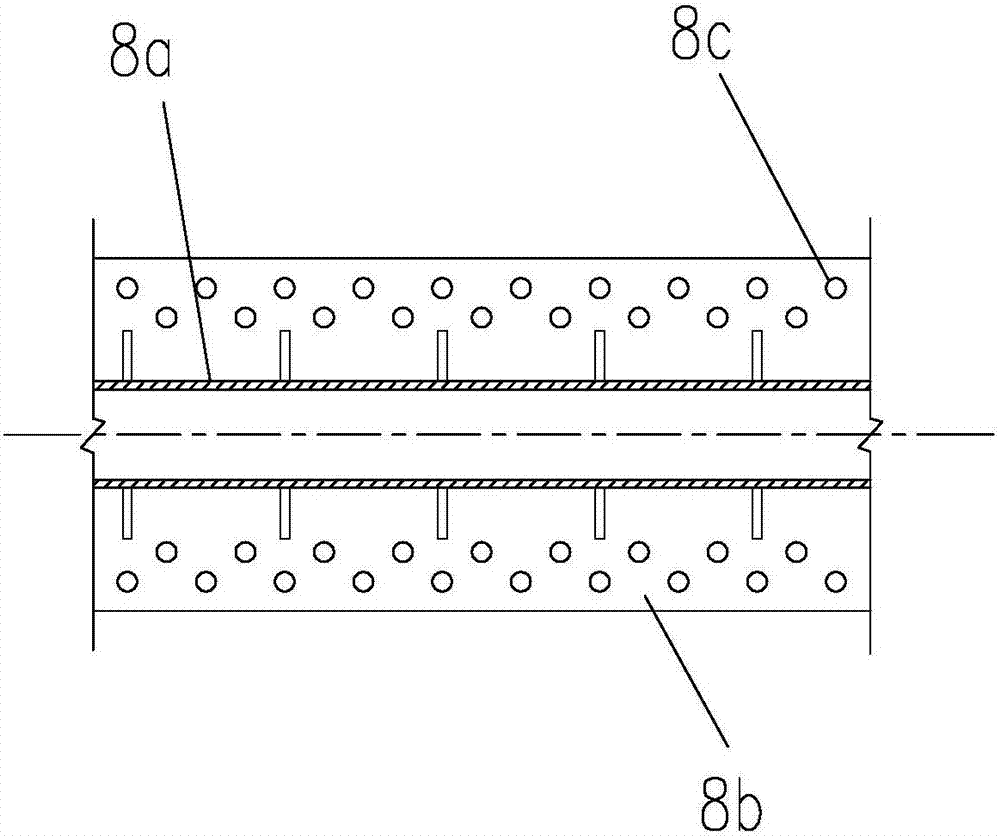

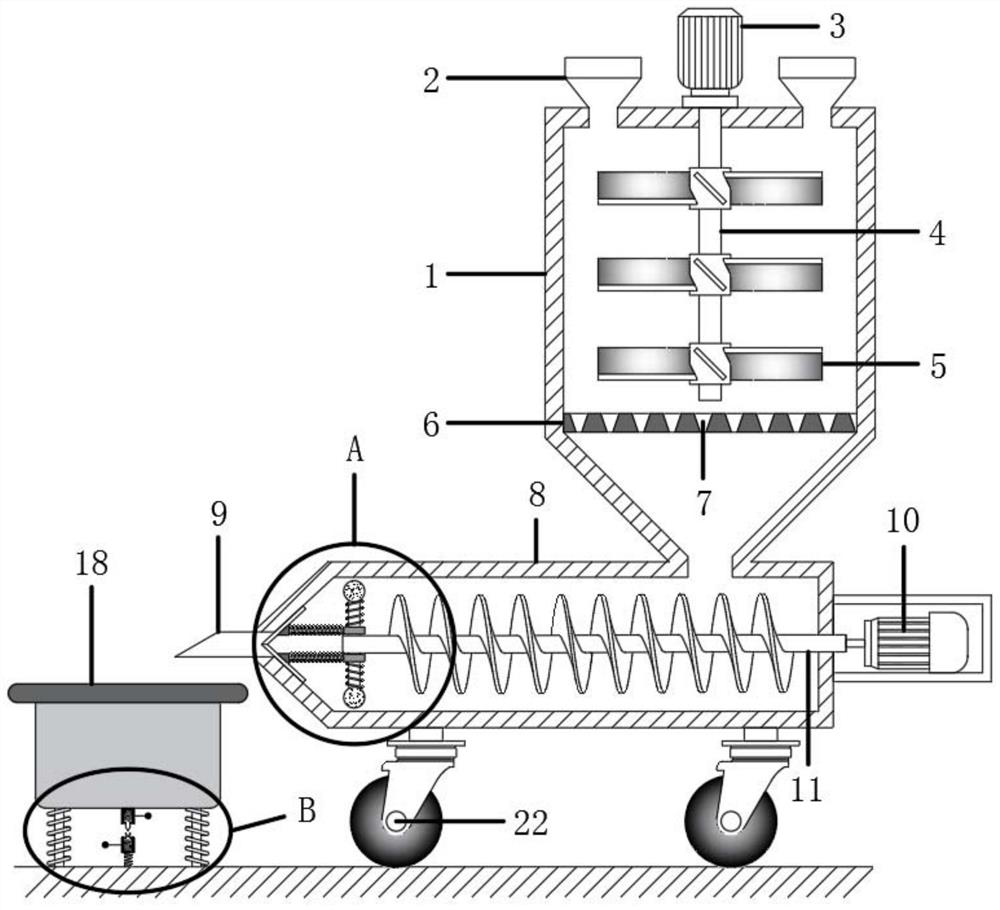

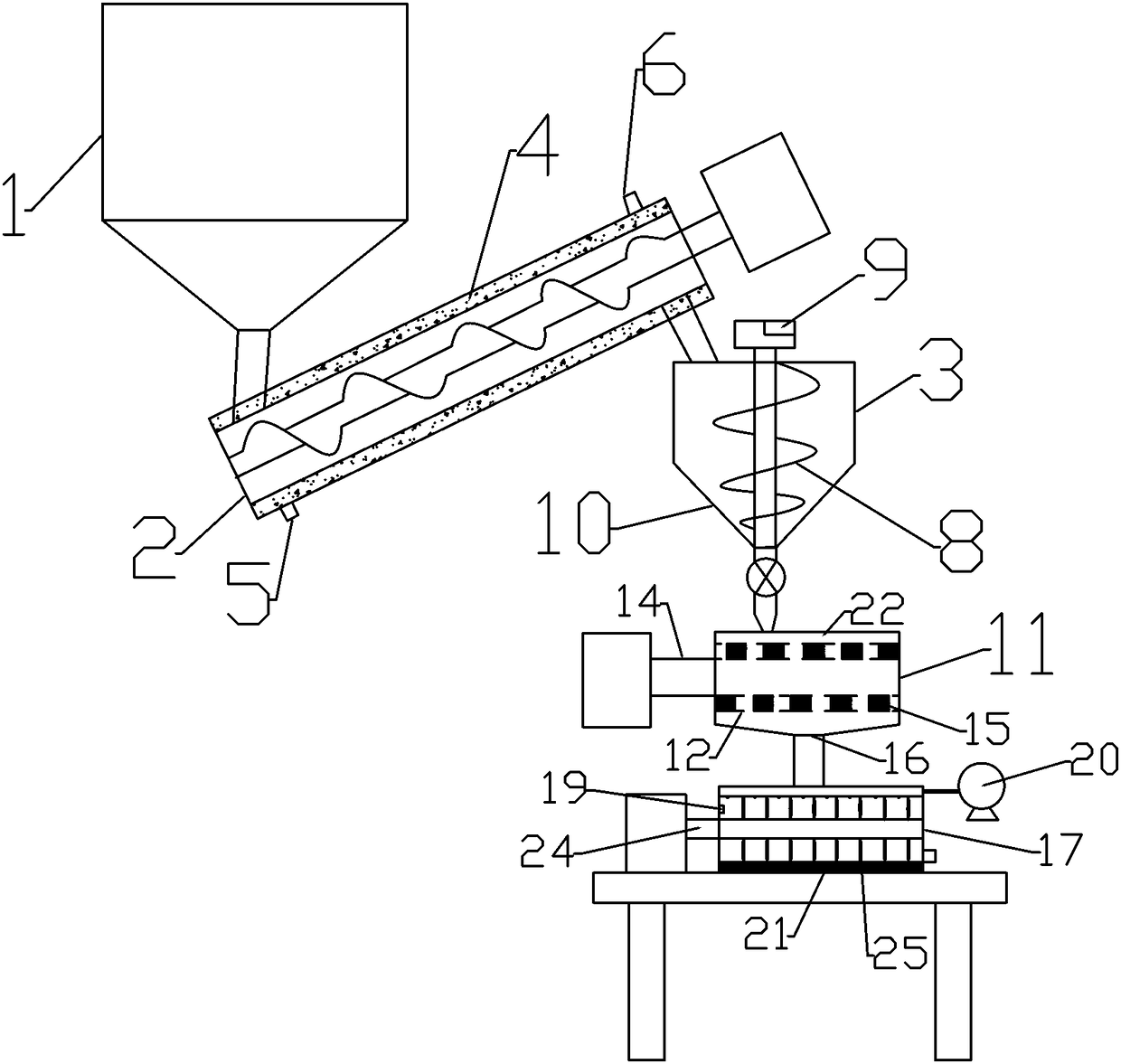

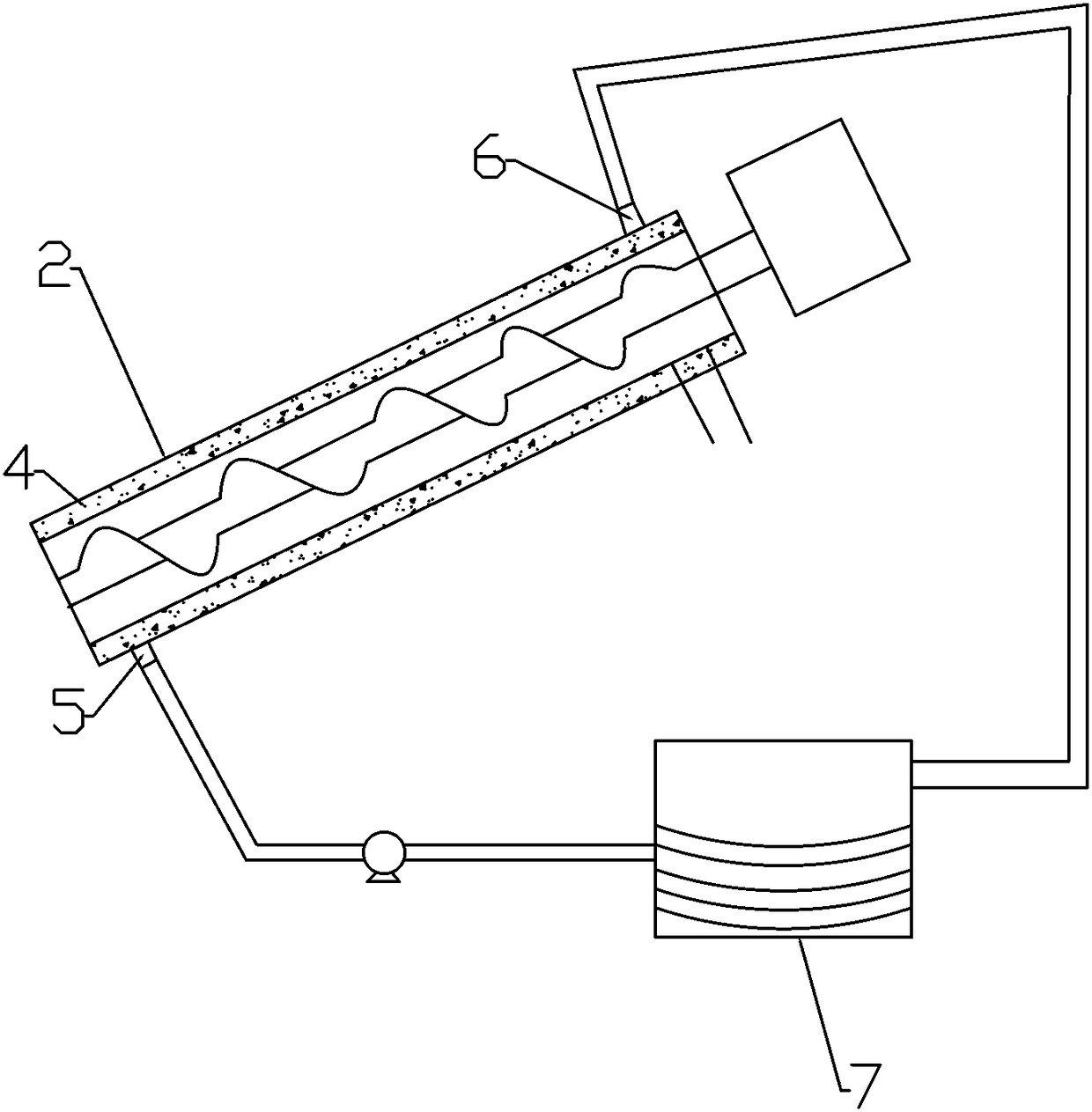

Closed multi-functional full-automatic grinding agitator

InactiveCN101596475AAvoid pollutionAvoid accumulationRotary stirring mixersGrain treatmentsCharge rateEngineering

The invention discloses a grinding agitating device, in particular to a closed multi-functional full-automatic grinding agitator. The invention comprises a feeding device, a grinding device and an agitating device and is characterized in that the agitating device is arranged on the front end of the agitator to form a certain angle to the floor plane; the feeding device is arranged on the rear end of the agitator and the feeding device is positioned behind the lower part of the grinding device. The beneficial effect of the invention is that: a feeding head is arranged behind the lower part of the agitator, thus avoiding effectively the phenomenons of uneven feedstock and residual accumulation in the cavity, solving the problem of unsmooth baiting, uniforming the feeding, improving the control of the charging rate, saving the power and increasing the grinding quality and work efficiency. The agitating device is integrated with the grinding device, thus avoiding the dust pollution while working.

