Automatic feeder

An automatic feeding and container technology, applied in animal feeding devices, chemical instruments and methods, dissolution, etc., can solve the problems of increasing labor intensity and cumbersome process, and achieve controllable feeding duration, controllable feed amount, Effect without power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The application of the present invention will be described in detail below in conjunction with the accompanying drawings.

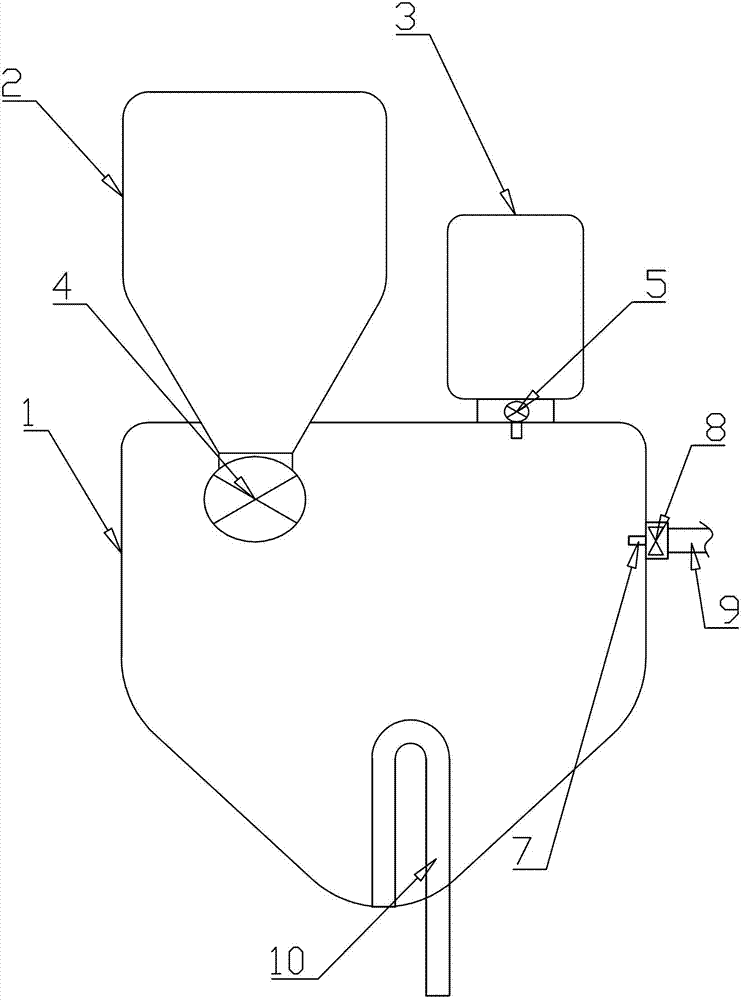

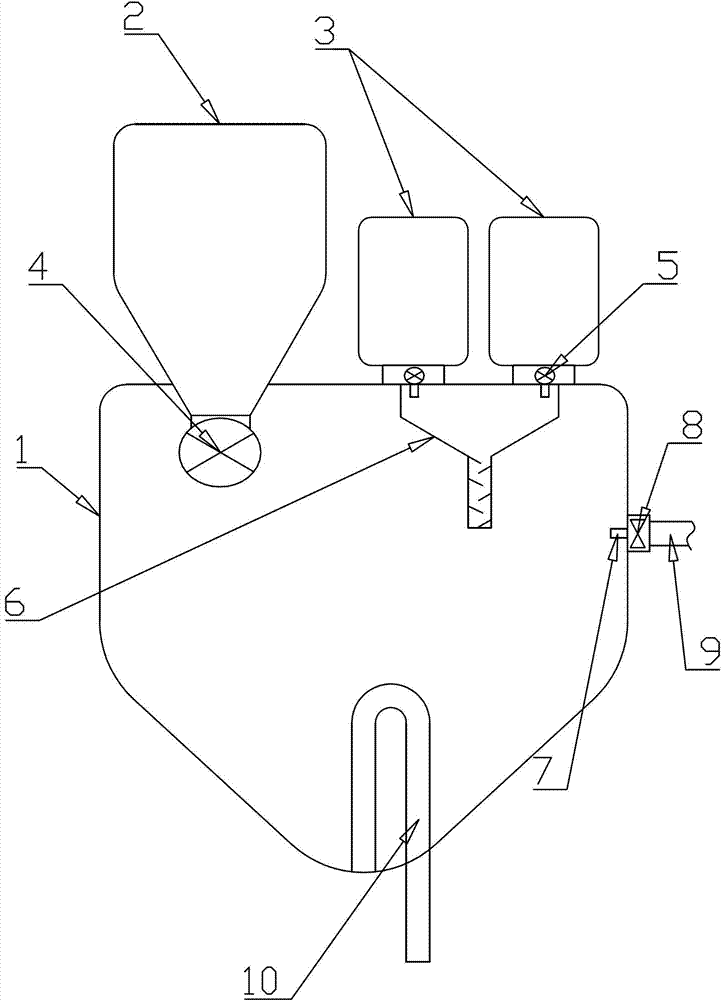

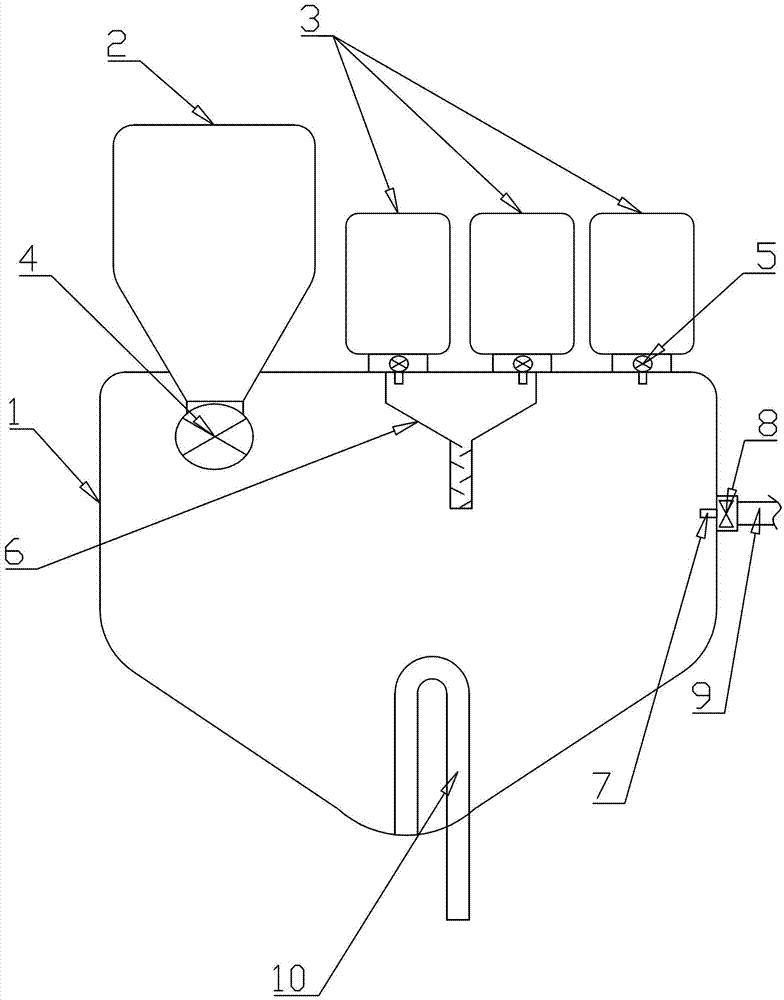

[0019] refer to figure 1 The first embodiment shown is an automatic feeder, which includes a container 1, a feed storage tank 2 installed above the container 1 and at least one liquid bottle 3 installed next to the feed storage tank 2, the feed intake of the feed storage tank 2 end and the infusion end of the liquid bottle 3 are directly or indirectly communicated with the inside of the container 1, the feeding end of the feed storage tank 2 is also equipped with an automatic switch device 4 for timing feeding, and the side wall of the container 1 is provided with a water inlet 7 , The bottom wall of the container 1 is equipped with a siphon discharge device for discharging the mixture in the container 1 to the outside of the tank.

[0020] By installing an automatic switch device 4 for timing feeding at the feeding end of the feed storage tank 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com