Patents

Literature

34results about How to "Damage fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

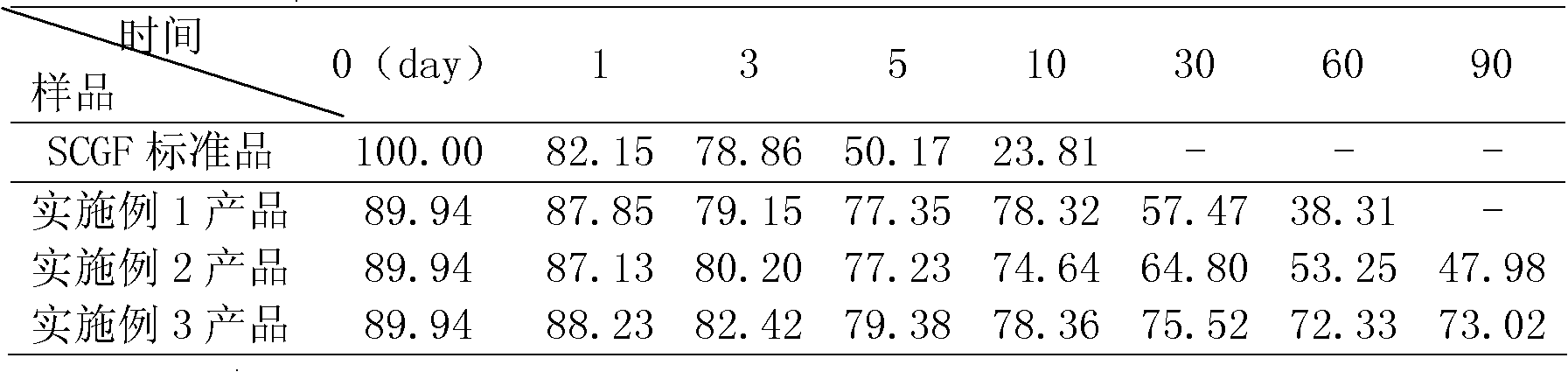

HSCGF liposome as well as preparation and application thereof

ActiveCN102512370AKeep aliveImprove stabilityCosmetic preparationsHair removalCholesterolPhospholipid

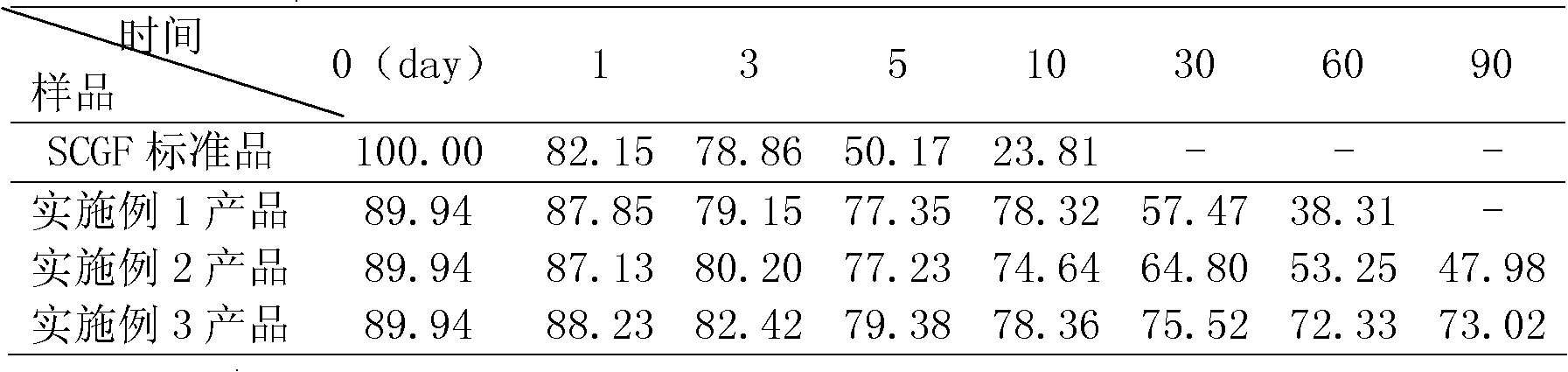

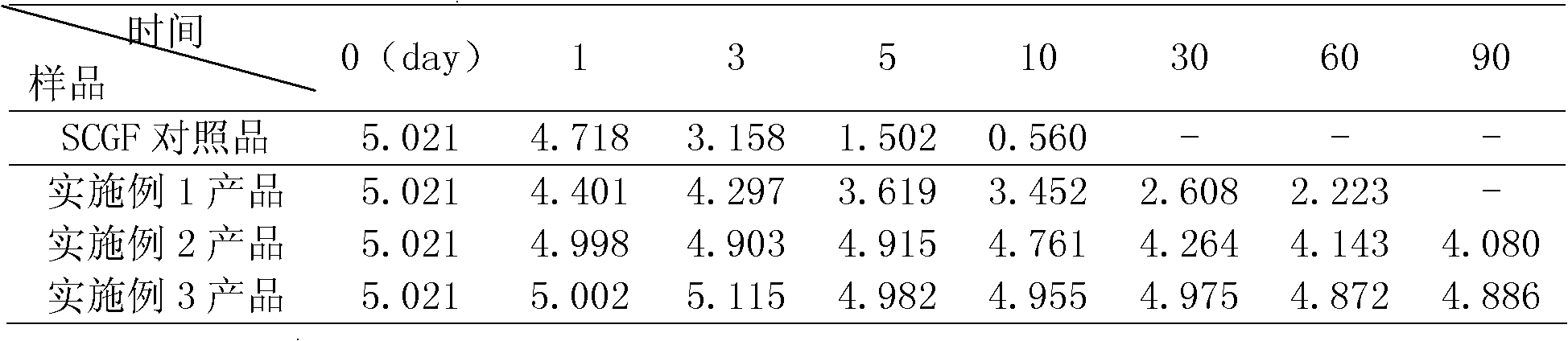

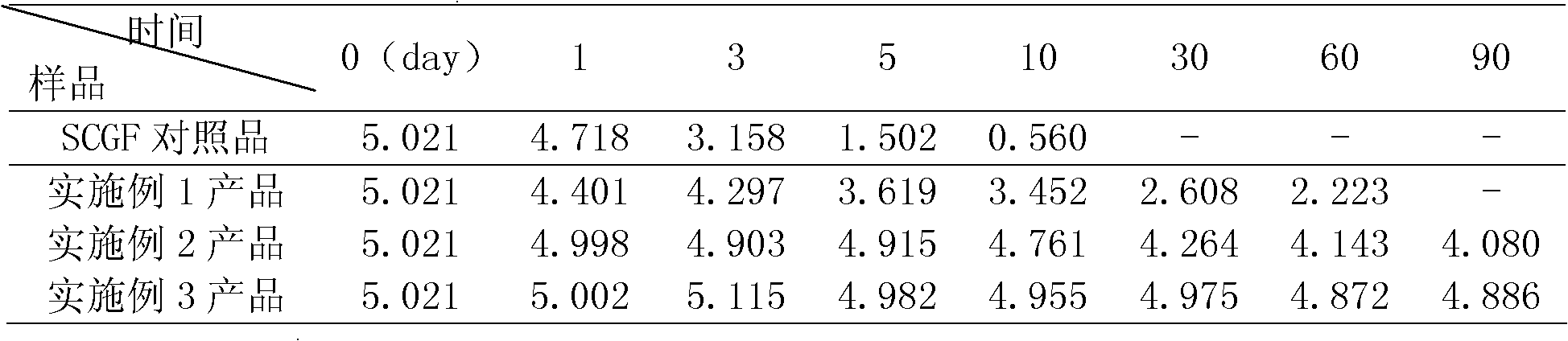

The invention discloses an HSCGF (Human Stem Cell Growth Factor) liposome as well as the preparation and the application thereof. The HSCGF liposome comprises 2.0 to 4.0 percent of HSCGF, 8.0 to 10.0 percent of phosphatide, 2.5 to 3.5 percent of cholesterol and 10 to 25 percent of protecting agents. The HSCGF is prepared into liposome, the activity of the HSCGF is kept effectively, the stability of SCGF (Stem Cell Growth Factor) can be improved obviously, skin can be promoted to absorb and utilize the SCGF, and the HSCGF liposome has the advantages of good affinity, no toxicity or side effects, and wide application range. The anti-wrinkle performance of cosmetics containing the HSCGF coated with the liposome can still be kept well after the stability is examined for three months. The HSCGF liposome is used as raw material and other active materials and auxiliary materials are used as supplements so as to prepare frequently-used medicine forms to illustrate the drug effect of the SCGF, so that the bioavailability can be improved.