Owner:郝中山

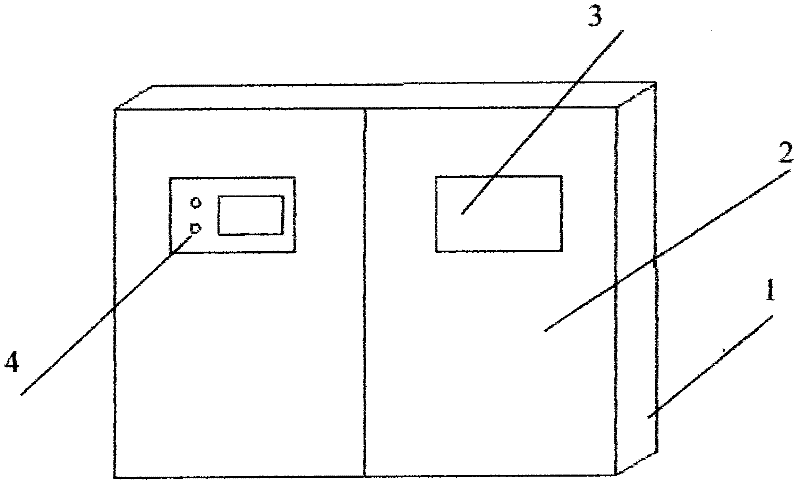

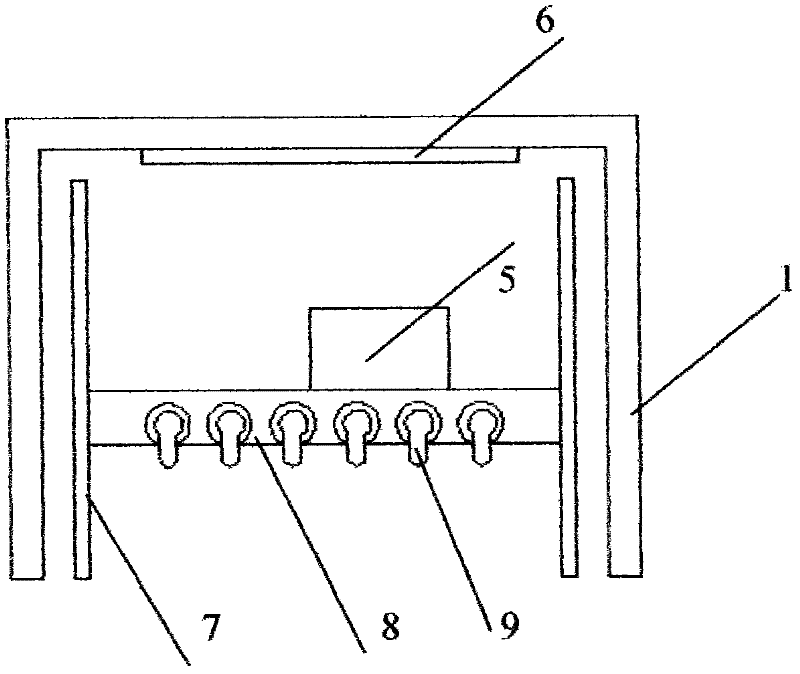

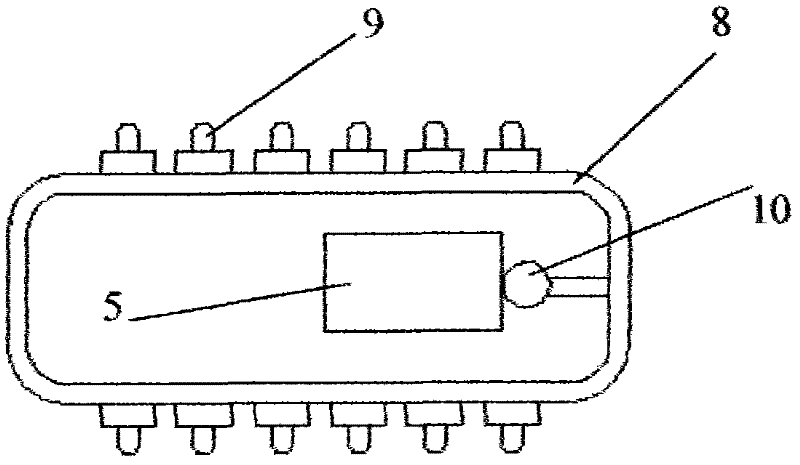

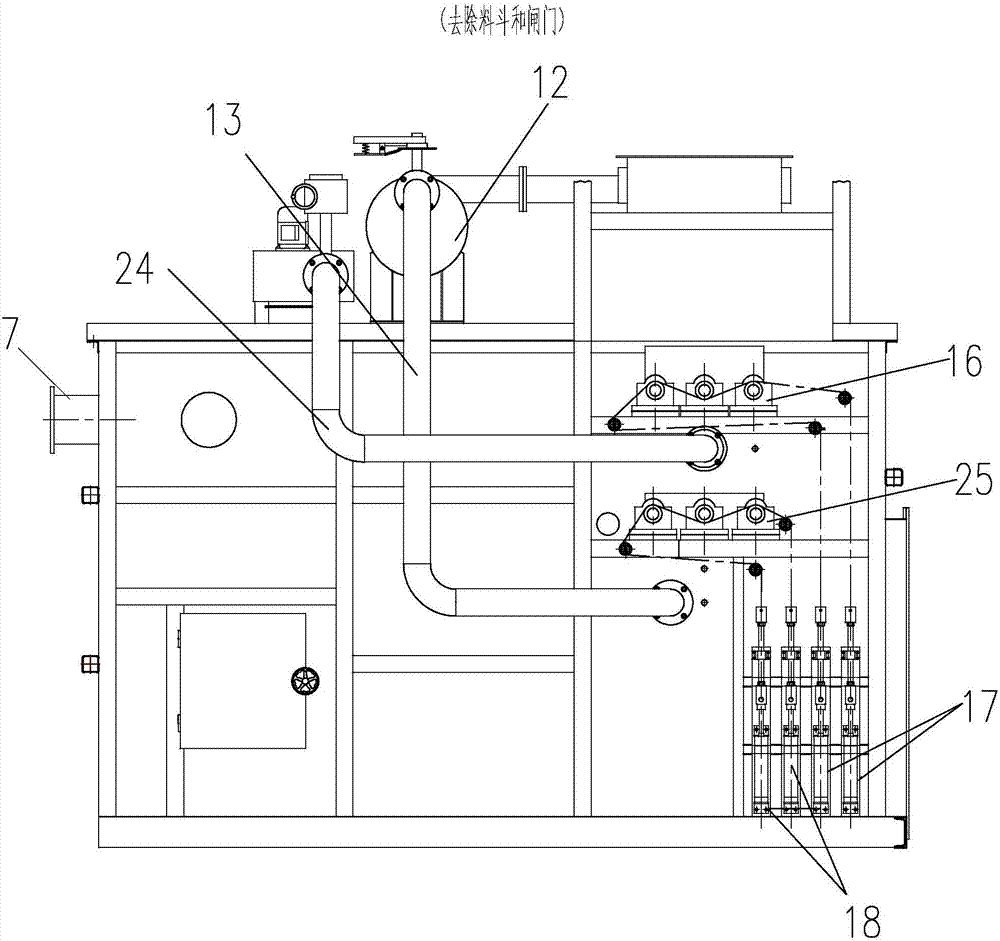

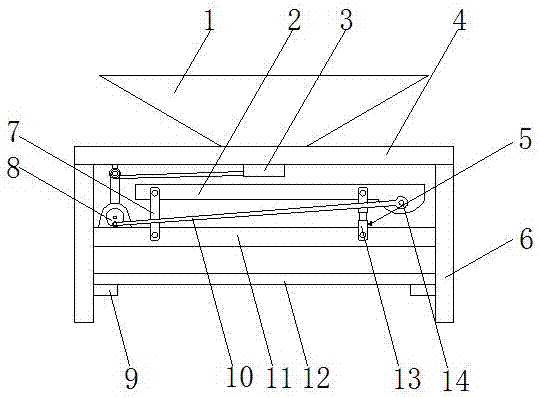

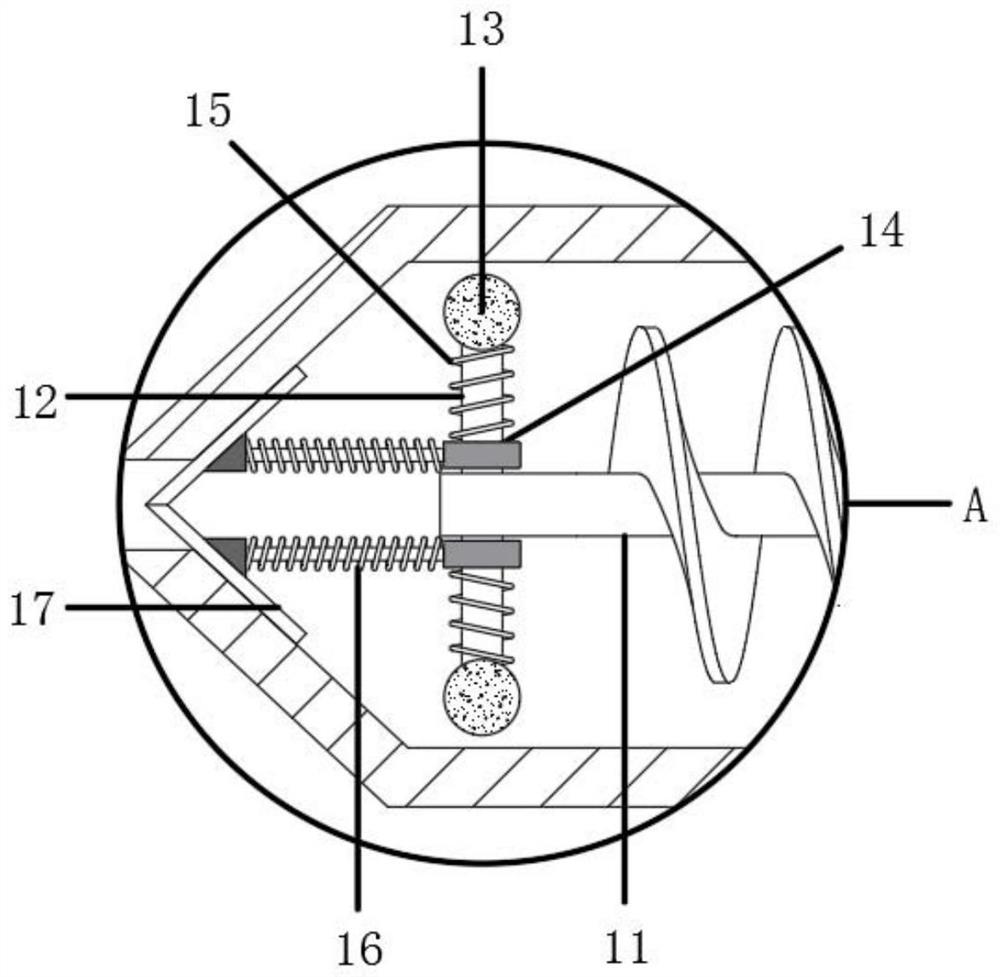

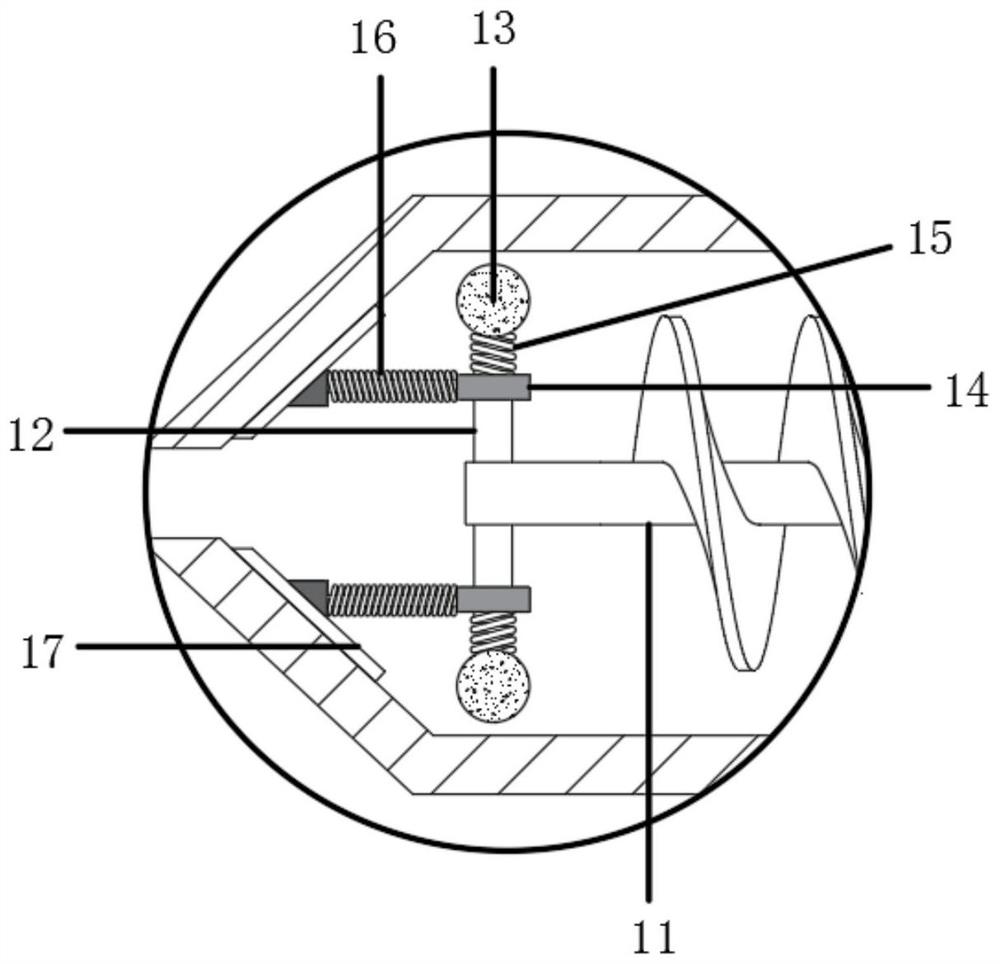

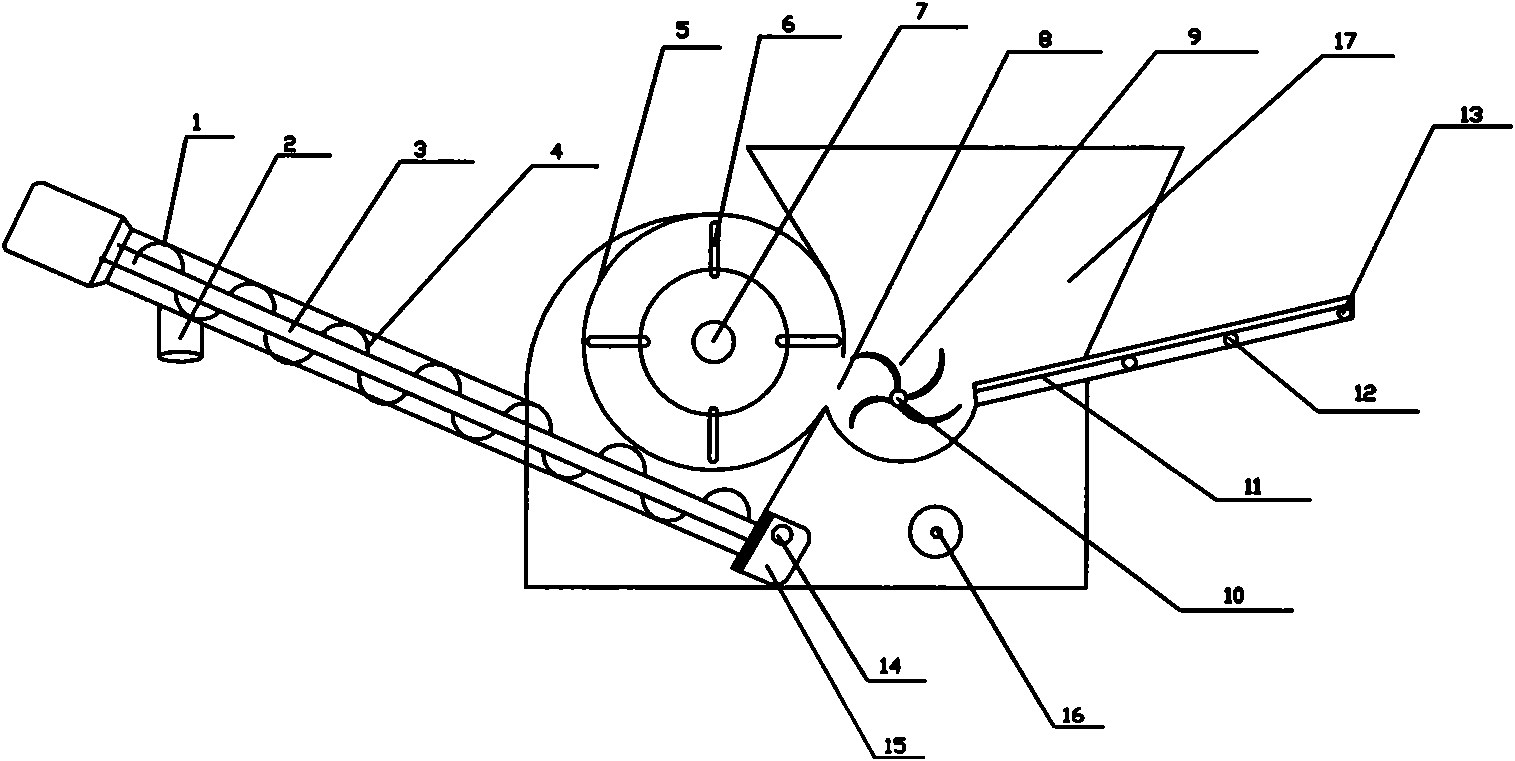

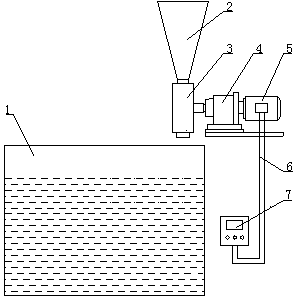

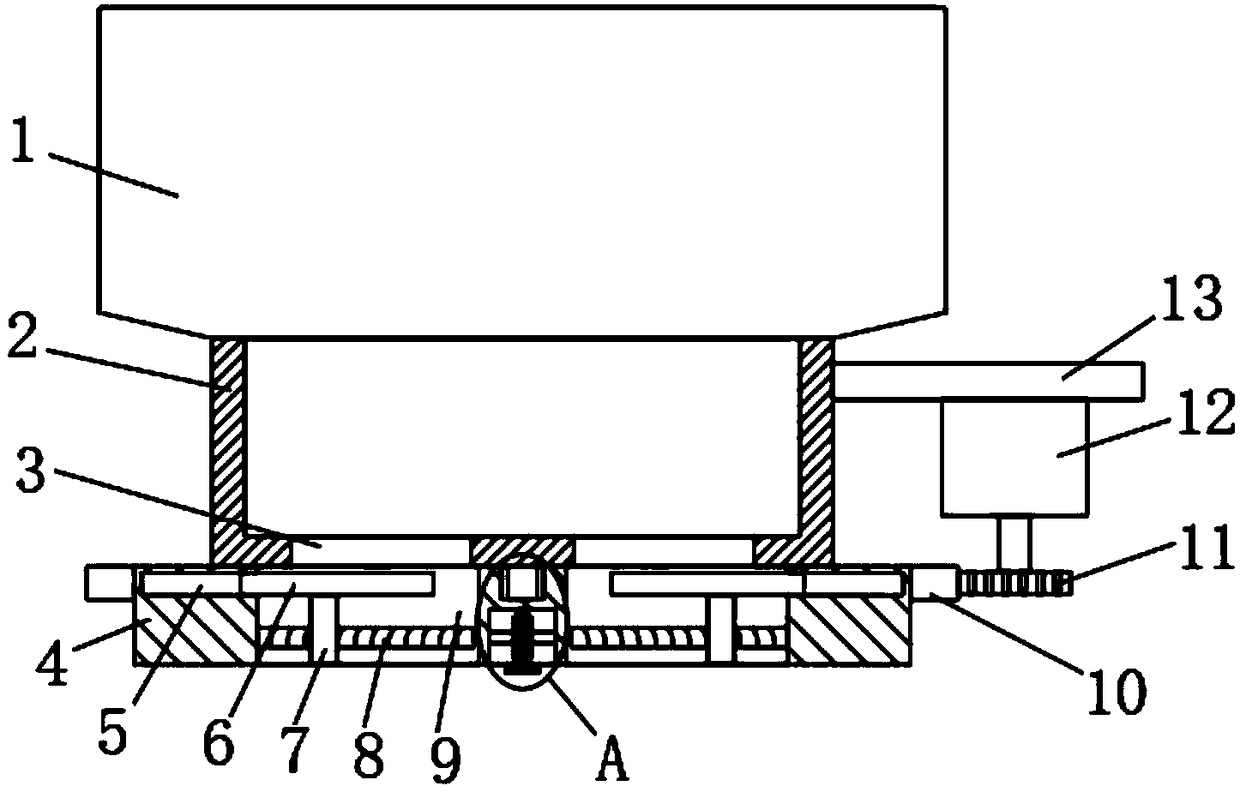

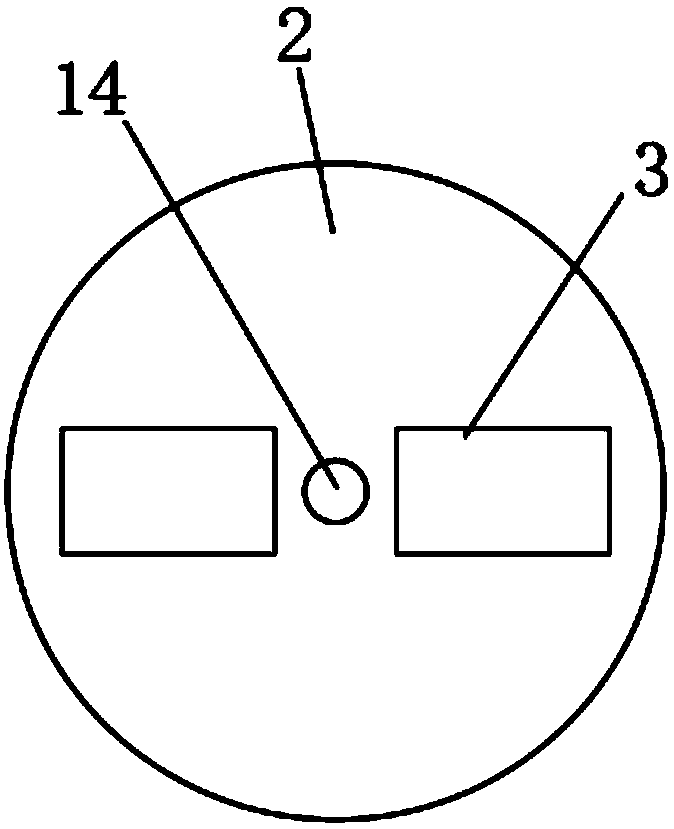

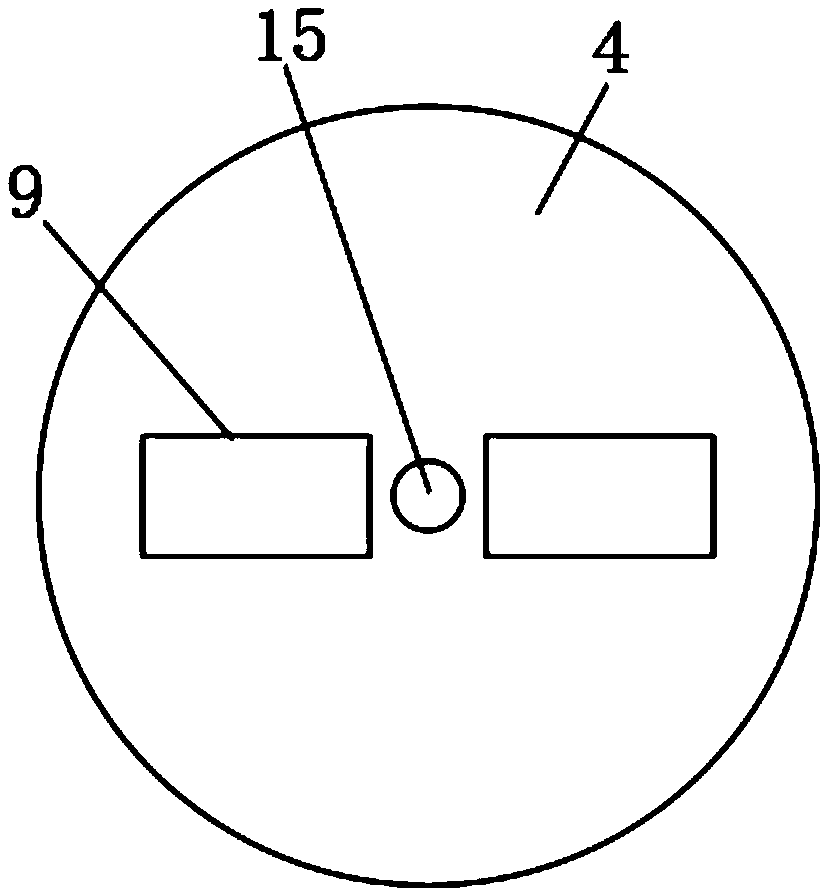

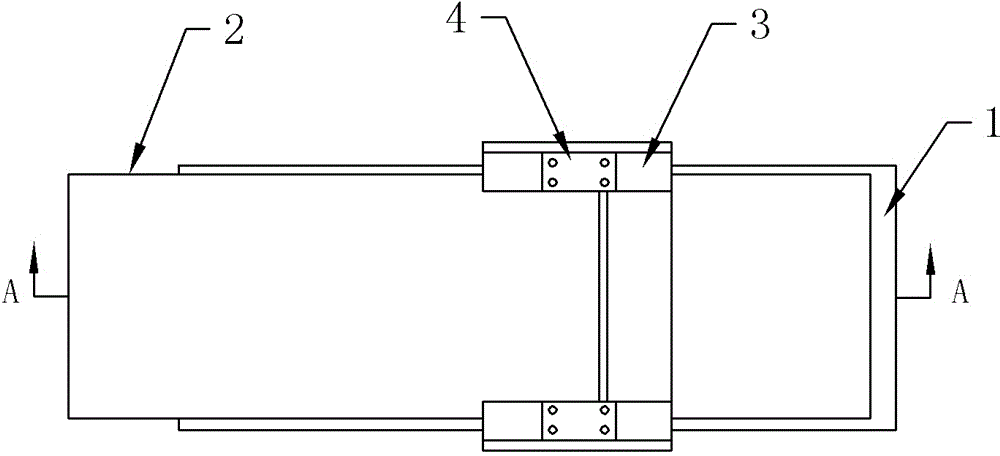

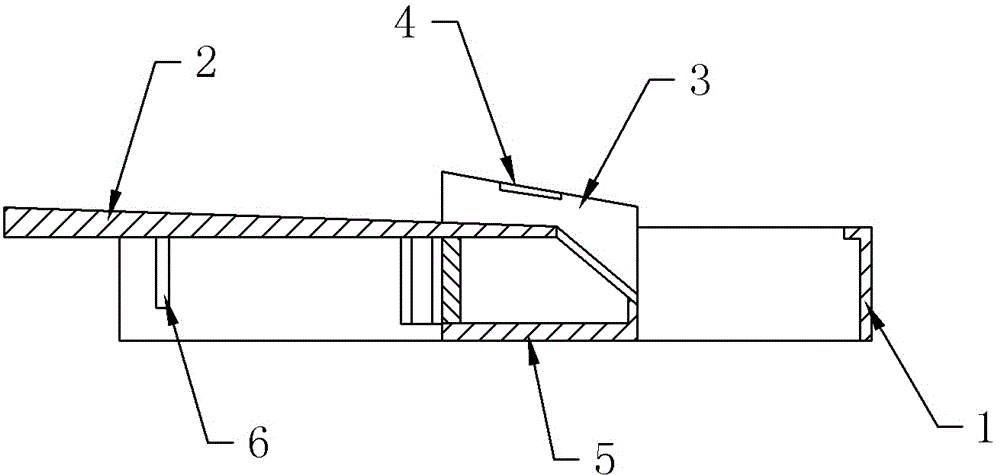

Automatic feeding device for goldfish bowl

InactiveCN104335946ARealize automatic feeding actionAutomatic feeding timingPisciculture and aquariaImpellerProgrammable logic controller

The invention discloses an automatic feeding device for a goldfish bowl. The automatic feeding device for the goldfish bowl comprises a fish bowl (1), and is characterized by also comprising a feeding hopper (2), an impeller discharge valve (3), a speed reducer (4), a motor (5) and an electric cabinet (7), wherein a PLC (programmable logic controller) is mounted in the electric cabinet (7); the electric cabinet (7) is connected with the motor (5) through a lead (6); the feeding hopper (2) is connected with the material inlet of the impeller discharge valve (3); the impeller discharge valve (3) is connected with the input shaft of the speed reducer (4); the motor (5) is connected with the input shaft of the speed reducer (4). The device can regularly and automatically feed fish meal, is controllable in feed amount, and has a long service life.

Owner:HUANGSHI ZHIYUN ELECTROMECHANICAL TECH INST

Technology for breeding lobsters

InactiveCN105994033APosition is easy to controlEat normallyClimate change adaptationPisciculture and aquariaAquaculture

The invention belongs to the field of aquaculture, and particularly discloses a technology for breeding lobsters. The technology comprises the steps of arranging a pond, cleaning the pond, conducting primary trial rearing, fertilizing water, conducting secondary trail rearing and conducting formal stocking. According to the technology, reasons of trial rearing failures can be easily determined, whether the problem in the pond cleaning step or in the water fertilizing step can be quickly distinguished, potential hazard can be eliminated in time, and the success rate of formal stocking can be improved.

