Movable numerical control grinding apparatus for grinding steel rail and control method thereof

A mobile and pushing device technology, which is applied to machine tools suitable for grinding workpiece planes, automatic grinding control devices, grinding/polishing safety devices, etc., which can solve low grinding precision, large safety hazards, and low work efficiency and other problems, to achieve the effect of increasing the grinding contact area, reducing grinding heat, and reducing the amount of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A specific implementation of a mobile numerically controlled grinding device suitable for rail grinding and its control method will be described in detail below in conjunction with the accompanying drawings.

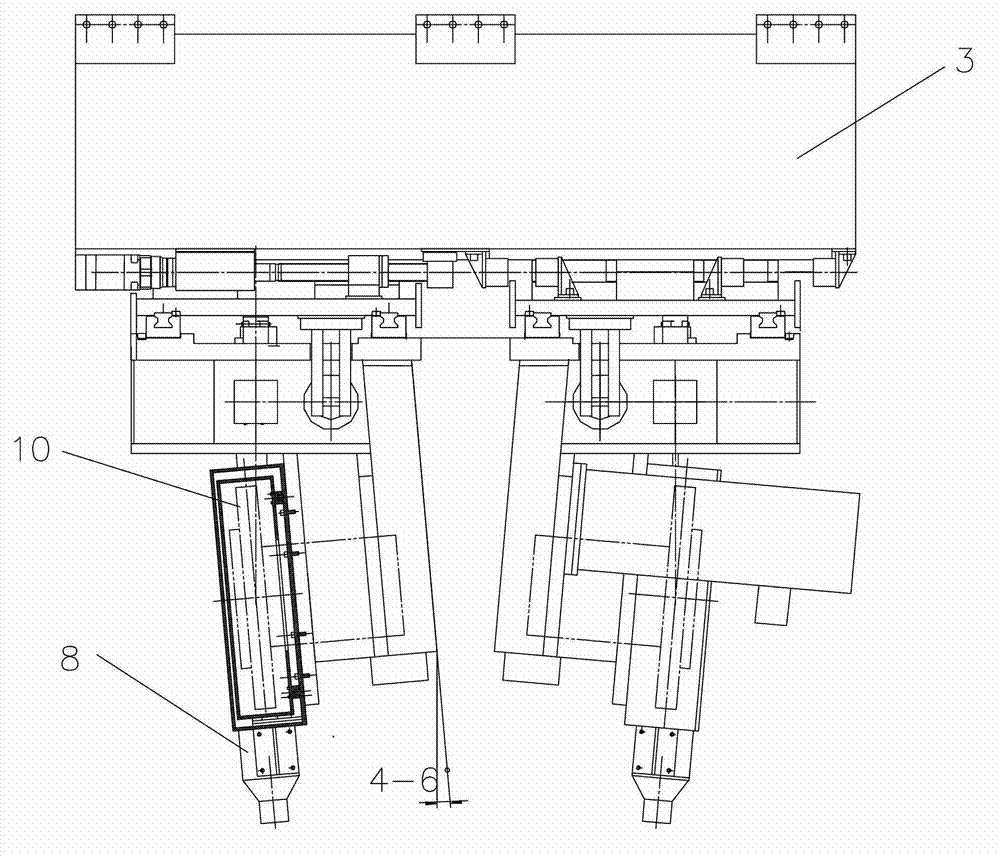

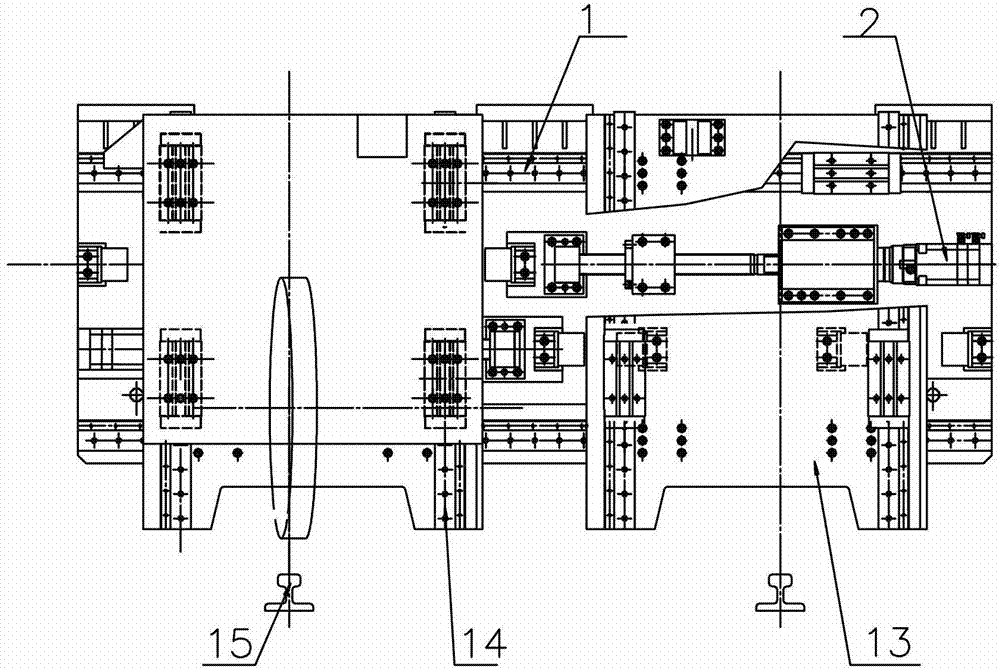