Owner:GUANGZHOU SALIAI BIOLOGICAL GENETIC ENG CO LTD

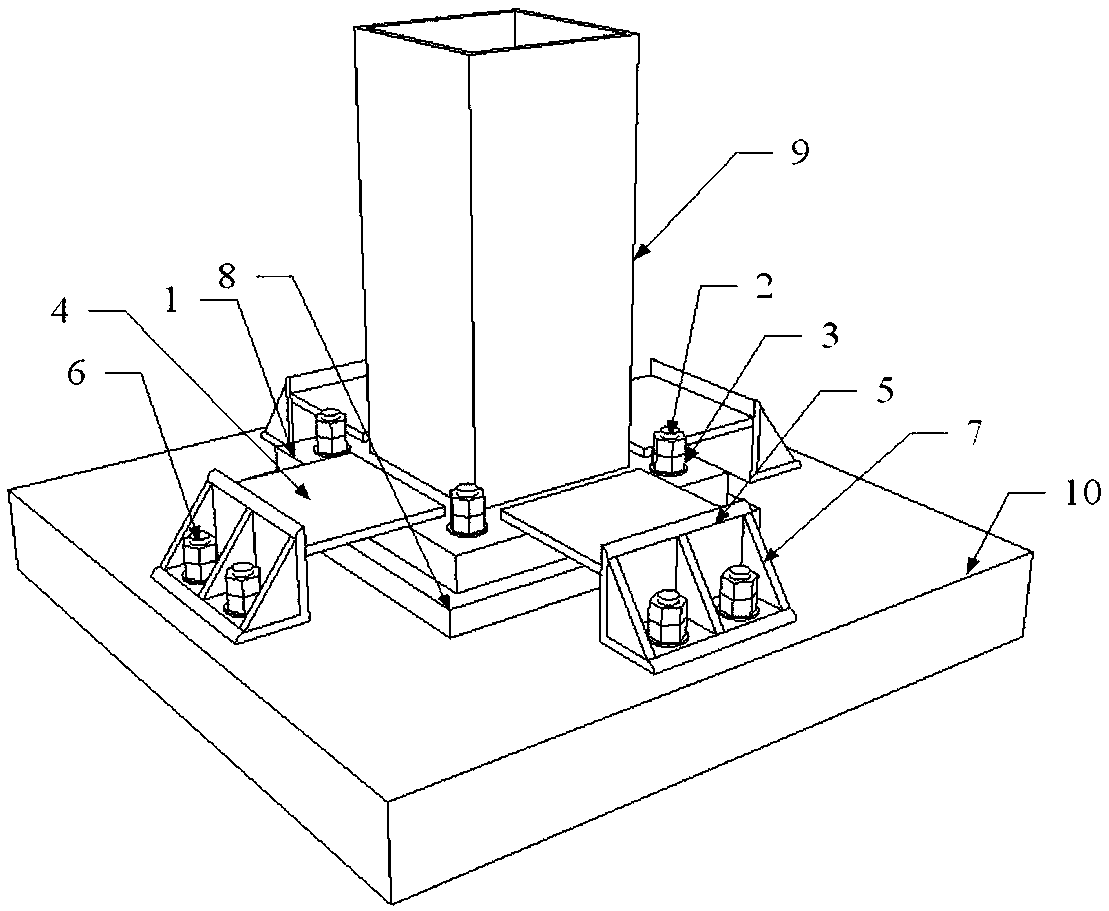

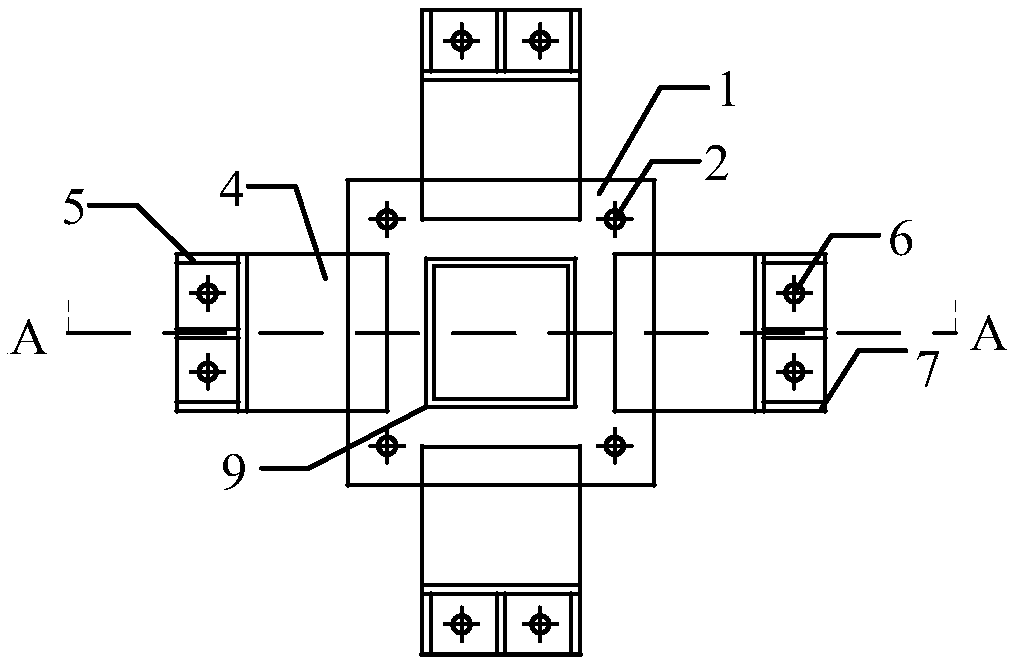

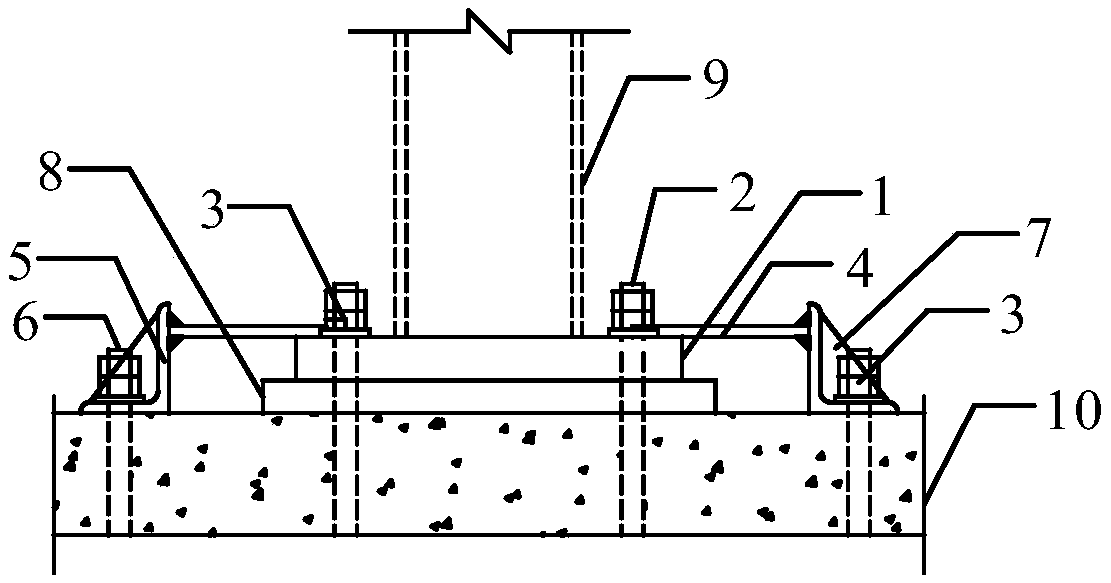

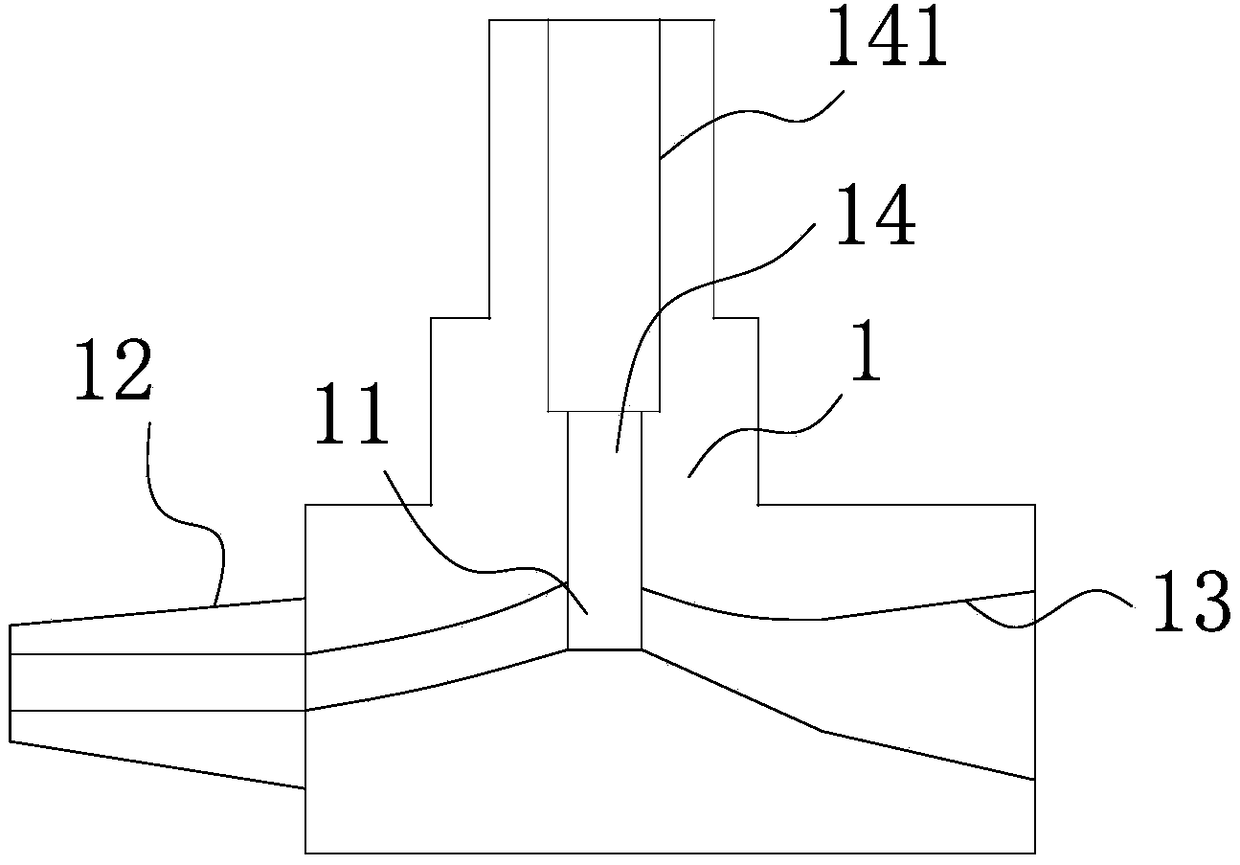

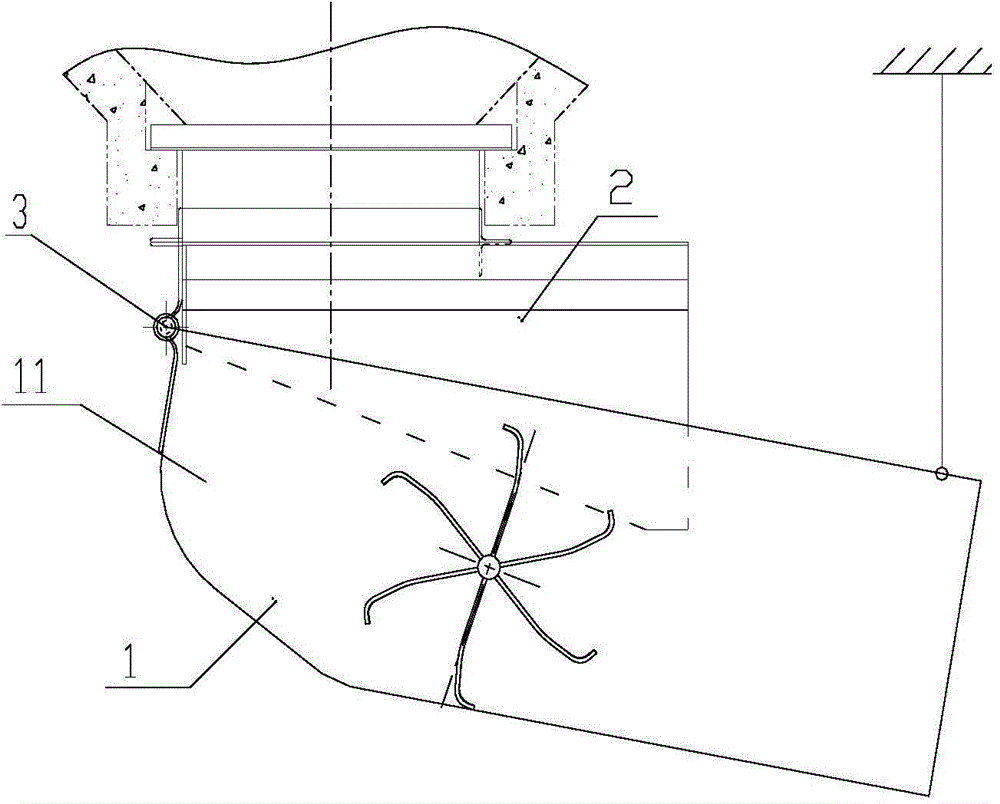

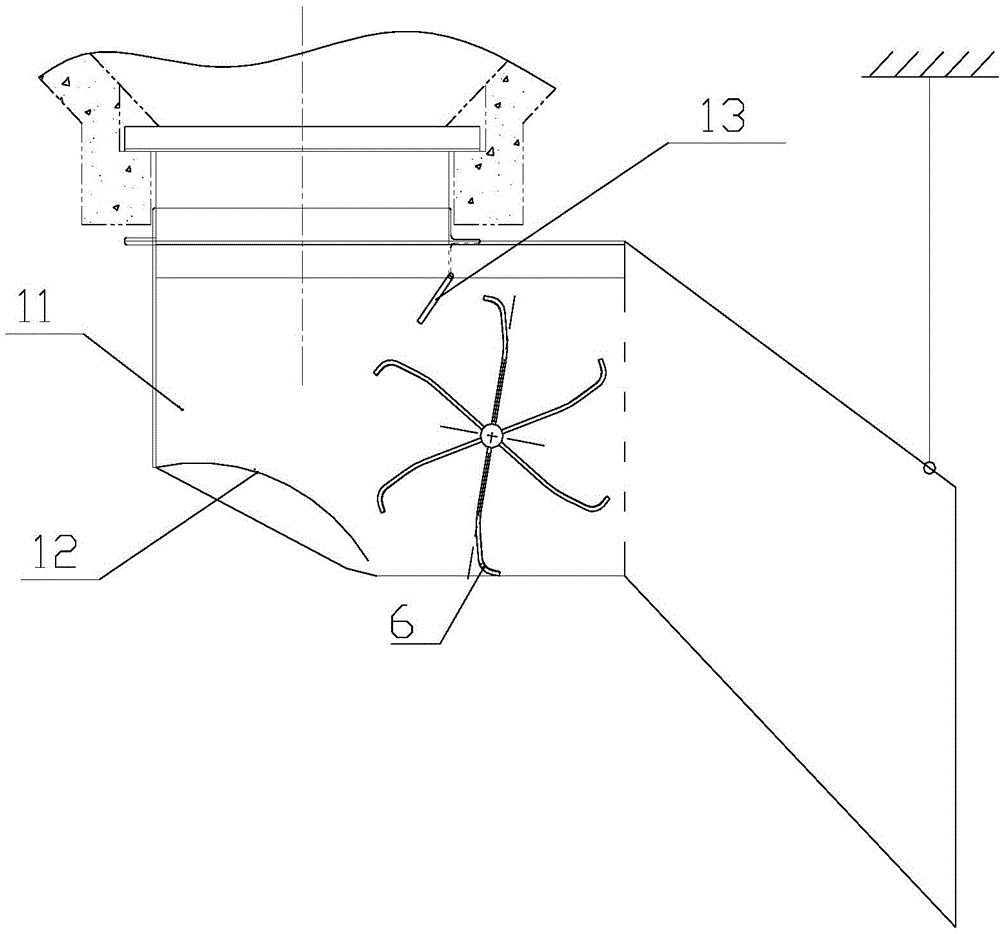

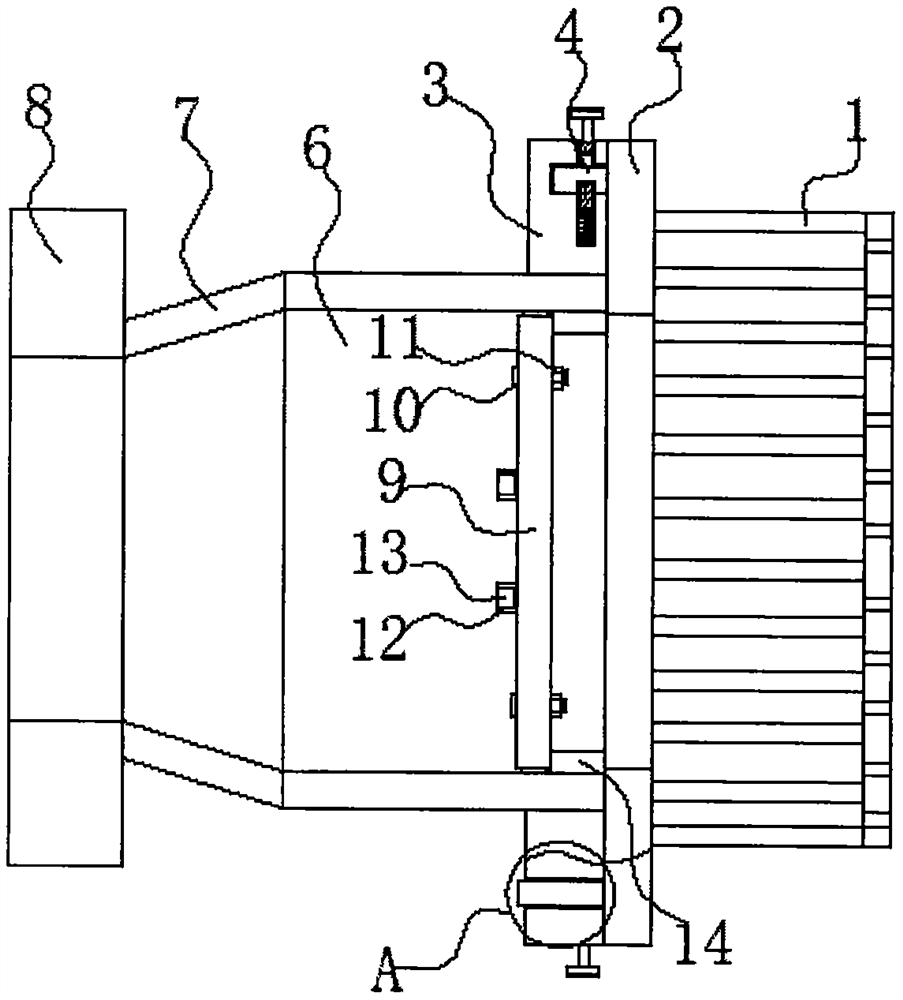

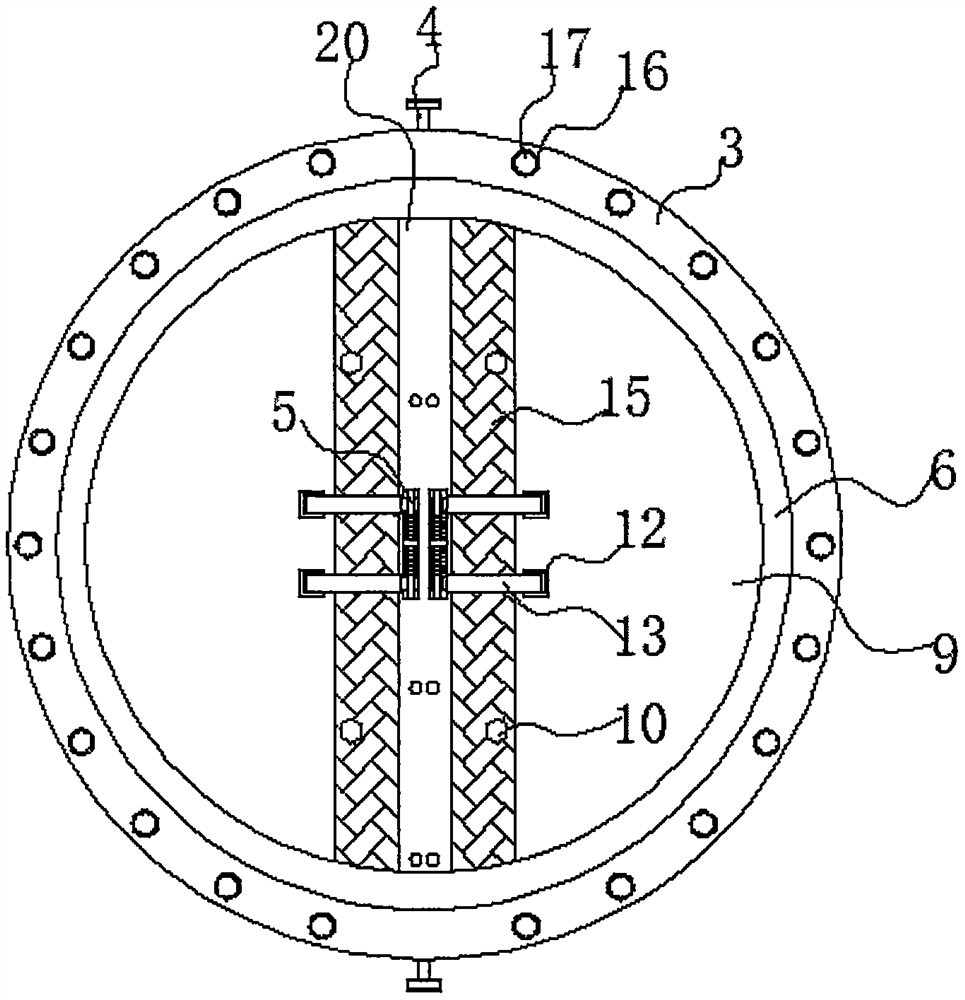

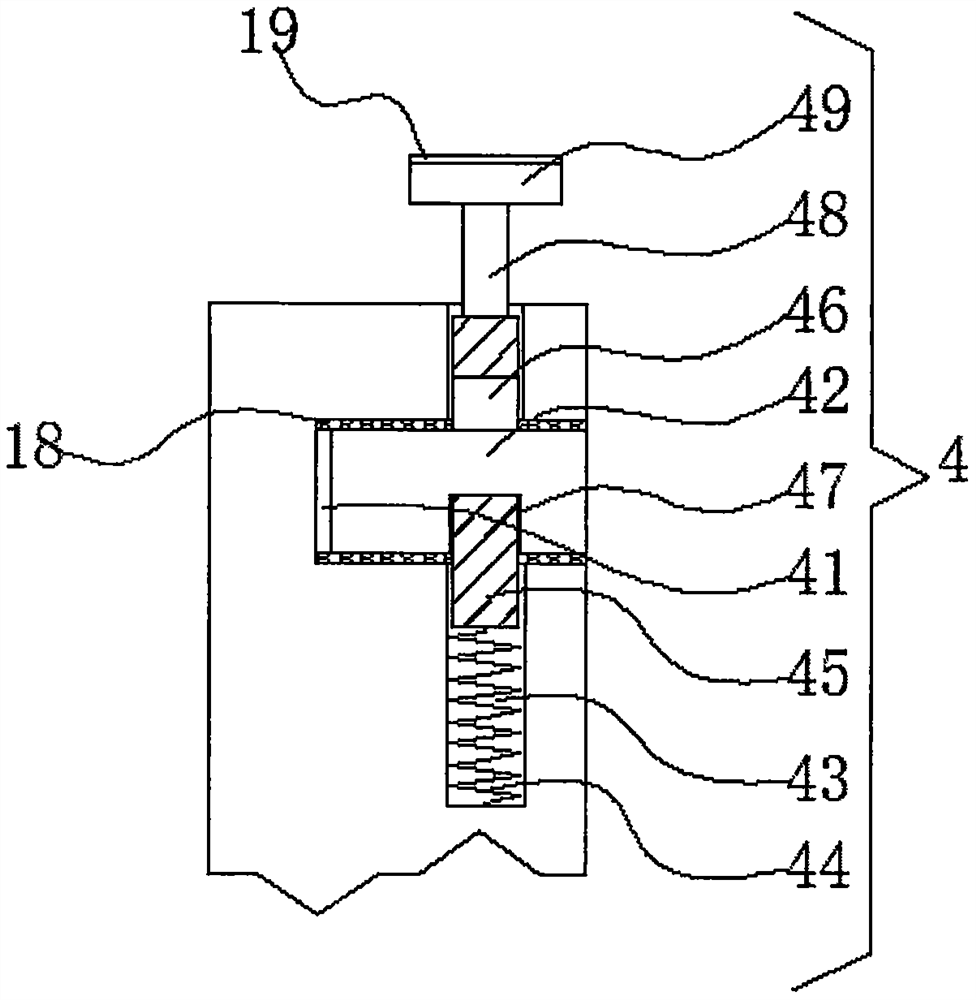

High-energy-consumption exposed steel column foot capable of being quickly repaired after earthquake and construction and maintenance method thereof

PendingCN108756005ADamage controllableQuick changeFoundation engineeringProtective buildings/sheltersHigh energySteel columns

The invention relates to a high-energy-consumption exposed steel column foot capable of being quickly repaired after an earthquake and a construction and maintenance method thereof. The high-energy-consumption exposed steel column foot comprises a concrete foundation, a mortar cushion, a steel column bottom plate and outer bottom plates which are arranged on the periphery of a steel column, wherein the concrete foundation, the mortar cushion, the steel column bottom plate and the outer bottom plates are arranged from bottom to top. The outer bottom plates are connected with the concrete foundation through angle steel; the top corner and one edge of each piece of angle steel are located on the concrete foundation; one end of each outer bottom plate is connected with the steel column bottomplate, the other end of each outer bottom plate is connected with the other edge of the corresponding angle steel; inner foundation anchor bolts penetrate through the steel column bottom plate and themortar cushion to be pre-embedded into the concrete foundation; and outer foundation anchor bolts penetrate through the angle steel to be pre-embedded into the concrete foundation. The high-energy-consumption exposed steel column foot capable of being quickly repaired after the earthquake has good earthquake-resistant performance and energy consumption capability, and the quick repairing capability, is easy to construct, controllable in damage, high in energy consumption capability and capable of reducing structural damage under the earthquake effect, and has high engineering application value.

Owner:DALIAN UNIV OF TECH

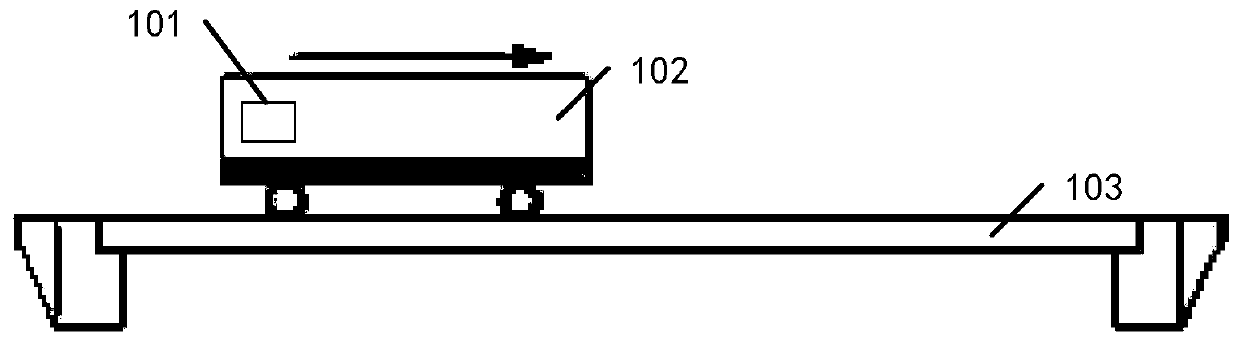

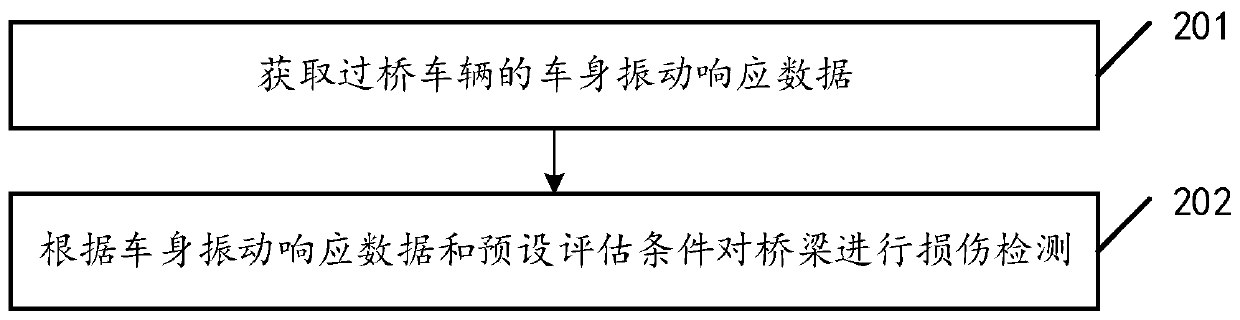

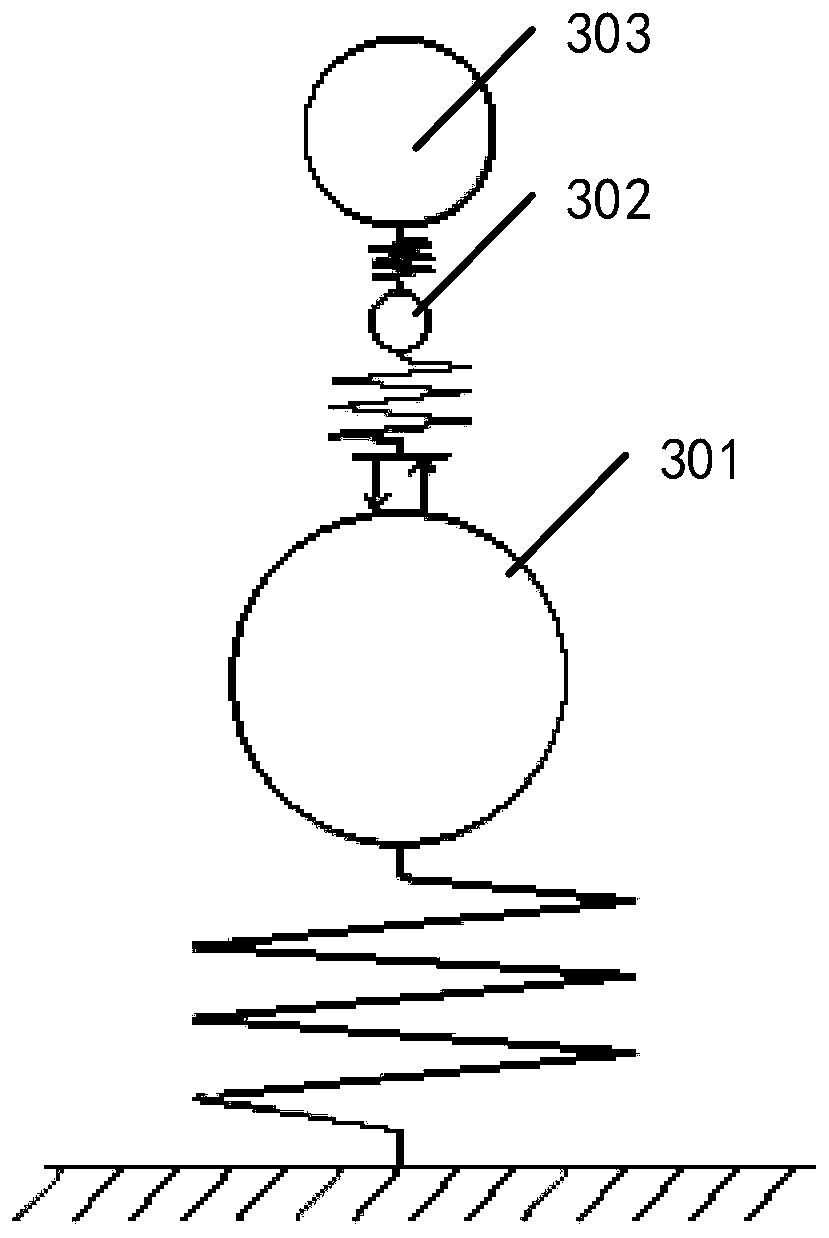

Method for quickly detecting damage to bridge and related devices

ActiveCN111373252ADamage fastEasy maintenanceAnalysing solids using sonic/ultrasonic/infrasonic wavesComputer scienceBody vibration

The embodiment of the application discloses a method for quickly detecting damage to a bridge and related devices. Through the embodiment of the application, the bridge is tested for damage based on the vehicle body vibration response data and preset evaluation conditions of the vehicle passing the bridge. The response data is easier to obtain and maintenance is convenient. Therefore, it can effectively improve the speed and portability of the bridge indirect damage identification method.

Owner:HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN (INSTITUTE OF SCIENCE AND TECHNOLOGY INNOVATION HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN)