Owner:王玉英

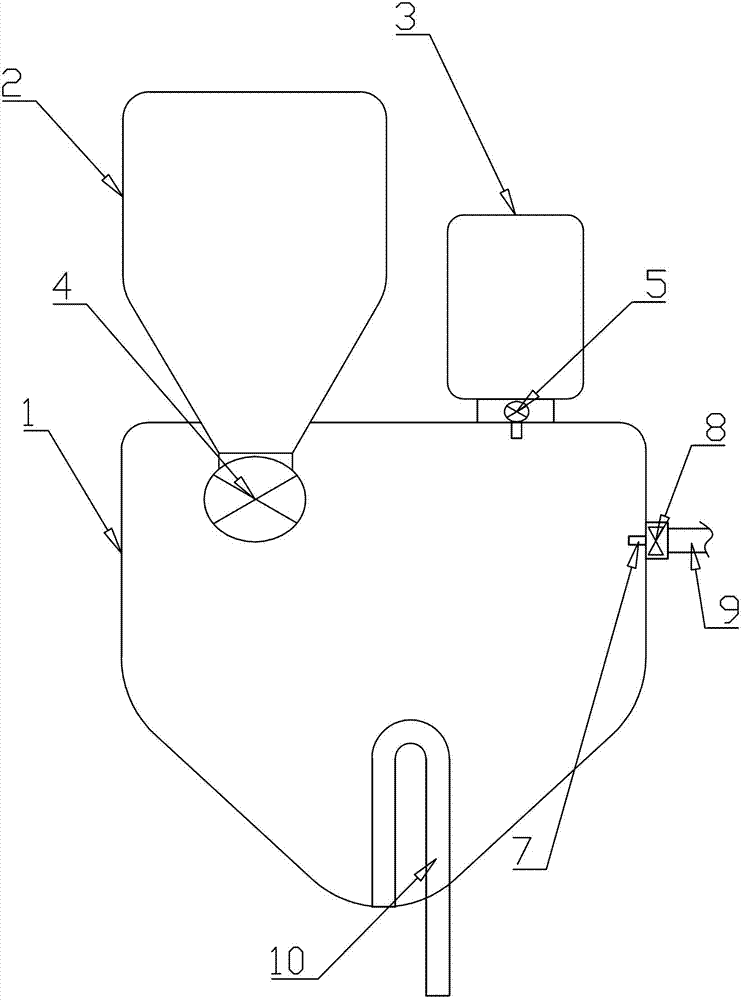

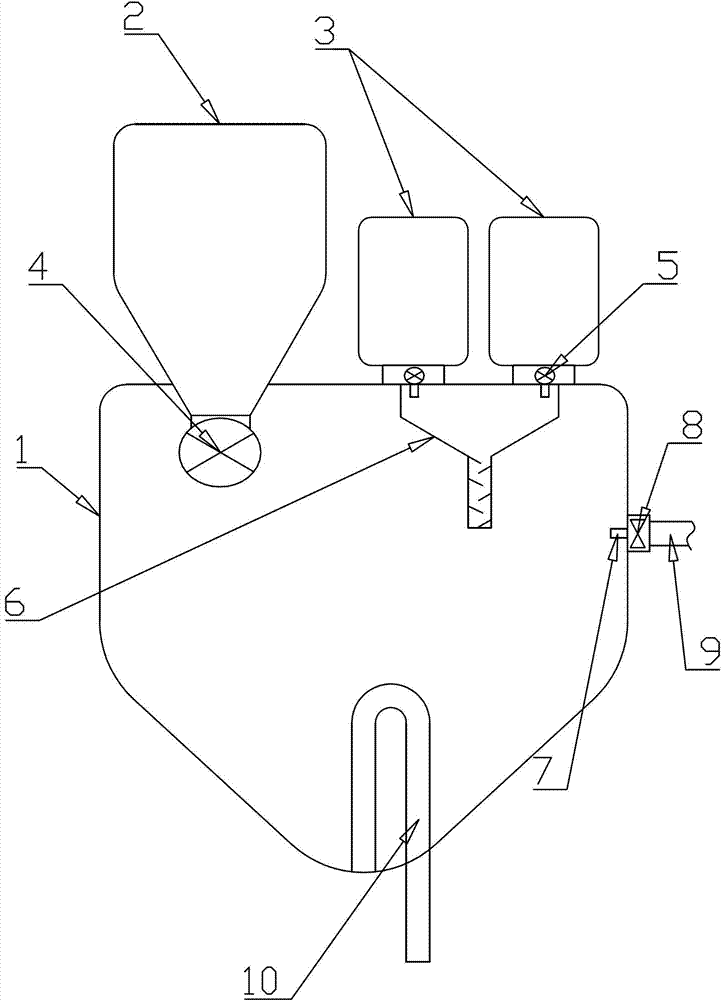

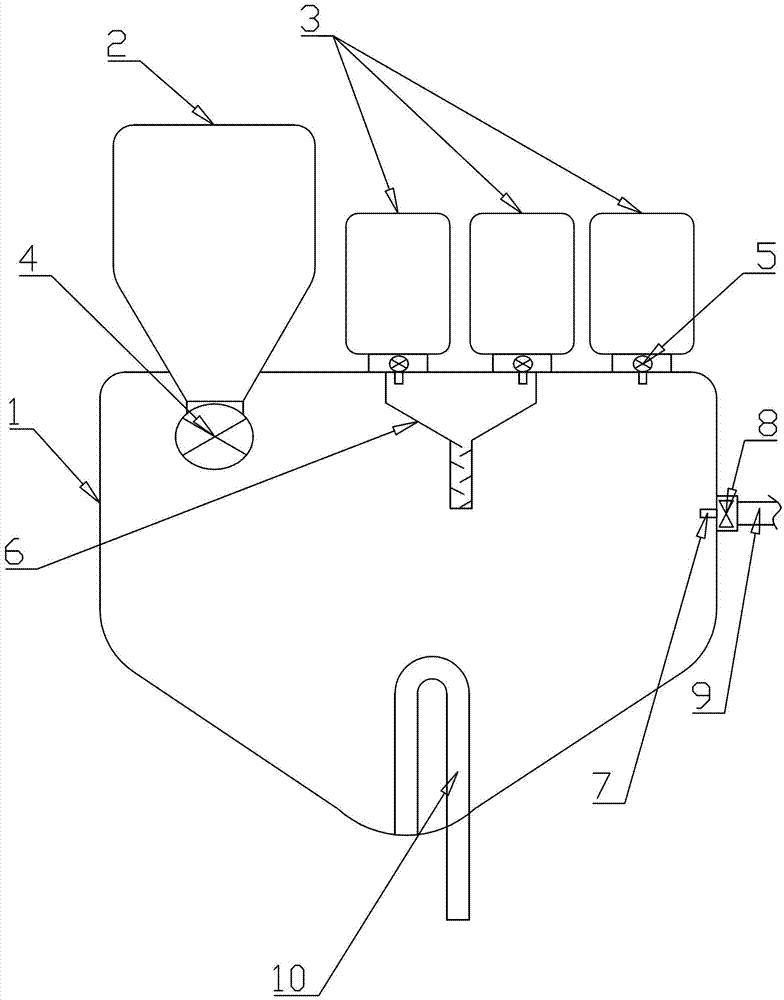

Automatic feeder

ActiveCN103537224AWell mixedFully dilutedTransportation and packagingAnimal feeding devicesWater flowEngineering

The invention discloses an automatic feeder. The automatic feeder comprises a container, a feed storage tank mounted above the container and at least one liquid bottle mounted beside the feed storage tank, wherein the feeding end of the feed storage tank is directly or indirectly communicated with the inner part of the container by the liquid transmitting end of the liquid bottle; the feeding end of the feed storage tank is further provided with an automatic opening / closing device for feeding at regular time; a water inlet is formed in the side wall of the container; a siphon liquid discharging device for discharging a mixture in the container out of the tank is mounted on the bottom wall of the container. According to the automatic feeder, the automatic opening / closing device for feeding at regular time is mounted at the feeding end of the feed storage tank and medicine liquid of the liquid bottle flows into the container under the effect of gravity; when pre-set time is up, the automatic opening / closing device starts to work; feed in the feed storage tank is fed into the inner part of the container to be mixed with the medicine liquid in the container and water flows from the water inlet to sufficiently mix the feed and the medicine liquid; when the water level in the container is higher than a siphon water level of the siphon liquid discharging device, mixed liquid in the container is discharged out of the container due to a siphon effect.

Owner:SOLIS HIGHT TECH INC SHENZHEN

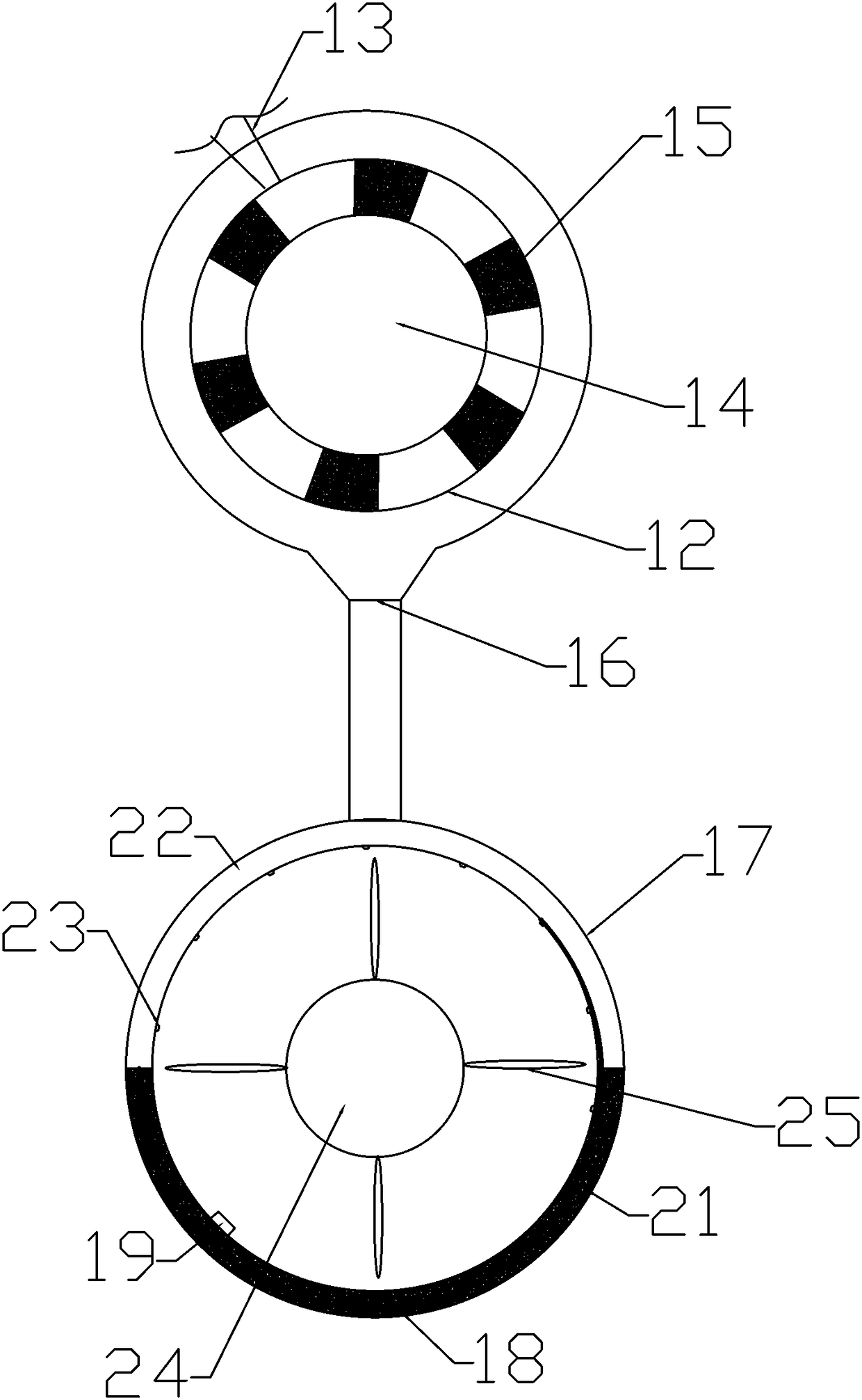

Feed processing system for piglets

InactiveCN108323783AUniform particle sizeImprove drying effectFeeding-stuffDrying machine combinationsEngineeringHandling system

The invention relates to the field of feed processing, in particular to a feed processing system for piglets. The system comprises a hopper; the lower end of the hopper is conveyed into a metering device through a hoister; the lower end of the metering device is a conical hopper; the lower end of the conical hopper is connected to a horizontal cylindrical crushing device; a cylindrical filter screen cover is arranged near the edge in the crushing device; the upper end of the filter screen cover communicates with a feeding pipe; the central part of the crushing device is provided with a stirring shaft I; milling blocks are uniformly distributed on the circumference of the stirring shaft I; the end part of each milling block is in contact with the filter screen cover; the lower end of the crushing device is provided with a conical discharging port; and the discharging port is connected to a stoving device. The processing system is reasonable in design and simple to operate, enables feedto be uniformly crushed, has a good stoving effect, facilitates the storage of feed, needs less labor, saves production cost, and has strong practicality.

