Bored cooling calendaring roller

A technology of cooling water channel and roller body, applied in the field of tire manufacturing equipment, can solve the problems of low possibility of complete repair, long repair time, damage, etc., and achieve the effects of short time, complete repair and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

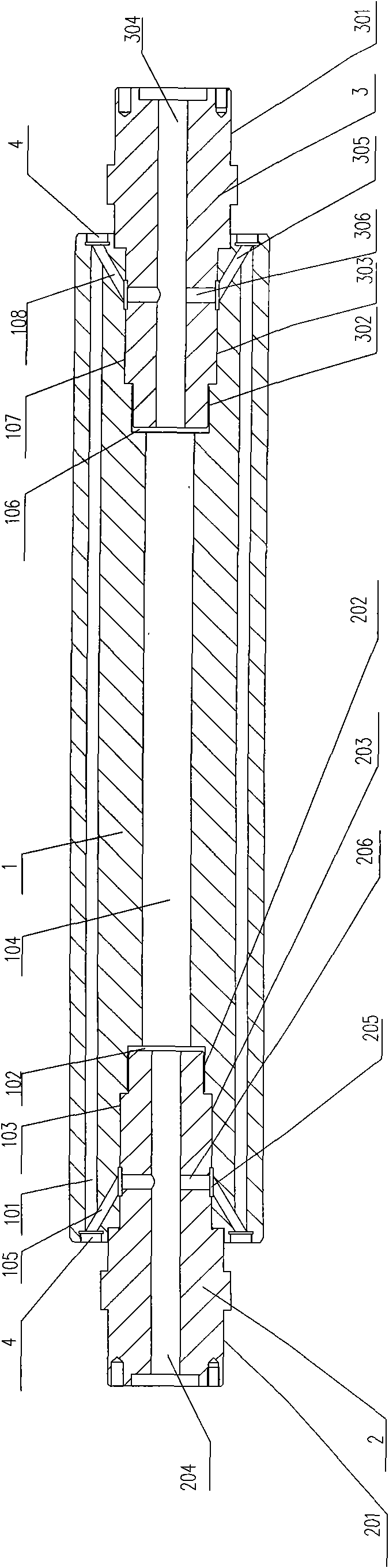

[0010] In the accompanying drawings, a drilled cooling calender roll includes a roll body 1 and a first roll shaft 2 and a second roll shaft 3 connected to both ends of the roll body 1 .

[0011] Wherein the roller body 1 is formed by one-time integral casting. During the casting process, the circumferential working roll surface of the roll body 1 is rapidly cooled to obtain a chilled layer on the surface.

[0012] Eighteen axial through holes 101 for cooling the circumferential work roll surface are opened at equal intervals on the roll body 1 with the same radius. A cooling water passage hole 104 is opened on the roller body 1 along its axis.

[0013] The first roller shaft 2 and the second roller shaft 3 are made of No. 45 steel.

[0014] The free end of the first roller shaft 2 is machined with a first bearing mounting surface 201, and the connecting end is coaxially processed with a first threaded connection surface 202 and a first joint surface 203 sequentially from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com