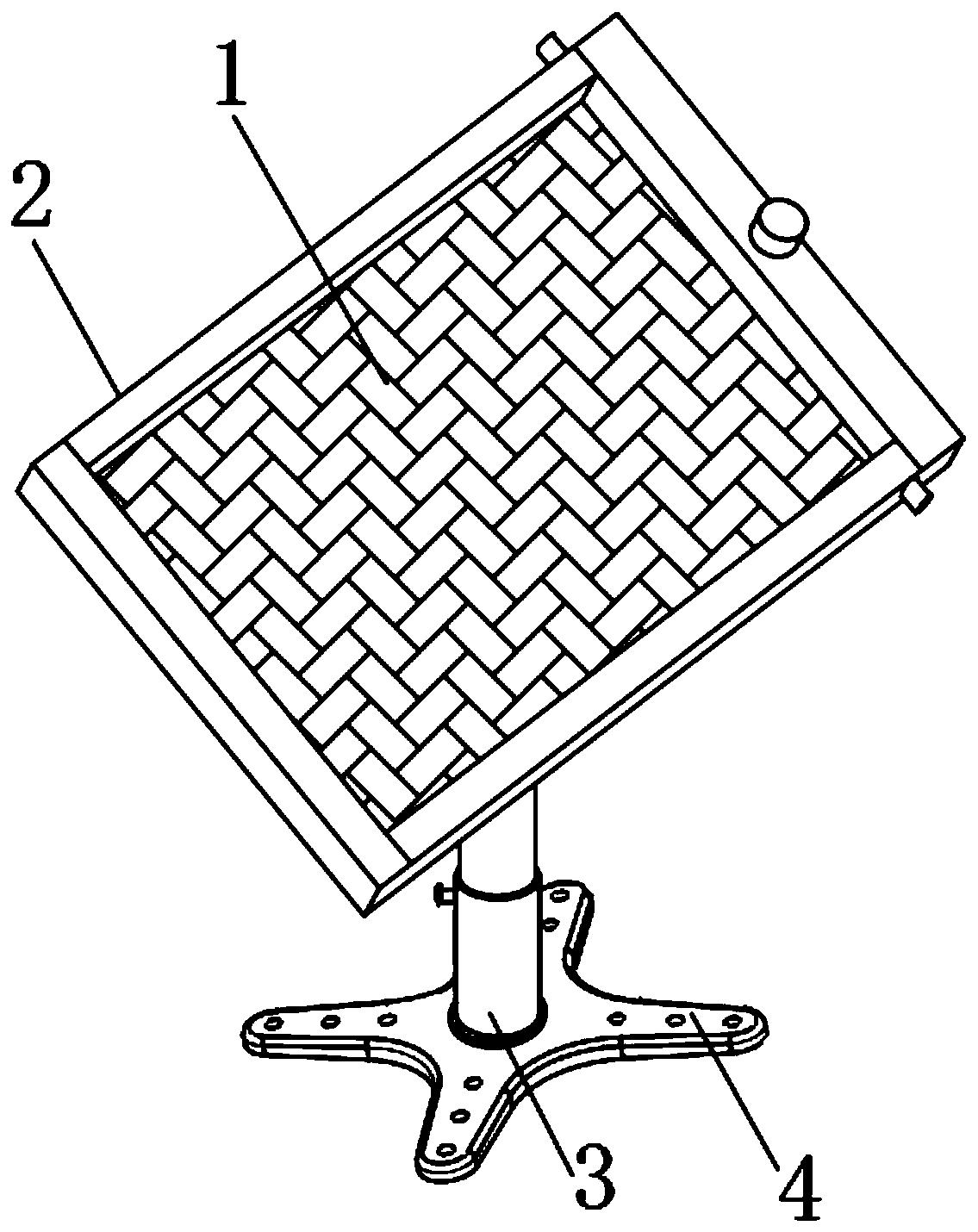

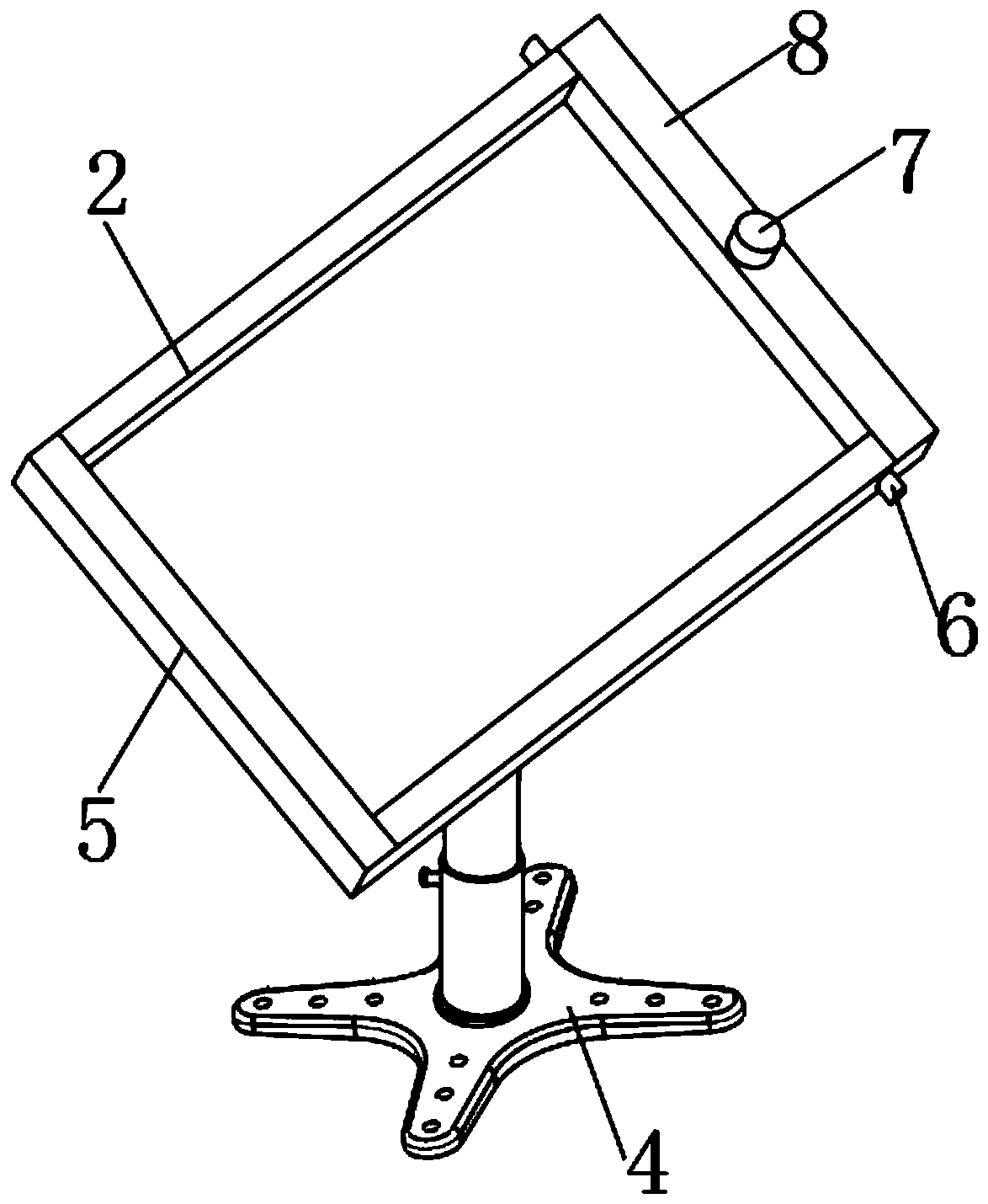

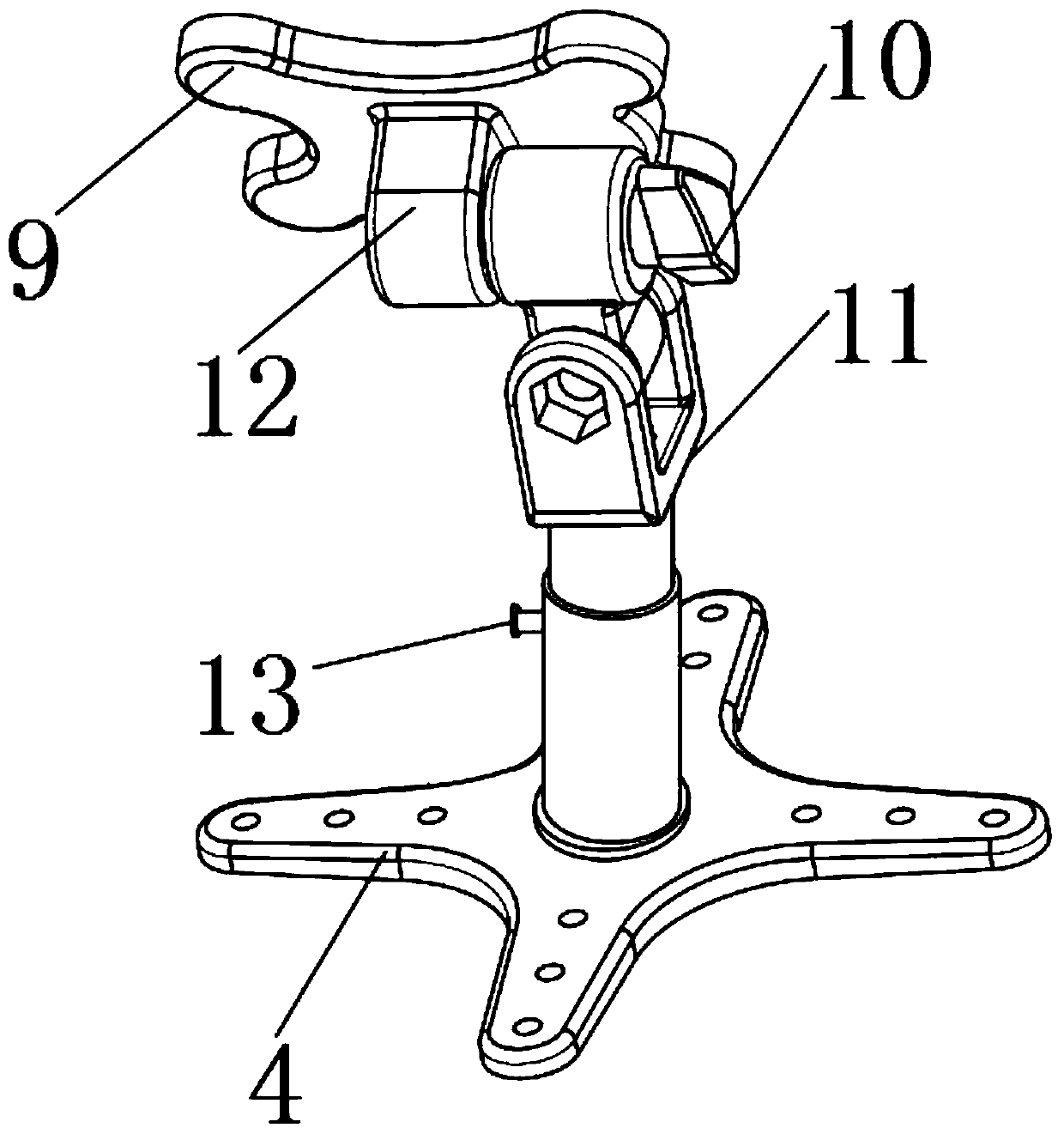

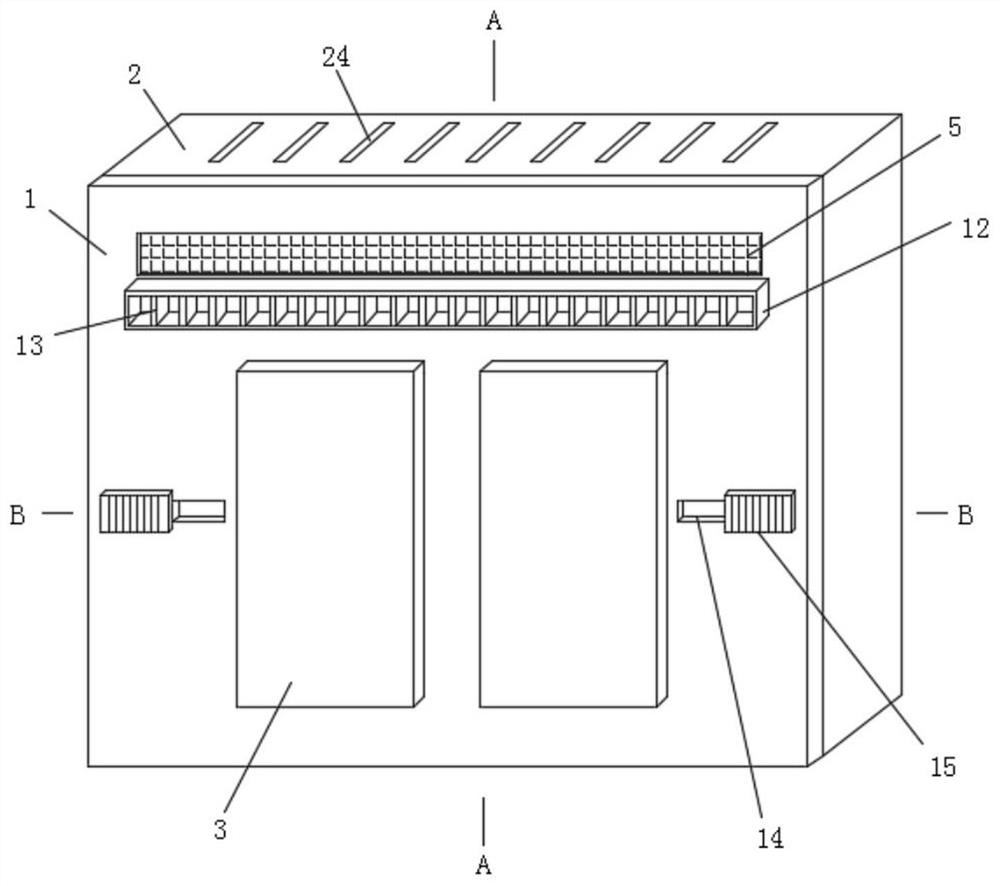

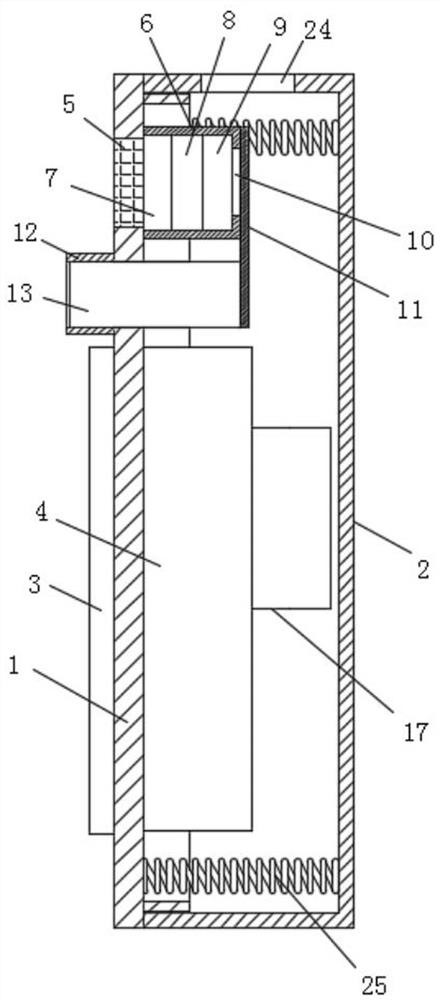

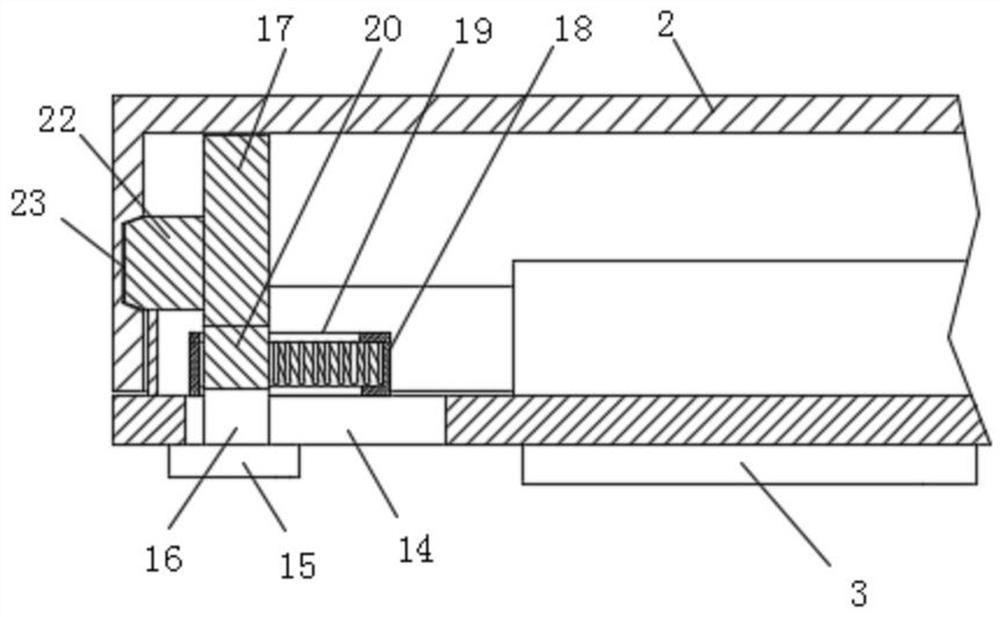

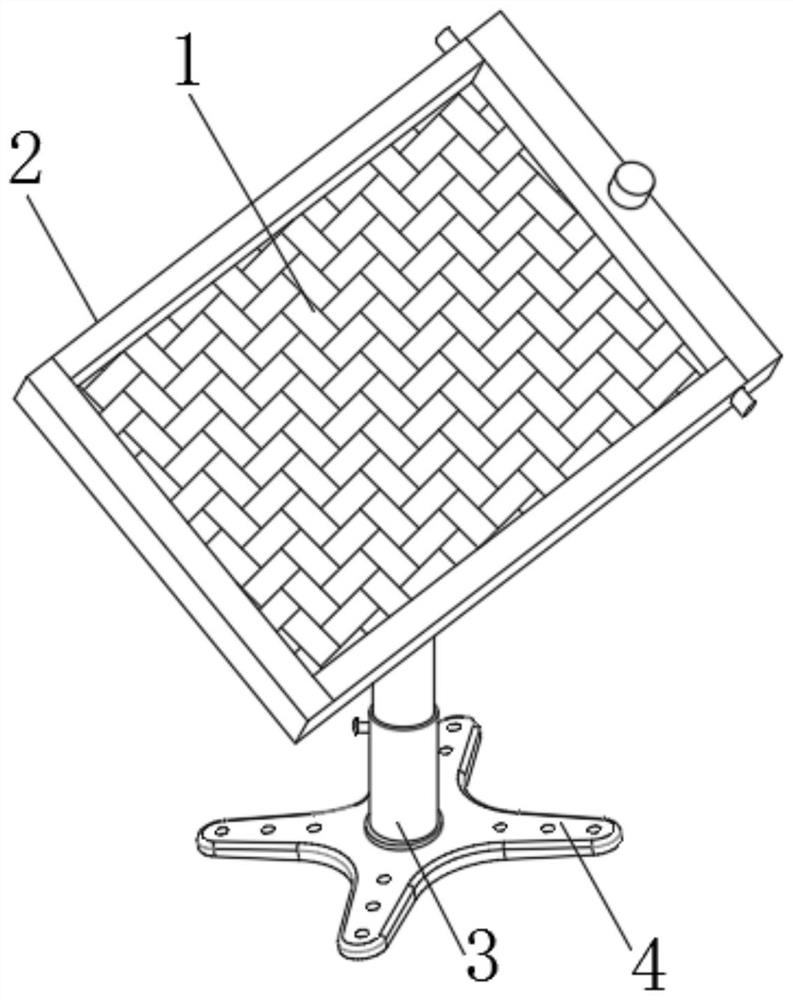

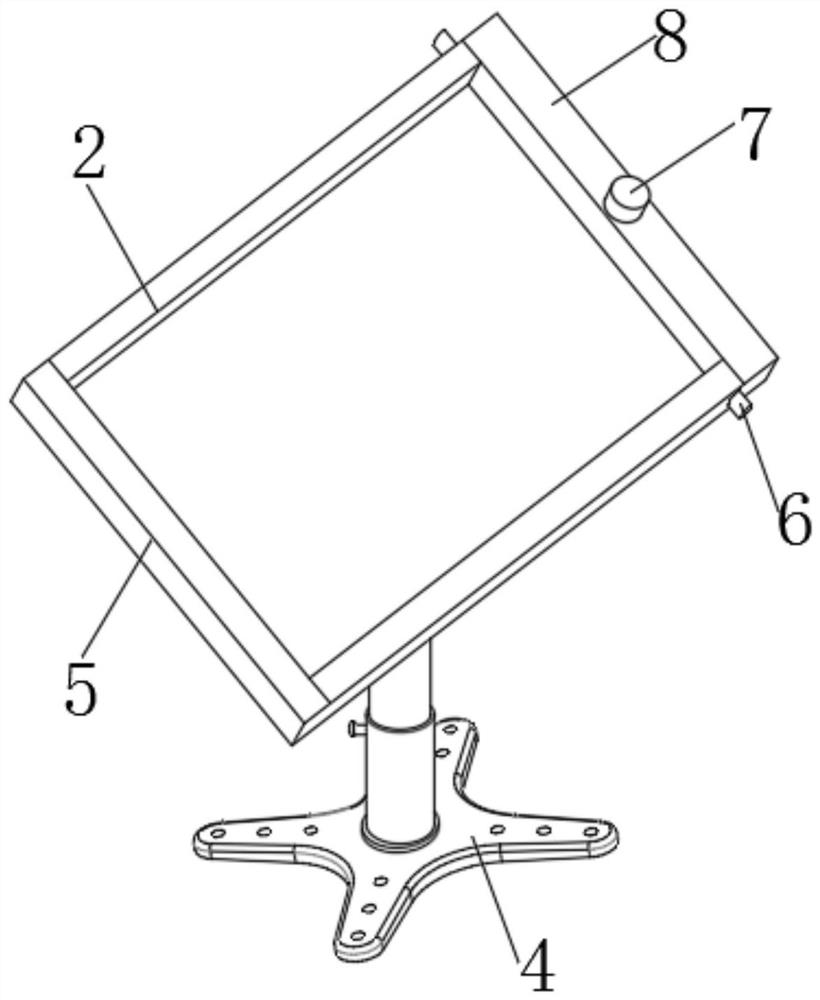

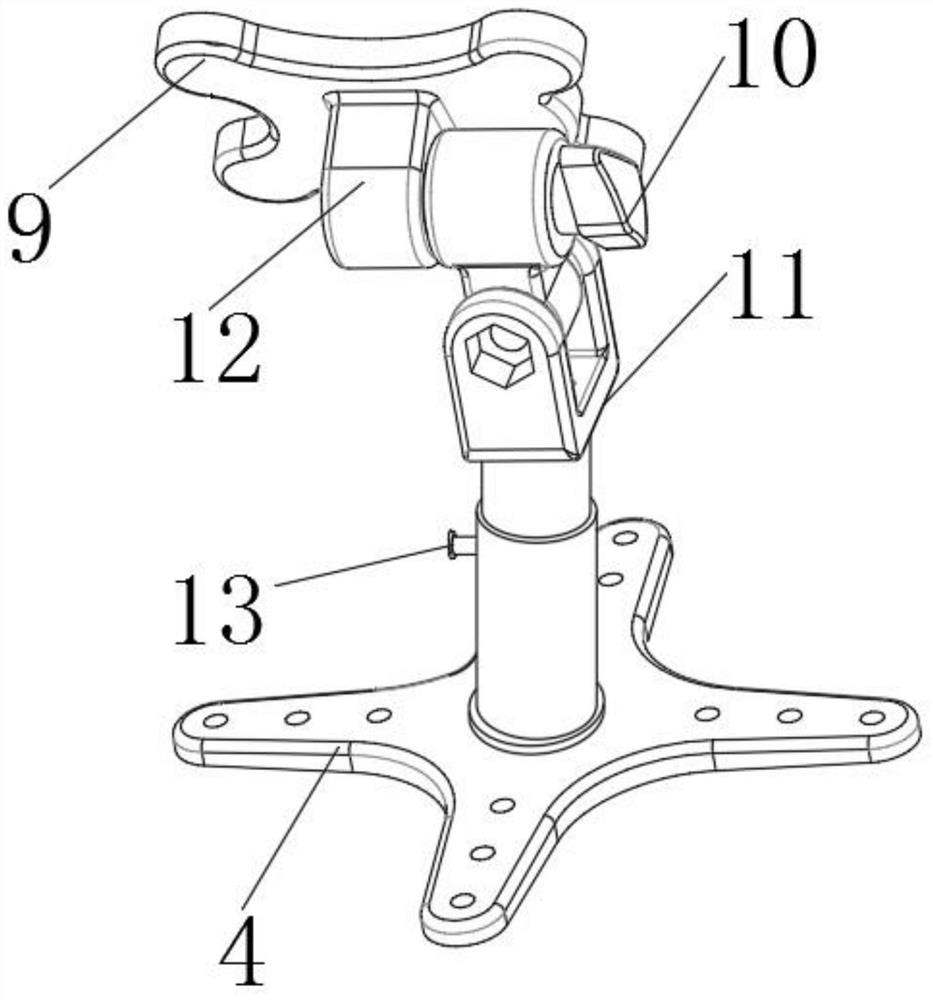

Internet intelligent conference tablet

ActiveCN109725684AStable positionOptimize locationStands/trestlesDigital processing power distributionThe InternetEngineering

Owner:广州林电智能科技有限公司

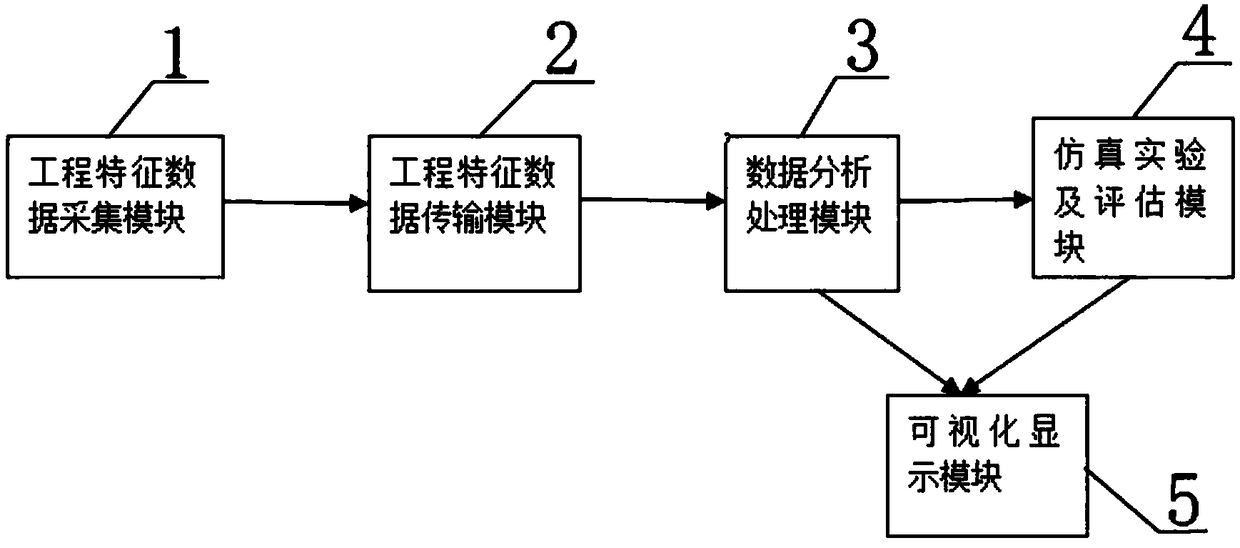

Underground construction damage simulation evaluation system and method

InactiveCN108399313ADamage fastGeometric CADDesign optimisation/simulationComputational modelEngineering

The invention relates to an underground construction damage simulation evaluation system and method. The system comprises an engineering feature data collecting module, an engineering feature data transmitting module, a data analysis processing module, a simulation experiment and evaluation module and a visualized display module. Existing underground construction facility surface elevation data, engineering structure strength and position data and engineering internal geometric dimension data are collected and transmitted, the collected data is analyzed and fused, and engineering model parameters are constructed; according to engineering parameters and the engineering effect calculation model, a simulation experiment is performed, engineering damage effect data is obtained through calculation, and the engineering survival rate is estimated again; the evaluation result is visually displayed. The engineering facility damage can be rapidly evaluated; the evaluation result is visually displayed, and the scientific basis is provided for protection scheme formulation and reinforcement and reconstruction. The system and method can be widely applied to underground construction facility damage pre-prediction and damage post-evaluation.