Owner:郑州慧合中赢科技有限公司

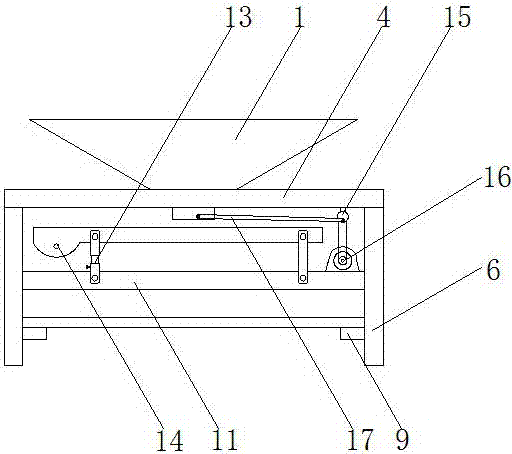

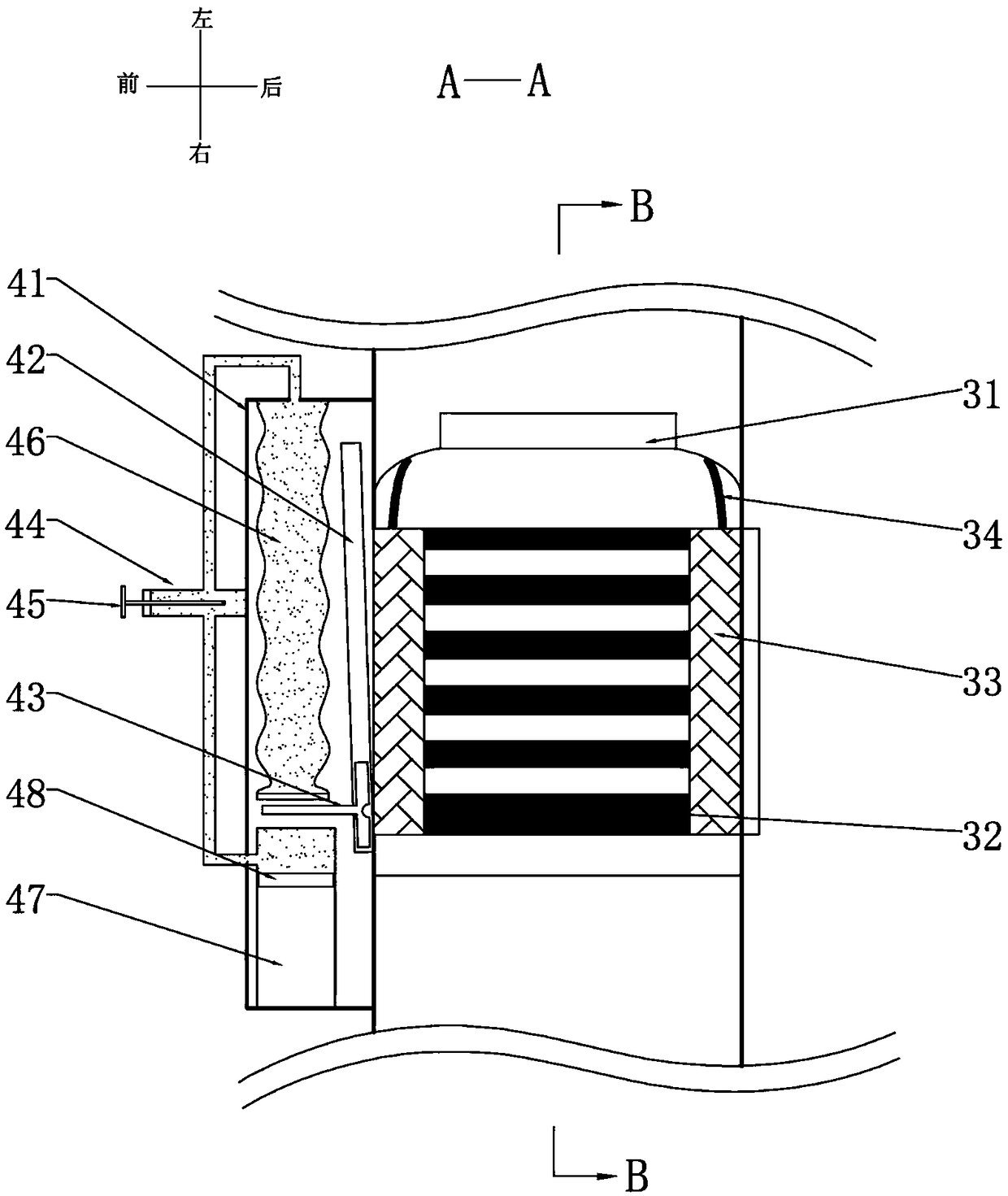

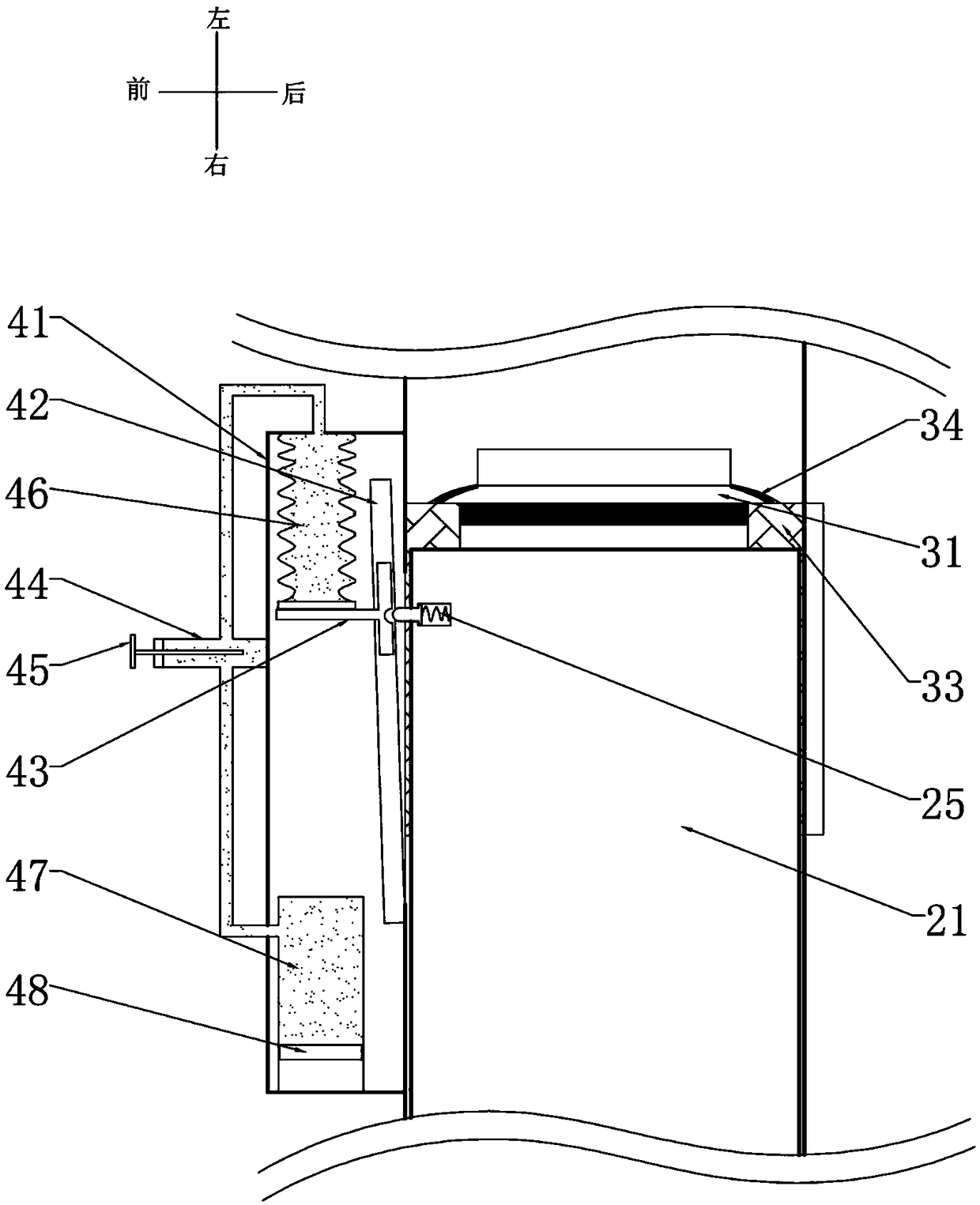

Fixed-point quantitative feeding machine

ActiveCN108651313AFeed amount controllableAvoid wastingAnimal feeding devicesAvicultureSlide plateEngineering

The invention relates to the field of feeding, in particular to a fixed-point quantitative feeding machine. The fixed-point quantitative feeding machine comprises a bearing assembly, a sliding block,sliding plate assemblies and reduction assemblies. The bearing assembly comprises a feeding tube, a feeding port, a clamp spring, a fixed rod, a recycle cylinder and a telescopic rod, and is used forbearing other assemblies; the sliding block comprises a sliding block main body, a feeding channel, sliding block friction pieces, a clamp column and a clamp column spring, and is used for deploying feed and controlling the amount of sprinkled feed; the sliding plate assemblies comprise sliding plate grooves, sliding plate main bodies, sliding friction pieces and sliding plate contact corners, andare used for cooperating with the siding block to control whether to sprinkle the feed or not; the reduction assemblies comprise shells, push plate grooves, push plates, valve body shells, flow blocking pieces, aqueous capsules, water cylinders and press plates, and are used for controlling the slide-down speed of the sliding block. The fixed-point quantitative feeding machine can pour the feed at fixed points quantitatively above a feeding pond and only pours the feed at one point in the feeding process, and other outlets are closed; the feeding amount of the fixed-point quantitative feedingmachine can be controlled; the fixed-point quantitative feeding machine is provided with a feed recycle assembly and can avoid feed waste.

Owner:江苏大财纳农牧科技有限公司

Plastic raw material feeding equipment

The invention discloses plastic raw material feeding equipment. The plastic raw material feeding equipment comprises a storage barrel, wherein the lower end of the storage barrel is connected with anunloading tube; the lower end of the unloading tube is of a sealed structure; the lower end of the unloading tube is symmetrically equipped with two first leaking holes in a penetrating mode; a rotaryplate is arranged below the unloading tube; the middle part of the lower end of the unloading tube is fixedly connected with a rotary shaft; the middle part of the upper end of the rotary plate is equipped with a rotary slot; the rotary shaft is rotatably connected onto the inner bottom wall of the rotary slot; a drive mechanism for driving the rotary plate to rotate is arranged on the side wallof the unloading tube; the rotary plate abuts against the lower end of the unloading tube; two second leaking holes are symmetrically formed in the rotary plate in the penetrating mode; the two secondleaking holes separately correspond to the two first leaking holes in position; and blocking mechanisms are arranged in the second leaking holes. Through intermittent unloading, unloading is uniform,so that sustainable stability conveying is realized; and conveying amount can be regulated and controlled.

Owner:江门市江海区颖轩投资咨询有限公司

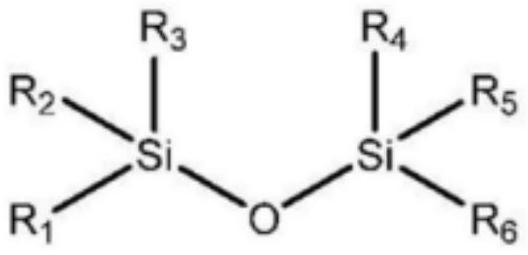

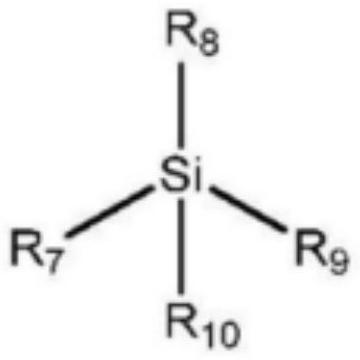

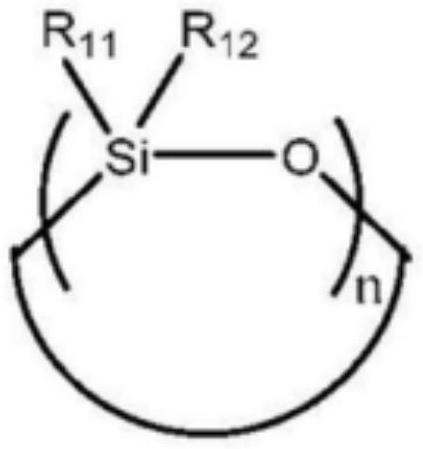

Transparent wear-resistant film layer, plastic surface modification method and product

PendingCN113897592AFeed amount controllableCoating quality is stablePretreated surfacesChemical vapor deposition coatingIon bombardmentSurface modification

The invention discloses a transparent wear-resistant film layer, a plastic base material modification method and a product. The plastic base material modification method comprises the following steps that ion bombardment is carried out on at least one plastic base material positioned in a cavity of PECVD (Plasma Enhanced Chemical Vapor Deposition) coating equipment to clean and activate the plastic base material; and a transparent wear-resistant film layer is formed on the surface of the activated plastic base material through deposition by taking a siloxane monomer as a reaction raw material through a plasma enhanced chemical vapor deposition method.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

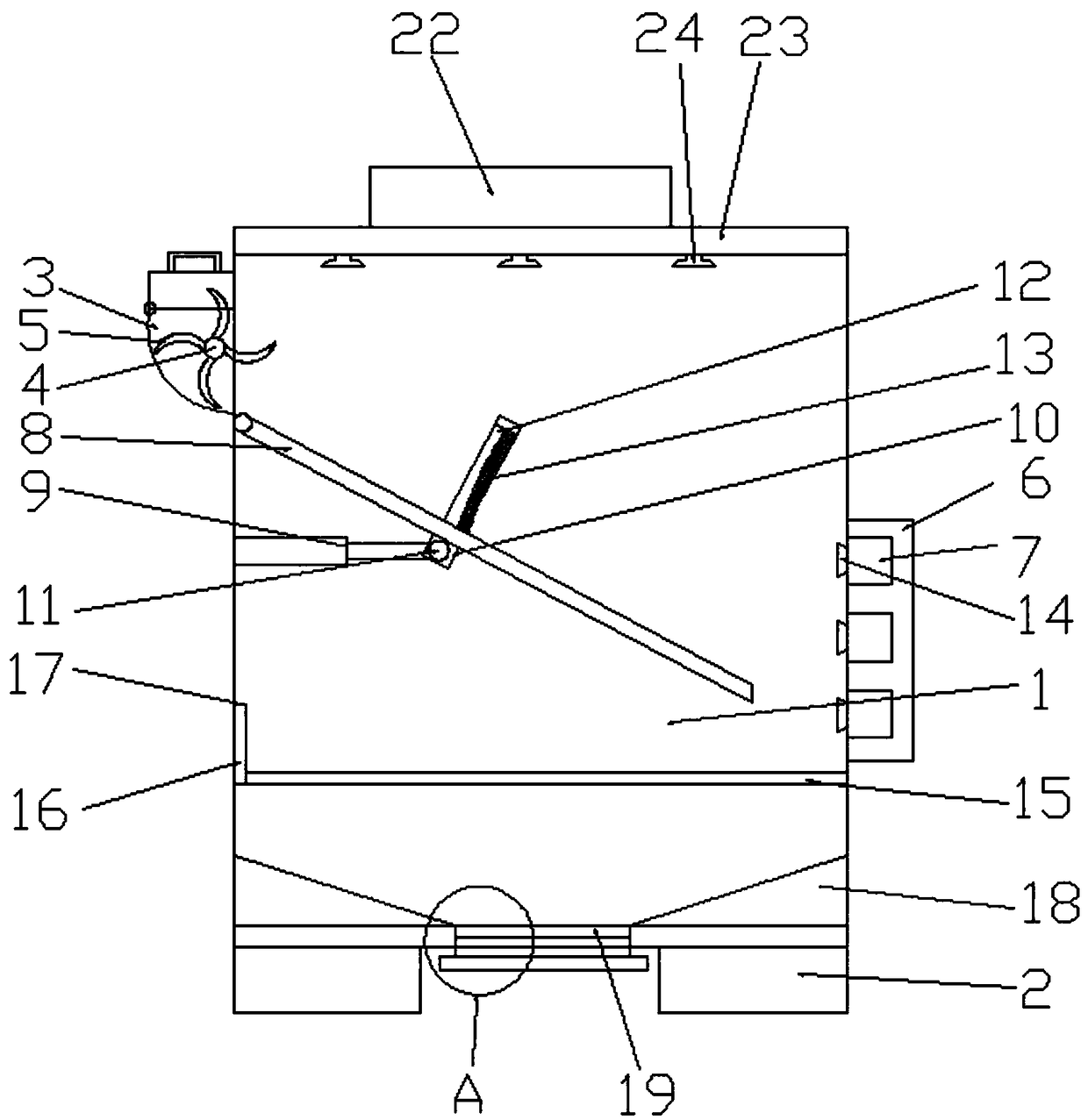

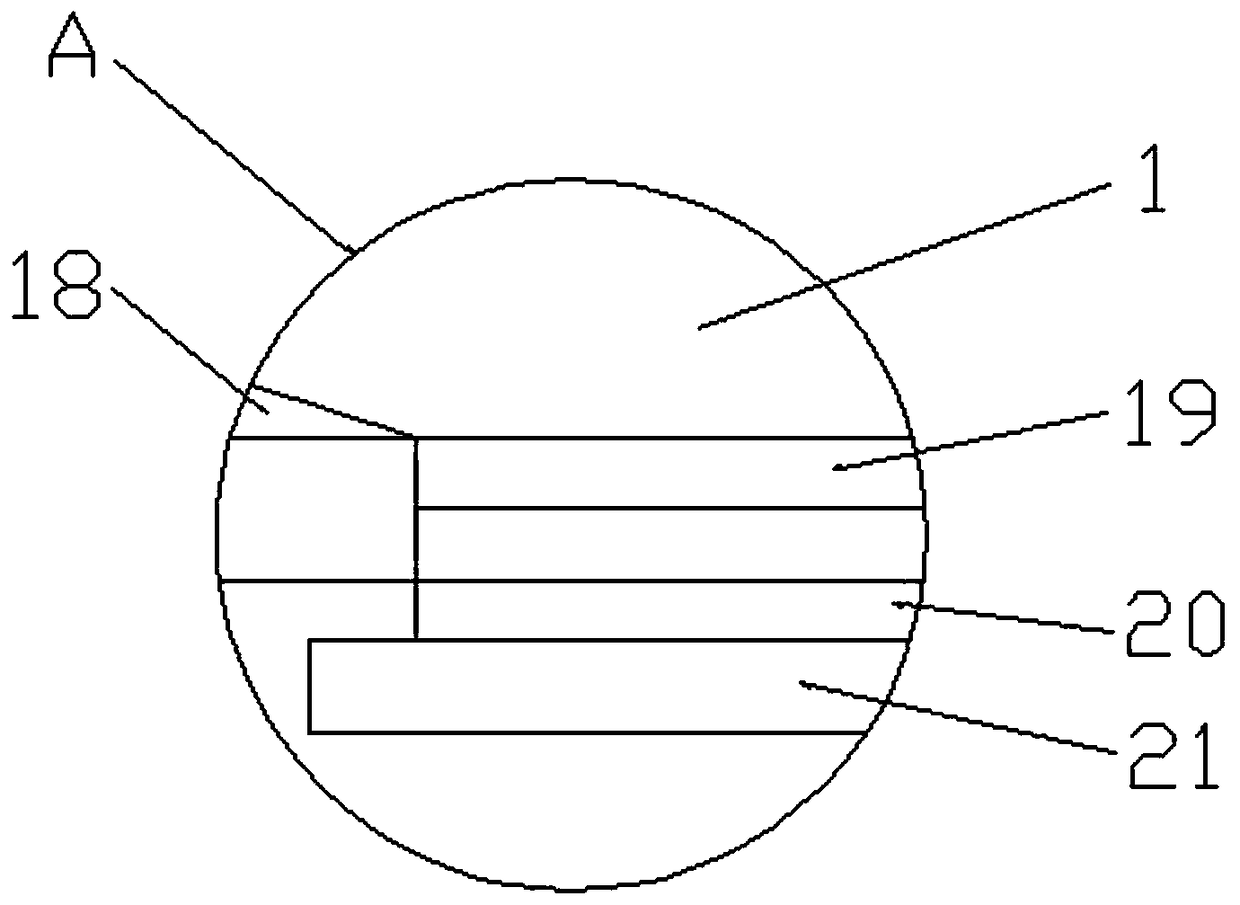

Animal incubator and production method thereof

InactiveCN102342251BConducive to epidemic preventionGood treatment effectAnimal feeding devicesAnimal housingTemperature controlSurveillance camera

The invention relates to an animal incubator and a production method thereof and belongs to equipment which has integrated functions of nursing young animals, protecting and raising. The animal incubator mainly comprises box body, wherein a nursing device, a temperature control device, an illumination lamp and a monitoring camera are arranged in the box body; and an ultraviolet sterilization lamp and an audio device which can be synchronously opened or closed in the process of nursing are also arranged at the top of the interior of a box body. The invention aims at providing the animal incubator which can be used for nursing multiple young animals with fixed amounts in fixed time points at the same time, is convenient for the immunizing and treating of the animals and also can create suitable temperature and humidity, so that the survival rate and reproductive rate of the young animals are improved and the problem of the batch breeding is solved.

