A rolling harrow environmental protection energy saving high efficiency feeder

An environmentally friendly and energy-saving feeder technology, applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems of difficult position adjustment of the whole machine, easy wear of the bottom plate of the hopper, and easy jamming of the scraper chain. Achieve the effects of flexible and convenient material cleaning, quick and easy maintenance, and reduction of environmental pollution and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

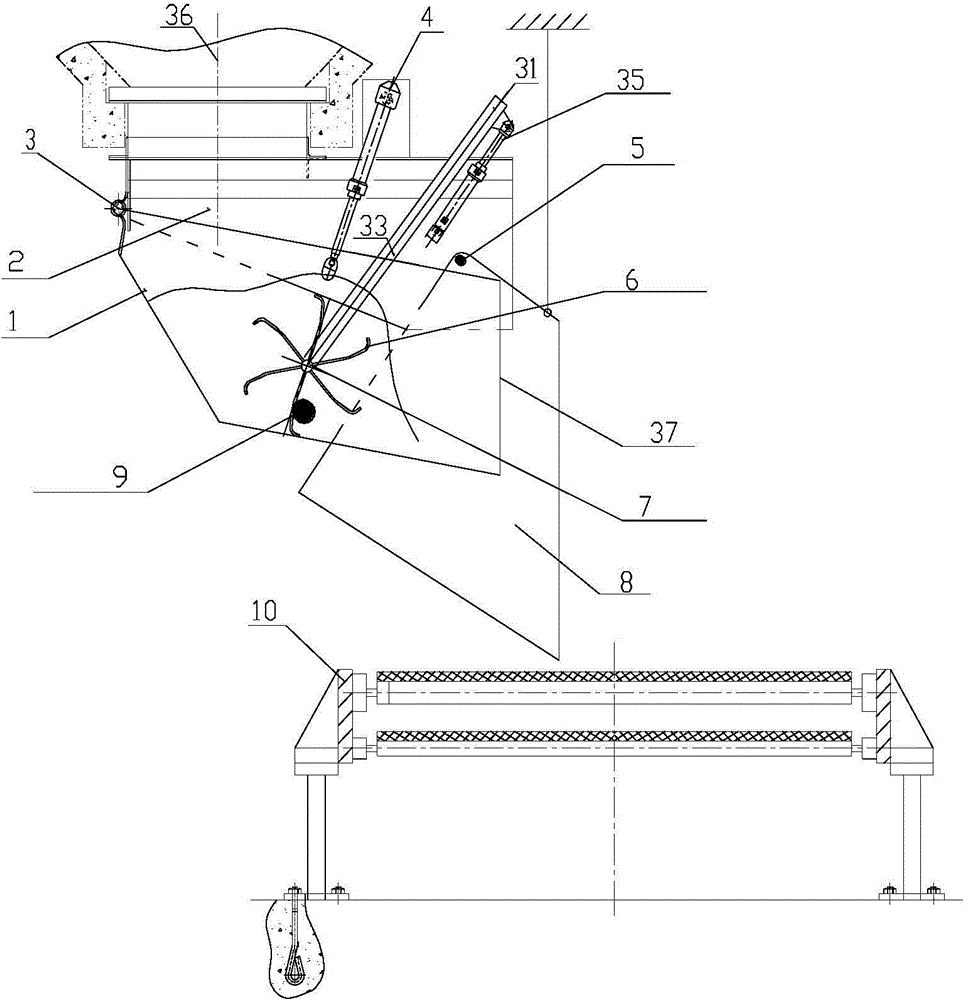

[0046] figure 1 It is the roller harrow environmental protection energy saving high efficiency feeder described in embodiment 1. The feeder includes a guide hopper, the guide hopper includes a fixed guide hopper 2 and a rotating guide hopper 1, the top of the fixed guide hopper 2 is connected to the discharge port, and the rotating guide hopper 1 is located below the fixed guide hopper 2, and through the rotation of the side The shaft I3 and the variable inclination control system are rotationally connected with the fixed guide hopper 2. The tilt angle control system adopted in this embodiment is the hydraulic cylinder 4 . In addition, the variable inclination control system can also use cylinders, lead screws, sprockets and chains, hydraulic jacks, ropes and rope reels, gears and racks, positionable slideways, sliding hanging bars, hanging holes, or any of the above components. Combination, etc., that is, a multi-level variable inclination control system is formed to ensure...