Owner:INST OF DEFENSE ENG ACADEMY OF MILITARY SCI PLA CHINA

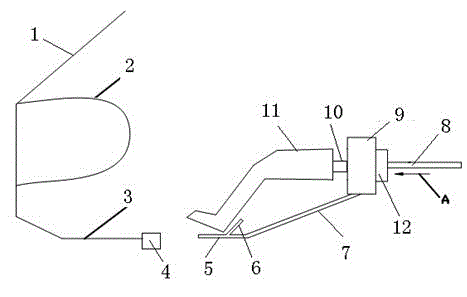

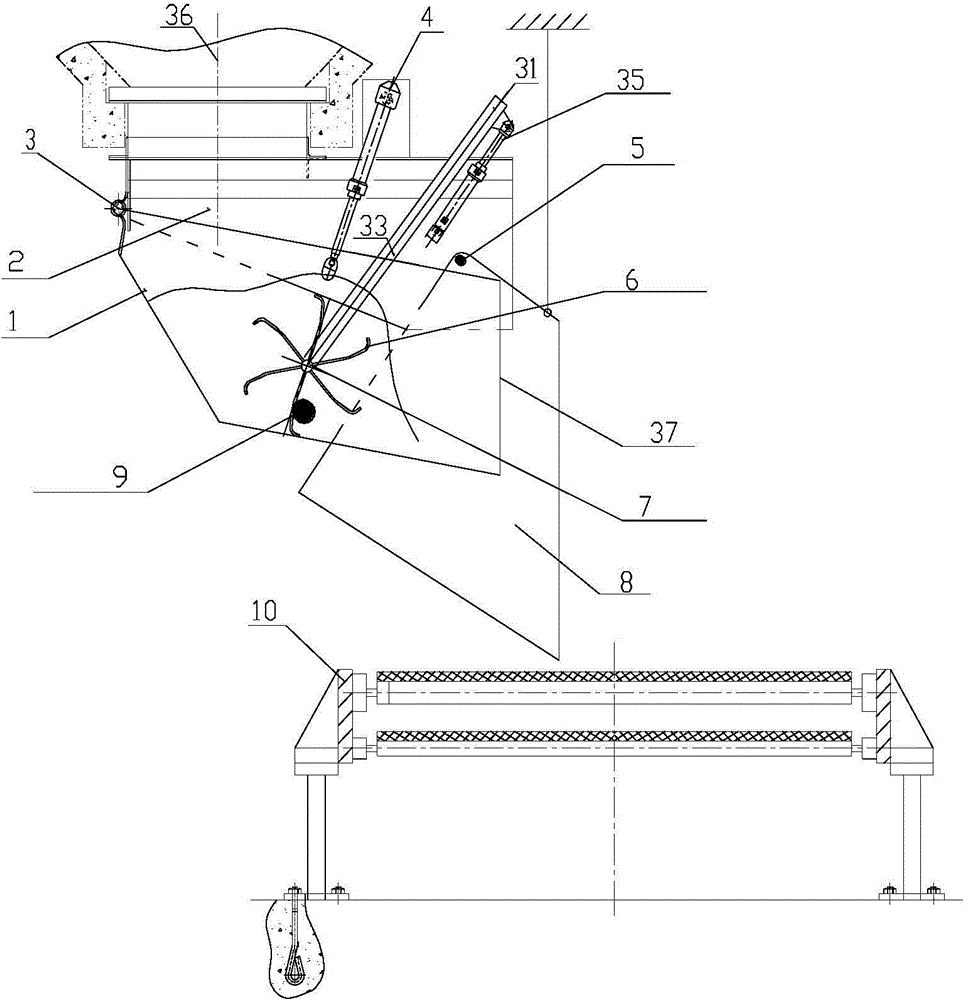

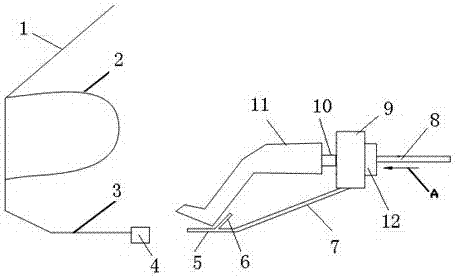

Dummy lower limb impact test method

ActiveCN104931221ADamage fastRapid assessmentVehicle testingShock testingDashboardPhysical medicine and rehabilitation

The invention discloses a dummy lower limb impact test method. According to the method, dummy lower limb impact test equipment is adopted and includes an impact test object device, a dummy lower limb, a guide rail, a sliding device, a foot loading device, a loading device, a stopping device, a sensor group and an upper computer. The method includes the following steps of: 1, preparation work; step 2, loading; step 3, releasing; and step 4, data collection and analysis. With the dummy lower limb impact test method of the invention adopted, a dynamic impact process of the dummy lower limb, a vehicle dashboard and floor can be accurately simulated; dummy lower limb damage value data can be acquired in a test process, so that damage to the lower limb of a passenger which caused by the vehicle dashboard, the floor, a foot pad and the like can be quickly assessed.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

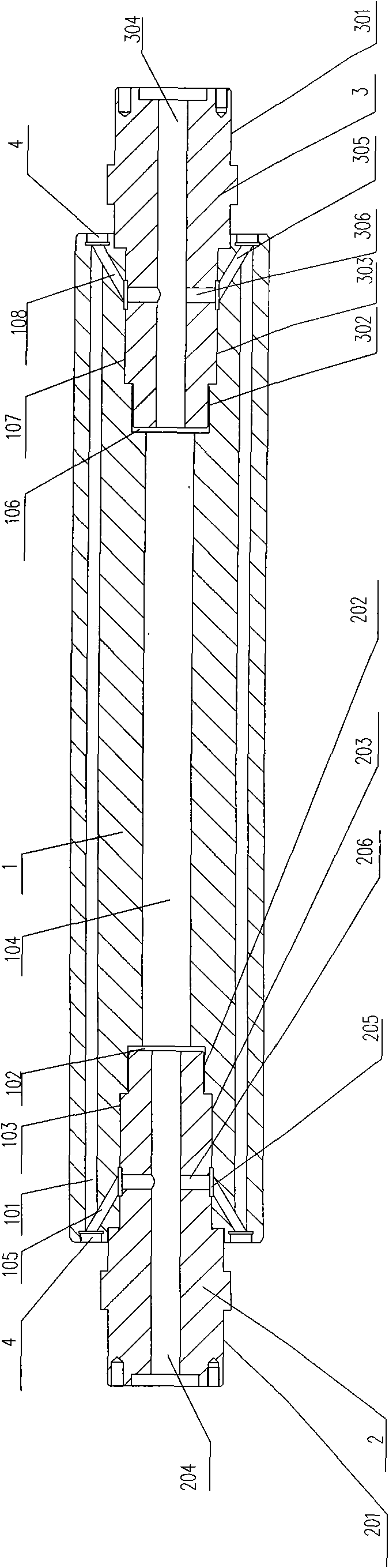

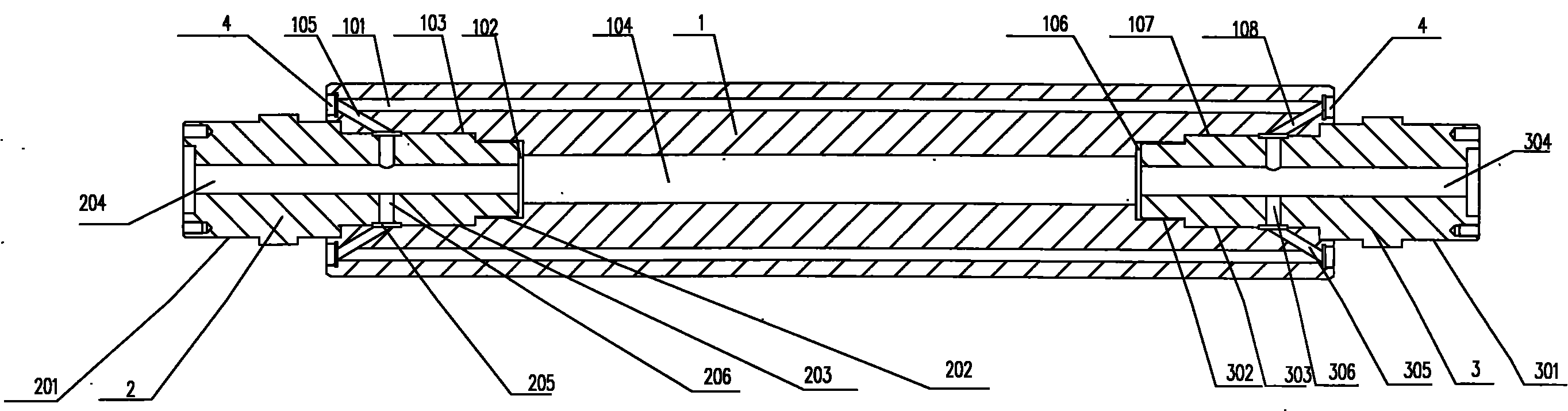

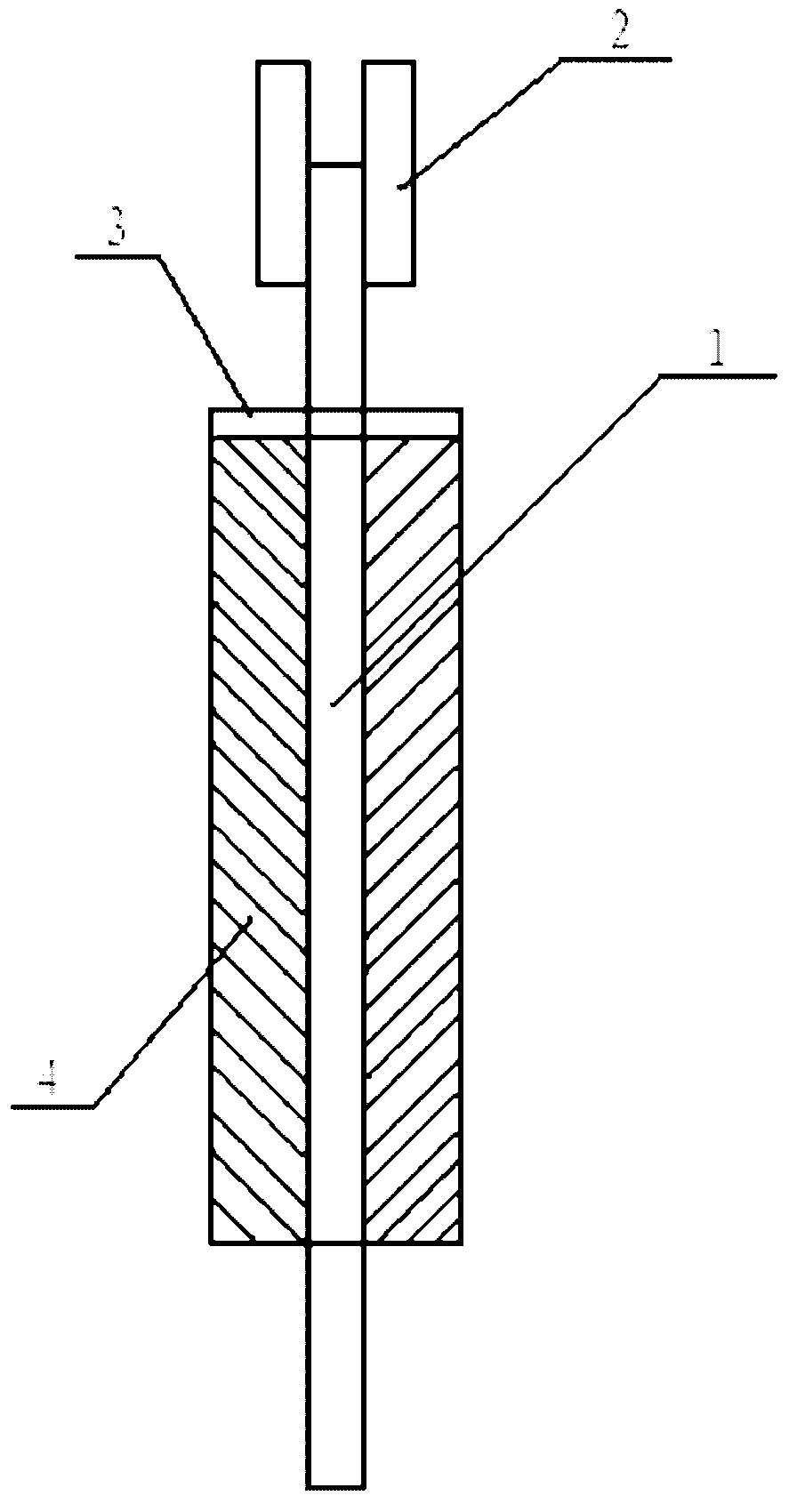

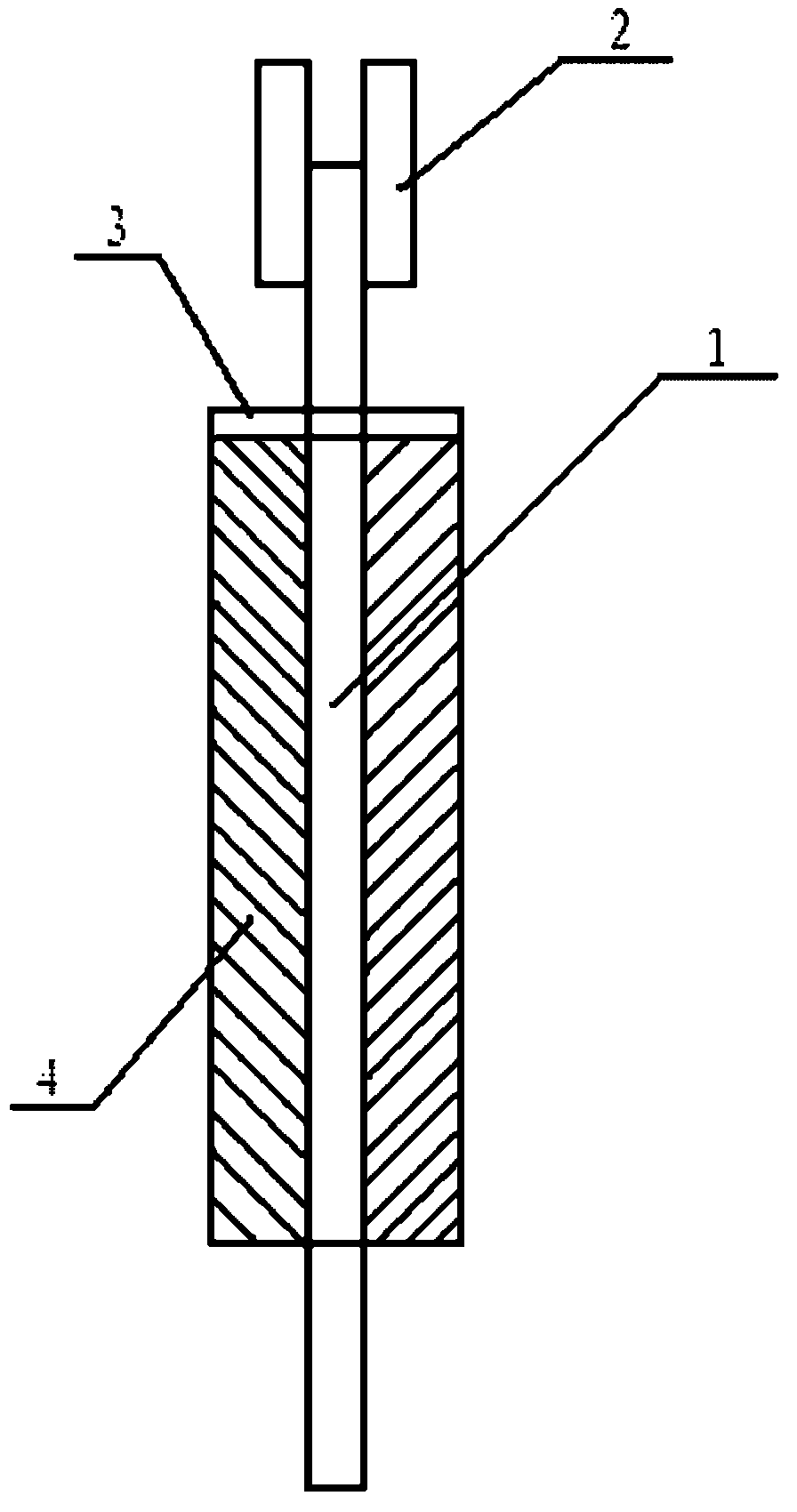

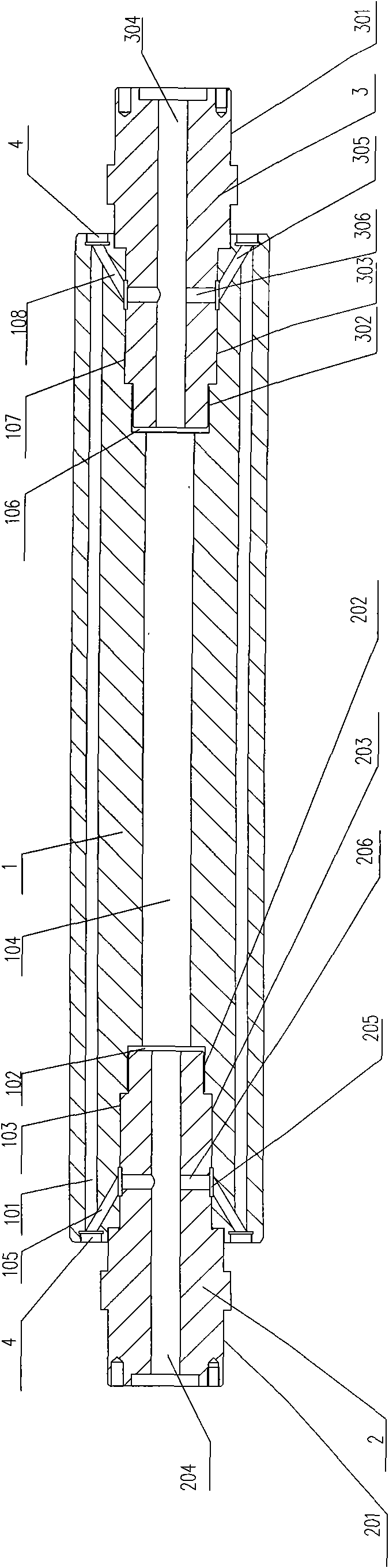

Bored cooling calendaring roller

The invention relates to a bored cooling calendaring roller, comprising a roller body as well as a first roller shaft and a second roller shaft which are respectively connected with the two ends of the roller body; wherein the roller body is provided with an axial through hole of a cooling working roller surface. The roller is characterized in that the first roller shaft and the second roller shaft are respectively provided with a cooling water channel hole which is communicated with a cooling water channel through hole on the roller body, the shaft body circumference surfaces of the first roller shaft and the second roller shaft are respectively provided with an annular water tank, the annular water tanks are respectively communicated with the cooling water channel hole by virtue of intercommunicating holes on the shaft bodies, the two ends of the axial through hole of the cooling working roller surface which is reserved on the roller body are respectively communicated with the annular water tanks on the shaft body circumference surfaces of the first and second roller shafts by virtue of oblique communicating holes, and the two end parts of the axial through hole are respectivelyprovided with a seal element used for sealing the axial through hole. The invention has the advantages of reasonable structure, and rapid repairing when being damaged, and is easy to process and reliable in use.

Owner:PRINX CHENGSHAN (SHANDONG) TIRE COMPANY LTD

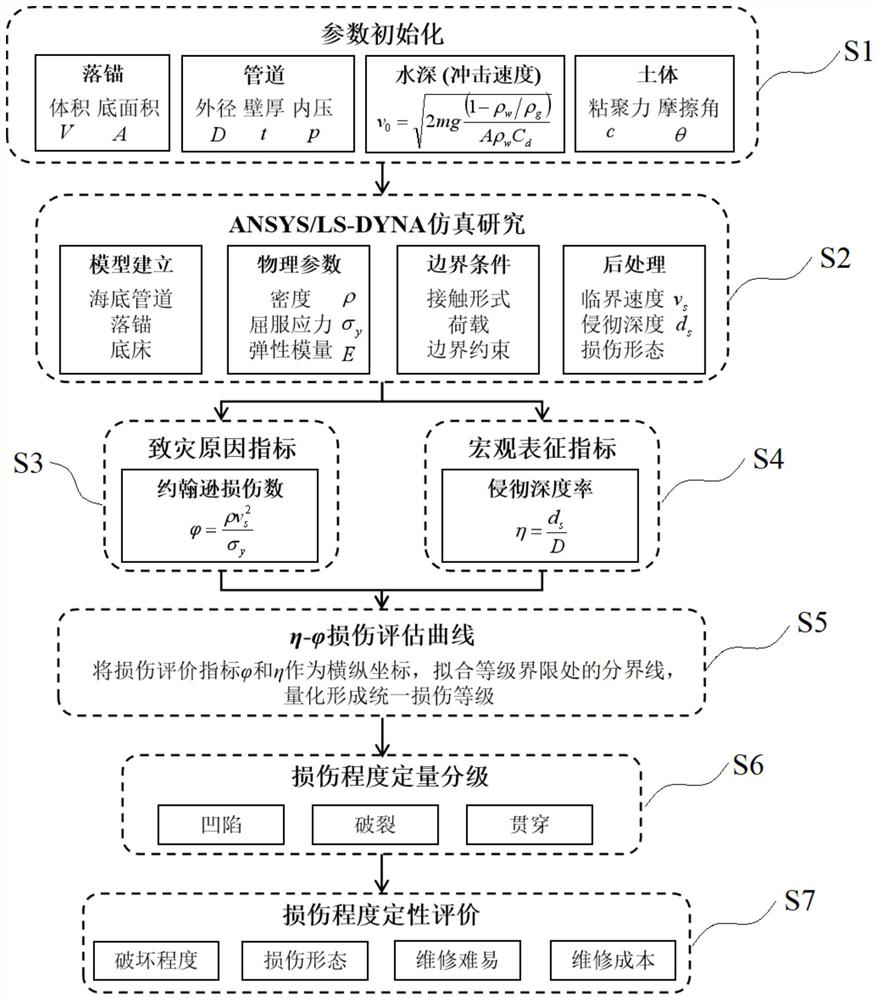

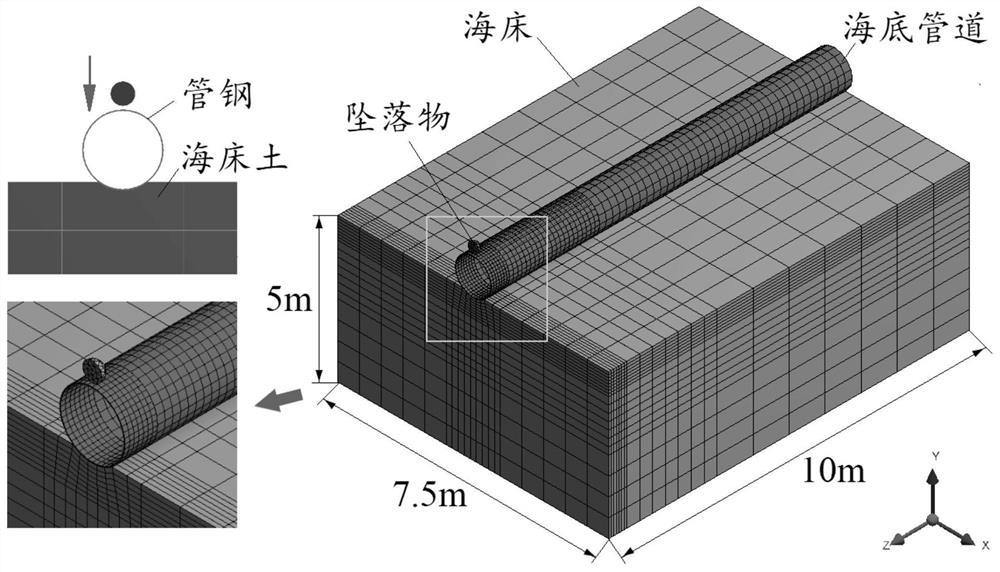

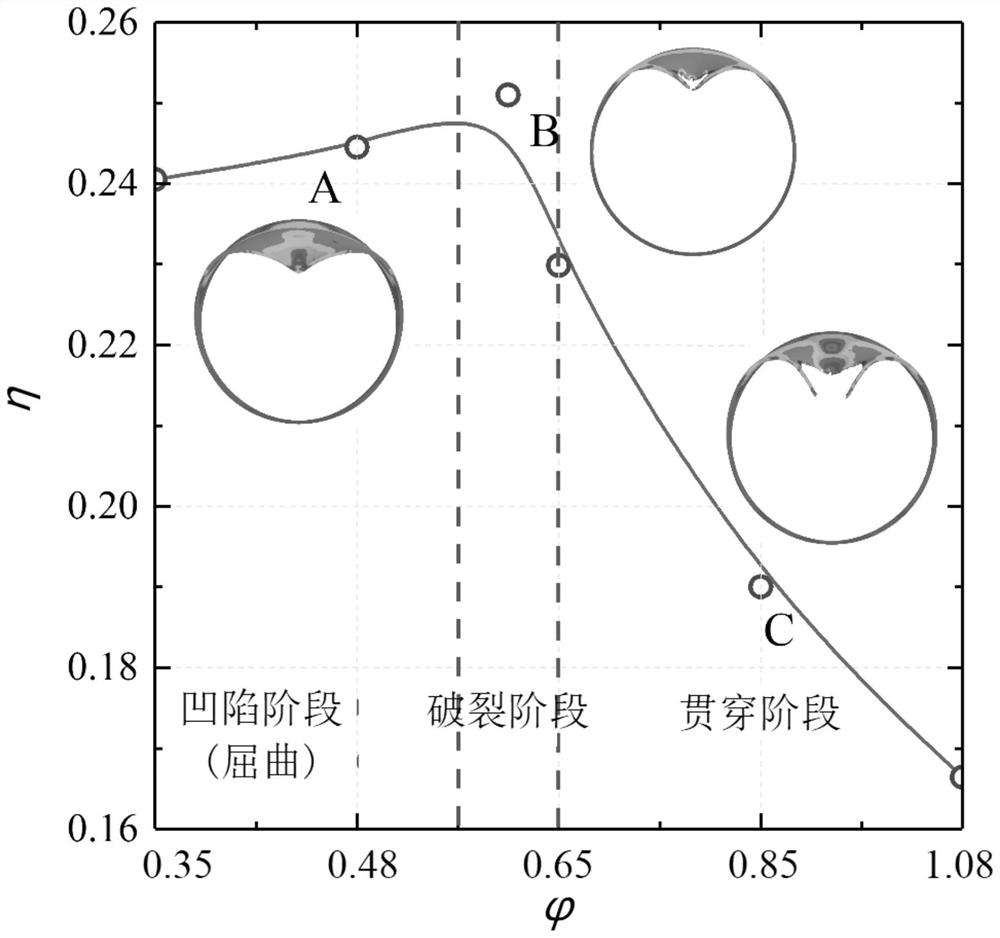

Submarine pipeline damage analysis method

PendingCN113806976AAvoid complexityImprove universalityDesign optimisation/simulationConstraint-based CADMacroscopic scaleAlgorithm