Owner:泸西县沐塘果牧种养殖有限公司

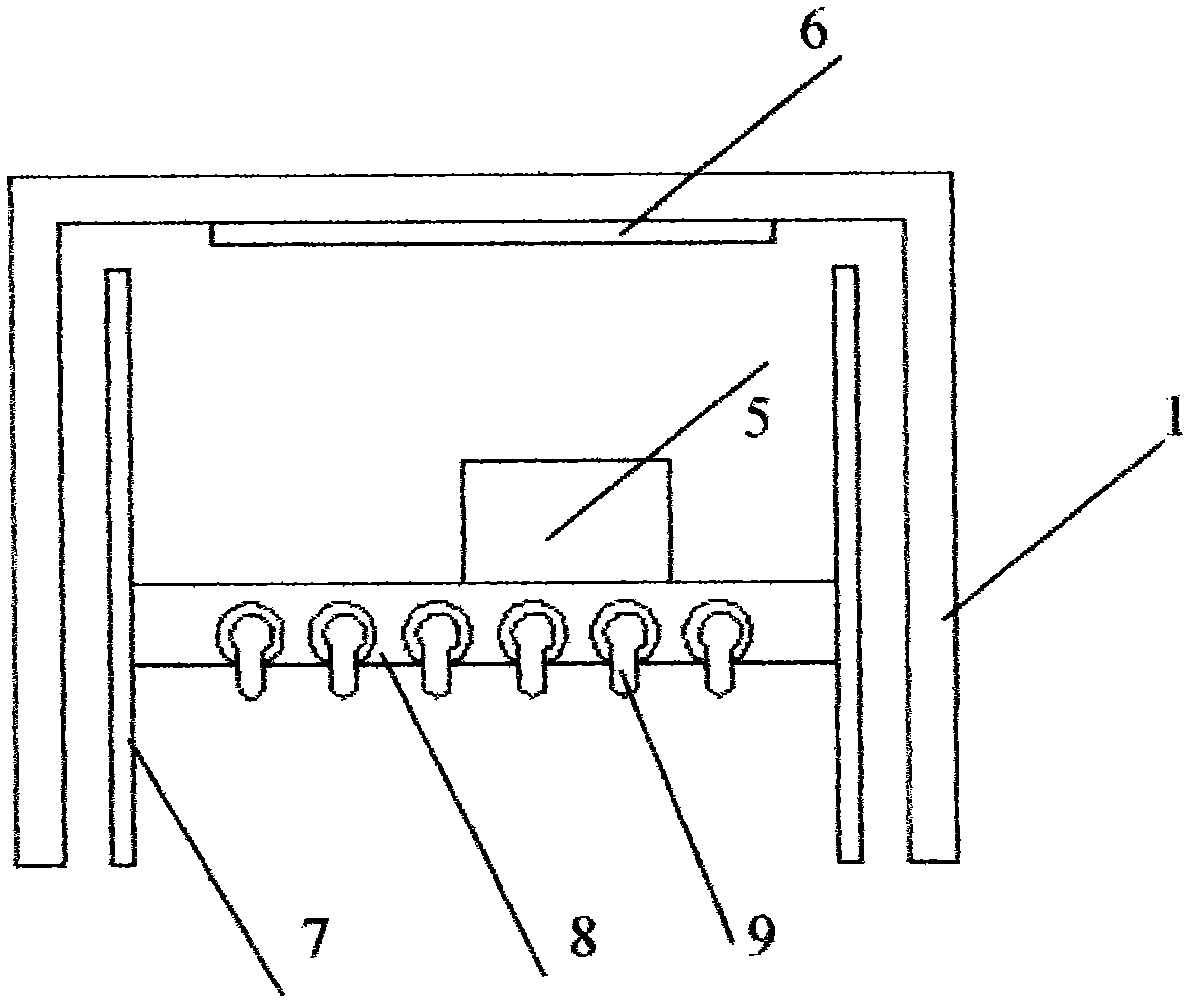

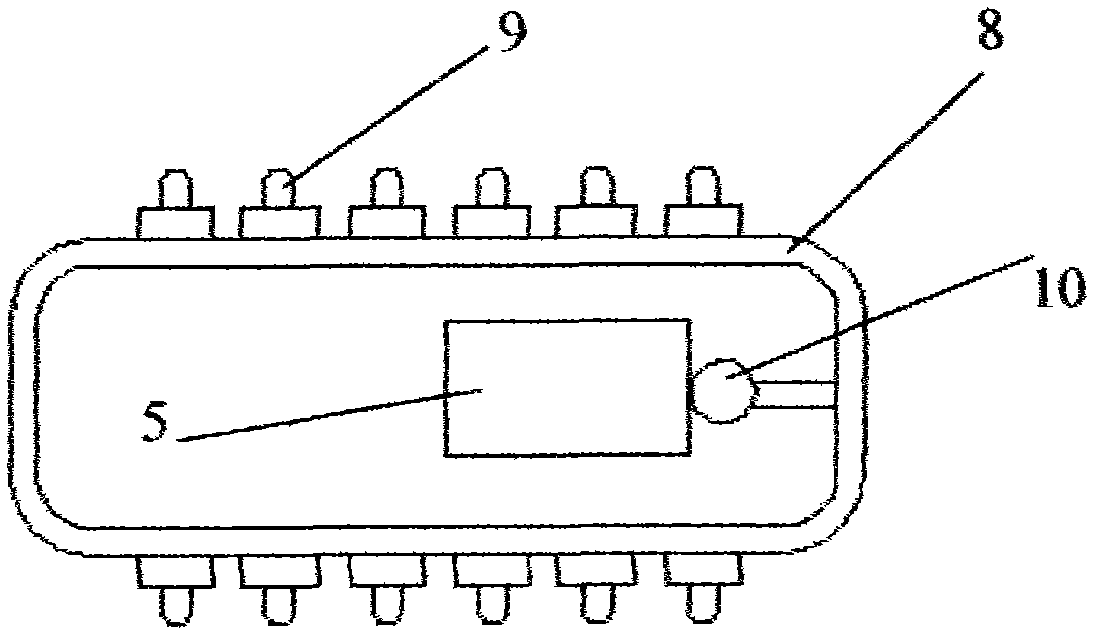

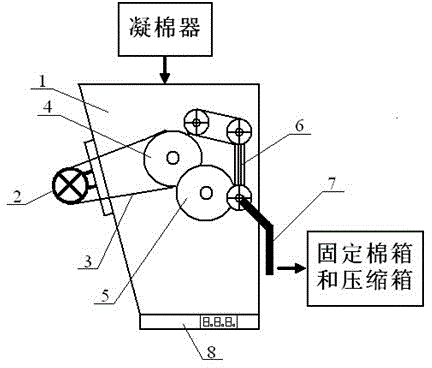

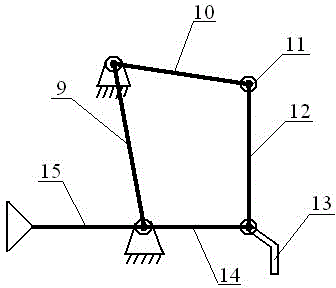

Feeder of small type short fiber packing machine

The invention discloses a feeder of a small type short fiber packing machine. The structure of the feeder comprises a shell, a transmission mechanism, a link mechanism, a rake tooth and an electrical control device, wherein the transmission mechanism is installed outside the shell; the transmission mechanism consists of a motor, a transmission belt, a chain, a belt wheel and a chain wheel; the link mechanism is installed in the shell; the rake tooth is installed on a connecting link of the link mechanism; the electrical control device is installed in the shell; and the electrical control device comprises a control module, a detection module and a nixie tube displayer. The invention discloses the feeder of the small type short fiber packing machine; the feeder is rational in design and simple and compact in structure, and has excellent performances of high speed, high reliability, long service life and low price, and a function of availably controlling the feeding amount, thereby being quite applicable for the small type short fiber packing machine with lower annular output and relatively lower speed.

Owner:SUZHOU XUNXIAN TEXTILE TECH CO LTD

Puffed chub bait

InactiveCN108669359AAvoid absorbing and dissolvingSolve perishableFood processingClimate change adaptationYeastSlag

The invention relates to the field of fish baits, and in particular relates to a puffed chub bait. The puffed chub bait comprises the following raw materials in parts by weight: 30 to 46 parts of soybean meal, 8 to 17 parts of fish meal, 5 to 11 parts of earthworm powder, 12 to 25 parts of spirulina powder, 4 to 13 yeast powder, 0.5 to 2.9 parts of sesame oil, 1 to 7 parts of tea slag, 0.1 to 0.6parts of modified graphite, and 3 to 18 parts of additives. The puffed chub bait is rich in nutrients and easy to absorb. The bait fed to water floats on water surface, and the feeding amount is easyto control. After the puffed bait has increased flavor and good palatability, and can play a food calling effect.

Owner:国营无为县水产养殖场

Feeding and discharging structure of brick press

The invention discloses a feeding and discharging structure of a brick press. The feeding and discharging structure comprises a feed box and a conveying belt. The conveying belt is located below a discharge port of the feed box. The feeding and discharging structure is characterized by further comprising a leakage hopper, a distribution oil cylinder, a feeding hopper, a closing plate, an upper mold cover plate and a pressure delivery part; the discharging hopper is located on the discharging side of the conveying belt, a leakage port is formed in the lower portion of the leakage hopper, a piston rod of the distribution oil cylinder is connected with the feeding hopper, the leakage port is formed over the motion path of the feeding hopper, the closing plate and the pressure delivery part are connected to the top face of the feeding hopper, the closing plate can close the leakage port in a matched mode, and the upper mold cover plate is connected to the bottom face of the feeding hopper. The feeding and discharging structure of the brick press can easily control the feeding amount and is relatively simple in structure.