Embodiment 2

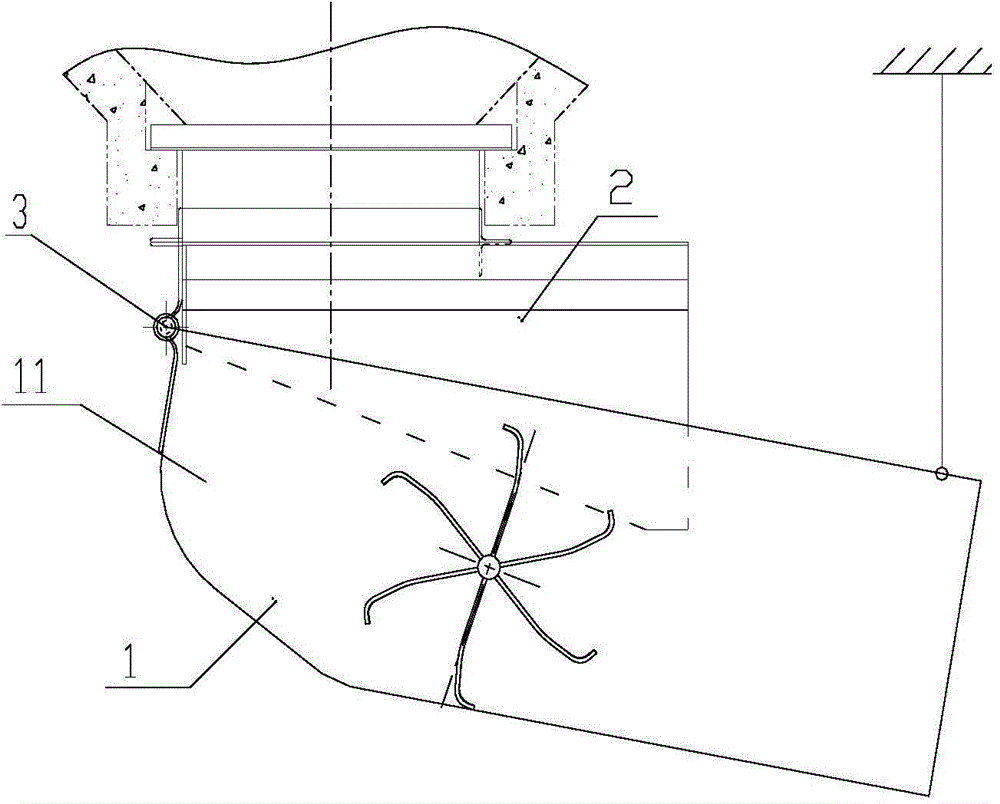

[0053] figure 2 It is the roller harrow environmental protection energy-saving high-efficiency feeder described in embodiment 2. The difference from Embodiment 1 is that the guide hopper 11 in this embodiment is an integral variable-angle type, that is, the guide hopper 11 includes a rotating guide hopper 1 and a fixed guide hopper 2, and the rotary guide hopper 1 and the fixed guide hopper 2 pass through the side The rotation axis I3 is connected.

[0054] Others are with embodiment 1.

Embodiment 3

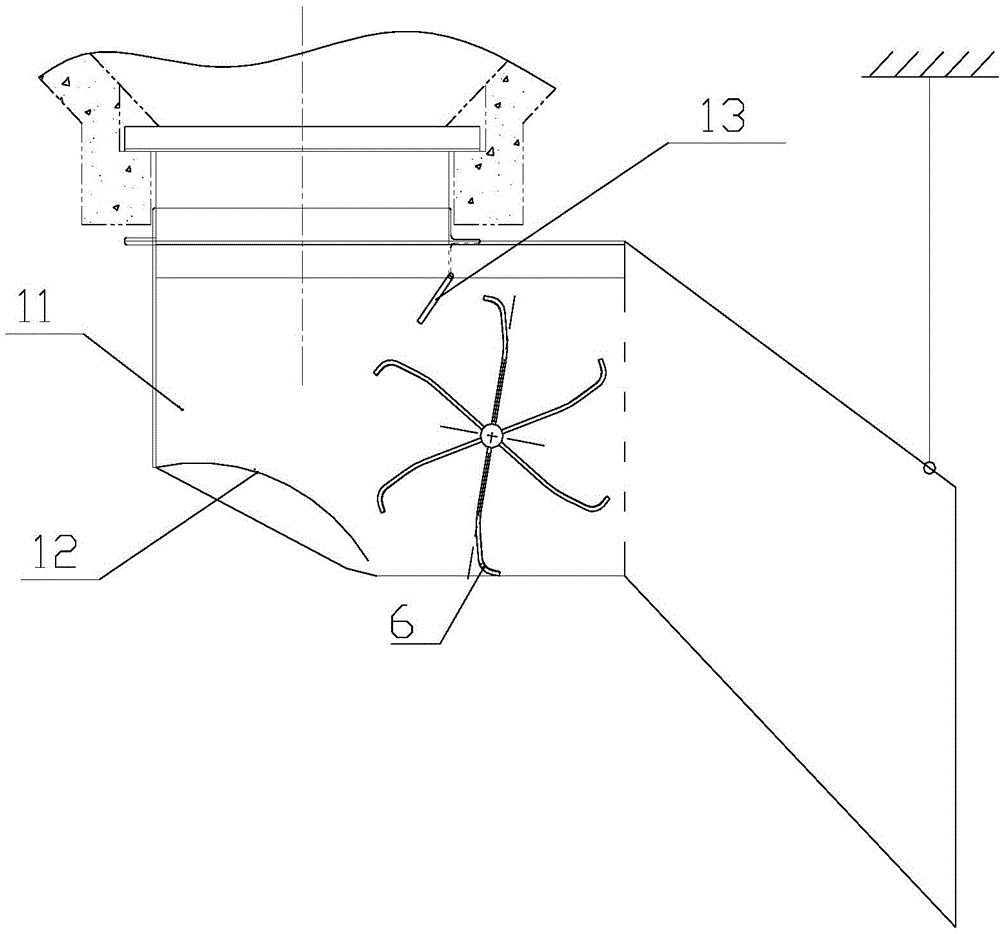

[0056] image 3 It is the roller harrow environmental protection energy-saving high-efficiency feeder described in embodiment 3. The difference from Embodiment 1 is that the guide hopper 11 in this embodiment is a knuckle self-sliding type, that is, the discharge end of the guide hopper 11 is provided with a downward knuckle part, that is, the inclination angle at the bottom of the material receiving part of the guide hopper 11 is less than The bottom of the discharge end is chamfered. The self-sliding of the material is more convenient through the corner part, and the energy consumption is reduced. The bottom of the hopper 11 is provided with an anti-smashing device 12 towards the feeding end of the hopper to prevent the material from dropping a large impact on the hopper. The anti-smashing device can be an elastic steel plate or the like. The top of the front part of the rolling rake 6 is provided with a material retaining plate 13, and one end of the material retaining pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com