The invention discloses a submarine pipeline damage analysis method. The method comprises the following steps: initializing parameters; obtaining a critical impact speed vs and a penetration depth ds through numerical simulation; establishing a Johnson damage number and a penetration depth rate index eta based on the parameters; fitting a damage analysis curve through parameter points, dividing a boundary of each penetration mode, and quantifying to form a unified damage grade; giving out the damage degree and maintenance suggestion evaluation of each grade; finally, obtaining the position relation of the parameter points of the next accident on the damage analysis curve, and obtaining a damage conclusion directly. According to the method, the complexity of selecting a large number of index systems in traditional analysis is avoided, various penetration modes can be evaluated more macroscopically, the impact damage evaluation of the submarine pipeline can be quickly obtained, and the method has the characteristics of convenience, universality, quickness and the like.

Owner:HOHAI UNIV

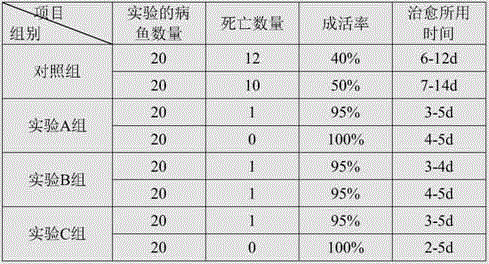

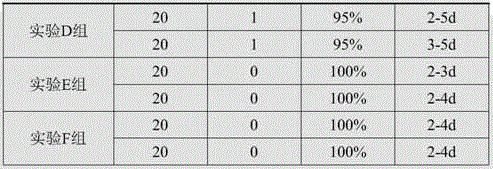

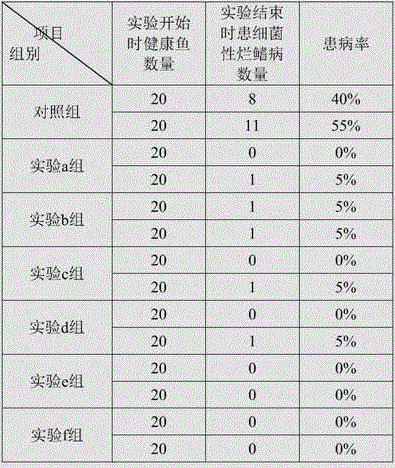

Feed additive for preventing and treating turbot fin rot and preparation method thereof

InactiveCN105410481AGood synergistic effectEnhanced inhibitory effectClimate change adaptationAnimal feeding stuffLycoris radiataHoneycomb

The invention belongs to the technical field of aquaculture, relates to a feed additive for preventing and treating turbot fin rot and also relates to a preparation method of the feed additive. The feed additive is composed of the following components, by weight: 35-42 parts of duckweed, 26-33 parts of cortex pseudolaricis, 26-33 parts of houttuynia cordata, 26-32 parts of lycoris radiata, 26-32 parts of fructus cnidii, 24-30 parts of prunella vulgaris, 23-30 parts of astragalus sinicus, 8-16 parts of honeycomb, 22-29 parts of muskmelon pedicel, 19-27 parts of seeds of grapes, 17-25 parts of ephedra, 18-24 parts of asarum, 18-24 parts of roots of oriental stephania root, 16-23 parts of divaricate saposhnikovia, 15-22 parts of angelica decursiva, 14-22 parts of scutellaria baicalensis and 14-20 parts of abrus precatorius. The feed additive can effectively prevent and treat the turbot fin rot.

Owner:QINGDAO HAIZHIYUAN INTELLIGENT TECH

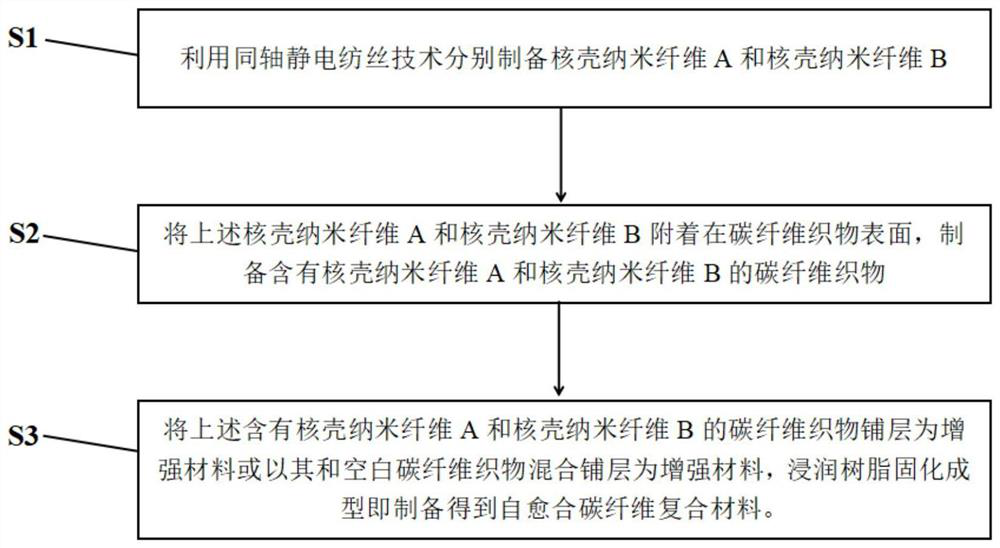

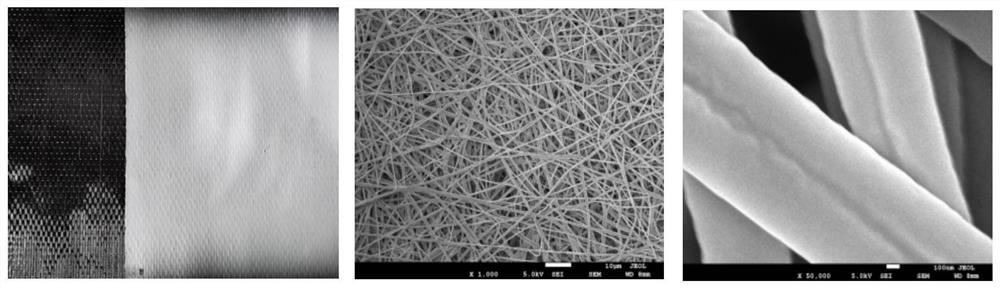

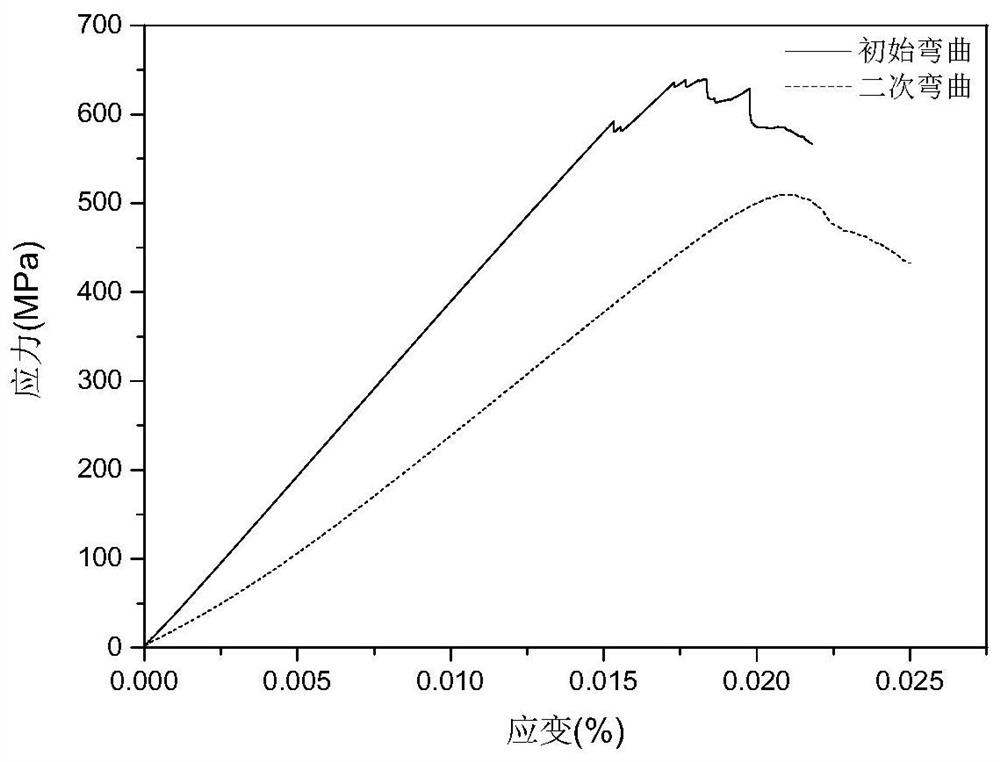

Core-shell nano fiber type self-healing carbon fiber composite material and preparation method thereof

The invention discloses a core-shell nano fiber type self-healing carbon fiber composite material and a preparation method thereof. The preparation method comprises the following steps of: separatelypreparing a core-shell nanofiber A and a core-shell nanofiber B by means of a coaxial electrospinning technique; attaching the two to the surface of the carbon fiber fabric; then paving the carbon fiber fabric containing the core-shell nanofiber A and the core-shell nanofiber B as a reinforcing material or paving a mixture of the carbon fiber fabric and a blank carbon fiber fabric as the reinforcing material; and infiltrating a resin to cure and form the self-healing carbon fiber composite material. When the composite material is damaged, a healing agent resin in the core-shell nanofiber A anda healing agent curing agent in the core-shell nanofiber B flow out and are blended to fill damage cracks to achieve quick curing to repair damage under thermal excitation, so that self-healing is achieved. By adopting the coaxial electrospinning technique, the method is stable in process and easy to operate and achieves industrial and large-scaled production favorably.

Owner:WUHAN UNIV OF TECH

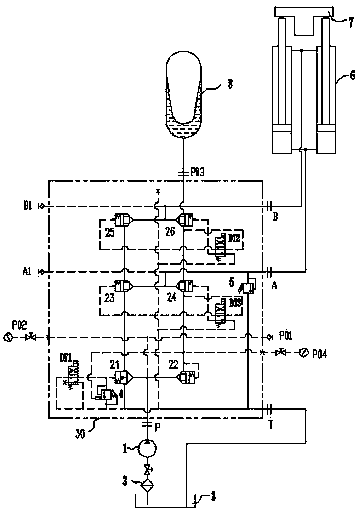

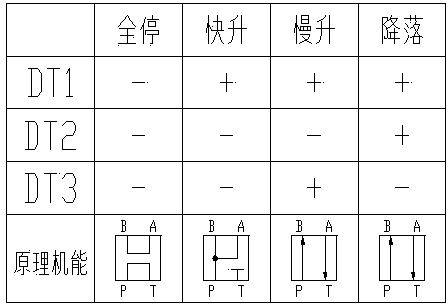

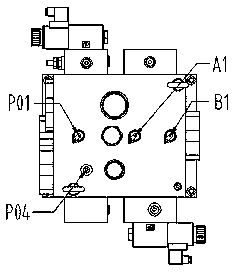

High frequency hammer pile hydraulic system of hydraulic hammer pile machine and hammering cartridge valve of hydraulic hammer pile machine

ActiveCN104353770ARealize two-way high-frequency pass-stopGuaranteed unobstructedForging press drivesControl engineeringFuel tank

The invention discloses a high frequency hammer pile hydraulic system of a hydraulic hammer pile machine. The high frequency hammer pile hydraulic system of the hydraulic hammer pile machine comprises a hydraulic pump, a cover plate valve group and an electromagnetic valve group, wherein an oil suction input end of the hydraulic pump is connected into an oil tank, the cover plate valve group is connected with a hammering oil cylinder and controls the stretching action of the hammering oil cylinder, the cover plate valve group comprises three cover plate valves, a first oil port of a first cover plate valve and a first oil port of a second cover plate valve are connected in series and are connected to the hydraulic pump, a first oil port of a third cover plate valve and a first oil port of a fourth cover plate valve are connected in series and are connected to a rodless cavity of the hammering oil cylinder, a first oil port of a fifth cover plate valve and a first oil port of a sixth cover plate valve are connected in series and are connected to a rod cavity of the hammering oil cylinder, and the electromagnetic valve group comprises three electromagnetic valves to control the on / off of the cover plate valves. The invention aims at providing the high frequency hammer pile hydraulic system of the hydraulic hammer pile machine to meet the two-way high-frequency on / off of an hydraulic oil way and guarantee the smoothness of the oil way, in addition, the high frequency hammer pile hydraulic system of the hydraulic hammer pile machine is efficient and stable, and the working efficiency is improved. The invention further discloses a hammering cartridge valve of the hydraulic hammer pile machine, integrated with the cover plate valve group, the electromagnetic valve group and the related oil path of the hydraulic system.

Owner:HUNAN MINGCHENG MASCH MFG CO LTD

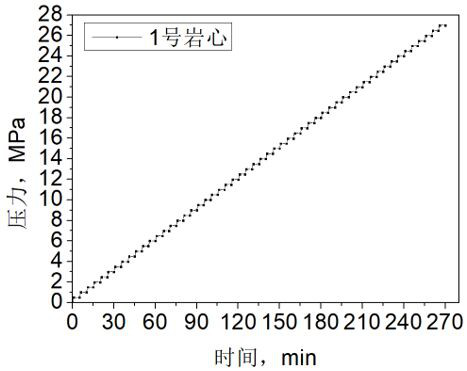

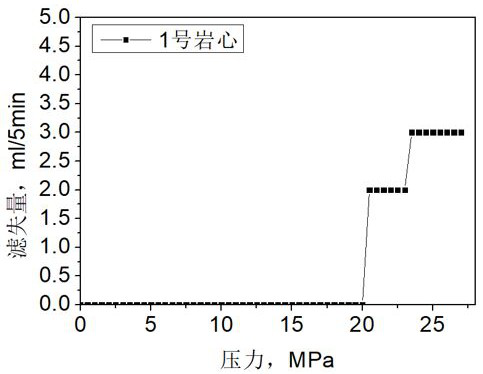

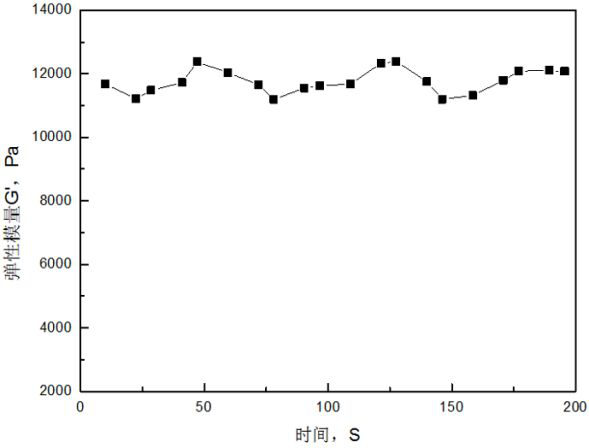

Temporary plugging well killing fluid for fractured reservoirs, and application and preparation method thereof

ActiveCN111925783ADamage fastReduce harmDrilling compositionSealing/packingPolymer compositionPetroleum engineering

The invention provides a temporary plugging well killing fluid for fractured reservoirs and application and a preparation method thereof. The temporary plugging well killing fluid comprises a base solution and degradable shape memory polymer particles, the base solution is a composite gel, the degradable shape memory polymer particles are composed of polymers with different deformation recovery amounts, and the degradable shape memory polymer particles are injected into a reservoir stratum through a base solution carrying pump, enter a fractured reservoir stratum, expand due to temperature response, and recover the shape. Temporary plugging and well killing can be achieved for a fractured gas well, low-damage well repair of low-pressure-coefficient and ultralow-pressure-coefficient and low-yield gas wells can be met, the fluidity is good at the ground temperature, and pumping injection is easy. After entering the fractured reservoir, the pressure bearing performance is rapidly improved, the subsequent clear water workover fluid loss is greatly reduced, the operation safety is ensured, and the reservoir damage is reduced. Shape memory polymer particles with different degradation periods can be selected according to the operation requirements, and can be completely degraded after the operation is completed, and the flow-back and the production recovery are fast.