Owner:CHONGQING RUIXUAN HAOBANG NEW BUILDING MATERIAL

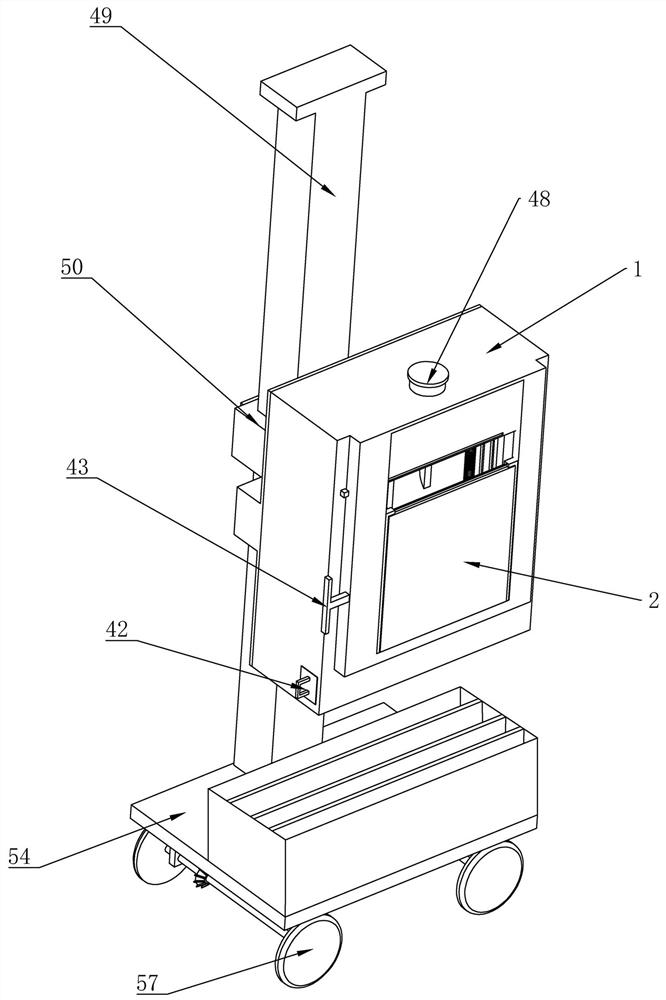

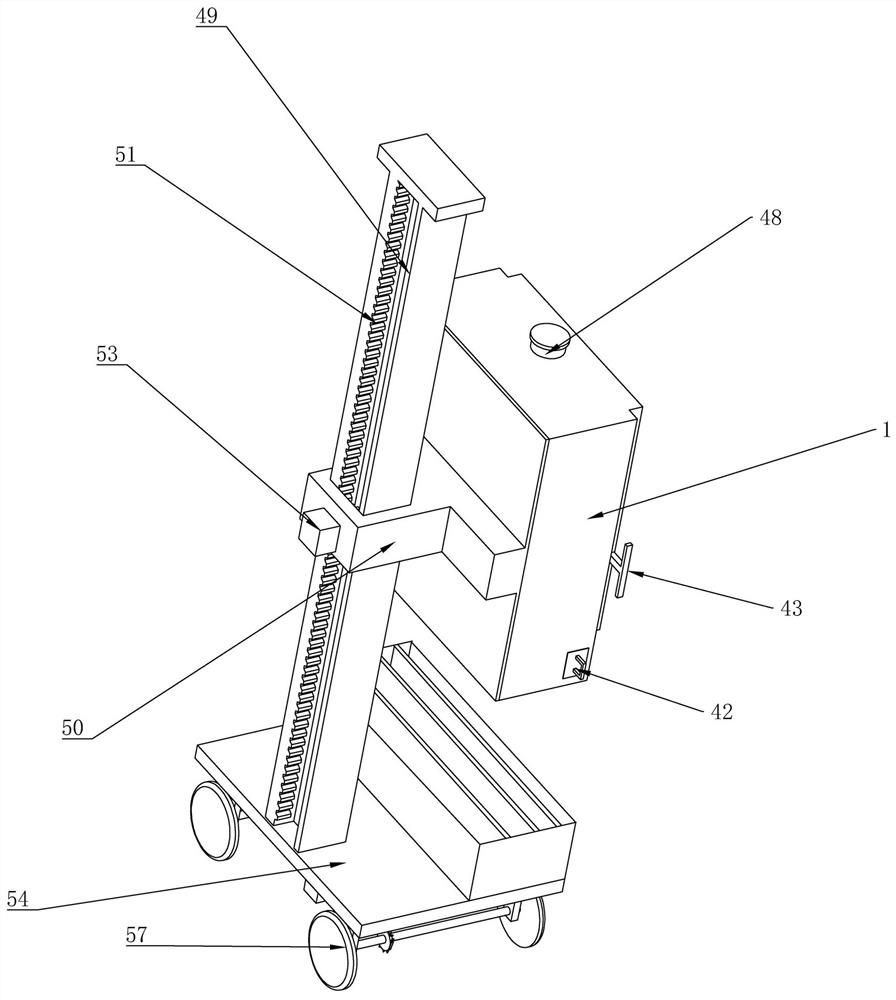

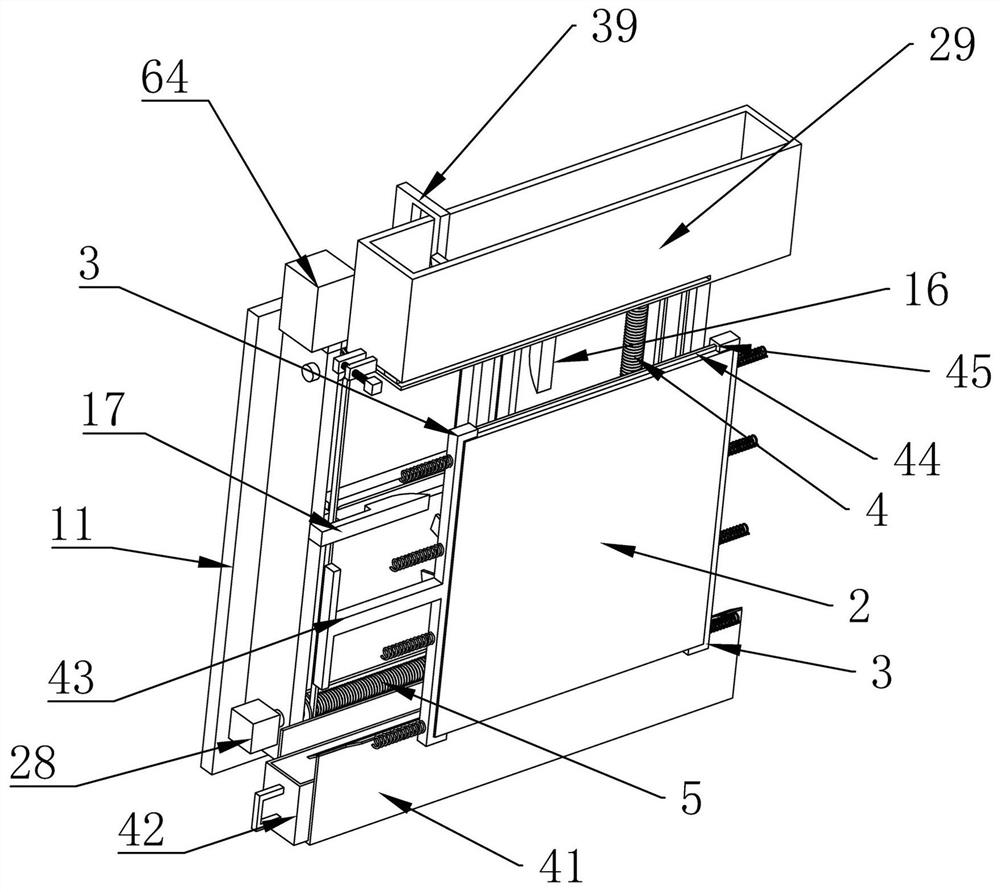

Wall printing device based on computer processing

ActiveCN112706508BOutflow smoothlyFit the actual needsScreen printersPrinting press partsScreen printingTextile printer

The invention relates to a computer big data image processing device, which effectively solves the problems that the existing device cannot automatically load materials, the efficiency of manual coating is low, and the quality of manual printing is not good; the technical solution is to include a printing cabinet, a printing There is a silk screen board on the cabinet, a fixed frame on the screen board, a lifting reciprocating screw rod on the printing cabinet, a translational reciprocating screw rod connected to the printing cabinet, and a lifting rod slidingly connected between the two lifting reciprocating screw rods. There is a translation rod slidingly connected between the two translational reciprocating screw rods. There is a printing frame on one side of the screen plate, and an upper scraper and a lower scraper are slidingly connected to the side of the printing frame. The upper scraper and the lower scraper are in contact with the screen plate. Connection; the invention spreads the paint evenly by setting a sliding printing frame, automatically feeds the material by setting a feeding trough, and adjusts the diversity of screen printing patterns through a detachable and connected screen printing plate, so that customers have more The selection space has high universality and practicality.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

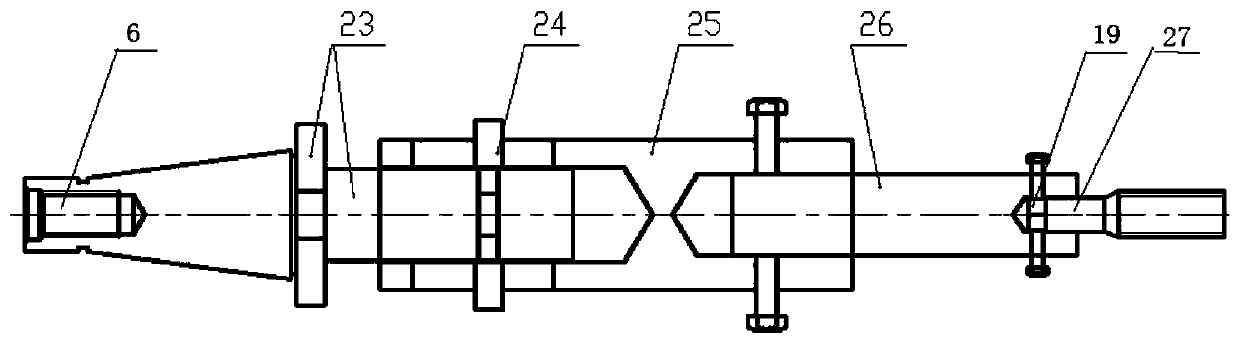

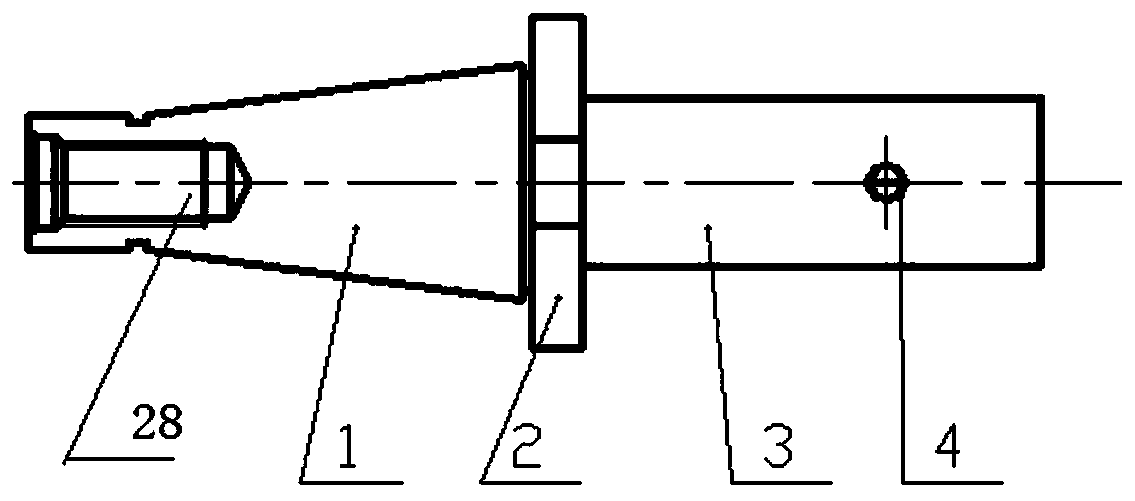

Tap fixture for tapping of milling machine

The invention relates to a tap fixture for tapping of a milling machine, which belongs to the field of mechanical processing equipment. The tap fixture for tapping of the milling machine is characterized by including a connecting head (23), a positioning pin (24), a sliding sleeve (25), and a chuck (26); the connecting head (23) is assembled and connected with a milling machine head (6); the chuck(26) is assembled and connected with a tap shank (27); and the connecting head (23) and the chuck (26) are assembled and connected through the sliding sleeve (25). The tap fixture for tapping of themilling machine is designed reasonably; after the fixture is connected to the machine head, the concentricity can be ensured, and the slide way can freely move axially; therefore, the feed rate is controllable, and the thread accuracy is ensured; and the selection and design of the diameter of each part realize the function of transmitting torque and protect the tap from breaking.