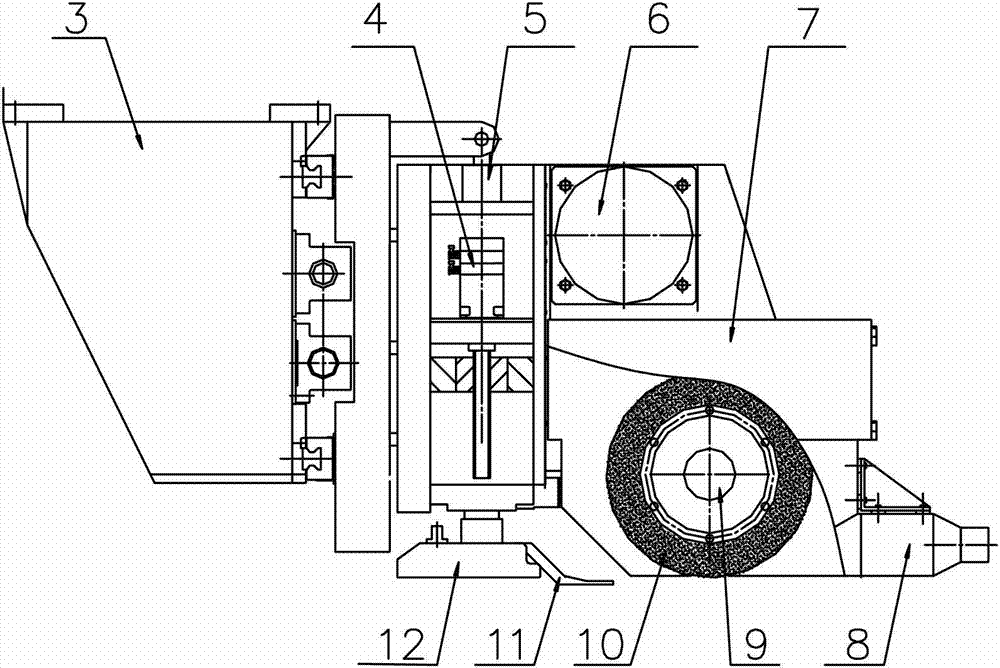

[0025] Such as figure 1 , 2 , 3. A mobile CNC grinding device suitable for rail grinding includes a transverse guide rail 1, a transverse servo feed system 2, a support frame 3, a longitudinal servo feed system 4, an oil cylinder 5, and a grinding wheel adaptive feedback device 6, Self-positioning mobile protective cover 7, dust suction device 8, spindle system 9, grinding wheel 10, lateral precision positioning device 11, positioning shoe 12, cross carriage 13, longitudinal guide rail 14, steel rail 15 and other components, on the support frame Two sets of mutually independent mechanical arms that can move freely laterally are installed, and the mechanical arms are controlled by a numerical control system, and a grinding device is installed on the mechanical arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com