Owner:PETROCHINA CO LTD

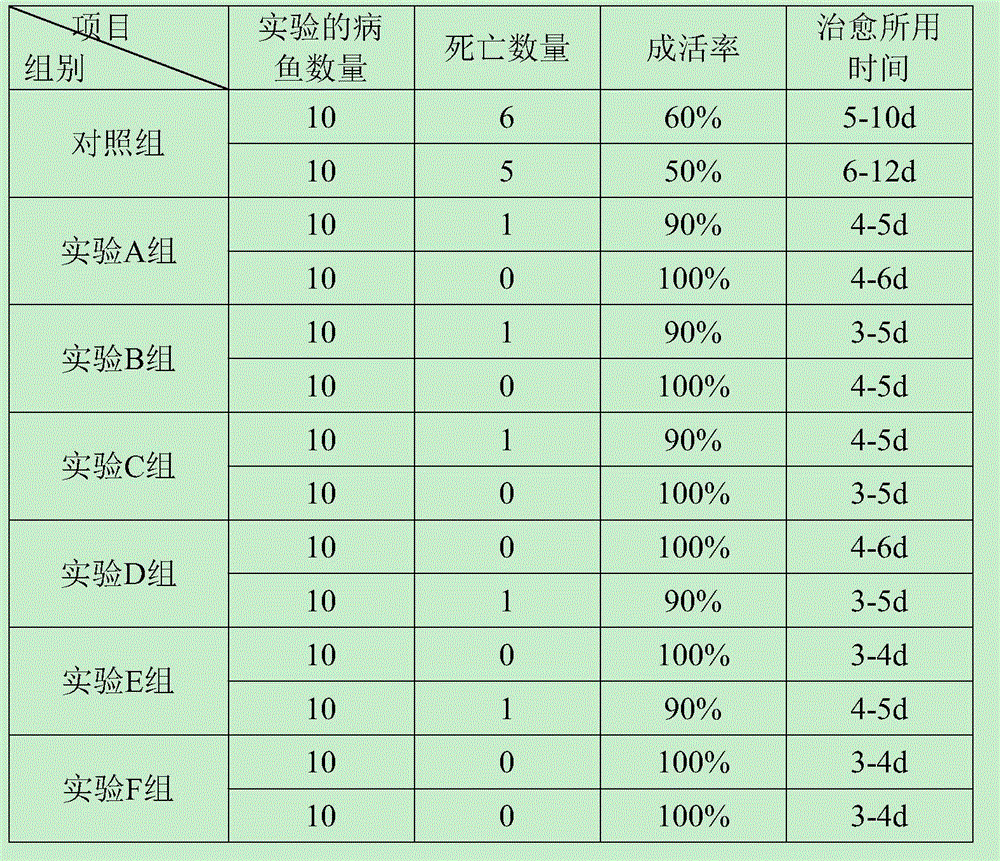

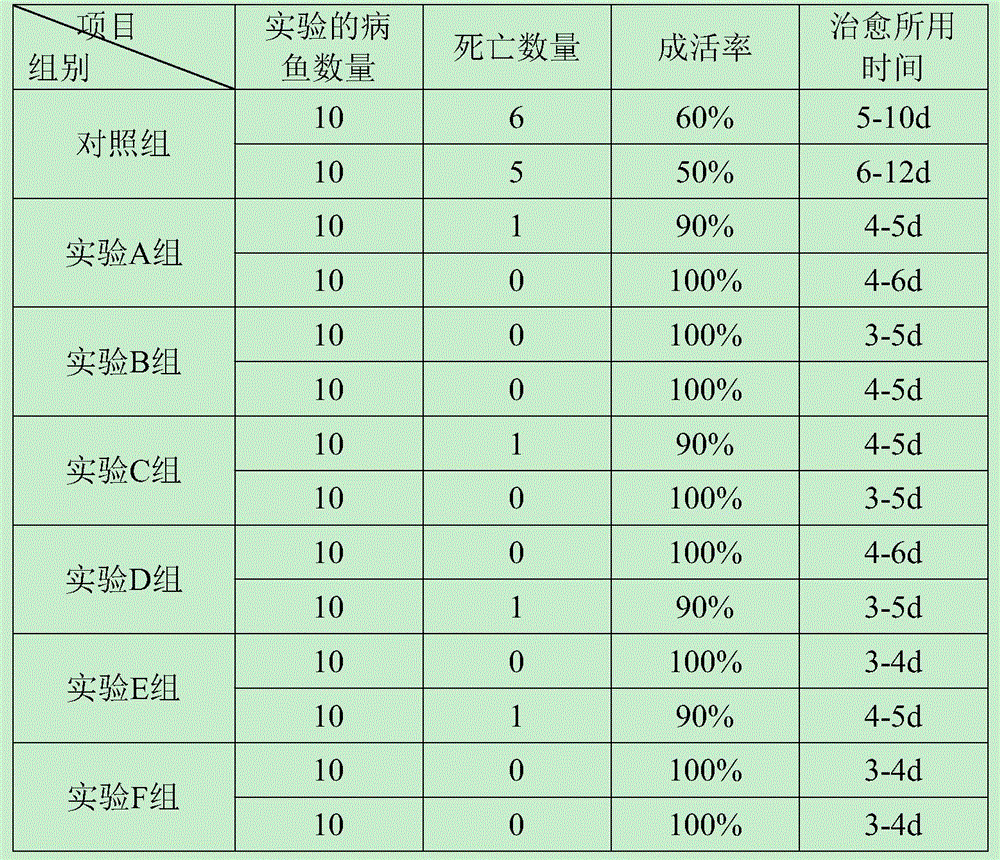

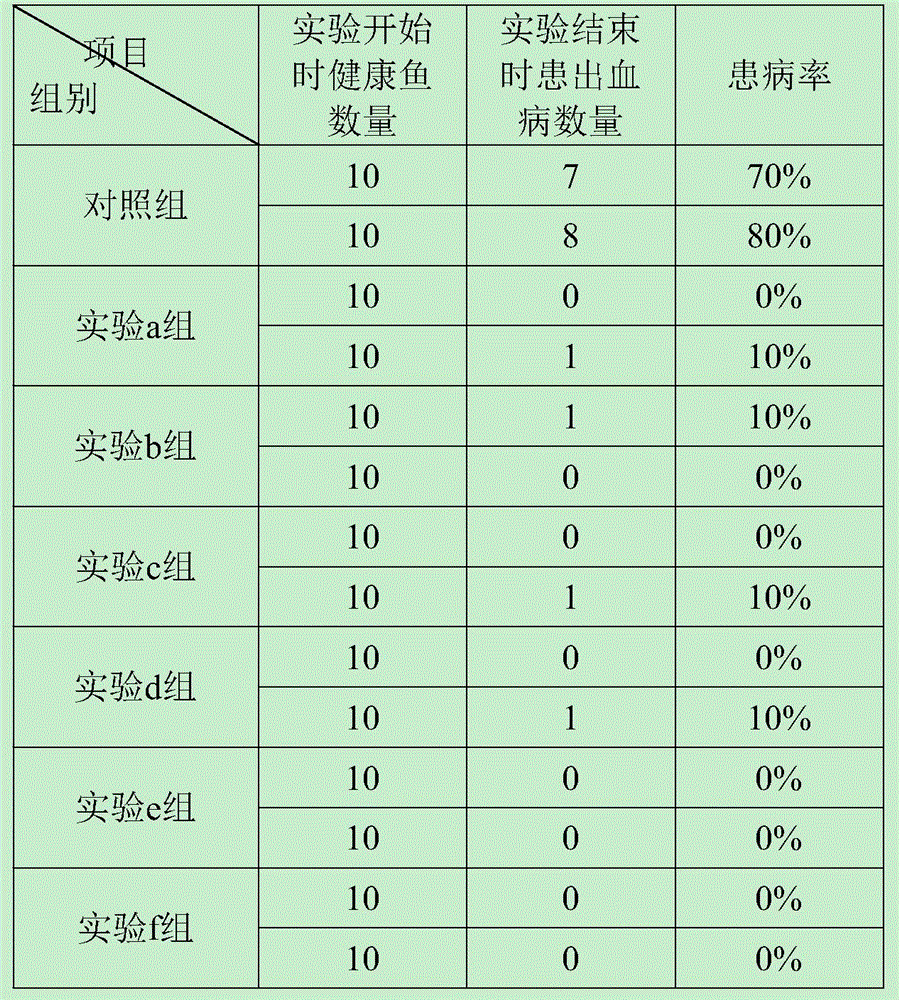

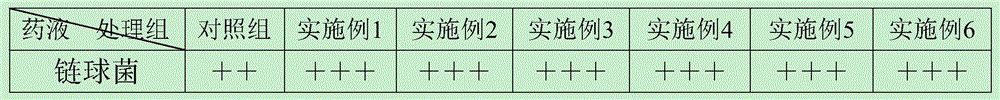

Powder for preventing and treating plecoglossus altivelis hemorrhagic disease and preparation method thereof

InactiveCN105381356AGood healing effectInhibition of survivalAntibacterial agentsOrganic active ingredientsLacquerBitter gourd

The invention belongs to the technical field of aquaculture, relates to powder for preventing and treating a plecoglossus altivelis hemorrhagic disease and further relates to a preparation method of the powder for preventing and treating the plecoglossus altivelis hemorrhagic disease. The powder for preventing and treating the plecoglossus altivelis hemorrhagic disease is prepared from, by mass, 37-44 parts of sweetgum resin, 28-36 parts of rhizoma dryopteris crassirhizomae, 28-36 parts of spina gleditsiae, 27-35 parts of clinopodium megalanthum, 27-33 parts of Indian epimeredi herbs, 9-15 parts of cicada slough, 23-30 parts of aconitum gymnandrum, 23-30 parts of dried lacquer, 22-30 parts of mulberry leaves, 21-29 parts of peucedani decursivi radix, 20-28 parts of ophiopogon japonicus, 20-28 parts of glutinosae rice roots, 18-28 parts of bitter gourd, 19-27 parts of portulaca oleracea, 17-26 parts of elecampane inula root, 16-26 parts of tree peony bark, 16-25 parts of sophora flavescens, 14-25 parts of reed rhizomes and the like. The powder is used for preventing and treating the plecoglossus altivelis hemorrhagic disease.

Owner:QINGDAO HAIZHIYUAN INTELLIGENT TECH

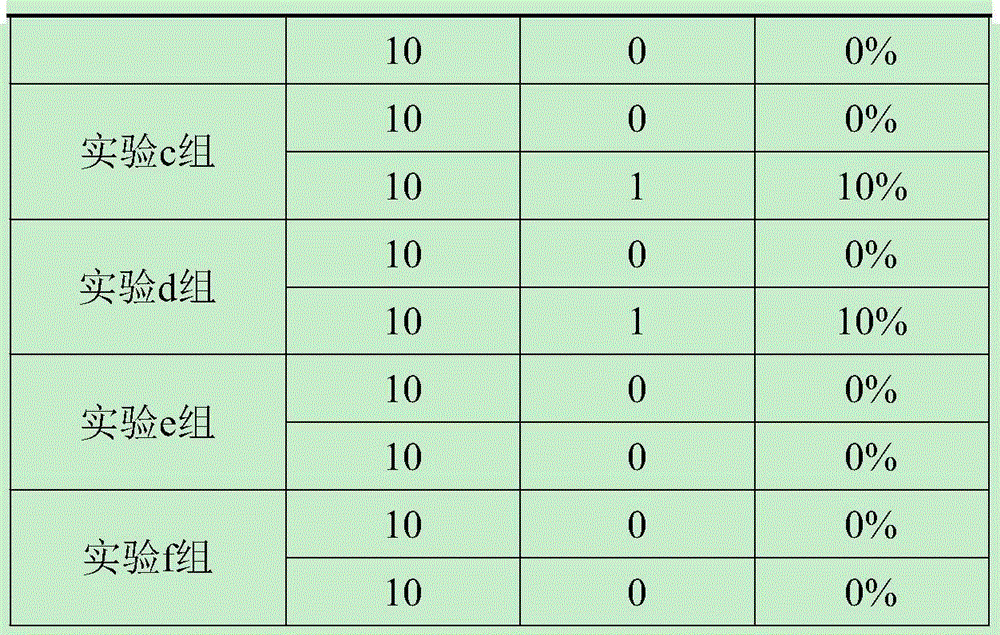

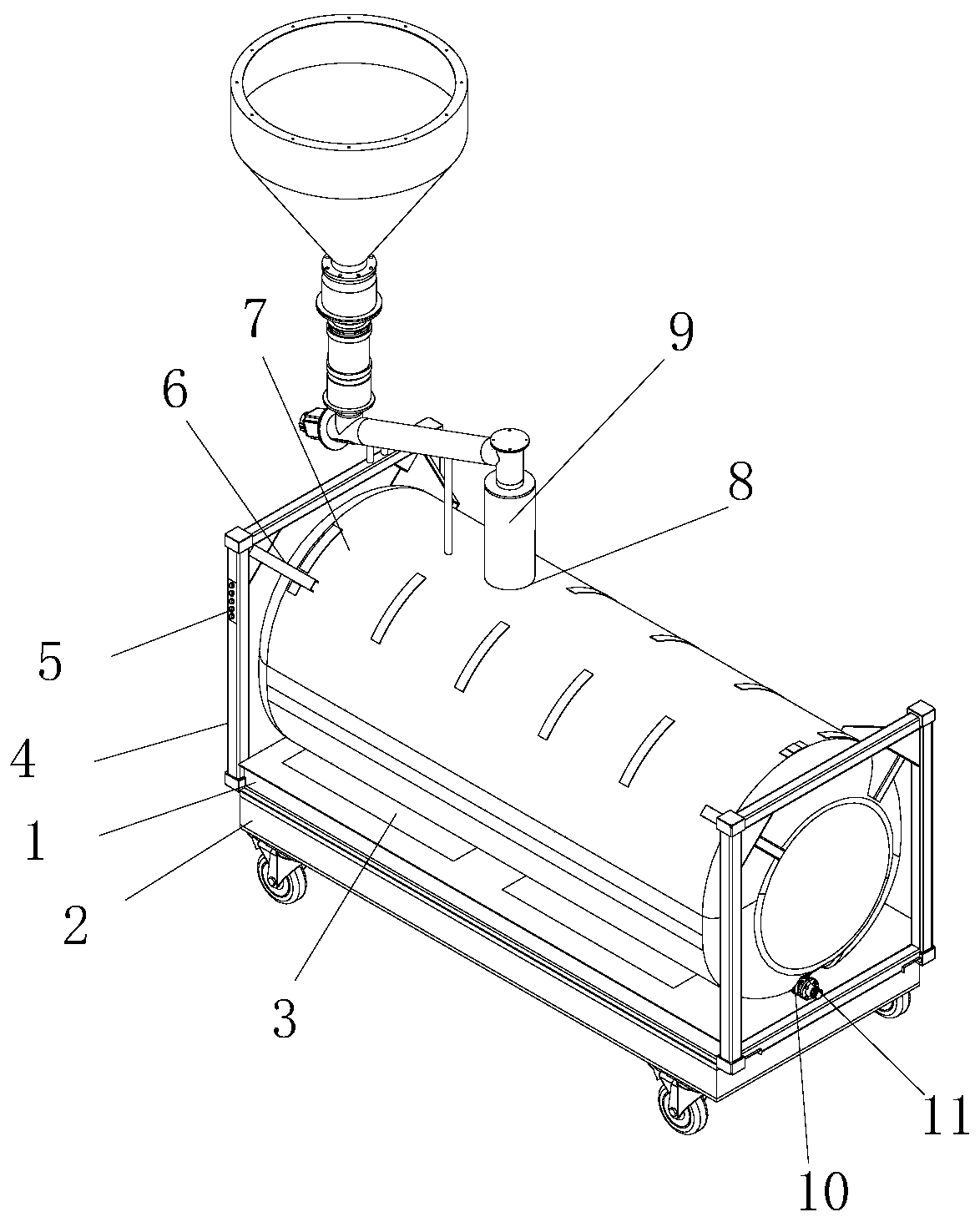

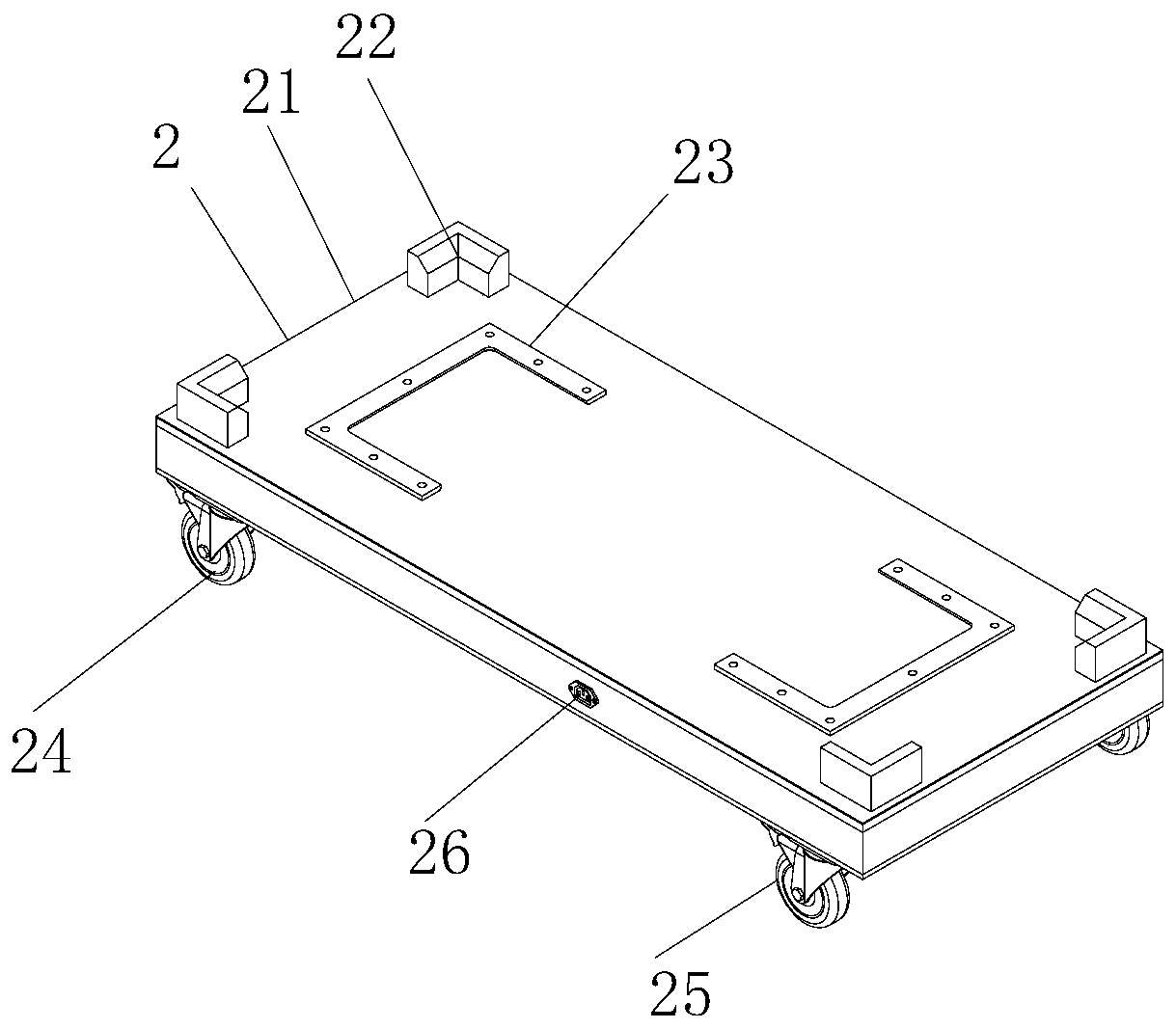

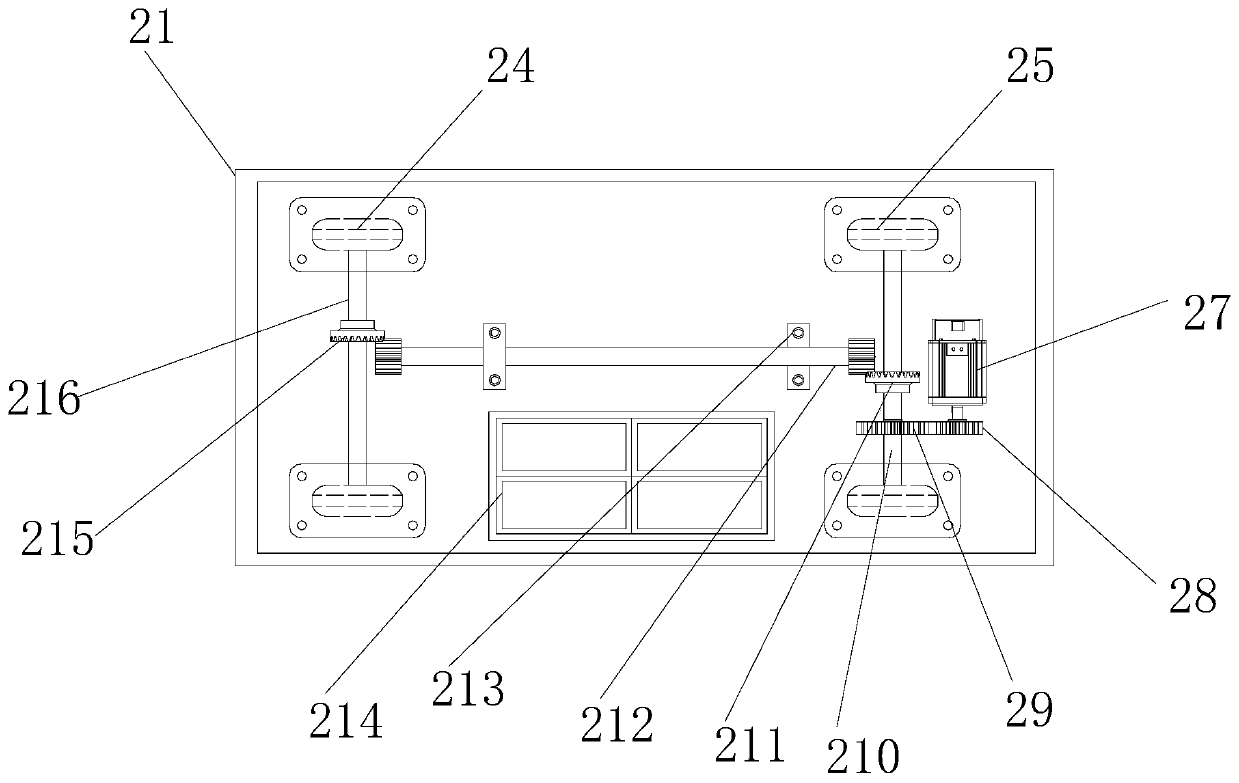

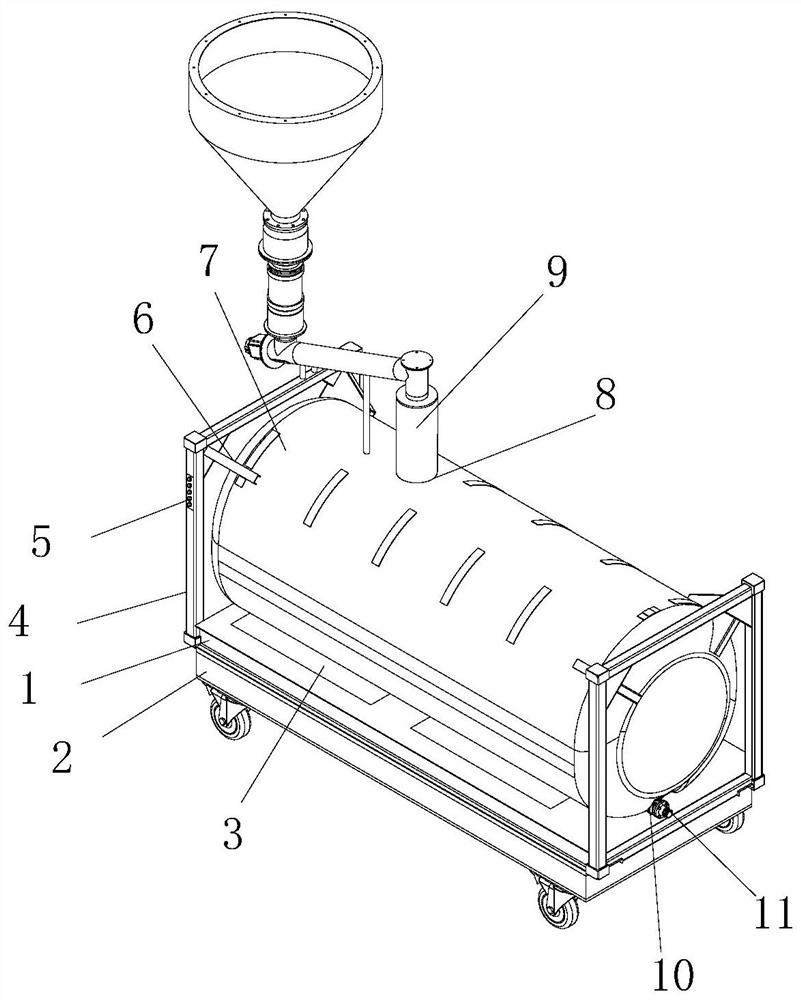

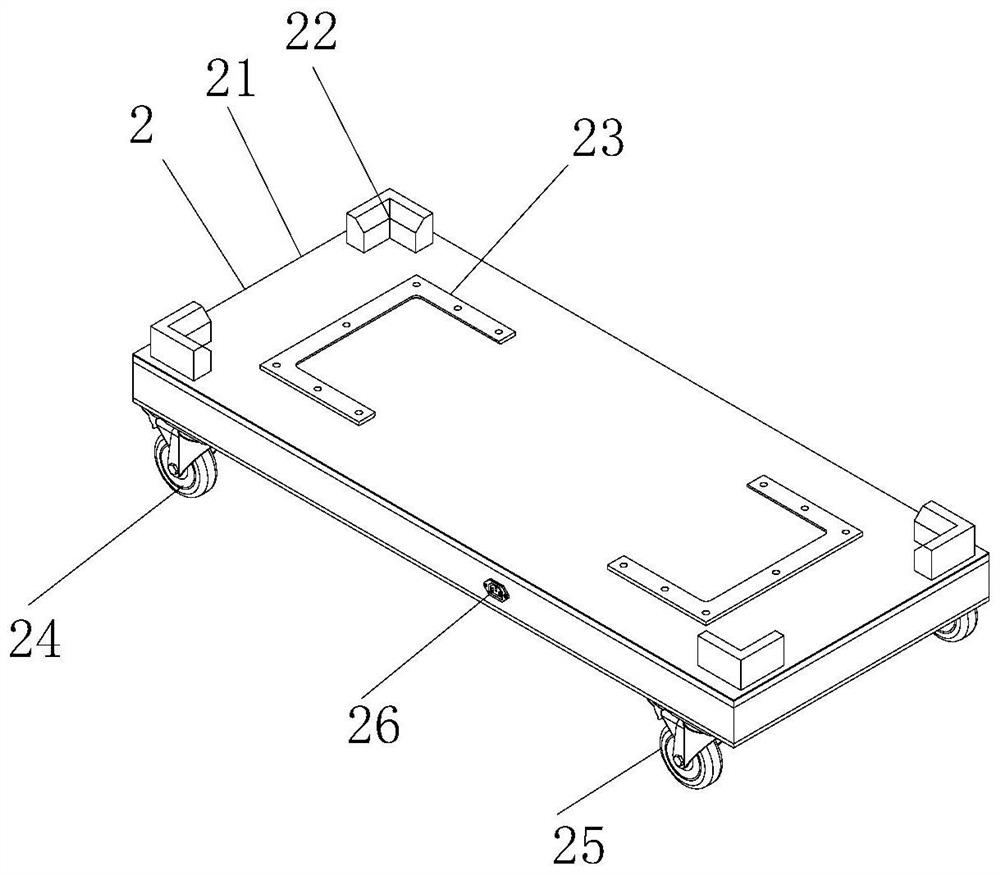

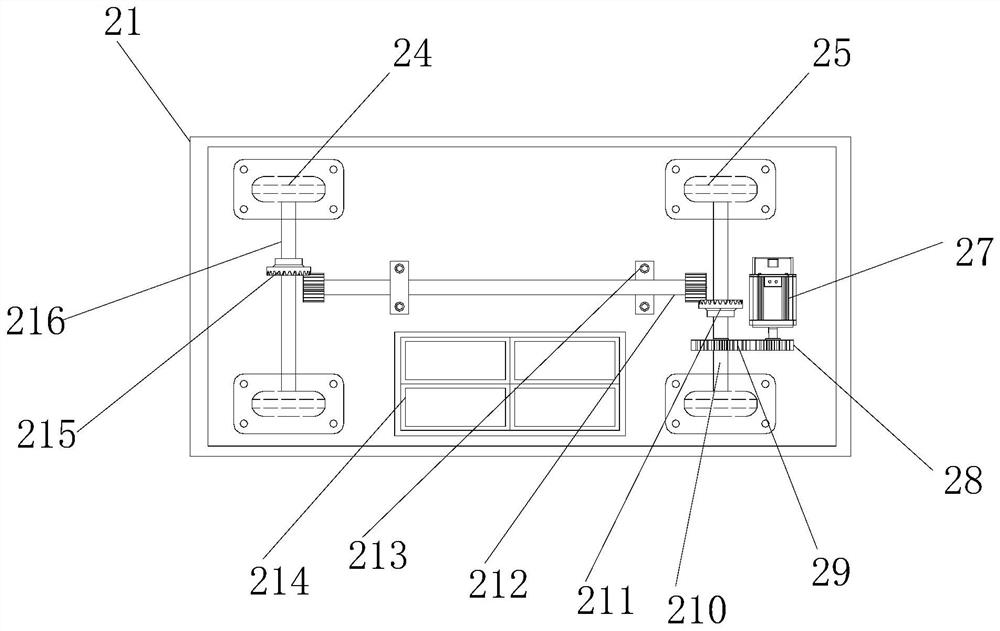

Conveying tank for chemical industry production

ActiveCN109775157AVibration Efficiently OffsetDamage fastLarge containersChemical industryPre treatment

The invention discloses a conveying tank for chemical industry production. The conveying tank for the chemical industry production comprises a bottom plate, a protecting frame, a controller, a movingdevice, a damping device and a pre-treating device. Due to that chemical raw materials are poured into a storing tank, and solids are easily formed in the chemical raw materials or the chemical raw materials are not uniform, the pre-treating device is arranged on the top part of the protecting frame; the raw materials are filled through a feeding bucket on the top part of the pre-treating device and then pass through a first connecting pipe and a second connecting pipe at the bottom part, and finally the materials enter a conveying pipe through a feeding pipe; a second motor is started to workthrough a control button on the controller; an output shaft at the right side of the second motor starts rotating, and an auger is driven to start working; the raw materials in the conveying pipe aredriven to spirally convey to a discharging pipe; the raw materials are discharged into a filling port through a third connecting pipe and finally enter the storing tank for storing, and thus the filling work is finished, and the problems that solids are formed during feeding, the raw materials are not uniform and the pre-treating effect is poor can be solved.