Owner:TANGSHAN IRON & STEEL GROUP +1

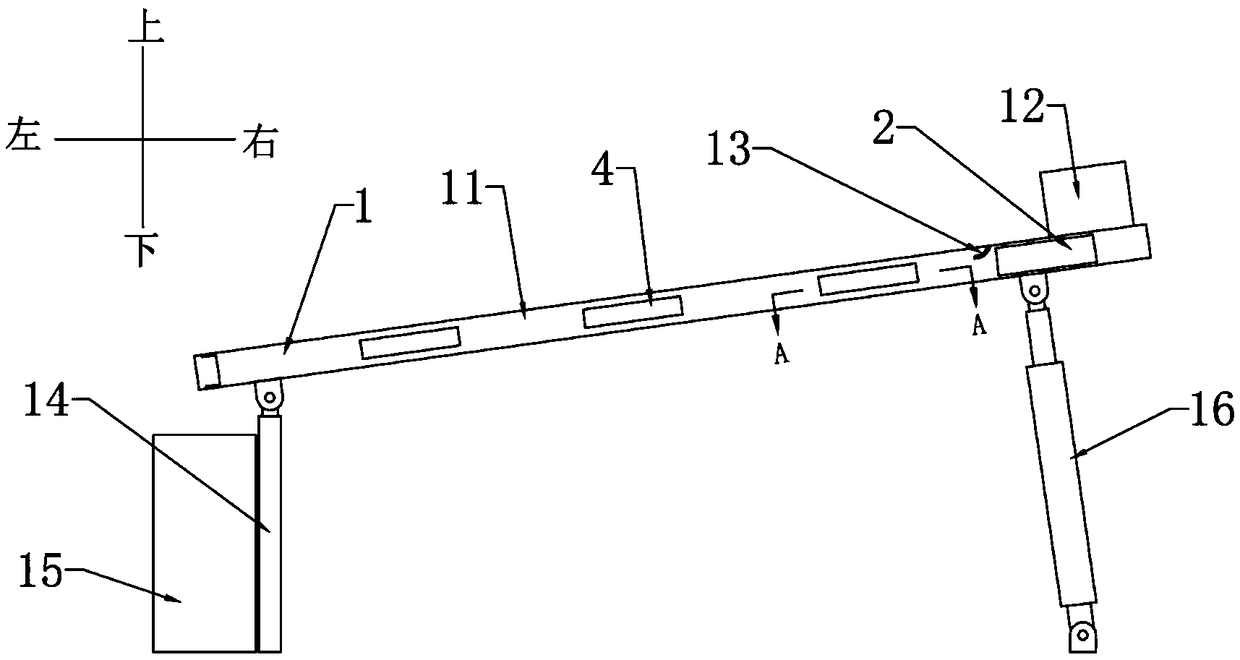

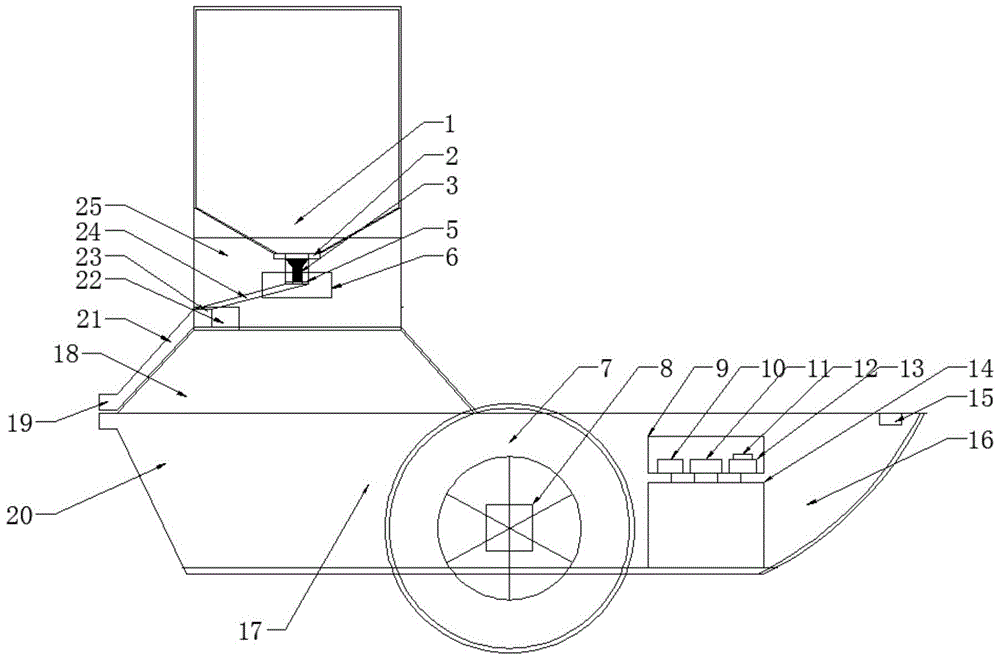

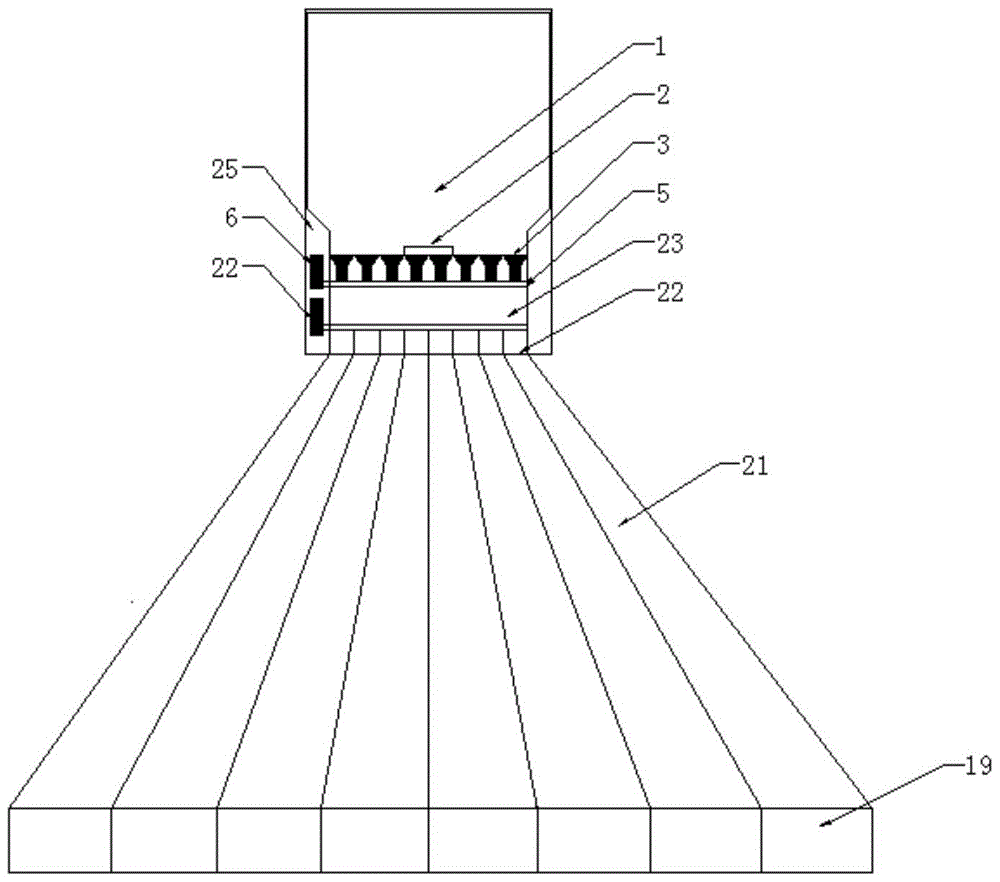

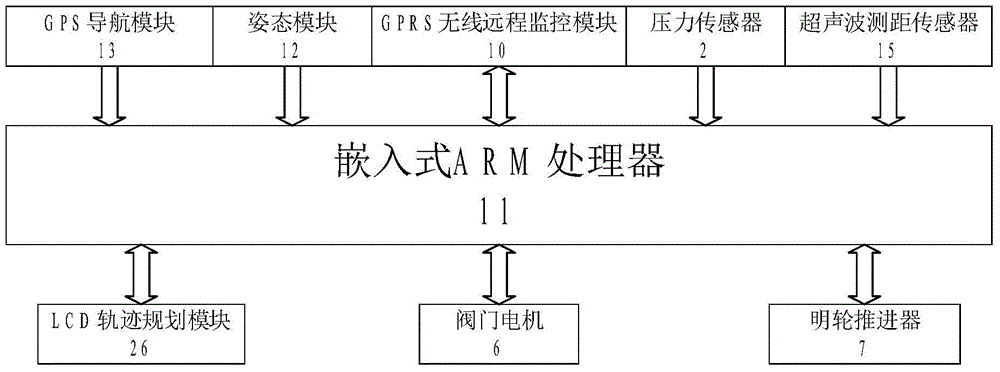

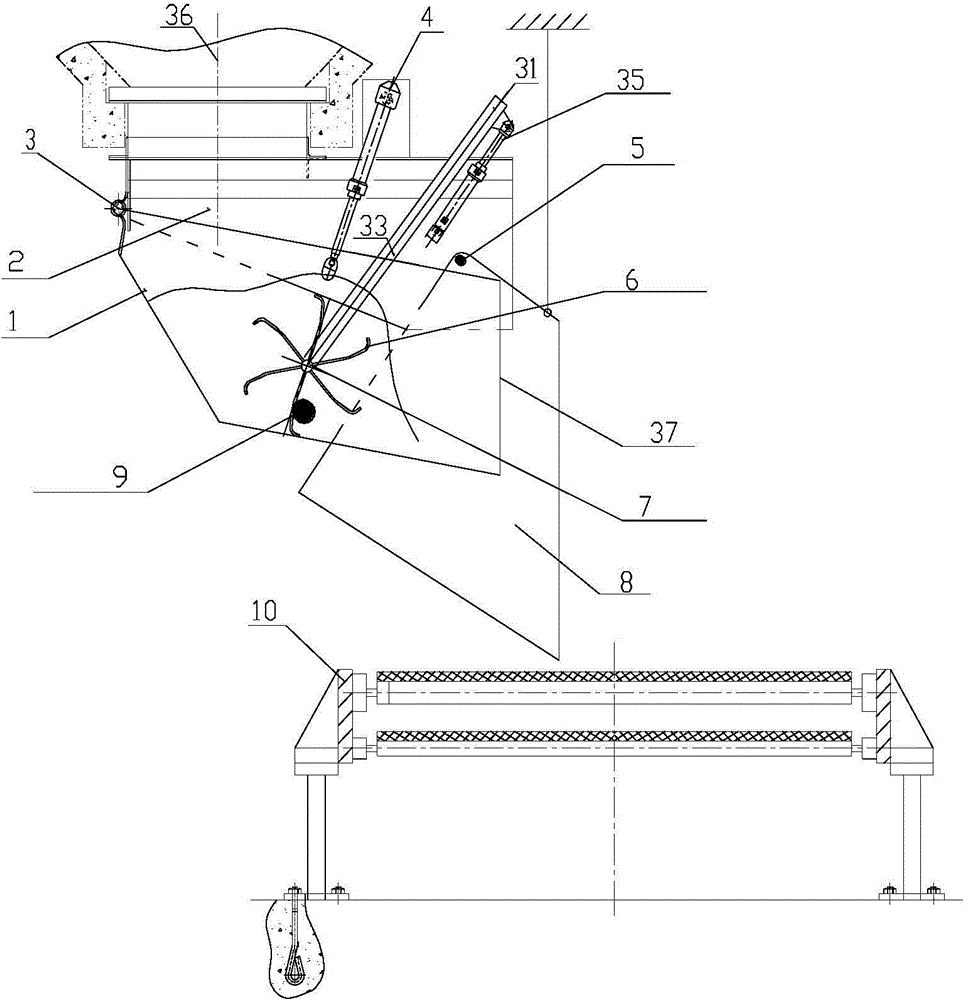

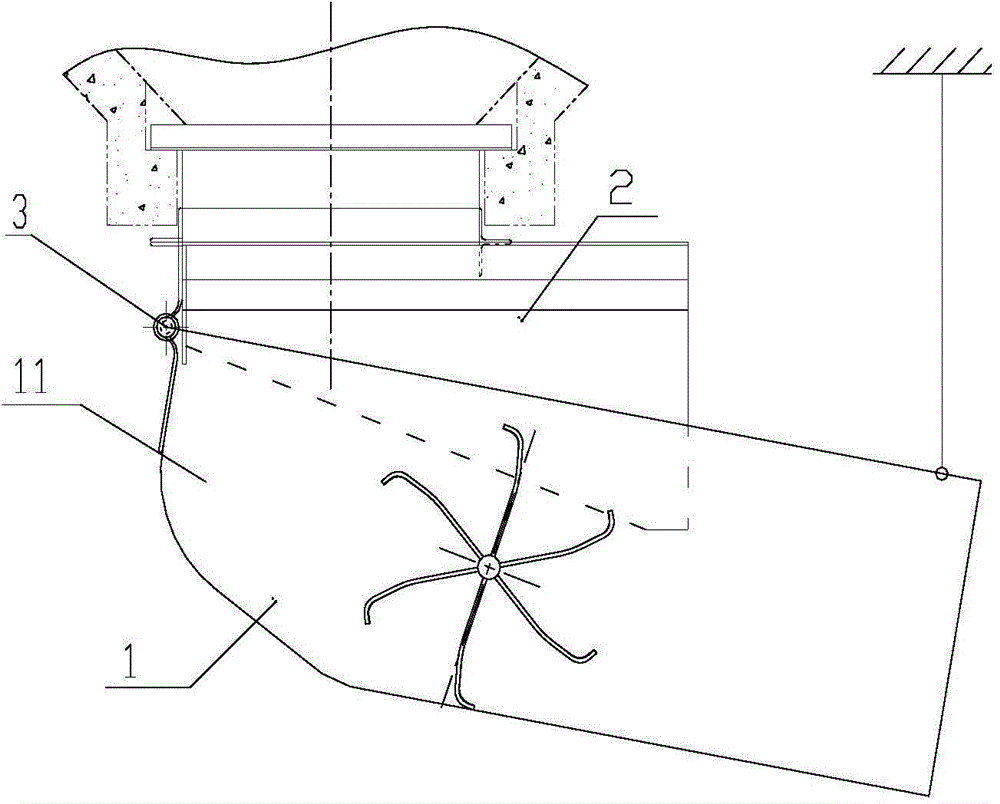

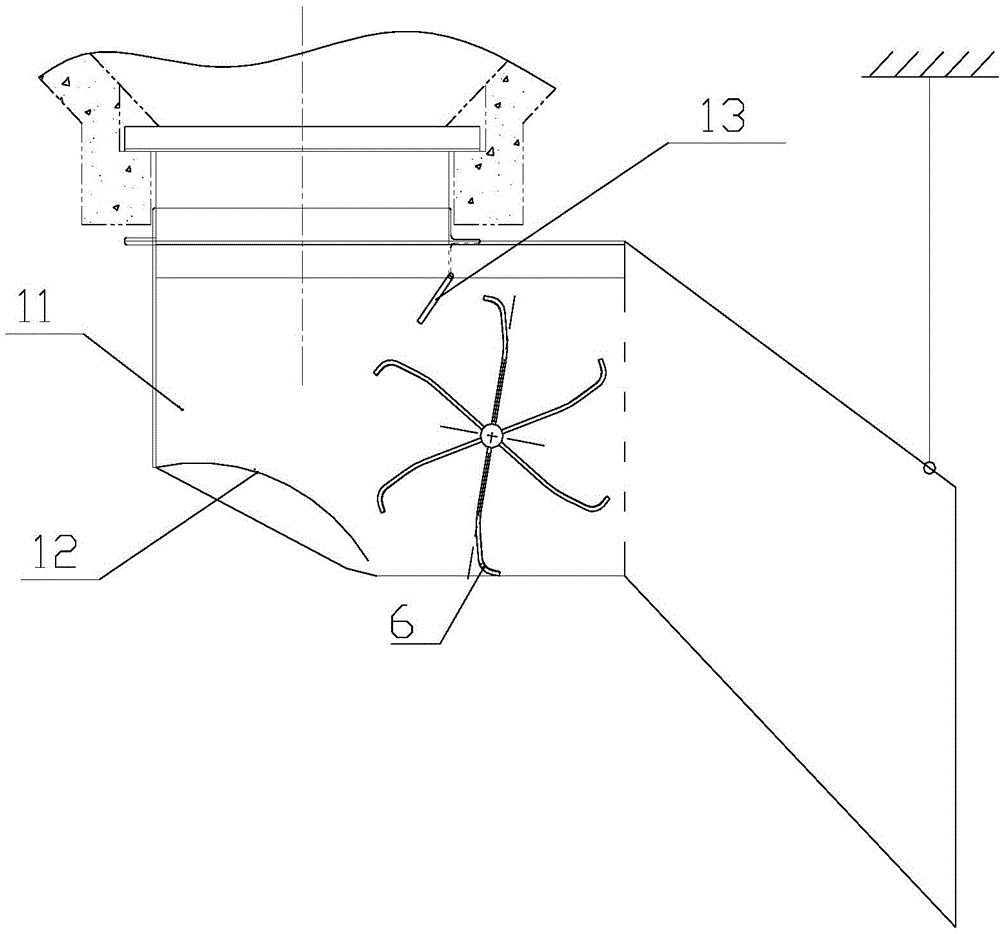

A fully automatic uniform bait casting boat for river crab breeding

ActiveCN104430188BImplement Feedback ControlEvenly distributedPisciculture and aquariaElectrical controlGps navigation

The invention provides a full-automatic uniform feeding boat for river crab culture. The full-automatic uniform feeding boat for river crab culture comprises a boat body, an automatic feeding device and an electrical control device. The automatic feeding device is arranged on the stern of the boat body and comprises a hopper, pressure sensors, a plurality of funnels, bait valves, a valve motor and a plurality of material guide pipes. The funnels are arranged at the bottom of the hopper side by side, the two sides of each funnel are both provided with the pressure sensors, the bottom of each funnel is provided with one bait valve communicated with the corresponding material guide pipe, the opening degree of each bait valve is controlled by the valve motor, and the material guide pipes obliquely extend to the outside of the stern. The electrical control device comprises an embedded ARM processor, a GPS navigation module, an attitude module, a GPRS wireless remote monitoring module and an ultrasonic distance measuring sensor, wherein the GPS navigation module, the attitude module, the GPRS wireless remote monitoring module and the ultrasonic distance measuring sensor are connected with the embedded ARM processor respectively, and the embedded ARM processor is further connected with the pressure sensors and the valve motor. According to the full-automatic uniform feeding boat for river crab culture, feedback control over the feeding amount is achieved, and track control is flexible.

Owner:江苏亦耀实业有限公司

Intensive culture method of large water surface water tank

InactiveCN105393966BIncrease productionGood yieldClimate change adaptationPisciculture and aquariaDiseaseEcological environment

The invention discloses a large-water surface water tank type intensive culturing method. Culture is conducted in independent culturing environment formed water tanks or water channels. Fishes are cultured in a large lake with net cages sleeved in the water tank; characteristics of excellent water quality of a large water surface and inadequate utilization of resource are fully utilized to output of the large water surface can be increased by 15 to 50 kg / mu and 30% of efficiency can be improved; by the use of the culturing method, diseases can be prevented, fishes can be easily caught, bait casting amount can be controlled, fodder use can be reduced, stable water temperature and quality can be achieved and influence to the ecological environment can be reduced; bait utilization rate can be effectively improved; effects on water quality of the whole large lake surface can be reduced; pollution of water quality of each independent water tank or water channel can be avoided; and besides, survival competition between the cultured fishes and local fish species can be avoided and damage to fish genetic resource can be prevented.

Owner:HUNAN UNIV OF ARTS & SCI

A rolling harrow environmental protection energy saving high efficiency feeder

ActiveCN102530579BWith self-slip functionReduce loadLoading/unloadingConveyor partsEnvironmental resistanceGrain weight

The invention belongs to the field of material conveying, and specifically discloses a feeding method and a high-efficiency and energy-saving rolling-harrow feeding machine, by which fed materials are different in grain size, unequal in grain weight, different in quality, and large and controllable in quantity. The high-efficiency and energy-saving rolling-harrow feeding machine comprises a material guide hopper and a rolling harrow, wherein the rolling harrow comprises a harrow shaft and / or harrow cylinder and the like, the harrow shaft and / or harrow cylinder and the like are arranged on the side part, upper part and / or side upper part of a material, and located between the feed end and discharge end of the material guide hopper or located outside the discharge end of the material guide hopper, and the harrow shaft and / or harrow cylinder are / is arranged perpendicular to the flow direction of the material. By using the method and machine disclosed by the invention, an effect that through setting a material-harrowing bearing and a shaft barrel outside materials, the materials are harrowed from positions beside and / or above the materials, thereby controlling the flow quantity of the materials such as coal and the like; and through real-time adjustment controlling, the purpose of improving efficiency, saving energy, and realizing the optimal feed reshipment is achieved.

Owner:刘素华

Computer big data image processing equipment

ActiveCN112706508AOutflow smoothlyFit the actual needsScreen printersPrinting press partsScreen printingTextile printer

The invention relates to computer big data image processing equipment. The problems that an existing device cannot achieve automatic feeding, the manual coating efficiency is low, and the manual operation printing effect and quality are poor are effectively solved. According to the technical scheme, the computer big data image processing equipment comprises a printing cabinet, wherein a silk screen plate is arranged on the printing cabinet; a fixing frame is arranged on the silk screen plate; lifting reciprocating lead screws are arranged on the printing cabinet; the printing cabinet is rotationally connected with translation reciprocating lead screws; a lifting rod is slidably connected between the two lifting reciprocating lead screws; a translation rod is slidably connected between the two translation reciprocating lead screws; a printing frame is arranged on one side of the silk screen plate; and an upper scraper and a lower scraper are slidably connected to one side of the printing frame and are in contact connection with the silk screen plate. According to the computer big data image processing equipment provided by the invention, by arranging the sliding printing frame, paint is evenly smeared; by arranging a discharging groove, automatic feeding is achieved; and the diversity of screen printing patterns is adjusted through the detachably-connected silk screen plate, so that more selection space is provided for customers, and high universality and practicability are achieved.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

A kind of lobster farming technique

InactiveCN105994033BPosition is easy to controlEat normallyClimate change adaptationPisciculture and aquariaAquaculture

The invention belongs to the field of aquaculture, and particularly discloses a technology for breeding lobsters. The technology comprises the steps of arranging a pond, cleaning the pond, conducting primary trial rearing, fertilizing water, conducting secondary trail rearing and conducting formal stocking. According to the technology, reasons of trial rearing failures can be easily determined, whether the problem in the pond cleaning step or in the water fertilizing step can be quickly distinguished, potential hazard can be eliminated in time, and the success rate of formal stocking can be improved.

Owner:王玉英

Lobster breeding technology

InactiveCN109220931APosition is easy to controlEat normallyClimate change adaptationPisciculture and aquariaAquacultureFertilizer

The invention belongs to the field of aquaculture and specifically discloses a lobster breeding technology. The technology comprises the steps of arrangement of a pond, cleaning of the pond, primary trial breeding, fertilizer and water management, secondary trial breeding and formal stocking. According to the technology, causes of failure of trial breeding are determined easily, convenience is provided for quickly distinguishing whether or not a problem occurs during cleaning of the pond or fertilizer and water management has a problem, potential hazards are conveniently eliminated in time, and the success rate of formal stocking is increased.

Owner:和县明信水产养殖专业合作社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com