Ridge type planogrinder

A gantry grinder and bridge-type technology, which is applied in the field of machine tools, can solve the problems that parts cannot be ground, the maximum grinding width and length of gantry grinders, and the weight of parts, etc., so as to broaden the processing range, realize precision grinding, The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

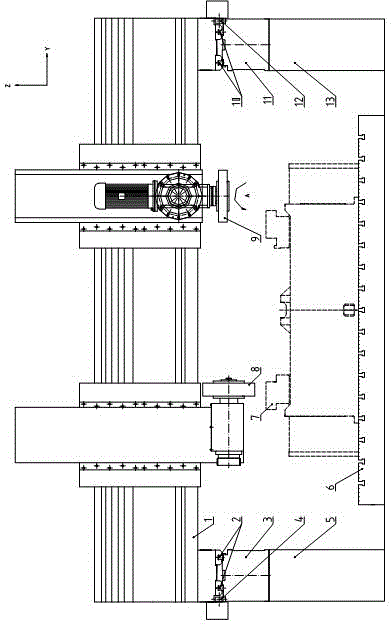

[0011] exist figure 1 Among them, the present invention is provided with left column 5, right column 13, and left bed 3 and right bed 11 are respectively positioned on left column 5 and right column 13, and left bed 3 and right bed 11 are provided with left straight line respectively. Guide rail 2, right linear guide rail 10, beam 1 is located on left linear guide rail 2, right linear guide rail 10, horizontal grinding wheel 8 and vertical grinding wheel 9 are installed on beam 1, workbench 6 is fixed on the ground below beam 1, The processing part 7 is placed on the workbench 6, and the beam 1 is synchronously driven by the left driving device 4 and the right driving device 12.

[0012] The processing parts 7 and the workbench 6 of the present invention are fixed on the foundation, the horizontal grinding wheel 8 and the vertical grinding wheel 9 can move independently on the beam 1 along the Y axis and the Z axis, and the vertical grinding wheel 9 can move along the A The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com