Owner:山东鼎泰新能源有限公司

Novel connecting rod plunger piston mechanism of press machine

The invention relates to a novel connecting rod plunger piston mechanism of a press machine; a one-way connecting pin is arranged on the top of a connecting rod of the press machine; the upper half end of the connecting rod of the press machine is provided with a rigid alloy tile; and the connecting rod of the press machine and the rigid alloy tile are arranged in holes of two sets of plunger pistons. After the scheme is adopted, the defects that the connecting pin is easy to deform due to large stamping force, and the plunger pistons are rapidly damaged, inconvenient to lubricate and difficult to maintain can be effectively avoided; and furthermore, the parts are small in volume, so that the whole structure of the press machine is compact.

Owner:赵亚州

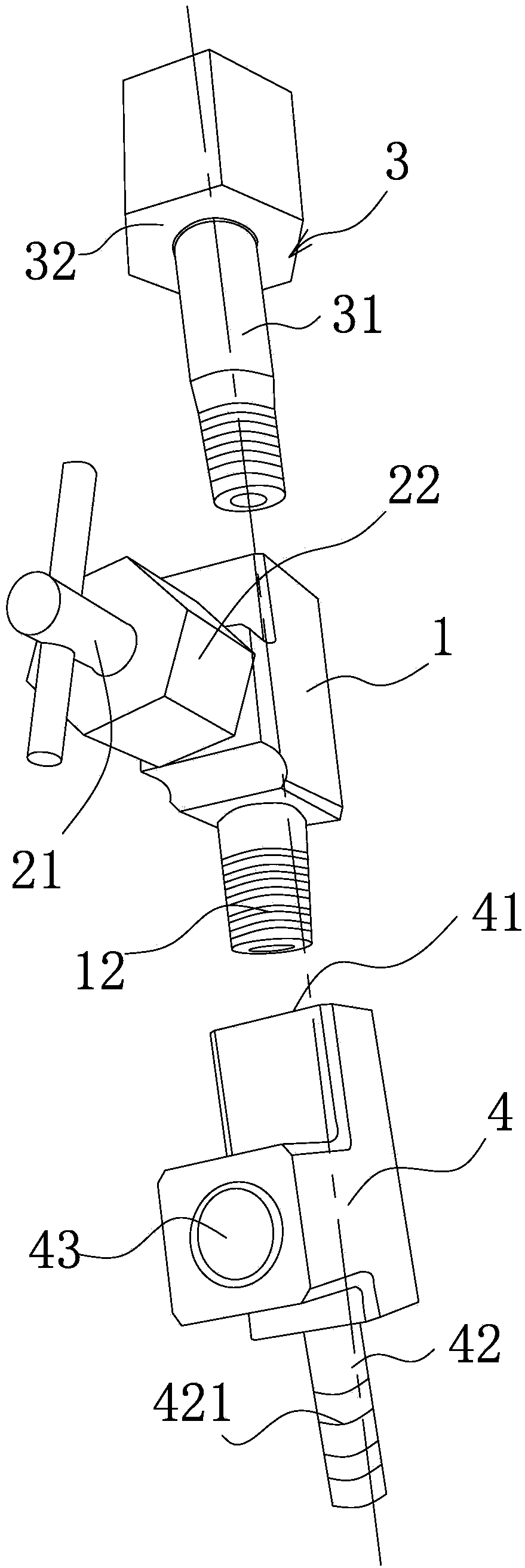

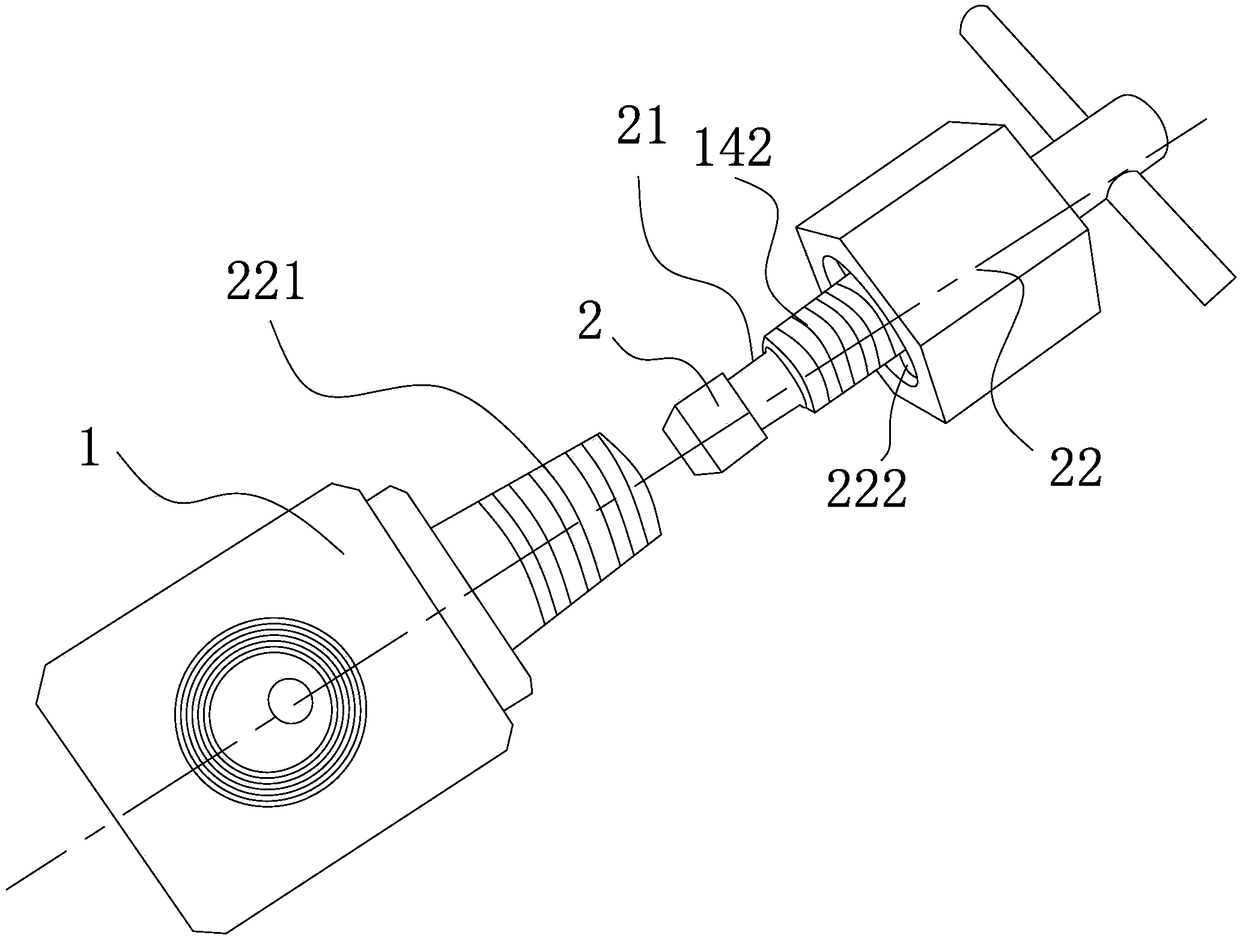

Valve body

PendingCN109027262AReasonable designEasy to assemble and disassembleSpindle sealingsLift valveEngineeringControl rod

The invention relates to the technical field of valves, in particular to a valve. The valve comprises a valve body with a convex cross section, a water passing cavity in a closed splayed shape is formed in the valve body, a valve body connecting pipe is arranged at one end of the valve body, a valve body main hole is formed in the other end of the valve body, a valve element mounting hole is formed between the valve body main hole and the valve body connecting pipe, the valve body main hole, the valve body connecting pipe and the valve element mounting hole communicate with the water passing cavity, a detachable valve element is arranged in the water passing cavity, a control rod is connected to the valve element, one end of the control rod is arranged in the valve element mounting hole, the other end of the control rod extends out of the valve element mounting hole, the outer end of the control rod is provided with a mounting base in a penetrating manner, the mounting base and the valve body are detachably connected, a seal structure is arranged among the mounting base, the control rod and the valve body, a detachable dual-way joint is connected into the valve body main hole, andthe valve body connecting pipe is connected with a convex three-way joint. Compared with the prior art, the valve body has the beneficial effects of being reasonable in design and convenient to dismount and mount.

Owner:ZHEJIANG DEQING CONCEPTFE PLASTIC PROD

A transport tank for chemical production

ActiveCN109775157BVibration Efficiently OffsetDamage fastLarge containersChemical industryElectric machinery

Owner:山东鼎泰新能源有限公司

Ointment for treating soft tissue injury

InactiveCN104189669ADamage fastShort course of treatmentAerosol deliveryOintment deliveryCaesalpinia sappanPhysiology

The invention relates to ointment for treating soft tissue injury. The ointment is prepared from the following raw medicinal materials in parts by weight: 15-25 parts of uncaria laevigata, 10-20 parts of myrrh, 10-25 parts of safflower carthamus, 10-25 parts of dragon's blood, 10-25 parts of polygonum cuspidatum, 15-20 parts of radix paeoniae rubra, 1-5 parts of radix ampelopsis, 6-10 parts of cassia twig, 6-10 parts of herba lycopi, 10-15 parts of cape jasmine, 15-25 parts of aconitum pendulum, 8-12 parts of rhizoma drynariae, 20-25 parts of centipeda minima, 10-15 parts of cowherb seed, 30-35 parts of cortex acanthopanacis, 20-30 parts of musk, 15-20 parts of radix scrophulariae, 25-30 parts of paris polyphylla, 15-20 parts of cortex lycii radicis, 20-30 parts of rhizoma sparganii, 30-50 parts of radix cyathulae, 25-35 parts of caesalpinia sappan, 20-30 parts of lycopodium clavatum, 40-60 parts of dipsacus root and 100-180 parts of emulsifier. The ointment is externally applied to relax the muscles, stimulate the blood circulation, diminish swelling and relieve pain, and is capable of healing the soft tissue injury if used continuously.

Owner:陈小华

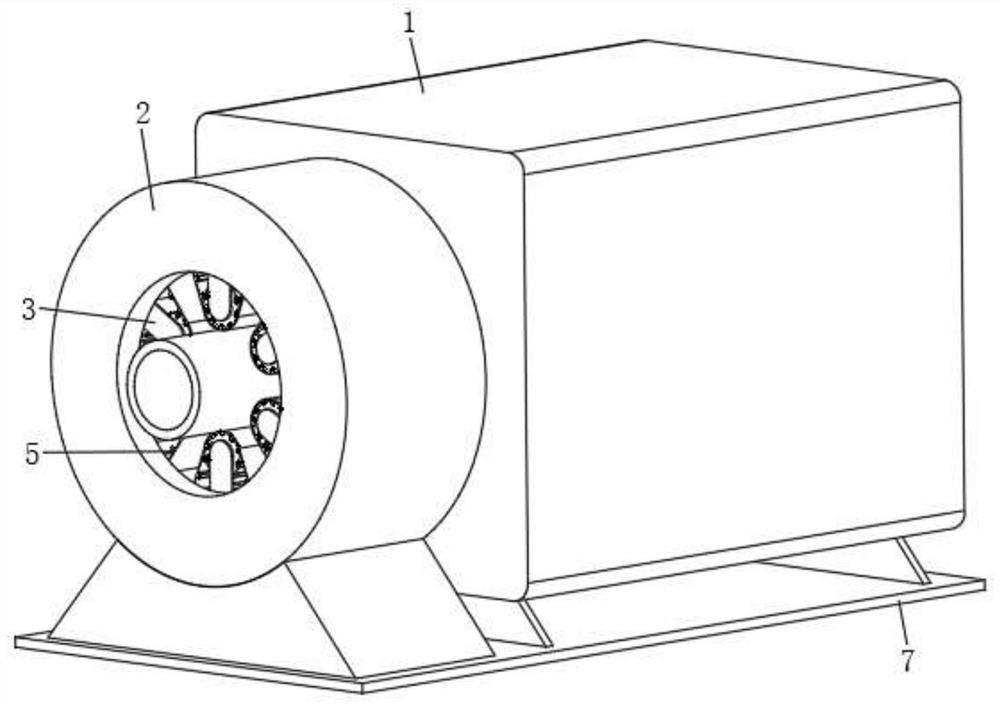

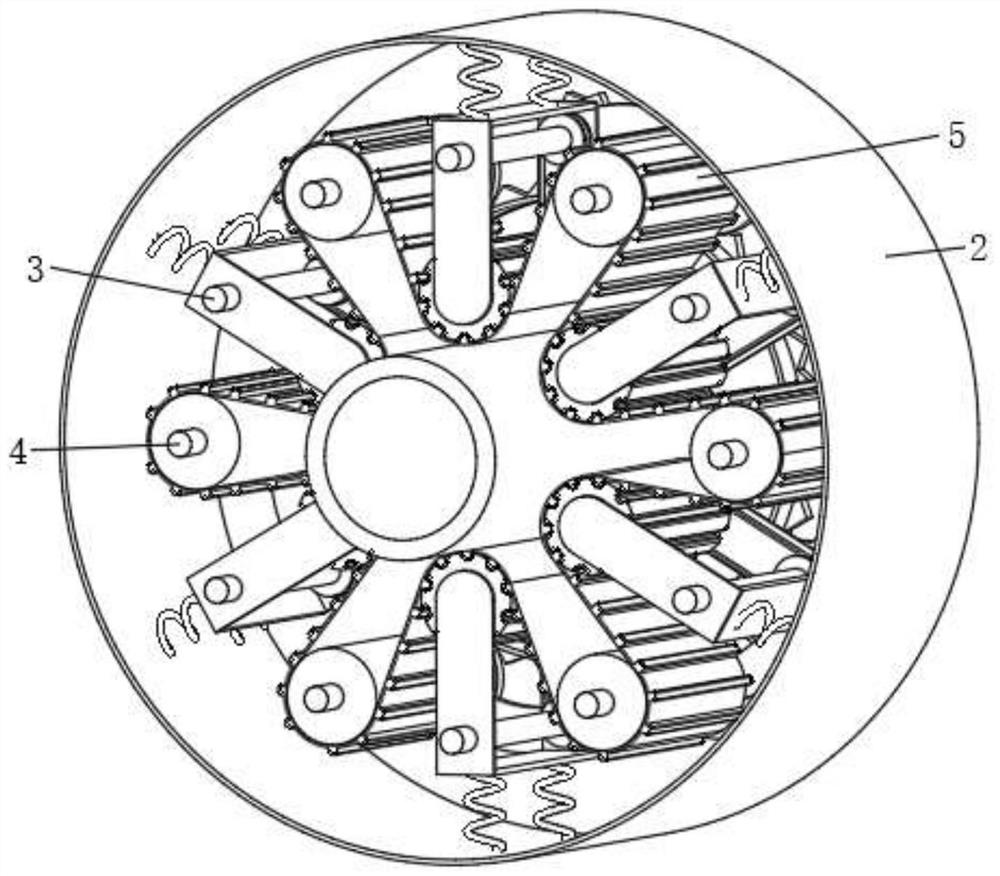

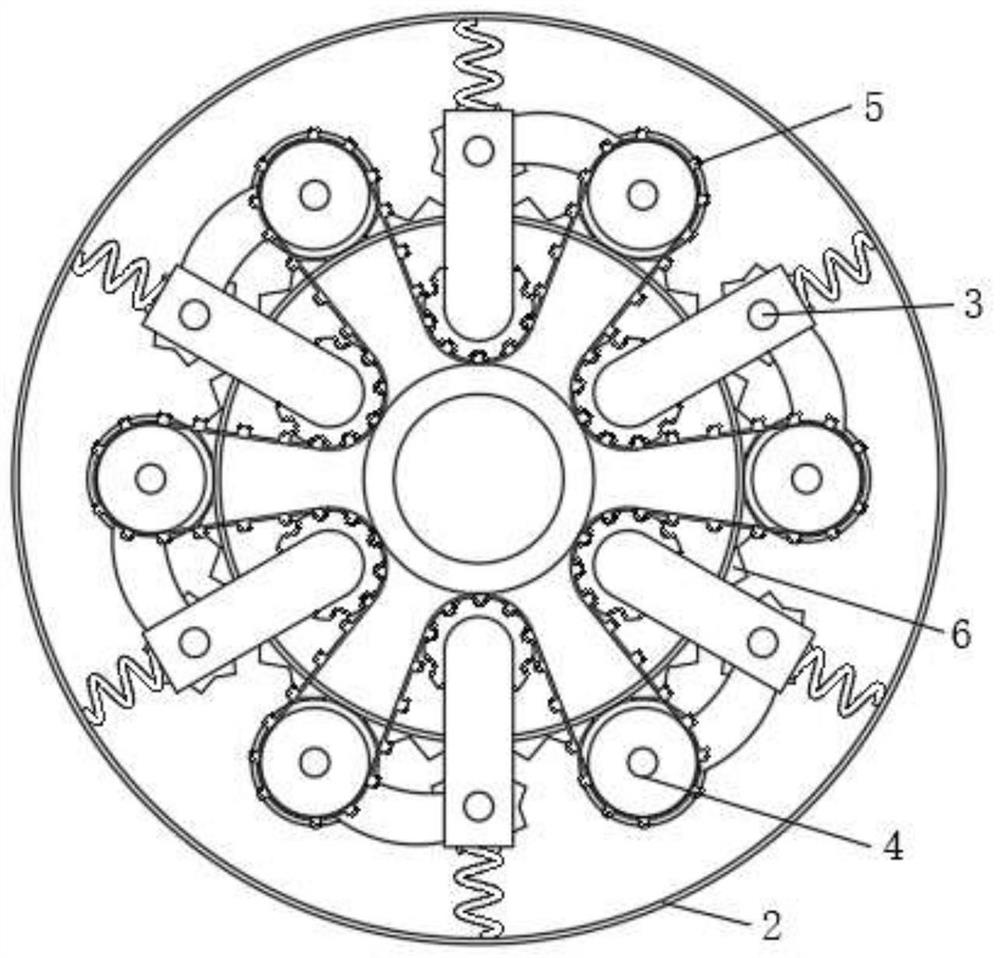

Motor bearing state monitoring and early warning device and heat dissipation and lubrication device for bearing

PendingCN114838058ADamage fastShort lifeThermometer detailsBearing repair/replacementThermodynamicsElectric machinery

The invention relates to the field of bearing monitoring, and discloses a motor bearing state monitoring and early warning device and a heat dissipation and lubrication device for a bearing, the heat dissipation and lubrication device for the bearing comprises a bearing seat, a rotating roller, an elastic metal belt and a heat dissipation and lubrication device, the rotating roller is arranged in the bearing seat, and the elastic metal belt is arranged in the bearing seat; the elastic metal belt rotates under rotation of the rotating roller, and the heat dissipation and lubrication device is fixedly arranged in the bearing seat, dissipates heat and lubricates when the rotating roller rotates, and automatically dissipates heat and lubricates the bearing while detecting the state of the bearing, so that the durability of the bearing is improved.

