Edge grinding machine for arc angle of glass

The technology of arc angle and edge grinding machine is applied to machine tools, grinding machines, grinding/polishing equipment and other directions suitable for grinding workpiece edges, which can solve the problems of high price, low efficiency and troublesome placement of grinding centers. Achieving high-efficiency precision grinding, overcoming the effects of high price and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

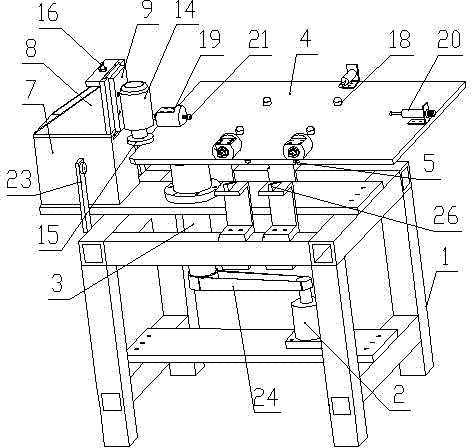

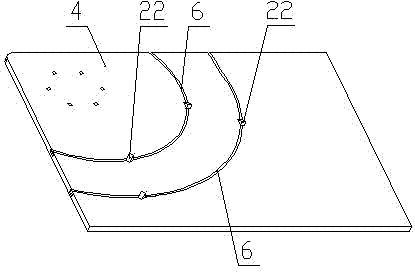

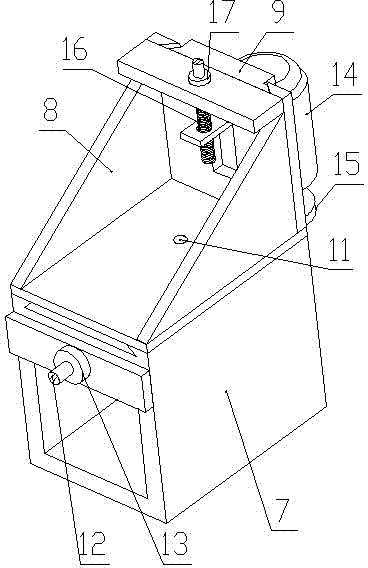

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the glass arc angle edging machine of the present invention includes a frame 1, a main drive motor 2 arranged on the frame 1, a transmission shaft 3 which rotates and is vertically arranged on the frame 1, and a transmission shaft 3 which is horizontally arranged on the frame 1. The platen 4 at the upper end of the shaft 3, the main drive motor 2 is connected to the drive shaft 3 through transmission, the platen 4 is a rectangular structure, the joint between the drive shaft 3 and the lower surface of the platen 4 is close to a corner of the platen 4, and the frame 1 is provided with an arc-shaped track 5 centered on the centerline of the drive shaft 3, and the lower surface of the table 4 is provided with an arc-shaped groove 6 matching the arc-shaped track 5. The table 4 is provided with a glass clamping mechanism. The frame 1 is provided with an edge grinding device adjacent to the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com