Special disk type feeding device of double-ended grinding machine

A double-face grinding machine and feeding device technology, which is applied in the direction of grinding machines, machine tools suitable for grinding workpiece planes, grinding feed movement, etc., can solve the fatigue of feeding personnel, unfavorable long-term and durable processing of machine tools, and cannot meet the high precision of workpieces Requirements and other issues to achieve the effect of improving the processing range and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

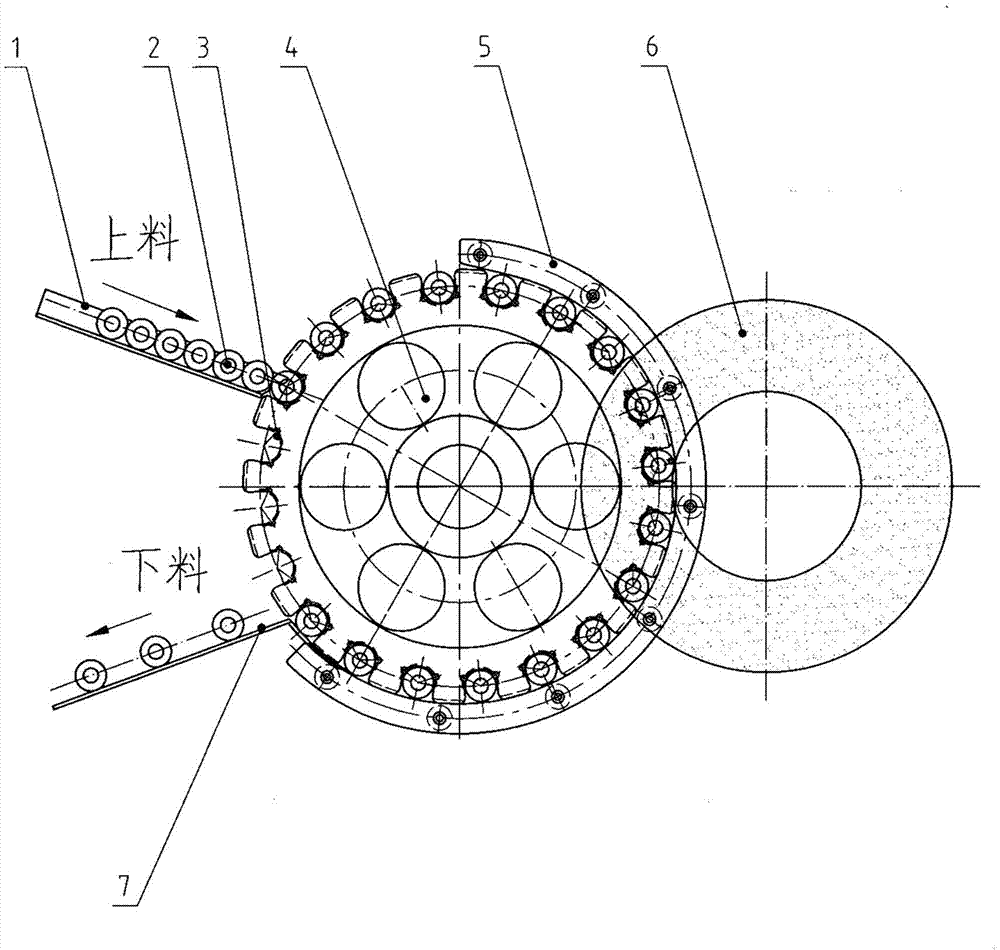

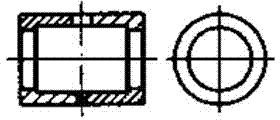

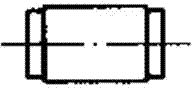

[0011] Such as figure 1 , figure 2 , image 3 As shown, the present invention relates to a special disc-type feeding device for a double-end grinding machine, which is provided with a feeding bracket 1, a workpiece 2, an arc seat 3, a feeding disc 4, a grinding retainer 5, a grinding wheel 6, and a feeding bracket 7. It is characterized in that: the feeding bracket 1 is placed obliquely, the lower end of the feeding bracket 1 is connected to the opening of the arc seat 3, and the arc seat 3 is installed in the opening of the feeding disc 4, and the workpiece 2 From the feeding bracket 1 into the arc seat 3 in the feeding disc 4, a grinding retainer 5 is provided on the right side of the feeding disc 4, and the grinding retainer 5 is used to fix the workpiece 2 on the arc seat 3 The inside will not fall out. At the left and right ends of the grinding retainer 5, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com