Method for optimizing laminated structure printed board expanding and shrinking matching and laminated structure printed board

A laminated structure and printed board technology, applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problems of limited product processing range, plate utilization, production efficiency, and process capability improvement limitations, etc. Achieve the effect of improving the alignment between lamination layers and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

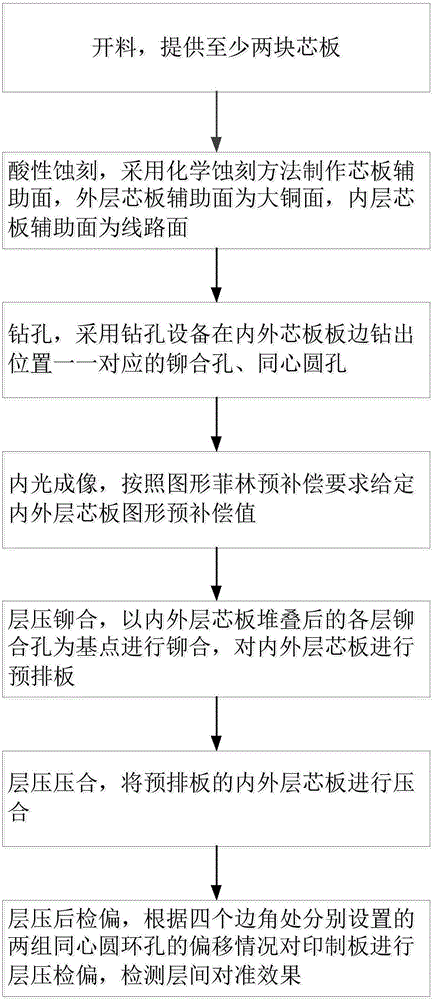

[0031] Such as figure 1 As shown, the method for optimizing the expansion and shrinkage matching of a laminated structure printed board in this embodiment includes the following steps:

[0032] S1. Cut the material and provide at least two core boards. According to the design requirements, the substrate core board is cut and cut, and the warp and weft directions of the board must be consistent. One of the two core boards is used as the outer core board, and the other is used as the inner core board.

[0033] S2. Acid etching, the auxiliary surface of the core board is made by chemical etching method, the auxiliary surface of the outer core board is the large copper surface, and the auxiliary surface of the inner core board is the circuit surface. Acid etching is carried out on the substrate core board. The copper foil on the surface of the outer core board is etched with an acid etching liquid to form a large copper surface. The copper foil on the surface of the inner core bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com