Owner:江苏欧斯特精密机械有限公司

HSCGF liposome as well as preparation and application thereof

ActiveCN102512370BKeep aliveImprove stabilityCosmetic preparationsHair removalSide effectCholesterol

Owner:GUANGZHOU SALIAI BIOLOGICAL GENETIC ENG CO LTD

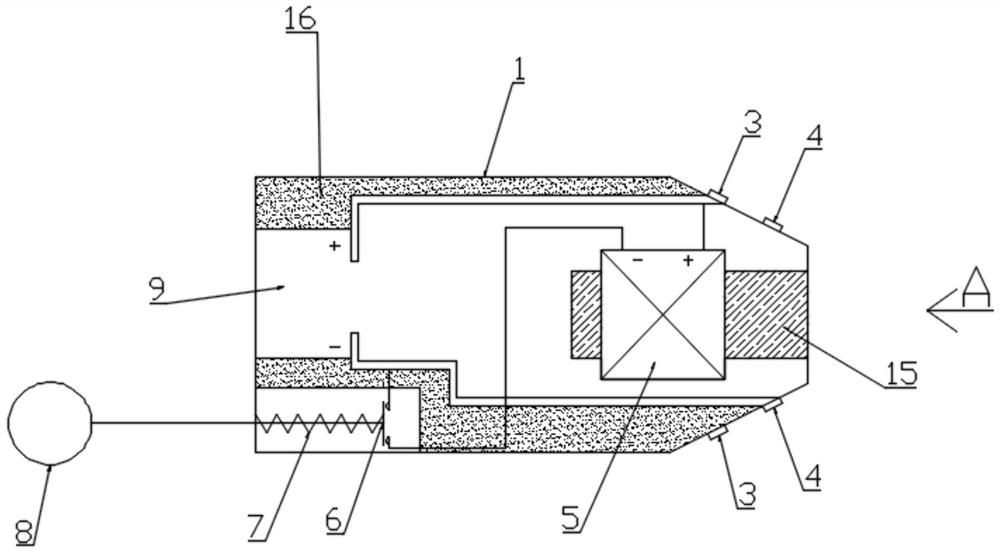

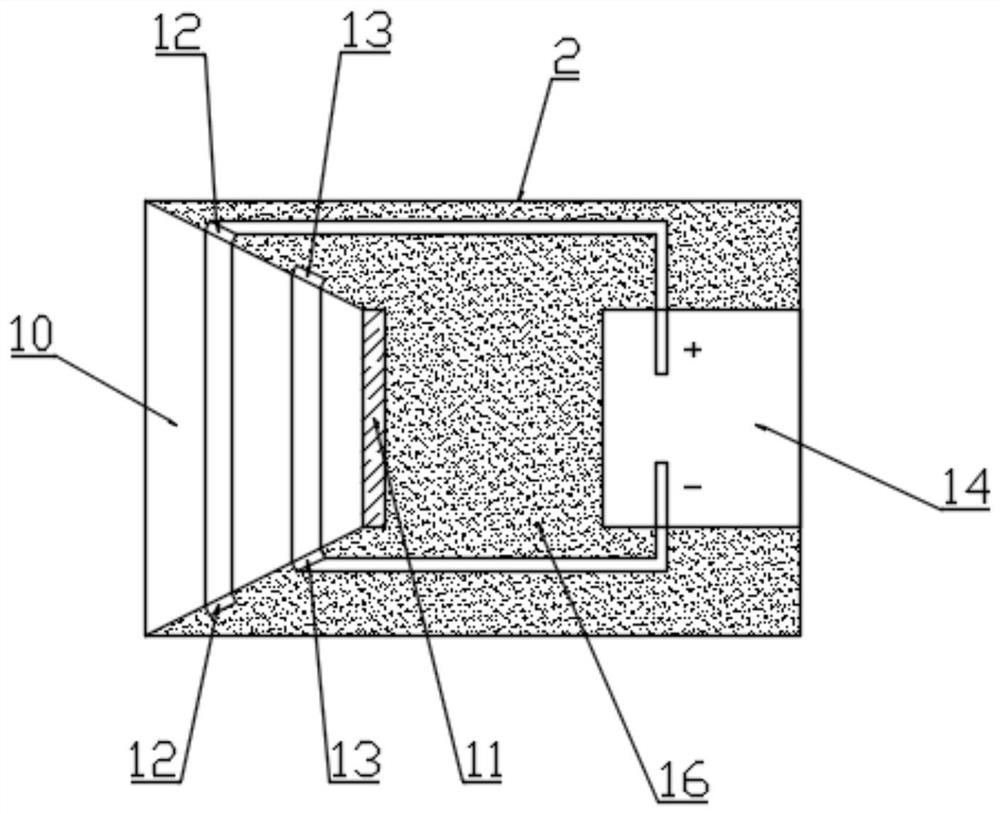

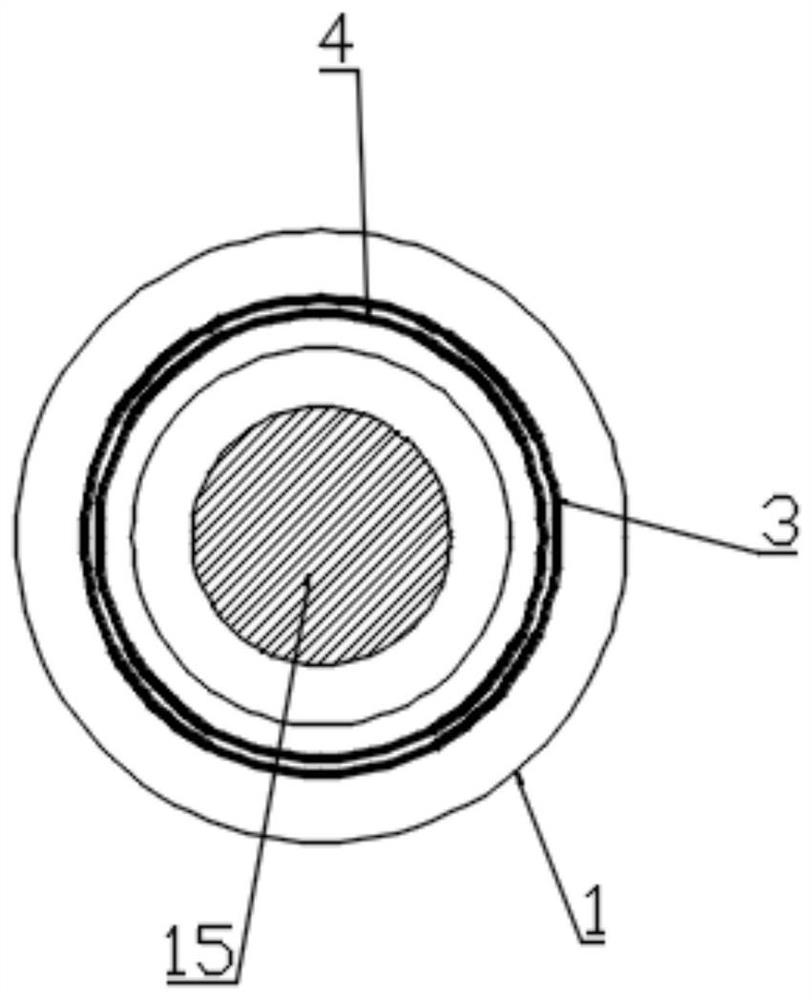

Electric ship charging quick connection device

PendingCN113922166AEasy to insertAvoid easy breakawayEngagement/disengagement of coupling partsCoupling contact membersEngineeringStructural engineering

The invention discloses an electric ship charging quick connection device, which comprises a plug and a socket, the plug is cylindrical, the front end of the plug is in a circular truncated cone shape, and the front end of the plug can be inserted into the socket; a positive electrode contact a and a negative electrode contact a are arranged on the outer surface of the plug; an electromagnet, an electromagnetic switch and a spring are arranged in the plug, the positive electrode contact a is connected with the anode of the electromagnet, the cathode of the electromagnet is connected with the electromagnetic switch, the electromagnetic switch is provided with the spring, and the spring is connected with a pull ring; the socket is provided with an insertion port, soft iron is arranged in the insertion port, and a positive electrode contact b and a negative electrode contact b are arranged on the inner wall of the insertion port; according to the invention, the plug and the socket are quickly connected in a magnetic manner and are not easy to fall off due to external force, and an effective, safe and stable connection state is realized.

Owner:JIANGSU XINHANG ELECTRICAL

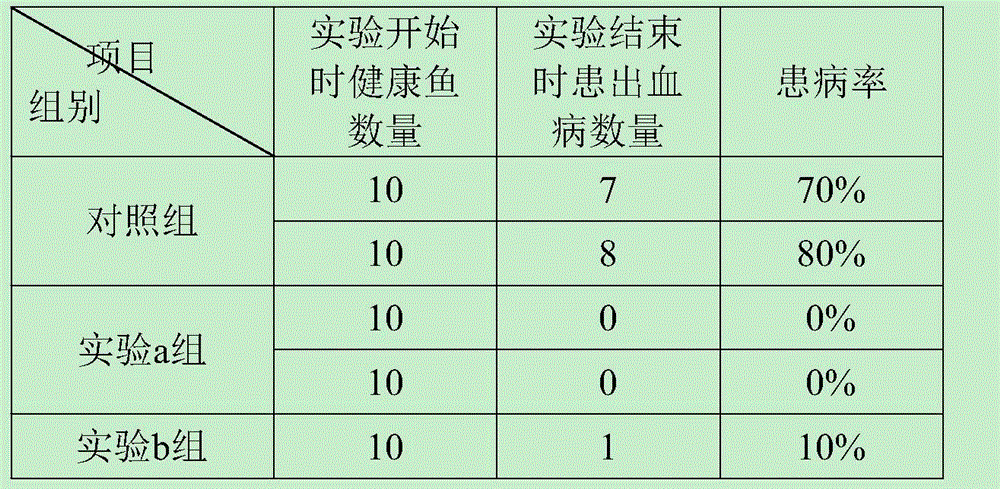

A compound preparation for preventing and treating ayu hemorrhagic disease and a preparing method thereof

InactiveCN105535747AGood healing effectInhibition of survivalAntibacterial agentsAnthropod material medical ingredientsLacquerBitter gourd

The invention belongs to the technical field of aquatic product cultivation, relates to a compound preparation for preventing and treating ayu hemorrhagic disease and relates to a preparing method of the compound preparation. The compound preparation comprises following components by mass: 37-44 parts of beautiful sweetgum resin, 28-36 parts of male fern rhizome, 28-36 parts of Chinese honeylocust spine, 27-35 parts of common cnidium fruit, 27-33 parts of Indian epimeredi herb, 9-15 parts of cicada slough, 23-30 parts of aconitum gymnandrum, 23-30 parts of dried lacquer, 22-30 parts of mulberry leaves, 21-29 parts of angelica decursiva, 20-28 parts of dwarf lilyturf tuber, 20-28 parts of root of glutinous rice, 18-28 parts of bitter gourd, 19-27 parts of purslane herb, 17-26 parts of inula root, 16-26 parts of tree peony root bark, 16-25 parts of lightyellow sophora root, 14-25 parts of reed rhizome, and the like. The compound preparation can effectively prevent and treat the ayu hemorrhagic disease.

Owner:QINGDAO HAIZHIYUAN INTELLIGENT TECH

A rolling harrow environmental protection energy saving high efficiency feeder

ActiveCN102530579BWith self-slip functionReduce loadLoading/unloadingConveyor partsEnvironmental resistanceGrain weight

The invention belongs to the field of material conveying, and specifically discloses a feeding method and a high-efficiency and energy-saving rolling-harrow feeding machine, by which fed materials are different in grain size, unequal in grain weight, different in quality, and large and controllable in quantity. The high-efficiency and energy-saving rolling-harrow feeding machine comprises a material guide hopper and a rolling harrow, wherein the rolling harrow comprises a harrow shaft and / or harrow cylinder and the like, the harrow shaft and / or harrow cylinder and the like are arranged on the side part, upper part and / or side upper part of a material, and located between the feed end and discharge end of the material guide hopper or located outside the discharge end of the material guide hopper, and the harrow shaft and / or harrow cylinder are / is arranged perpendicular to the flow direction of the material. By using the method and machine disclosed by the invention, an effect that through setting a material-harrowing bearing and a shaft barrel outside materials, the materials are harrowed from positions beside and / or above the materials, thereby controlling the flow quantity of the materials such as coal and the like; and through real-time adjustment controlling, the purpose of improving efficiency, saving energy, and realizing the optimal feed reshipment is achieved.

Owner:刘素华

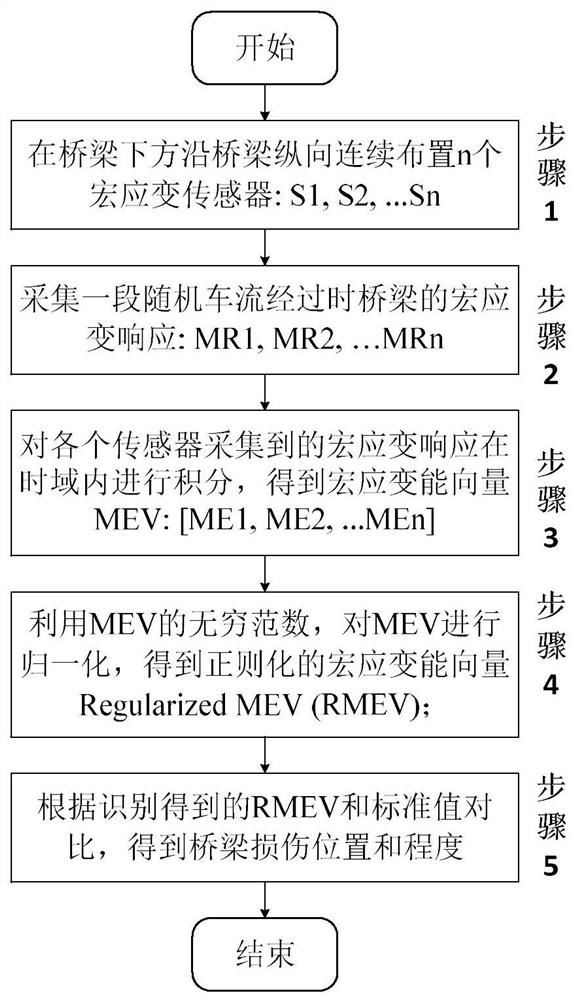

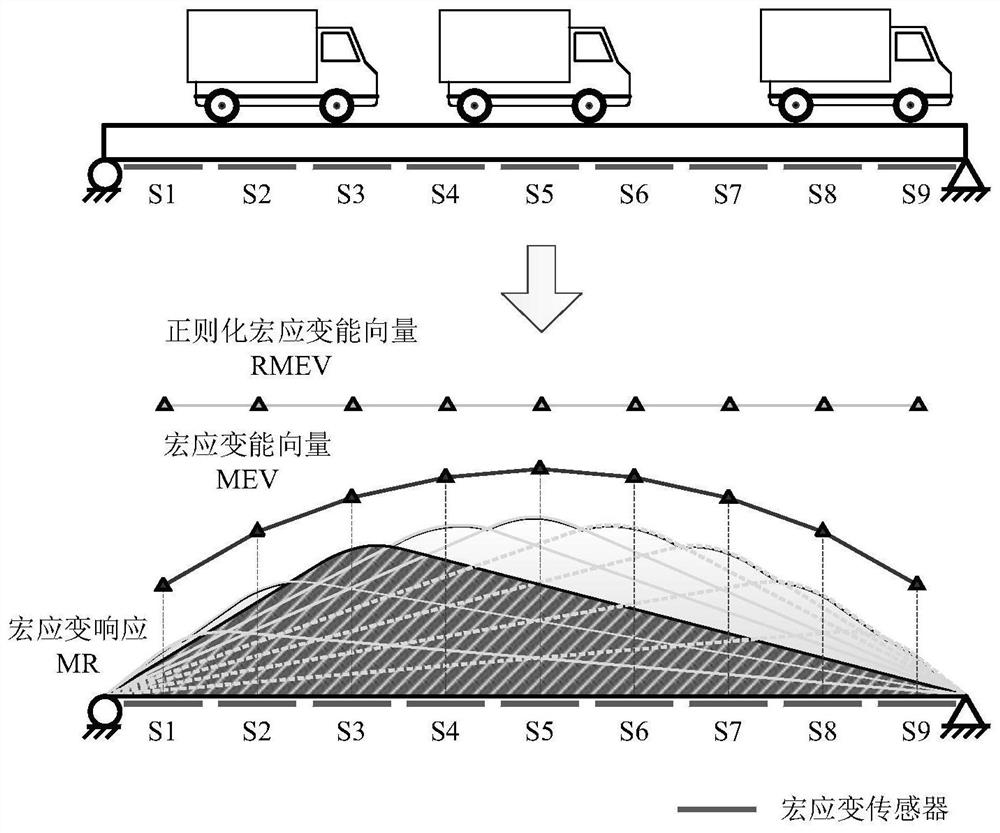

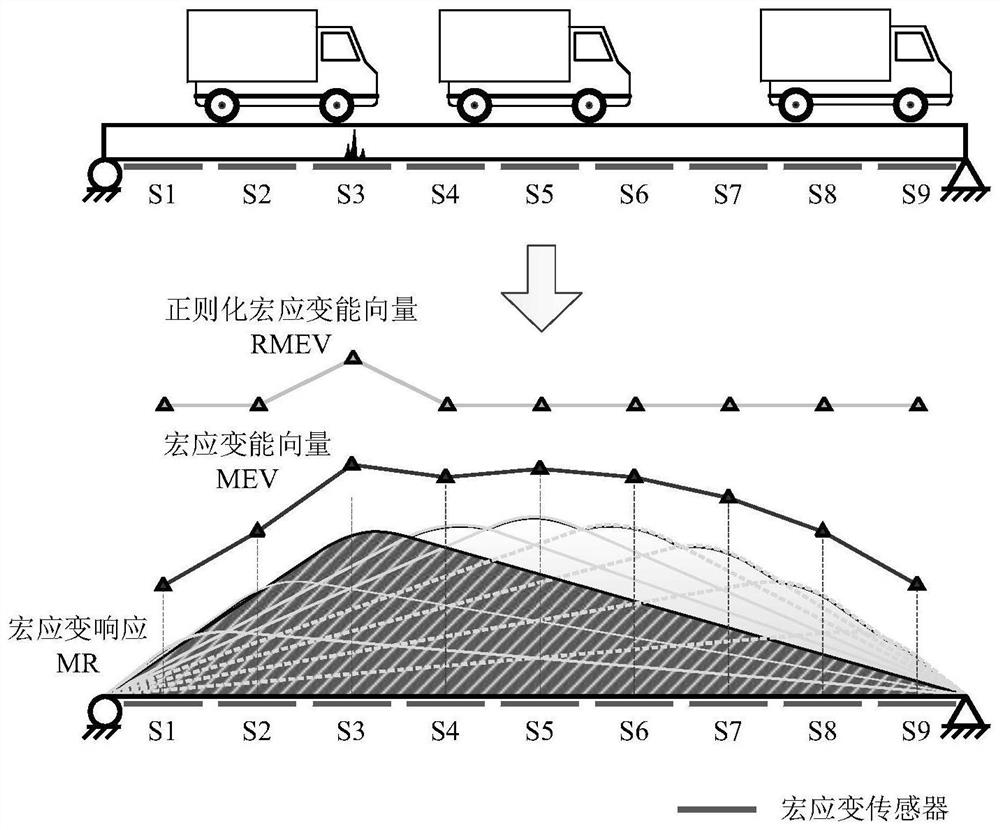

Bridge damage rapid identification method based on macro strain energy under random traffic flow

PendingCN112326418ANo need to interrupt traffic or restrict traffic conditionsDamage fastMaterial strength using repeated/pulsating forcesComplex mathematical operationsTime domainStrain energy

The invention discloses a bridge damage rapid identification method based on macro strain energy under random traffic flow. The method comprises the following steps: continuously installing n macro strain sensors below a bridge along a bridge span direction; collecting a macro strain response of the bridge when a section of random traffic flow passes; integrating the macro strain response acquiredby each sensor in a time domain to obtain a macro strain energy vector; regularizing the macro strain energy vector by using the infinite norm of the macro strain energy vector to obtain a regularized macro strain energy vector; and comparing the identified regularized macro strain energy vector RMEV with a standard value to obtain the bridge damage position and degree. The structural damage position and degree can be effectively, accurately and rapidly judged under the random traffic flow working condition, and traffic interruption or traffic condition limitation is not needed.

Owner:CHANGAN UNIV

Acidizing fluid for green algae and disease infected cell in porphyra haitanensis cultivation and treating method thereof

The invention discloses an acidizing fluid for green algae and a disease infected cell in porphyra haitanensis cultivation and a treating method thereof. A solvent for the acidizing fluid is clean seawater, and solute for the acidizing fluid is at least one of hydrochloric acid and citric acid, wherein the concentration expressed in percentage by weight of the solute in the acidizing fluid is 0.3to 1.5 percent. The green algae and the disease infected cell can be quickly killed by a treating method of preparing the acidizing fluid, shipping, dipping for 15 to 20 seconds and rinsing, killing effect is better, the killing rate is over 90 percent, and the influence on the growth of the porphyra haitanensis is less. The treating method has the advantages of no restriction of natural condition, labor intensity reduction and the like.

Owner:NINGBO UNIV

Dummy lower limb impact test method

The invention discloses a dummy lower limb impact test method. According to the method, dummy lower limb impact test equipment is adopted and includes an impact test object device, a dummy lower limb, a guide rail, a sliding device, a foot loading device, a loading device, a stopping device, a sensor group and an upper computer. The method includes the following steps of: 1, preparation work; step 2, loading; step 3, releasing; and step 4, data collection and analysis. With the dummy lower limb impact test method of the invention adopted, a dynamic impact process of the dummy lower limb, a vehicle dashboard and floor can be accurately simulated; dummy lower limb damage value data can be acquired in a test process, so that damage to the lower limb of a passenger which caused by the vehicle dashboard, the floor, a foot pad and the like can be quickly assessed.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Bored cooling calendaring roller

The invention relates to a bored cooling calendaring roller, comprising a roller body as well as a first roller shaft and a second roller shaft which are respectively connected with the two ends of the roller body; wherein the roller body is provided with an axial through hole of a cooling working roller surface. The roller is characterized in that the first roller shaft and the second roller shaft are respectively provided with a cooling water channel hole which is communicated with a cooling water channel through hole on the roller body, the shaft body circumference surfaces of the first roller shaft and the second roller shaft are respectively provided with an annular water tank, the annular water tanks are respectively communicated with the cooling water channel hole by virtue of intercommunicating holes on the shaft bodies, the two ends of the axial through hole of the cooling working roller surface which is reserved on the roller body are respectively communicated with the annular water tanks on the shaft body circumference surfaces of the first and second roller shafts by virtue of oblique communicating holes, and the two end parts of the axial through hole are respectivelyprovided with a seal element used for sealing the axial through hole. The invention has the advantages of reasonable structure, and rapid repairing when being damaged, and is easy to process and reliable in use.

Owner:PRINX CHENGSHAN (SHANDONG) TIRE COMPANY LTD

Intelligent voice control switch

InactiveCN112638068AEasy to disassembleTo achieve a fixed connectionClosed casingsCasings/cabinets/drawers detailsEngineeringControl switch

The invention discloses an intelligent voice control switch which comprises a switch panel and a switch visible box. A sound groove is formed in the upper portion of the front side surface of the switch panel, a device box is fixedly installed at the sound groove in the rear side surface of the switch panel, a heat dissipation notch is formed in the rear side of the device box, and a heat dissipation device is installed at the position, below the sound groove, of the front side surface of the switch panel. And an elastic buffer device is used for providing pressure for a pressing plate to enable an ejector block to be clamped with a limiting groove in the corresponding position so that the switch panel is fixedly connected with the switch visible box, the voice control switch is simple to disassemble, and the elastic buffer device is used for providing pressure for the pressing plate to enable the ejector block to be clamped with the limiting groove in the corresponding position. Therefore, the switch panel and the switch visible box are fixedly connected, there is no damage during disassembly, heat in the device box can be absorbed through a heat absorption plate, and cooling fins can exchange heat with outside air so that the temperature of a main control chip in the device box is reduced, and the service life of the main control chip is prolonged.

Owner:ANHUI SHILIN LIGHTING

An Internet intelligent conference tablet

ActiveCN109725684BStable positionOptimize locationStands/trestlesDigital processing power distributionThe InternetStructural engineering

Owner:广州林电智能科技有限公司

Anti-backflow bottom valve of plastic mixed-flow pump

InactiveCN112746976AExtended service lifeReduced service lifePump componentsCheck valvesMixed flowStructural engineering

The invention relates to the technical field of bottom valves, in particular to an anti-backflow bottom valve of a plastic mixed-flow pump. The anti-backflow bottom valve comprises a connecting pipe, one end of the connecting pipe is connected with a funnel pipe, one end of the funnel pipe is connected with a flange, the other end of the connecting pipe is connected with a protection mechanism, a limiting ring plate is fixed to one side in the connecting pipe, a fixed plate is fixed to the middle of one side of the position, on one side of the limiting ring plate, in the connecting pipe, waterproof cloth is rotationally connected to the two sides of the fixed plate, a valve clack is fixed to one side of the waterproof cloth, bolts are arranged on the two sides of the valve clack, one end of each bolt penetrates through the waterproof cloth and the valve clack and is connected with a nut, connecting groove plates are fixed to the two sides of the valve clack, and a rotating rod is rotationally connected in each connecting groove plate. According to the anti-backflow bottom valve, a water pump can be protected through a protection cover, water entering the water pump can be filtered once through the protection cover, impurities in the water cannot be sucked into the water pump and a valve element, and a rotor of the water pump is protected.

Owner:潘连山

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com