A precise grinding method for working face of semi-coupling

A semi-coupling and working surface technology, which is applied in the direction of grinding workpiece brackets, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of difficult control of size and shape and position tolerances, and meet processing requirements, Simple method and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific implementation mode 1: Combination Figure 1~Figure 8 To describe this embodiment, a method for precise grinding of the working surface of a half coupling of this embodiment, the steps are as follows:

[0032] 1. Rough grinding:

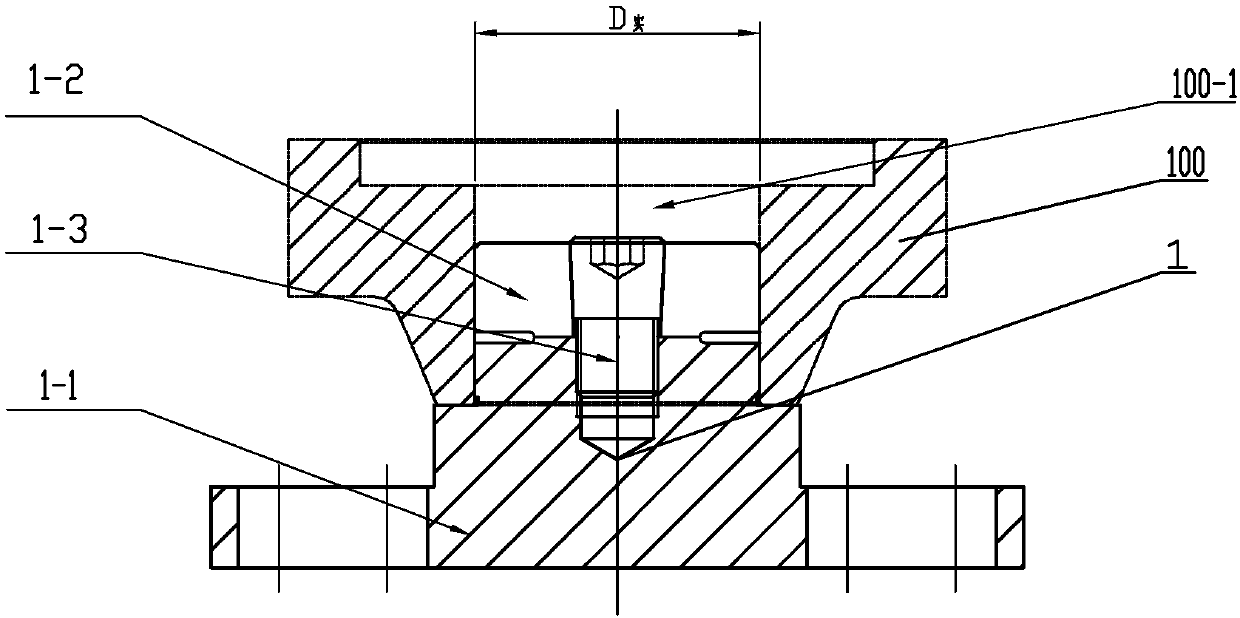

[0033] Using mechanical internal tightening tooling 1, the workpiece 100 can be clamped by tightening the first inner hole 100-1 of the workpiece 100;

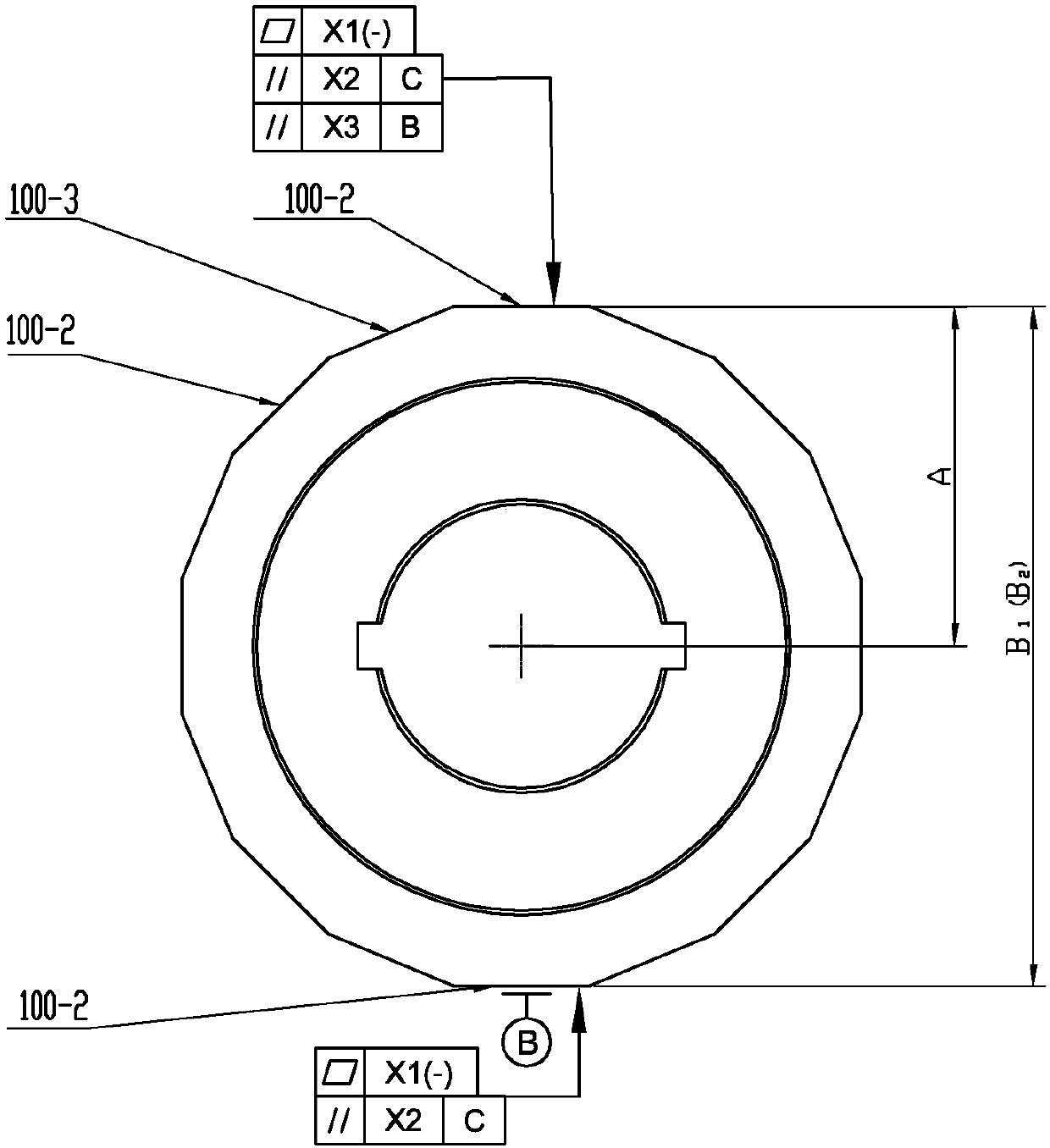

[0034] After clamping, symmetrical grinding is used to rough-grind the working surface 100-2 of the workpiece 100, that is, after grinding a working surface 100-2, move the grinding spindle to start grinding the symmetrical working surface 100-2. After finishing a set of symmetrical working faces 100-2, grind the adjacent working faces 100-2 in the same way until all working faces 100-2 are rough-ground;

[0035] After rough grinding, install a dial indicator on the spindle of the machine tool, use the dial indicator to hit the lowest point 200 of the first inner hole of the workpiece and th...

specific Embodiment approach 2

[0051] Specific implementation manner 2: Use a special grinding wheel dressing tool for machine tools to finish the grinding wheel before the finish grinding. Such a design is beneficial to improve the flatness requirement of the working face 100-2. Other components and connection relationships are the same as those in the first embodiment.

specific Embodiment approach 3

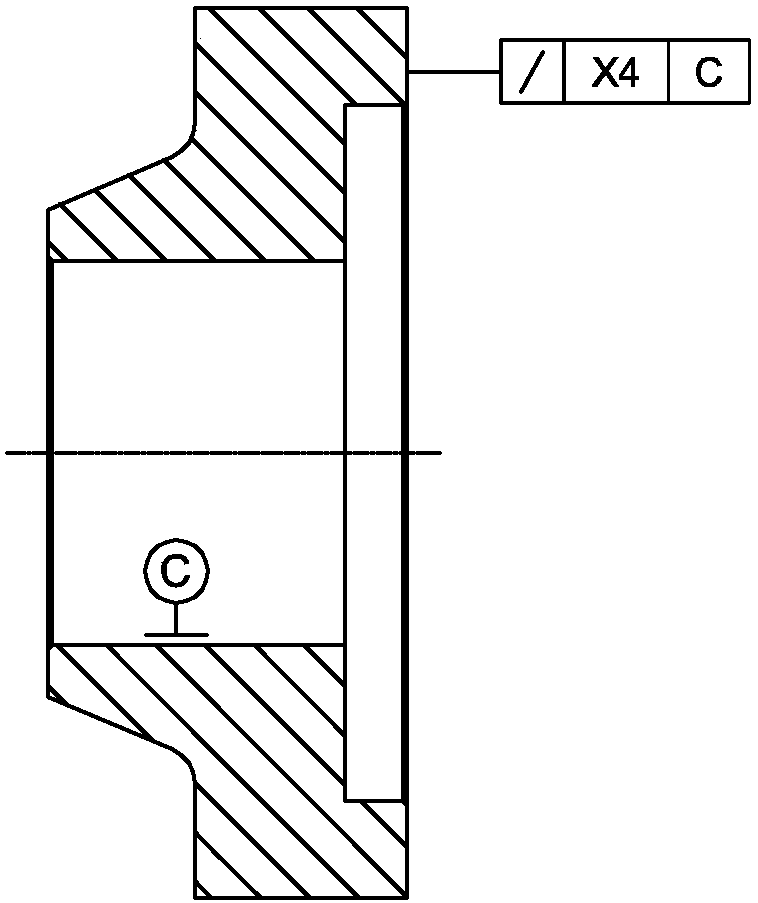

[0052] Specific implementation mode three: combination image 3 , Figure 5 , Image 6 with Figure 7 Explaining this embodiment, the mechanical internal tightening tooling 1 includes a base 1-1, a tightening positioning post 1-2, and a tightening pin 1-3. The upper part of the base 1-1 is processed with a positioning shoulder 1-5, and the base 1 The lower end of -1 is provided with a number of long holes 1-1-1 evenly distributed along the circumferential direction and fixed with the machine tool table by bolts. The tightening positioning column 1-2 is located at the upper end of the base 1-1 and the tightening positioning column 1-2 A taper pin hole 1-2-1 is opened in the center of the spool, and the expansion and positioning column 1-2 is evenly distributed along its circumferential direction with a number of expansion joints 1-2-2 and each expansion joint 1-2-2 points to the axis The center setting, the tightening positioning column 1-2 and the base 1-1 are fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com